headlamp DATSUN 610 1969 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 112 of 171

stopper

to

the

overrunning

clutch

side

and

removing

the

stopper

clip

Remove

the

stopper

and

overrunning

clutch

as

shown

inFig

M

7

Oean

the

dismantled

components

and

check

them

for

wear

or

damage

Cbeck

the

brushes

and

renew

them

if

worn

below

6

5mm

0

257

in

Fit

new

brushes

if

the

brush

contact

is

loose

Cbeck

the

brush

holders

and

spring

clips

and

make

sure

that

they

are

not

bent

or

distorted

The

brushes

should

move

freely

in

their

housings

and

can

be

eased

with

a

file

if

necessary

The

brush

spring

tension

should

be

approximately

0

8kg

1

76Ib

and

can

be

checked

with

a

spring

balance

as

shown

in

Fig

M

S

Armature

assembly

Make

sure

that

the

surface

of

the

commutator

is

not

rough

or

pitted

Oean

and

lightly

polish

with

a

No

500

emery

cloth

if

necessary

If

the

commutator

is

badly

worn

or

pitted

it

should

be

skimmed

in

a

lathe

only

a

light

cut

must

be

taken

to

remove

the

minimum

amount

of

metal

If

the

commutator

diameter

wear

limit

of

0

2mm

0

OS

in

is

exceeded

the

assembly

must

be

renewed

Undercut

the

mica

between

the

commutator

segments

when

the

depth

of

mica

from

the

surface

of

the

segment

is

less

than

0

2mm

0

08

in

The

depth

should

be

between

0

5

0

8mm

0

0197

0

0315

in

as

shown

in

Fig

M

9

The

armature

shaft

should

be

checked

for

straightness

by

mounting

between

the

centres

of

lathe

and

positioning

a

dial

gauge

as

shown

in

Fig

M

I

O

Renew

the

armature

if

the

bend

of

the

shaft

exceeds

0

08mm

0

0031

in

Field

coils

testing

Test

the

field

coils

for

continuity

by

connecting

a

circuit

tester

between

the

positive

terminal

of

the

field

coil

and

the

positive

terminal

of

the

brush

holder

as

shown

in

Fig

M

I

I

If

a

reading

is

not

obtained

the

field

circuit

or

coil

is

open

Cbnnect

the

tester

to

the

yoke

and

field

coil

positive

teoninal

as

shown

in

Fig

M

12

to

check

the

field

coils

for

earthing

Unsolder

the

connected

part

of

each

coil

and

check

the

circuit

for

earthing

in

a

similar

manner

Renew

the

field

coils

if

they

are

open

earthed

or

short

circuited

Outch

assembly

The

overrunning

clutch

must

be

replaced

if

it

is

slipping

or

dragging

Examine

the

pinion

and

sleeve

making

sure

that

the

sleeve

is

able

to

slide

freely

along

the

armature

shaft

spline

Inspect

the

pinion

teeth

for

signs

of

rubbing

and

check

the

fly

wheel

ring

gear

for

damage

or

wear

Bearings

Inspect

the

metal

bearing

bushes

for

wear

and

side

play

The

bushes

must

be

renewed

if

the

clearance

between

the

bearing

bush

and

armature

shaft

is

in

excess

of

0

02mm

0

008

in

New

bearing

bushes

must

be

pressed

in

so

that

they

are

flush

with

the

end

of

the

case

and

reamed

ou

t

to

give

a

clearance

of

0

03

0

10

mm

0

0012

0

0039

in

H

Solenoid

assembly

Inspect

the

solenoid

contact

surface

and

replace

if

showing

signs

of

wear

or

roughness

Replace

the

pinion

sleeve

spring

if

weakened

Check

the

series

coil

by

connecting

an

8

12

volt

supply

between

the

Sand

M

terminals

as

shown

in

Fig

M

13

The

series

coil

is

normal

if

the

plunger

operates

Test

the

shunt

coil

by

connecting

the

S

terminal

the

M

terminal

and

the

solenoid

body

as

shown

in

the

lower

illustration

of

Fig

M

13

Open

the

M

terminal

when

the

plunger

is

operated

the

shunt

coil

is

satisfactory

if

the

plunger

stays

in

the

operated

position

Measure

the

length

L

between

theylonger

adjusting

nut

and

solenoid

cover

Press

the

plunger

against

a

firm

surface

as

shown

in

Fig

M

14

and

check

that

the

dimension

is

within

the

figures

given

Turn

the

adjusting

nut

if

necessary

until

the

required

dimension

is

obtained

STARTER

MOTOR

Assembly

and

Installation

The

assembly

and

installation

procedures

are

a

reversal

of

the

removal

and

dismantling

operations

When

assembling

the

starter

smear

the

armature

shaft

spline

with

grease

and

lightly

oil

the

bearing

bushes

and

pinion

ALTERNATOR

The

alternator

is

driven

by

the

fan

belt

and

has

an

advant

age

over

a

dynamo

in

that

it

provides

current

at

low

engine

speeds

thereby

avoiding

battery

drain

Maintenance

is

not

normally

required

but

the

tension

of

the

fan

belt

should

be

checked

and

adjusted

if

necessary

as

described

in

the

section

COOLING

SYSTEM

Care

must

be

taken

not

to

overtighten

the

fan

belt

or

the

alternator

bearings

will

be

overloaded

The

alternator

output

can

be

checked

with

the

alternator

in

the

vehicle

by

carrying

out

the

following

test

Ensure

that

the

battery

is

fully

charged

Withdraw

the

connectors

from

the

alternator

F

and

N

terminals

and

connect

a

jumper

lead

between

the

F

and

A

terminals

Connect

a

voltmeter

to

the

E

and

A

alternator

terminals

with

the

negative

lead

to

terminal

E

and

the

positive

lead

to

the

terminal

A

as

shown

in

Fig

M

IS

Switch

the

headlamps

on

to

full

beam

and

start

the

engine

Increase

the

engine

speed

gradually

and

note

the

reading

on

the

voltmeter

when

the

engine

reaches

a

speed

of

approximately

lOaD

rpm

The

alternator

is

operating

satisfactorily

if

the

voltmeter

shows

a

reading

above

12

5

volts

If

the

reading

is

below

12

5

volts

the

alternator

is

defective

and

should

be

removed

for

inspection

ALTERNATOR

Removal

Disconnect

the

negative

lead

from

the

battery

and

the

two

lead

wires

and

connector

from

the

alternator

Slacken

the

alter

nator

mounting

bolts

and

take

off

the

fan

belt

Take

out

the

mounting

bolts

and

withdraw

the

alternator

from

the

vehicle

III

Page 115 of 171

inter

ill

1

@

fl@

2mm

O

07e7

in

l

r

Fig

M

27

Measuring

the

brush

spring

pressure

oo

fI

f

Fig

M

29

R

h

the

headlamp

Ied

beam

AMM

E

iER

HO

to

SA

HO

N

SWITCH

1

VOLTMETER

115

to

2OV

I

I

Fig

M

31

Testing

and

adjusting

the

horn

114

J

GJ

Fig

M

28

Tightening

the

puUey

nut

HORN

RELAY

L

IBGIGY

tt

t

e

q

HO

N

r

FUSIBLE

LINK

IO

e5

REO

FUS

E

BOX

20A

El

Sl

I

10

STOP

LAMP

SWITCH

HORN

eu

TTON

eATT

RY

Fig

M

JO

Circuit

diagram

for

the

horn

system

Fig

M

32

Adjusting

the

horn

volume

and

tone

Page 116 of 171

ALTERNATOR

Dismantling

Refening

to

Fig

M

16

remove

the

pulley

nut

and

take

off

the

pulley

rim

fan

and

spacer

Withdraw

the

brush

holder

retaining

screws

and

remove

the

brush

holder

cover

Withdraw

the

holder

and

brushes

as

shown

in

Fig

M

17

Slacken

and

remove

the

three

through

bolts

and

separate

the

diode

housing

from

the

drive

end

housing

by

tapping

the

front

bracket

lightly

with

a

wooden

mallet

Fig

M

18

Remove

the

screws

from

the

bearing

retainer

and

separate

the

rotor

from

the

front

cover

Fig

M

19

Remove

the

rear

bearing

from

the

rotor

assembly

with

the

aid

of

a

puller

as

shown

in

Fig

M

2D

Take

off

the

diode

cover

and

unsolder

the

three

stator

coil

lead

wires

from

the

diode

terminal

Remove

the

A

terminal

nut

and

diode

installation

nut

and

remove

the

diode

assembly

Do

not

force

the

diode

assembly

when

removing

or

it

may

be

damaged

Remove

the

stator

from

the

rear

cover

ALTERNATOR

Inspection

Use

an

ohmmeter

as

shown

in

Fig

M

21

to

test

the

rotor

field

coil

Apply

the

tester

between

the

slip

rings

and

check

that

the

resistance

is

approximately

4

4

ohms

at

normal

ambient

temperature

Check

the

conductivity

between

slip

ring

and

rotor

core

as

shown

in

Fig

M

22

if

conductivity

exists

the

field

coil

or

slip

ring

must

be

earthing

and

the

rotor

assembly

should

be

renewed

Cbeck

the

stator

to

ensure

that

there

is

conductivity

retween

the

individual

stator

coil

terminals

as

shown

in

Fig

M

23

If

there

is

no

conductivity

between

the

individual

terminals

the

stator

is

defective

Check

each

lead

wire

including

the

neutral

wire

as

shown

in

Fig

M

24

If

there

is

conductivity

between

any

wire

and

the

stator

COTe

the

stator

core

is

earthing

and

the

stator

must

be

replaced

Diodes

Three

positive

diodes

are

mounted

on

the

positive

plate

and

three

negative

diodes

are

mounted

on

the

negative

plate

The

diodes

allow

current

to

flow

in

one

direction

only

The

diodes

on

the

positive

plate

only

allow

current

to

flow

from

the

terminal

to

the

positive

plate

whilst

the

diodes

on

the

negative

plate

only

allow

current

to

flow

from

the

negative

plate

to

the

terminal

A

diode

which

allows

current

to

flow

in

ooth

directions

or

does

not

allow

current

to

flow

in

the

correct

direction

is

unserviceable

and

all

six

diodes

must

be

replaced

Use

a

tester

as

shown

in

Figs

M

25

and

M26

to

check

each

diode

Brushes

Check

the

movement

of

the

brushes

in

their

holders

The

brushes

should

move

freely

and

can

be

eased

in

necessary

by

carefully

ming

the

sides

Oean

the

brush

holders

before

replacing

the

brushes

Renew

the

brushes

if

they

are

worn

below

a

length

of

7mm

0

275

in

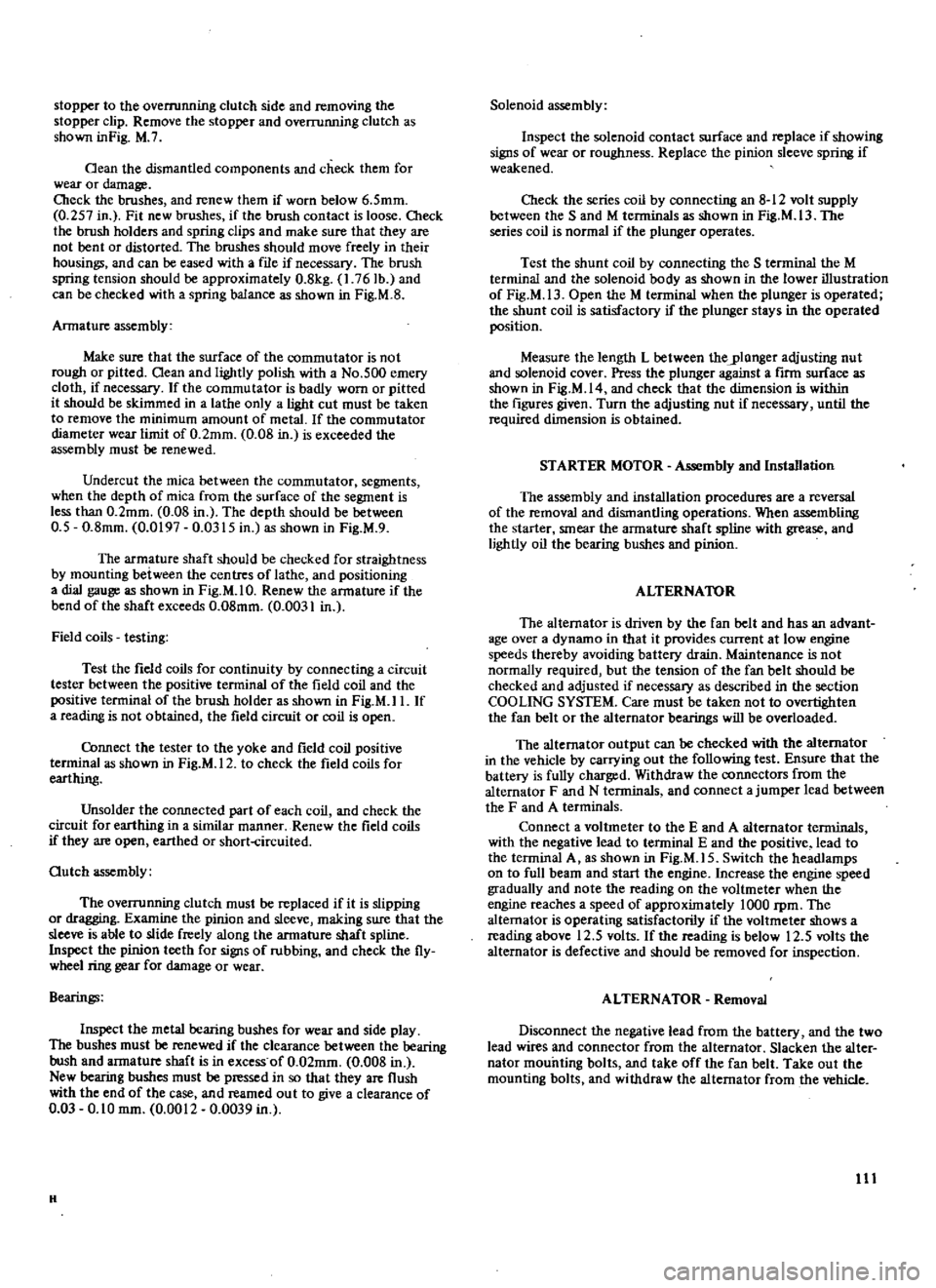

With

the

brush

projecting

approximately

2mm

0

08

in

from

the

holder

it

is

possible

to

measure

the

brush

spring

pressure

using

a

spring

balance

as

shown

in

Fig

M

27

The

pressure

of

a

new

brush

should

be

255

345

grammes

9

0

12

2

oz

the

pressure

will

however

decrease

by

approxi

mately

20

grammes

per

I

amm

0

039

in

of

wear

ALTERNATOR

Assembly

and

Installation

Asssembly

is

a

reversal

of

the

dismantling

prQcedure

noting

the

following

points

The

stator

coil

lead

wires

must

be

resoldered

to

the

diode

assembly

terminal

as

quickly

as

possible

or

the

diodes

may

be

damaged

When

installing

the

diode

A

tenninal

make

sure

that

the

insulating

bushing

and

tube

are

correctly

fitted

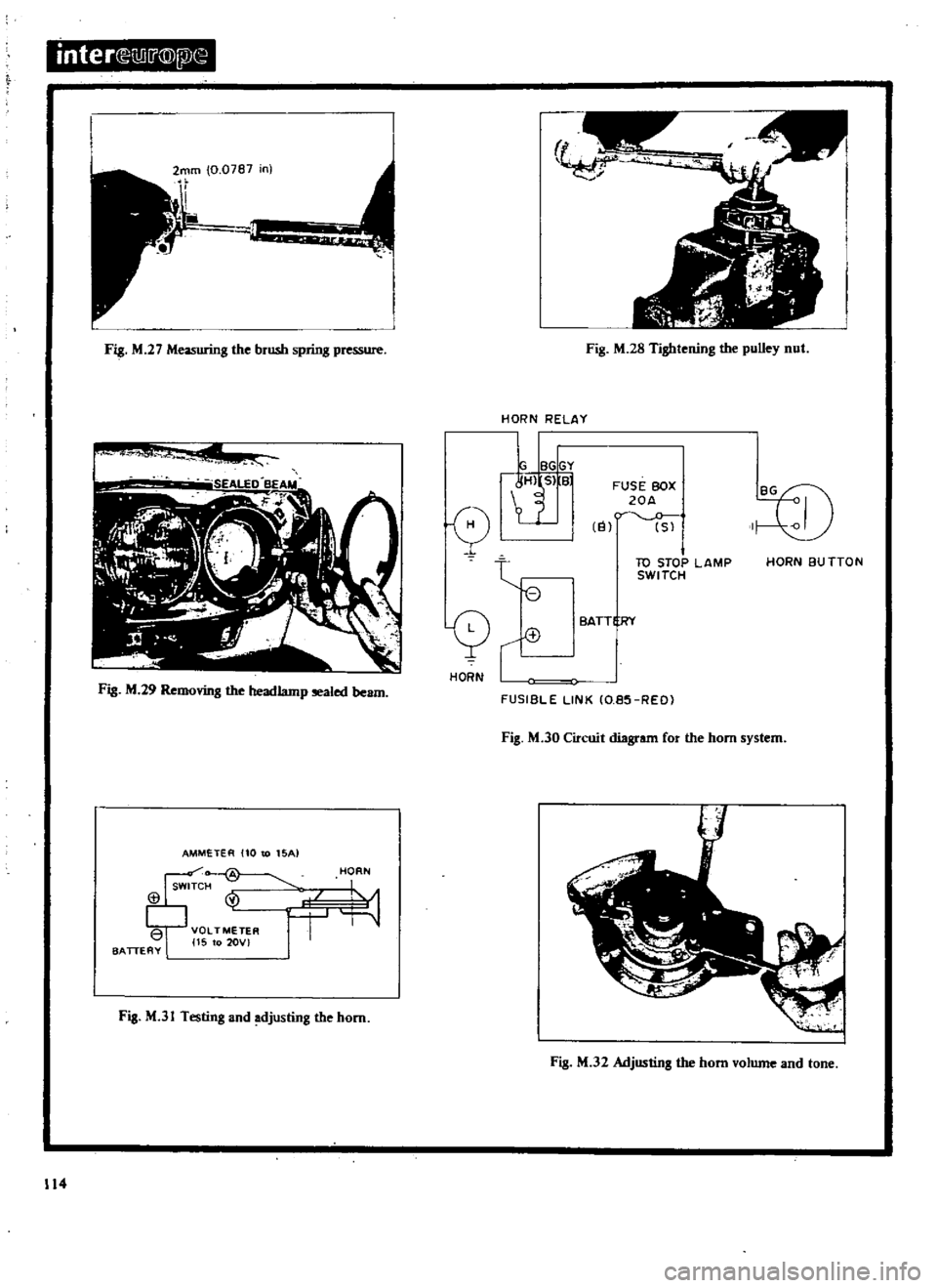

The

pulley

nut

should

he

tightened

to

a

torque

reading

of

350

400

kg

cm

301

344Ib

in

Mount

the

assembly

in

a

vice

as

shown

in

Fig

M

28

and

when

the

pulley

is

tightened

make

sure

that

the

deflection

of

the

pulley

groove

does

not

exceed

O

3mm

m

o

118

in

ilEA

D

LAMPS

Replacing

All

weather

type

sealed

beam

headlamp

units

are

fitted

to

the

vehicle

Each

lamp

is

of

the

double

fIlament

type

with

a

full

beam

filament

of

50W

and

a

dipped

beam

filament

of

40W

The

replacement

of

the

sealed

beam

unit

can

be

carried

out

as

follows

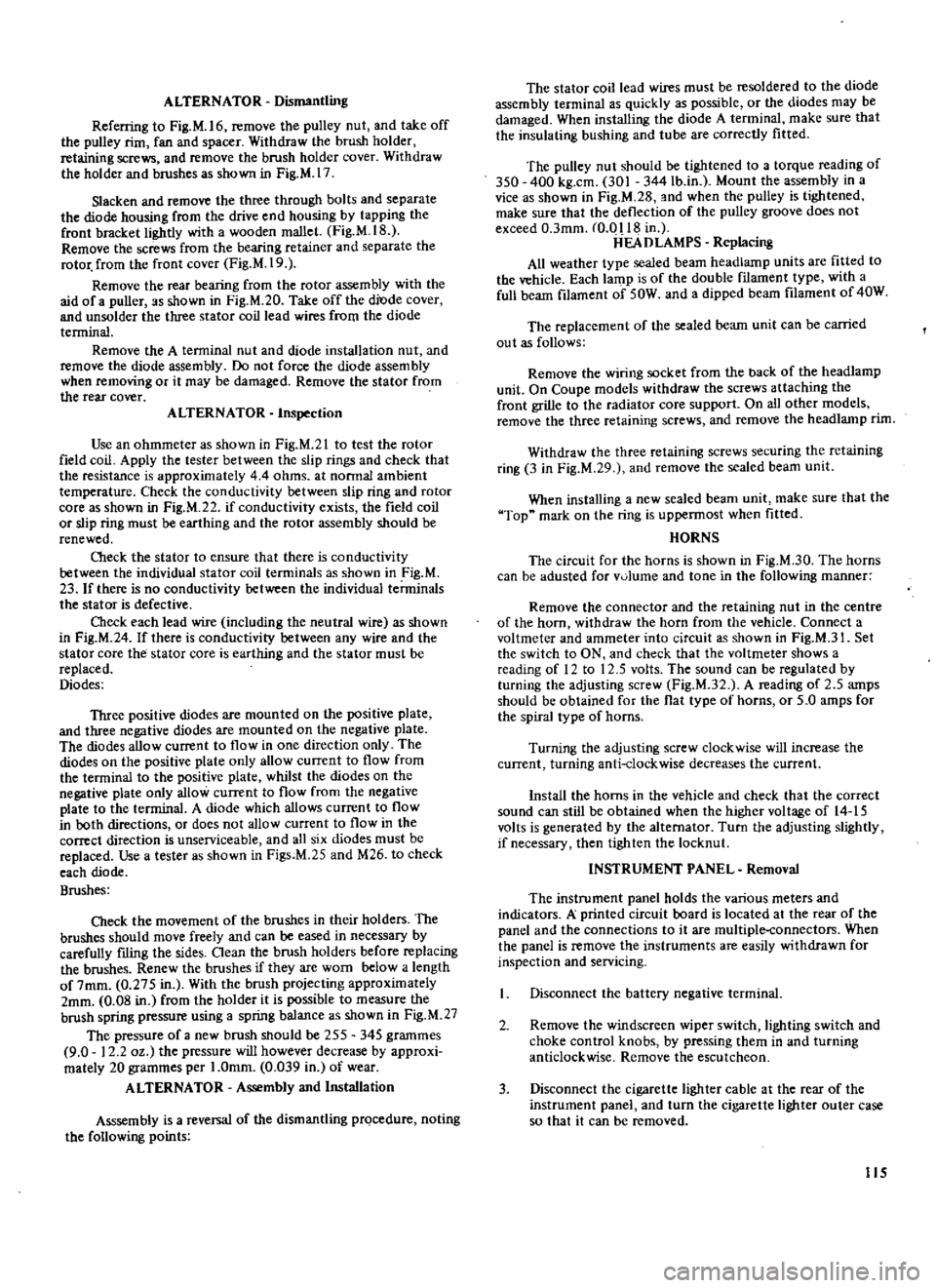

Remove

the

wiring

socket

from

the

back

of

the

headlamp

unit

On

Coupe

models

withdraw

the

screws

attaching

the

front

grille

to

the

radiator

core

support

On

all

other

models

remove

the

three

retaining

screws

and

remove

the

headlamp

rim

Withdraw

the

three

retaining

screws

securing

the

retaining

ring

3

in

Fig

M

29

and

remove

the

sealed

beam

unit

When

installing

a

new

sealed

beam

unit

make

sure

that

the

Top

mark

on

the

ring

is

uppennost

when

fitted

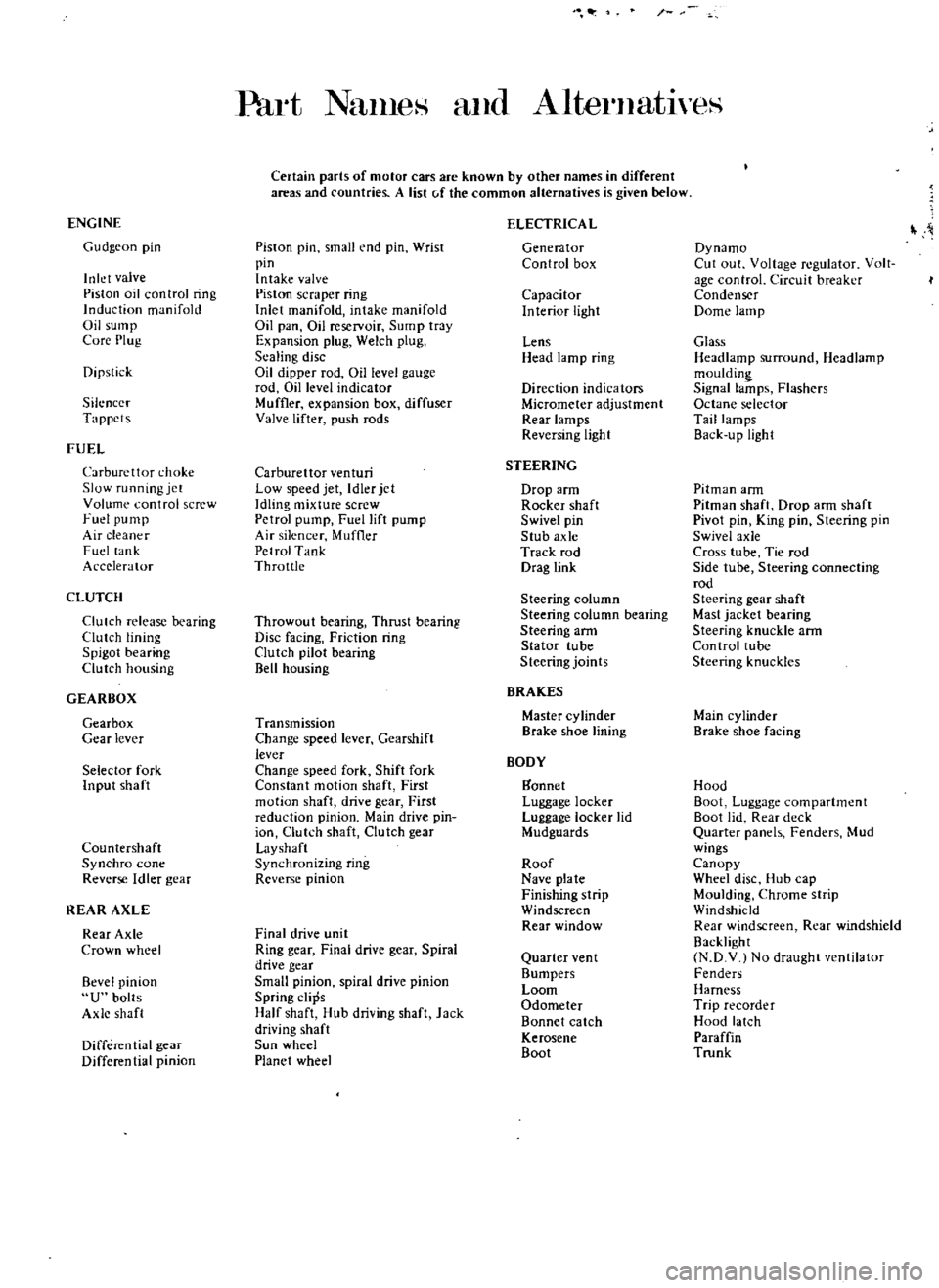

HORNS

The

circuit

for

the

horns

is

shown

in

Fig

M

30

The

horns

can

be

adusted

for

v01ume

and

tone

in

the

following

manner

Remove

the

connector

and

the

retaining

nut

in

the

centre

of

the

horn

withdraw

the

horn

from

the

vehicle

Connect

a

voltmeter

and

ammeter

into

circuit

as

shown

in

Fig

M

3I

Set

the

switch

to

ON

and

check

that

the

voltmeter

shows

a

reading

of

12

to

12

5

volts

The

sound

can

be

regulated

by

turning

the

adjusting

screw

Fig

M

32

A

reading

of

2

5

amps

should

be

obtained

for

the

flat

type

of

horns

or

5

0

amps

for

the

spiral

type

of

horns

Turning

the

adjusting

screw

clockwise

will

increase

the

current

turning

anti

clockwise

decreases

the

current

Install

the

horns

in

the

vehicle

and

check

that

the

correct

sound

can

still

be

obtained

when

the

higher

voltage

of

14

15

volts

is

generated

by

the

alternator

Turn

the

adjusting

slightly

if

necessary

then

tighten

the

locknut

INSTRUMENT

PANEL

Removal

The

instrument

panel

holds

the

various

meters

and

indicators

A

printed

circuit

board

is

located

at

the

rear

of

the

panel

and

the

connections

to

it

are

multiple

connectors

When

the

panel

is

remove

the

instruments

are

easily

withdrawn

for

inspection

and

servicing

Disconnect

the

battery

negative

terminal

2

Remove

the

windscreen

wiper

switch

lighting

switch

and

choke

control

knobs

by

pressing

them

in

and

turning

anticlockwise

Remove

the

escutcheon

3

Disconnect

the

cigarette

lighter

cable

at

the

rear

of

the

instrument

panel

and

turn

the

cigarette

lighter

outer

case

so

that

it

can

be

removed

115

Page 170 of 171

Part

NanleH

and

AlternatlyeS

Certain

parts

of

motor

cars

are

known

by

other

names

in

different

areas

and

countries

A

list

c

f

the

common

alternatives

is

given

below

ENGINE

ELECTRICA

L

Gudgeon

pin

Piston

pin

small

end

pin

Wrist

Generator

Dynamo

pin

Control

box

Cut

out

Voltage

regulator

Volt

Inlet

valve

Intake

valve

age

control

Circuit

breaker

Piston

oil

control

ring

Piston

scraper

ring

Capacitor

Condenser

Induction

manifold

Inlet

manifold

intake

manifold

Interior

light

Dome

lamp

Oil

sump

Oil

pan

Oil

reservoir

Sump

tray

Core

Plug

Expansion

plug

Welch

plug

Lens

Glass

Sealing

disc

Head

lamp

ring

Headlamp

surround

Headlamp

Dipstick

Oil

dipper

rod

Oil

level

gauge

mouldin

rod

Dillevel

indicator

Direction

indicators

Signal

lamps

Flashers

Silencer

Muffler

expansion

box

diffuser

Micrometer

adjustment

Octane

selector

Tappets

Valve

lifter

push

rods

Rear

lamps

Tail

lamps

Reversing

light

Back

u

pUgh

t

FUEL

Carburettor

choke

Carburettor

venturi

STEERING

Slow

running

jet

Low

speed

jet

Idler

jet

Drop

arm

Pitman

ann

Volume

control

screw

Idling

mixture

screw

Rocker

shaft

Pitman

shaft

Drop

ann

shaft

Fuel

pump

Petrol

pump

Fuel

lift

pump

Swivel

pin

Pivot

pin

King

pin

Steering

pin

Air

cleaner

Air

silencer

Muffler

Stub

axle

Swivel

axle

Fuel

lank

Petrol

Tank

Track

rod

Cross

tube

Tie

rod

Accelerator

Throttle

Drag

link

Side

tube

Steering

connecting

rod

CLUTCH

Steering

column

Steering

gear

shaft

Clutch

release

bearing

Throwout

bearing

Thrust

bearing

Steering

column

bearing

Mast

jacket

bearing

Clutch

lining

Disc

facing

Friction

ring

Steering

arm

Steering

knuckle

ann

Spigot

bearing

Clutch

pilot

bearing

Stator

tube

Control

tube

Clutch

housing

Bell

housing

Steering

joints

Steering

knuckles

GEARBOX

BRAKES

Gearbox

Transmission

Master

cylinder

Main

cylinder

Gear

lever

Change

speed

lever

Gearshift

Brake

shoe

lining

Brake

shoe

facing

lever

BODY

Selector

fork

Change

speed

fork

Shift

fork

Input

shaft

Constant

motion

shaft

First

gannet

Hood

motion

shaft

drive

gear

First

Luggage

locker

Boot

Luggage

compartment

reduction

pinion

Main

drive

pin

Luggage

locker

lid

Boot

lid

Rear

deck

ion

Clutch

shaft

Clutch

gear

Mudguards

Quarter

panels

Fenders

Mud

Countershaft

Layshaft

wings

Synchro

cone

Synchronizing

ring

Roof

Canopy

Reverse

Idler

gear

Reverse

pinion

Nave

plate

Wheel

disc

Hub

cap

Finishing

strip

Moulding

Chrome

strip

REAR

AXLE

Windscreen

Windshield

Rear

Axle

Final

drive

unit

Rear

window

Rear

windscreen

Rear

windshield

Crown

wheel

Ring

gear

Final

drive

gear

Spiral

Backlight

drive

gear

Quarter

ven

t

N

D

V

No

draught

ventilator

Bevel

pinion

Small

pinion

spiral

drive

pinion

Bumpers

Fenders

Loom

Harness

U

bolts

Spring

clips

Odometer

Trip

recorder

Axle

shaft

Half

shaft

Hub

driving

shaft

Jack

Bonnet

catch

Hood

latch

driving

shaft

Kerosene

Paraffin

Differential

gear

Sun

wheel

Boot

Trunk

Differential

pinion

Planet

wheel