technical specifications DATSUN 610 1969 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1969, Model line: 610, Model: DATSUN 610 1969Pages: 171, PDF Size: 10.63 MB

Page 23 of 171

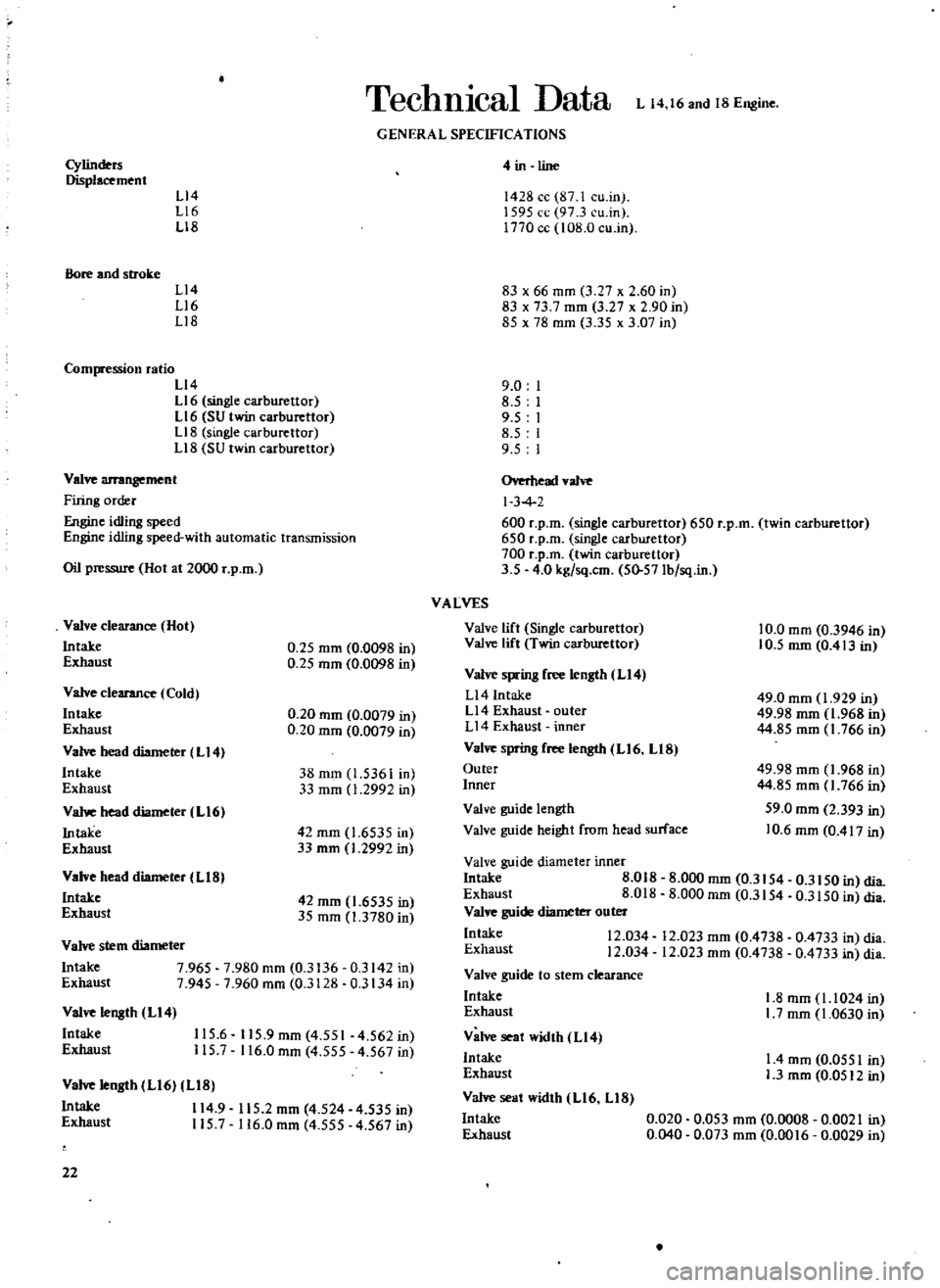

TechnIcal

Data

L

14

16

and

18

Engine

GENERAL

SPECIFICATIONS

Cylinders

Displacement

L14

L16

L18

Bore

and

stroke

L14

L16

Ll8

Compression

ratio

L14

L16

single

carburettor

L16

SU

twin

carburettor

L18

single

carburettor

Ll8

SU

twin

carburettor

Valve

arrangement

Firing

order

e

idling

speed

Engine

idling

speed

with

automatic

transmission

Oil

pressure

Hot

at

2000

r

p

m

Valve

clearance

Hot

Intake

Exhaust

0

25

mm

0

0098

in

0

25

mm

0

0098

in

Valve

clearance

Cold

Intake

Exhaust

Va

head

diameter

L14

Intake

Exhaust

Vahoe

head

diameter

L16

Intake

Exhaust

0

20

mm

0

0079

in

0

20

mm

0

0079

in

38

mm

1

5361

in

33

mm

1

2992

in

42

mm

1

6535

in

33

rom

1

2992

in

Valve

head

diameter

L18

Intake

Exhaust

42

mm

1

6535

in

35

mm

1

3780

in

Valve

stem

diameter

Intake

7

965

7

980

mm

0

3136

0

3142

in

Exhaust

7

945

7

960

mm

0

3128

0

3134

in

Valve

length

L14

Intake

Exhaust

115

6

115

9mm

4

551

4

562in

115

7

116

0

mm

4

555

4

567

in

Valve

length

L16

LIB

Intake

114

9

115

2

mm

4

524

4

535

in

Exhaust

115

7

116

0

mm

4

555

4

567

in

22

4

in

line

1428

cc

87

1

cu

in

1595

cc

97

3

cu

in

1770

cc

108

0

cu

in

83

x

66

mm

3

27

x

2

60

in

83

x

73

7

mm

3

27

x

2

90

in

85

x

7B

mm

3

35

x

3

07

in

9

0

8

5

9

5

8

5

9

5

Overhead

valve

I

3

4

600

r

p

m

single

carburettor

650

r

p

m

twin

carburettor

650

r

p

m

single

carburettor

700

r

p

m

twin

carburettor

3

5

4

0

kg

sq

cm

50

57Ib

sq

in

VALVES

Valve

lift

Single

carburettor

Valve

lift

Twin

carburettor

10

0

mm

0

3946

in

10

5

mm

0

413

in

Valve

spring

free

length

LI4

Ll4

Intake

Ll4

Exhaust

outer

L14

Exhaust

inner

Valve

sprin8

free

length

L16

LIB

Outer

Inner

49

0

mm

1

929

in

49

98

mm

1

968

in

44

85

mm

1

766

in

49

98

mm

1

968

in

44

85

mm

1

766

in

59

0

mm

2

393

in

10

6

mm

0

417

in

Valve

guide

length

Valve

guide

height

from

head

surface

Valve

guide

diameter

inner

Intake

8

018

Exhaust

8

018

Valve

guide

diameter

outer

Intake

12

034

Exhaust

12

034

Valve

guide

to

stem

clearance

Intake

Exhaust

Valve

seat

width

L14

Intake

Exhaust

Valve

seat

width

L16

LIB

Intake

Exhaust

8

000

mm

0

3154

0

3150

in

clia

8

000

mm

0

3154

0

3150

in

clia

12

023

mm

0

4738

0

4733

in

clia

12

023

mm

0

4738

0

4733

in

clia

1

8

mm

1

1024

in

I

7

mm

1

0630

in

I

4

mm

0

0551

in

1

3

mm

0

0512

in

0

020

0

053

mm

0

0008

0

0021

in

0

040

0

073

mm

0

0016

0

0029

in

Page 46 of 171

The

coil

spring

clutch

pressure

plate

can

be

lapped

with

a

surface

grinder

to

remove

dents

or

scratches

only

the

minimum

amount

of

metal

should

be

removed

to

restore

the

surface

Check

the

plate

for

distortion

by

placing

it

on

a

surface

plate

with

the

friction

face

towards

the

surface

plate

Press

the

pressure

plate

down

and

insert

a

feeler

gauge

of

1

0mm

0

0039

in

between

the

pressure

plate

and

surface

plate

If

it

is

possible

to

insert

the

feeler

gauge

then

the

pressure

plate

must

be

repaired

or

replaced

The

plate

can

be

skimmed

but

the

maximum

amount

of

metal

that

can

be

removed

is

1

0mm

0

0039in

CLUTCH

SPRING

Diaphragm

clutch

With

the

diaphragm

spring

assembled

to

the

pressure

plate

inspect

the

spring

height

and

load

in

the

following

manner

Place

distance

pieces

of

7

8

mm

0

307

in

on

the

base

plate

as

shown

in

Fig

E

3

and

bolt

down

the

clutch

cover

using

the

special

bolts

provided

with

the

kit

Meas

Jre

the

height

B

in

Fig

E

5

at

a

diameter

of

44mm

1

732

in

The

release

fingers

should

not

exceed

a

height

of

43

45

mm

1

693

1

772

in

from

the

base

plate

Replace

the

spring

if

the

height

is

in

excess

of

the

figures

quoted

Press

the

dutch

down

as

shown

in

Fig

E

6

to

a

depth

of

7

8mm

0

307

in

or

until

the

clutch

driven

plate

upper

surface

lines

up

with

the

clutch

cover

mounting

face

If

the

load

applied

is

less

than

350

kg

770

lbs

it

will

be

necessary

to

renew

the

diaphragm

spring

Do

not

press

the

clutch

disc

down

by

more

than

9mm

0

35

in

or

the

diaphragm

spring

may

be

broken

CLUTCH

SPRINGS

Coil

spring

clutch

The

clutch

springs

must

be

replaced

as

a

set

if

any

of

the

springs

are

found

to

be

defective

Specifications

for

the

springs

are

given

in

Technical

Data

at

the

end

of

this

section

Generally

a

spring

may

be

considered

faulty

if

when

assembled

the

load

is

reduced

by

more

than

15

or

if

the

free

length

has

altered

by

more

than

1

5mm

0

0590

in

or

if

the

deflection

B

to

A

in

Fig

E

7

exceeds

5mm

per

100mm

0

2

in

per

3

94

in

Release

Bearing

The

release

bearing

should

be

renewed

if

excessively

worn

or

if

roughness

can

be

felt

when

the

bearing

is

turned

by

hand

The

bearing

should

also

be

renewed

if

the

grease

has

leaked

away

or

if

the

clearance

between

the

clutch

cover

and

inner

diameter

of

the

sleeve

is

more

than

0

5

mm

0

0197

in

The

bearing

can

be

removed

using

a

conventional

puller

as

shown

in

Fig

E

8

Two

types

of

release

bearings

are

available

and

care

must

be

taken

when

fitting

onto

the

bearing

sleeve

The

release

bearing

should

be

pressed

into

place

on

the

diaphragm

spring

type

of

clutch

with

a

force

of

400

kg

880

lbs

applied

at

the

outer

race

as

shown

in

Fig

E

9

On

the

coil

spring

clutch

the

same

force

must

be

applied

at

the

inner

race

as

shown

in

Fig

E

IO

It

should

be

possible

to

turn

the

bearing

freely

and

smoothly

when

it

is

pressed

into

place

CLUTCH

Assembly

Coil

spring

type

Press

the

pin

into

the

eyebolt

and

through

the

lug

on

the

pressure

plate

Place

the

three

distance

pieces

on

the

surface

of

the

base

plate

of

the

special

tool

ST20050000

and

position

the

pressure

plate

pressure

springs

and

retainers

on

the

plate

Set

the

retracting

springs

on

the

cover

and

insert

the

release

levers

through

the

spring

Place

the

clutch

cover

over

the

pressure

plate

and

springs

making

sure

that

the

retracting

springs

do

not

become

dislodged

or

distorted

Compress

the

pressure

springs

by

screwing

the

special

set

bolts

into

the

holes

in

the

cover

Tighten

the

bolts

gradually

in

a

diagonal

pattern

to

avoid

distorting

the

cover

Place

the

release

levers

on

the

eye

bolts

and

screw

OR

the

securing

nuts

Place

retaining

hooks

under

the

release

levers

and

remove

the

clutch

assembly

from

the

base

plate

slackening

the

set

bolts

in

a

diagonal

pattern

COIL

SPRING

CLUTCH

Adjusting

Screw

the

centre

pillar

into

the

base

plate

and

place

the

high

finger

over

the

pillar

The

height

of

the

release

levers

must

be

adjusted

by

turning

the

eye

bolt

nuts

until

the

tops

of

the

release

levers

are

just

touching

the

tip

of

the

gauge

See

Fig

E

11

Remove

the

centre

pillar

when

the

release

levers

are

correctly

adjusted

and

screw

in

the

actuating

lever

Fig

E

12

Turn

the

actuating

mechanism

several

times

to

bed

down

the

parts

and

then

recheck

the

height

of

the

release

levers

Check

for

run

out

as

near

to

the

edge

as

possible

and

readjust

if

the

deviation

is

more

than

0

5

mrn

0

020

in

CLUTCH

InsWlation

Ensure

that

the

friction

faces

are

free

from

oil

and

grease

and

place

the

driven

plate

on

the

flywheel

The

longer

chamfered

splined

end

of

the

assembly

should

face

the

gearbox

Use

a

spare

drive

shaft

to

align

the

driven

plate

The

shaft

must

be

inserted

through

the

splined

hub

of

the

driven

plate

and

into

the

pilot

bearing

of

the

flywheel

Place

the

clutch

cover

into

position

on

the

flywheel

and

tighten

the

dutch

bolts

gradually

in

a

diagonal

pattern

to

a

torque

reading

of

1

5

2

2

kgm

11

16Ib

ft

Remove

the

dummy

shaft

and

the

restraining

hooks

from

the

release

levers

Refit

the

release

bearing

and

the

bell

housing

CLUTCH

PEDAL

Removal

and

Installation

Remove

the

clevis

pin

from

the

end

of

the

master

cylinder

pushrod

and

disconnect

the

pushrod

Remove

the

return

spring

Remove

the

pushrod

after

slackening

the

pushrod

adjuster

Coil

spring

clutch

only

Remove

the

pedal

lever

securing

bolt

slacken

the

handbrake

bracket

bolts

and

lift

out

the

pedal

Clean

all

parts

thoroughly

and

check

them

for

wear

or

damage

paying

particular

attention

to

the

rubber

parts

return

spring

and

pedal

lever

bush

Installation

of

the

clutch

pedal

is

a

reversal

of

the

removal

procedures

45

Page 58 of 171

FOUR

SPEED

GEARBOX

Removal

and

Installation

The

removal

and

installation

procedures

for

the

four

speed

gearbox

are

similar

to

those

previously

described

for

the

three

speed

gearbox

However

the

floor

mounted

gear

lever

must

be

removed

from

the

controllevef

bracket

in

addition

to

the

operations

already

detailed

FOUR

SPEED

GEARBOX

Dismantling

Drain

the

oil

from

the

gearbox

Remove

the

dust

coveT

and

release

the

spring

securing

the

clutch

withdrawal

lever

Remove

the

withdrawal

lever

and

release

bearing

from

the

clutch

housing

as

described

in

the

section

CLurCH

Remove

the

clevis

pin

securing

the

striking

rod

to

the

control

lever

Remove

the

speedometer

drive

pinion

assembly

and

with

draw

the

rear

extension

housing

Disengage

the

striking

rod

from

the

selector

rod

gates

Remove

the

gearbox

covers

See

Figs

F

26

and

F

27

Unscrew

the

three

detent

ball

plugs

and

remove

the

spriags

and

detent

balls

Drive

out

the

pins

securing

the

selector

forks

to

the

rods

and

withdraw

the

forks

and

rods

Lock

the

main

shaft

by

moving

the

first

second

and

third

fourth

coupling

sleeve

into

gear

at

the

same

time

and

release

the

ffiainshaft

nut

Remove

the

countershaft

and

the

gear

cluster

together

with

the

two

needle

roller

bearings

and

spacers

Remove

the

snap

ring

holding

the

revep

e

idler

gear

and

withdraw

the

reverse

idler

gears

and

shaft

Fig

F

28

Take

off

the

bolts

securing

the

mainshaft

bearing

retainer

to

the

gearbox

case

Fig

F

29

Withdraw

the

mainshaft

assembly

Fig

F

30

and

the

main

drive

shaft

The

mainshaft

can

be

dismantled

in

the

following

manner

Release

the

third

fourth

synchronizer

unit

snap

ring

and

with

draw

the

hub

complete

with

coupling

sleeve

Remove

the

third

speed

gearwheel

and

the

needle

roller

bearing

from

the

main

shaft

Take

off

the

mainshaft

nut

and

locking

plate

Remove

the

speedometer

drive

gear

with

the

retaining

ball

Withdraw

the

mainshaft

reverse

gear

and

the

hub

Press

off

the

mainshaft

bearing

complete

with

the

bearing

retainer

Remove

the

thrust

washer

and

the

first

speed

gear

together

with

the

needle

roller

bearing

taking

care

not

to

lose

the

small

baU

used

to

locate

the

thrust

washer

Slide

off

the

first

speed

gearwheel

bush

Withdraw

the

first

second

synchronizer

and

hub

Remove

the

second

speed

gearwheel

and

needle

roller

bearing

FOUR

SPEED

GEARBOX

Installation

Refer

to

the

instructions

given

for

the

three

speed

gearbox

and

to

Technical

Data

for

the

specifications

applicable

to

the

different

gearboxes

FOUR

SPEED

GEARBOX

Assembly

Assembly

of

the

gearbox

is

similar

to

the

procedures

previously

described

for

the

three

speed

gearbox

with

the

following

exceptions

When

assembling

the

main

drive

gear

bearing

on

the

shaft

insiall

the

spacer

and

select

a

new

snap

ring

to

eliminate

all

end

float

between

bearing

and

snap

ring

Snap

rings

are

available

in

five

thicknesses

from

1

52

1

77mm

0

06

0

07

in

The

assembly

procedures

for

the

Warner

type

synchronizers

are

similar

to

the

instructions

previously

described

for

the

three

speed

gearbox

Refer

to

THREE

SPEED

GEARBOX

Assembly

for

further

details

To

assemble

the

Servo

F4C63

type

synchronizers

proceed

as

follows

Place

the

gear

on

a

clean

flat

surface

and

install

the

synchronizer

ring

on

the

inner

side

of

theclutch

gear

Fit

the

thrust

block

into

place

as

shown

in

Fig

F

31

Place

the

anchor

block

and

brake

band

into

position

and

fit

the

circlip

into

the

groove

in

the

gear

to

secure

the

synchromesh

assembly

When

assembling

the

mainshaft

select

a

snap

ring

which

will

give

an

end

float

between

0

05

0

15

mm

0

002

0

006in

to

the

third

speed

gearwheel

Snap

rings

are

available

in

five

sizes

from

1

40

mm

0

0551

in

to

1

60

mm

0

0630

in

thick

ness

Tighten

the

locknut

at

the

rear

of

the

mainshaft

to

a

torque

reading

of

7

1

kgm

51

87Ib

ft

Assemble

the

reverse

idler

gear

as

shown

in

Fig

F

32

The

reverse

idler

driven

gear

3

should

be

placed

on

the

end

of

the

reverse

shaft

1

with

the

longest

spline

and

retained

with

a

suitable

snap

ring

2

Install

the

reverse

shaft

and

gear

assembly

into

the

gearbox

case

from

the

rear

with

the

thrust

washer

4

between

the

gear

and

the

case

Fit

the

thrust

washer

5

and

idler

gear

6

18

teeth

and

secure

with

a

suitable

snap

ring

2

The

end

float

of

the

gear

should

be

checked

and

adjusted

to

0

1

O

3mm

0

004

0

012

in

by

selecting

a

suitable

snap

ring

2

Five

thicknesses

of

snap

rings

are

available

from

I

lmm

0

043in

to

1

5mm

0

06in

See

Technical

Data

for

F4W63

and

F4C63

gearboxes

Adjust

the

counter

gear

end

float

to

0

05

0

15

mm

0

002

0

006in

by

selecting

a

thrust

washer

of

the

required

thickness

Thrust

washers

are

available

in

five

thicknesses

from

2

40

2

60

mm

0

094

0

102

in

When

assembling

the

selector

mechanisms

Fig

F

33

fit

the

first

second

selector

forks

I

and

the

third

fourth

selector

forks

2

onto

the

coupling

sleeves

and

insert

the

first

second

fork

rod

3

Fit

an

interlock

plunger

4

and

the

third

fourth

speed

selector

rod

5

Do

not

forget

the

interlock

pin

7

A

section

through

the

selector

and

interlock

mechanism

is

given

in

Fig

F

34

Install

an

interlock

plunger

6

and

assemble

the

reverse

selector

fork

8

and

fork

rod

9

Secure

the

selector

forks

to

the

rods

with

the

retaining

pins

10

Place

a

check

ball

and

spring

into

each

of

the

holes

and

screw

the

plug

down

to

a

torque

reading

of

1

7

2

1

Jegm

12

3

15

2

Ib

ft

after

coating

the

threads

with

sealing

com

pound

Install

the

rear

extension

housing

engaging

the

striking

rod

with

the

fork

rod

gates

and

tighten

the

housing

bolts

to

a

torque

reading

of

1

6

2

5

kgm

12

18Ib

ft

Fit

the

front

and

bottom

covers

and

tighten

the

bolts

to

a

torque

reading

of

1

1

1

8

kgm

8

13Ib

ft

57

Page 62 of 171

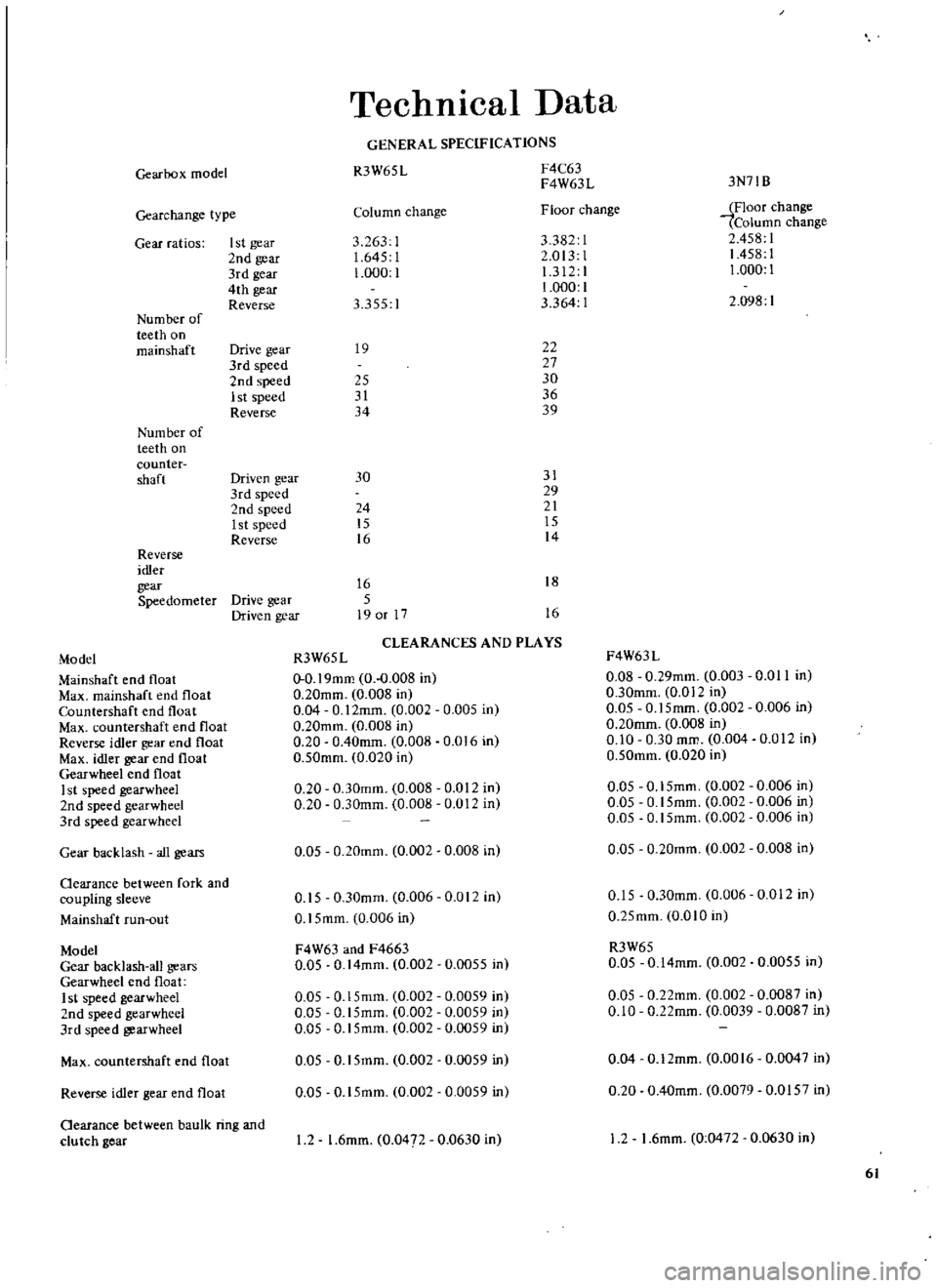

Gearbox

mode

Gearchange

type

Gear

ratios

I

st

gear

2nd

gear

3rd

gear

4th

gear

Reverse

Num

ber

of

teeth

on

mainshaft

Drive

gear

3rd

speed

2nd

speed

1st

speed

Reverse

Num

ber

of

teeth

on

counter

shaft

Driven

gear

3rd

speed

2nd

speed

1st

speed

Reverse

Reverse

idler

gear

Speedometer

Drive

gear

Driven

gear

Technical

Data

GENERAL

SPECIFICATIONS

R3W65

L

F4C63

F4W63L

Column

change

Floor

change

3

263

1

3382

1

1

645

I

2

013

1

1

000

1

1

312

1

1

000

1

3

355

I

3

364

1

19

22

27

25

30

31

36

34

39

3N71B

iFloor

change

Column

change

2

458

1

1458

1

1

000

1

2

098

1

30

31

29

24

21

15

15

16

14

16

18

5

19

or

17

16

CLEARANCES

AND

PLAYS

Model

R3W65L

F4W63L

Mainshaft

end

float

0

0

19mm

0

0

008

in

0

08

0

29mm

0

003

0

0

II

in

Max

mainshaft

end

float

0

20mm

0

008

in

0

30mm

0

012

in

Countershaft

end

float

0

04

0

12mm

0

002

0

005

in

0

05

0

15mm

0

002

0

006

in

Max

countcrshaft

end

float

0

20mm

0

008

in

0

20mm

0

008

in

Reverse

idler

gear

end

float

0

20

0

40mm

0

008

0

016

in

0

10

0

30

mm

0

004

0

012

In

Max

idler

gear

end

float

0

50mm

0

020

in

0

50mm

0

020

in

Gearwheel

end

float

I

st

speed

gearwheel

0

20

0

30mm

0

008

0

012

in

0

05

0

15mm

0

002

0

006

in

2nd

speed

gearwheel

0

20

0

30mm

0

008

0

012

in

0

05

0

15mm

0

002

0

006

in

3rd

speed

gearwheel

0

05

0

15mm

0

002

0

006

in

Gear

backlash

all

gears

0

05

0

20mm

0

002

0

008

in

0

05

0

20mm

0

002

0

008

in

Oearance

between

fork

and

coupling

sleeve

0

15

0

30mm

0

006

0

012

in

0

15

0

30mm

0

006

0

012

in

Mallshaft

run

out

0

15mm

0

006

in

0

25mm

OmO

in

Model

F4W63

and

F4663

R3W65

Gear

backlash

all

gears

0

05

0

14mm

0

002

0

0055

in

0

05

0

14mm

0

002

0

0055

in

Gearwheel

end

float

1

st

speed

gearwheel

0

05

0

15mm

0

002

0

0059

in

0

05

O

22mm

0

002

0

0087

in

2nd

speed

gearwheel

0

05

0

15mm

0

002

0

0059

in

0

10

0

22mm

0

0039

0

0087

in

3rd

speed

gearwheel

0

05

0

15mm

0

002

0

0059

in

Max

countershaft

end

float

0

05

0

15mm

0

002

0

0059

in

0

04

0

12mm

0

0016

0

0047

in

Reverse

idler

gear

end

float

0

05

0

15mm

0

002

0

0059

in

0

20

0

40mm

0

0079

0

0157

in

Oearance

between

baulk

ring

and

clu

tch

gear

I

2

1

6mm

0

047

0

0630

in

12

1

6mm

0

0472

0

0630

in

61

Page 76 of 171

Rear

Axle

Rear

SuspensIon

DESCRIPTION

REAR

AXLE

AND

SUSPENSION

Removal

Saloons

COIL

SPRINGS

Saloons

REAR

SHOCK

ABSORBERS

Saloons

REAR

SUSPENSION

ARM

Saloons

DESCRIPTION

Saloon

models

are

fitted

with

independent

rear

suspension

with

semi

trailing

arms

suspension

arms

coil

springs

and

telescopic

hydraulic

double

acting

shock

absorbers

The

differ

ential

gear

carrier

and

suspension

member

is

mounted

directly

onto

the

body

structure

via

rubber

mountings

See

Fig

H

I

Estate

cars

and

1800

ce

Vans

are

fitted

with

a

semi

floating

rear

axle

with

semi

elliptic

leaf

springs

and

telescopic

hydraulic

shock

absorbers

mounted

on

rubrer

bushes

See

Fig

H

2

REAR

AXLE

AND

SUSPENSION

Removal

Saloon

models

I

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

disconnect

the

hand

brake

linkage

and

the

return

spring

Fig

H

3

3

Remove

the

exhaust

tail

pipe

and

silencer

4

Disconnect

the

brake

hoses

and

plug

the

openings

to

prevent

the

ingress

of

dirt

5

Remove

the

propeller

shaft

assembly

as

described

in

the

relevant

section

after

marking

the

propeller

rear

flange

and

differential

pinion

flange

6

Jack

up

the

suspension

ann

and

remove

the

shock

absorber

lower

mountings

taking

care

not

to

lose

the

rubber

bushings

7

Place

ajack

under

the

centre

of

the

suspension

member

and

differential

carrier

and

remove

the

nuts

securing

the

suspension

member

to

the

body

7

in

Fig

H

3

Remove

the

differential

mounting

nuts

8

8

Carefully

lower

and

remove

the

suspension

assembly

REAR

SUSPENSION

Inspection

Saloons

Examine

all

parts

for

wear

and

damage

paying

particular

attention

to

the

rubber

bushes

in

the

suspension

arms

and

the

bump

rubbers

Check

the

condition

of

the

spring

rubber

insulators

in

the

suspension

member

and

differential

mounting

memrer

The

rubber

insulators

must

be

replaced

if

the

dimension

A

in

Fig

H

4

is

less

than

5mm

0

2

in

REAR

AXLE

SHAFTS

BEARINGS

AND

SEALS

Saloons

DRNE

SHAFTS

REAR

AXLE

Removal

Estate

cars

and

Vans

REAR

SPRING

Estate

cars

and

Vans

REAR

SHOCK

ABSORBERS

Estate

cars

and

Vans

REAR

SUSPENSION

Installation

Saloons

Installation

is

a

reversal

of

the

removal

procedures

noting

the

following

points

Ensure

that

the

suspension

member

and

differential

mount

ing

member

are

correctly

aligned

as

shown

in

Fig

U

5

and

insert

the

rubber

insulators

from

the

underside

of

the

vehicle

Tighten

the

differential

mounting

member

the

suspension

member

and

lower

shock

absorber

nuts

to

the

specified

tighten

ing

torques

COIL

SPRINGS

Removal

Saloons

Jack

up

the

rear

of

the

vehicle

and

support

it

on

stands

2

Remove

the

road

wheels

and

disconnect

the

handbrake

linkage

and

return

spring

3

Remove

the

drive

shaft

flange

nuts

at

the

wheel

side

Fig

H

6

and

the

bump

rubber

securing

nuts

4

Place

ajack

under

the

suspension

ann

and

remove

the

shock

absorber

from

the

lower

mounting

bracket

Carefully

lower

the

jack

and

remove

the

coil

spring

spring

scat

and

bump

rubber

Fig

H7

COIL

SPRINGS

Installation

Saloons

Oleck

the

coil

springs

for

signs

of

deformation

or

cracks

Test

the

spring

for

its

free

length

and

height

under

load

and

compare

the

figures

obtained

with

the

information

in

Technical

Data

Inspect

all

rubber

parts

and

replace

any

which

are

damaged

or

deformed

Installation

is

a

reversal

of

the

removal

procedure

making

sure

that

the

flat

face

of

the

spring

is

at

the

top

REAR

SHOCK

ABSORBERS

Removal

and

Installation

Saloons

Remove

the

trim

in

the

boot

trunk

and

take

off

the

two

nuts

securing

the

upper

shock

absorber

mounting

See

Fig

H

S

Detach

the

shock

absorber

from

the

lower

mounting

bracket

The

shock

absorber

should

be

tested

and

the

fIgUres

com

pared

with

the

specifications

in

Technical

Data

Cbeck

for

oil

leaks

and

cracks

Make

sure

that

the

shaft

is

straight

and

that

the

rubber

bushes

are

not

damaged

or

defonned

Renew

all

unsatis

75