service DATSUN B110 1973 Service Owners Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 390 of 513

ENGINE

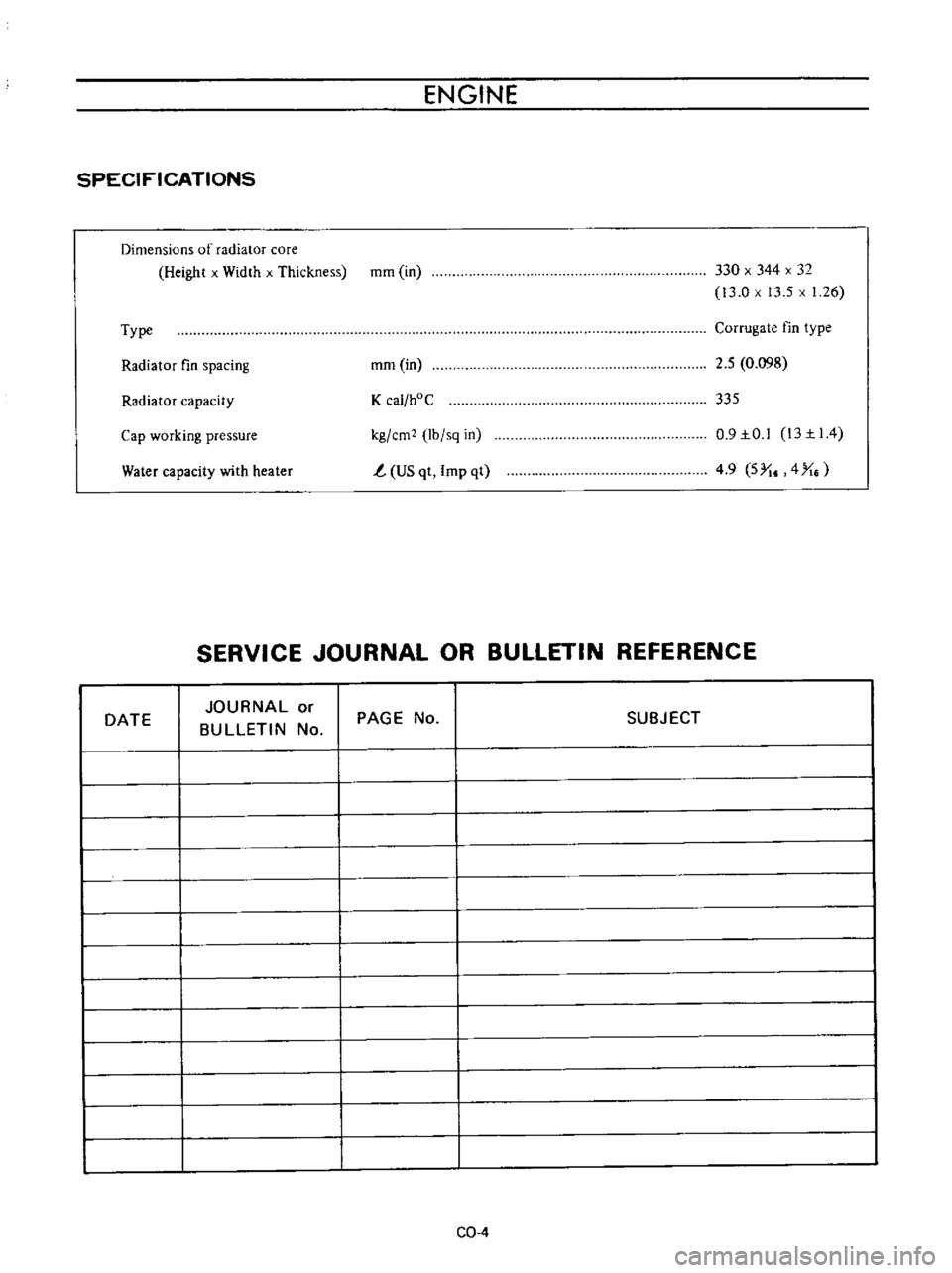

SPECIFICATIONS

Dimensions

of

radiator

core

Height

x

Width

x

Thickness

mm

in

330

x

344

x

32

13

0

x

13

5

x

1

26

Type

Corrugate

fin

type

Radiator

fin

spacing

mm

in

2

5

0

098

Radiator

capacity

K

cal

hoC

335

Water

capacity

with

heater

kg

em

lb

sq

in

t

US

qt

Imp

qt

0

9IO

l

13II4

4

9

5

I

4

X

Cap

working

pressure

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

CQ

4

Page 396 of 513

FUEl

SYSTEM

FUEL

STRAINER

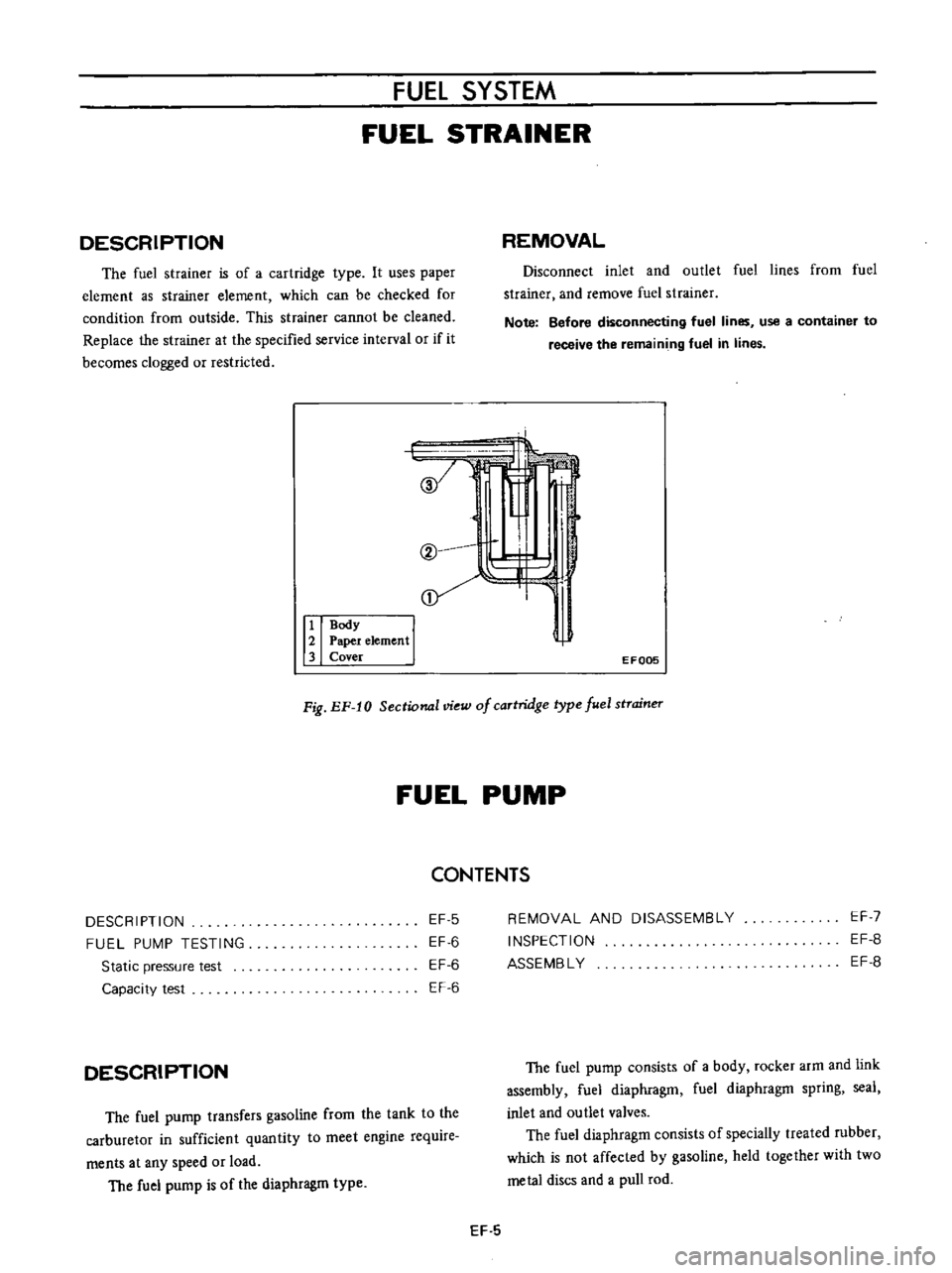

DESCRIPTION

The

fuel

strainer

is

of

a

cartridge

type

It

uses

paper

element

as

strainer

element

which

can

be

checked

for

condition

from

outside

This

strainer

cannot

be

cleaned

Replace

the

strainer

at

the

specified

service

interval

or

if

it

becomes

clogged

or

restricted

REMOVAL

Disconnect

inlet

and

outlet

fuel

lines

from

fuel

strainer

and

remove

fuel

strainer

Note

Before

disconnecting

fuel

lines

use

a

container

to

receive

the

remaining

fuel

in

lines

r

@

I

I

Il

QY

I

I

I

elementl

3

Cover

@

EF005

Fig

EF

10

Sectional

view

of

caTtridge

type

fuel

stTaineT

FUEL

PUMP

CONTENTS

DESCRIPTION

FUEL

PUMP

TESTING

Static

pressure

test

Capacity

test

EF

5

EF

6

EF

6

EF

6

DESCRIPTION

The

fuel

pump

transfers

gasoline

from

the

tank

to

the

carburetor

in

sufficient

quantity

to

meet

engine

require

ments

at

any

speed

or

load

The

fuel

pump

is

of

the

diaphragm

type

REMOVAL

AND

DISASSEMBLY

INSPECTION

ASSEMBLY

EF

7

EF

B

EF

B

The

fuel

pump

consists

of

a

body

rocker

arm

and

link

assembly

fuel

diaphragm

fuel

diaphragm

spring

seal

inlet

and

outlet

valves

The

fuel

diaphragm

consists

of

specially

treated

rubber

which

is

not

affected

by

gasoline

held

together

with

two

metal

discs

and

a

pull

rod

EF

5

Page 399 of 513

ENGINE

INSPECTION

Check

the

upper

and

lower

bodies

for

cracks

2

Check

the

valve

assembly

for

wear

of

the

valve

and

valve

spring

Blow

the

valve

assembly

by

breath

to

examine

its

function

3

Check

the

diaphragm

for

small

holes

cracks

and

wear

4

Check

the

rocker

arm

for

wear

at

the

portion

in

contact

with

the

camshaft

5

Check

the

rocker

arm

pin

for

wear

since

a

worn

pin

may

cause

oil

leakage

6

Check

all

other

components

for

any

abnormalities

and

replace

with

new

parts

as

required

ASSEMBLY

Assembly

is

done

in

reverse

order

of

disassembly

For

reassembly

and

reinstallation

the

following

matters

should

be

noted

Use

new

gasket

2

Lubricate

the

rocker

arm

link

rocker

arm

pin

and

lever

pin

before

installation

3

To

test

the

function

position

the

fuel

pump

assem

bly

about

I

meter

3

3

ft

above

fuel

level

with

a

pipe

connecting

the

fuel

pump

and

the

fuel

strainer

and

operate

the

rocker

afm

by

hand

If

fuel

is

drawn

up

soon

after

the

rocker

arm

is

released

the

function

of

the

pump

is

satisfactory

CARBURETOR

CONTENTS

DESCRIPTION

STRUCTURE

AND

OPERATION

EF

8

EF

9

EF

10

EF

11

EF

12

EF

12

EF

12

EF

14

EF

14

EF

15

EF

15

EF

16

EF

16

Primary

system

Secondary

system

Anti

dieseling

solenoid

valve

Float

system

Electric

automatic

choke

ADJUSTMENT

Idling

adjustment

Fuel

level

adjustment

Fast

idle

adjustment

Vacuum

break

adjustment

Choke

un

loader

adjustment

DESCRIPTION

The

carburetors

are

of

a

downdraft

type

which

is

designed

and

built

to

increase

power

and

fuel

economy

as

Bi

metal

setting

Adjustment

of

interlock

opening

of

primary

and

secondary

throttle

valves

Dash

pot

adjustment

MAJOR

SERVICE

OPERATIONS

Removal

Disassembly

Cleaning

and

inspection

Assembly

and

installation

JETS

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EF

17

EF

18

EF

18

EF

19

EF

19

EF

19

EF

21

EF

22

EF

22

EF

22

EF

22

well

as

to

reduce

the

emission

of

exhaust

gases

These

carburetors

present

several

distinct

features

of

importance

to

the

car

owners

A

summary

of

features

is

as

follows

EF

8

Page 410 of 513

FUEl

SYSTEM

MA

JOR

SERVICE

OPERATIONS

A

completely

adjusted

and

serviced

carburetor

will

provide

the

engine

with

proper

mixture

at

all

speeds

Periodical

overhauling

which

cleans

all

components

and

passages

will

recover

the

originally

designed

performance

producing

the

engine

with

proper

gasoline

and

air

ratio

at

all

speeds

Passages

and

holes

of

the

carburetor

must

be

cleaned

carefully

Use

only

carburetor

solvent

and

com

pressed

air

to

clean

aU

passages

and

discharge

holes

Never

use

wire

or

other

pointed

tool

otherwise

accurately

calibrated

carburetor

will

be

affected

Removal

Remove

the

air

cleaner

2

Disconnect

the

fuel

line

vacuum

line

automatic

choke

harness

and

anti

dieseling

solenoid

harness

from

carburetor

3

Remove

the

throttle

lever

4

Remove

four

nuts

and

washers

retaining

the

carbuTe

tor

to

the

manifold

if

necessary

5

Lift

the

carburetor

and

remove

from

the

manifold

6

Remove

and

discard

the

gasket

used

between

the

carburetor

and

manifold

Disassembly

The

main

jets

and

needle

valves

on

both

primary

and

secondary

sides

are

accessible

from

outside

of

the

carbure

tor

for

disassembly

2

Remove

throttle

return

spring

3

Remove

pump

lever

shaft

take

out

pump

lever

and

pump

connecting

rod

4

Remove

rubber

pipe

from

choke

piston

5

Loosen

off

bolts

securing

servo

diaphragm

in

posi

tion

take

out

diaphragm

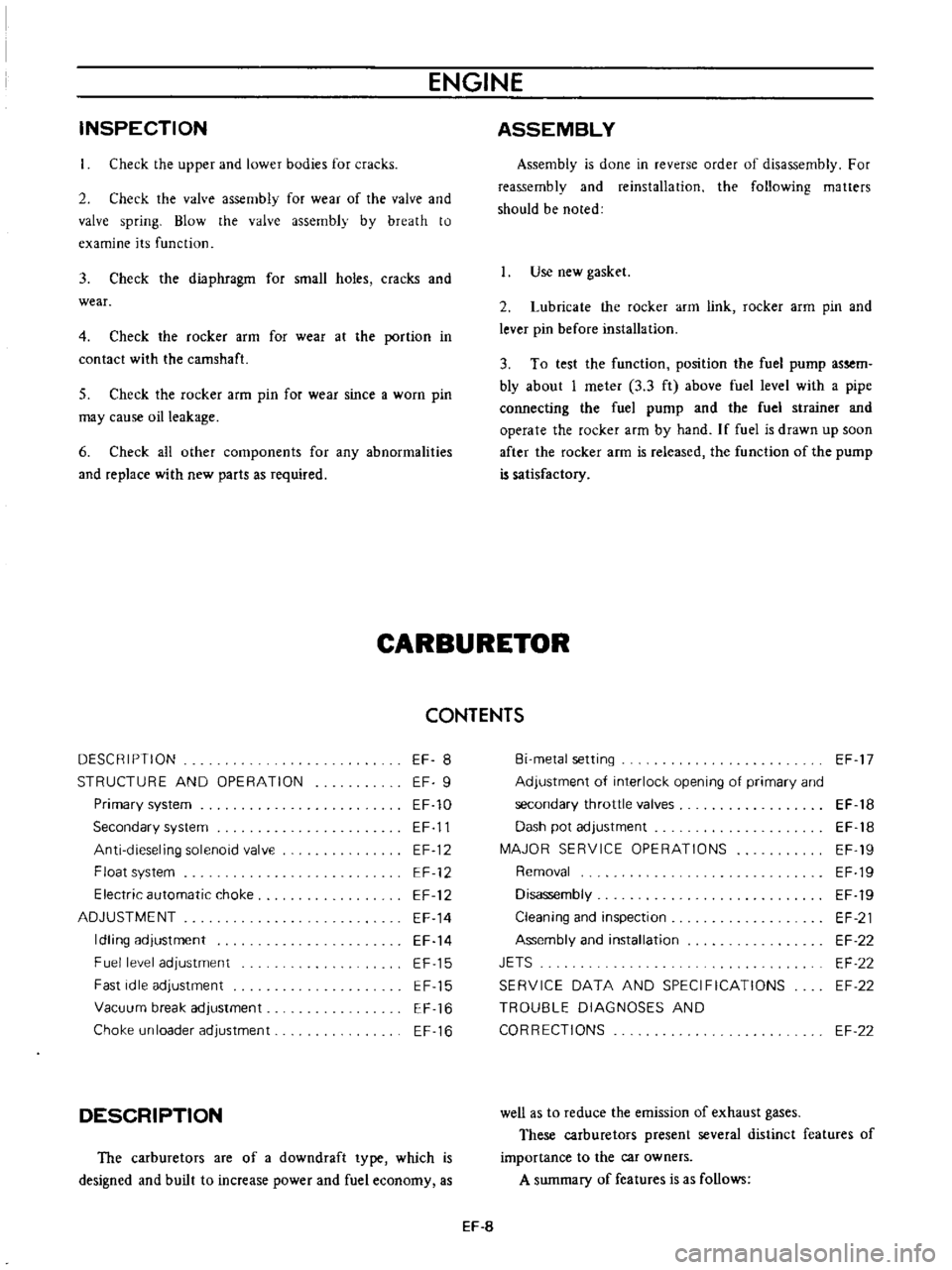

6

Back

off

total

of

five

bolts

which

hold

choke

in

position

and

remove

rods

of

starter

system

take

out

choke

chamber

In

removing

chamber

exercise

care

to

avoid

damaging

float

EF

19

ilia

Fig

EF

32

Removing

choke

dwmherand

seroo

diaphragm

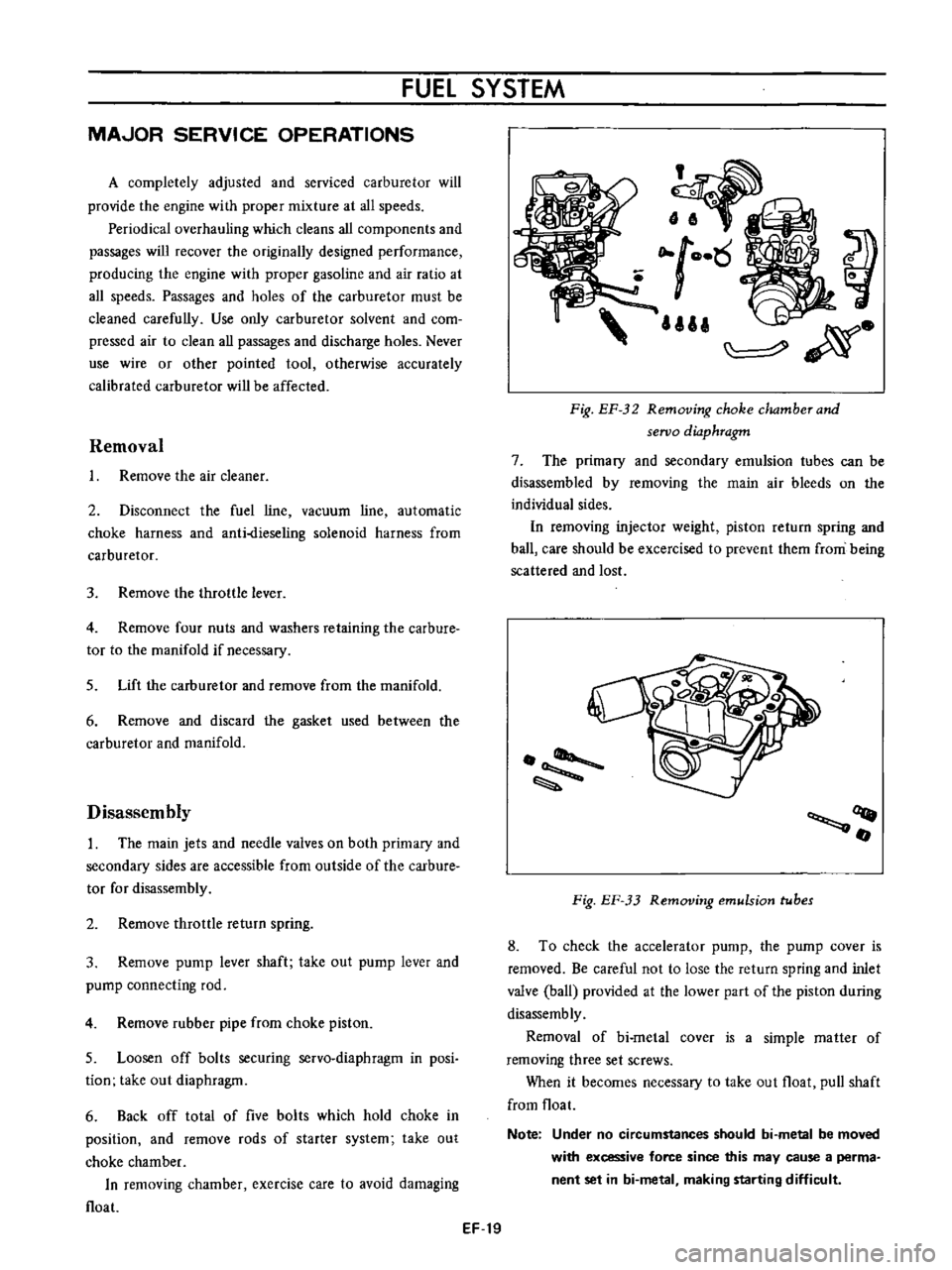

7

The

primary

and

secondary

emulsion

tubes

can

be

disassembled

by

removing

the

main

air

bleeds

on

the

individual

sides

In

removing

injector

weight

piston

return

spring

and

ball

care

should

be

excercised

to

prevent

them

from

being

scattered

and

lost

OQ

fI

Fig

EF

33

Removing

emulsion

tubes

8

To

check

the

accelerator

pump

the

pump

cover

is

removed

Be

careful

not

to

lose

the

return

spring

and

inlet

valve

ball

provided

at

the

lower

part

of

the

piston

during

disassemb

ly

Removal

of

bi

metal

cover

is

a

simple

matter

of

removing

three

set

screws

When

it

becomes

necessary

to

take

out

float

pull

shaft

from

float

Note

Under

no

circumstances

should

bi

metal

be

moved

with

excessive

force

since

this

may

cause

a

perma

nent

set

in

bi

metal

making

starting

difficult

Page 412 of 513

FUEL

SYSTEM

5

Check

venturi

clusters

for

loose

or

worn

parts

If

damage

or

looseness

exists

replace

cluster

assembly

6

Check

the

linkage

for

operating

condition

7

Inspect

the

operation

of

accelerating

pump

Pour

gasoline

into

the

float

chamber

and

operate

the

throttle

lever

Check

condition

of

gasoline

injection

from

the

accelerating

nozzle

Assembly

and

instalIetion

Assemble

and

install

the

carburetor

in

reverse

sequence

of

disassembly

and

removal

Replace

the

gaskets

if

necessary

When

disassembling

and

reassembling

the

interlock

link

and

related

components

be

careful

not

to

bend

or

deform

SPECIFICATIONS

AND

SERVICE

DATA

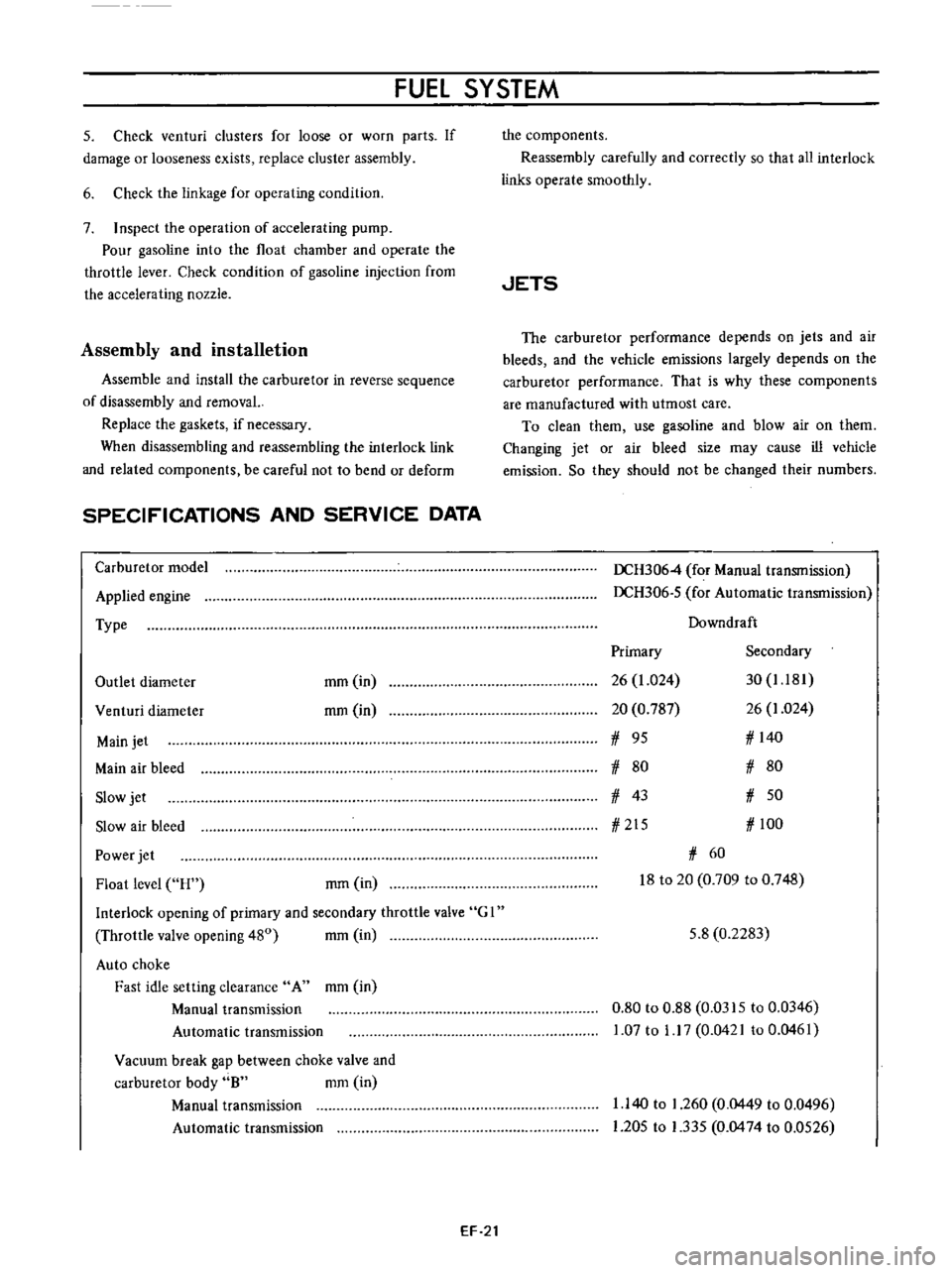

Carburetor

model

Applied

engine

Type

Outlet

diameter

mm

in

rom

in

Venturi

diameter

Main

jet

Main

air

bleed

Slow

jet

Slow

air

bleed

Power

jet

Float

level

H

rom

in

Interlock

opening

of

primary

and

secondary

throttle

valve

G

I

Throttle

valve

opening

480

mm

in

Auto

choke

Fast

idle

setting

clearance

A

mm

in

Manual

transmission

Automatic

transmission

Vacuum

break

gap

between

choke

valve

and

carburetor

body

8

mm

in

Manual

transmission

Automatic

transmission

EF

21

the

components

Reassembly

carefully

and

correctly

so

that

all

interlock

links

operate

smoothly

JETS

The

carburetor

performance

depends

on

jets

and

air

bleeds

and

the

vehicle

emissions

largely

depends

on

the

carburetor

performance

That

is

why

these

components

are

manufactured

with

utmost

care

To

clean

them

use

gasoline

and

blow

air

on

them

Changing

jet

or

air

bleed

size

may

cause

ill

vehicle

emission

So

they

should

not

be

changed

their

numbers

DCH3064

for

Manual

transmission

DCH306

5

for

Automatic

transmission

Downdraft

Primary

Secondary

26

1

024

30

1

181

20

0

787

26

1

024

1

95

1

140

1

80

1

80

1

43

1

50

1

215

1

100

1

60

18

to

20

0

709

to

0

748

5

8

0

2283

0

80

to

0

88

0

0315

to

0

0346

1

07

to

1

17

0

0421

to

0

0461

1

140

to

1

260

0

0449

to

0

0496

1

205

to

1

335

0

0474

to

0

0526

Page 419 of 513

DATE

ENGINE

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

EF

28

Page 423 of 513

ENGINE

ElECTRICAL

SYSTEM

5

If

the

specific

gravity

is

above

1

260

200C

or

680F

after

charging

adjust

it

by

adding

distilled

water

6

Keep

any

open

flame

away

from

the

place

where

the

battery

is

being

charged

7

Replace

vent

plugs

and

clean

the

upper

face

of

the

battery

after

charging

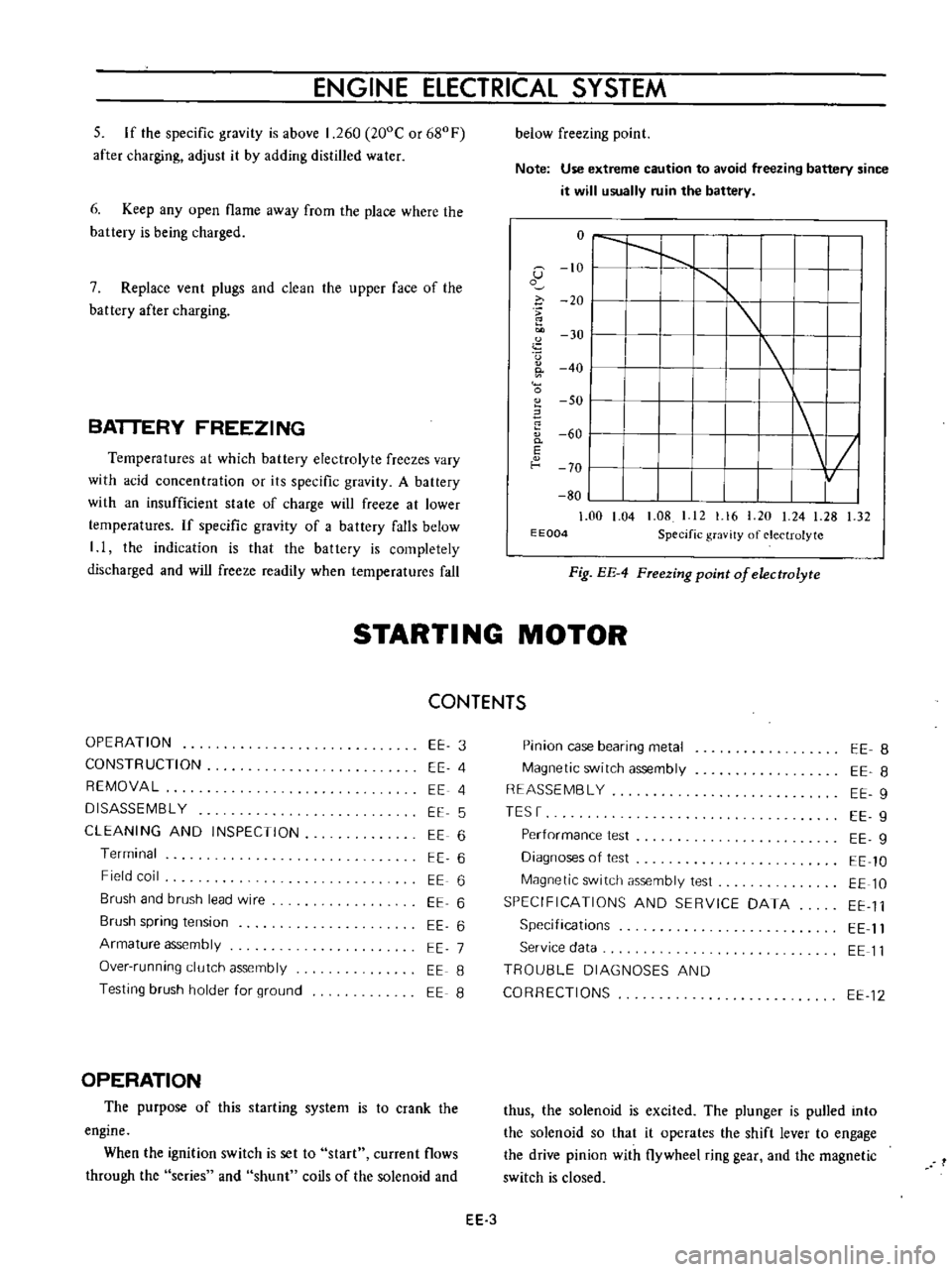

BATTERY

FREEZING

Temperatures

at

which

battery

electrolyte

freezes

vary

with

acid

concentration

or

its

specific

gravity

A

battery

with

an

insufficient

state

of

charge

will

freeze

at

lower

temperatures

If

specific

gravity

of

a

battery

falls

below

I

I

the

indication

is

that

the

battery

is

completely

discharged

and

will

freeze

readily

when

temperatures

fall

below

freezing

point

Note

Use

extreme

caution

to

avoid

freezing

battery

since

it

will

usually

ruin

the

battery

o

I

I

1

G

10

I

1

o

i

20

I

u

30

I

I

0

40

I

0

SO

I

60

0

I

E

f

o

70

I

80

1

00

1

04

1

08

I

12

1

16

20

24

1

28

1

32

E

E004

Specific

gravity

of

electrolyte

Fig

EE

4

FTeezing

point

of

electrolyte

STARTI

NG

MOTOR

CONTENTS

OPERATION

CONSTRUCTION

REMOVAL

DISASSEMBL

Y

CLEANING

AND

INSPECTION

Terminal

Field

coil

Brush

and

brush

lead

wire

Brush

spring

tension

Armature

assembly

Over

running

clutch

assembly

Testing

brush

holder

for

ground

EE

3

EE

4

EE

4

EE

5

EE

6

EE

6

EE

6

EE

6

EE

6

EE

7

EE

8

EE

8

OPERATION

The

purpose

of

this

starting

system

is

to

crank

the

engine

When

the

ignition

switch

is

set

to

start

current

flows

through

the

series

and

shunt

coils

of

the

solenoid

and

Pinion

case

bearing

metal

Magnetic

switch

assembly

REASSEMBL

Y

TESr

Performance

test

Diagnoses

of

test

Magnetic

switch

assembly

test

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Service

data

TROU8LE

DIAGNOSES

AND

CORRECTIONS

EE

8

EE

8

EE

9

EE

9

EE

g

EE

10

EE

10

EE

11

EE

11

EE

11

EE

12

thus

the

solenoid

is

excited

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

engage

the

drive

pinion

with

flywheel

ring

gear

and

the

magnetic

switch

is

closed

EE

3

Page 429 of 513

ENGINE

ElECTRICAL

SYSTEM

shunt

coil

is

satisfactory

if

the

plunger

is

attracted

continuously

s

SERIES

COIL

S

SHUNT

COIL

Fig

EE

21

Inspecting

series

and

shunt

coils

When

measuring

the

L

dimension

depress

the

plunger

against

a

wall

and

measure

the

length

L

between

the

adjusting

nut

and

magnetic

switch

cover

as

shown

in

Figure

EE

22

and

adjust

if

necessary

II

L

T

Plunger

L

dimension

31

7

to

32

3

mm

1

248

to

1

272

in

I

11

I

Adjusting

nut

121

Plunger

adjuster

Fig

BE

22

Adjusting

L

dimension

REASSEMBLY

Reassemble

the

starting

motor

in

reverse

sequence

of

disassembly

When

assembling

be

sure

to

apply

grease

to

the

armature

shaft

spline

and

apply

oil

to

the

rear

cover

and

gear

case

bearing

metals

and

pinion

slightly

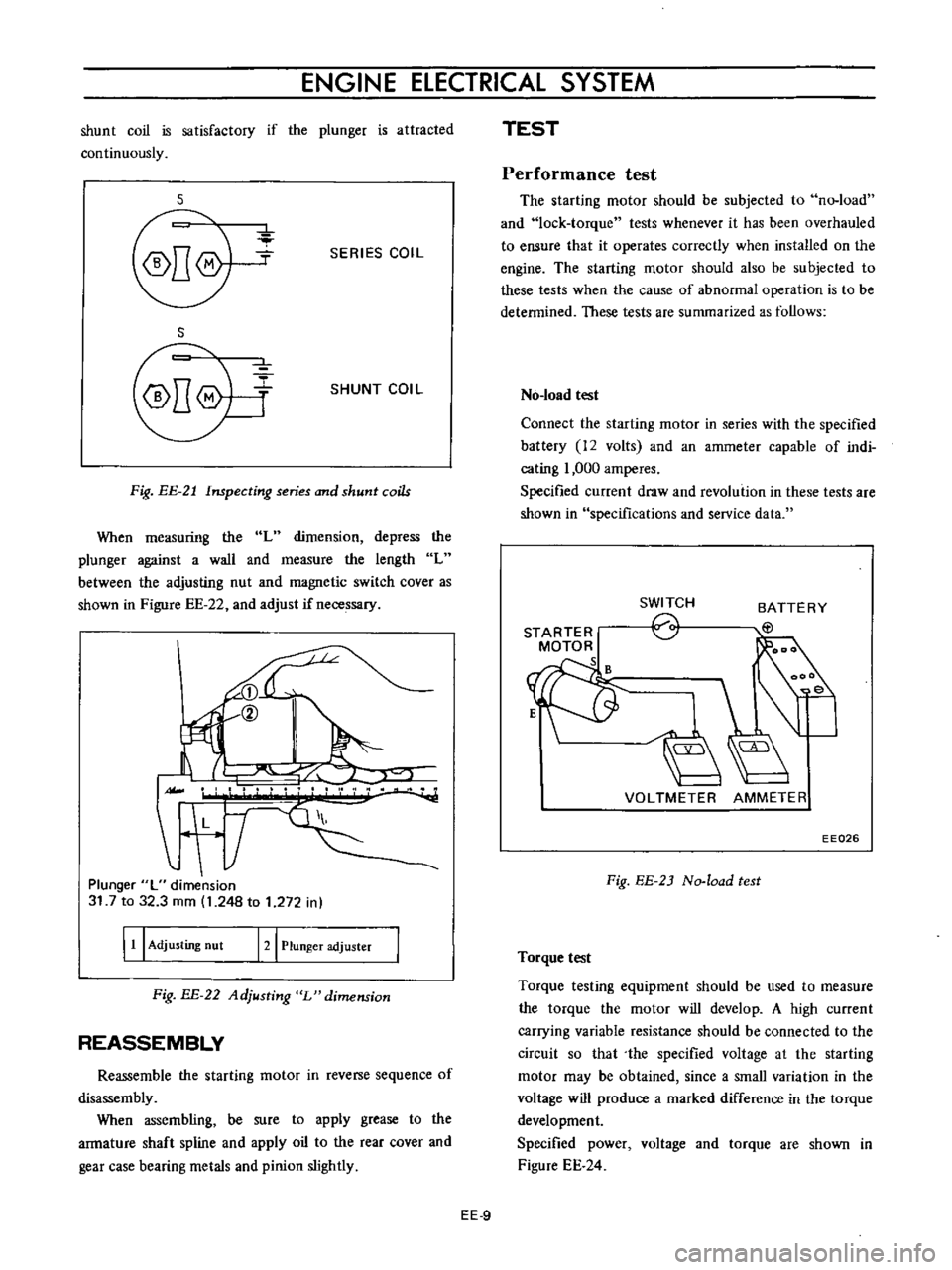

TEST

Performance

test

The

starting

motor

should

be

subjected

to

no

load

and

lock

torque

tests

whenever

it

has

been

overhauled

to

ensure

that

it

operates

correctly

when

installed

on

the

engine

The

starting

motor

should

also

be

subjected

to

these

tests

when

the

cause

of

abnormal

operation

is

to

be

determined

These

tests

are

summarized

as

follows

No

load

test

Connect

the

starting

motor

in

series

with

the

specified

battery

12

volts

and

an

ammeter

capable

of

indi

cating

1

000

amperes

Specified

current

draw

and

revolution

in

these

tests

are

shown

in

specifications

and

service

data

STARTER

MOTOR

s

SWITCH

o

BATTERY

EtJ

VOLTMETER

AMMETER

EE026

Fig

EE

2J

No

load

test

Torque

test

Torque

testing

equipment

should

be

used

to

measure

the

torque

the

motor

will

develop

A

high

current

carrying

variable

resistance

should

be

connected

to

the

circuit

so

that

the

specified

voltage

at

the

starting

motor

may

be

obtained

since

a

small

variation

in

the

voltage

will

produce

a

marked

difference

in

the

torque

development

Specified

power

voltage

and

torque

are

shown

in

Figure

EE

24

EE

9

Page 431 of 513

ENGINE

ElECTRICAL

SYSTEM

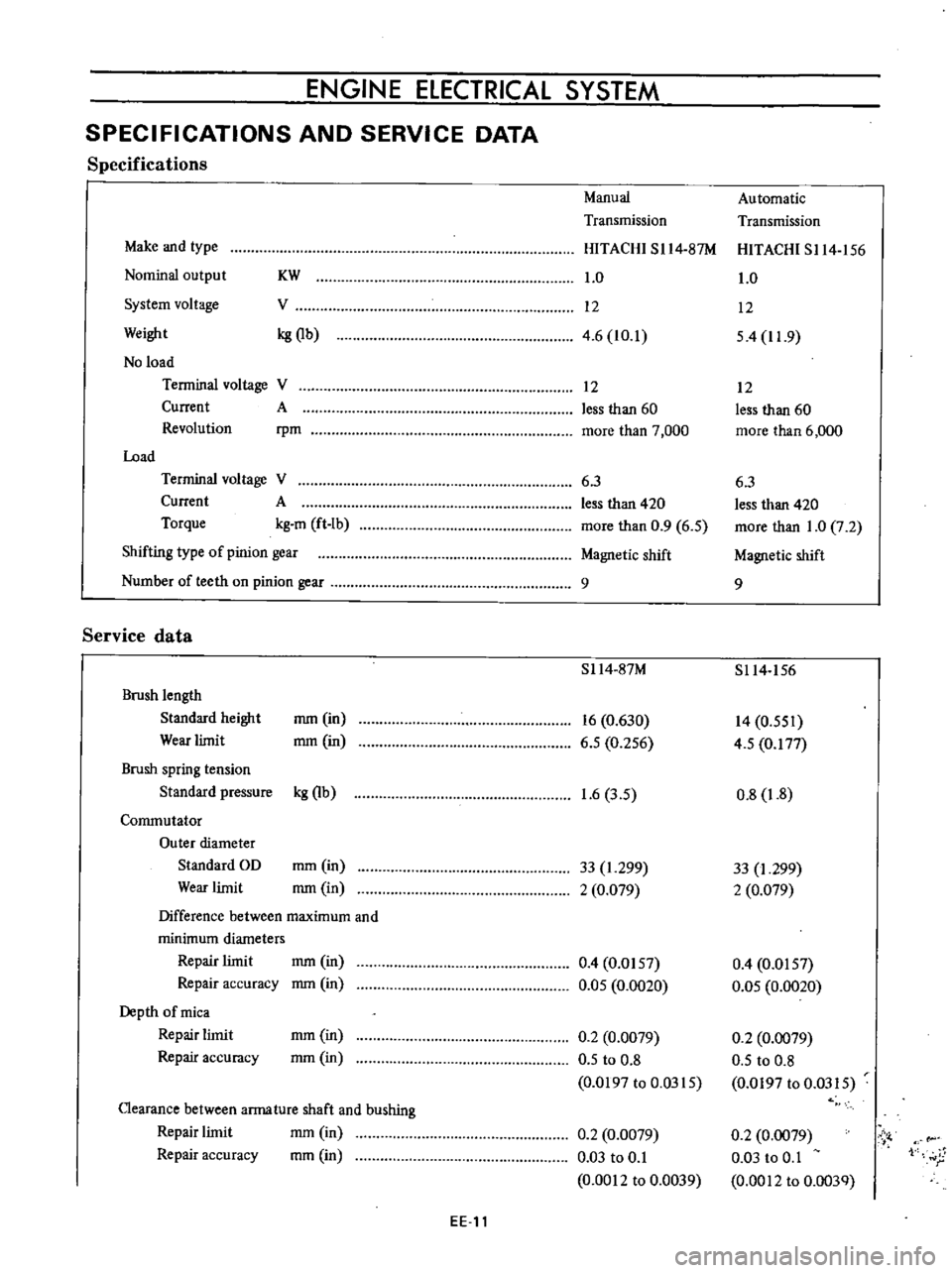

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Manual

Automatic

Transmission

Transmission

Make

and

type

HITACHI

SI14

87M

HITACHI

S114

156

Nominal

output

KW

1

0

1

0

System

voltage

V

12

12

Weight

kg

Qb

4

6

10

1

54

11

9

No

load

Terminal

voltage

V

12

12

Current

A

less

than

60

less

than

60

Revolution

rpm

more

than

7

000

more

than

6

000

Load

Terminal

voltage

V

6

3

6

3

Current

A

less

than

420

less

than

420

Torque

kg

m

ft

Ib

more

than

0

9

6

5

more

than

1

0

7

2

Shifting

type

of

pinion

gear

Magnetic

shift

Magnetic

shift

Number

of

teeth

on

pinion

gear

9

9

Service

data

S114

87M

S114

156

Brush

length

Standard

height

mm

in

16

0

630

14

0

551

Wear

limit

mm

in

6

5

0

256

4

5

0

177

Brush

spring

tension

Standard

pressure

kg

Qb

1

6

3

5

0

8

1

8

Commutator

Outer

diameter

Standard

OD

mm

in

33

1

299

33

I

299

Wear

limit

mm

in

2

0

079

2

0

079

Difference

between

maximum

and

minimum

diameters

Repair

limit

mm

in

0

4

0

0157

0

4

0

0157

Repair

accuracy

mm

in

0

05

0

0020

0

05

0

0020

Depth

of

mica

Repair

limit

mm

in

0

2

0

0079

0

2

0

0079

Repair

accuracy

mm

in

0

5

to

0

8

0

5

to

0

8

0

0197

to

0

0315

0

0197

to

0

0315

Clearance

between

arma

ture

shaft

and

bushing

mm

in

Repair

limit

0

2

0

0079

0

2

0

0079

Vi

Repair

accuracy

mm

in

0

03

to

0

1

0

03

to

0

1

1

r

0

0012

to

0

0039

0

0012

to

0

003Q

EE

11

Page 436 of 513

ENGINE

r

Ignition

switJ

c

o

iArm

ture

j

i

i

VC2

P

tP2

d

I

I

I

PI

I

ll

Rl

L

I

I

lRJ

t

R

I

Field

e

I

I

I

I

Ps

I

1

I

I

n

I

coil

M

4

i

f

I

L

1

J

Alternator

Voltage

regulator

Fig

EE

2B

ChaTging

ciTcuit

II

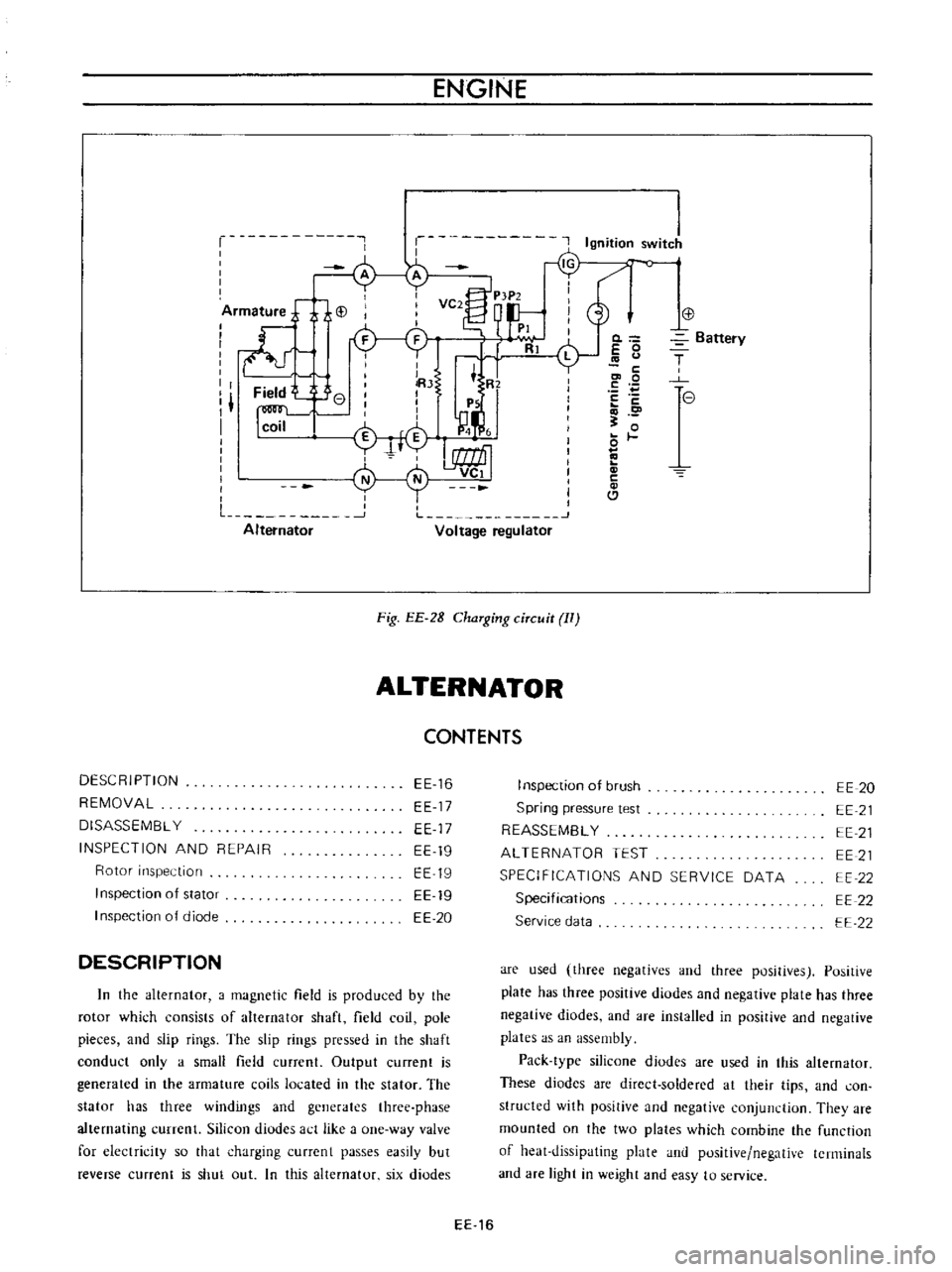

ALTERNATOR

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

REPAIR

Rotor

inspection

Inspection

of

stator

I

nspection

of

diode

EE

16

EE

17

EE

17

EE

19

EE

19

EE

19

EE

20

DESCRIPTION

In

the

alternator

a

magnetic

field

is

produced

by

the

rotor

which

consists

of

alternator

shaft

field

coil

pole

pieces

and

slip

rings

The

slip

rings

pressed

in

the

shaft

conduct

only

a

small

field

current

Output

current

is

generated

in

the

armature

coils

located

in

the

stator

The

stator

has

three

windings

and

generates

three

phase

alternating

currenl

Silicon

diudes

act

like

a

one

way

valve

for

electricity

so

that

charging

currcnt

passes

easily

but

reverse

current

is

shut

out

In

this

alternator

six

diodes

0

E

0

c

co

0

E

c

o

0

c

Cl

Battery

T

e

I

nspection

of

brush

Spring

pressure

test

REASSEMBL

Y

ALTERNATOR

TEST

SPECIFICATIONS

AND

SERVICE

DATA

Specifications

Service

data

EE

20

EE

21

EE

21

EE

21

EE

22

EE

22

EE

22

are

used

three

negatives

and

three

positives

Positive

plate

has

three

positive

diodes

and

negative

plate

has

three

negative

diodes

and

are

installed

in

positive

and

negative

plates

as

an

assembly

Pack

type

silicone

diodes

are

used

in

this

alternator

These

diodes

are

direct

soldered

at

their

tips

and

con

structed

with

positive

and

negative

conjunction

They

are

mounted

on

the

two

plates

which

combine

the

function

of

heat

dissipating

plate

and

positive

negative

terminals

and

are

light

in

weight

and

easy

to

service

EE

16