brake fluid DATSUN 610 1969 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 48 of 171

CLUTCH

PEDAL

Adjusting

400

and

1600

cc

models

Adjust

the

pedal

height

to

209

mm

8

22

in

with

the

pedal

stop

slackened

off

by

altering

the

length

of

the

master

cylinder

push

rod

See

Fig

E

13

Tighten

the

pedal

stop

and

obtain

a

pedal

height

of

207

ffim

8

15

in

for

Left

Hand

drive

models

or

182

mID

7

I7

in

for

Right

Hand

drive

models

Secure

the

stop

by

tightening

the

locknut

and

make

sure

that

the

points

illustrated

are

correctly

greased

CLlTfCH

PEDAL

Adjusting

1800cc

models

Adjust

the

pedal

height

to

175

mm

6

89

in

by

adjusting

the

pedal

stop

See

Fig

E

13

then

retighten

the

locknut

A

to

a

torque

reading

of

0

79

1

07

kgm

6

8Ib

ft

Turn

the

master

cylinder

push

rod

to

obtain

a

play

between

1

Smm

0

04

0

2

in

at

the

clevis

pin

then

tighten

the

locknut

B

to

a

torque

reading

of

0

79

1

07

kgm

6

8

Ib

ft

Ensure

when

adjusting

the

play

that

the

port

on

the

master

cylinder

is

not

blocked

too

small

a

play

at

the

clevis

pin

may

block

the

port

Bend

the

clevis

pin

over

completely

CLlTfCH

MASTER

CYLINDER

Removal

and

Dismantling

Disconnect

the

push

rod

from

the

clevis

Fig

E

14

Detach

the

fluid

line

from

the

master

cylinder

and

pump

the

fluid

into

a

suitable

container

3

Withdraw

the

retaining

bolts

and

remove

the

master

cylinder

assembly

from

the

vehicle

To

dismantle

the

master

cylinder

remove

the

filler

cap

and

drain

away

the

fluid

Pull

back

the

dust

cover

and

remove

the

snap

ring

the

stopper

push

rod

piston

assembly

and

return

spring

Oean

the

components

in

brake

fluid

and

check

them

for

wear

or

damage

Renew

the

cylinder

and

piston

if

uneven

wear

has

taken

place

the

clearance

between

the

cylinder

and

piston

must

not

exceed

0

13

mm

0

005

in

Renew

the

dust

cover

oil

reservoir

filler

cap

and

fluid

line

if

necessary

Reassembly

of

the

master

cylinder

is

a

reversal

of

the

dismantling

procedure

take

care

to

soak

the

components

in

brake

fluid

and

assemble

them

while

still

wet

When

the

master

cylinder

is

installed

in

the

vehicle

make

sure

that

the

pedal

height

is

adjusted

as

previously

described

and

bleed

the

hydraulic

system

by

following

the

procedures

given

under

the

heading

CLlTfCH

SYSTEM

Bleeding

CLlTfCH

SLAVE

CYLINDER

Removal

and

Dismantling

Remove

the

return

spring

2

Disconnect

the

fluid

line

from

the

slave

cylinder

D

3

Disconnect

the

push

rod

from

the

clutch

withdrawal

lever

4

Take

out

the

mounting

bolts

and

withdraw

the

slave

cylinder

from

the

clutch

housing

To

dismantle

the

slave

cylinder

remove

the

dust

cover

and

snap

ring

and

withdraw

the

remaining

parts

from

the

cylinder

Oean

all

components

carefully

and

check

them

for

signs

of

damage

or

wear

renew

any

part

found

to

be

defective

and

fit

a

new

piston

seal

CLUTCH

SLAVE

CYLINDER

Assembly

and

Installation

Reassembly

is

a

reversal

of

the

dismantling

procedure

Ensure

that

the

parts

are

dipped

in

brake

flu

d

before

assembling

and

that

the

piston

seal

is

correctly

installed

When

the

slave

cylinder

is

installed

in

the

vehicle

bleed

the

hydraulic

system

by

following

the

procedures

given

under

the

heading

CLlTfCH

SYSTEM

Bleeding

The

push

rod

must

be

adjusted

so

that

the

withdrawal

lever

has

an

end

play

of

2

0

2

3

mm

0

078

0

091

in

details

of

this

operation

are

given

below

CLlTfCH

WITHDRAWAL

LEVER

Adjusting

The

correct

adjustment

of

the

clutch

withdrawal

lever

is

most

essential

as

insufficient

clearance

between

the

clutch

release

bearing

and

the

diaphragm

will

cause

the

clutch

to

slip

On

the

other

hand

an

excessive

clearance

will

prevent

the

clutch

from

disengaging

correctly

The

clearance

between

the

release

bearing

and

diaphragm

or

release

levers

can

be

adjusted

in

the

following

manner

Slacken

the

locknut

Fig

E

IS

and

screw

the

push

rod

fully

home

with

the

adjusting

nut

Return

the

adjusting

nut

I

3

4

turns

to

adjust

the

play

at

the

end

of

the

clutch

withdrawal

lever

to

2

0

2

3

mm

0

078

0

091

in

This

will

give

a

clear

ance

of

approximately

1

3

mm

0

051

in

between

the

release

bearing

and

the

diaphragm

spring

or

release

levers

NOTE

When

adjusting

clutch

pedal

free

travel

at

the

withdrawal

lever

it

is

essential

to

check

that

the

clutch

driven

plate

has

not

worn

by

more

than

2mm

0

08

in

otherwise

the

clutch

will

slip

even

if

it

is

correctly

adjusted

See

Technical

Data

for

the

relevant

clutch

driven

plate

thickness

CLUTCH

SYSTEM

Bleeding

The

clutch

system

must

be

bled

after

it

has

been

dismantled

or

if

any

part

of

the

circuit

has

been

opened

This

operation

should

also

be

carried

out

if

the

fluid

level

in

the

reservoir

has

been

allowed

to

fall

and

pennit

air

to

enter

the

system

The

presence

of

air

in

the

system

may

be

noticed

by

incorrect

disengagement

of

the

clutch

but

in

any

case

if

air

is

suspected

the

clutch

must

be

bled

in

the

following

manner

Remove

the

dust

cap

from

the

slave

cylinder

bleed

screw

Connect

a

length

of

tube

to

the

bleed

screw

and

immerse

the

47

Page 51 of 171

other

end

of

the

tube

into

a

clean

container

partly

filled

with

brake

fluid

Top

up

the

master

cylinder

reservoir

with

recommended

fluid

and

open

the

bleed

screw

approximately

three

quarters

of

a

turn

Depress

the

clutch

pedal

slowly

and

hold

it

completely

down

re

tighten

the

bleed

screw

and

allow

the

pedal

to

return

slowly

Repeat

the

operation

until

the

fluid

emerging

from

the

tube

is

free

from

air

bubbles

It

should

be

noted

that

assistance

will

be

required

when

carrying

out

bleeding

operations

as

not

only

must

the

fluid

entering

the

glass

container

be

watched

but

also

the

clutch

pedal

has

to

be

operated

and

the

reservoir

topped

up

frequently

throughout

the

procedure

When

the

fluid

is

completely

free

from

air

bubbles

the

bleed

screw

should

be

retightened

on

a

down

stroke

of

the

pedal

Finally

remove

the

bleed

tube

and

replace

the

dust

cap

TechnIcal

Data

Outch

type

Pressure

spring

Free

length

Fitted

length

and

load

Side

distortion

Permissible

deterioration

of

spring

force

Outch

release

levers

Oearance

between

release

bearing

and

diaphragm

spring

release

levers

Height

between

diaphragm

spring

and

flywheel

Height

between

release

levers

and

flywheel

Outch

driven

plate

Outer

diameter

Inner

diameter

Thickness

of

facingS

Total

friction

area

TIrickness

of

clutch

plate

Free

Compressed

No

of

torsion

springs

Permissible

minimum

depth

of

rivet

heads

from

facing

surface

Permissible

run

out

of

clutch

facing

P

rmissible

free

play

of

splines

Outch

pedal

1400

and

1600cc

models

Pedal

height

in

the

rest

position

P

da1

free

stroke

P

da1

effort

Master

cylinder

Diameter

Maximum

clearance

between

piston

and

cylinder

Pressure

plate

Permissible

refacing

limit

Outch

pedal

180Occ

models

P

da1

height

Play

at

clevis

pin

Full

stroke

P

da1

effort

50

Diaphragm

spring

or

coil

spring

52

3mm

2

059

in

29

2mm

44

2kg

1

149

in

197

t

4

4

lb

5mm

per

IOOmm

0

2in

per

3

94

in

15

1

2

I

4mm

0

047

0

055

in

44

t

Imm

1

732

t

0

039

in

50

5

t

0

05mm

1

988

t

0

0197

in

200mm

7

87

in

130mm

5

12in

3

5mm

0

140in

362

sq

cm

56

11

sq

in

8

6

9

0mm

0

3386

o

3543in

7

65

7

95mm

0

3012

o

3130in

6

O

3mm

0

0118

in

0

5mm

0

0197

in

0

4mm

0

0157

in

182mm

7

17in

R

H

D

207mm

8

15in

L

H

D

25mm

0

984in

15kg

33

lb

15

87mm

0

625in

O

13mm

0

005lin

Imm

0

0394in

175mm

6

89in

1

5mm

0

04

0

20in

135mm

5

3lin

10

5kg

23Ib

Page 80 of 171

factory

parts

Installation

is

a

reversal

of

the

removal

procedure

REAR

SUSPENSION

ARM

Removal

and

Installation

Saloon

I

J

ad

up

the

car

at

the

rear

and

support

it

on

stands

2

Remove

the

road

wheel

and

brake

drum

as

described

in

the

section

BRAKES

3

Disconnect

the

drive

shaft

from

the

axle

shaft

4

Disconnect

the

handbrake

cable

from

the

equalizer

bracket

and

the

wheel

cylinder

lever

Disconnect

the

brake

hose

from

the

brake

line

by

removing

the

lock

spring

and

then

withdrawing

through

the

connector

Plug

the

end

of

the

brake

line

to

avoid

loss

of

fluid

and

ingress

of

dirt

5

Remove

the

wheel

bearing

locknut

Fig

H

9

the

rear

axle

shaft

wheel

bearings

and

oil

seal

Remove

the

rear

brake

assembly

from

the

suspension

ann

See

section

BRAKES

6

Jack

up

the

suspension

arm

to

relieve

the

tension

on

the

shock

absorber

and

disconnect

the

shock

absorber

from

the

lower

mounting

Lower

the

jack

gradually

and

remove

the

coil

spring

seat

and

bump

rubber

7

Remove

the

bolts

securing

the

suspension

arm

to

the

suspension

member

Fig

H

IO

and

withdraw

the

suspension

arm

The

rubber

bushes

can

be

drawn

out

of

the

suspension

arm

if

necessary

using

the

special

tool

ST

38280000

Fig

H

Il

O1eck

the

suspension

arm

for

distortion

or

cracks

and

inspect

the

rubber

bushes

for

signs

of

wear

or

damage

Renew

any

part

which

is

unsatisfactory

Installation

is

a

reversal

of

the

removal

procedure

Tighten

all

the

suspension

arm

mounting

bolts

with

the

weight

of

the

vehicle

resting

on

the

rear

wheels

The

self

locking

nuts

must

be

renewed

at

each

overhaul

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloon

Removal

and

Dismantling

I

Raise

the

vehicle

at

the

rear

and

place

stands

under

the

body

member

2

Remove

the

road

wheel

and

brake

drum

3

Disconnect

the

drive

shaft

from

the

axle

shaft

and

remove

the

wheel

bearing

locknut

The

special

wrench

ST

38060001

can

be

used

to

hold

the

flange

as

shownin

Fig

H

12

4

Withdraw

the

axle

shaft

assembly

as

shown

in

Fig

H

13

using

the

special

tool

ST

07640000

and

sliding

hammer

ST

36230000

Remove

the

rear

axle

drive

flange

5

Use

a

suitable

drift

or

special

tool

ST

37750000

See

Fig

H

14

to

drive

out

the

inner

bearing

and

oil

seal

F

6

Remove

the

grease

retainer

and

withdraw

the

outer

bearing

with

a

conventional

puller

DO

NOT

re

use

this

outer

bearing

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloon

Assembly

and

Installation

Oleck

the

axle

shaft

for

straightness

make

sure

that

it

is

not

cracked

or

damaged

in

any

way

00

NOT

heat

the

shaft

if

attempting

to

re

straighten

Make

sure

that

the

lip

of

the

oil

seal

is

not

damaged

or

distorted

Check

the

bearing

for

excessive

wear

and

damage

Oean

the

wheel

bearings

the

oil

seal

and

the

inside

of

the

axle

housing

When

installing

the

wheel

bearings

the

sealed

side

of

the

outer

bearing

should

face

the

wheel

and

the

sealed

side

of

the

inner

bearing

should

face

the

differential

See

Fig

H

IS

Pressure

must

be

applied

to

the

inner

race

when

fitting

When

replacing

the

suspension

arm

check

that

the

distance

piece

is

0

05

mm

0

002

in

shorter

than

the

length

of

the

housing

dimension

LI

See

Fig

H

16

The

distance

piece

and

axle

housing

code

markings

must

coincide

The

wheel

bearing

grease

must

be

replaced

every

50

000

km

30

000

miles

Pack

the

wheel

bearings

with

grease

at

the

positions

shown

in

Fig

H

IS

and

coat

the

lip

of

the

oil

seal

Renew

the

locknut

and

oil

seal

at

each

overhaul

Wheel

bearing

adjustment

Tighten

the

locknut

to

the

specified

torque

reading

of

25

33

kgm

181

239

lb

ft

and

check

that

the

rear

axle

shaft

end

play

does

not

exceed

0

15

mm

0

006

in

with

a

turning

torque

of

less

than

7

kg

em

6

11b

in

for

the

1400

and

1600cc

models

510

series

or

4

5

kg

em

3

91b

in

for

the

1800cc

610

series

If

the

correct

end

play

or

turning

torque

cannot

be

obtained

it

will

be

necessary

to

change

the

distance

piece

See

above

DRIVE

SHAFTS

Removal

and

Dismantlill8

Disconnect

the

end

flanges

and

remove

the

shaft

See

Fig

H

17

The

drive

shaft

should

only

be

dismantled

to

lubricate

the

splines

This

operation

will

only

be

necessary

every

two

years

or

50

000

km

30

000

miles

Remove

the

universal

joint

spider

at

the

differential

side

Refer

to

the

propeller

shaft

section

Remove

the

snap

ring

securiilg

the

sleeve

yoke

plug

and

take

out

the

plug

Compress

the

drive

shaft

and

remove

the

snap

ring

and

stopper

Fig

H

17

Disconnect

the

boot

and

split

the

shaft

Make

sure

that

the

balls

and

spacers

are

retained

DRIVE

SHAFTS

Inspection

and

Assembly

The

drive

shaft

should

be

replaced

as

an

assembly

if

any

part

is

found

to

be

defective

Check

the

shaft

for

straightness

damage

or

wear

Old

79

Page 84 of 171

Front

SuspensIon

DESCRIPTION

WHEEL

HUBS

WHEEL

BEARINGS

Adjusting

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

DESCRIPTION

The

front

suspension

is

of

the

strut

type

with

the

coil

spring

and

hydraulic

damper

units

mounted

on

the

suspension

member

and

transverse

link

assembly

See

FigJ

1

Vertical

movement

of

the

suspension

is

controlled

by

the

strut

assembly

the

tension

rod

absorbs

the

forward

and

backward

movement

of

the

transverse

links

whilst

side

move

ment

of

the

body

is

controlled

by

the

stabilizer

rod

which

is

attached

to

the

body

and

transverse

links

WHEEL

HUBS

Removal

1

Jack

up

the

vehicle

remove

the

road

wheel

and

disconnect

the

brake

hose

at

the

strut

outer

casing

bracket

as

described

under

the

previous

heading

Plug

the

opened

end

of

the

hose

to

prevent

loss

of

fluid

2

Remove

the

brake

calliper

assembly

or

the

brake

drum

as

described

in

the

section

BRAKES

3

Remove

the

grease

cap

from

the

hub

by

tapping

lightly

at

the

joint

using

a

screwdriver

and

hammer

4

Withdraw

the

cotter

pin

from

the

wheel

bearing

locknut

and

remove

the

nut

Remove

the

wheel

hub

together

with

the

wheel

bearing

and

washer

Fig

J

2

On

cars

fitted

with

disc

brakes

the

hub

is

removed

complete

with

brake

disc

5

The

wheel

bearing

outer

race

can

be

removed

from

the

hub

using

a

drift

as

shown

in

Fig

I

3

WHEEL

HUBS

Inspection

and

Overhaul

Gean

the

hub

and

bearings

by

washing

in

petrol

Examine

the

grease

seal

and

make

sure

that

it

is

not

worn

or

cracked

renew

the

seal

if

necessary

Ensure

that

the

races

are

not

pitted

or

scored

rotate

them

and

check

for

signs

of

wear

and

play

A

sectional

view

of

the

wheel

bearing

assembly

is

given

in

Fig

14

to

provide

an

indication

of

the

points

to

be

checked

WHEEL

HUB

AND

BEARING

Installation

The

wheel

bearing

outer

race

can

be

refitted

with

a

suitable

drift

or

special

tool

ST

35310000

Fill

the

wheel

hub

and

the

hub

cap

to

the

positions

shown

in

Fig

J

5

with

multi

purpose

grease

Fill

the

spaces

between

the

bearing

rollers

and

the

lip

of

the

grease

seal

with

the

same

type

of

grease

Lightly

smear

the

spindle

shaft

and

threads

the

bearing

washer

and

bearing

lock

SPRING

AND

STRUT

ASSEMBLY

TRANSVERSE

LINK

AND

LOWER

BALL

JOINT

FRONT

WHEEL

ALIGNMENT

ADJUSTING

THE

STEERING

ANGLE

nut

with

grease

and

assemble

the

parts

onto

the

wheel

spindle

Make

sure

that

dirt

and

foreign

matter

does

not

adhere

to

the

greased

surfaces

Adjust

the

wheel

bearings

as

described

under

the

following

heading

WHEEL

BEARINGS

Adjusting

The

wheel

bearings

can

be

adjusted

with

the

road

wheel

the

hub

cap

and

the

bearing

locknut

cotterpin

removed

as

previously

described

Tighten

the

wheel

bearing

locknut

to

a

torque

reading

of

3

0

3

5

kgm

21

7

25

3lb

ft

Turn

the

hub

several

times

in

each

direction

to

settle

the

bearing

and

then

retighten

the

bearing

locknut

to

the

specified

torque

reading

Slacken

the

bearing

locknut

to

an

angle

between

40

to

700

a

ay

from

the

previously

tightened

position

and

align

the

cotter

pin

hole

with

the

hole

in

the

spindle

Turn

the

wheel

hub

a

few

times

in

each

direction

and

then

measure

the

torque

required

to

cause

the

hub

to

turlI

A

spring

balance

should

be

used

as

shown

m

Rig

J

p

make

sure

that

the

brake

pads

are

not

binding

on

the

disc

type

of

brake

unit

and

check

that

the

force

required

to

turn

the

hub

is

within

the

following

fIgures

Wheel

bearing

rotation

starting

torque

1800ce

With

new

bearing

7

0

kg

cm

97

in

oz

1400

1600cc

With

new

bearing

8

0

kg

cm

111

2

in

oz

With

used

bearing

4

0

kg

cm

56

0

in

oz

Starting

torque

at

the

hub

bolt

lWth

new

bearing

ith

used

bearings

1

57

kg

3

46

lb

0

7

kg

1

541b

Adjust

the

locknut

slightly

if

the

fIgures

do

not

conform

and

replace

the

cotterpin

Refit

the

hub

cap

and

the

road

wheel

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

Removal

Jack

up

the

front

of

the

vehicle

and

place

stands

under

the

ront

side

members

Remove

the

road

wheels

and

the

splash

board

3

Disconnect

the

front

brake

hoses

and

remove

the

brake

hose

locking

springs

Withdraw

the

plates

and

remove

the

hoses

from

the

strut

assembly

Plug

the

ends

of

the

hoses

to

prevent

the

ingress

of

dirt

and

loss

of

fluid

4

Remove

the

cotter

pin

from

the

tie

rod

ball

joint

remove

83

Page 88 of 171

the

castle

nut

and

detach

the

tie

rod

from

the

knuckle

arm

5

Remove

the

tension

rod

securing

nuts

Fig

J

7

remove

the

bolts

and

withdraw

the

tension

rod

Withdraw

the

nut

shown

arrowed

in

FigJ

8

and

remove

the

stabilizer

6

Support

the

engine

with

suitable

lifting

tackle

so

that

the

engine

mounting

bolts

can

be

removed

and

the

suspension

crossmember

detached

from

the

engine

FigJ

9

7

Place

ajack

under

the

crossmember

Remove

the

bolts

indicated

in

Fig

J

IO

and

separate

the

crossmember

from

the

body

8

Remove

the

strut

assembly

upper

attachment

self

locking

nuts

at

both

sides

Fig

J

ll

and

lower

the

front

suspension

assembly

to

remove

it

from

the

vehicle

FRONT

AXLE

AND

SUSPENSION

ASSEMBLY

Installation

Installation

is

a

reversal

of

the

removal

procedure

noting

the

following

points

Make

sure

that

all

rubber

parts

are

free

from

wear

and

deterioration

Any

part

of

the

suspension

assembly

which

has

been

damaged

or

distorted

must

be

replaced

The

front

wheel

alignment

should

be

checked

after

completing

the

installation

a

brief

description

is

given

at

the

end

of

this

section

Camber

and

castor

angles

are

preset

and

cannot

be

adjusted

SPRING

AND

STRUf

ASSEMBLY

Removal

and

Installation

The

strut

assembly

consists

of

the

outer

casing

piston

rod

piston

rod

guide

and

cylinder

etc

An

exploded

view

of

the

components

is

given

in

Fig

J

12

The

inner

components

must

be

replaced

as

a

complete

assembly

Replacement

and

overhaul

procedures

for

the

inner

components

together

with

the

removal

of

the

front

springs

should

only

be

carried

out

by

a

specialist

Datsun

workshop

The

strut

assembly

can

be

removed

prior

to

dismantling

by

following

the

procedures

outlined

below

Jack

up

the

front

of

the

vehicle

and

support

it

on

stands

2

Disconnect

the

brake

hose

from

the

strut

assembly

bracket

as

previously

described

under

the

heading

FRONT

AXLE

and

SUSPENSION

ASSEMBLY

Removal

3

Remove

the

stabilizer

bar

and

tension

rod

from

the

trans

verse

links

Loosen

and

remove

the

knuckle

arm

fixing

bolts

Fig

J

9

And

separate

the

strut

assembly

from

the

ball

joints

4

Remove

the

strut

assembly

upper

attachment

self

locking

nuts

Fig

J

11

and

withdraw

the

strut

assembly

from

the

body

Fig

J

13

Installation

is

a

reversal

of

the

removal

procedure

Ensure

that

the

bolts

are

tightened

to

the

specified

torque

readings

given

under

TIGHTENING

TORQUES

SPRING

AND

STRUT

ASSEMBLY

Dismantling

and

Assembly

Care

must

be

taken

when

dismantling

the

assembly

to

ensure

that

aU

parts

are

maintained

in

a

clean

condition

Clamp

the

suspension

strut

assembly

in

a

vice

and

fit

the

special

attachment

ST

2770000

I

to

the

lower

end

of

the

strut

Prise

off

the

dust

cover

snap

ring

Use

the

coil

spring

compressor

ST

35650001

to

slightly

compress

the

spring

Remove

the

self

locking

nut

and

take

off

the

mounting

insulator

thrust

bearing

spring

seat

and

bump

rubber

Slacken

the

spring

compressor

and

remove

the

spring

Push

down

the

shock

absorber

piston

until

it

bottoms

and

remove

the

gland

packing

with

the

special

tool

ST

35500001

Fig

J

14

Remove

the

O

ring

from

the

piston

rod

guide

and

lift

out

the

piston

rod

and

cy

linder

assembly

00

NOT

separate

the

piston

and

cylinder

which

are

serviced

as

a

complete

assembly

Drain

all

fluid

from

the

suspension

unit

and

shock

absorber

assembly

Wash

all

parts

thoroughly

not

rubber

parts

in

petrol

or

a

suitable

solvent

The

gland

packing

and

0

ring

must

be

renewed

at

each

overhaul

Always

refill

with

the

correct

grade

of

fresh

oil

in

accordance

with

the

information

in

the

table

below

ATSUGI

KAYABA

Part

No

54302

UO

100

UOl10

325

cc

332

cc

54302

3

U0500

1

54302

N

1200

325

cc

300

cc

The

oil

quantity

is

extremely

critical

as

it

will

affect

the

damping

power

of

the

shock

absorber

To

assemble

fit

the

rubber

O

ring

on

the

top

of

the

piston

rod

and

refit

the

gland

packing

Take

care

that

the

oil

seal

does

not

become

damaged

during

the

latter

operation

Lift

the

piston

rod

up

by

approximately

90

mm

3

5

in

before

tightening

the

gland

packing

to

facilitate

bleeding

then

tighten

the

packing

to

a

torque

reading

of

7

13

kgm

51

94Jb

ft

Bleed

the

shock

absorber

by

pumping

the

piston

rod

up

and

down

until

the

pressure

is

the

same

in

both

directions

Position

the

coil

spring

bump

rubber

spring

seat

and

dust

cover

on

the

top

of

the

piston

rod

The

piston

rod

must

be

in

the

fully

extended

position

Compress

the

spring

fit

the

strut

mounting

insulator

and

bearing

assembly

Tighten

the

self

locking

nut

to

a

torque

reading

of

6

7

5

kgm

43

541b

ft

SPRING

AND

STRUT

ASSEMBLY

Installation

Installation

is

a

reversal

of

the

removal

procedure

Thoroughly

grease

the

parts

marked

in

Fig

J

15

Tighten

the

fixing

bolts

to

the

torque

readings

given

in

TIGHfENING

TORQUES

TRANSVERSE

LINK

AND

LOWER

BALL

JOINT

Removal

The

transverse

link

with

rubber

bushing

is

connected

to

the

suspension

crosSlTIember

by

a

mounting

bolt

as

shown

in

Fig

J

11

and

to

the

strut

assembly

via

the

lower

ball

joint

87

Page 100 of 171

BrakIng

System

DESCRIPTION

MASTER

CYLINDER

Removal

dismantling

and

Overhaul

BRAKE

LINES

Replacing

BRAKE

WARNING

LIGHT

SWITCH

FRONT

DRUM

BRAKE

Removal

inspection

and

Overhaul

REAR

DRUM

BRAKE

Removal

inspection

and

Overhaul

FRONT

DRUM

BRAKE

Adjusting

DESCRIPTION

The

vehicle

is

fitted

with

either

disc

brakes

or

two

leading

shoe

type

drum

brakes

for

the

front

wheels

and

leading

trailing

shoe

type

drum

brakes

for

the

rear

wheels

All

brakes

are

hydraulically

operated

from

the

brake

pedal

with

the

rear

brakes

additionally

operated

by

a

mechanical

handbrake

and

linkage

system

Either

a

single

or

a

tandem

master

cylinder

can

be

fitted

The

tandem

master

cylinder

provides

a

dual

braking

circuit

in

which

the

front

and

rear

brakes

are

separately

supplied

If

ODe

circuit

fails

the

other

circuit

will

still

operate

and

provide

a

reduced

but

efficient

braking

action

The

brake

pipes

are

double

wall

steel

tubes

and

are

galvanized

at

the

sections

beneath

the

vehicle

floor

to

prevent

corrosion

MASTER

CYLINDER

Removal

Either

a

tandem

or

single

master

cylinder

can

be

fitted

to

the

vehicle

Fig

L

I

shows

a

cross

sectional

view

through

the

tandem

master

cylinder

and

Fig

L

2

a

cross

sectional

view

through

the

single

master

cylinder

The

removal

and

dismantling

procedures

are

similar

for

both

types

and

are

carried

out

in

the

following

manner

1

Remove

the

clevis

pin

and

separate

the

brake

pedal

from

the

master

cylinder

push

rod

2

Disconnect

the

brake

tubes

from

the

master

cylinder

3

Remove

the

master

cylinder

mounting

bolts

withdraw

the

shims

and

take

out

the

master

cylinder

assembly

MASfER

CYLINDER

Dismantling

and

Overhaul

Drain

the

brake

fluid

from

the

cylinder

and

remove

the

stopper

bolt

Remove

the

dust

cover

the

snap

ring

the

stopper

ring

and

the

pusbrod

assembly

Take

out

the

primary

piston

and

secondary

piston

assemblies

and

the

piston

spring

Remove

the

valve

cap

and

take

out

the

valve

assembly

Oean

all

the

components

with

brake

fluid

and

check

them

for

wear

or

damage

Make

sure

that

the

cylinder

bore

and

piston

are

not

damaged

or

unevenly

worn

The

clearance

between

cylinder

and

piston

must

not

exceed

0

15mm

0

006

in

REAR

DRUM

BRAKE

Adjusting

FRONT

DISC

BRAKE

Friction

pads

FRONT

DISC

BRAKE

Removal

and

Dismantling

FRONT

DISC

BRAKE

Assembly

and

Installation

HANDBRAKE

Removal

and

Installation

BLEEDING

THE

HYDRAULIC

SYSTEM

BRAKE

PEDAL

ADJUSTMENT

Check

the

return

springs

for

damage

or

loss

of

tension

Replace

any

part

which

is

in

an

unsatisfactory

condition

MASfER

CYLINDER

Assembly

and

Installation

Assembly

of

the

master

cylinder

is

a

reversal

of

the

dismantling

procedure

noting

the

following

points

Wet

the

cylinder

bore

and

piston

etc

with

brake

fluid

before

assembling

Care

must

be

taken

to

prevent

dust

and

foreign

matter

entering

the

cylinder

and

reservoir

Ensure

that

cups

and

soals

are

not

damaged

when

locating

them

After

the

master

cylinder

is

reinstalled

the

system

must

be

bled

and

the

pedal

height

adjusted

as

described

under

the

appropriate

headings

BRAKE

LINES

Replacing

The

layout

of

the

metal

brake

pipes

and

flexible

hoses

is

shown

in

Fig

L

3

The

brake

pipes

can

be

removed

by

taking

off

the

flare

nuts

at

both

ends

of

the

pipe

and

removing

the

clips

securing

the

pipe

to

the

body

Similarly

the

brake

hoses

can

be

removed

by

taking

off

the

flare

nuts

Thoroughly

clean

the

pipe

or

hose

after

removing

from

the

vehicle

and

check

for

collapsing

cracking

or

rusting

of

the

pipe

and

for

signs

of

expansion

and

weakening

of

the

hose

Any

pipe

or

hose

which

is

not

in

a

satisfactory

condition

must

be

renewed

Remove

any

dust

from

the

brake

clip

and

replace

the

clip

if

the

vinyl

coating

is

torn

Installation

is

a

reversal

of

the

removal

procedure

Make

sure

that

the

brake

pipes

cannot

vibrate

against

any

part

of

the

vehicle

and

the

brake

hoses

are

not

twisted

and

rubbing

against

the

tyres

or

suspension

units

If

the

brake

hose

is

disconnected

from

the

three

way

connector

on

the

rear

axle

housing

it

will

be

necessary

to

fit

a

new

copper

sealing

washer

Do

not

overtighten

the

installation

flare

nuts

the

correct

tightening

torques

are

as

follows

Three

way

connector

master

cylinder

and

brake

hoses

1

5

1

8

kgm

II

13Ib

ft

Fill

the

master

cylinder

with

recommended

fluid

and

bleed

the

system

as

described

under

the

appropriate

heading

Make

sure

that

fluid

is

not

leaking

from

any

part

of

the

system

by

fully

depressing

the

brake

pedal

for

several

seconds

Check

the

pipes

and

connections

and

replace

any

defective

part

99

Page 102 of 171

BRAKE

WARNING

UGHT

SWITCH

A

hydraulically

operated

warning

light

switch

is

located

in

the

engine

compartment

Fig

LA

The

front

and

rear

brake

systems

of

the

dual

circuit

are

connected

to

the

switch

which

provides

a

warning

via

the

warning

light

on

the

instrument

panel

when

a

pressure

difference

of

13

17

kg

sq

cm

185

242Ib

sq

in

occurs

between

the

front

and

rear

brake

systems

The

switch

cannot

be

repaired

and

must

be

renewed

if

faulty

FRONT

DRUM

BRAKE

Removal

1

Jack

up

the

front

of

the

vehicle

and

support

it

on

stands

2

Remove

the

brake

drum

and

the

hub

cap

and

hub

assembly

3

Disconnect

the

brake

pipe

at

the

bracket

on

the

front

suspension

strut

as

previously

described

in

the

section

FRONT

SUSPENSION

4

Unhook

the

two

return

springs

shown

in

Fig

L

5

and

remove

the

brake

shoes

5

Disconnect

the

bridge

pipe

3

in

Fig

L

6

and

remove

the

two

wheel

cylinders

6

Take

out

the

installation

bolts

and

withdraw

the

brake

backplate

from

the

spindle

FRONT

DRUM

BRAKE

Inspection

and

Overhaul

Examine

the

brake

drums

for

scoring

and

out

of

round

The

maximum

permissible

inner

diameter

of

the

drums

must

not

exceed

228

6mm

9

00

in

and

out

of

round

should

be

below

0

02mm

0

0008in

The

brake

shoe

linings

must

re

renewed

when

worn

down

to

a

thickness

of

1

5mm

0

06

in

or

below

Renew

the

linings

if

they

are

contaminated

in

any

way

or

incorrectly

seated

The

complete

set

of

linings

must

be

replaced

if

any

single

lining

is

unsatisfactory

O1eck

the

shoe

return

springs

and

if

they

have

become

weakened

replace

them

Withdraw

the

pistons

and

springs

from

the

wheel

cylinders

and

inspect

the

bore

of

the

cylinders

for

signs

of

wear

corrosion

or

damage

Renew

the

cylinder

and

the

piston

if

the

clearance

between

the

two

exceeds

O

15mm

0

006

in

Renew

the

rubber

boots

and

cups

FRONT

DRUM

BRAKE

Assembly

and

Installation

Assembly

and

installation

is

a

reversal

of

the

removal

and

dismantling

procedure

noting

the

fOllowing

points

Apply

a

thin

layer

of

special

grease

to

the

piston

cup

and

other

rubber

parts

when

assembling

the

wheel

cylinder

The

internal

components

of

the

cylinder

should

be

dipped

in

brake

fluid

and

assembled

whilst

still

wet

Install

the

wheel

cylinders

on

the

brake

backplate

and

smear

the

cylinder

backplate

and

cylinder

lever

fulcrum

with

grease

Fig

L

8

Tighten

the

backplate

mounting

bolts

to

a

torque

reading

of

2

7

3

7

kgm

19

5

26

71b

ft

Adjust

the

brake

shoes

and

bleed

the

hydraulic

system

as

described

under

the

appropriate

headings

REAR

DRUM

BRAKE

REMOVAL

Fig

L

IO

Jack

up

the

vehicle

at

the

rear

and

support

it

on

stands

Remove

the

road

wheel

2

Release

the

handbrake

remove

the

clevis

pin

3

from

the

rear

wheel

cylinder

lever

4

see

Fig

L

9

Disconnect

the

handbrake

cable

2

and

remove

the

return

spring

I

3

Remove

the

brake

drum

Remove

the

shoe

retainers

the

return

springs

and

brake

shoes

Fig

L

II

4

Disconnect

the

fluid

line

from

the

wheel

cylinders

and

plug

the

opened

end

to

prevent

to

loss

of

fluid

5

Remove

the

dust

cover

adjusting

shims

and

plates

then

remove

the

wheel

cylinder

from

the

backplate

6

The

brake

backplate

and

axle

shaft

assembly

can

be

with

drawn

if

necessary

by

taking

out

the

four

flange

bolts

and

removing

the

assembly

as

described

in

the

section

REAR

AXLE

AND

REAR

SUSPENSION

REAR

DRUM

BRAKE

Inspection

and

Overhaul

The

inspection

and

overhaul

procedures

fpr

the

rear

drum

brakes

are

similar

to

those

previously

described

for

the

front

drum

brakes

Tighten

the

brake

backplate

mounting

bolts

to

a

torque

reading

of

3

9

5

3

kgm

28

38Ib

ft

FRONT

DRUM

BRAKE

Adjusting

Jack

up

the

vehicle

and

pump

the

brake

pedal

several

times

With

the

brake

drum

installed

turn

one

of

the

adjusting

cams

clockwise

until

the

brake

shoe

is

in

contact

with

the

drum

This

operation

is

carried

out

from

the

rear

of

the

backplate

When

the

brake

shoe

contacts

the

drum

turn

the

cam

in

the

opposite

direction

until

the

shoe

is

just

clear

and

the

brake

drum

can

be

rotated

freely

by

hand

Repeat

the

operation

on

the

other

adjusting

cam

and

then

depress

the

brake

pedal

to

make

sure

that

the

brakes

are

working

correctly

The

adjusters

must

be

released

slightly

if

the

brake

drum

binds

when

turned

by

hand

Fig

L

12

shows

the

adjusting

cams

REAR

DRUM

BRAKE

Adjusting

Jack

up

the

vehicle

at

the

rear

and

pump

the

brake

pedal

several

times

Turn

the

brake

shoe

adjuster

Fig

L

13

until

the

101

Page 104 of 171

brake

shoe

is

in

contact

with

the

drum

The

adjuster

must

be

turned

from

the

rear

of

the

backplate

and

the

drum

turned

by

hand

When

the

shoe

contacts

the

drum

turn

the

adjuster

in

the

opposite

direction

until

the

shoe

is

just

clear

and

the

drum

can

be

rotated

freely

by

hand

Depress

the

brake

pedal

and

make

sure

that

the

brakes

operate

correctly

The

adjusters

must

be

released

slightly

if

the

brake

shoe

binds

FRONT

DISC

BRAKE

Friction

pads

Fig

L

14

The

disc

brakes

are

self

adjusting

but

the

friction

pads

should

be

checked

for

wear

every

5

000

km

3

000

miles

and

replaced

if

the

thickness

of

the

friction

lining

on

any

pad

is

less

than

1

0mm

0

004

in

In

effect

this

means

that

renewal

is

necessary

when

the

total

thickness

of

pad

and

lining

is

less

than

8

4mm

0

24

in

To

replace

the

friction

pads

proceed

as

follows

Siphon

out

some

of

the

fluid

in

the

master

cylinder

reservoir

Jack

up

the

front

of

the

vehicle

and

remove

the

road

wheel

Remove

the

anti

rattle

clip

from

the

calliper

plate

Fig

L

lS

Unhook

the

hanger

spring

and

withdraw

the

brake

pads

and

shims

Fig

L

17

It

should

be

noted

that

the

friction

pads

must

be

replaced

as

a

set

and

renewed

at

both

sides

of

the

vehicle

otherwise

the

braking

action

will

be

uneven

Oean

the

calliper

and

pad

at

their

installation

positions

Press

the

pistons

into

the

calliper

bores

so

that

the

new

friction

Pads

can

be

installed

The

pistons

can

be

installed

by

applying

light

pressure

as

shown

in

Fig

L

16

but

care

must

be

taken

to

avoid

pushing

them

too

far

or

the

groove

of

the

piston

will

damage

the

seal

If

the

pistons

are

pushed

down

excessively

it

will

be

necessary

to

dismantle

the

calliper

as

described

under

the

appropriate

heading

Assemble

the

anti

squeal

shims

to

the

friction

pads

with

the

arrow

mark

on

the

shims

pointing

in

the

direction

of

forward

disc

rotation

Refit

the

pads

and

retaining

pins

and

assemble

the

coil

spring

to

the

retaining

pin

furthest

away

from

the

air

bleed

screw

After

installing

the

new

pads

and

shims

depress

the

brake

pedal

several

times

to

reposition

the

pistons

in

the

calliper

O1eck

the

fluid

level

in

the

master

cylinder

reservoir

and

refill

to

the

correct

level

FRONT

DISC

BRAKE

Removal

and

Dismantling

1

Jack

up

the

front

of

the

vehicle

remove

the

road

wheel

and

take

out

the

friction

pads

2

Disconnect

the

brake

hose

from

the

brake

tube

and

plug

the

opened

end

to

prevent

the

loss

of

fluid

3

Remove

the

bolts

securing

the

brake

calliper

to

the

knuckle

flange

and

remove

the

calliper

assembly

Fig

L

IS

4

Remove

the

hub

nut

and

withdraw

the

hub

and

disc

To

dismantle

the

calliper

remove

the

anti

rattle

clip

and

withdraw

the

brake

pads

Remove

the

tension

springs

and

pull

the

cylinder

out

of

the

calliper

Blow

out

the

piston

with

com

pressed

air

applied

at

the

brake

hose

connection

Oean

the

components

in

brake

fluid

and

examine

them

for

signs

of

wear

or

damage

The

cylinder

walls

can

be

carefully

polished

with

fine

emery

cloth

if

they

are

rusted

or

contaminated

If

the

parts

are

excessively

corroded

they

should

be

renewed

Replace

the

pistons

if

they

are

unevenly

worn

damaged

or

rusted

The

sliding

surface

of

the

piston

is

plated

and

no

attempt

should

be

made

to

use

emery

cloth

or

similar

abrasives

for

cleaning

purposes

Check

the

thickness

of

the

friction

pads

as

previously

described

and

replace

them

if

necessary

Renew

the

piston

seals

and

the

dust

covers

O1eck

the

brake

disc

for

scoring

and

out

of

round

The

standard

disc

thickness

is

10

Omm

0

0394

in

and

must

not

be

reground

below

8

4mm

0

3307

in

Check

the

disc

run

out

with

a

dial

gauge

as

shown

in

Fig

L

19

Position

the

gauge

near

the

outer

diameter

and

check

that

the

run

out

does

not

exceed

0

06mm

0

0024

in

FRONT

BRAKE

DISC

Assembly

and

Installation

Rinse

the

cylinder

bore

with

brake

fluid

and

fit

the

piston

seal

into

the

cylinder

groove

Fig

L

20

Fit

the

wiper

seal

and

lightly

grease

the

bore

of

the

cylinder

Clean

the

brake

disc

and

fit

it

to

the

hub

Install

the

hub

to

the

knuckle

spindle

Carefully

insert

the

piston

into

the

cylinder

until

the

face

of

the

piston

is

almost

flush

with

the

wiper

seal

retainer

The

relieved

part

of

the

piston

should

face

the

piston

pin

Fit

the

cylinder

to

the

calliper

plate

and

secure

in

position

with

the

two

torsion

springs

Assemble

the

hold

down

pin

the

spring

washer

and

the

nut

to

the

support

bracket

Secure

the

nut

with

a

cotter

pin

Assemble

the

calliper

to

the

mounting

bracket

using

the

pivot

pin

washer

spring

washer

and

nut

Tighten

the

nut

and

secure

with

a

cotter

pin

Hook

the

hold

down

bracket

to

the

top

of

the

mounting

bracket

and

turn

the

calliper

plate

to

make

sure

that

it

can

slide

smoothly

Fit

the

calliper

assembly

to

the

knuckle

flange

Fit

a

shim

to

the

inner

pad

and

insert

the

pad

Draw

the

calliper

towards

the

chassis

and

insert

the

lower

cuts

on

the

pad

into

the

mounting

bracket

and

push

the

pad

in

until

it

contacts

the

piston

Move

the

calliper

away

from

the

chassis

and

insert

the

upper

cuts

Centre

the

indentation

of

the

outer

pad

in

the

calliper

plate

Fit

the

anti

rattle

clip

Fig

L

14

103

Page 106 of 171

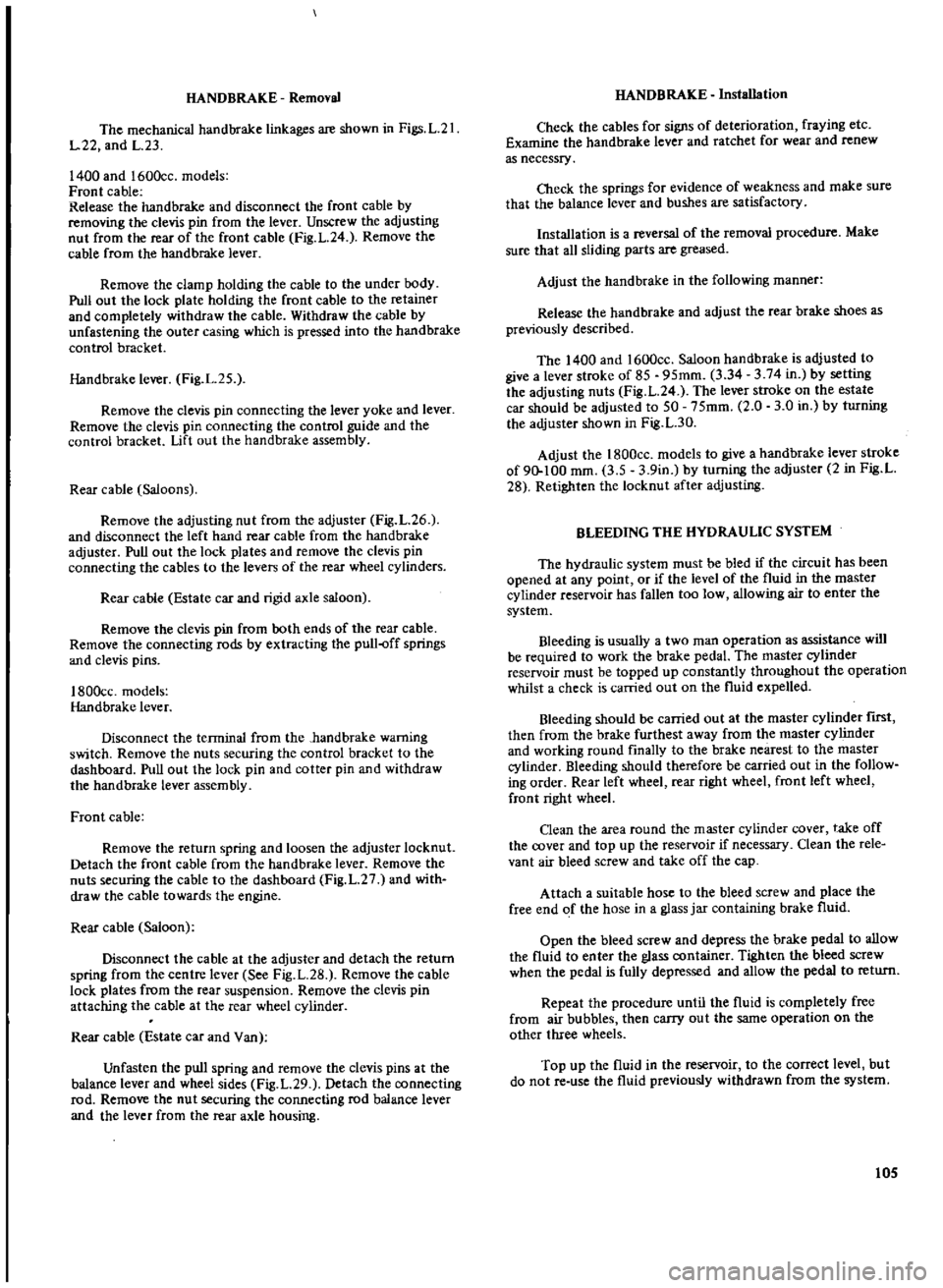

HAND

BRAKE

Removal

The

mechanical

handbrake

linkages

are

shown

in

Figs

L

21

1

22

and

1

23

1400

and

1600cc

models

Front

cable

Release

the

hand

brake

and

disconnect

the

front

cable

by

removing

the

clevis

pin

from

the

lever

Unscrew

the

adjusting

nut

from

the

rear

of

the

front

cable

Fig

L

24

Remove

the

cable

from

the

hand

brake

lever

Remove

the

clamp

holding

the

cable

to

the

under

body

Pull

out

the

lock

plate

holding

the

front

cable

to

the

retainer

and

completely

withdraw

the

cable

Withdraw

the

cable

by

unfastening

the

outer

casing

which

is

pressed

into

the

handbrake

control

bracket

Handbrake

lever

Fig

1

25

Remove

the

clevis

pin

connecting

the

lever

yoke

and

lever

Remove

the

clevis

pin

connecting

the

control

guide

and

the

control

bracket

Lift

out

the

handbrake

assembly

Rear

cable

Saloons

Remove

the

adjusting

nut

from

the

adjuster

Fig

L

26

and

disconnect

the

left

hand

rear

cable

from

the

handbrake

adjuster

Pull

out

the

lock

plates

and

remove

the

clevis

pin

connecting

the

cables

to

the

levers

of

the

rear

wheel

cylinders

Rear

cable

Estate

car

and

rigid

axle

saloon

Remove

the

clevis

pin

from

both

ends

of

the

rear

cable

Remove

the

connecting

rods

by

extracting

the

puU

off

springs

and

clevis

pins

1800cc

models