stop start DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 405 of 513

ENGINE

AD

JUSTMENT

Idling

adjustment

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

and

calibrated

Warm

up

the

engine

sufficiently

2

Continue

engine

operation

for

one

minute

under

idling

speed

3

Adjust

throttle

adjusting

screw

so

that

engine

speed

is

800

rpm

in

N

position

for

automatic

transmission

4

Check

ignition

timing

if

necessary

adjust

it

to

the

specifications

Ignition

timing

50

800

rpm

5

Adjust

idle

adjusting

screw

so

that

ca

percentage

is

1

5

t

0

5

6

Repeat

the

adjustments

as

described

in

steps

3

and

5

above

so

that

ca

percentage

is

1

5

to

5

at

800

rpm

Cautions

a

On

automatic

transmission

equipped

model

check

must

be

done

in

the

0

position

Be

sure

to

apply

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Hold

brake

pedal

while

stepping

down

on

accelerator

pedal

Otherwise

car

will

rush

out

dangerously

7

On

automatic

transmission

equipped

model

make

sure

that

the

adjustment

has

been

made

with

the

selector

lever

in

N

position

And

then

check

the

specifications

with

the

lever

in

D

position

Insure

that

CO

percent

and

idle

speed

are

as

follows

Idle

rpm

650

ca

percentage

with

lever

in

D

position

15

to

5

If

necessary

adjust

by

progressively

turning

throttle

adjusting

screw

and

idle

adjusting

screw

until

correct

adjustments

are

made

Notes

a

Do

not

attempt

to

screw

down

the

id

Ie

adjusting

screw

completely

to

avoid

damage

to

the

EF

14

tip

which

will

tend

to

cause

malfunctions

b

After

idle

adjustment

has

been

made

shift

the

lever

to

N

or

p

position

for

automatic

transmission

c

Remove

wheel

chocks

before

starting

the

car

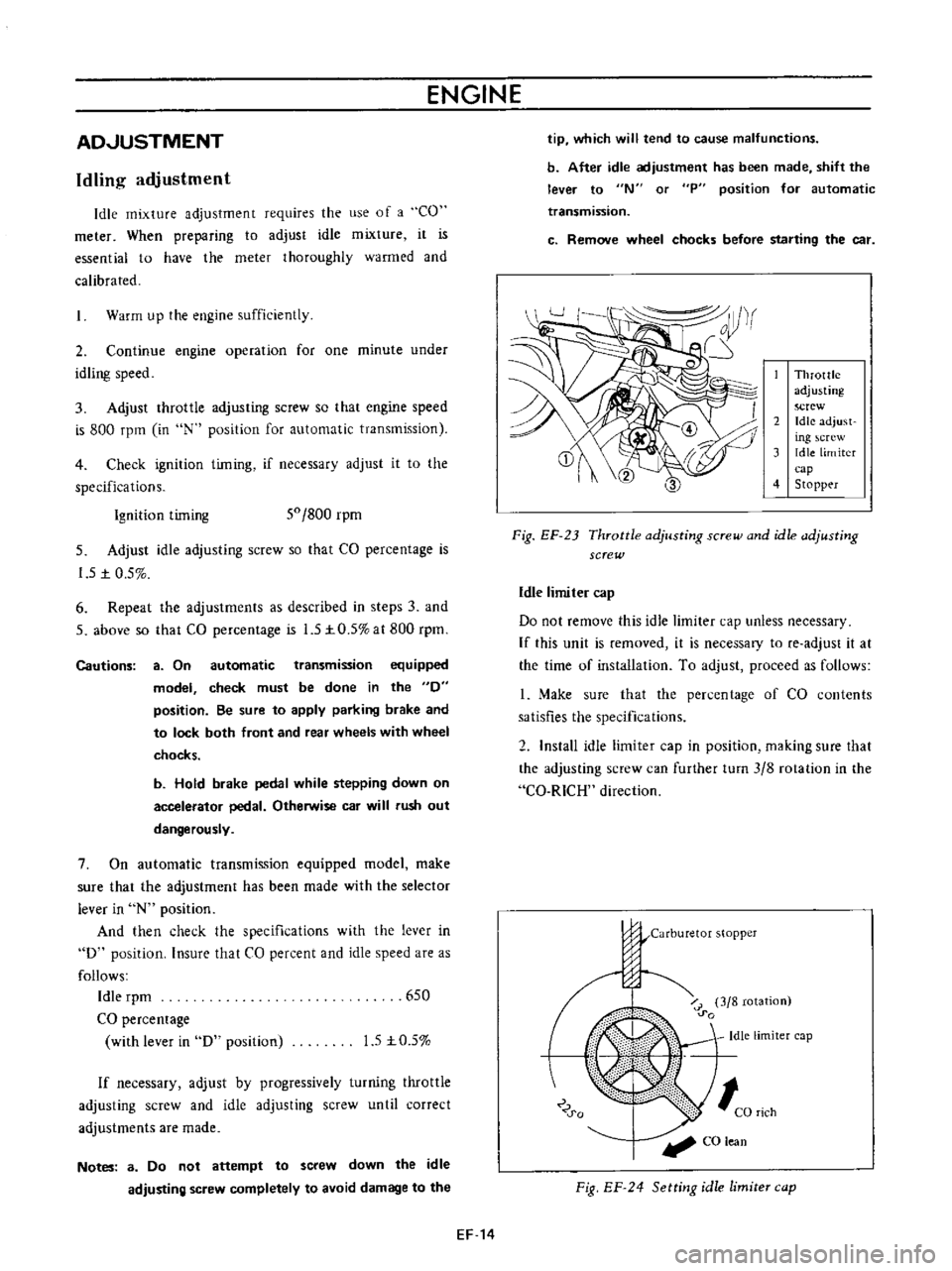

Throttle

adjusting

screw

2

Idle

adjust

ing

crew

3

Idle

limiter

cap

4

Stopp

r

Fig

EF

23

Throttle

adjusting

screw

and

idle

adjusting

screw

Idle

limiter

cap

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

fe

adjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

Make

sure

that

the

percentage

of

CO

contents

satisfies

the

specifications

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

further

turn

3

8

rotation

in

the

Ca

RICH

direction

j

j

Carburetor

stopper

o

u

o

i

r

3

8

rotation

0

0

Idle

limiter

cap

0

0

CO

lean

Fig

EF

24

Setting

idle

limite

cap

Page 424 of 513

When

the

contacts

stationary

and

movable

are

dused

the

motor

operates

to

crank

the

engine

and

the

series

coil

of

the

solenoid

is

cut

out

The

magnetic

force

of

the

shunt

coil

is

sufficient

to

hold

the

pinion

in

mesh

after

shifting

the

system

When

the

engine

is

operated

and

the

ignition

switch

is

set

to

ON

the

series

coil

demagnetizes

the

shunt

coil

and

the

return

spring

actuates

the

plunger

to

return

to

the

original

position

Consequently

the

motor

stops

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

over

running

clutch

The

over

running

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

so

as

to

engage

or

disengage

with

the

ring

gear

teeth

The

over

running

clutch

is

designed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

and

to

permit

the

pinion

over

running

the

armature

when

the

engine

is

started

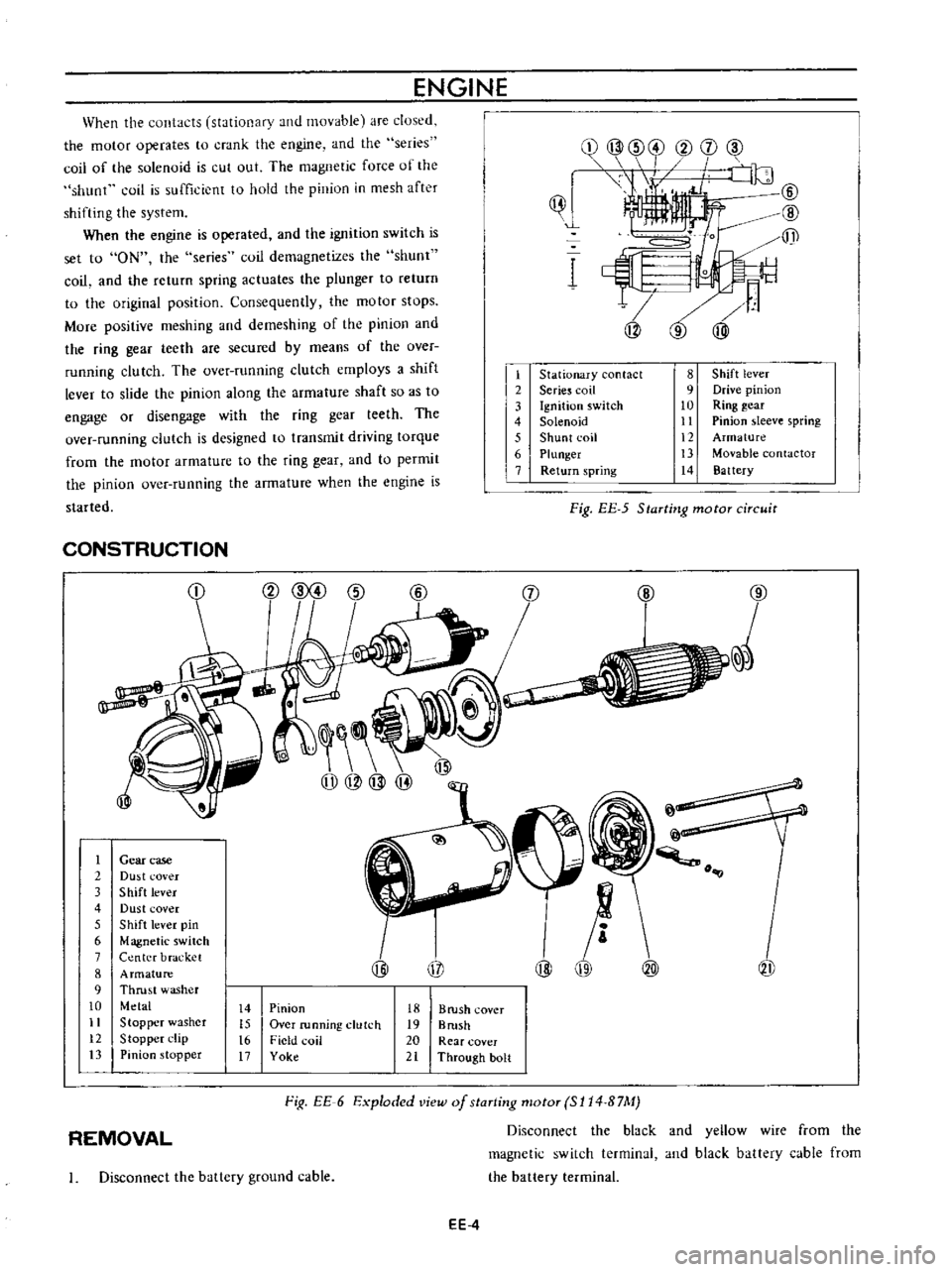

ENGINE

ijJ

1

t

2

3

4

5

6

7

Stationary

contact

Serie

coil

Ignition

switch

Solenoid

Shunt

coil

Plunger

Return

spring

8

Shift

lever

9

Drive

pinion

10

Ring

gear

11

Pinion

sleeve

spring

12

Armature

13

Movable

contactor

14

Battery

Fig

EE

5

Starting

motor

circuit

CONSTRUCTION

1

2

3

4

5

6

7

8

9

10

11

12

13

j

@

Gear

case

Du

t

cover

Shift

lever

Dust

cover

Shift

lever

pin

Magnetic

switch

Center

bracket

Armature

Thrust

washer

Metal

Stopper

washer

Stopper

l

lip

Pinion

stopper

@

@

o

@

i

1I

@

@

@

14

15

t6

17

Pinion

Over

running

clutch

Field

coil

Yoke

18

B

rush

cover

19

Brush

20

Rear

cover

21

Through

bolt

Fig

EE

6

Exploded

view

of

staTting

motoT

SI14

B7M

Disconnect

the

black

and

yellow

wire

from

the

magnetic

switch

terminal

and

black

battery

cable

from

the

battery

terminal

REMOVAL

I

Disconnect

the

ballery

ground

cable

EE

4

Page 425 of 513

ENGINE

ELECTRICAL

SYSTEM

2

Remove

two

bolts

llsed

to

secure

the

starting

motor

on

the

clutch

housing

Pull

the

starter

assembly

forward

and

remove

the

starting

motor

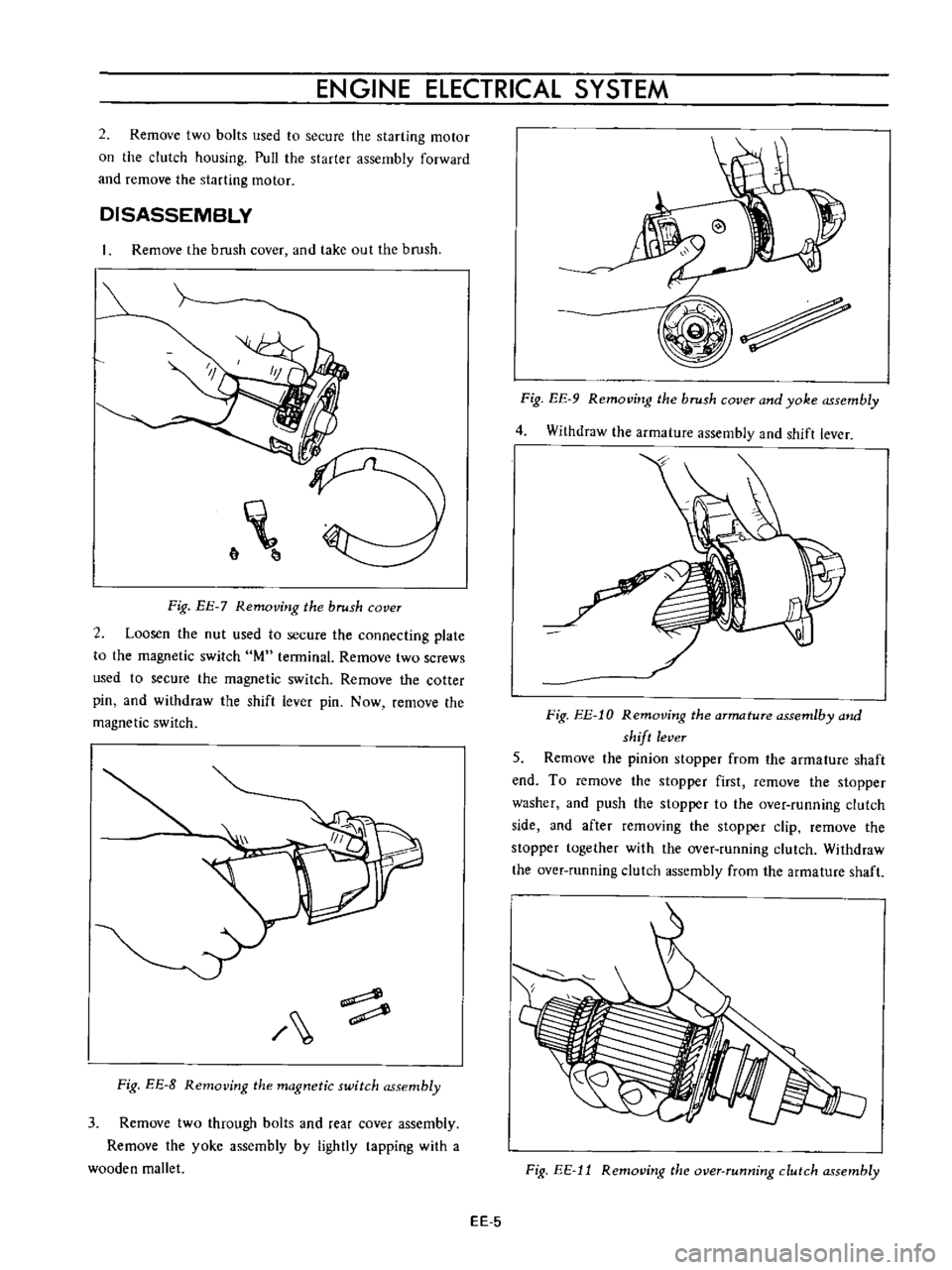

DISASSEMBLY

Remove

the

brush

cover

and

take

out

the

brush

6

Fig

EE

7

Removing

the

brush

cover

2

Loosen

the

nut

used

to

secure

the

connecting

plate

to

the

magnetic

switch

M

terminal

Remove

two

screws

used

to

secure

the

magnetic

switch

Remove

the

cotter

pin

and

withdraw

the

shift

lever

pin

Now

remove

the

magnetic

switch

Fig

EE

8

Removing

the

magnetic

switch

assembly

3

Remove

two

through

bolts

and

rear

cover

assembly

Remove

the

yoke

assembly

by

lightly

tapping

with

a

wooden

mallet

Fig

EE

9

Removing

the

brush

cover

and

yoke

assembly

4

Withdraw

the

armature

assembly

and

shift

lever

Fig

EE

l0

Removing

the

armature

assemlby

and

shift

lever

5

Remove

the

pinion

stopper

from

the

armature

shaft

end

To

remove

the

stopper

first

remove

the

stopper

washer

and

push

the

stopper

to

the

over

running

clutch

side

and

after

removing

the

stopper

clip

remove

the

stopper

together

with

the

over

running

clutch

Withdraw

the

over

running

clutch

assembly

from

the

armature

shaft

Fig

EE

11

Removing

the

over

running

clutch

assembly

EE

5

Page 430 of 513

ENGINE

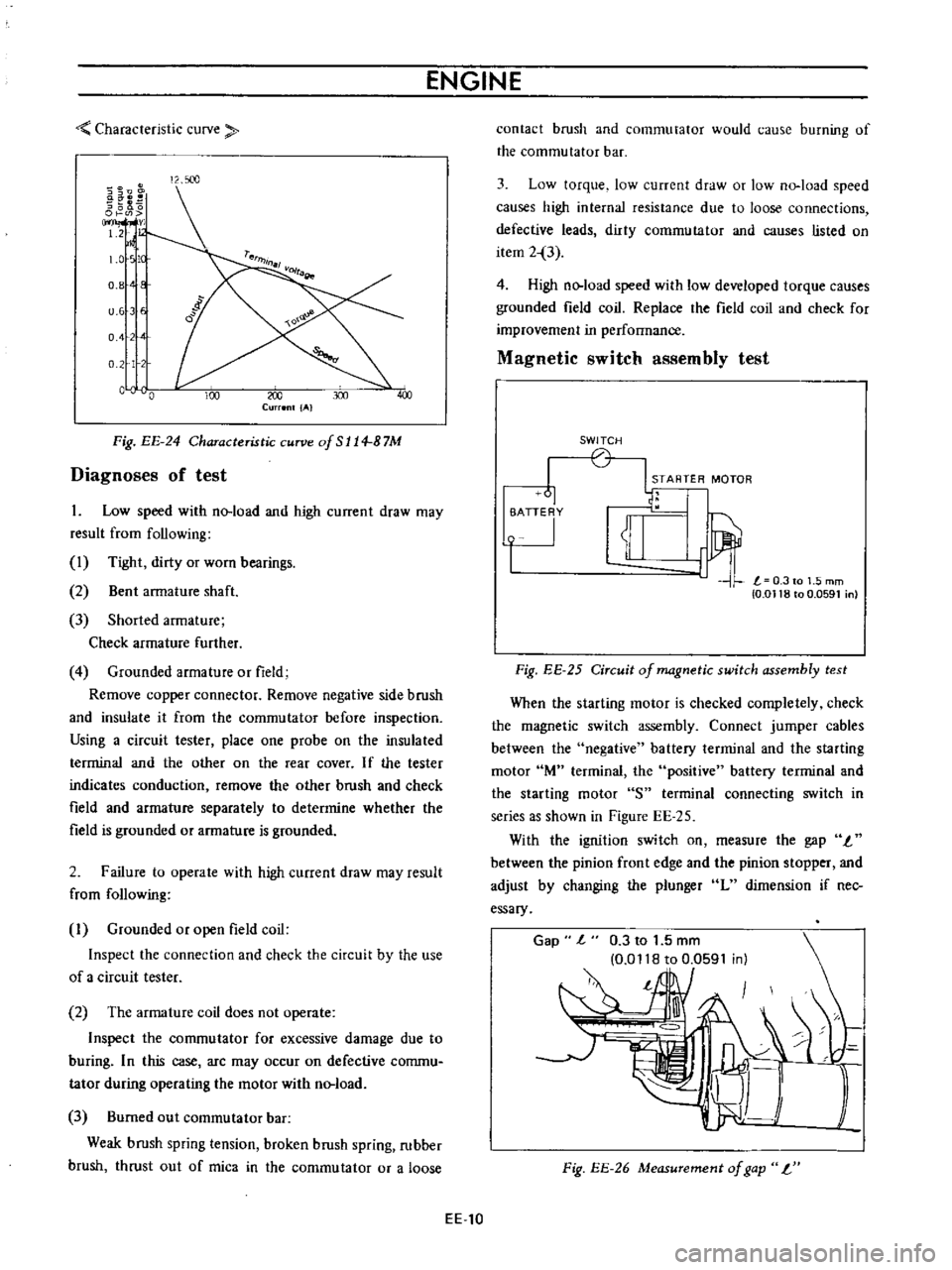

Characteristic

curve

i

8

s

l00

0

OJ

m

v

1

2

1

0

tc

0

8

E

u

6

E

o

4

0

2

L

c

0

00

J

300

Current

IAI

Fig

EE

24

Characteristic

curve

of

S

114

B

7M

Diagnoses

of

test

1

Low

speed

with

no

load

and

high

current

draw

may

result

from

following

1

Tight

dirty

or

worn

bearings

2

Bent

armature

shaft

3

Shorted

armature

Check

armature

further

4

Grounded

armature

or

field

Remove

copper

connector

Remove

negative

side

brush

and

insulate

it

from

the

commutator

before

inspection

Using

a

circuit

tester

place

one

probe

on

the

insulated

terminal

and

the

other

on

the

rear

cover

If

the

tester

indicates

conduction

remove

the

other

brush

and

check

field

and

armature

separately

to

determine

whether

the

field

is

grounded

or

armature

is

grounded

2

Failure

to

operate

with

high

current

draw

may

result

from

following

I

Grounded

or

open

field

coil

Inspect

the

connection

and

check

the

circuit

by

the

use

of

a

circuit

tester

2

The

armature

coil

does

not

operate

Inspect

the

commutator

for

excessive

damage

due

to

buring

In

this

case

arc

may

occur

on

defective

commu

tator

during

operating

the

motor

with

no

load

3

Burned

out

commutator

bar

Weak

brush

spring

tension

broken

brush

spring

rubber

brush

thrust

out

of

mica

in

the

commutator

or

a

loose

EE

10

contact

brush

and

commutator

would

cause

burning

of

the

commutator

bar

3

Low

torque

low

current

draw

or

low

no

load

speed

causes

high

internal

resistance

due

to

loose

connections

defective

leads

dirty

commutator

and

causes

listed

on

item

2

3

4

High

no

load

speed

with

low

developed

torque

causes

grounded

field

coil

Replace

the

field

coil

and

check

for

improvement

in

performance

Magnetic

switch

assembly

test

SWITCH

STARTER

MOTOR

61

1u

i

T

0

0118

to

0

0591

n

Fig

EE

25

Circuit

of

magnetic

switch

assembly

test

When

the

starting

motor

is

checked

completely

check

the

magnetic

switch

assembly

Connect

jumper

cables

between

the

negative

battery

terminal

and

the

starting

motor

lM

terminal

the

positive

battery

terminal

and

the

starting

motor

S

terminal

connecting

switch

in

series

as

shown

in

Figure

EE

25

With

the

ignition

switch

on

measure

the

gap

I

between

the

pinion

front

edge

and

the

pinion

stopper

and

adjust

by

changing

the

plunger

L

dimension

if

nec

essary

Gap

l

0

3

to

1

5

mm

0

0118

to

0

0591

in

l

Fig

EE

26

Measurement

of

gap

L

Page 432 of 513

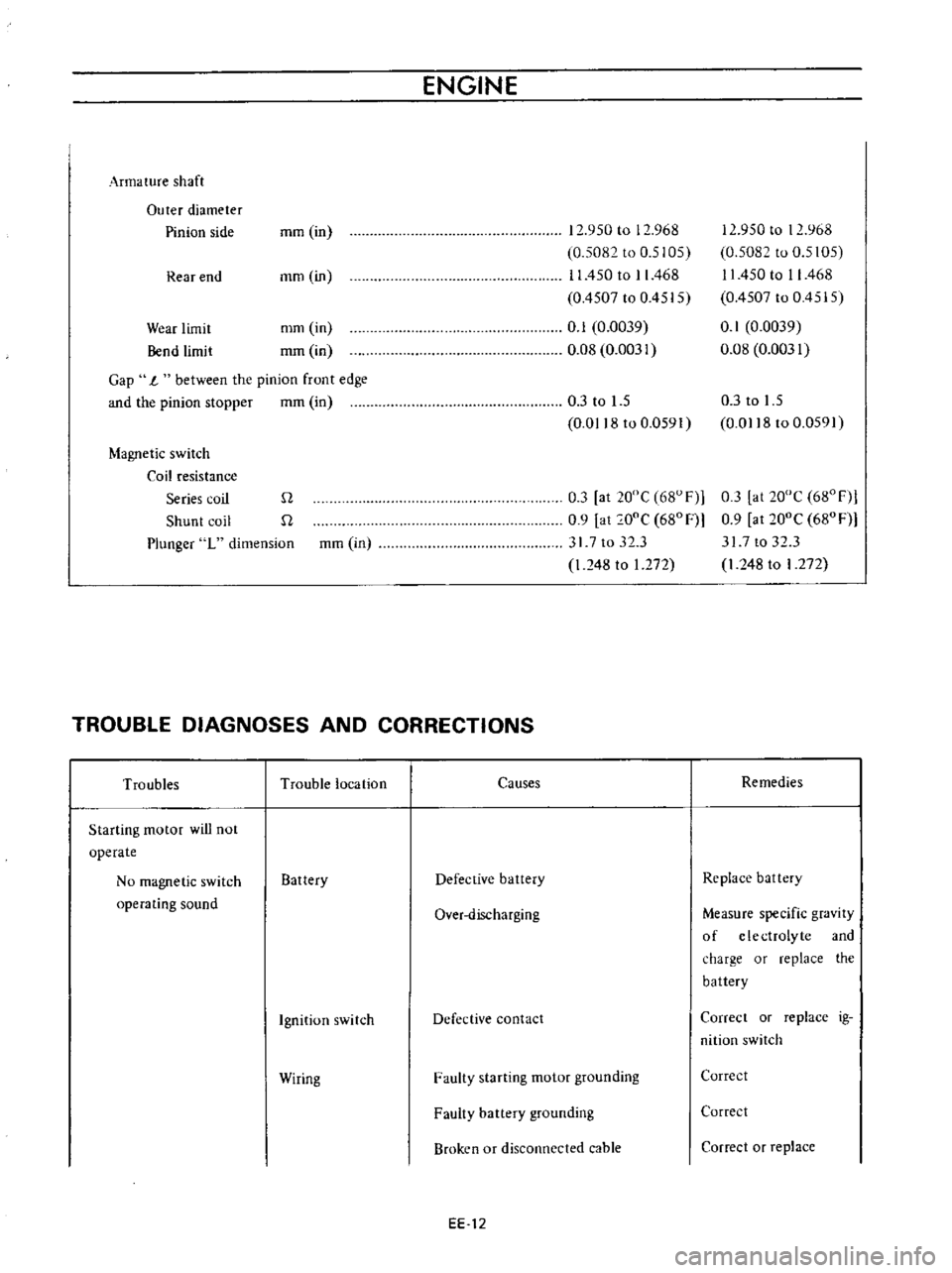

ENGINE

Arma

ture

shaft

Outer

diameter

Pinion

side

mm

in

12

950

to

12

968

0

5082

to

0

5105

11

450

to

II

468

0

4507

to

0

4515

0

1

0

0039

0

08

0

0031

Rear

end

mm

in

Wear

limit

Bend

limit

mm

in

mm

in

Gap

1

between

the

pinion

front

edge

and

the

pinion

stopper

mm

in

0

3

to

1

5

0

0118

to

0

0591

Magnetic

switch

Coil

resistance

Series

cuil

Q

Shunt

coil

n

Plunger

L

dimension

mm

in

0

3

at

20De

68UF

0

9

at

ooe

680F

317t032

3

l

248

to

1

272

TROUBLE

DIAGNOSES

AND

CORRECTIONS

12

950

to

12

968

0

5082

to

0

5105

11

450

to

II

468

0

4507

to

0

4515

l

0

1

0

0039

0

08

0

0031

0

3

to

1

5

0

0118

to

0

0591

0

3

at

20De

680Fl

0

9

at

200e

680F

317

to

32

3

l

248

to

I

272

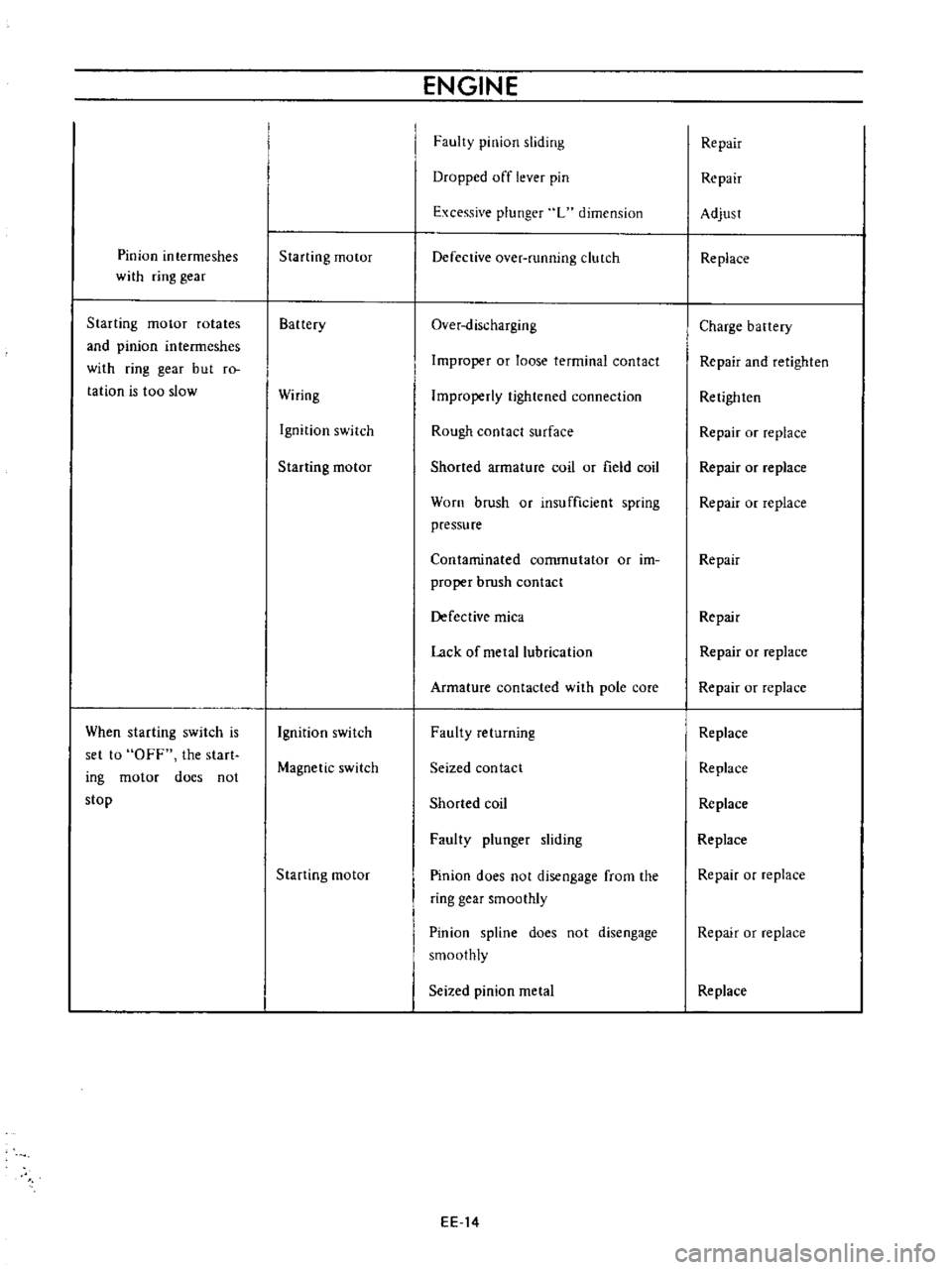

Troubles

Trouble

location

Causes

Remedies

Starting

motor

will

not

operate

No

magnetic

switch

Battery

Defective

battery

Replace

battery

operating

sound

Over

discharging

Measure

specific

gravity

of

e

Ie

ctrolyte

and

ch

lrge

or

replace

the

battery

Ignition

switch

Defective

contact

Correct

or

replace

ig

nition

switch

Wiring

Faulty

starting

motor

grounding

Correct

Faulty

battery

grounding

Correct

Broken

or

disconnected

cable

Correct

or

replace

EE

12

Page 434 of 513

Pinion

intermeshes

with

ring

gear

Starting

motor

rotates

and

pinion

intermeshes

with

ring

gear

but

ro

tation

is

too

slow

When

starting

switch

is

set

to

OFF

the

start

ing

motor

does

not

stop

Starting

motor

Battery

Wiring

Ignition

switch

Starting

motor

Ignition

switch

Magnetic

switch

Starting

motor

ENGINE

Faulty

pinion

sliding

Dropped

off

lever

pin

Excessive

plunger

L

dimension

Defective

over

running

clutch

Over

discharging

Improper

or

loose

terminal

contact

Improperly

tightened

connection

Rough

contact

surface

Shorted

armature

coil

or

field

coil

Worn

brush

or

insufficient

spring

pressure

Contaminated

commutator

or

im

proper

brush

contact

Defective

mica

Lack

of

metal

lubrication

Armature

contacted

with

pole

core

Faulty

returning

Seized

contact

Shorted

coil

Faulty

plunger

sliding

Pinion

does

not

disengage

from

the

ring

gear

smoothly

Pinion

spline

does

not

disengage

smoothly

Seized

pinion

metal

EE

14

Repair

Repair

Adjust

Replace

Charge

battery

Repair

and

retighten

Retighten

Repair

or

replace

Repair

or

replace

Repair

or

replace

Repair

Repair

Repair

or

replace

Repair

or

replace

Replace

Replace

Replace

Replace

Repair

or

replace

Repair

or

replace

Replace