torque DATSUN 610 1969 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 72 of 171

greased

Install

the

flange

washer

and

pinion

nut

Tighten

the

nut

to

a

torque

reading

of

14

17

kgm

101

130

Ib

fL

If

the

cotter

pin

hole

is

not

correctly

aligned

a

suitable

washer

should

be

fitted

Do

NOT

adjust

by

overtightening

the

pinion

nul

Van

Lubricate

the

front

bearing

with

oil

and

place

it

in

the

carrier

Grease

the

lip

of

the

oil

seal

and

install

it

to

the

final

drive

housing

Install

the

drive

pinion

the

new

collapsible

spacer

and

the

drive

flange

Fit

the

drive

pinion

nut

and

tighten

temporarily

until

all

slackness

is

eliminated

from

the

front

and

rear

of

the

drive

pinion

NOTE

Ensure

that

oil

and

grease

have

been

completely

removed

from

the

threads

of

the

pinion

gear

the

pinion

nut

and

the

washer

Tighten

the

pinion

nut

and

check

the

preload

with

a

preload

gauge

As

the

nut

is

tightened

to

the

specified

torque

reading

of

13

20

kgm

94

0

144

6Ib

fL

the

preload

must

be

measured

at

every

five

to

ten

degrees

turn

of

the

pinion

nut

As

the

pinion

nut

is

tightened

the

stepped

portion

of

the

spacer

is

deformed

See

Fig

G

29

J

and

the

length

between

the

bearings

adjusted

The

drive

pinion

bearing

preload

with

oil

seal

and

new

bearing

is

7

15

kg

cm

6

1

13

0

lb

in

Turn

the

drive

pinion

to

settle

the

bearing

and

re

check

the

preload

and

tightening

torque

If

the

preload

rate

is

exceeded

it

will

be

necessry

to

fit

a

new

spacer

the

old

spa

cr

cannot

be

reused

and

the

preload

must

not

be

adjusted

by

loosening

the

pinion

nul

Side

bearing

pre

load

adjusting

If

the

original

side

bearings

arc

to

be

used

the

shims

must

be

of

the

same

thickness

as

those

previously

fitted

To

select

shims

for

new

side

bearings

proceed

as

follows

The

standard

width

of

the

side

bearings

is

given

in

Technical

Data

This

width

must

be

measured

before

attempting

to

calculate

the

required

thickness

of

the

adjusting

shims

Place

a

weight

of

approximately

5

kg

5

5

lb

and

of

predetermined

height

onto

the

side

bearing

as

shown

in

Fig

G

30

Mcasure

the

width

of

the

bearing

with

a

dial

gauge

as

illustrated

turning

the

bearing

two

or

three

times

to

gain

an

accurate

meaSurement

Dimensional

variations

from

the

standard

measurements

are

marked

on

the

left

side

bearing

housing

of

the

gear

carrier

on

the

right

side

bearing

housing

of

the

gear

carrier

and

on

the

differential

case

These

variations

are

marked

in

units

of

l

lOOmm

and

are

used

for

the

f

rmula

to

calculate

t1H

thickness

of

the

adjusting

shims

in

the

following

manner

Where

TI

equals

the

left

side

bearing

shim

crownwhecl

side

T2

equals

the

right

side

bearing

shim

pinion

gear

A

equals

the

figure

marked

on

the

left

side

bearing

housing

B

equals

the

figure

marked

on

the

right

side

bearing

housing

C

and

0

equals

the

figure

marked

on

the

differential

case

and

E

and

F

is

the

difference

bctween

the

width

of

the

side

bearings

and

the

standard

bearing

width

H

the

figure

marked

on

the

crownwhcel

Fig

G

31

The

following

formulae

can

now

be

used

to

deter

mine

the

required

shim

thicknessl

s

for

both

side

bearings

I

OOcc

Estate

car

Left

side

bearing

TI

A

C

D

H

x

0

01

0

100

E

Right

side

bearingT2

B

D

H

x

0

01

0

090

F

I800cc

Van

Left

side

bearingTI

A

C

D

H

xO

OI

0

175

E

Right

side

bcaringT2

8

D

H

x

0

01

0

150

F

As

an

example

where

A

1

B

C

2

D

3

E

0

02mm

H

I

The

formula

for

the

left

side

bearing

is

T

I

I

1

3

1

x

0

01

0

175

0

02

0

205mm

1400

and

1600cc

Estate

car

The

required

thickness

of

shim

can

be

found

using

the

following

formula

in

a

similar

manner

to

that

previously

described

for

the

1800cc

models

Left

side

bearing

T

I

A

C

D

E

7

Right

side

bearing

T2

B

D

F

6

Shims

are

available

in

five

thicknesses

of

0

05

0

07

0

10

0

20

and

0

50

mm

0

002

0

0028

0

0039

0

0079

and

0

0197

in

Fit

the

selected

side

bearing

adjusting

shims

on

the

differential

cage

and

press

in

the

side

bearing

inner

races

using

a

suitable

ddfL

nstall

the

differential

cage

into

the

carrier

and

fit

the

bearing

caps

Ensure

that

the

marks

on

the

caps

coincide

with

the

marks

on

the

carrier

Tighten

the

bearing

cap

bolts

to

the

specified

torque

reading

See

Tighte

ing

torques

Measure

the

dimension

between

the

outer

edges

of

the

left

and

right

hand

caps

using

a

large

micrometer

as

shown

in

Fig

G

32

This

dimension

should

be

198

40

198

55

mm

7

8110

7

8169

in

for

the

1400

and

1600

ce

Estate

cars

and

1800

ce

Van

and

173

23

17329

mm

6

8201

6

8244

inl

for

the

1800

cc

Estate

cars

Measure

the

backlash

of

the

crownwhcel

and

pinion

with

a

dial

gauge

The

backlash

must

be

adjusted

to

0

13

0

18

mm

0

005

0

007

in

on

the

1800

CC

models

and

to

0

15

0

20mm

0

006

0

008

in

on

the

1400

and

1600

cc

models

Adjustment

can

be

carried

out

by

moving

side

bearing

shims

from

the

right

hand

side

to

the

left

hand

side

if

the

backlash

is

too

high

or

vice

verca

if

the

backlash

is

too

low

Tighten

the

bearing

cap

bolts

to

the

specified

torque

reading

after

adjusting

Ensure

that

the

run

out

at

the

rear

of

the

crown

wheel

does

not

exceed

O

05mm

0

002

in

Finally

heck

the

tooth

contact

pattern

as

described

below

TOOTH

CONTACT

PATTERN

Checking

The

final

check

on

reassembly

is

an

inspection

of

the

tooth

contact

markings

of

the

crownwhed

and

pinion

Apply

a

coal

of

red

lead

in

oil

to

4

or

5

teeth

of

the

crown

wheel

Turn

the

crownwheel

backwards

and

forwards

several

times

to

obtain

a

clear

impression

of

the

contact

areas

Heel

contact

Fig

G

3

1

71

Page 74 of 171

increase

the

thickness

of

the

drive

pinion

adjusting

shim

and

washer

to

move

the

drive

pinion

closer

to

the

crown

wheel

A

correct

contact

pattern

showing

the

impressioll

ithill

a

range

of

2

3

to

4

of

the

distance

bct

l

en

t

h

tip

lllU

till

root

of

the

teeth

under

no

load

Toe

contact

Fig

G

34

Rcdu

e

the

thickness

of

the

drive

pinion

adjusting

shim

and

washer

to

move

the

drive

pinion

away

from

the

crown

wheel

It

will

be

neCL

ssary

to

rc

check

the

backlash

bl

tW

Cl1

drivt

pinion

and

crown

wheel

if

the

adjusting

shim

1l1d

washer

arc

changed

Flank

contact

Fig

G

35

DIFFERENTIAL

Installation

This

pattern

should

be

adjusted

in

a

similar

manner

to

toe

contact

Face

contact

Fig

G

36

Installation

of

the

differential

carrier

is

J

reversal

of

the

removal

procedure

Reference

should

be

made

to

the

section

REAR

AXLE

AND

REAR

SUSPENSION

for

a

dl

saipIion

of

the

operations

required

to

replace

the

axle

shafts

This

pattern

should

be

adjusted

in

a

similar

manner

to

heel

contact

Correct

contact

Fig

G

37

Technical

Data

PROPELLER

SHAFT

Axial

play

of

spider

journal

0800

Axial

play

of

spider

journal

1400

and

1600

cc

0

Q2

mm

0

0008

in

0

08

mm

0

003

in

Max

run

out

of

shaft

Wear

limit

of

spider

diameter

0

6

mm

0

024

in

0

15

mm

0

006

in

Permissible

dynamic

unbalance

Two

joint

shaft

Three

joint

sh

lft

15

gr

em

0

208

in

oz

at

4000

rpm

35

gr

cm

0

5

in

oz

at

5800

rpm

FINAL

GEAR

RATIOS

1800cc

Saloon

6101

ISOOcc

Estate

Car

610

1800cc

Van

610

1600cl

SJloon

610

1400

and

1600cc

510

4

Door

Saloon

RHO

4

Door

Saloon

LHD

De

Lu

e

4

Door

Saloon

RHO

SSS

4

Door

Saloon

RHO

Door

Saloon

LHO

3700

3

889

4

375

3

900

4375

4111

3

889

3

900

3

700

DRIVE

PINION

InitiJI

turning

torque

without

oil

sea

Saloon

modds

Estate

CJr

models

7

10

kg

em

0

506

0

723Ib

ft

10

13

kg

em

0

723

0

940Ib

ft

Thickness

of

pinion

height

adjusting

washers

1400

and

1600

CC

Saloon

1400

and

1600cc

510

Thickncss

of

pinion

height

adjusting

washers

0800

cc

Saloon

0

4

mm

0

078

0

086

0

094

in

3

09

3

66mm

0

1

17

0

1441

in

in

increments

of

0

03

mm

0

00

I

in

Thickness

of

pinion

height

adjusting

washers

0800

n

Estate

car

0

050

0

070

0

100

0

200

0

500mm

0

0020

0

0028

0

0039

0

0079

0

0197

in

Thickness

of

pinion

height

adjusting

washers

1800

CL

Van

37

97111m

0

0933

0

I

69

in

in

increments

of

0

03

mm

0

00

I

in

73

Page 76 of 171

Rear

Axle

Rear

SuspensIon

DESCRIPTION

REAR

AXLE

AND

SUSPENSION

Removal

Saloons

COIL

SPRINGS

Saloons

REAR

SHOCK

ABSORBERS

Saloons

REAR

SUSPENSION

ARM

Saloons

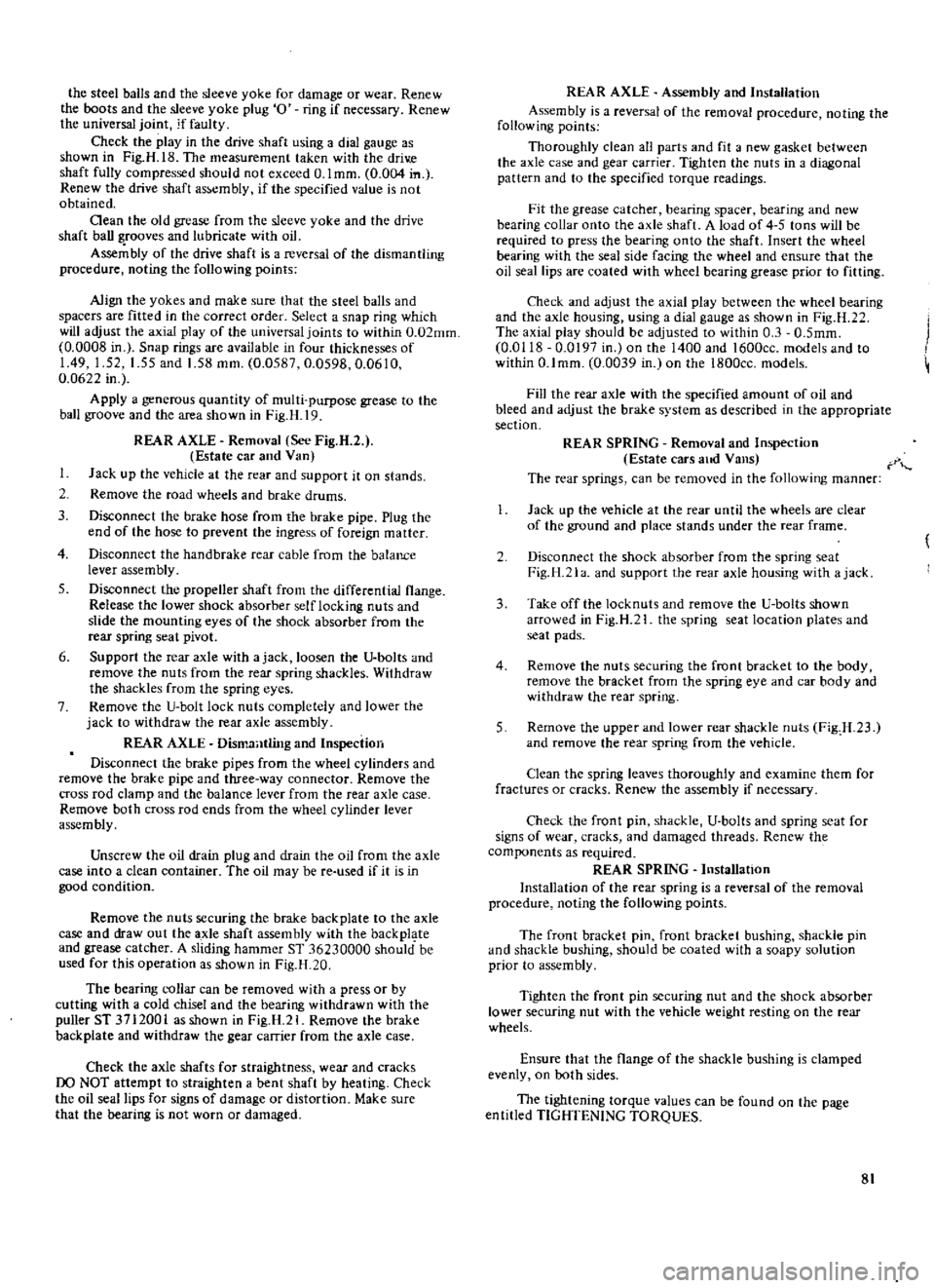

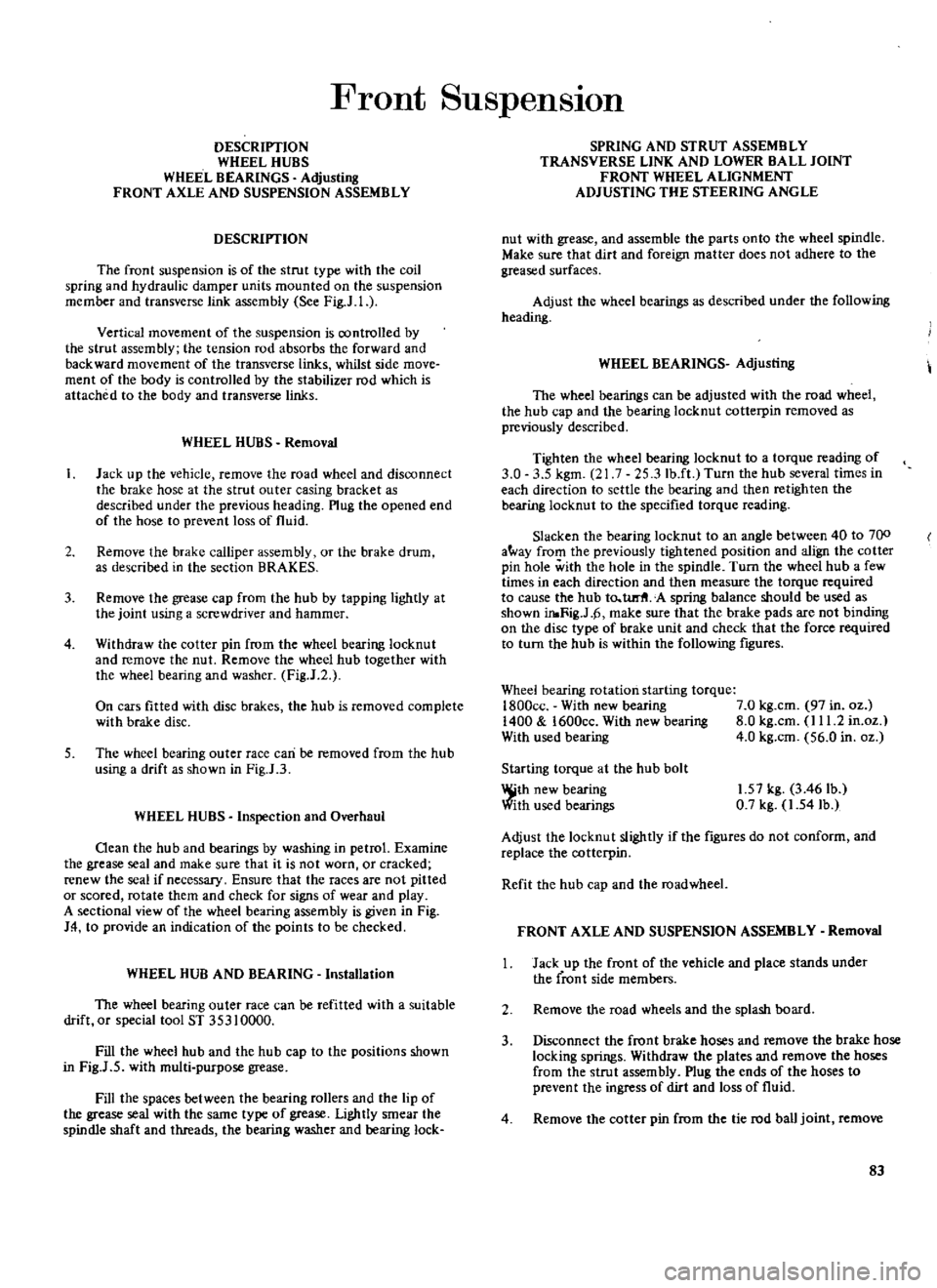

DESCRIPTION

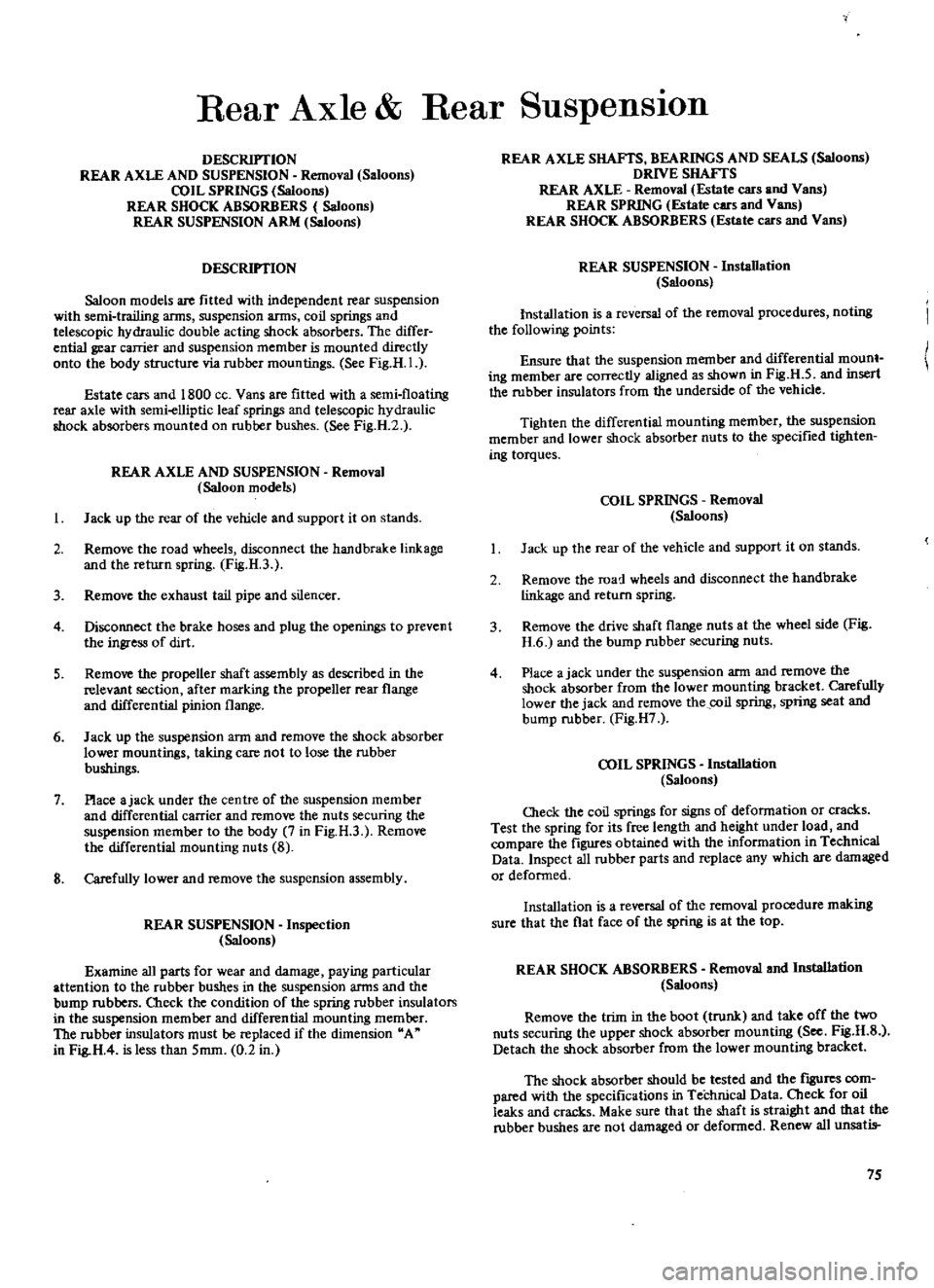

Saloon

models

are

fitted

with

independent

rear

suspension

with

semi

trailing

arms

suspension

arms

coil

springs

and

telescopic

hydraulic

double

acting

shock

absorbers

The

differ

ential

gear

carrier

and

suspension

member

is

mounted

directly

onto

the

body

structure

via

rubber

mountings

See

Fig

H

I

Estate

cars

and

1800

ce

Vans

are

fitted

with

a

semi

floating

rear

axle

with

semi

elliptic

leaf

springs

and

telescopic

hydraulic

shock

absorbers

mounted

on

rubrer

bushes

See

Fig

H

2

REAR

AXLE

AND

SUSPENSION

Removal

Saloon

models

I

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

disconnect

the

hand

brake

linkage

and

the

return

spring

Fig

H

3

3

Remove

the

exhaust

tail

pipe

and

silencer

4

Disconnect

the

brake

hoses

and

plug

the

openings

to

prevent

the

ingress

of

dirt

5

Remove

the

propeller

shaft

assembly

as

described

in

the

relevant

section

after

marking

the

propeller

rear

flange

and

differential

pinion

flange

6

Jack

up

the

suspension

ann

and

remove

the

shock

absorber

lower

mountings

taking

care

not

to

lose

the

rubber

bushings

7

Place

ajack

under

the

centre

of

the

suspension

member

and

differential

carrier

and

remove

the

nuts

securing

the

suspension

member

to

the

body

7

in

Fig

H

3

Remove

the

differential

mounting

nuts

8

8

Carefully

lower

and

remove

the

suspension

assembly

REAR

SUSPENSION

Inspection

Saloons

Examine

all

parts

for

wear

and

damage

paying

particular

attention

to

the

rubber

bushes

in

the

suspension

arms

and

the

bump

rubbers

Check

the

condition

of

the

spring

rubber

insulators

in

the

suspension

member

and

differential

mounting

memrer

The

rubber

insulators

must

be

replaced

if

the

dimension

A

in

Fig

H

4

is

less

than

5mm

0

2

in

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloons

DRNE

SHAFTS

REAR

AXLE

Removal

Estate

cars

and

Vans

REAR

SPRING

Estate

cars

and

Vans

REAR

SHOCK

ABSORBERS

Estate

cars

and

Vans

REAR

SUSPENSION

Installation

Saloons

Installation

is

a

reversal

of

the

removal

procedures

noting

the

following

points

Ensure

that

the

suspension

member

and

differential

mount

ing

member

are

correctly

aligned

as

shown

in

Fig

U

5

and

insert

the

rubber

insulators

from

the

underside

of

the

vehicle

Tighten

the

differential

mounting

member

the

suspension

member

and

lower

shock

absorber

nuts

to

the

specified

tighten

ing

torques

COIL

SPRINGS

Removal

Saloons

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

and

disconnect

the

handbrake

linkage

and

return

spring

3

Remove

the

drive

shaft

flange

nuts

at

the

wheel

side

Fig

H

6

and

the

bump

rubber

securing

nuts

4

Place

ajack

under

the

suspension

ann

and

remove

the

shock

absorber

from

the

lower

mounting

bracket

Carefully

lower

the

jack

and

remove

the

coil

spring

spring

scat

and

bump

rubber

Fig

H7

COIL

SPRINGS

Installation

Saloons

Oleck

the

coil

springs

for

signs

of

deformation

or

cracks

Test

the

spring

for

its

free

length

and

height

under

load

and

compare

the

figures

obtained

with

the

information

in

Technical

Data

Inspect

all

rubber

parts

and

replace

any

which

are

damaged

or

deformed

Installation

is

a

reversal

of

the

removal

procedure

making

sure

that

the

flat

face

of

the

spring

is

at

the

top

REAR

SHOCK

ABSORBERS

Removal

and

Installation

Saloons

Remove

the

trim

in

the

boot

trunk

and

take

off

the

two

nuts

securing

the

upper

shock

absorber

mounting

See

Fig

H

S

Detach

the

shock

absorber

from

the

lower

mounting

bracket

The

shock

absorber

should

be

tested

and

the

fIgUres

com

pared

with

the

specifications

in

Technical

Data

Cbeck

for

oil

leaks

and

cracks

Make

sure

that

the

shaft

is

straight

and

that

the

rubber

bushes

are

not

damaged

or

defonned

Renew

all

unsatis

75

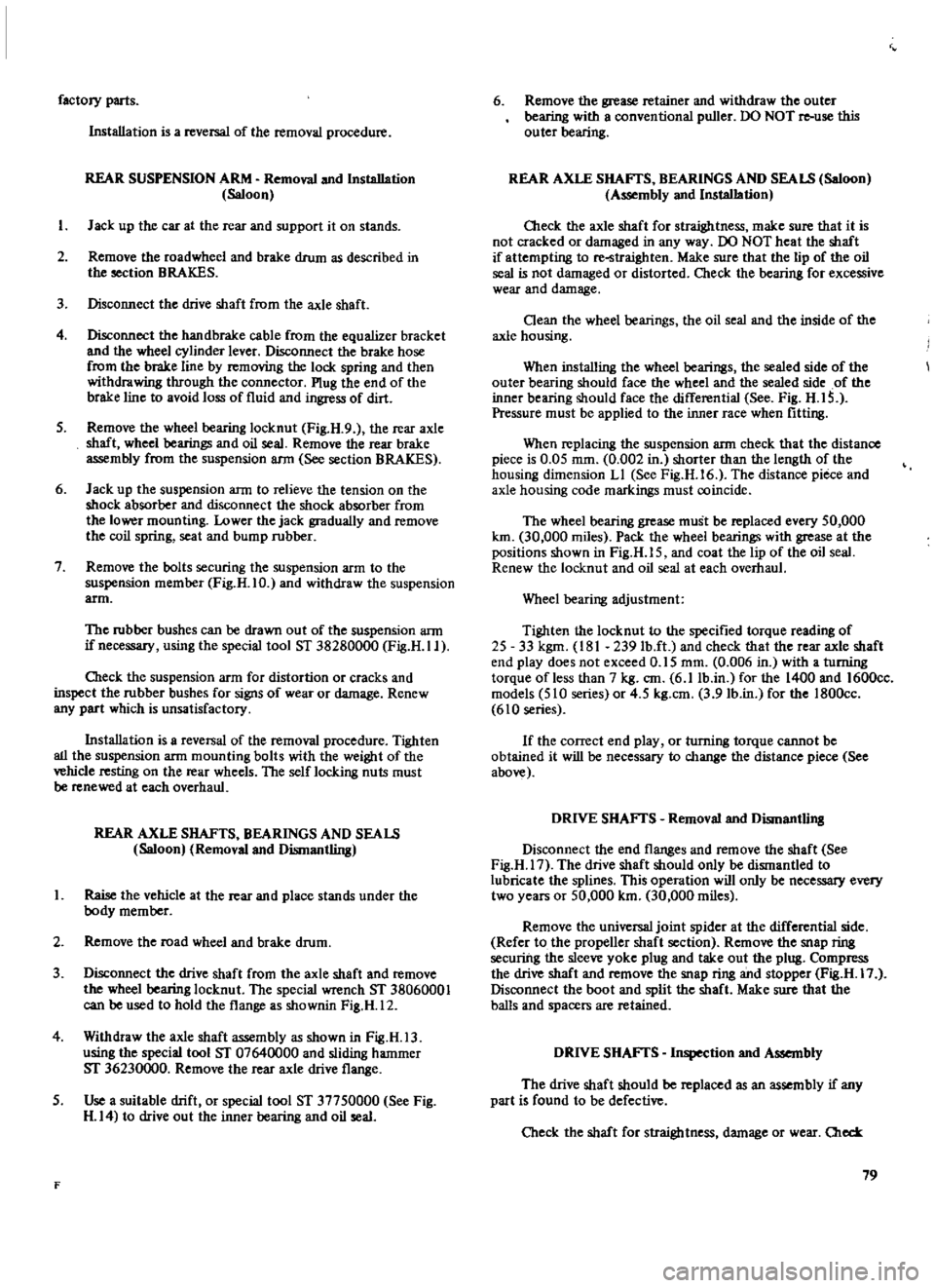

Page 77 of 171

inter

T

r

if

J

II

10

4

9

A

I

I

I

s

tf

4

J

y

r

1

Sl

f

n1

2

8wpmsion

arm

3

MountinK

buuJDror

4

DiffomtiDJ

OIl1rtlnt

insulaior

J

CoU

P

inI

6

Bump

rubber

7

Sf1TinI

mzt

8

S1tock

absorber

9

I

Jm

tlrtifi

10

Differentli1l

mount

nlf

ober

II

Differentitzl

CtUTio

Fig

H

I

Independent

rear

suspension

Saloons

7

w

A

i

I

I

l

il

1

t

J1

0

11

I

j

1

I

J

71

Iii

I

1

V

1

A

3

1

DiffomtiDJ

CtUTio

2

R

I1

u

eazu

I

1

3

L

ll

Sf11inI

4

Shock

abJOriJer

FJ8

H

2

Rear

r

utate

cars

and

Vans

FJ8

H

4

OIecking

the

mounting

insulators

wn

0

6

t

iO

T

t

1Vt

1

1

j

J3

J

111

1

Q

i

n

f

I

1

I

J

0

J

I

I

I

0

l

5

i

1

a

c

u

T

11

0

to

lS

Oq

m

80

to

108

ft

lb

J

iI

Front

20mm

1

200

mm

O

787

n

041

2

in1

410mm

16

1

n

Di

member

CD

T

7

0

to

10

0

q

m

51

to

72

ft

lb

T

20

0

to

30

0

kg

m

145

to

217

fHb

j

T

Tilhtening

torque

Om

FJ8

8

3

Rear

suspension

removal

T

7

0

to

10

q

m

5lI072

ft

Ib

Flg

D

S

Rear

suspension

imtallation

i

76

Page 80 of 171

factory

parts

Installation

is

a

reversal

of

the

removal

procedure

REAR

SUSPENSION

ARM

Removal

and

Installation

Saloon

I

J

ad

up

the

car

at

the

rear

and

support

it

on

stands

2

Remove

the

road

wheel

and

brake

drum

as

described

in

the

section

BRAKES

3

Disconnect

the

drive

shaft

from

the

axle

shaft

4

Disconnect

the

handbrake

cable

from

the

equalizer

bracket

and

the

wheel

cylinder

lever

Disconnect

the

brake

hose

from

the

brake

line

by

removing

the

lock

spring

and

then

withdrawing

through

the

connector

Plug

the

end

of

the

brake

line

to

avoid

loss

of

fluid

and

ingress

of

dirt

5

Remove

the

wheel

bearing

locknut

Fig

H

9

the

rear

axle

shaft

wheel

bearings

and

oil

seal

Remove

the

rear

brake

assembly

from

the

suspension

ann

See

section

BRAKES

6

Jack

up

the

suspension

arm

to

relieve

the

tension

on

the

shock

absorber

and

disconnect

the

shock

absorber

from

the

lower

mounting

Lower

the

jack

gradually

and

remove

the

coil

spring

seat

and

bump

rubber

7

Remove

the

bolts

securing

the

suspension

arm

to

the

suspension

member

Fig

H

IO

and

withdraw

the

suspension

arm

The

rubber

bushes

can

be

drawn

out

of

the

suspension

arm

if

necessary

using

the

special

tool

ST

38280000

Fig

H

Il

O1eck

the

suspension

arm

for

distortion

or

cracks

and

inspect

the

rubber

bushes

for

signs

of

wear

or

damage

Renew

any

part

which

is

unsatisfactory

Installation

is

a

reversal

of

the

removal

procedure

Tighten

all

the

suspension

arm

mounting

bolts

with

the

weight

of

the

vehicle

resting

on

the

rear

wheels

The

self

locking

nuts

must

be

renewed

at

each

overhaul

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloon

Removal

and

Dismantling

I

Raise

the

vehicle

at

the

rear

and

place

stands

under

the

body

member

2

Remove

the

road

wheel

and

brake

drum

3

Disconnect

the

drive

shaft

from

the

axle

shaft

and

remove

the

wheel

bearing

locknut

The

special

wrench

ST

38060001

can

be

used

to

hold

the

flange

as

shownin

Fig

H

12

4

Withdraw

the

axle

shaft

assembly

as

shown

in

Fig

H

13

using

the

special

tool

ST

07640000

and

sliding

hammer

ST

36230000

Remove

the

rear

axle

drive

flange

5

Use

a

suitable

drift

or

special

tool

ST

37750000

See

Fig

H

14

to

drive

out

the

inner

bearing

and

oil

seal

F

6

Remove

the

grease

retainer

and

withdraw

the

outer

bearing

with

a

conventional

puller

DO

NOT

re

use

this

outer

bearing

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloon

Assembly

and

Installation

Oleck

the

axle

shaft

for

straightness

make

sure

that

it

is

not

cracked

or

damaged

in

any

way

00

NOT

heat

the

shaft

if

attempting

to

re

straighten

Make

sure

that

the

lip

of

the

oil

seal

is

not

damaged

or

distorted

Check

the

bearing

for

excessive

wear

and

damage

Oean

the

wheel

bearings

the

oil

seal

and

the

inside

of

the

axle

housing

When

installing

the

wheel

bearings

the

sealed

side

of

the

outer

bearing

should

face

the

wheel

and

the

sealed

side

of

the

inner

bearing

should

face

the

differential

See

Fig

H

IS

Pressure

must

be

applied

to

the

inner

race

when

fitting

When

replacing

the

suspension

arm

check

that

the

distance

piece

is

0

05

mm

0

002

in

shorter

than

the

length

of

the

housing

dimension

LI

See

Fig

H

16

The

distance

piece

and

axle

housing

code

markings

must

coincide

The

wheel

bearing

grease

must

be

replaced

every

50

000

km

30

000

miles

Pack

the

wheel

bearings

with

grease

at

the

positions

shown

in

Fig

H

IS

and

coat

the

lip

of

the

oil

seal

Renew

the

locknut

and

oil

seal

at

each

overhaul

Wheel

bearing

adjustment

Tighten

the

locknut

to

the

specified

torque

reading

of

25

33

kgm

181

239

lb

ft

and

check

that

the

rear

axle

shaft

end

play

does

not

exceed

0

15

mm

0

006

in

with

a

turning

torque

of

less

than

7

kg

em

6

11b

in

for

the

1400

and

1600cc

models

510

series

or

4

5

kg

em

3

91b

in

for

the

1800cc

610

series

If

the

correct

end

play

or

turning

torque

cannot

be

obtained

it

will

be

necessary

to

change

the

distance

piece

See

above

DRIVE

SHAFTS

Removal

and

Dismantlill8

Disconnect

the

end

flanges

and

remove

the

shaft

See

Fig

H

17

The

drive

shaft

should

only

be

dismantled

to

lubricate

the

splines

This

operation

will

only

be

necessary

every

two

years

or

50

000

km

30

000

miles

Remove

the

universal

joint

spider

at

the

differential

side

Refer

to

the

propeller

shaft

section

Remove

the

snap

ring

securiilg

the

sleeve

yoke

plug

and

take

out

the

plug

Compress

the

drive

shaft

and

remove

the

snap

ring

and

stopper

Fig

H

17

Disconnect

the

boot

and

split

the

shaft

Make

sure

that

the

balls

and

spacers

are

retained

DRIVE

SHAFTS

Inspection

and

Assembly

The

drive

shaft

should

be

replaced

as

an

assembly

if

any

part

is

found

to

be

defective

Check

the

shaft

for

straightness

damage

or

wear

Old

79

Page 82 of 171

the

steel

balls

and

the

sleeve

yoke

for

damage

or

wear

Renew

the

boots

and

the

sleeve

yoke

plug

0

ring

if

necessary

Renew

the

universal

joint

jf

faulty

Check

the

play

in

the

drive

shaft

using

a

dial

gauge

as

shown

in

Fig

H

18

The

measurement

taken

with

the

dri

le

shaft

fully

compressed

should

not

exceed

O

lmm

0

004

in

Renew

the

drive

shaft

as

embly

if

the

specified

value

is

not

obtained

Oean

the

old

grease

from

the

sleeve

yoke

and

the

drive

shaft

ball

grooves

and

lubricate

with

oil

Asse

bly

of

the

drive

shaft

is

a

reversal

of

the

dismantling

procedure

noting

the

following

points

Align

the

yokes

and

make

sure

that

the

steel

balls

and

spacers

are

fitted

in

the

correct

order

Select

a

snap

ring

which

will

adjust

the

axial

play

of

the

universaIjoints

to

within

0

02mm

0

0008

in

Snap

rings

are

available

in

four

thicknesses

of

1

49

1

52

1

55

and

1

58

mm

0

0587

0

0598

0

0610

0

0622

in

Apply

a

generous

quantity

of

multi

purpose

grease

to

the

ball

groove

and

the

area

shown

in

Fig

H

19

REAR

AXLE

Removal

See

Fig

H

2

Estate

car

and

Van

Jack

up

the

vehicle

at

the

rear

and

support

it

on

stands

Remove

the

road

wheels

and

brake

drums

I

3

Disconnect

the

brake

hose

from

the

brake

pipe

Plug

the

end

of

the

hose

to

prevent

the

ingress

of

foreign

matter

4

Disconnect

the

handbrake

rear

cable

from

the

balance

lever

assembly

5

Disconnect

the

propeller

shaft

from

the

differential

flange

Release

the

lower

shock

absorber

self

locking

nuts

and

slide

the

mounting

eyes

of

the

shock

absorber

from

the

rear

spring

seat

pivot

6

Support

the

rear

axle

with

ajack

loosen

the

U

bolts

and

remove

the

nuts

from

the

rear

spring

shackles

Withdraw

the

shackles

from

the

spring

eyes

7

Remove

the

V

bolt

lock

nuts

completely

and

lower

the

jack

to

withdraw

the

rear

axle

assembly

REAR

AXLE

Dismailtling

and

Inspection

Disconnect

the

brake

pipes

from

the

wheel

cylinders

and

remove

the

brake

pipe

and

three

way

connector

Remove

the

cross

rod

clamp

and

the

balance

lever

from

the

rear

axle

case

Remove

both

cross

rod

ends

from

the

wheel

cylinder

lever

assembly

Unscrew

the

oil

drain

plug

and

drain

the

oil

from

the

axle

case

into

a

clean

container

The

oil

may

be

re

used

if

it

is

in

good

condition

Remove

the

nuts

securing

the

brake

backplate

to

the

axle

case

and

draw

out

the

axle

shaft

assembly

with

the

backpl

te

and

grease

catcher

A

sliding

hammer

ST

36230000

should

be

used

for

this

operation

as

shown

in

Fig

H

2Q

The

bearing

collar

can

be

removed

with

a

press

or

by

cutting

with

a

cold

chisel

and

the

bearing

withdrawn

with

the

puller

ST

3712001

as

shown

in

Fig

H

2t

Remove

the

brake

backplate

and

withdraw

the

gear

carrier

from

the

axle

case

Check

the

axle

shafts

for

straightness

wear

and

cracks

00

NOT

attempt

to

straighten

a

bent

shaft

by

heating

Check

the

oil

seal

lips

for

signs

of

damage

or

distortion

Make

sure

that

the

bearing

is

not

worn

or

damaged

REAR

AXLE

Assembly

and

Installation

Assembly

is

a

reversal

of

the

removal

procedure

noting

the

following

points

Thoroughly

clean

all

parts

and

fit

a

new

gasket

between

the

axle

case

and

gear

carrier

Tighten

the

nuts

in

a

diagonal

pattern

and

to

the

specified

torque

readings

Fit

the

grease

catcher

bearing

spacer

bearing

and

new

bearing

collar

onto

the

axle

shaft

A

load

of

4

5

tons

will

be

required

to

press

the

bearing

onto

the

shaft

Insert

the

wheel

bearing

with

the

seal

side

facing

the

wheel

and

ensure

that

the

oil

seal

lips

are

coated

with

wheel

bearing

grease

prior

to

fitting

Check

and

adjust

the

axial

play

between

the

wheel

bearing

and

the

axle

housing

using

a

dial

gauge

as

shown

in

Fig

H

22

The

axial

play

should

be

adjusted

to

within

0

3

0

5mm

0

0118

0

0197

in

on

the

1400

and

1600cc

models

and

to

within

O

lmm

0

0039

in

on

the

1800cc

models

Fill

the

rear

axle

with

the

specified

amount

of

oil

and

bleed

and

adjust

the

brake

system

as

described

in

the

appropriate

section

REAR

SPRING

Removal

and

Inspection

Estate

cars

aud

Vans

The

rear

springs

can

be

removed

in

the

following

manner

Jack

up

the

vehicle

at

the

rear

until

the

wheels

are

clear

of

the

ground

and

place

stands

under

the

rear

frame

Disconnect

the

shock

absorber

from

the

spring

seat

Fig

H

21a

and

support

the

rear

axle

housing

with

ajack

3

Take

off

the

locknuts

and

remove

the

U

bolts

shown

arrowed

in

Fig

H

2t

the

spring

seat

location

plates

and

seat

pads

4

Remove

the

nuts

securing

the

front

bracket

to

the

body

remove

the

bracket

from

the

spring

eye

and

car

body

and

withdraw

the

rear

spring

5

Remove

the

upper

and

lower

rear

shackle

nuts

Fig

H

23

and

remove

the

rear

spring

from

the

vehicle

Clean

the

spring

leaves

thoroughly

and

examine

them

for

fractures

or

cracks

Renew

the

assembly

if

necessary

Check

the

front

pin

shackle

U

boIts

and

spring

seat

for

signs

of

wear

cracks

and

damaged

threads

Renew

the

components

as

required

REAR

SPRING

Installation

Installation

of

the

rear

spring

is

a

reversal

of

the

removal

procedure

noting

the

following

points

The

front

bracket

pin

front

bracket

bushing

shackle

pin

and

shackle

bushing

should

be

coated

with

a

soapy

solution

prior

to

assembly

Tighten

the

front

pin

securing

nut

and

the

shock

absorber

lower

securing

nut

with

the

vehicle

weight

resting

on

the

rear

wheels

Ensure

that

the

flange

of

the

shackle

bushing

is

clamped

evenly

on

both

sides

The

tightening

torque

values

can

be

found

on

the

page

entitled

TIGHTENING

TORQUES

81

Page 83 of 171

REAR

SHOCK

ABSORBERS

Replacing

Estate

cars

and

Vans

Jack

up

the

reaT

of

the

vehicle

and

place

stands

under

the

rear

axle

housing

Disconnect

the

lower

end

of

the

rear

shock

absorber

from

the

spring

seat

Fig

H

23

Remove

the

shock

absorber

upper

attachment

nuts

and

withdraw

the

shock

absorber

The

upper

attachment

nuts

are

located

behind

the

Tear

seat

backrest

as

shown

in

Fig

H

24

Check

the

shock

absorber

for

leakage

or

cracks

and

make

sure

that

the

shaft

is

straight

Inspect

the

rubber

bushings

for

damage

and

deterioration

Renew

all

defective

components

lnstallation

is

a

reversal

of

the

removal

procedures

Tighten

the

upper

and

lower

shock

absorber

attachment

nuts

to

the

torque

readings

stipulated

in

TIGlITENING

TORQUES

NOTE

The

weight

of

the

vehicle

must

be

resting

on

the

fear

wheels

when

tightening

the

lower

mounting

to

damp

the

rubber

bushes

in

an

unloaded

position

TechnICal

Data

I

Type

Independent

suspension

with

semi

tralllI1g

arms

or

semi

floating

COIL

SPRINGS

14

2mm

0

559

in

14

5mm

0

571

in

90

mm

3

543

in

306

mm

12

047

in

299

mm

II

772

in

290

mm

11417

in

I

1400

and

1600cc

Wire

diameter

Wire

diameter

hard

suspension

Coil

diameter

Free

length

R

H

Free

length

L

H

Free

length

Hard

suspension

1800cc

Wire

diameter

Coil

diameter

Free

length

RHD

R

H

Free

length

RHD

L

H

Free

length

LHD

both

Free

length

Hard

suspension

RHD

R

H

RHD

L

H

LHD

both

14

5

mm

0

571

in

90

3

54

in

321

mm

12

6

in

307

mm

12

1

in

321

mm

12

6

in

306

mm

12

0

in

299

mm

I

1

8

in

306

mm

12

0

in

SHOCK

ABSORBERS

34

56

kg

75

123

lb

21

39

kg

46

86

lb

SHOCK

ABSORBERS

Estate

cars

and

Vans

1400

and

1600cc

estate

cars

and

rigid

axle

sedan

Piston

diameter

2S

mm

0

984

in

Stroke

205

mm

8

071

in

Max

length

518

mm

20

39

in

Damping

force

at

0

3

in

see

Estate

cars

Expansion

Compression

Damping

force

at

0

3m

jsec

Sedan

Expansion

Compression

1400

and

1600

cc

Piston

diameter

Piston

diameter

Hard

suspension

Stroke

Max

length

Damping

force

at

0

3m

sec

Expansion

Compression

1800

cc

Stroke

Max

lengtb

Damping

force

at

0

3

m

sec

Expansion

Compression

82

35

mm

1

378

in

40

mm

1

575

in

206

mm

8

110

in

568

mm

22

362

in

45

kg

99

21b

28

kg

61

7

lb

220

mm

8

60

in

595

mm

23

4

in

90

kg

198

4

lb

50

kg

110

3

lb

75

kg

165

4Ib

40

kg

88

2

lb

1800cc

Estate

cars

Stroke

Max

length

Damping

force

at

O

3m

sec

Estate

cars

Expansion

Compression

205mm

8

071

in

518

mm

20

39

in

63

87

kg

139

192

lb

33

43

kg

73

95

lb

Damping

force

at

0

3

m

sec

Estate

car

and

Van

with

hard

suspension

Expansion

Compression

97

131

kg

214

289

lb

29

43

kg

64

95

lb

REAR

SPRINGS

1400

and

1600cc

Estate

car

Length

Width

Thickness

No

of

leaves

Free

camber

Laden

camber

1200mm

47

2

in

60

mm

f2

362

in

6

mm

0

236

in

4

137

mm

5

394

in

15

mm

265

kg

0

59

in

584

lb

Spring

eye

bolt

diameter

Front

Rear

45

mm

I

772

in

30

mm

U81

in

1400

and

1600

cc

Free

camber

Laden

cam

her

rigid

axle

sedan

100

mm

3

937

in

15mm

250

kg

0

591

in

551

lb

1800cc

Estate

Laden

camber

Turning

torque

15

mm

265

kg

0

591

in

1

584

lb

2

2

kg

mm

123

Ib

in

REAR

AXLE

SHAFT

less

than

4

5

kg

cm

3

91b

in

less

than

0

1

S

mm

0

006

in

DRIVE

SHAFT

AND

JOURNAL

Spring

constant

End

play

Sliding

resistance

1400

and

1600

cc

Sliding

resistance

1800cc

0

15

kg

0

33

lib

less

than

20

kg

44

lb

Radial

play

of

ball

spline

less

than

O

lmm

0

004

in

Page 84 of 171

Front

SuspensIon

DESCRIPTION

WHEEL

HUBS

WHEEL

BEARINGS

Adjusting

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

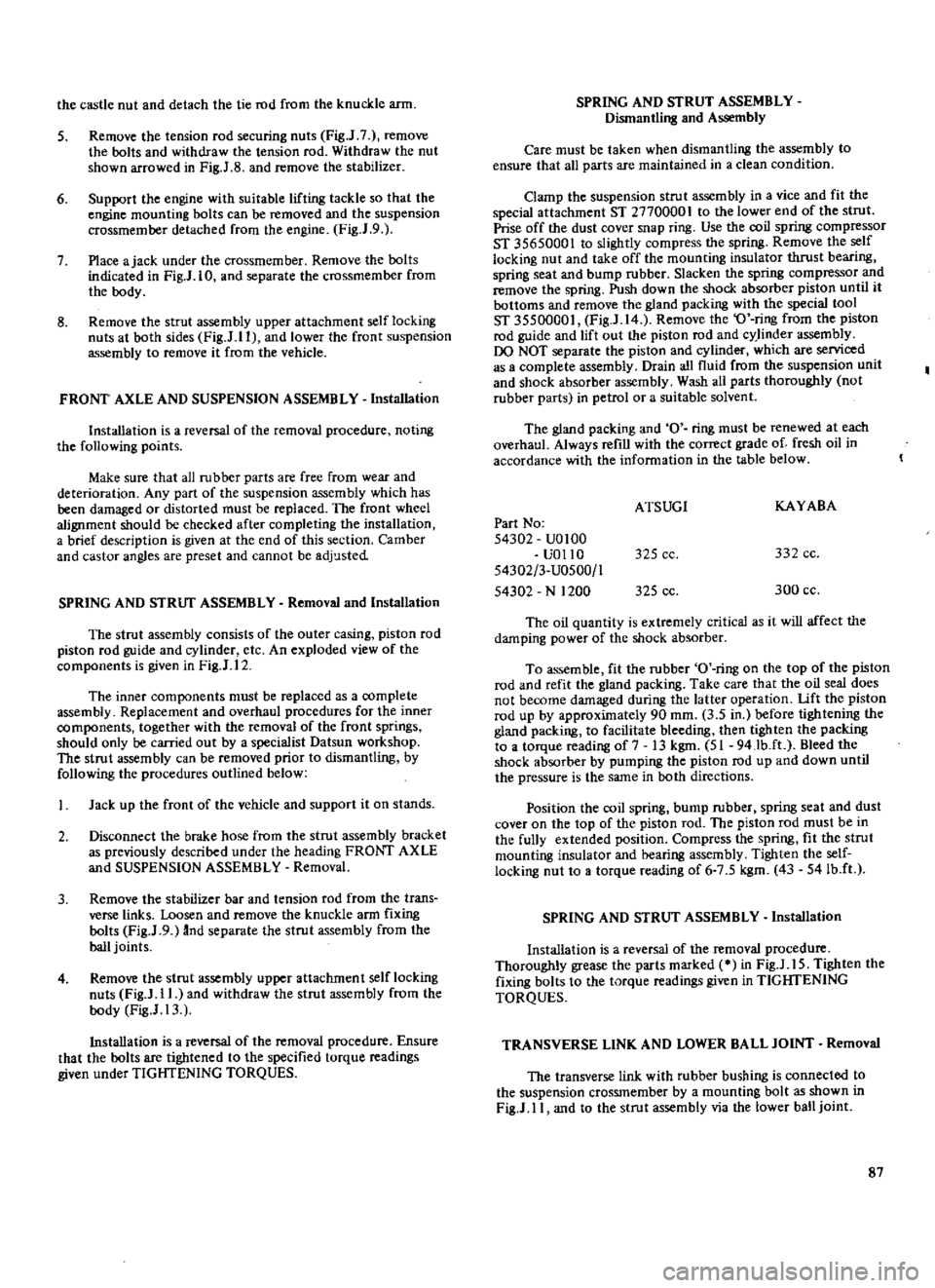

DESCRIPTION

The

front

suspension

is

of

the

strut

type

with

the

coil

spring

and

hydraulic

damper

units

mounted

on

the

suspension

member

and

transverse

link

assembly

See

FigJ

1

Vertical

movement

of

the

suspension

is

controlled

by

the

strut

assembly

the

tension

rod

absorbs

the

forward

and

backward

movement

of

the

transverse

links

whilst

side

move

ment

of

the

body

is

controlled

by

the

stabilizer

rod

which

is

attached

to

the

body

and

transverse

links

WHEEL

HUBS

Removal

1

Jack

up

the

vehicle

remove

the

road

wheel

and

disconnect

the

brake

hose

at

the

strut

outer

casing

bracket

as

described

under

the

previous

heading

Plug

the

opened

end

of

the

hose

to

prevent

loss

of

fluid

2

Remove

the

brake

calliper

assembly

or

the

brake

drum

as

described

in

the

section

BRAKES

3

Remove

the

grease

cap

from

the

hub

by

tapping

lightly

at

the

joint

using

a

screwdriver

and

hammer

4

Withdraw

the

cotter

pin

from

the

wheel

bearing

locknut

and

remove

the

nut

Remove

the

wheel

hub

together

with

the

wheel

bearing

and

washer

Fig

J

2

On

cars

fitted

with

disc

brakes

the

hub

is

removed

complete

with

brake

disc

5

The

wheel

bearing

outer

race

can

be

removed

from

the

hub

using

a

drift

as

shown

in

Fig

I

3

WHEEL

HUBS

Inspection

and

Overhaul

Gean

the

hub

and

bearings

by

washing

in

petrol

Examine

the

grease

seal

and

make

sure

that

it

is

not

worn

or

cracked

renew

the

seal

if

necessary

Ensure

that

the

races

are

not

pitted

or

scored

rotate

them

and

check

for

signs

of

wear

and

play

A

sectional

view

of

the

wheel

bearing

assembly

is

given

in

Fig

14

to

provide

an

indication

of

the

points

to

be

checked

WHEEL

HUB

AND

BEARING

Installation

The

wheel

bearing

outer

race

can

be

refitted

with

a

suitable

drift

or

special

tool

ST

35310000

Fill

the

wheel

hub

and

the

hub

cap

to

the

positions

shown

in

Fig

J

5

with

multi

purpose

grease

Fill

the

spaces

between

the

bearing

rollers

and

the

lip

of

the

grease

seal

with

the

same

type

of

grease

Lightly

smear

the

spindle

shaft

and

threads

the

bearing

washer

and

bearing

lock

SPRING

AND

STRUT

ASSEMBLY

TRANSVERSE

LINK

AND

LOWER

BALL

JOINT

FRONT

WHEEL

ALIGNMENT

ADJUSTING

THE

STEERING

ANGLE

nut

with

grease

and

assemble

the

parts

onto

the

wheel

spindle

Make

sure

that

dirt

and

foreign

matter

does

not

adhere

to

the

greased

surfaces

Adjust

the

wheel

bearings

as

described

under

the

following

heading

WHEEL

BEARINGS

Adjusting

The

wheel

bearings

can

be

adjusted

with

the

road

wheel

the

hub

cap

and

the

bearing

locknut

cotterpin

removed

as

previously

described

Tighten

the

wheel

bearing

locknut

to

a

torque

reading

of

3

0

3

5

kgm

21

7

25

3lb

ft

Turn

the

hub

several

times

in

each

direction

to

settle

the

bearing

and

then

retighten

the

bearing

locknut

to

the

specified

torque

reading

Slacken

the

bearing

locknut

to

an

angle

between

40

to

700

a

ay

from

the

previously

tightened

position

and

align

the

cotter

pin

hole

with

the

hole

in

the

spindle

Turn

the

wheel

hub

a

few

times

in

each

direction

and

then

measure

the

torque

required

to

cause

the

hub

to

turlI

A

spring

balance

should

be

used

as

shown

m

Rig

J

p

make

sure

that

the

brake

pads

are

not

binding

on

the

disc

type

of

brake

unit

and

check

that

the

force

required

to

turn

the

hub

is

within

the

following

fIgures

Wheel

bearing

rotation

starting

torque

1800ce

With

new

bearing

7

0

kg

cm

97

in

oz

1400

1600cc

With

new

bearing

8

0

kg

cm

111

2

in

oz

With

used

bearing

4

0

kg

cm

56

0

in

oz

Starting

torque

at

the

hub

bolt

lWth

new

bearing

ith

used

bearings

1

57

kg

3

46

lb

0

7

kg

1

541b

Adjust

the

locknut

slightly

if

the

fIgures

do

not

conform

and

replace

the

cotterpin

Refit

the

hub

cap

and

the

road

wheel

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

Removal

Jack

up

the

front

of

the

vehicle

and

place

stands

under

the

ront

side

members

Remove

the

road

wheels

and

the

splash

board

3

Disconnect

the

front

brake

hoses

and

remove

the

brake

hose

locking

springs

Withdraw

the

plates

and

remove

the

hoses

from

the

strut

assembly

Plug

the

ends

of

the

hoses

to

prevent

the

ingress

of

dirt

and

loss

of

fluid

4

Remove

the

cotter

pin

from

the

tie

rod

ball

joint

remove

83

Page 88 of 171

the

castle

nut

and

detach

the

tie

rod

from

the

knuckle

arm

5

Remove

the

tension

rod

securing

nuts

Fig

J

7

remove

the

bolts

and

withdraw

the

tension

rod

Withdraw

the

nut

shown

arrowed

in

FigJ

8

and

remove

the

stabilizer

6

Support

the

engine

with

suitable

lifting

tackle

so

that

the

engine

mounting

bolts

can

be

removed

and

the

suspension

crossmember

detached

from

the

engine

FigJ

9

7

Place

ajack

under

the

crossmember

Remove

the

bolts

indicated

in

Fig

J

IO

and

separate

the

crossmember

from

the

body

8

Remove

the

strut

assembly

upper

attachment

self

locking

nuts

at

both

sides

Fig

J

ll

and

lower

the

front

suspension

assembly

to

remove

it

from

the

vehicle

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

Installation

Installation

is

a

reversal

of

the

removal

procedure

noting

the

following

points

Make

sure

that

all

rubber

parts

are

free

from

wear

and

deterioration

Any

part

of

the

suspension

assembly

which

has

been

damaged

or

distorted

must

be

replaced

The

front

wheel

alignment

should

be

checked

after

completing

the

installation

a

brief

description

is

given

at

the

end

of

this

section

Camber

and

castor

angles

are

preset

and

cannot

be

adjusted

SPRING

AND

STRUf

ASSEMBLY

Removal

and

Installation

The

strut

assembly

consists

of

the

outer

casing

piston

rod

piston

rod

guide

and

cylinder

etc

An

exploded

view

of

the

components

is

given

in

Fig

J

12

The

inner

components

must

be

replaced

as

a

complete

assembly

Replacement

and

overhaul

procedures

for

the

inner

components

together

with

the

removal

of

the

front

springs

should

only

be

carried

out

by

a

specialist

Datsun

workshop

The

strut

assembly

can

be

removed

prior

to

dismantling

by

following

the

procedures

outlined

below

Jack

up

the

front

of

the

vehicle

and

support

it

on

stands

2

Disconnect

the

brake

hose

from

the

strut

assembly

bracket

as

previously

described

under

the

heading

FRONT

AXLE

and

SUSPENSION

ASSEMBLY

Removal

3

Remove

the

stabilizer

bar

and

tension

rod

from

the

trans

verse

links

Loosen

and

remove

the

knuckle

arm

fixing

bolts

Fig

J

9

And

separate

the

strut

assembly

from

the

ball

joints

4

Remove

the

strut

assembly

upper

attachment

self

locking

nuts

Fig

J

11

and

withdraw

the

strut

assembly

from

the

body

Fig

J

13

Installation

is

a

reversal

of

the

removal

procedure

Ensure

that

the

bolts

are

tightened

to

the

specified

torque

readings

given

under

TIGHTENING

TORQUES

SPRING

AND

STRUT

ASSEMBLY

Dismantling

and

Assembly

Care

must

be

taken

when

dismantling

the

assembly

to

ensure

that

aU

parts

are

maintained

in

a

clean

condition

Clamp

the

suspension

strut

assembly

in

a

vice

and

fit

the

special

attachment

ST

2770000

I

to

the

lower

end

of

the

strut

Prise

off

the

dust

cover

snap

ring

Use

the

coil

spring

compressor

ST

35650001

to

slightly

compress

the

spring

Remove

the

self

locking

nut

and

take

off

the

mounting

insulator

thrust

bearing

spring

seat

and

bump

rubber

Slacken

the

spring

compressor

and

remove

the

spring

Push

down

the

shock

absorber

piston

until

it

bottoms

and

remove

the

gland

packing

with

the

special

tool

ST

35500001

Fig

J

14

Remove

the

O

ring

from

the

piston

rod

guide

and

lift

out

the

piston

rod

and

cy

linder

assembly

00

NOT

separate

the

piston

and

cylinder

which

are

serviced

as

a

complete

assembly

Drain

all

fluid

from

the

suspension

unit

and

shock

absorber

assembly

Wash

all

parts

thoroughly

not

rubber

parts

in

petrol

or

a

suitable

solvent

The

gland

packing

and

0

ring

must

be

renewed

at

each

overhaul

Always

refill

with

the

correct

grade

of

fresh

oil

in

accordance

with

the

information

in

the

table

below

ATSUGI

KAYABA

Part

No

54302

UO

100

UOl10

325

cc

332

cc

54302

3

U0500

1

54302

N

1200

325

cc

300

cc

The

oil

quantity

is

extremely

critical

as

it

will

affect

the

damping

power

of

the

shock

absorber

To

assemble

fit

the

rubber

O

ring

on

the

top

of

the

piston

rod

and

refit

the

gland

packing

Take

care

that

the

oil

seal

does

not

become

damaged

during

the

latter

operation

Lift

the

piston

rod

up

by

approximately

90

mm

3

5

in

before

tightening

the

gland

packing

to

facilitate

bleeding

then

tighten

the

packing

to

a

torque

reading

of

7

13

kgm

51

94Jb

ft

Bleed

the

shock

absorber

by

pumping

the

piston

rod

up

and

down

until

the

pressure

is

the

same

in

both

directions

Position

the

coil

spring

bump

rubber

spring

seat

and

dust

cover

on

the

top

of

the

piston

rod

The

piston

rod

must

be

in

the

fully

extended

position

Compress

the

spring

fit

the

strut

mounting

insulator

and

bearing

assembly

Tighten

the

self

locking

nut

to

a

torque

reading

of

6

7

5

kgm

43

541b

ft

SPRING

AND

STRUT

ASSEMBLY

Installation

Installation

is

a

reversal

of

the

removal

procedure

Thoroughly

grease

the

parts

marked

in

Fig

J

15

Tighten

the

fixing

bolts

to

the

torque

readings

given

in

TIGHfENING

TORQUES

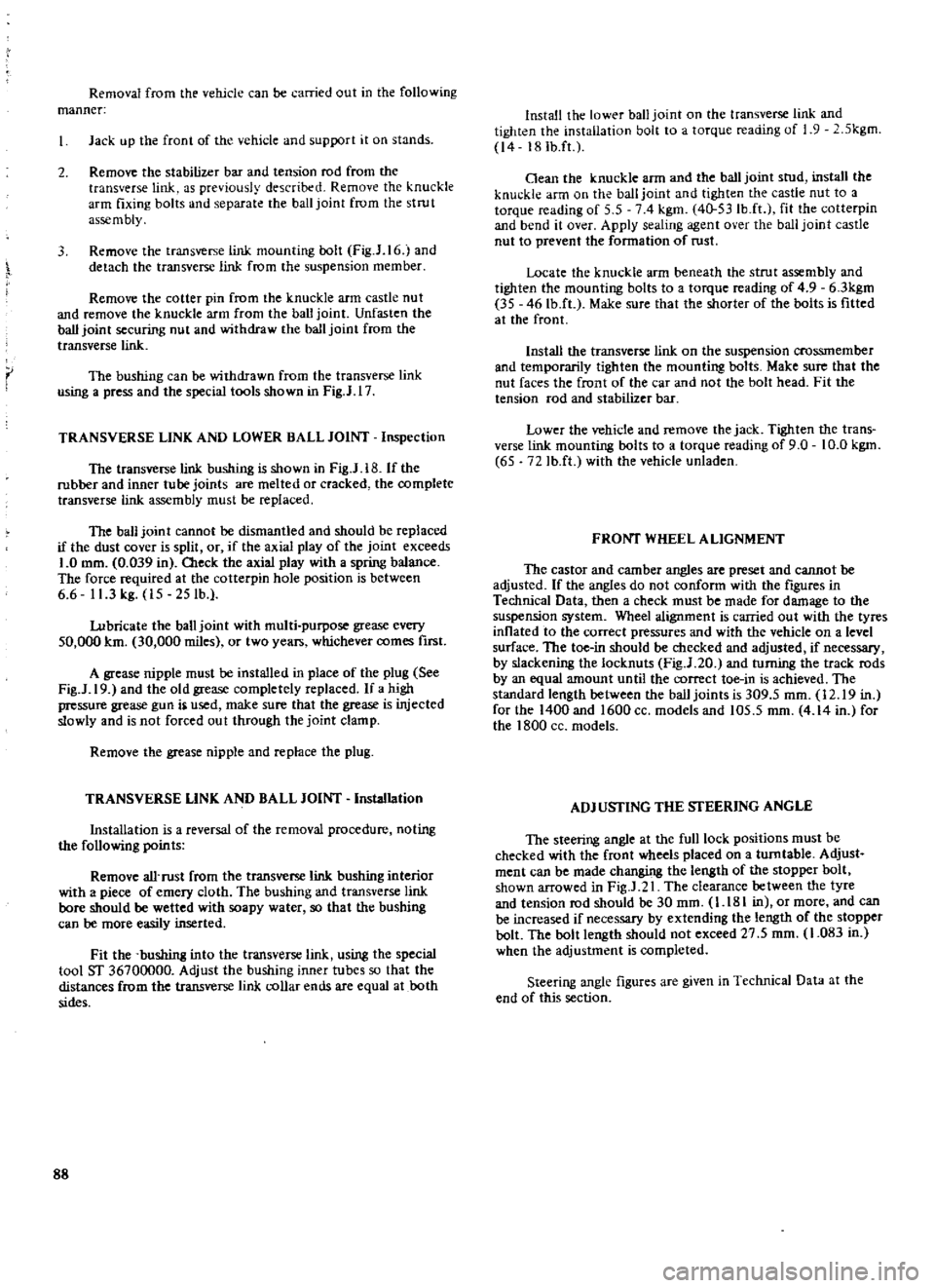

TRANSVERSE

LINK

AND

LOWER

BALL

JOINT

Removal

The

transverse

link

with

rubber

bushing

is

connected

to

the

suspension

crosSlTIember

by

a

mounting

bolt

as

shown

in

Fig

J

11

and

to

the

strut

assembly

via

the

lower

ball

joint

87

Page 89 of 171

Removal

from

the

vehicle

can

be

carried

out

in

the

following

manner

Jack

up

the

front

of

the

vehicle

and

support

it

on

stands

2

Remove

the

stabilizer

bar

and

tension

rod

from

the

transverse

link

as

previously

described

Remove

the

knuckle

arm

fixing

bolts

and

separate

the

ball

joint

from

the

strut

asse

m

bly

3

Remove

the

transverse

link

mounting

bolt

Fig

J

16

and

detach

the