service DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 440 of 513

ENGINE

Stator

core

EE044

Fig

EE

41

Testing

stator

for

ground

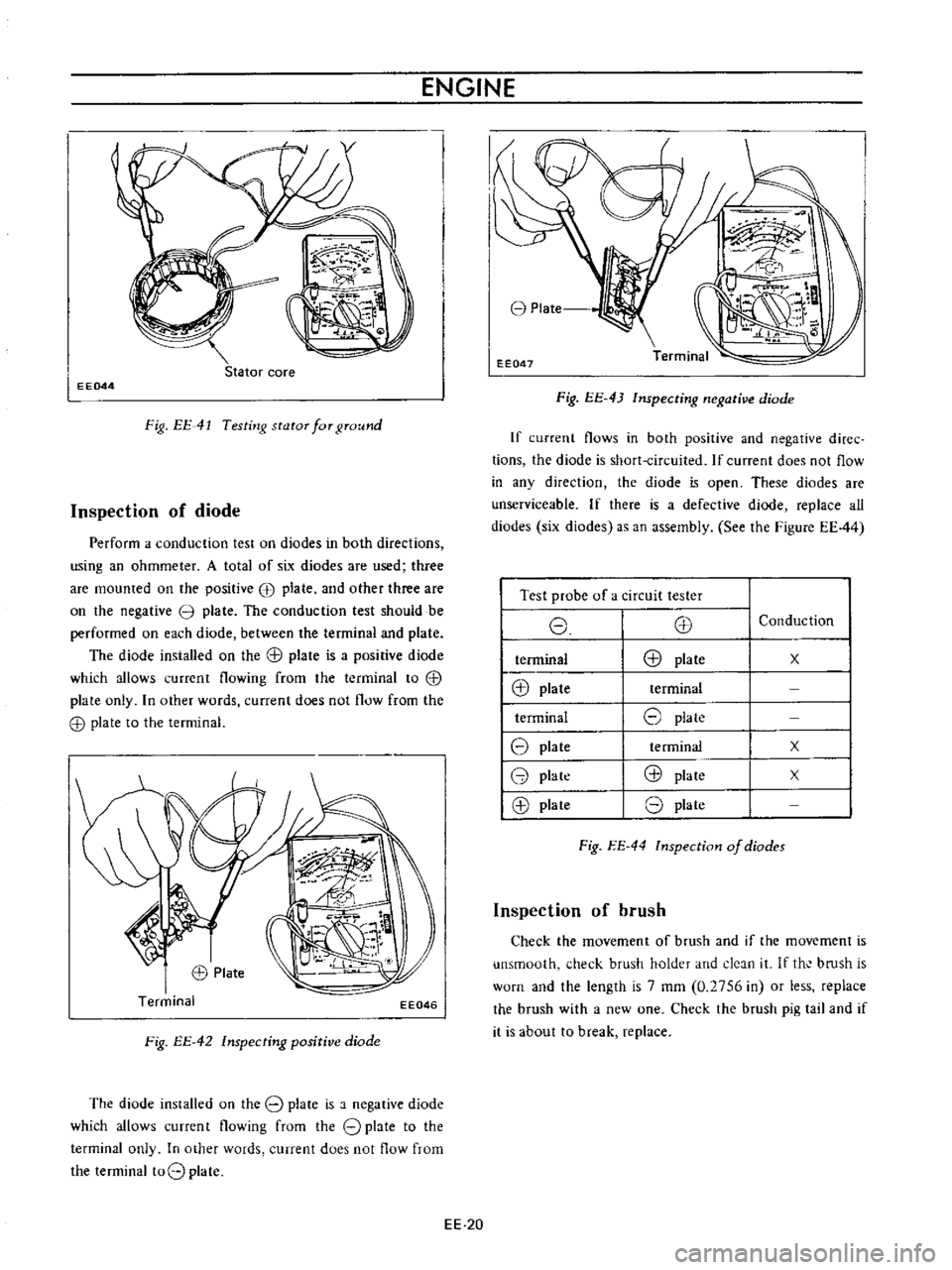

Inspection

of

diode

Perform

a

conduction

test

on

diodes

in

both

directions

using

an

ohmmeter

A

total

of

six

diodes

are

used

three

are

mounted

on

the

positive

EB

plate

and

other

three

are

on

the

negative

3

plate

The

conduction

test

should

be

performed

on

each

diode

between

the

terminal

and

plate

The

diode

installed

on

the

G

l

plate

is

a

positive

diode

which

allows

current

flowing

from

the

terminal

to

G

l

plate

only

In

other

words

current

does

not

flow

from

the

G

l

plate

to

the

terminal

EE046

Fig

EE

42

Inspecting

positive

diode

The

diode

installed

on

the

8

plate

is

a

negative

diode

which

allows

current

flowing

from

the

8

plate

to

the

terminal

only

In

other

words

current

does

not

flow

from

the

terminal

t08

plate

EE

20

8

Plate

EE047

Fig

EE

43

Inspecting

negative

diode

If

current

flows

in

both

positive

and

negative

diree

tions

the

diode

is

short

circuited

If

current

does

not

flow

in

any

direction

the

diode

is

open

These

diodes

are

unserviceable

If

there

is

a

defective

diode

replace

all

diodes

six

diodes

as

an

assembly

See

the

Figure

EE44

I

Test

probe

of

a

circuit

tester

I

8

E8

I

terminal

E8

plate

I

@

plate

terminal

I

terminal

8

plate

18

plate

te

rminal

18

plate

@

plate

18

plate

8

plate

Conduction

x

x

x

Fig

EE

44

lnspection

of

diodes

Inspection

of

brush

Check

the

movement

of

brush

and

if

the

movement

is

unsmooth

check

brush

holder

and

deJn

it

If

th

bmsh

is

worn

and

the

length

is

7

mm

0

2756

in

or

less

replace

the

brush

with

a

new

one

Check

the

brush

pig

tail

and

if

it

is

about

to

break

replace

Page 442 of 513

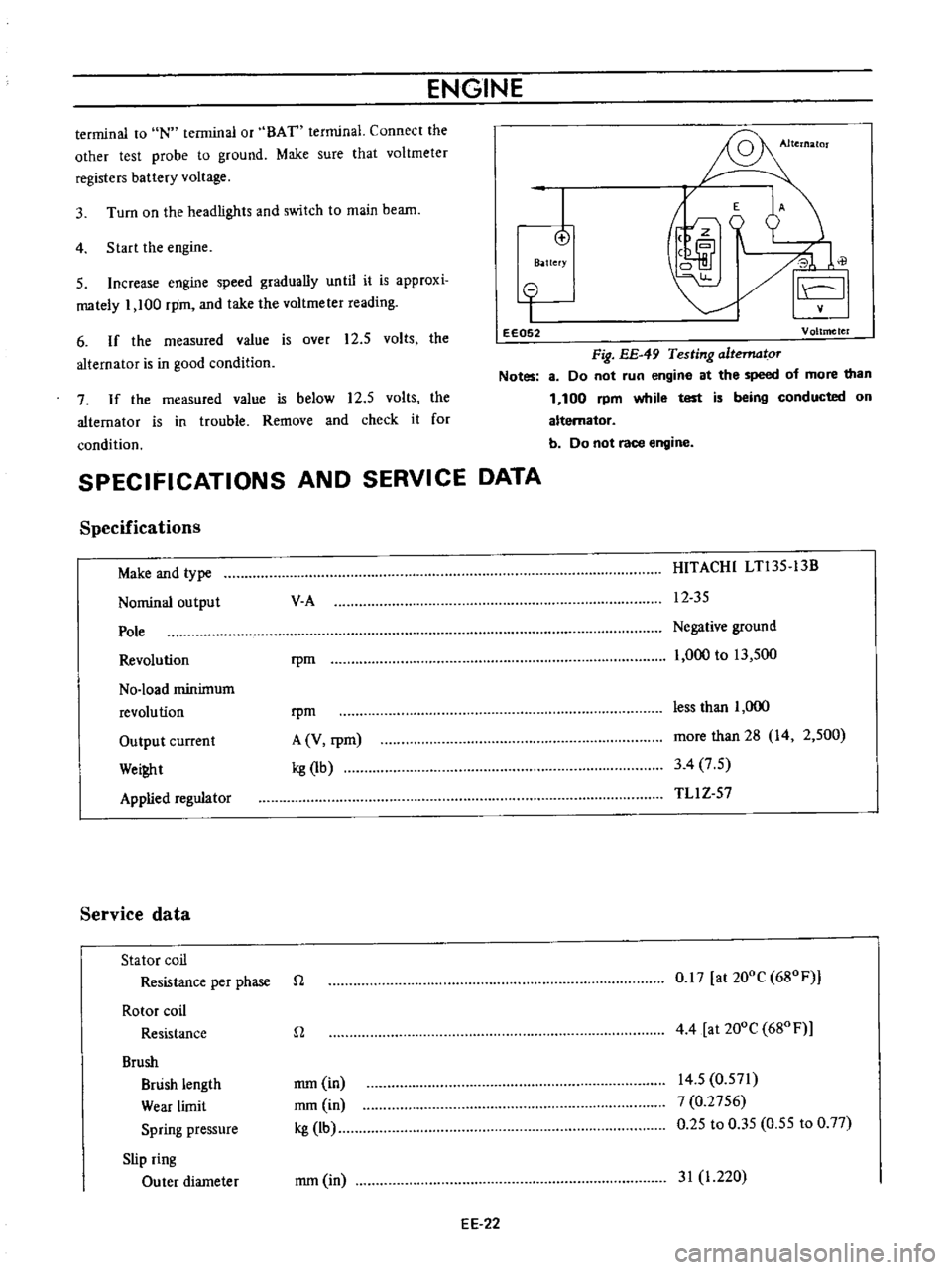

ENGINE

terminal

to

IN

terminal

or

BAT

terminal

Connect

the

other

test

probe

to

ground

Make

sure

that

voltmeter

registers

battery

voltage

4

Start

the

engine

3

Turn

on

the

headlights

and

switch

to

main

beam

I

o

B

ttefY

E

A

J

0

il

I

5

Increase

engine

speed

gradually

until

it

is

approxi

mately

1

100

rpm

and

take

the

voltmeter

reading

6

If

the

measured

value

is

over

12

5

volts

the

alternator

is

in

good

condition

o

I

eE052

Voltmeter

Fig

EE

49

Testing

altematoT

Notes

8

Do

not

run

engine

at

the

speed

of

more

than

1

100

rpm

while

test

is

being

conducted

on

alternator

b

Do

not

race

engine

7

If

the

measured

value

is

below

12

5

volts

the

alternator

is

in

trouble

Remove

and

check

it

for

condition

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Make

and

type

Nominal

output

Pole

Revolution

No

load

minimum

revolution

Output

current

Wei

t

Applied

regulator

Service

data

Stator

coil

Resistance

per

phase

Rotor

coil

Resistance

Brush

Brush

length

Wear

limit

Spring

pressure

Slip

ring

Outer

diameter

V

A

HITACHI

LTl35

13B

12

35

rpm

Negative

ground

1

000

to

13

500

rpm

A

V

rpm

kg

1b

less

than

1

000

more

than

28

14

2

500

3

4

7

5

TLl

Z

57

n

0

17

at

200C

680F

n

4

4

at

200e

680

F

mm

in

mm

in

kg

lb

14

5

0

571

7

0

2756

0

25

to

0

35

0

55

to

0

77

mm

in

31

1

220

EE

22

Page 443 of 513

Charge

relay

SPECIFICATIONS

AND

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

ENGINE

ElECTRICAL

SYSTEM

Reduction

limit

Repair

limit

Repair

accuracy

mm

in

mm

in

mm

in

REGULATOR

CONTENTS

DESCRIPTiON

MEASUREMENT

OF

REGULATING

VOLTAGE

ADJUSTMENT

Voltage

regu

lator

EE

23

EE

24

EE

25

EE

25

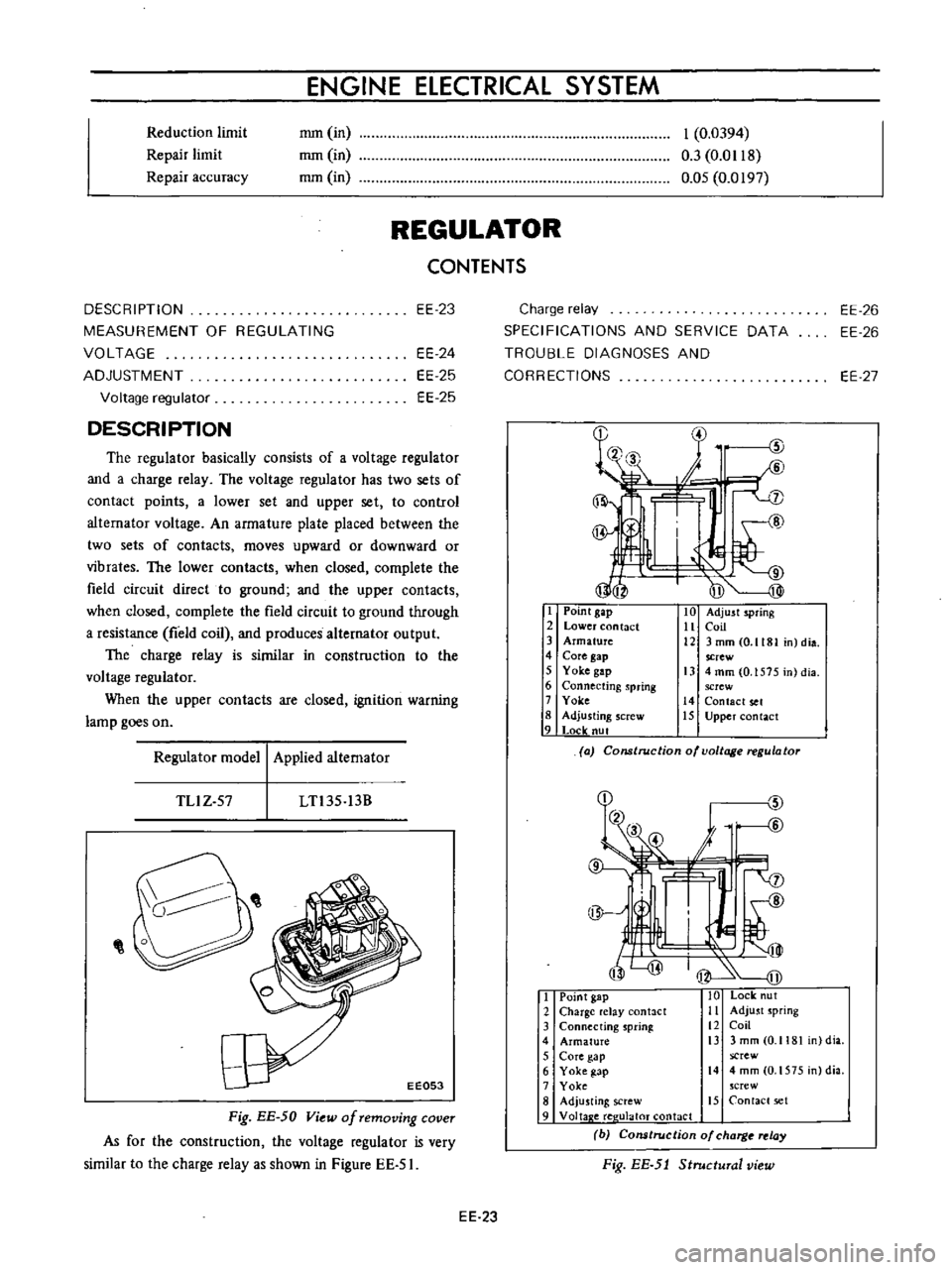

DESCRIPTION

I

0

0394

0

3

0

0118

0

05

0

0197

EE

26

EE

26

EE

27

1

I

T

r

@

V

The

regulator

basically

consists

of

a

voltage

regulator

and

a

charge

relay

The

voltage

regulator

has

two

sets

of

contact

points

a

lower

set

and

upper

set

to

control

altemator

voltage

An

armature

plate

placed

between

the

two

sets

of

contacts

moves

upward

or

downward

or

vibrates

The

lower

contacts

when

closed

complete

the

field

circuit

direct

to

ground

and

the

upper

contacts

when

closed

complete

the

field

circuit

to

ground

through

a

resistance

field

coil

and

produces

alternator

output

The

charge

relay

is

similar

in

construction

to

the

voltage

regulator

When

the

upper

contacts

are

closed

ignition

warning

lamp

goes

on

I

Point

gap

2

Lower

contact

3

Armature

4

Core

gap

5

Yoke

gap

6

Connecting

spring

7

Yoke

8

Adjusting

screw

9

Locle

nut

10

Adjust

spring

11

Coil

12

3mmCO

1181

n

dia

screw

13

4

mm

0

1575

in

dia

screw

14

Contact

set

15

Upper

contact

Regulator

model

Applied

alternator

a

Construction

of

voltage

regulator

TLlZ

57

LTl35

13B

I

Point

gap

10

Lock

ut

2

Charge

elay

antact

Ii

Adjust

spring

3

Connecting

sprinl

12

Coil

4

Armature

i3

3

mm

0

1181

dia

5

Core

gap

screw

6

Yoke

gap

14

4mm

O

1575

n

dia

7

Yoke

crew

8

Adju

ting

screw

15

Contact

set

9

Voltap

e

ree

ulaloT

contact

b

Cons

rue

ion

of

charg

relay

Fig

EE

5J

Structural

view

Fig

EE

50

View

of

removing

cover

As

for

the

construction

the

voltage

regulator

is

very

similar

to

the

charge

relay

as

shown

in

Figure

EE

51

EE

23

Page 446 of 513

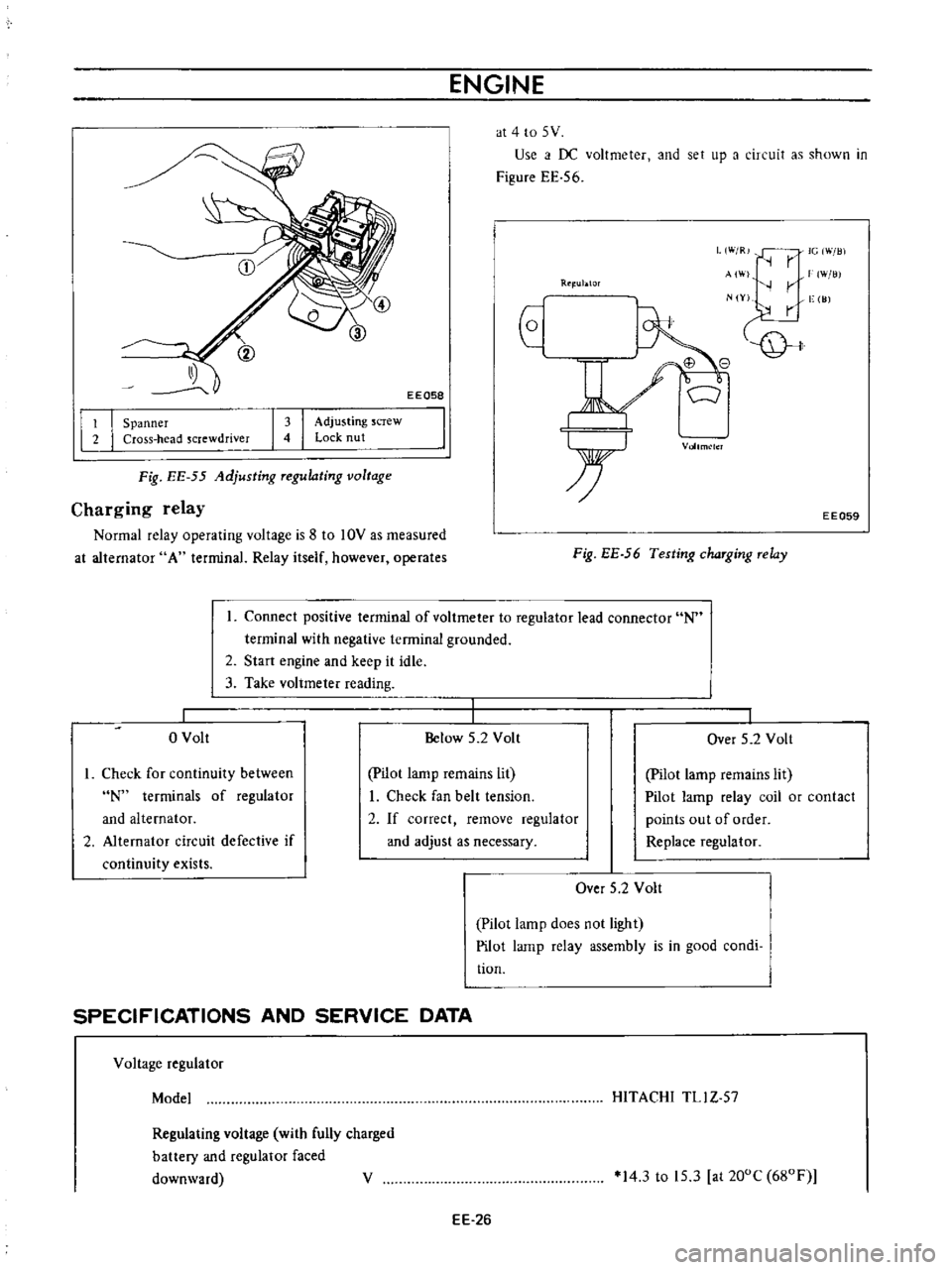

ENGINE

at

4

to

5

V

Use

i

f

DC

voltmeter

and

set

up

a

circuit

as

shown

in

Figure

EE

56

EEQ58

L

W

R

IG

Will

r

AI

W

lli

r

N

Y

vge

I

JJ

Rtl

ublOr

I

I

Spanner

Cross

head

screwdriver

I

I

Adjusting

screw

Lock

nut

Vollm

lcl

Fig

EE

55

Adjusting

Tegulating

voltage

Charging

relay

Normal

relay

operating

voltage

is

8

to

10V

as

measured

at

alternator

A

terminal

Relay

itself

however

operates

EE059

Fig

EE

56

Testing

chaTging

Telay

Connect

positive

terminal

of

voltmeter

to

regulator

lead

connector

N

terminal

with

negative

terminal

grounded

2

Start

engine

and

keep

it

idle

3

Take

voltmeter

reading

o

Volt

Below

5

2

Volt

I

Over

5

2

Volt

I

Check

for

continuity

between

N

terminals

of

regulator

and

alternator

2

Alternator

circuit

defective

if

continuity

exists

pilot

lamp

remains

lit

I

Check

fan

belt

tension

2

If

correct

remove

regulator

and

adjust

as

necessary

Pilot

lamp

remains

lit

Pilot

lamp

relay

coil

or

contact

points

out

of

order

Replace

regulator

Over

5

2

Volt

Pilot

lamp

does

not

light

Pilot

lamp

relay

assembly

is

in

good

condi

tion

SPECIFICATIONS

AND

SERVICE

DATA

Voltage

regulator

Model

HITACHI

TLl

Z

57

Regulating

voltage

with

fully

charged

battery

and

regulator

faced

downward

V

14

3

to

15

3

at

200C

680F

EE

26

Page 449 of 513

ENGINE

ElECTRICAL

SYSTEM

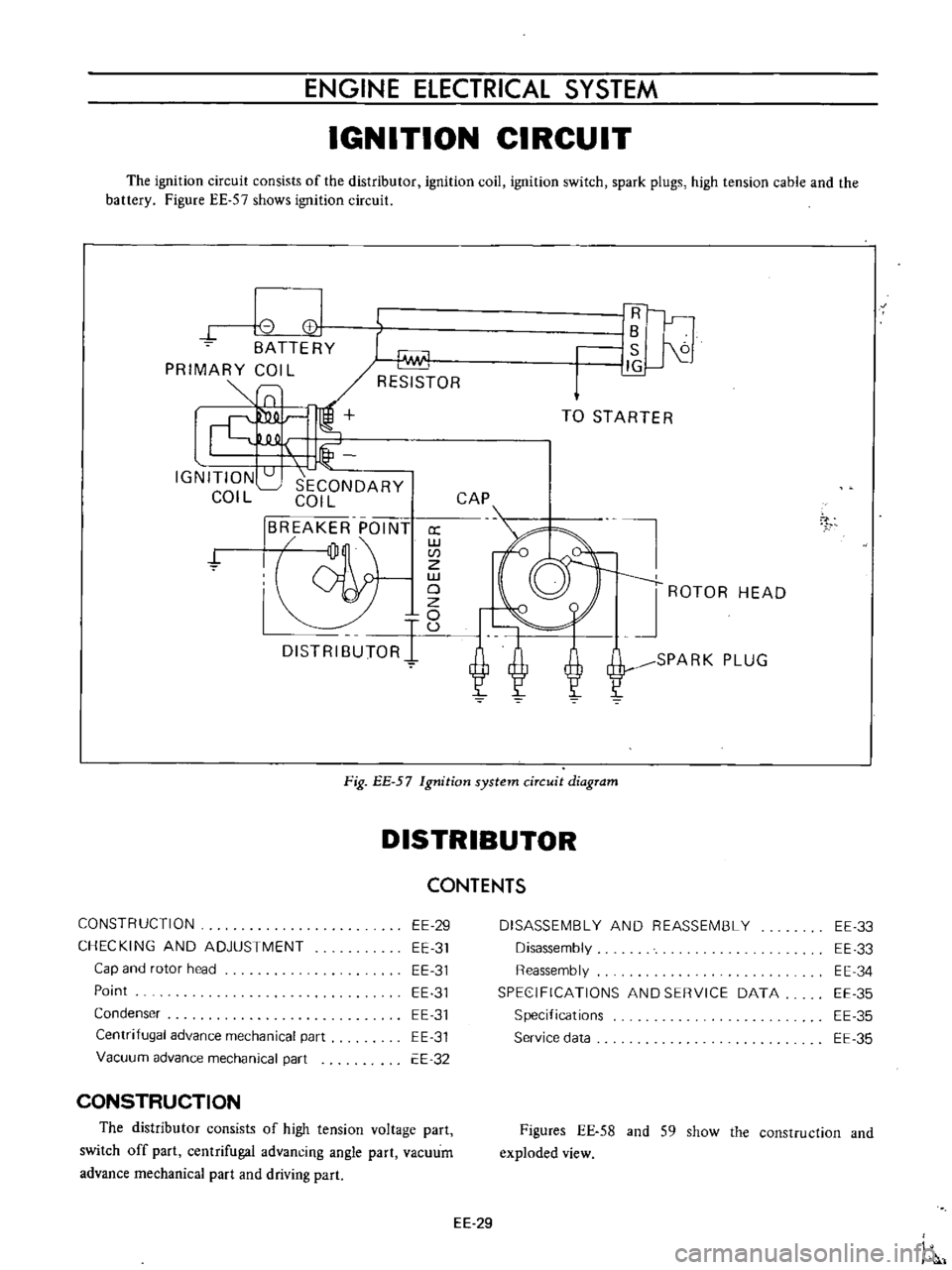

IGNITION

CIRCUIT

The

ignition

circuit

consists

of

the

distributor

ignition

coil

ignition

switch

spark

plugs

high

tension

cable

and

the

battery

Figure

EE

57

shows

ignition

circuit

8

I

CC

BATTERY

PRIMARY

COIL

SlO

Lf

IGNITION

SECONDARY

COIL

COIL

BREAKER

POINT

jJ

a

w

CI

Z

w

19

DISTRIBUTORI

U

1Fl

r

lB

S

J1G

TO

STARTER

CAP

ROTOR

HEAD

SPARK

PLUG

7

Fig

EE

57

Ignition

system

circuit

diagram

DISTRIBUTOR

CONSTRUCTION

CHECKING

AND

ADJUSTMENT

Cap

and

rotor

head

Point

Condenser

Centrifugal

advance

mechanical

part

Vacuum

advance

mechanical

part

EE

29

EE

31

EE

31

EE

31

EE

31

EE

31

EE

32

CONSTRUCTION

The

distributor

consists

of

high

tension

voltage

part

switch

off

part

centrifugal

advancing

angle

part

vacuum

advance

mechanical

part

and

driving

part

CONTENTS

DISASSEMBLY

AND

REASSEMBLY

Disassembly

Reassembly

SPEC

IFICATIONS

AND

SERVICE

DATA

Specifications

Service

data

EE

33

EE

33

EE

34

EE

35

EE

35

EE

35

Figures

EE

58

and

S9

show

the

construction

and

exploded

view

EE

29

Page 455 of 513

ENGINE

ElECTRICAL

SYSTEM

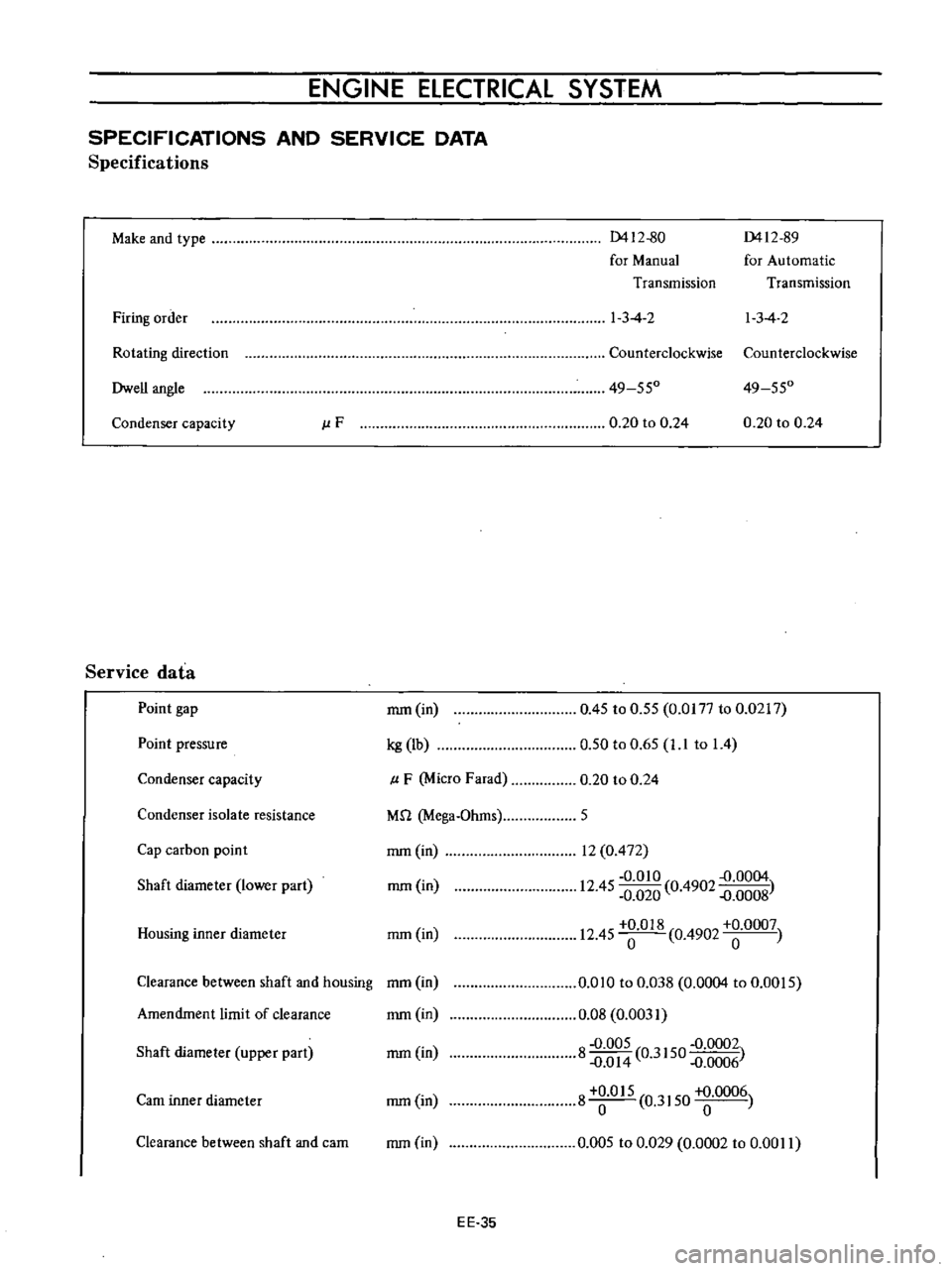

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Make

and

type

0412

80

0412

89

for

Manual

for

Automatic

Transmission

Transmission

Firing

order

1

3

4

2

I

3

4

2

Rotating

direction

Counterclockwise

Counterclockwise

Dwell

angle

49

550

49

550

Condenser

capacity

J

lF

0

20

to

0

24

0

20

to

0

24

Service

data

Point

gap

mm

in

0

45

to

0

55

0

0177

to

0

0217

0

50

to

0

65

1

1

to

1

4

Point

pressure

kg

lb

Condenser

capacity

p

F

Micro

Farad

0

20

to

0

24

Condenser

isolate

resistance

M

1

Mega

Ohms

5

Cap

carbon

point

mm

in

rom

in

Housing

inner

diameter

mm

in

12

0

472

0

010

D

0004

12

45

0

020

0

4902

D

0008

12

45

018

0

4902

0007

Shaft

diameter

lower

part

Clearance

between

shaft

and

housing

mm

in

Amendment

limit

of

clearance

mm

in

0

010

to

0

Q38

0

0004

to

0

0015

0

08

0

0031

8

0

005

0

3150

0

0002

D

O

14

D

0006

8

O

15

0

3150

0006

0

005

to

0

029

0

0002

to

0

00

II

Shaft

diameter

upper

part

mm

in

earn

inner

diameter

rom

in

Clearance

between

shaft

and

cam

mm

in

EE

35

Page 457 of 513

ENGINE

ElECTRICAL

SYSTEM

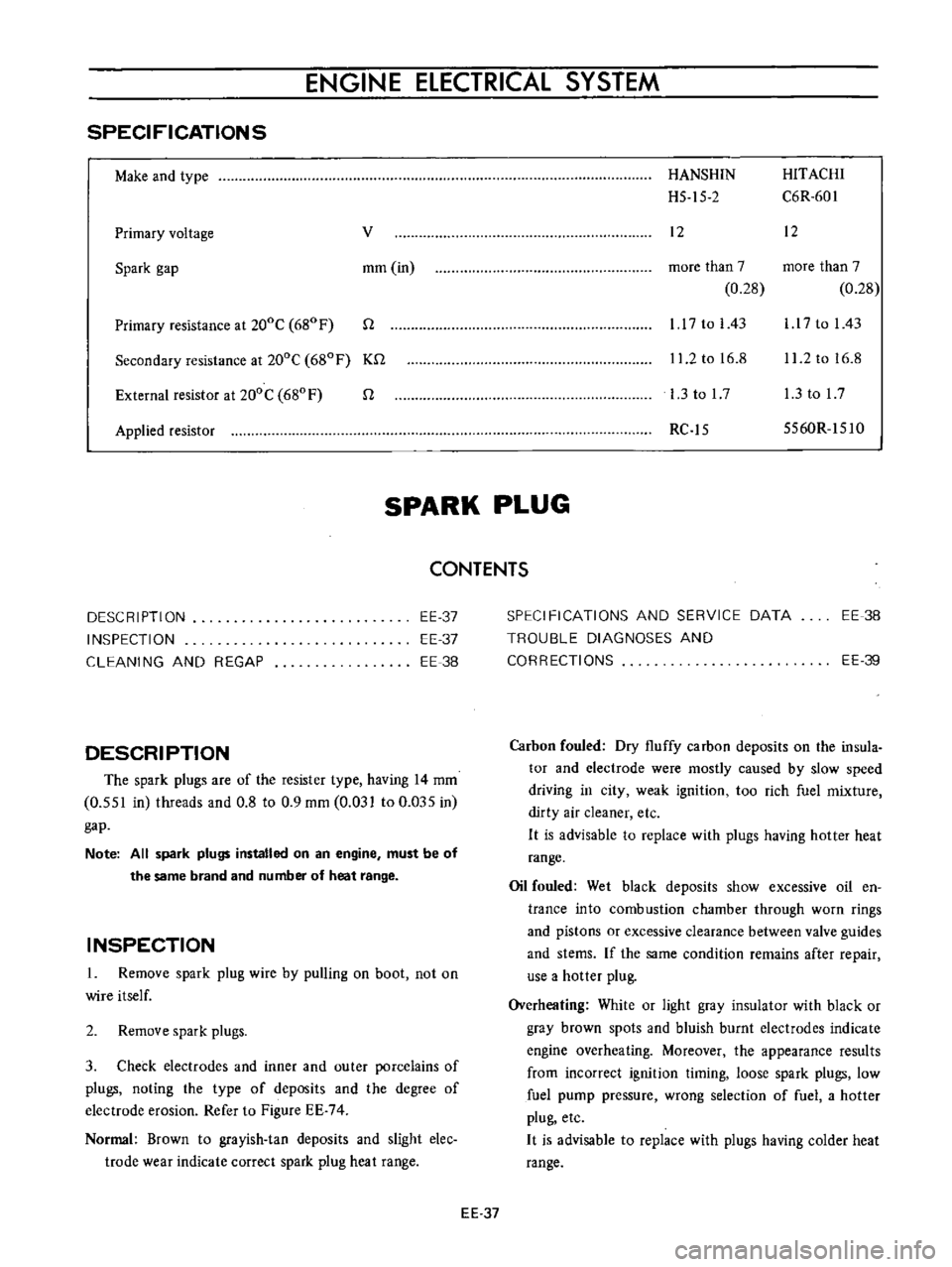

SPECIFICATIONS

Make

and

type

Primary

voltage

v

Spark

gap

mm

in

Primary

resistance

at

200C

680

F

n

Secondary

resistance

at

200C

680F

Kn

External

resistor

at

200C

680

F

n

Applied

resistor

HANSHIN

HITACHI

H5

15

2

C6R

601

12

12

more

than

7

more

than

7

0

28

0

28

1

17

to

I

43

l

l

7

to

I

43

11

2

to

16

8

11

2

to

16

8

l

3tol7

l

3tol7

RC

15

5560R

151O

SPARK

PLUG

CONTENTS

DESCRIPTION

INSPECTION

CLEANING

AND

REGAP

EE

37

EE

37

EE

38

DESCRIPTION

The

spark

plugs

are

of

the

resister

type

having

14

mm

0

551

in

threads

and

0

8

to

0

9

mm

0

031

to

0

Q35

in

gap

Note

All

spark

plugs

installed

on

an

engine

must

be

of

the

same

brand

and

number

of

heat

range

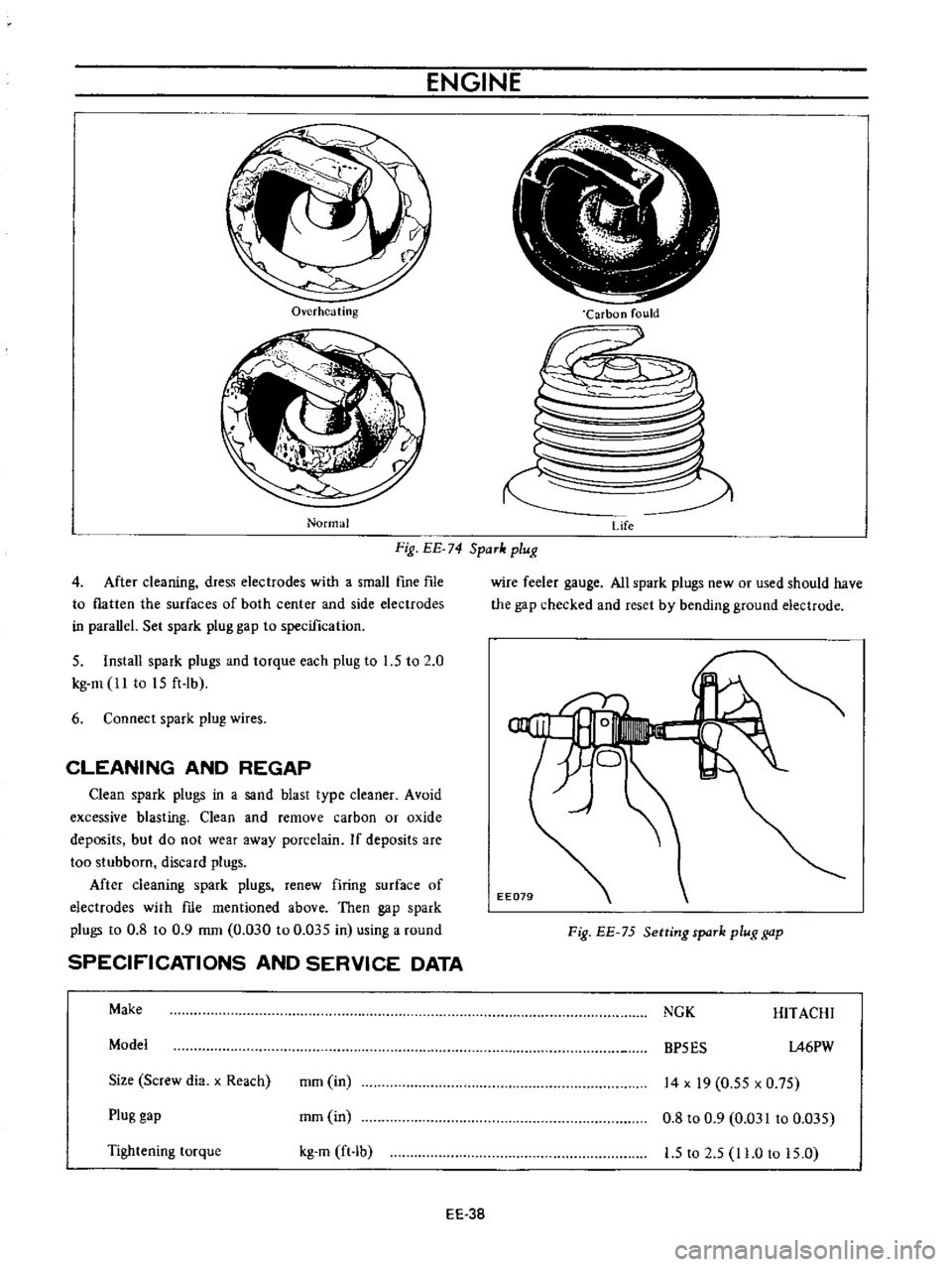

INSPECTION

1

Remove

spark

plug

wire

by

pulling

on

boot

not

on

wire

itself

2

Remove

spark

plugs

3

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Figure

EE

74

Normal

Brown

to

grayish

tan

deposits

and

slight

elec

trode

wear

indicate

correct

spark

plug

heat

range

SPECIFICATIONS

AND

SERVICE

DATA

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EE

38

EE

39

Carbon

fouled

Dry

fluffy

carbon

deposits

on

the

insula

tor

and

electrode

were

mostly

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

H

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

show

excessive

oil

en

trance

into

combustion

chamber

through

worn

rings

and

pistons

or

excessive

clearance

between

valve

guides

and

stems

If

the

same

condition

remains

after

repair

use

a

hotter

plug

Overheating

White

or

light

gray

insulator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

Moreover

the

appearance

results

from

incorrect

ignition

timing

loose

spark

plugs

low

fuel

pump

pressure

wrong

selection

of

fuel

a

hotter

plug

etc

H

is

advisable

to

replace

with

plugs

having

colder

heat

range

EE

37

Page 458 of 513

ENGINE

Overheating

Normal

Carbon

fould

Fig

EE

74

SpaTk

plug

Life

4

After

cleaning

dress

electrodes

with

a

small

fine

fIle

to

flatten

the

surfaces

of

both

center

and

side

electrodes

in

parallel

Set

spark

plug

gap

to

specification

5

Install

spark

plugs

and

torque

each

plug

to

1

5

to

2

0

kg

m

ll

to

15

ft

lb

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

discard

plugs

Mter

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

above

Then

gap

spark

plugs

to

0

8

to

0

9

mm

0

030

to

0

035

in

using

a

round

SPECIFICATIONS

AND

SERVICE

DATA

Make

Model

Size

Screw

dia

x

Reach

mm

in

Plug

gap

mm

in

Tightening

torque

kg

m

ft

b

EE

38

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

Fig

EE

75

Setting

spaTk

plug

gap

NGK

HITACHI

BP5ES

1A6PW

14

x

19

0

55

x

0

75

0

8

to

0

9

0

031

to

0

035

1

5

to

2

5

11

0

to

15

0

Page 461 of 513

DATE

ENGINE

ElECTRICAL

SYSTEM

SERVICE

JOURNAL

OR

BUl

LETIN

REFE

RENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

EE

41

Page 469 of 513

15

Lift

up

the

engine

toward

the

front

INSTALLATION

Install

the

engine

in

reverse

sequence

of

removal

CHASSIS

Fig

ER

14

Lifting

up

engine

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

ER

6

SUBJECT