battery DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 306 of 513

EMISSION

CONTROL

AND

TUNE

UP

EMISSION

CONTROL

SYSTEM

AN

D

ENGINE

TUNE

UP

CONTENTS

BASIC

MECHANICAL

SYSTEM

ET

Checking

and

adjusting

dash

pot

Adjusting

intake

and

exhaust

valve

automatic

transmission

model

only

ET

9

clearances

ET

1

Checking

carburetor

return

spring

ET

9

Checking

and

adjustin9

drive

belt

ET

2

Checking

choke

mechanism

choke

valve

Retightening

cylinder

head

bolts

manifold

and

linkagel

ET

9

nuts

and

carburetor

securing

nuts

ET

2

Checking

anti

dieseling

solenoid

ET

9

Checking

engine

oil

ET

2

Replacing

fuel

filter

ET

10

Replacing

oil

filter

ET

3

Checking

fuel

lines

hoses

pipings

Changing

engine

coolant

L

L

C

ET

3

connections

etc

ET10

Checking

cooling

system

hoses

and

THROTTLE

OPENER

CONTROL

SYSTEM

ET

10

connections

ET

4

Checking

and

adjusting

throttle

opener

ET

13

Checking

vacuum

fittings

hoses

and

TRANSMISSION

CONTROLLED

VACUUM

connections

ET

4

ADVANCE

SYSTEM

ET

17

Checking

engine

compression

ET

4

Checking

electrical

advance

control

system

ET

19

Checking

exhaust

manifold

heat

control

AUTOMATIC

TEMPERATURE

CONTROL

AIR

valve

ET

5

CLEANER

A

T

C

AIR

CLEANER

ET

20

IGNITION

AND

FUEL

SYSTEM

ET

5

Replacing

carburetor

air

cleaner

filter

ET

20

Checking

battery

ET

5

Checking

hot

air

control

valve

ET

20

Checking

and

adjusting

ignition

timing

ET

5

CRANKCASE

EMISSION

CONTROL

Checking

or

replacing

distributor

breaker

SYSTEM

ET

22

point

condenser

and

spark

plugs

ET

6

Checking

or

replacing

PCV

valve

ET

23

Checking

distributor

ignition

wiring

and

Checking

ventilation

hoses

ET

23

ignition

coil

ET

7

EVAPORATIVE

EMISSION

CONTROL

Checking

distributor

cap

and

rotor

ET

7

SYSTEM

ET

23

Adjusting

carburetor

id

Ie

rpm

and

Checking

engine

compartment

hose

mixture

ratio

ET

8

connections

and

fuel

vapor

control

valves

ET

23

Checking

fuel

tank

vacuum

relief

valve

operation

ET

24

BASIC

MECHANICAL

SYSTEM

1

Start

engine

and

run

it

until

it

is

heated

to

operating

temperature

or

at

least

more

than

800C

I760F

of

engine

oil

temperature

then

stop

engine

Adjusting

intake

and

exhaust

valve

clearances

Valve

clearance

adjustment

should

be

made

while

engine

is

stationary

To

adjust

proceed

as

follows

2

Rotate

crankshaft

to

bring

No

1

cylinder

in

top

dead

center

on

its

compression

stroke

3

Remove

valve

rocker

cover

to

gain

access

to

valve

ET

1

Page 310 of 513

EMISSION

CONTROL

AND

TUNE

UP

reading

cylinders

through

spark

plug

hole

Repeat

compression

check

on

these

cylinders

1

If

compression

improves

considerably

piston

rings

are

defective

2

If

compression

does

not

improve

valves

are

sticking

or

seating

improperly

3

If

two

adjacent

cylinders

indicate

low

compression

and

injecting

oil

on

pistons

does

not

increase

compres

sion

the

cause

may

be

a

cylinder

head

gasket

leak

between

the

cylinders

Engine

oil

and

coolant

in

cylinder

could

result

from

this

problem

Compression

pressure

12

S

to

14

S

kg

cm2

178

to

206

psi

at

3S0

rpm

Checking

exhaust

manifold

heat

control

valve

Check

heat

control

valve

for

proper

operation

If

it

does

not

operate

properly

trouble

is

due

to

excess

carbon

on

shaft

or

damaged

shaft

Clean

if

necessary

The

bimetal

should

be

also

checked

for

proper

function

IGNITION

AND

FUEL

SYSTEM

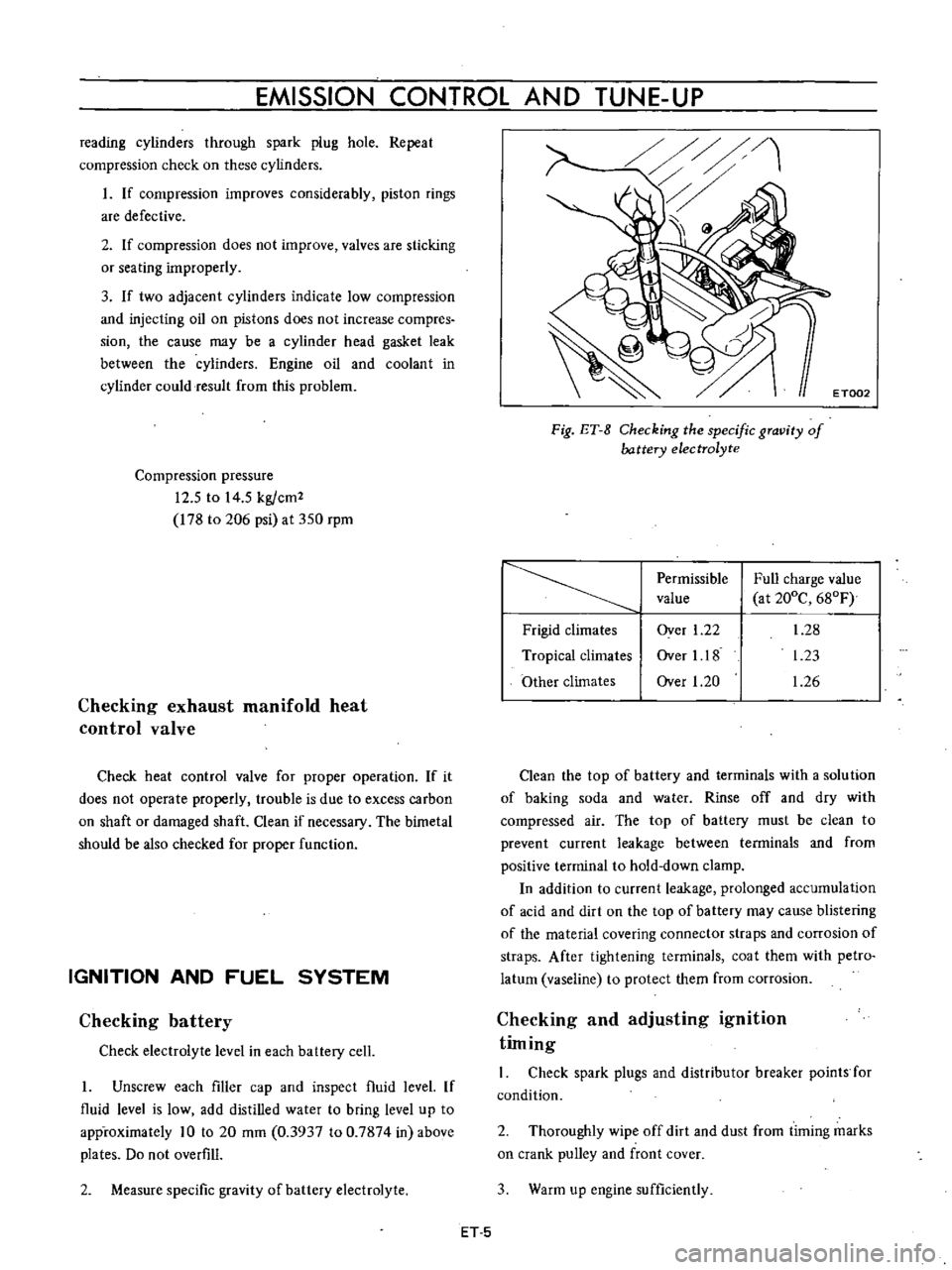

Checking

battery

Check

electrolyte

level

in

each

battery

celL

L

Unscrew

each

filler

cap

and

inspect

fluid

leveL

If

fluid

level

is

low

add

distilled

water

to

bring

level

up

to

app

roximately

10

to

20

mm

0

3937

to

0

7874

in

above

plates

Do

not

overfilL

2

Measure

specific

gravity

of

battery

electrolyte

ET002

Fig

ET

B

Checking

the

specific

gravity

of

battery

electrolyte

Permissible

Full

charge

value

value

at

200C

68OF

Frigid

climates

Over

1

22

1

28

Tropical

climates

Over

1

18

1

23

Other

climates

Over

L

20

1

26

Clean

the

top

of

battery

and

terminals

with

a

solu

lion

of

baking

soda

and

water

Rinse

off

and

dry

with

compressed

air

The

top

of

battery

must

be

clean

to

prevent

current

leakage

between

terminals

and

from

positive

terminal

to

hold

down

clamp

In

addition

to

current

leakage

prolonged

accumulation

of

acid

and

dirt

on

the

top

of

battery

may

cause

blistering

of

the

material

covering

connector

straps

and

corrosion

of

straps

After

tightening

terminals

coat

them

with

petro

laturn

vaseline

to

protect

them

from

corrosion

Checking

and

adjusting

ignition

timing

I

Check

spark

plugs

and

distributor

breaker

points

for

condition

2

Thoroughly

wipe

off

dirt

and

dust

from

timing

marks

on

crank

pulley

and

front

cover

3

Warm

up

engine

sufficiently

ET

5

Page 316 of 513

EMISSION

CONTROL

AND

TUNE

UP

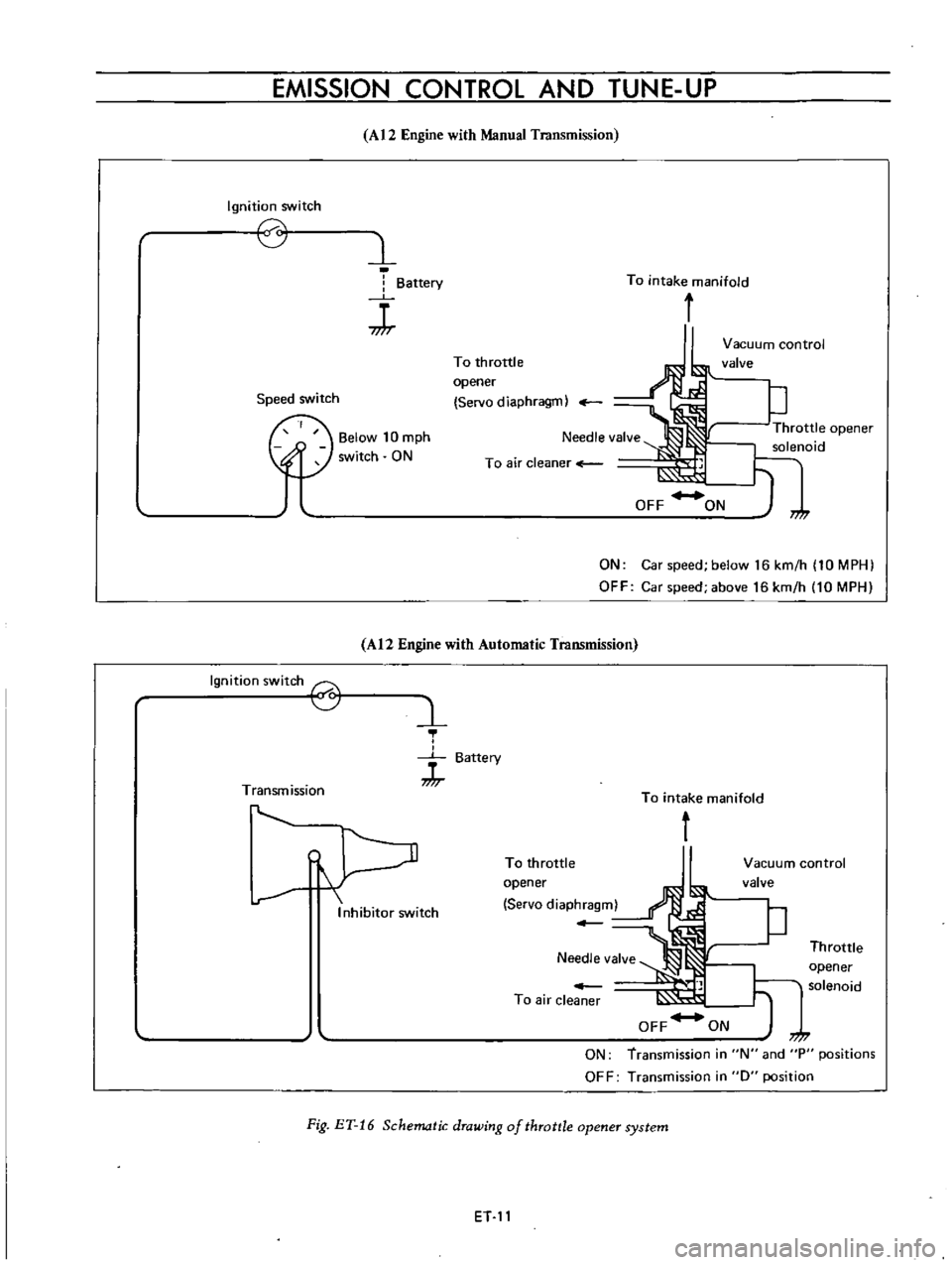

Ignition

switch

0

Speed

switch

Ignition

switch

6

Transmission

A12

Engine

with

Manual

Transmission

l

Battery

J

Below

10

mph

switch

ON

To

throttle

opener

Servo

diaphragm

Needle

valve

To

air

cleaner

To

intake

manifold

f

Vacuum

control

valve

p

Throttle

opener

noid

ON

Car

speed

below

16

km

h

10

MPH

OFF

Car

speed

above

16

km

h

10

MPH

A12

Engine

with

Automatic

Transmission

Inhibitor

switch

1

J

Battery

To

intake

manifold

t

ET

11

OFF

ON

Fig

BY

16

Schematic

drawing

of

throttle

opener

system

To

throttle

opener

Servo

diaphragm

Vacuum

control

valve

P

Throttle

t

opener

solenoid

7

7

ON

transmission

in

N

and

P

positions

OFF

Transmission

in

0

position

Page 323 of 513

ENGINE

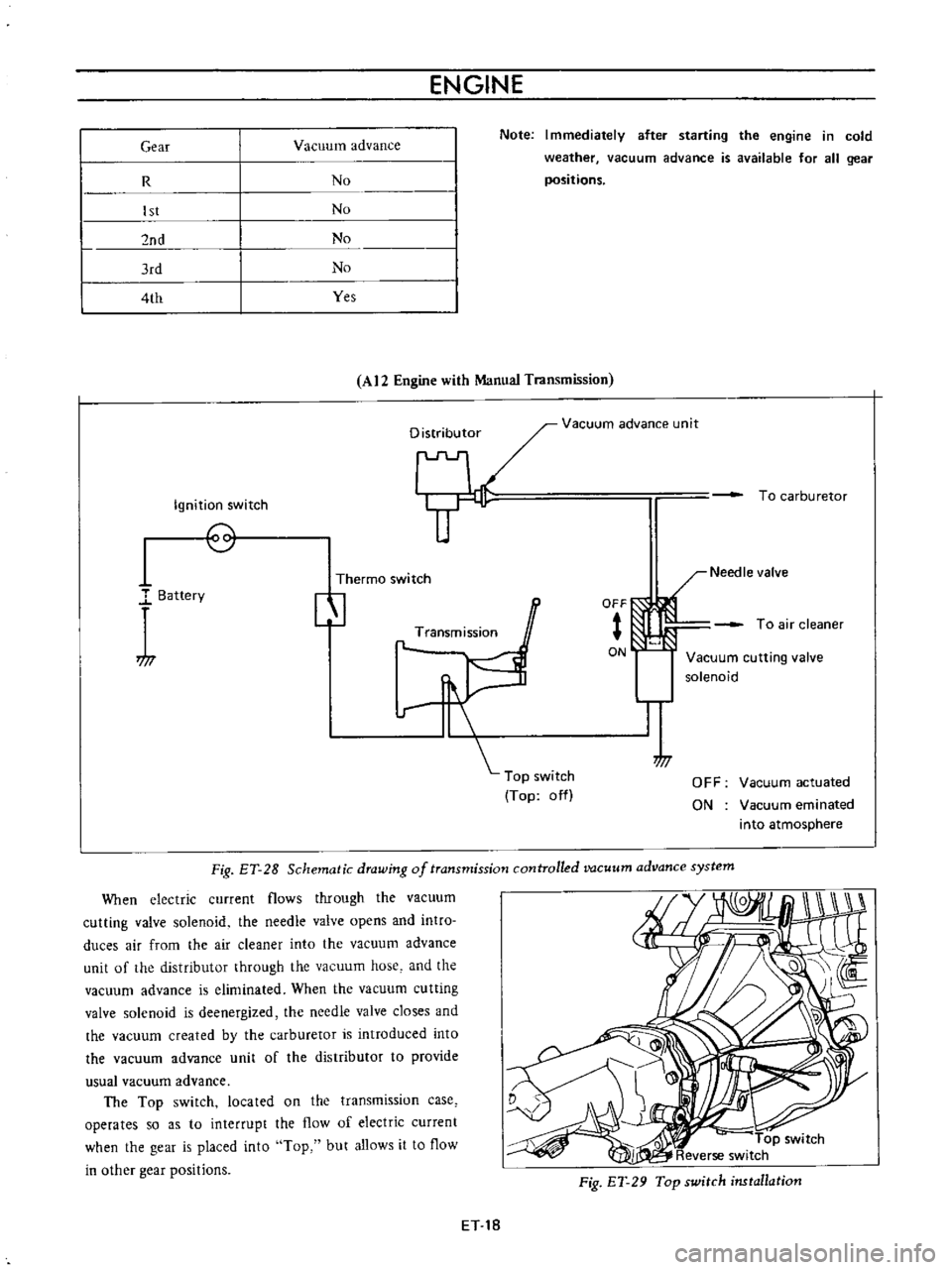

Gear

Vacuum

advance

Note

R

No

1st

No

2nd

No

3rd

No

4th

Yes

Immediately

after

starting

the

engine

in

cold

weather

vacuum

advance

is

available

for

all

gear

positions

A12

Engine

with

Manual

Transmission

Distributor

Ignition

switch

8

1

J

Battery

Thermo

switch

9

Transmission

L

r

l

r

Vacuum

advance

unit

To

carburetor

Needle

valve

OFF

l

To

air

cleaner

ON

Vacuum

cutting

valve

solenoid

Top

switch

Top

off

I

7

1

OFF

Vacuum

actuated

ON

Vacuum

eminated

into

atmosphere

Fig

ET

28

Schematic

drawing

of

transmission

controlled

vacuum

advance

system

When

electric

current

flows

through

the

vacuum

cutting

valve

solenoid

the

needle

valve

opens

and

intro

duces

air

from

the

air

cleaner

into

the

vacuum

advance

unit

of

the

distributor

through

the

vacuum

hose

and

the

vacuum

advance

is

eliminated

When

the

vacuum

cutting

valve

solenoid

is

deenergized

the

needle

valve

closes

and

the

vacuum

created

by

the

carburetor

is

introduced

into

the

vacuum

advance

unit

of

the

distributor

to

provide

usual

vacuum

advance

The

Top

switch

located

on

the

transmission

case

operates

so

as

to

interrupt

the

flow

of

electric

current

when

the

gear

is

placed

into

Top

but

allows

it

to

flow

in

other

gear

positions

Fig

ET

29

Top

switch

installation

ET

18

Page 330 of 513

EMISSION

CONTROL

AND

TUNE

UP

SERVICE

DATA

AND

SPECIFICATIONS

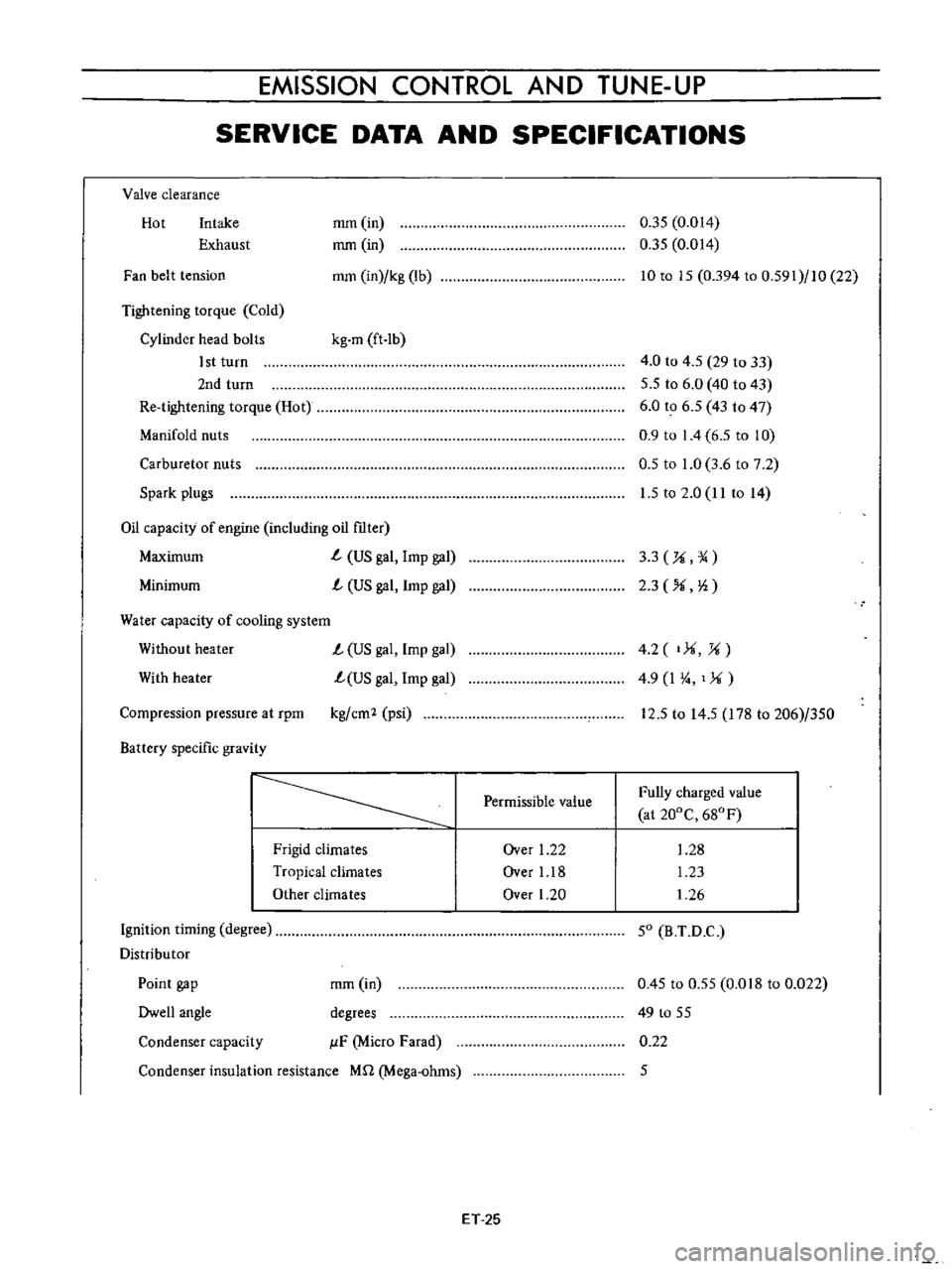

Valve

clearance

Hot

Intake

Exhaust

mm

in

rom

in

rom

in

kg

lb

0

35

0

014

0

35

0

014

10

to

15

0

394

to

0

591

10

22

Fan

belt

tension

Tightening

torque

Cold

Cylinder

head

bolts

kg

m

ft

lb

1st

turn

2nd

turn

Re

tightening

torque

Hot

Manifold

nuts

Carburetor

nuts

4

0

to

4

5

29

to

33

5

5

to

6

0

40

to

43

6

0

to

6

5

43

to

47

0

9

to

I

4

6

5

to

10

0

5

to

1

0

3

6

to

7

2

1

5

to

2

0

II

to

14

Spark

plugs

Oil

capacity

of

engine

including

oil

ftIter

Maximum

L

US

gal

Imp

gal

L

US

gal

Imp

gal

3

3

U

14

2

3

Ii

Minimum

Water

capacity

of

cooling

system

Without

heater

L

US

gal

Imp

gal

With

heater

L

US

gal

Imp

gal

4

2

1

U

4

9

I

4

11

12

5

to

14

5

I78

to

206

350

Compression

pressure

at

rpm

kg

em

psi

Battery

specific

gravity

Permissible

value

Fully

charged

value

at

200C

680F

Frigid

climates

Tropical

climates

Other

elima

tes

Over

1

22

Over

1

18

Over

1

20

1

28

1

23

1

26

Ignition

timing

degree

Distributor

50

B

T

D

C

Condenser

capacity

mm

in

degrees

IlF

Micro

Farad

0

45

to

0

55

0

018

to

0

022

49

to

55

0

22

5

Point

gap

Dwell

angle

Condenser

insulation

resistance

Mil

Mega

ohms

ET

25

Page 331 of 513

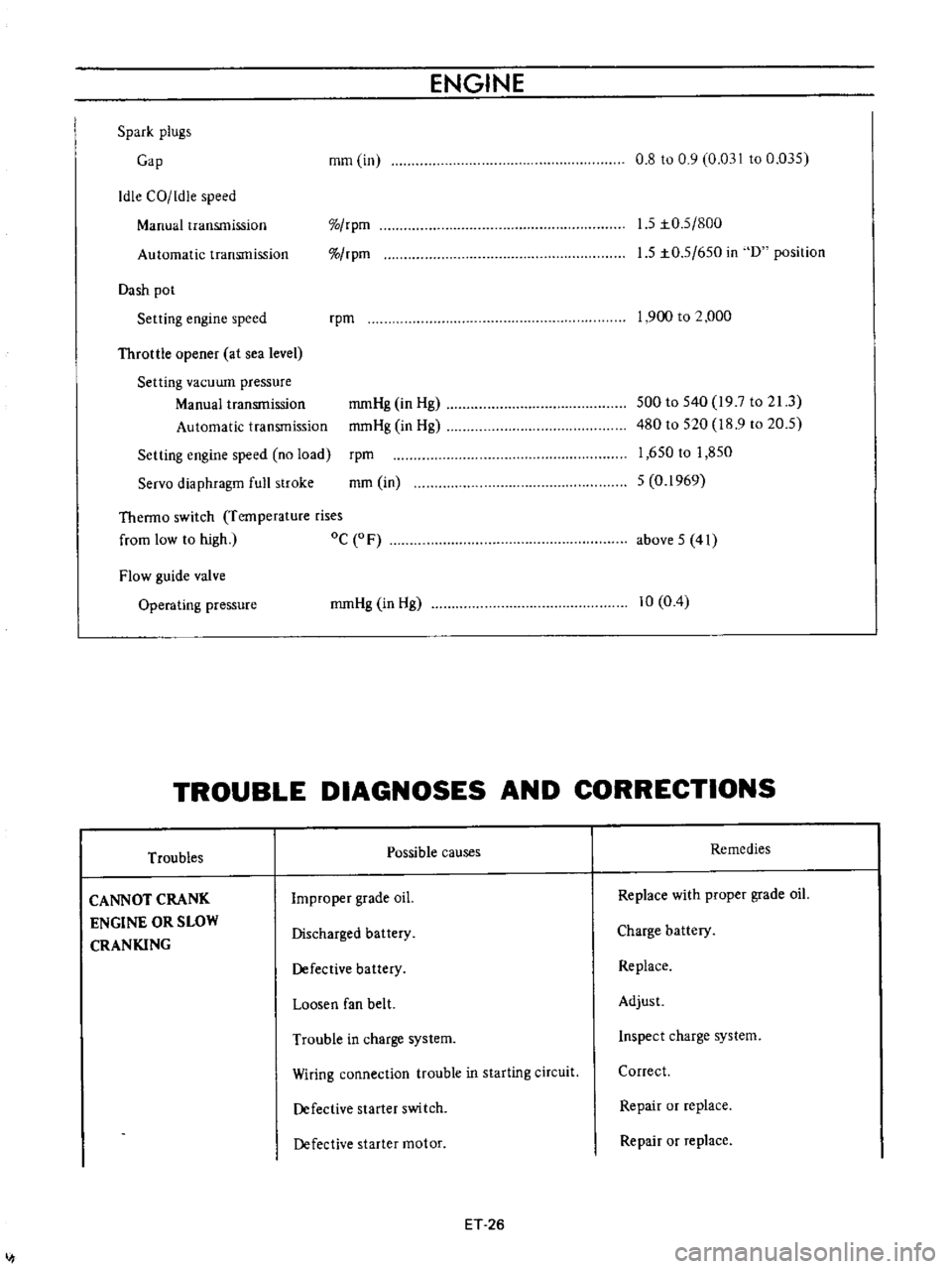

ENGINE

Spark

plugs

Cap

mm

in

0

8

to

0

9

0

03110

0

035

Idle

CO

ldie

speed

Manual

transmission

rpm

rpm

1

5

to

5

800

1

5

to

5

650

in

D

position

Automatic

transmission

Dash

pot

Setting

engine

speed

rpm

1

900

to

2

000

Throttle

opener

at

sea

level

Setting

vacuwn

pressure

Manual

transmission

Automatic

transmission

Setting

engine

speed

no

load

Servo

diaphragm

full

stroke

rpm

mm

in

500

to

540

19

7

to

21

3

480

to

520

18

9

to

20

5

1

650

to

1

850

5

0

1969

mmHg

in

Hg

mmHg

in

Hg

Theono

switch

Temperature

rises

from

low

to

high

oC

0

F

above

5

41

Flow

guide

valve

Opera

ting

pressure

mmHg

in

Hg

10

0

4

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Troubles

Possible

causes

Remedies

CANNOT

CRANK

ENGINE

OR

SLOW

CRANKING

Improper

grade

oiL

Replace

with

proper

grade

oiL

Discharged

battery

Charge

battery

Defective

battery

Replace

Loosen

fan

belt

Adjust

Trouble

in

charge

system

Inspect

charge

system

Wiring

connection

trouble

in

starting

circuit

Correct

Defective

starter

switch

Repair

or

replace

Defective

starter

motor

Repair

or

replace

ET

26

I

Page 332 of 513

EMISSION

CONTROL

AND

TUNE

UP

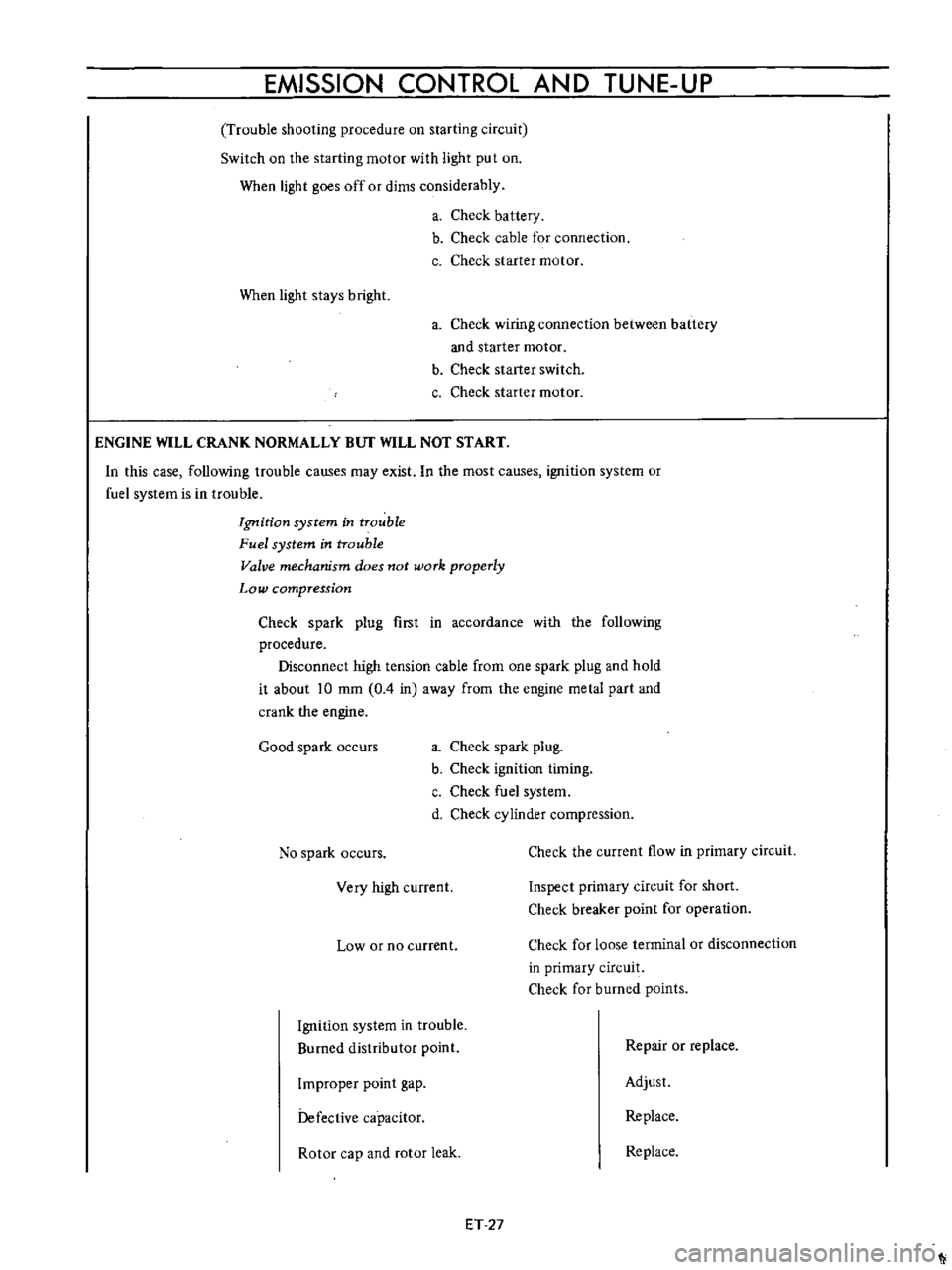

Trouble

shooting

procedure

on

starting

circuit

Switch

on

the

starting

motor

with

light

put

on

When

light

goes

off

or

dims

considerably

a

Check

battery

b

Check

cable

for

connection

c

Check

starter

motor

When

light

stays

bright

a

Check

wiring

connection

between

battery

and

starter

motor

b

Check

starter

switch

c

Check

starter

motor

ENGINE

WILL

CRANK

NORMALLY

BUT

WILL

NOT

START

In

this

case

following

trouble

causes

may

exist

In

the

most

causes

ignition

system

or

fuel

system

is

in

trouble

Ignition

system

in

trouble

Fuel

system

in

trouble

Valve

mechanism

does

not

work

properly

Low

compression

Check

spark

plug

first

in

accordance

with

the

following

procedure

Disconnect

high

tension

cable

from

one

spark

plug

and

hold

it

about

10

rom

0

4

in

away

from

the

engine

metal

part

and

crank

the

engine

Good

spark

occurs

a

Check

spark

plug

b

Check

ignition

timing

Check

fuel

system

d

Check

cylinder

compression

No

spark

occurs

Check

the

current

flow

in

primary

circuit

Very

high

current

Inspect

primary

circuit

for

short

Check

breaker

point

for

operation

Low

or

no

current

Check

for

loose

terminal

or

disconnection

in

primary

circuit

Check

for

burned

points

Ignition

system

in

trouble

Burned

distributor

point

Repair

or

replace

Improper

point

gap

Adjust

Defective

capacitor

Replace

Rotor

cap

and

rotor

leak

Replace

ET

27

ti

Page 420 of 513

DATSUN

1200

MODEL

B

11

0

SERIES

L

NISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

EE

ENGINE

ELECTRICAL

SYSTEM

BATTERY

STARTING

MOTOR

CHARGING

CIRCUIT

ALTERNATOR

REGULATOR

IGNITIO

N

CIRCUIT

DISTRIBUTOR

IGNITION

COIL

SPARK

PLUG

EEl

EE

3

EE

15

EE

16

EE

23

EE

29

EE

29

EE

36

EE

37

Page 421 of 513

ENGINE

ElECTRICAL

SYSTEM

BATTERY

CONTENTS

REMOVAL

CHECKING

ELECTROLYTE

LEVEL

CHECKING

SPECIFIC

GRAVITY

EE

1

EE

l

EE

1

REMOVAL

Disconnect

the

negative

terminal

first

and

then

the

positive

terminal

2

Remove

the

retainer

nuts

and

take

off

retainer

3

Release

retainer

bolts

and

remove

battery

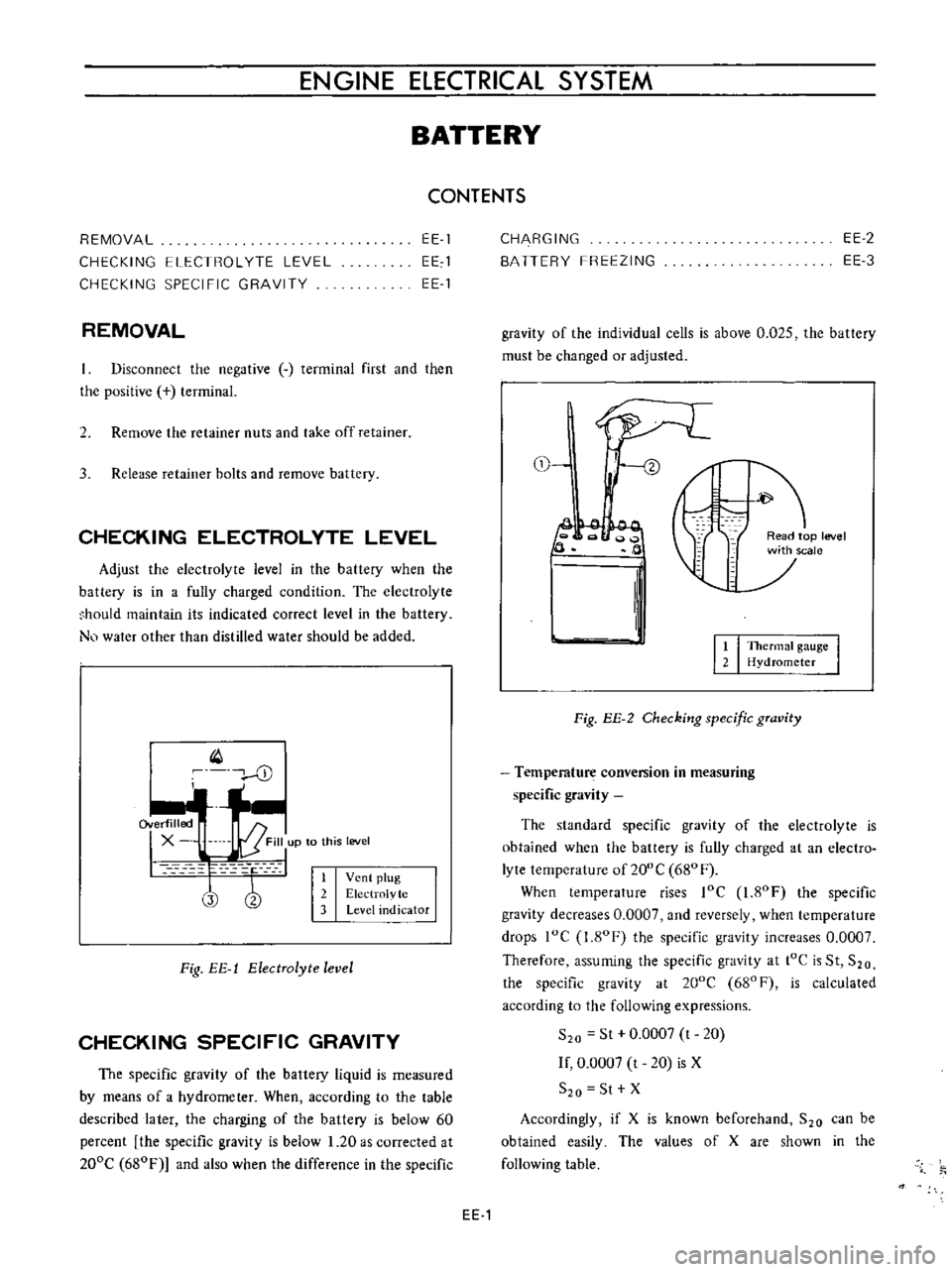

CHECKING

ELECTROLYTE

LEVEL

Adjust

the

electrolyte

level

in

the

battery

when

the

battery

is

in

a

fully

charged

condition

The

electrolyte

hould

maintain

its

indicated

correct

level

in

the

battery

N

water

other

than

distilled

water

should

be

added

Q

cD

I

1

Vent

plug

2

Electrolvte

3

Level

indicator

Fig

EE

1

ElectTolyte

level

CHECKING

SPECIFIC

GRAVITY

The

specific

gravity

of

the

battery

liquid

is

measured

by

means

of

a

hydrometer

When

according

to

the

table

described

later

the

charging

of

the

battery

is

below

60

percent

the

specific

gravity

is

below

1

20

as

corrected

at

200e

680F

and

also

when

the

difference

in

the

specific

CHARGING

BATTERY

FREEZING

EE

2

EE

3

gravity

of

the

individual

cells

is

above

0

025

the

battery

must

be

changed

or

adjusted

tl

f

ead

p

level

jSCale

2

II

It

I

TheTmat

gauge

I

2

Hydrometer

Fig

EE

2

Checking

specific

gTavity

Temperature

conversion

in

measuring

specific

gravity

The

standard

specific

gravity

of

the

electrolyte

is

obtained

when

the

battery

is

fully

charged

at

an

electro

lyte

temperature

of

200

e

680

F

When

temperature

rises

loe

1

80F

the

specific

gravity

decreases

0

0007

and

reversely

when

temperature

drops

loe

I

ROF

the

specific

gravity

increases

0

0007

Therefore

assuming

the

specific

gravity

at

tOe

is

St

S20

the

specific

gravity

at

200e

680F

is

calculated

according

to

the

following

expressions

S

o

St

0

0007

t

20

If

0

0007

t

20

is

X

S

o

St

X

Accordingly

if

X

is

known

beforehand

S

o

can

be

obtained

easily

The

values

of

X

are

shown

in

the

following

table

EE

1

Page 422 of 513

ENGINE

Temperature

Oc

of

Temperature

C

F

x

Temperature

Oc

F

x

0

32

0

0

014

14

572

28

82

4

0

004

0

006

33

8

IS

59

0

19

I

84

2

0

013

2

35

6

16

60

8

0

003

30

86

0

0

007

3

37

4

0

012

17

61

6

0

001

31

87

8

0

008

4

39

2

18

64

4

32

89

6

0

011

0

001

5

41

0

19

66

2

33

91

4

0

009

6

42

8

0

010

20

68

0

0

34

93

2

0

010

7

44

6

0

009

21

69

8

35

95

0

0

001

0

01l

8

46

4

22

71

6

36

96

8

0

008

9

48

2

23

73

4

0

002

37

98

6

0

012

10

50

0

0

007

24

75

2

0

003

38

100

4

0

013

II

51

8

25

77

0

39

t02

2

0

006

0

004

12

53

6

16

78

8

40

104

0

0

Ot4

13

55

4

0

005

27

80

6

0

005

The

state

of

discharge

of

the

battery

can

be

determined

by

checking

the

specific

gravity

according

to

the

follow

ing

table

The

electrolyte

level

should

be

satisfactory

U

tn

l

k

1

I

P

I

IZf

I

r7

42

I

bt

7

J

I

I

11

0

I

M

I

L

J

I

10

20

30

0

50

60

70

aD

90

100

Charging

condition

Fig

EE

3

Charging

condition

CHARGING

When

the

specific

gravity

of

he

electrolyte

is

below

1

20

with

the

electrolyte

level

being

satisfactory

it

is

necessary

to

recharge

the

battery

Whenever

a

quick

x

Converted

specific

gravity

520

V

9d

f

o

1

28

u

1

6

c

E

1

24

l

22

o

0

U5

S

I

1

1

2

1

10

1

NON

M

i

Electrolyte

temperature

lOCI

charge

is

carried

out

the

negative

terminal

of

the

battery

must

be

disconnected

The

corroded

terminal

posts

of

the

battery

should

be

cleaned

with

warm

water

of

bicarbonate

of

soda

solution

prior

to

charging

The

following

points

should

be

observed

in

charging

If

the

electrolyte

level

is

below

the

plates

add

distilled

water

2

Remove

all

the

vent

plugs

and

keep

them

at

a

particular

place

3

Keep

the

electrolyte

temperature

below

450C

l130F

during

charging

4

During

charging

the

voltage

increases

gradually

until

it

reaches

the

particular

maximum

value

2

5

Vice

II

The

charging

is

completed

when

this

value

stays

almost

constant

for

more

than

one

hour

and

all

cells

gas

freely

EE

2