technical data DATSUN 610 1969 Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 140 of 171

that

it

is

clear

of

the

oil

hole

Install

the

bearing

caps

and

tighten

the

bolts

to

a

torque

reading

of

10

0

1

LO

kgm

72

3

79

51b

ft

The

standard

main

bearing

clearance

is

0

03

0

06

mm

0

0012

0

0024

in

with

a

wear

limit

of

0

1

mm

0

0039

in

If

the

specified

limit

is

exceeded

an

undersize

bearing

must

be

fitted

and

the

crankshaft

journal

ground

accordingly

Bearings

are

available

in

four

undersizes

See

Technical

Data

Connecting

rod

bearing

clearance

Check

the

connecting

rod

bearing

clearances

in

a

similar

manner

to

the

main

bearing

clearances

The

standard

clearance

is

0

03

0

06

mm

0

0012

0

0024

in

with

a

wear

limit

of

0

1

mm

0

0039

in

Undersize

bearings

must

be

fitted

and

the

crankpins

reground

if

the

specified

limit

is

exceeded

Bearings

are

available

in

four

undersizes

See

Technical

Data

Fitting

the

crankshaft

bearings

Check

the

fit

of

the

bearing

shells

in

the

following

manner

Install

the

bearings

on

the

main

bearing

caps

and

cylinder

block

bearing

recess

and

tighten

the

cap

bolts

to

the

specified

torque

reading

of

10

0

11

0

kgm

72

3

79

5

Ib

ft

Slacken

one

of

the

cap

baits

and

check

the

clearance

between

the

cap

and

cylinder

block

with

a

feeler

gauge

as

described

for

the

L14

Ll6

and

LIS

engines

The

bearing

crush

should

be

from

0

to

0

04

mm

0

to

0

0016

in

Replace

the

bearing

if

the

clearance

is

not

correct

Check

the

connecting

rod

bearings

in

a

similar

manner

after

tightening

the

rod

cap

bolts

to

a

torque

reading

of

4

5

5

0

kgm

32

6

36

2

Ib

ft

ENGINE

Assembling

Make

sure

that

all

components

are

perfectly

clean

before

starting

to

assemble

the

engine

Refer

to

the

instructions

given

for

the

L14

U6

and

LIS

engines

Cylinder

Head

Install

the

valve

spring

seats

and

valves

Fit

the

oil

seal

rings

on

the

valve

stems

and

place

the

seal

ring

covers

over

the

oil

seal

rings

Note

that

a

gap

of

from

0

3

to

0

7

mm

0

0118

to

0

0276

in

should

be

present

between

the

seal

ring

cover

and

spring

seat

If

the

gap

is

less

than

0

3

mm

0

0118

in

the

oil

seal

ring

or

the

cover

must

be

replaced

Assemble

the

valve

springs

and

retainers

Compress

the

valve

springs

and

install

the

cotters

See

instructions

for

the

LI4

U6

and

Ll8

engines

Assemble

the

camshaft

brackets

valve

rockers

seats

spacers

and

springs

on

the

rocker

shafts

in

the

order

shown

in

Fig

A

l

O

Note

that

the

exhaust

rocker

shaft

has

identification

marks

but

the

intake

rocker

shaft

has

not

Make

sure

that

the

oil

holes

point

in

the

direction

shown

It

may

be

advisable

to

insert

any

convenient

bolts

into

the

bolt

holes

of

the

front

and

rear

cam

shaft

brackets

to

prevent

the

assembly

from

being

displaced

Mount

the

camshaft

on

the

head

fit

the

rocker

assembly

and

tighten

the

nuts

Make

sure

that

the

mark

on

the

flange

of

the

camshaft

is

aligned

with

the

arrow

mark

on

the

No

I

earn

shaft

bracket

as

shown

in

Fig

A

II

Pistons

and

connecting

rods

Assemble

the

pistons

gudgeon

pins

and

connecting

rods

in

accordance

with

the

cylinder

numbers

Heat

the

piston

to

a

temperature

of

500

to

600

1220

to

1400F

and

press

the

gudgeon

pin

in

by

hand

The

pistons

and

connecting

rods

must

be

assembled

as

shown

in

Fig

A

12

with

the

arrow

mark

on

the

head

of

the

piston

pointing

to

the

front

of

the

engine

Fit

new

clips

to

both

ends

of

the

gudgeon

pins

as

indicated

in

Fig

A

13

Fit

the

piston

rings

with

the

marks

facing

upwards

Place

the

bearings

on

the

connecting

rods

and

caps

making

sure

that

the

backs

of

the

bearing

shells

are

perfectly

clean

Assembling

the

engine

Insert

the

oilscal

into

the

grooves

of

the

cylinder

block

and

rear

bearing

cap

Fit

the

seal

down

with

the

speCial

tool

ST49750000

if

available

as

shown

in

Fig

A

14

and

trim

off

the

excess

with

a

knife

Apply

sealing

agent

to

the

oil

plug

and

install

it

in

the

cylinder

block

Fit

the

main

bearings

lubricate

with

clean

engine

oil

and

install

the

crankshaft

Fit

the

bearing

caps

and

tighten

the

bolts

to

a

torque

reading

of

10

0

to

I

LO

kgm

72

3

to

79

5

Ib

ft

Note

that

liquid

packing

should

be

applied

to

the

rear

bear

ing

cap

surfaces

as

shown

in

Fig

A

15

Fit

the

thrust

washers

at

both

sides

of

the

No

2

bearing

with

the

oil

channel

in

the

washers

facing

the

thrust

face

of

the

crankshaft

Install

the

rear

bearing

cap

side

seal

so

that

is

projects

0

2

to

0

6

mm

0

008

to

0

024

in

from

the

lower

surface

of

the

cylind

r

block

then

apply

liquid

packing

to

the

projecting

tip

Install

the

engine

rear

plate

Fit

the

flywheel

and

tighten

the

bolts

to

a

lorque

reading

of

10

0

to

11

0

kgm

72

3

to

79

5

ib

ft

using

new

lock

washers

Lubricate

the

crankshaft

journals

pistons

and

cylinder

bores

with

clean

engine

oil

and

install

the

piston

and

connecting

rod

assemblies

The

pistons

should

be

arranged

so

that

the

arrow

marks

face

towards

the

front

and

with

the

piston

ring

gaps

at

1800

to

each

other

Make

sure

the

gaps

do

not

face

to

the

thrust

side

of

the

piston

or

in

the

same

axial

direction

as

the

gudgeon

pin

Install

the

connecting

rod

caps

o

that

the

marks

face

the

same

way

and

tighten

the

bolts

to

a

torque

reading

of

4

5

to

5

0

kgm

32

6

to

36

2

Ib

ft

Bend

the

lock

washers

as

shown

in

FigA16

Fit

the

oil

jet

to

the

front

of

the

cylinder

block

Install

the

chain

tensioner

and

stopper

crankshaft

sprocket

and

timing

chain

Note

that

the

timing

mark

on

the

chain

must

be

aligned

with

the

mark

on

the

sprocket

as

shown

in

Fig

A

17

Smear

the

mounting

face

of

the

oil

pump

with

sealing

agent

Three

Bond

No

4

or

equivalent

install

the

pump

and

tempora

rily

tighten

the

mounting

bolts

Adjust

the

tension

of

the

oil

pump

chain

using

the

pin

as

the

central

point

then

tighten

the

mounting

bolts

Install

the

oil

thrower

Fit

the

chain

cover

into

position

after

coating

the

new

cover

gasket

with

sealing

compound

Cut

off

the

projecting

parts

of

the

gasket

Fit

the

crankshaft

pulley

and

tighten

the

pulley

nut

to

a

torque

reading

of

15

0

to

20

0

kgm

108

5

to

144

61b

ft

Bend

the

lock

washer

Install

the

oil

strainer

and

oil

pump

Invert

the

engine

and

set

the

No

I

piston

to

T

D

C

of

the

compression

stroke

Note

that

the

notch

on

the

crankshaft

S9

Page 144 of 171

carrying

out

extensive

tests

with

the

necessary

equipment

The

hoses

and

connectors

can

of

course

be

checked

for

signs

of

leakage

and

corrected

as

necessary

Also

the

tension

of

the

air

pump

belt

IGNITION

TIMING

AND

IDLING

SPEED

Emission

control

system

The

ignition

timing

should

be

set

and

the

idling

speed

mixture

adjusted

in

the

folloWing

manner

Run

the

engine

until

it

reaches

its

normal

operating

tem

perature

Connect

an

ignition

tachometer

and

timing

light

observ

ing

the

manufacturers

instructions

NOTE

If

the

vehicle

is

equipped

with

automatic

transmission

make

sure

that

the

dashpot

does

not

prevent

the

throttle

from

closing

Turn

the

throttle

shaft

arm

adjusting

screw

anti

clock

wise

so

that

the

tip

of

the

screw

is

clear

of

the

throttle

shaft

arm

see

Fig

A

26

Turn

the

throttle

adjusting

screw

to

set

the

idling

speed

to

700

r

p

m

650

rpm

for

automatic

transmission

Adjust

the

ignition

timing

to

5

A

T

D

C

Refererence

should

be

made

to

the

instructions

given

in

the

section

IGNITION

SYSTEM

for

the

L14

L16

and

LI8

engines

for

ignition

timing

details

Turn

the

idling

adjustment

screw

and

throttle

adjusting

screw

until

the

engine

runs

smoothly

a

t

the

correct

idling

speed

Turn

the

idling

adjustment

screw

clockwise

until

the

engine

speed

starts

to

drop

as

a

weaker

mix

ture

is

obtained

Now

turn

the

idling

adjustment

screw

anti

clockwise

by

one

turn

one

and

a

half

turns

for

automatic

transmission

to

obtain

a

richer

mix

ture

Adjust

the

idling

speed

to

700

rpm

650

rpm

for

automatic

transmission

by

turning

the

throttle

adjusting

screw

Make

sure

that

the

ignition

timing

remains

at

50

A

T

D

C

Turn

the

throttle

shaft

ann

adjusting

screw

clockwise

until

the

tip

of

the

screw

just

contacts

the

throttle

shaft

ann

The

screw

must

not

exert

pressure

on

the

throttle

shaft

arm

EMISSION

CONTROL

SYSTEM

Maintenance

The

system

should

be

inspected

and

serviced

every

I

2

months

or

20

000

km

12

000

miles

whichever

comes

fIrst

to

make

sure

that

the

exhaust

emissions

are

maintained

at

the

minimum

level

Check

the

carburettor

choke

setting

and

adjust

as

described

in

the

section

FUEL

SYSTEM

Check

the

carburettor

idling

speed

mixture

and

adjust

if

necessary

as

described

under

the

heading

IGNITION

TIMING

AND

IDLING

SPEED

in

this

section

2

Check

the

distributor

earn

dwell

angle

and

also

the

condi

tion

of

the

contact

breaker

points

Check

the

ignition

timing

and

adjust

if

necessary

The

distributor

dwell

angle

should

be

adjusted

to

49

55

degrees

and

the

points

gap

to

0

45

0

55

mm

0

0177

0

0217

in

3

Remove

and

clean

the

sparking

plugs

Renew

any

plug

with

badly

worn

electrodes

Set

the

plug

gaps

to

0

80

0

90

mm

0

0315

0

0355

in

by

adjusting

the

earth

electrode

IGNITION

SYSTEM

The

maintenance

and

servicing

procedures

for

the

compo

nents

of

the

ignition

system

on

vehicles

fitted

with

the

GIS

engine

are

basically

similar

to

the

instructions

previously

given

for

the

Ll4

LI6

and

LIS

engines

The

distributor

is

however

of

a

different

type

Either

an

Hitachi

0416

57

distributor

being

fitted

or

an

Hitachi

0423

53

if

the

vehicle

is

equipped

with

an

emission

control

system

The

distributors

have

different

advance

curve

characteristics

as

shown

in

Technical

Data

IGNITION

TIMING

Check

the

ignition

timing

with

a

timing

light

as

previously

described

for

the

LI4

L16

and

L

8

engines

Disconnect

the

distributor

vacuum

line

and

run

engine

at

idling

speed

or

slightly

below

The

timing

should

be

set

at

8

BTDCj600

rpm

for

the

D416

57

distributor

or

at

5

ATDCj600

rpm

for

the

D423

53

distributor

fItted

to

engines

with

emission

control

systems

IGNITION

DISTRIBUTOR

Maintenance

Maintenance

instructions

are

similar

to

those

given

for

the

L14

LI6

and

L18

engines

Set

the

contact

breaker

points

gap

to

0

45

0

55

mm

0

0177

0

0217

in

as

previously

described

SPARKING

PLUGS

The

sparking

plugs

should

be

inspected

and

cleaned

at

regular

intervals

and

renewed

at

approximately

20

000

kIn

12

000

miles

Clean

the

plugs

thoroughly

and

make

sure

they

are

of

the

same

type

and

heat

range

File

the

centre

electrode

nat

before

adjusting

the

gap

Set

the

gap

to

0

8

0

9mm

0

031

0

035

in

if

the

engine

is

fItted

with

emission

control

system

or

to

0

7

0

8

mm

0

028

0

031

in

if

emission

control

is

not

fitted

Adjustment

must

always

be

made

by

bending

the

earth

electrode

TechnIcal

Data

GENERAL

SPECIFICATION

GI8

Engine

Cylinders

Bore

and

stroke

Displacemen

t

Valve

arrangemen

t

Firing

order

Engine

idler

speed

Compression

ratio

Oil

pressure

at

3000

r

p

m

4

in

line

85x80

mm

3

346x3

150

in

1

815

cc

110

8

cu

in

OHC

134

2

600

r

p

m

STD

8

3

I

4

7

to

5

5

kgjsq

cm

66

8

to

78

2

Ibjsq

in

LIQUID

PACKING

APPLICATION

Cylinder

block

2

Cylinder

head

Oil

gallery

blind

plug

Expansion

plug

Gas

breather

guide

Rear

bearing

cap

fitting

surface

Rear

bearing

cap

side

seal

both

ends

Expansion

plug

Rubber

plug

Rea

Manifold

heat

pipe

3

Chain

cover

gasket

both

sides

S13

Page 152 of 171

between

primary

throttle

valve

and

the

wall

of

the

throttle

chamber

can

be

adjusted

if

necessary

by

carefully

bending

the

choke

connecting

rod

3

THROTILE

VALVE

INTERLOCK

OPENING

With

the

primary

throttle

valve

of

the

type

DAK340

carburettor

opened

to

600

as

shown

in

Fig

B

9

the

adjusting

plate

3

should

contact

the

connecting

lever

J

This

being

the

point

before

the

secondary

throttle

valve

is

brough

into

operation

The

linkage

between

primary

and

secondary

throttles

is

working

correctly

if

the

clearance

G

between

primary

throttle

valve

and

the

wall

of

the

chamber

is

738

mm

0

3937

in

Adjust

if

necessary

by

carefully

bending

the

adjusting

plate

at

point

A

until

the

correct

setting

is

obtained

With

the

primary

throttle

valve

of

the

type

D3034C

car

burettor

opened

at

an

angle

of

500

the

connecting

link

3

in

Fig

B

IO

should

ge

at

the

extreme

left

of

the

slot

in

the

throttle

ann

4

With

the

linkage

positioned

as

shown

measure

the

clearance

between

primary

throttle

valve

and

the

wall

of

the

chamber

as

described

for

the

DAK340

carburettor

Adjustment

can

be

made

if

necessary

by

bending

the

connecting

link

until

the

correct

clearance

is

obtained

CARBURElTOR

Removing

and

Dismantling

The

carburettor

can

be

removed

by

following

the

instruc

tions

previously

given

for

carburettor

removal

on

the

Ll4

L16

and

LIB

engines

Dismantle

the

type

DAK340

carburettor

as

follows

Remove

the

primary

throttle

return

spring

Take

off

the

E

ring

and

remove

the

pump

and

connecting

rod

Remove

the

split

pin

and

choke

connecting

rod

Remove

the

secondary

throttle

return

spring

Remove

the

choke

wire

arm

choke

valve

shaft

and

valve

spring

Take

off

the

clip

and

remove

the

choke

lever

and

spring

To

dismantle

the

float

chamber

take

off

the

diaphragm

cover

and

remove

the

spring

and

diaphragm

Remove

the

diaphragm

chamber

and

gasket

Take

off

the

float

chamber

cover

and

remove

the

gasket

level

gauge

rubber

seal

and

float

Remove

the

screw

from

the

filter

and

withdraw

the

nipple

and

filter

Remove

the

needle

valve

Take

off

the

cylinder

cover

and

pump

cover

and

withdraw

the

piston

piston

return

spring

and

inlet

valve

Remove

the

primary

main

air

bleed

the

secondary

main

air

bleed

and

emulsion

tube

Take

off

the

small

venturi

and

remove

the

primary

and

secondary

slow

jets

and

slow

air

bleeds

Remove

the

drain

plugs

and

take

out

the

primary

and

secondary

main

jets

To

dismantle

the

throttle

chamber

remove

the

throttle

adjusting

screw

and

spring

and

the

idling

adjusting

screw

and

spring

Withdraw

the

throttle

lever

spring

hanger

sleeve

connecting

lever

return

plate

and

adjusting

plate

Withdraw

the

primary

throttle

valve

and

primary

throttle

shaft

Withdraw

the

secondary

throttle

valve

and

secondary

throttle

shaft

The

type

D3034C

carburettor

can

be

dismantled

as

follows

Detach

the

starting

connecting

rod

from

the

choke

lever

and

accelerator

pump

connecting

rod

Remove

the

air

horn

pump

rod

slow

jets

the

primary

and

secondary

small

venturies

Detach

the

primary

and

secondary

linkages

Take

off

the

diaphragm

chambe

cover

and

take

out

the

spring

and

diaphragm

Remove

the

diaphragm

chamber

and

gasket

Separate

the

float

chamber

from

the

throttle

chamber

take

off

the

float

chamber

cover

and

remove

the

components

Remove

the

inlet

strainer

and

float

valve

seat

Remove

the

main

jets

and

take

off

the

fuel

cut

off

valve

CARBURETTOR

Assembly

and

Installation

The

assembly

and

installation

of

the

carburettor

is

a

reversal

of

the

dismantling

and

removal

procedures

Clean

and

inspect

all

components

as

described

for

the

carburettors

fitted

to

the

Ll4

Ll6

and

LI8

engines

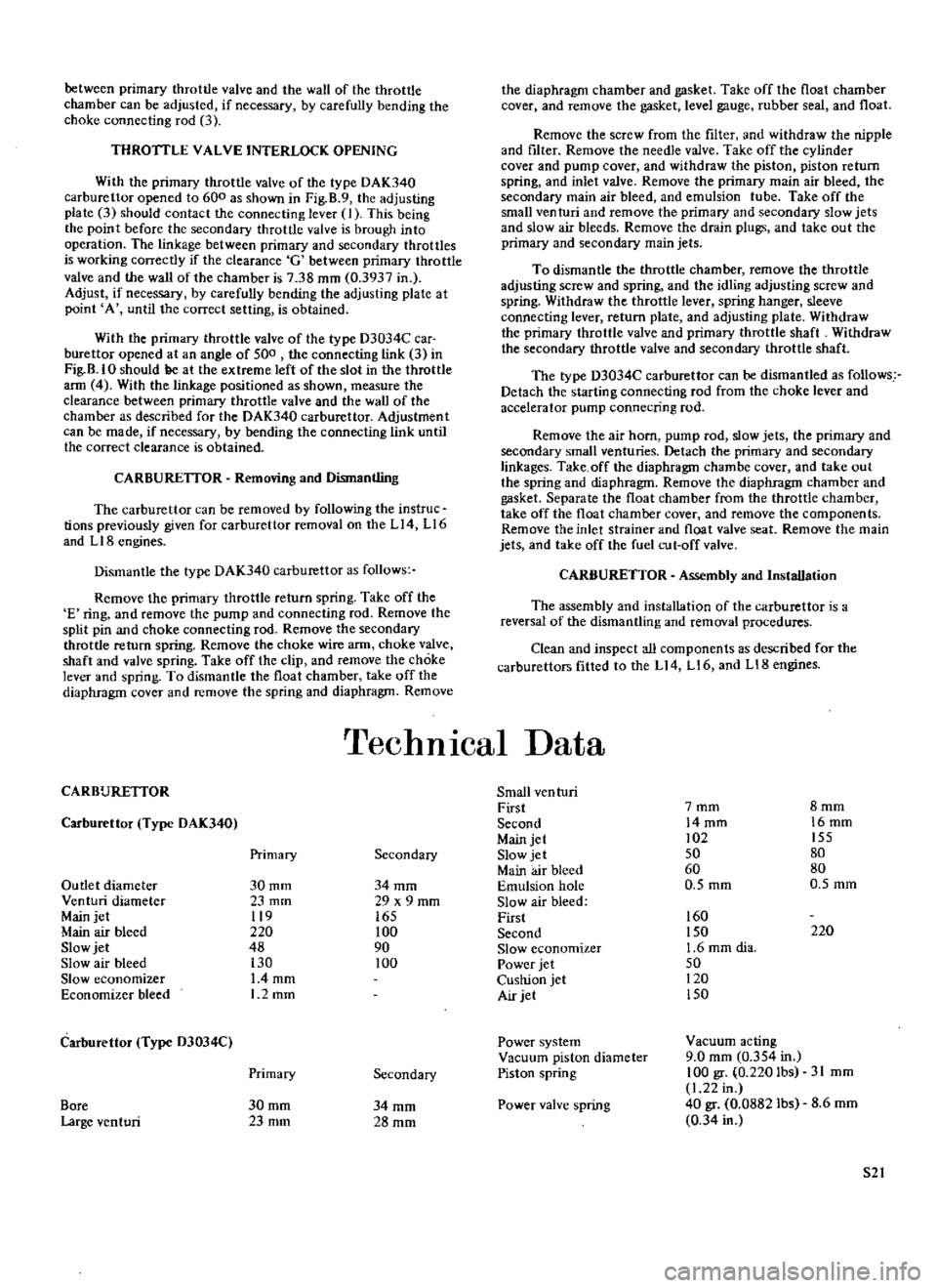

TechnIcal

Data

CARBURETIOR

Small

ven

turi

First

7mm

8mm

Carburettor

Type

DAK340

Second

14mm

16mm

Main

jet

02

155

Primary

Secondary

Slow

jet

50

80

Main

air

bleed

60

80

Outlet

diameter

30mm

34mm

Emulsion

hole

0

5

mm

O

5mm

Venturi

diameter

23

mm

29

x

9

mm

Slow

air

bleed

Main

jet

119

165

First

160

Main

air

bleed

220

100

Second

150

220

Slow

jet

48

90

Slow

economizer

1

6

mm

dia

Slow

air

bleed

130

100

Power

jet

50

Slow

economizer

L4mm

Cushion

jet

120

Economizer

bleed

1

2mm

Air

jet

150

Carburettor

Type

D3034C

Power

system

Vacllum

acting

Vacuum

piston

diameter

9

0

mm

0

354

in

Primary

Secondary

Piston

spring

100

gr

0

220

Ibs

31

mm

1

22

in

Bore

30mm

34mm

Power

valve

spring

40

gr

0

0882

lbs

8

6mm

Large

venturi

23mm

28mm

0

34

in

52

Page 154 of 171

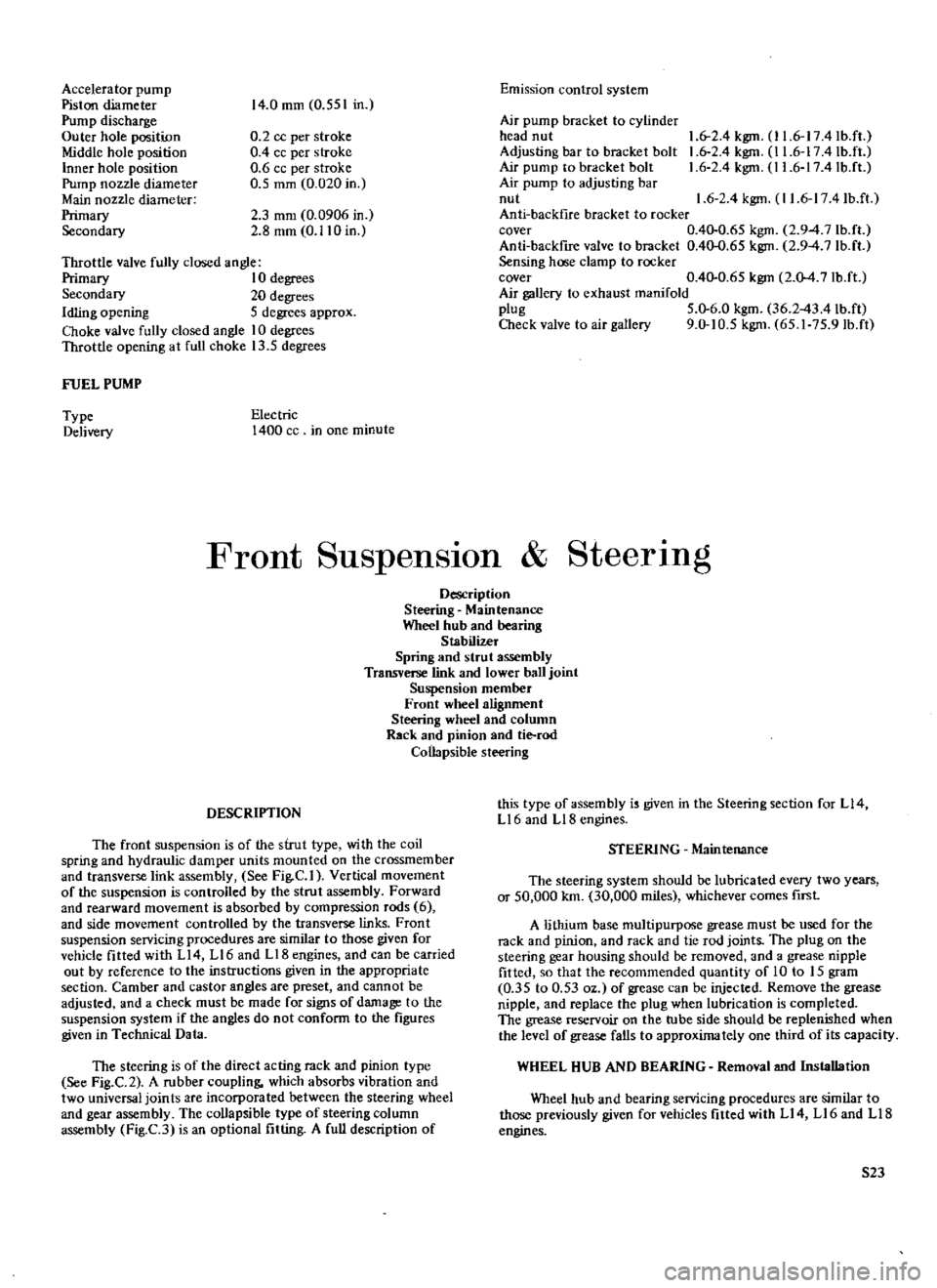

Accelerator

pump

Piston

diameter

Pump

discharge

Outer

hole

position

Middle

hole

position

Inner

hole

position

Pump

nozzle

diameter

Main

nozzle

diameter

Primary

Secondary

14

0

mm

0

551

in

0

2

cc

per

stroke

0

4

cc

per

stroke

0

6

cc

per

stroke

0

5

mm

0

020

in

2

3

mm

0

0906

in

2

8

mm

0

110

in

Throttle

valve

fully

closed

angle

Primary

10

degrees

Secondary

20

degrees

Idling

opening

5

degrees

approx

Choke

valve

fully

closed

angle

10

degrees

Throttle

opening

at

full

choke

13

5

degrees

FUEL

PUMP

Type

Delivery

Electric

1400

cc

in

one

minute

Emission

control

system

Air

pump

bracket

to

cylinder

head

nut

Adjusting

bar

to

bracket

bolt

Air

pump

to

bracket

bolt

Air

pump

to

adjusting

bar

nut

Anti

backfrre

bracket

to

rocker

cover

0

4Q

0

65

kgm

2

94

7

lb

ft

Anti

backfire

valve

to

bracket

0

4Q

O

65

kgm

2

94

7

lb

ft

Sensing

hose

clamp

to

rocker

cover

0

4Q

0

65

kgm

2

M

7

Ib

ft

Air

gallery

to

exhaust

manifold

plug

5

Q

6

0

kgm

36

243

4lb

ft

Check

valve

to

air

gallery

9

0

10

5

kgm

65

1

75

9Ib

ft

1

6

2

4

kgm

I

1

6

17

4Ib

ft

1

6

2

4

kgm

I

1

6

17

4Ib

ft

1

6

2

4

kgm

I

1

6

17

4

lb

ft

1

6

2

4

kgm

11

6

17

4Ib

ft

Front

SuspensIon

SteerIng

Description

Steering

Maintenance

Wheel

hub

and

bearing

Stabilizer

Spring

and

strut

assembly

Transverse

link

and

lower

ball

joint

Suspension

member

Front

wheel

alignment

Steering

wheel

and

column

Rack

and

pinion

and

tie

rod

Collapsible

steering

DESCRIPTION

The

front

suspension

is

of

the

strut

type

with

the

coil

spring

and

hydraulic

damper

units

mounted

on

the

crossmember

and

transverse

link

assembly

See

Fig

C

I

Vertical

movement

of

the

suspension

is

controlled

by

the

strut

assembly

Forward

and

rearward

movement

is

absorbed

by

compression

rods

6

and

side

movement

controlled

by

the

transverse

links

Front

suspension

servicing

procedures

are

similar

to

those

given

for

vehicle

fitted

with

L14

Ll6

and

LIB

engines

and

can

be

carried

out

by

reference

to

the

instructions

given

in

the

appropriate

section

Camber

and

castor

angles

are

preset

and

cannot

be

adjusted

and

a

check

must

be

made

for

signs

of

damage

to

the

suspension

system

if

the

angles

do

not

confonn

to

the

figures

given

in

Technical

Data

The

steering

is

of

the

direct

acting

rack

and

pinion

type

See

Fig

C

2

A

rubber

coupling

which

absorbs

vibration

and

two

universal

join

ts

are

incorpora

ted

between

the

steering

wheel

and

gear

assembly

The

collapsible

type

of

steering

column

assembly

Fig

C3

is

an

optional

fitting

A

full

description

of

this

type

of

assembly

i

given

in

the

Steering

section

for

L14

L16

and

L18

engines

STEERING

Maintenance

The

steering

system

should

be

lubricated

every

two

years

or

50

000

km

30

000

miles

whichever

comes

fIrst

A

lithium

base

multipurpose

grease

must

be

used

for

the

rack

and

pinion

and

rack

and

tie

rod

joints

The

plug

on

the

steering

gear

housing

should

be

removed

and

a

grease

nipple

fitted

so

that

the

recommended

quantity

of

10

to

15

gram

0

35

to

0

53

oz

of

grease

can

be

injected

Remove

the

grease

nipple

and

replace

the

plug

when

lubrication

is

completed

The

grease

reservoir

on

the

tube

side

should

be

replenished

when

the

level

of

grease

falls

to

approximately

one

third

ofits

capacity

WHEEL

HUB

AND

BEARING

Removal

and

Installation

Wheel

hub

and

bearing

servicing

procedures

are

similar

to

those

previously

given

for

vehicles

fitted

with

L14

LI6

and

LIB

engines

S23

Page 156 of 171

Remove

the

road

wheel

and

disconnect

the

brake

hose

at

the

connector

as

shown

in

Fig

C

4

of

this

section

Remove

the

brake

calliper

assembly

and

hub

cap

Withdraw

the

cotter

pin

and

remove

the

wheel

bearing

locknut

Remove

the

wheel

bearing

washer

and

take

off

the

hub

and

brake

disc

Fig

C

5

Remove

the

bearing

collar

take

out

the

outer

bearing

cage

and

prise

out

the

hub

grease

seal

Remove

the

inner

bearing

cage

and

drive

out

the

outer

races

of

the

inner

and

outer

bearings

using

the

special

drift

ST49120000

if

avail

able

Separate

the

brake

disc

from

the

hub

by

taking

out

the

retaining

bolts

as

shown

in

Fig

C

6

Installation

is

a

reversal

of

the

removal

procedure

Adjust

the

wheel

bearings

as

previously

described

taking

care

to

tighten

the

wheel

bearing

locknut

to

the

specified

torque

read

ing

of

3

0

to

3

5

kgm

21

7

to

25

3lb

ft

Turn

the

hub

several

times

to

settle

the

bearing

then

retighten

the

nut

to

the

same

figure

Slacken

the

locknut

by

a

quarter

turn

900

and

insert

the

cotter

pin

when

the

hole

in

the

spindle

is

aligned

with

the

hole

in

the

nut

Check

that

the

force

required

to

turn

the

hub

is

less

than

7

0

kg

cm

97

2

in

oz

STABILIZER

Removal

and

Installation

Remove

the

splash

board

and

take

off

the

bolts

I

in

Fig

C

7

which

attach

the

stabilizer

at

the

transverse

link

sides

Remove

the

bolts

attaching

the

stabilizer

bracket

2

to

the

frame

then

withdraw

the

stabilizer

Check

the

bar

and

rubber

components

for

signs

of

deforma

tion

or

damage

and

renew

as

necessary

Installation

is

a

reversal

of

the

removal

procedures

Tighten

the

fixing

bolts

to

a

torque

reading

of

1

2

to

I

7

kgm

8

7

to

12

3

lb

ft

at

the

transverse

link

side

and

1

9

to

2

5

kgm

13

7

to

18

llb

ft

at

the

frame

bracket

SPRING

AND

STRUT

ASSEMBLY

The

spring

and

strut

assembly

can

be

serviced

by

following

the

instructions

previously

given

for

the

assemblies

on

vehicles

fitted

with

the

L14

L16

and

Ll8engines

When

reassembling

make

sure

that

the

parts

shown

in

Fig

C

8

are

thomughly

greased

Installation

of

the

assembly

will

be

accomplished

more

easily

if

the

dust

cover

on

the

bonnet

ledge

is

removed

Tighten

the

nuts

and

bolts

to

a

torque

figures

given

in

TIGHTENING

TORQUES

TRANSVERSE

LINK

AND

LOWER

BALL

JOINT

The

transverse

link

and

lower

ball

joint

can

be

removed

in

a

similar

manner

to

the

parts

on

vehicles

fitted

with

L

14

L

16

and

L

18

engines

Renew

the

link

if

cracked

or

damaged

in

any

way

Check

the

measurement

A

in

Fig

C

9

The

measurement

between

front

and

rear

transverse

link

bushes

should

be

less

than

1

0

mm

0

039

in

Replace

the

bushes

if

necessary

The

lower

ball

joint

should

be

replaced

if

the

axial

play

of

the

joint

exceeds

0

03

to

0

6

mm

0

0012

to

0

0136

in

A

grease

nipple

must

be

installed

in

place

of

the

ball

joint

plug

so

that

the

joint

can

be

lubricated

with

multi

purpose

grease

as

previously

described

SUSPENSION

MEMBER

Removing

and

Installing

Jack

up

the

vehicle

and

support

it

on

stands

2

Remove

the

splash

board

Refer

to

Fig

C

I

0

and

detach

the

compression

rod

I

the

stabilizer

2

from

the

trans

verse

link

3

Detach

the

steering

linkage

from

the

suspen

sion

crossmember

4

3

Take

out

the

nuts

attaching

the

transverse

links

and

remove

the

links

at

both

sides

of

the

vehicle

4

Support

the

engine

with

a

hoist

as

shown

in

Fig

C

II

taking

care

not

to

damage

the

throttle

and

remote

control

linkages

and

then

remove

the

engine

mounting

bolts

at

both

sides

5

Remove

the

bolts

shown

arrowed

in

Fig

C

12

and

lift

the

suspension

member

away

Renew

the

suspension

member

if

it

is

cracked

or

deformed

in

any

way

Installation

is

a

reversal

of

the

removal

procedure

FRONT

WHEEL

ALIGNMENT

As

previously

stated

the

castor

and

camber

angles

are

preset

and

cannot

be

adjusted

A

thorough

check

should

be

made

of

the

steering

and

suspension

system

and

all

defective

parts

renewed

if

the

angles

are

incorrect

See

Technical

Data

The

front

wheels

should

toe

in

12

to

15

mm

0

4

7

to

0

59

in

Adjustment

can

be

carried

out

by

slackening

the

locknuts

1

in

Fig

C

13

and

then

turning

the

tie

rods

by

an

equal

amount

until

the

correct

toe

in

is

achieved

A

toe

in

gauge

will

of

course

be

required

for

this

operation

STEERING

WHEEL

AND

COLUMN

Removal

Disconnect

the

horn

wire

and

remove

the

horn

bar

Remove

the

steering

wheel

nut

and

pull

off

the

steering

wheel

2

Remove

the

turn

signal

and

lighting

switch

assembly

followed

by

the

steering

column

shell

covers

3

Remove

the

bolts

from

the

rubber

coupling

to

disconnect

the

lower

joint

See

Figs

C

14

and

C

I

5

if

the

car

is

fitted

with

right

hand

drive

The

lower

joint

upper

bolt

should

be

removed

to

disconnect

the

joint

if

the

car

is

fitted

with

left

hand

drive

4

Remove

the

cotter

pin

from

the

trunnion

and

disconnect

the

gearchange

rod

and

selector

rod

5

Remove

the

steering

column

upper

clamp

and

take

out

the

bolts

securing

the

lower

plate

STEERING

COLUMN

Dismantling

and

Assembling

Remove

the

C

washer

socket

screw

and

upper

bracket

bolt

Remove

the

lower

bracket

bolts

and

detach

the

remote

control

linkage

from

the

column

assembly

Remove

the

snap

ring

at

the

top

of

the

column

and

extract

the

column

shaft

from

the

jacket

Disconnect

the

rubber

coupling

from

the

lower

joint

then

remove

the

snap

ring

and

dismantle

the

lower

joint

S25

Page 160 of 171

Tighten

the

inner

socket

until

the

ball

seat

is

at

the

rack

end

then

back

off

the

socket

by

30

to

40

degrees

and

tighten

the

stop

nut

to

a

torque

reading

of

8

0

to

10

0

kgm

57

8

to

72

3

Ib

ft

as

shown

in

Fig

C

25

With

the

tie

rod

assembled

measure

the

force

required

to

swing

the

tie

rod

Hook

a

spring

balance

at

the

end

of

the

rod

as

shown

in

Fig

C

26

and

check

that

the

force

is

from

3

0

to

6

0

kgm

6

6

to

13

2

lb

Measure

the

stroke

of

the

rack

which

should

be

73

0

mm

2

874

in

Fit

grease

nipples

at

both

ends

of

the

rack

and

pinion

housing

Apply

multipurpose

ase

to

each

joint

until

a

small

quantity

of

grease

appears

at

the

out

let

hole

in

the

boot

Do

not

use

an

excessive

amount

of

grease

The

pinion

housing

should

be

lubricated

until

a

small

quantity

of

grease

appears

between

rack

and

housing

Remove

the

grease

nipple

and

fit

the

plug

Fit

the

boot

Fill

the

grease

reseIVoir

with

grease

and

attach

it

to

the

rack

housing

Adjust

the

length

of

the

tie

rods

at

both

sides

as

des

ribed

under

FRONT

WHEEL

ALIGNMENT

Assemble

the

steering

lower

joint

to

the

rack

and

pinion

and

tighten

the

lower

joint

bolt

to

a

torque

reading

of

4

0

to

5

0

kgm

29

0

to

36

0

Ib

ft

Installation

of

the

rack

and

pinion

assembly

is

a

reversal

of

the

removal

procedure

COLLAPSIBLE

STEERING

Removi

8

and

Dismantti

8

The

steering

coluJllfl

See

Fig

C

3

can

be

removed

in

a

similar

manner

to

the

standard

type

of

column

Take

care

not

to

drop

the

column

when

it

is

removed

from

the

vehicle

or

the

shaft

may

collapse

Do

not

exert

any

pressure

on

the

column

or

the

bellows

may

be

defonned

To

dismantle

proceed

as

follows

Remove

the

retaining

wire

and

pull

out

the

lower

shaft

Disconnect

the

control

linkage

if

the

vehicle

is

fitted

with

auto

matic

transmission

Slide

the

steering

shaft

bracket

away

With

draw

the

screws

and

separate

the

upper

and

lower

tubes

Assembly

is

a

reversal

of

the

dismantling

procedure

Note

that

the

slot

in

the

universal

joint

must

be

aligned

with

the

punch

mark

at

the

top

of

the

upper

steering

shaft

as

shown

in

Fig

C

28

When

installing

the

column

make

sure

that

the

bellows

do

not

become

bent

of

twisted

as

the

clamp

and

bottom

plate

bolts

are

tightened

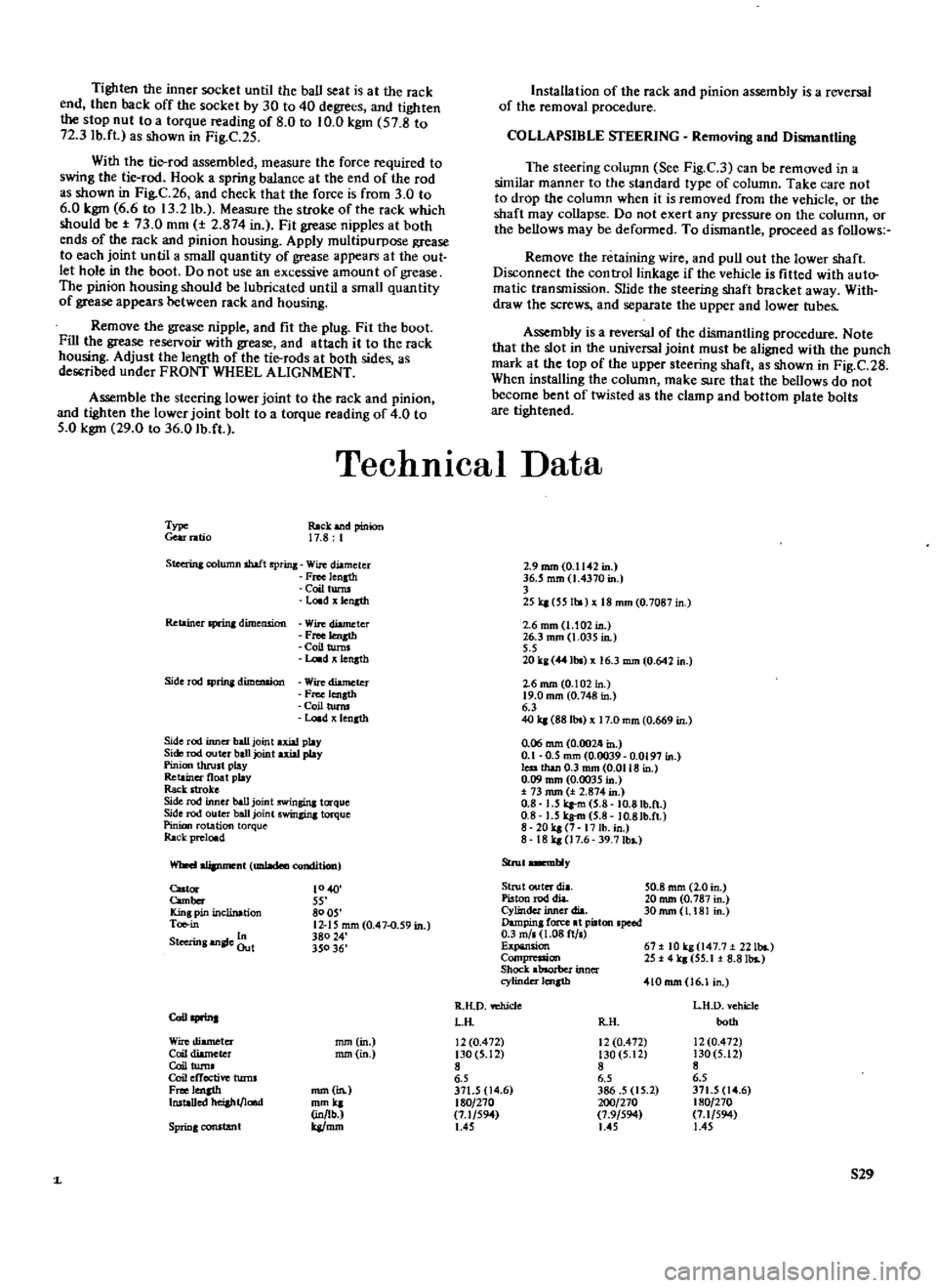

TechnICal

Data

TYP

Gear

I1ltio

Rack

and

pinion

17

8

I

Steerin

column

shaft

spring

Wire

diameter

Freelenath

CoiltW

llJ

Load

length

Retainer

sprinJ

dimension

Wire

diameter

F

CoilturnJ

l

oadxlensth

Side

rod

SPrina

dimeruion

Wire

diameter

Fn

elenath

Coil

turns

Load

x

lensth

Side

rod

inner

ball

joint

ax

ia

I

play

Side

rod

outer

ball

joint

uiaJ

play

Pinion

thrultplay

Retainer

float

play

Rack

moke

Side

rod

inner

ball

joint

swinsinl

torque

Side

rod

uter

ball

joint

swingina

torque

Pinion

oration

torque

Rack

pre1

d

Wheel

alipment

1IIl1a

a

ondition

Cut

c

m

Kinl

pin

inclination

Toe

in

S

In

teerinlan

eOut

10

40

8005

12

15

mm

0

47

0

59

in

38024

35036

2

9

mm

0

11

2

in

36

5

mm

1

4370

in

3

25q

551

18mm

0

7087

2

6

mm

1

102in

26

3

mm

1

035

in

5

5

20

kl

lbs

16

3

mm

0

642

in

26

mm

0

102

in

19

0

mm

0

748

in

6

3

40

q

88Ibs

17

0

mm

0

669

in

0

06

mm

0

002

m

0

1

0

5

mm

0

0039

0

0197

in

less

than

0

3

mm

0

0118

in

0

09

mm

0

0035

in

73

mm

t

2

87

in

0

8

1

5

q

m

5

8

10

8Ib

n

0

8

J

S

kg

m

5

8

JO

8Ib

ft

8

20q

7

17

lb

in

8

18

q

l7

6

39

7Ibs

Strut

DlelDbly

Strut

outer

Ilia

50

8

mm

2

0

in

Piston

rod

di

a

20

mm

0

787

in

Cylinder

inner

dia

30mm

I

181

in

Dampinl

force

at

pistonlpeed

0

3

m

I

1

08

ft

I

Expansion

67

IOq

I47

7

221bs

Compression

25

4kl

55

1

8

81bs

Shock

absorber

inner

cylinderlcngth

IOmm

16

1

in

R

IlD

vchicle

LH

D

ehide

CoiIsprina

LIi

IlIi

OOIh

Wire

diameter

mm

in

12

0

472

12

0

472

12

0

472

Coil

diameter

mm

in

130

5

12

130

5

12

130

5

12

Coil

Ium

S

Coil

effective

turnl

6

5

6

5

6

5

Free

lenJth

mm

in

371

5

14

6

386

5

15

2

371

5

14

6

Installed

hei

ht

load

mmq

180

270

200

270

180

270

in

lb

7

1

594

7

9

594

7

1

594

SpriDgCOfl

ltant

ka

mm

1

45

US

1

45

529

1

Page 166 of 171

Brake

pedal

Pedal

free

height

Full

stroke

of

pedal

head

Master

cylinder

Inner

dia

of

master

cylinder

with

Master

vac

without

Master

vac

Allowable

max

clearance

between

cylinder

wall

and

piston

Wheel

cylinder

Inner

dia

of

wheel

cylinder

Front

Rear

Allowable

max

clearance

between

cylinder

wall

and

piston

Brake

drum

and

rotor

Rear

brake

drum

inner

dia

Front

brake

rotor

outer

dia

Technical

Data

Drum

inside

out

of

roundness

below

0

05

mm

0

002

in

Limit

of

reconditioning

drum

in

dia

Run

out

of

the

rotor

Limit

of

reconditioning

rotor

in

thickness

183

mm

7

2

in

150

4

mm

5

9

0

158

in

22

22

mm

7

8

in

19

05

mm

3

4

in

Lining

dimension

Front

width

x

thickness

x

length

0

13

mm

0

0051

in

Rear

width

x

thickness

x

length

50

8

mm

2

in

20

64

mm

13

16

in

Material

Pad

width

x

thickness

x

length

0

18

mm

0

0709

in

Pad

material

228

6

mm

9

in

232

mm

9

130

in

Total

braking

area

Front

Rear

229

6

mm

9

039

in

below

0

06

mm

0

0024

in

8

4

mm

0

331

in

40

x

4

5

x

219

5

mm

1

575

x

1

772

x

8

642

in

40

x

4

5

x

219

5

mm

1

575

x

1

772

x

8

642

in

D233

397

x

9

x

86

mm

1

563

x

0

354

x

3

386

in

standard

M78S

option

Sl6D

114

2

em2

17

7

in

2

351

em2

54

4in

2

835

Page 169 of 171

1968

I

l

t

l

f

t

B

I

J

TECHNICAL

NOTES

ENGINE

DATA

DATSUN

WJ

G

N

B1

B1

l1

3

1

L

Pi

I

il

iUJ

4

RltiFtIn

GMrtlax

Diftel

ll

rti

earner

ry

20

1DI

KII

II2

ooo

M

17

Stlfring

Linklgt

Sell

Joints

IG

Gun

1

fittin

a

1

Stltrillg

SwiwI

II

Jointl

G

Gun

4

fittinlJLl

23

DISC

8RAKES

only

DRUM

BRAKES

chin

ry

4O

IJ

I

KM

24

DOJ

MI

n

o

badClrbumtorewery

40

lXI

KIIJ24

D1111

4

lII

ifold

11

Abo

IdIIr

Box

27

Umhlntlement

28

VlXCUI

element

16A

DRIVE

SHAFT

BAll

SPLINES

rlpe

ry

SO

OlXI

KM

30

OOO

MI

Saloon

Illy

UIWlt

Ht

ION

I

VALVE

Lt

l

tiMI

t

I

IDLING

SPEED

IspARK

PLUG

GAPIDISTR

POINT

GN

I

OWEn

ANGLE

I

STATIC

IGN

TlMING

STROB

twcm2

psi

INLET

mm

in

hot

hllcold

c

OUTlET

m

mm

incbll

mmJinc

r

dIgreer

BIDC

dIar

BTDC

n

m

RMer

to

Technical

Data

lYRES

I

STANDARD

SIZE

IFRDNT

PRESSUREI

REAR

PflESSUm

I

OPTIONAl51ZE

I

FRONT

PRESSURE

I

REAlI

l

lIESSUIE

I

BRAKES

PrwaulWkWem2

p

si

Ilarmlll

full

narltlll

full

normalJfull

nonnlllfull

W1NIIIUIII

TlUCKNEA

SHOE

mm

in

PAD

Ref

to

Technical

Data

TEST

lOAD

I

TOI

IN

iIlDUTlo

l

kO

lbl

front

mm

in

CAIll

BER

delftlllmin

CASTOR

I

KING

PU

INClNJ

TOE

lNliliOUTlo

I

dIon

min

min

I

rI

nmfin

CAMBEll

I

TOE

oIII

TURIIIS

I

rmin

d

It

laCK

sss

STEERING

GEOMETRY

U10

UtOS

WAGON

TORQUE

VALUES

mlD

b

h

TBA

R

ter

to

T

anal

Data

8D

I

V

BELT

TENSION

RAtJ

AP

PRES8

1

CLUTCH

PLAY

mmJinches

cm2

tIIi

mmJinct

4

5

5

5132

5

39

10

15

4

8

0

9

12

@

me

5

SOll13

4Pfl

12V

4QAh

NGKBP6E

FRAM

PH

2850

FRAM

CAGS1

5

60513

4Pfl

12V

50Ah

12V

60Ah

ImDIImI

t11

C

u

toIlho

AUTOSERVICE

DATA

CHART

I