ESP DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 7 of 513

AUTOMATIC

TRANSMISSION

Manual

linkage

The

hand

lever

motion

The

hand

lever

is

located

in

the

driver

s

com

part

men

mechanically

transmitted

from

the

remote

control

linkage

is

further

transmitted

to

the

inner

manual

lever

in

the

transmission

case

from

the

range

selector

lever

in

the

right

center

poc

tion

of

the

transmission

case

through

the

manual

shaft

The

inner

manual

lever

is

thereby

turned

A

pin

installed

on

the

bottom

of

the

inner

manual

lever

slides

the

manu

al

valve

spool

of

the

control

valve

and

thus

the

spool

is

appropriately

posi

lioned

opposing

to

each

select

position

The

parking

rod

pin

is

held

in

the

groove

on

the

top

of

the

inner

manual

plate

The

parking

rod

pin

operates

the

rod

at

p

range

and

operates

the

mechanical

lock

system

Moreover

the

above

described

manual

shaft

is

equipped

with

an

inhibitor

switch

A

rotor

inside

the

inhibitor

switch

rotates

in

response

to

each

range

When

the

range

is

selected

at

p

or

N

the

rotor

closes

the

starter

magnet

circuit

so

that

the

engine

can

be

started

When

the

range

is

selected

at

R

the

rotor

closes

the

back

up

lamp

circuit

and

the

back

up

lamp

lights

Vacuum

diaphragm

The

vacuum

diaphragm

is

installed

un

the

left

center

portion

of

the

transmission

case

The

internal

con

struction

of

the

vacuum

diaphragm

is

as

follows

A

rubber

diaphragm

forms

a

partition

in

the

center

The

engine

intake

manifold

negative

pressure

led

through

vacuum

tube

and

spring

force

are

applied

to

the

front

surface

of

the

rubber

diaphragm

and

atmospheric

pressure

is

applied

to

the

back

surface

A

difference

between

pressure

applied

to

the

front

and

back

surfaces

be

comes

a

vacuum

reaction

and

thus

the

throttle

valve

of

the

control

valve

inside

the

transmission

case

is

op

erated

When

accelerator

pedal

is

fully

de

pressed

and

the

carburetor

is

fully

upened

but

the

engine

speed

is

not

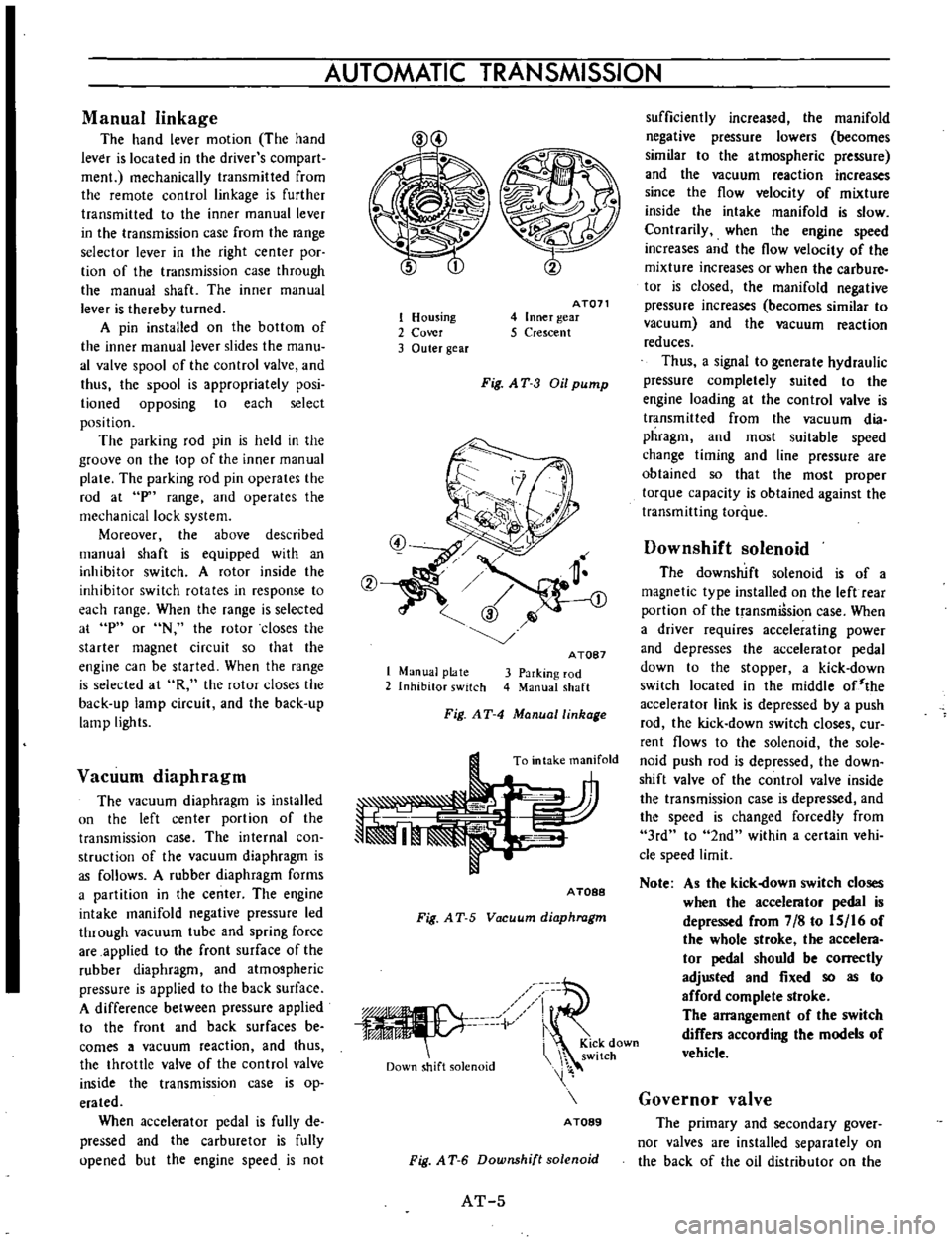

1

Housing

2

Cover

3

Outer

gear

AT071

4

Inner

gear

5

Crescent

Fig

AT

3

Oil

pump

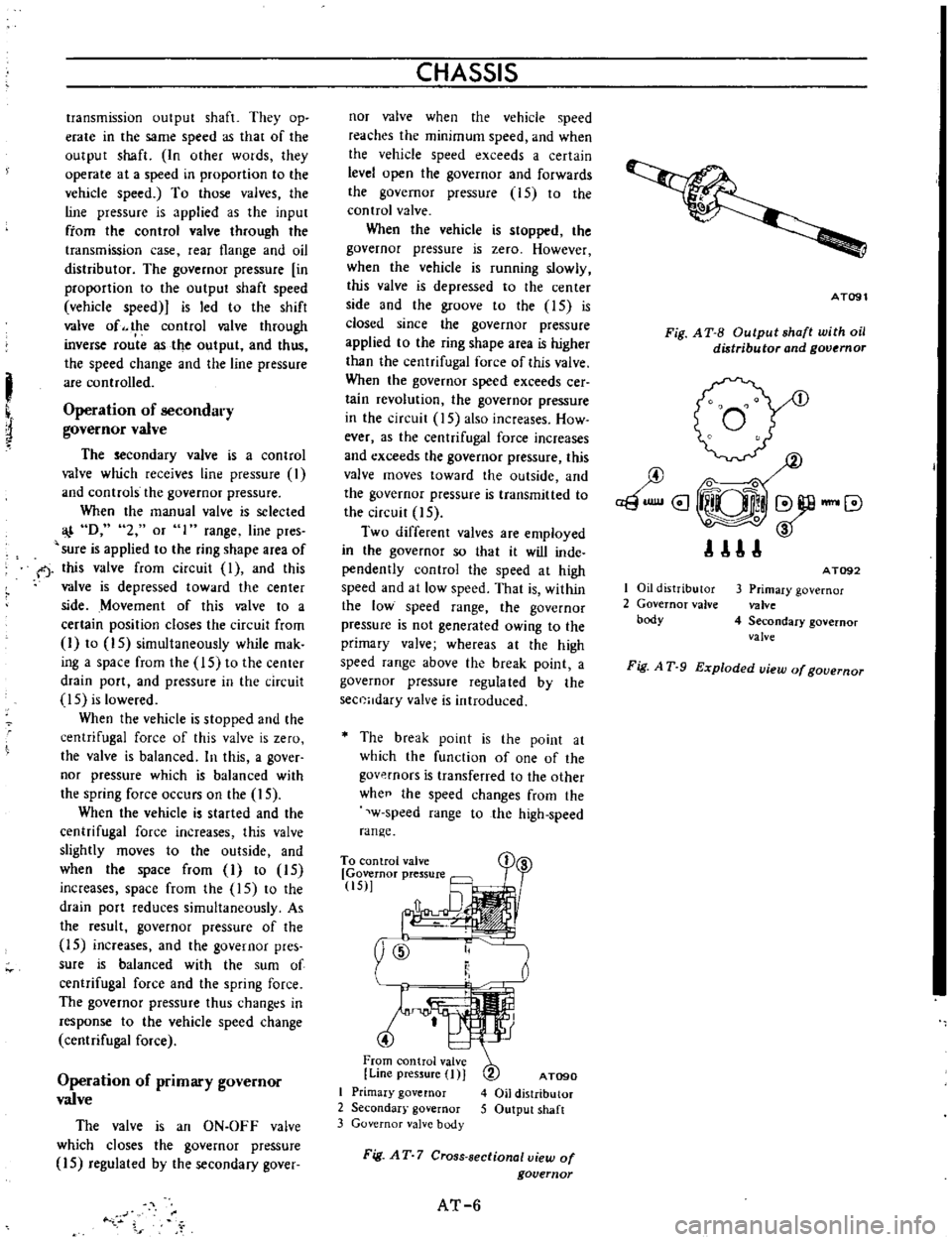

1

Manual

plate

2

Inhibitor

switch

A

TOB7

3

Parking

rod

4

Manual

shaft

Fig

AT

4

Manuallinhage

To

intake

manifold

A

TOBB

Fig

A

T

5

Vacuum

diaphragm

iV

Down

shift

solenoid

i

KiCk

down

switch

A

TOB9

Fig

A

T

6

Downshift

solenoid

AT

5

sufficiently

increased

the

manifold

negative

pressure

lowers

becomes

similar

to

the

atmospheric

pressure

and

the

vacuum

reaction

increases

since

the

flow

velocity

of

mixture

inside

the

intake

manifold

is

slow

Contrarily

when

the

engine

speed

increases

and

the

flow

velocity

of

the

mixture

increases

or

when

the

carbure

tor

is

closed

the

manifold

negative

pressure

increases

becomes

similar

to

vacuum

and

the

vacuum

reaction

reduces

Thus

a

signal

to

generate

hydraulic

pressure

completely

suited

to

the

engine

loading

at

the

control

valve

is

transmitted

from

the

vacuum

dia

phragm

and

most

suitable

speed

change

timing

and

line

pressure

are

obtained

so

that

the

most

proper

torque

capacity

is

obtained

against

the

transmitting

torque

Downshift

solenoid

The

downshift

solenoid

is

of

a

magnetic

type

installed

on

the

left

rear

portion

of

the

transmiSsion

case

When

a

driver

requires

accelerating

power

and

depresses

the

accelerator

pedal

down

to

the

stopper

a

kick

down

switch

located

in

the

middle

of

the

accelerator

link

is

depressed

by

a

push

rod

the

kick

down

switch

closes

cur

rent

flows

to

the

solenoid

the

sole

noid

push

rod

is

depressed

the

down

shift

valve

of

the

control

valve

inside

the

transmission

case

is

depressed

and

the

speed

is

changed

forcedly

from

3rd

to

2nd

within

a

certain

vehi

cle

speed

limit

Note

As

the

kick

own

switch

closes

when

the

accelerator

pedal

is

depressed

from

7

8

to

IS

16

of

the

whole

stroke

the

accelera

tor

pedal

should

be

correctly

adjusted

and

fixed

so

as

to

afford

complete

stroke

The

arrangement

of

the

switch

differs

according

the

models

of

vehicle

Governor

valve

The

primary

and

secondary

gover

nor

valves

are

installed

separately

on

the

back

of

the

oil

distributor

on

the

Page 8 of 513

I

transmission

output

shaft

They

op

erate

in

the

same

speed

as

that

of

the

output

shaft

In

other

wotds

they

operate

at

a

speed

in

proportion

to

the

vehicle

speed

To

those

valves

the

line

pressure

is

applied

as

the

input

ftom

the

control

valve

through

the

transmission

case

rear

flange

and

oil

distributor

The

governor

pressure

in

proportion

to

the

output

shaft

speed

vehicle

speed

is

led

to

the

shift

valve

of

the

control

valve

through

inverse

rou

te

as

the

output

and

thus

the

speed

change

and

the

line

pressure

are

controlled

Operation

of

secondary

governor

valve

The

secondary

valve

is

a

control

valve

which

receives

line

pressure

I

and

controls

the

governor

pressure

When

the

manual

valve

is

selected

D

2

or

1

range

line

pres

sure

is

applied

to

the

ring

shape

area

of

f

this

valve

from

circuit

I

and

this

valve

is

depressed

toward

the

center

side

Movement

of

this

valve

to

a

certain

position

closes

the

circuit

from

I

to

15

simultaneously

while

mak

ing

a

space

from

the

15

to

the

center

drain

port

and

pressure

in

the

circuit

IS

is

lowered

When

the

vehicle

is

stopped

and

the

centrifugal

force

of

this

valve

is

zero

the

valve

is

balanced

In

this

a

gover

nor

pressure

which

is

balanced

with

the

spring

force

occurs

on

the

15

When

the

vehicle

is

started

and

the

centrifugal

force

increases

this

valve

slightly

moves

to

the

outside

and

when

the

space

from

I

to

15

increases

space

from

the

15

to

the

drain

port

reduces

simultaneously

As

the

result

governor

pressure

of

the

15

increases

and

the

governor

pres

sure

is

balanced

with

the

sum

of

centrifugal

force

and

the

spring

force

The

governor

pressure

thus

changt

s

in

response

to

the

vehicle

speed

change

centrifugal

force

Operation

of

primary

governor

valve

The

valve

is

an

ON

OFF

valve

which

closes

the

governor

pressure

15

regulated

by

the

secondary

gover

CHASSIS

nor

valve

when

the

vehicle

speed

reaches

the

minimum

speed

and

when

the

vehicle

speed

exceeds

a

certain

level

open

the

governor

and

forwards

the

governor

pressure

15

to

the

control

valve

When

the

vehicle

is

stopped

the

governor

pressure

is

zero

However

when

the

vehicle

is

running

slowly

this

valve

is

depressed

to

the

center

side

and

the

groove

to

the

IS

is

closed

since

the

governor

pressure

applied

to

the

ring

shape

area

is

higher

than

the

centrifugal

force

of

this

valve

When

the

governor

speed

exceeds

cer

tain

revolution

the

governor

pressure

in

the

circuit

15

also

increases

How

ever

as

the

centrifugal

force

increases

and

exceeds

the

governor

pressure

this

valve

moves

toward

the

outside

and

the

governor

pressure

is

transmitted

to

the

circuit

15

Two

different

valves

are

employed

in

the

governor

so

that

it

will

inde

pendently

control

the

speed

at

high

speed

and

at

low

speed

That

is

within

the

low

speed

range

the

governor

pressure

is

not

generated

owing

to

the

primary

valve

whereas

at

the

high

speed

range

above

the

break

point

a

governor

pressure

regula

ted

by

the

sec0Hdary

valve

is

introduced

The

break

point

is

the

point

at

which

the

function

of

one

of

the

govp

rnors

is

transferred

to

the

other

whee

the

speed

changes

from

the

w

speed

range

to

the

high

speed

range

To

con

trol

valve

Governor

pressure

tiS

y

ID

t

4

From

control

valve

Line

pressure

I

J

I

Primary

governor

2

Secondar

governor

3

Governor

valve

body

AT090

4

Oil

distributor

5

Output

shaft

Fig

AT

7

Cross

sectional

view

of

governor

AT

6

AT091

Fig

A

T

B

Output

shaft

with

oil

distributor

and

governor

I

Oil

distributor

2

Governor

valve

body

AT092

3

Primary

governor

valve

4

Secondary

governor

valve

Fig

A

T

9

Exploded

uiew

of

gouernor

Page 9 of 513

IN

This

quality

product

has

been

packaged

by

hand

If

you

have

any

difficulty

please

mention

my

number

in

your

correspondence

Thank

you

2655

HURST

PERFORMANCE

INC

50

WEST

STREET

ROAD

WARMINSTER

PA

18974

ATTENTION

CUSTOMER

SERVICE

j

PLACE

STAMP

HERE

Page 10 of 513

LIMITED

WARRANTY

Your

Hurst

product

warranted

per

table

below

Irom

dale

01

purchase

against

defects

materinl

and

workmanship

Dur

ing

this

period

luch

defects

will

be

repoired

the

product

will

be

chllnQl

d

at

Huut

option

without

charge

This

war

onty

does

damiilge

used

bv

milu

lI

alteration

negligence

ALL

IMPLIED

WARRANTIES

INCLUDING

BUT

NOT

LIMITED

TO

WARRANTIES

OF

FITNESS

AND

MER

CHANTABllITV

ARE

LIMITED

IN

DURATION

TO

A

PE

RIOO

ENDING

WITH

THE

PERIOD

OF

THE

CORRESPOND

ING

EXPRESS

LIMITED

WARRANTY

AS

SET

FORTH

BE

LOW

UNDER

NO

CIRCUMSTANCES

WILL

HURST

BE

RE

SPONSI8LE

FOR

INCIDENTAL

OR

CONseQUENTIAL

DAMAGES

ARISING

FADM

OR

IN

CONNECTION

WITH

THE

INSTALLATION

OR

USE

OF

ANY

HURST

PRODUCT

Some

tates

do

not

allow

limitations

on

how

long

implied

warranty

lasts

do

not

allow

for

tha

Axclusion

limitation

of

incidental

nnlequantial

damages

the

above

limitations

may

not

apply

to

you

This

Warranty

givlIs

you

specific

legal

righta

and

you

may

also

have

other

rights

which

Vpry

from

state

to

state

Return

of

the

Product

Registration

Card

nOt

nndition

precedent

Warranty

nvAraga

and

performance

HURST

WARRANTY

PERIODS

from

cJ

ffI

of

purch

lt

I

Shift

rs

Air

Shocks

12monttlt

12

OOOmil

or

12month1

whch

ver

lim

gOd

vl

12montl1s

12montl1s

12montl1s

Aoeellories

Tr

Rlmission

Oil

Coolers

Autom

tic

Tr

umitsion

P

rh

Scl1i

f

rPloductt

J

c

udinll

producrr

u

d

fOT

rw

ingl

Bring

the

product

or

nd

it

pOttage

preplidf

Hurst

Performance

Inc

or

IIuthorized

doaler

If

you

end

the

product

pleas

write

letter

IIxplaining

the

01

your

difficulty

HURST

PERFORMANCE

INC

50

West

Street

Road

Warminnl

r

PennsylvlInlll18974

In

tha

ellenl

you

have

any

questions

rning

IInd

of

the

product

rning

pleese

write

Customer

Satisfaction

Depertment

lit

above

addreu

How

To

Get

Quick

Service

1

Peck

your

Hunt

product

r

nrefully

good

IriOn

with

plenty

of

newspape

s

u

celsior

padding

all

mund

it

and

till

lIly

Oamllge

transit

not

nv

red

by

the

warranty

2

Carefully

prinl

the

lrton

thlll

name

Ind

Iddrllu

01

Hurl

above

Don

t

forget

your

return

addreu

3

Put

I

tter

showing

desired

n

lIlope

addressed

HUrl

above

In

your

lettllr

plellSe

be

to

give

full

formation

such

date

and

place

of

purchase

your

full

name

IInd

address

and

the

reptllrS

d

sired

4

PASTE

ENVELOPE

TO

PACKAGE

S

Put

First

CIBst

stamp

nvelope

IInd

Parcel

Pall

stamps

package

then

mail

The

Post

Office

will

tell

yOU

the

proper

amount

of

postage

and

against

Iou

the

mDils

z

it

l

l

III

0

1168

a

o

o

i

g

I

o

0

DO

o

0

I

t

i

lL

5

I

0

q

II

1

I

if

18

0

l

q

t

tJ

w

j

b

00000

i

I

a

1

I

S

z

I

i

o

i

i

I

c

q

3

10

w

ol

8

q

1

5

lj

I

u

i

i

i

@

z

i

i

tii

I

f

8

ts

I

5

i

a

s

fl

00000000000000

C

a

0

u

Z

o

a

ti

a

w

a

u

J

C

o

a

lIt

c

l

l

c

l

J

Ci

I

J

I

I

a

1111

i

Z

iRI

1

Ii

iD

i

8

1

I

1I

o

0

1

o

011

Dl

DI

oj

o

Page 11 of 513

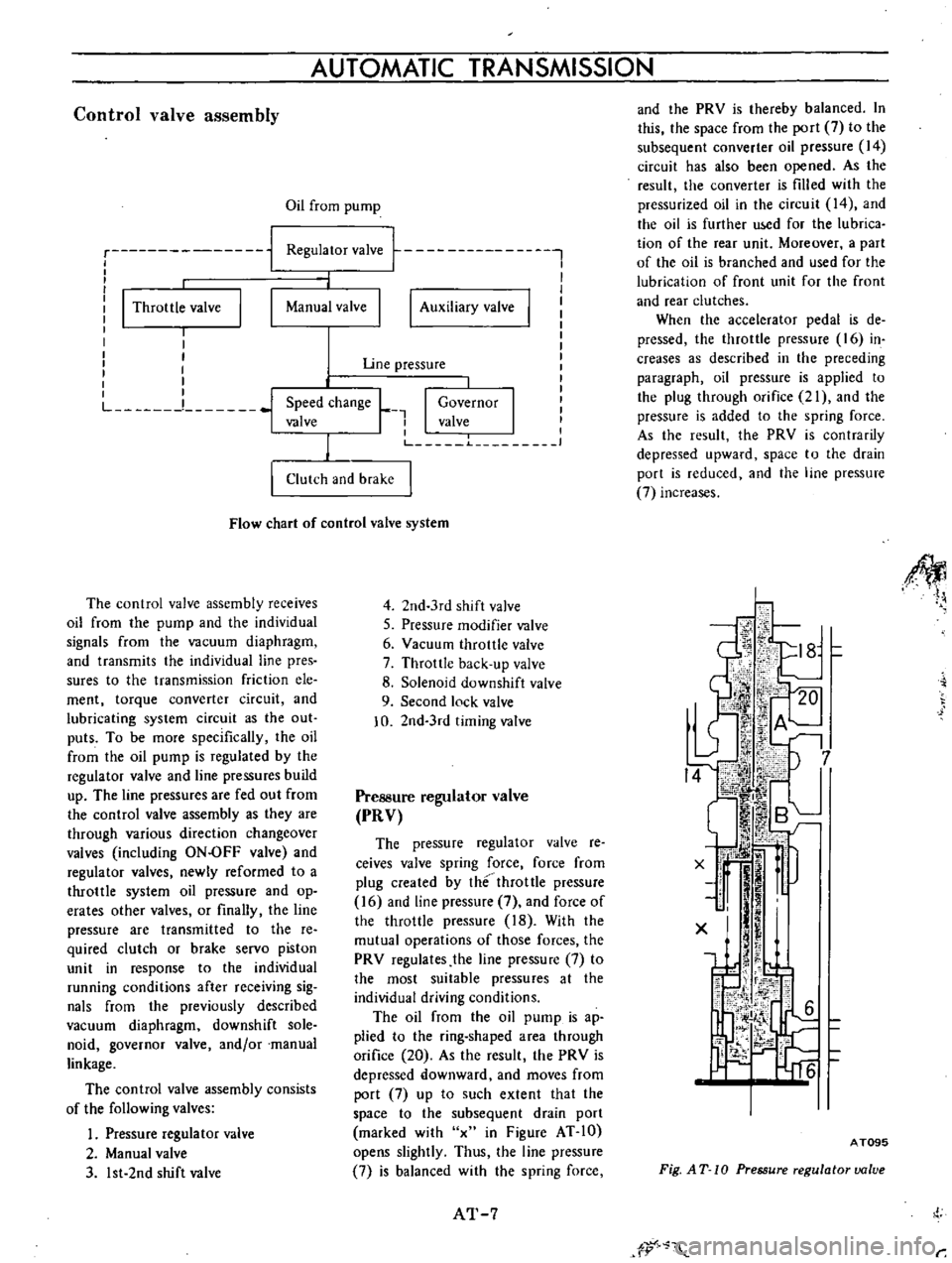

Control

valve

assembly

AUTOMATIC

TRANSMISSION

Oil

from

pump

ru

nn

i

I

I

I

Throttle

valve

I

I

1

m

nn

I

Auxiliary

valve

I

Regulator

valve

j

Manual

valve

I

Uoe

pressure

Speed

change

L

I

Governor

valve

I

I

valve

J

1

1

Clutch

and

brake

Flow

chart

of

control

valve

system

The

control

valve

assembly

receives

oil

from

the

pump

and

the

individual

signals

from

the

vacuum

diaphragm

and

transmits

the

individual

line

pres

sures

to

the

transmission

friction

ele

ment

torque

converter

circuit

and

lubricating

system

circuit

as

the

out

puts

To

be

more

specifically

the

oil

from

the

oil

pump

is

regulated

by

the

regulator

valve

and

line

pressures

build

up

The

line

pressures

are

fed

out

from

the

control

valve

assembly

as

they

are

through

various

direction

changeover

valves

including

ON

OFF

valve

and

regulator

valves

newly

reformed

to

a

throttle

system

oil

pressure

and

op

crates

other

valves

or

finally

the

line

pressure

are

transmitted

to

the

re

quired

clutch

or

brake

servo

piston

unit

in

response

to

the

individual

running

conditions

after

receiving

sig

nals

from

the

previously

described

vacuum

diaphragm

downshift

sole

noid

governor

valve

and

or

manual

linkage

The

control

valve

assembly

consists

of

the

following

valves

Pressure

regulator

valve

2

Manual

valve

3

1st

2nd

shift

valve

4

2nd

3rd

shift

valve

S

Pressure

modifier

valve

6

Yacuum

throttle

valve

7

Throttle

back

up

valve

8

Solenoid

downshift

valve

9

Second

lock

valve

0

2nd

3rd

timing

valve

Pressure

regulator

valve

PRV

The

pressure

regulator

valve

re

ceives

valve

spring

force

force

from

plug

created

by

the

throttle

pressure

16

and

line

pressure

7

and

force

of

the

throttle

pressure

18

With

the

mutual

operations

of

those

forces

the

PRY

regulates

the

line

pressure

7

to

the

most

suitable

pressures

at

the

individual

driving

conditions

The

oil

from

the

oil

pump

is

ap

plied

to

the

ring

shaped

area

through

orifice

20

As

the

result

the

PRY

is

depressed

downward

and

moves

from

port

7

up

to

such

extent

that

the

space

to

the

subsequent

drain

port

marked

with

x

in

Figure

AT

10

opens

slightly

Thus

the

line

pressure

7

is

balanced

with

the

spring

force

AT

7

and

the

PRY

is

thereby

balanced

In

this

the

space

from

the

port

7

to

the

subsequent

converter

oil

pressure

14

circuit

has

also

been

opened

As

the

result

the

converter

is

filled

with

the

pressurized

oil

in

the

circuit

14

and

the

oil

is

further

u

d

for

the

Iubrica

tion

of

the

rear

unit

Moreover

a

part

of

the

oil

is

branched

and

used

for

the

lubrication

of

front

unit

for

the

front

and

rear

clutches

When

the

accelerator

pedal

is

de

pressed

the

throttle

pressure

16

in

creases

as

described

in

the

preceding

paragraph

oil

pressure

is

applied

to

the

plug

through

orifice

21

and

the

pressure

is

added

to

the

spring

force

As

the

result

the

PRY

is

contrarily

depressed

upward

space

to

the

drain

port

is

reduced

and

the

line

pressure

7

increases

Afl

II

Jwi

06

A

J

L

I

7

I

tf

Iij

BL

i

il

J

jti

r

x

r

1

J

I

l

I

X

6

C

l

o

ii

J

f

A

T09S

Fig

AT

10

Pressure

regulator

value

tr

r

Page 15 of 513

4

to

the

circuit

17

is

timely

closed

and

with

the

space

from

the

circuit

17

to

the

upper

drain

being

about

to

open

the

back

up

pressure

17

which

is

lower

than

the

line

pressure

4

by

the

pressure

loss

due

to

the

space

from

the

circuit

4

to

the

circuit

17

is

balanced

with

the

spring

force

Further

when

speed

is

shifted

from

2nd

to

Low

at

the

range

I

line

pressure

is

led

from

the

circuit

12

and

the

line

pressure

is

applied

upward

to

the

bottom

of

the

valve

through

the

valve

hole

Consequently

the

valve

is

depressed

upward

and

locked

As

the

result

the

space

from

the

line

pressure

4

to

the

back

up

pressure

17

is

closed

completely

and

the

back

up

pressure

17

is

drained

upward

AT101

Fig

AT

16

Throttle

back

up

valve

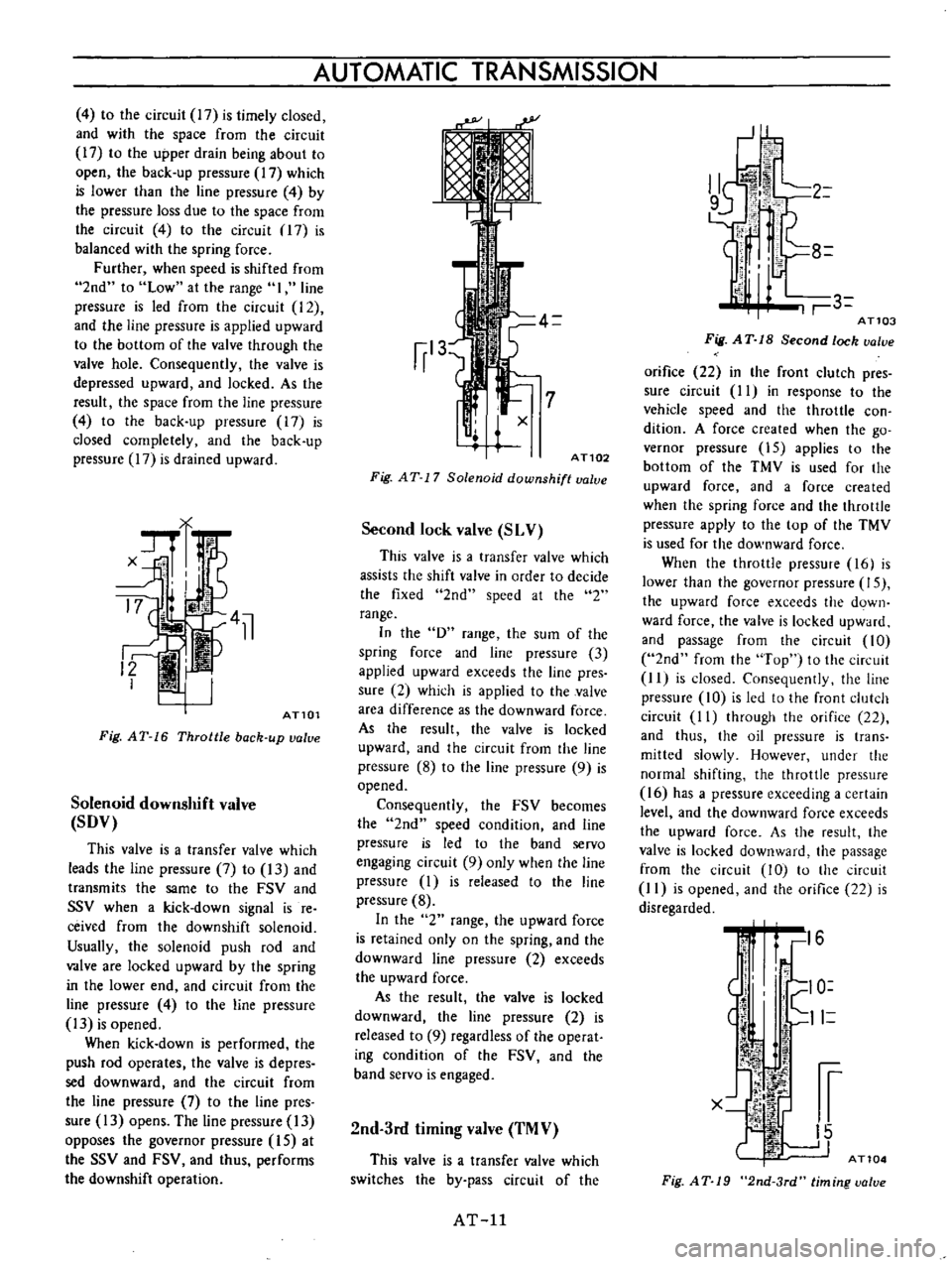

Solenoid

downshift

valve

SDV

This

valve

is

a

transfer

valve

which

leads

the

line

pressure

7

to

13

and

transmits

the

same

to

the

FSV

and

SSV

when

a

kick

down

signal

is

re

ceived

from

the

downshift

solenoid

Usually

the

solenoid

push

rod

and

valve

are

locked

upward

by

the

spring

in

the

lower

end

and

circuit

from

the

line

pressure

4

to

the

line

pressure

13

is

opened

When

kick

down

is

performed

the

push

rod

operates

the

valve

is

depres

sed

downward

and

the

circuit

from

the

line

pressure

7

to

the

line

pres

sure

13

opens

The

line

pressure

13

opposes

the

governor

pressure

15

at

the

SSV

and

FSV

and

thus

performs

the

downshift

operation

AUTOMATIC

TRANSMISSION

AT102

Fig

AT

17

Solenoid

downshift

value

Second

lock

valve

SLV

This

valve

is

a

transfer

valve

which

assists

the

shift

valve

in

order

to

decide

the

fixed

2nd

speed

at

the

2

range

In

the

D

range

the

sum

of

the

spring

force

and

line

pressure

3

applied

upward

exceeds

the

line

pres

sure

2

which

is

applied

to

the

valve

area

difference

as

the

downward

force

As

the

result

the

valve

is

locked

upward

and

the

circuit

from

the

line

pressure

8

to

the

line

pressure

9

is

opened

Consequently

the

FSV

becomes

the

2nd

speed

condition

and

line

pressure

is

led

to

the

band

servo

engaging

circuit

9

only

when

the

line

pressure

1

is

released

to

the

line

pressure

8

In

the

2

range

the

upward

force

is

retained

only

on

the

spring

and

the

downward

line

pressure

2

exceeds

the

upward

force

As

the

result

the

valve

is

locked

downward

the

line

pressure

2

is

released

to

9

regardless

of

the

operat

ing

condition

of

the

FSV

and

the

band

servo

is

engaged

2nd

3rd

timing

valve

TMV

This

valve

is

a

transfer

valve

which

switches

the

by

pass

circuit

of

the

AT

ll

J

2

3

ATl03

Fig

A

T

18

Second

lock

ualue

orifice

22

in

the

front

clutch

pres

sure

circuit

II

in

response

to

the

vehicle

speed

and

the

throttle

con

dition

A

force

created

when

the

go

vernor

pressure

15

applies

to

the

bottom

of

the

TMV

is

used

for

the

upward

force

and

a

force

created

when

the

spring

force

and

the

throttle

pressure

apply

to

the

top

of

the

TMV

is

used

for

the

downward

force

When

the

throttle

pressure

16

is

lower

than

the

governor

pressure

15

the

upward

force

exceeds

the

down

ward

force

the

valve

is

locked

upward

and

passage

from

the

circuit

10

2nd

from

the

Top

to

the

circuit

II

is

closed

Consequently

the

line

pressure

10

is

led

to

the

front

clutch

circuit

1

I

through

the

orifice

22

and

thus

the

oil

pressure

is

trans

mitted

slowly

However

under

the

normal

shifting

the

throttle

pressure

16

has

a

pressure

exceeding

a

certain

level

and

the

downward

force

exceeds

the

upward

force

As

the

result

the

valve

is

locked

downward

the

passage

from

the

circuit

10

to

the

circuit

1

I

is

opened

and

the

orifice

22

is

disregarded

1

i

16

I

O

11

l1

1

r

X

lp

I

15

J

AT104

Fig

AT

19

2nd

3rd

timing

ualue

Page 45 of 513

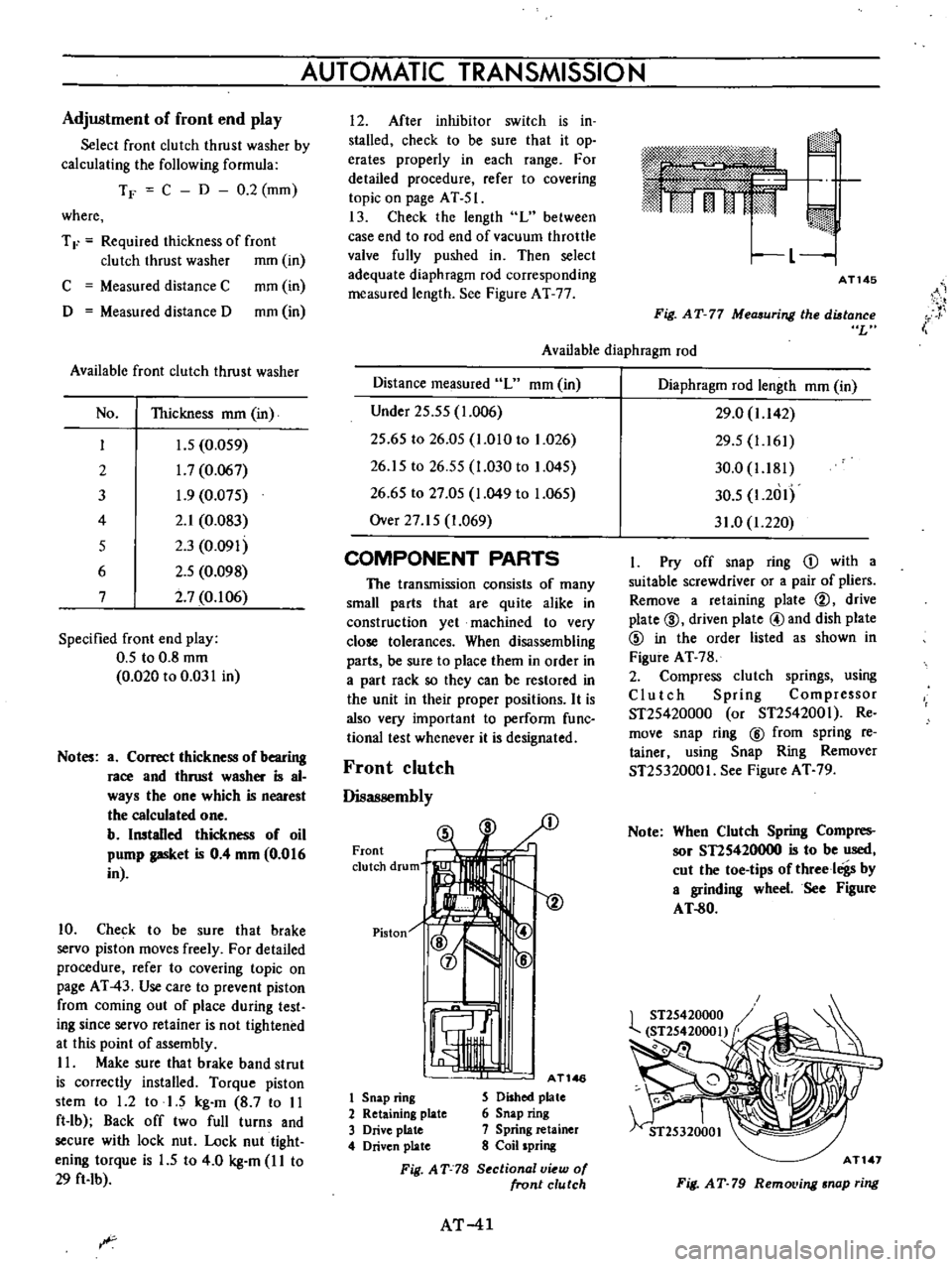

Adjustment

of

front

end

play

Select

front

clutch

thrust

washer

by

calculating

the

following

formula

TF

C

D

0

2

mm

where

T

F

Required

thickness

of

front

clutch

thrust

washer

mm

in

C

Measured

distance

C

mm

in

D

Measured

distance

D

mm

in

Available

front

clutch

thrust

washer

No

Thickness

mm

in

I

J

5

0

059

2

1

7

0

067

3

1

9

0

075

4

2

1

0

083

5

2

3

0

091

6

2

5

0

098

7

2

7

0

106

Specified

front

end

play

0

5

to

0

8

mm

0

020

to

0

031

in

Notes

a

Correct

thickness

of

bearing

race

and

thrust

washer

is

al

ways

the

one

which

is

nearest

the

calculated

one

b

Installed

thickness

of

oil

pump

gasket

is

0

4

mm

0

016

in

10

Check

to

be

sure

that

brake

servo

piston

moves

freely

For

detailed

procedure

refer

to

covering

topic

on

page

AT

43

Use

care

to

prevent

piston

from

coming

out

of

place

during

test

ing

since

servo

retainer

is

not

tightened

at

this

point

of

assembly

II

Make

sure

that

brake

band

strut

is

correctly

installed

Torque

piston

stem

to

1

2

to

1

5

kg

m

8

7

to

II

ft

lb

Back

off

two

full

turns

and

secure

with

lock

nut

Lock

nut

tight

ening

torque

is

1

5

to

4

0

kg

m

I

I

to

29

ft

Ib

AUTOMATIC

TRANSMISSION

I

2

After

inhibitor

switch

is

in

stalled

check

to

be

sure

that

it

op

erates

properly

in

each

range

For

detailed

procedure

refer

to

covering

topic

on

page

AT

51

13

Check

the

length

L

between

case

end

to

rod

end

of

vacuum

throttle

valve

fully

pushed

in

Then

select

adequate

diaphragm

rod

corresponding

measured

length

See

Figure

AT

77

m

rj

I

L

1

AT145

i

Fig

AT

77

Measuring

the

distance

L

Available

diaphragm

rod

Distance

measured

L

mm

in

Under

25

55

1

006

25

65

to

26

05

1

010

to

1

026

26

15

to

26

55

1

030

to

1

045

26

65

to

27

05

1

049

to

1

065

Over

27

15

1

069

COMPONENT

PARTS

The

transmission

consists

of

many

small

parts

that

are

quite

alike

in

construction

yet

machined

to

very

close

tolerances

When

disassembling

parts

be

sure

to

place

them

in

order

in

a

part

rack

so

they

can

be

restored

in

the

unit

in

their

proper

positions

It

is

also

very

important

to

perform

func

tional

test

whenever

it

is

designated

Front

clutch

Disassembly

Front

clutch

drum

Piston

1

AT146

1

Snap

ring

S

Dished

plate

2

Retaining

plate

6

Snap

ring

3

Drive

plate

7

Spring

retainer

4

Driven

plate

8

Coil

spring

Fig

AT

78

S

ctional

v

w

of

front

clutch

AT

41

Diaphragm

rod

length

mm

in

29

0

1

142

29

5

1

161

30

0

1

181

30

5

1

2

1I

31

0

1

220

I

Pry

off

snap

ring

D

with

a

suitable

screwdriver

or

a

pair

of

pliers

Remove

a

retaining

plate

@

drive

plate

@

driven

plate

@and

dish

plate

@

in

the

order

listed

as

shown

in

Figure

AT

78

2

Compress

clutch

springs

using

Clutch

Spring

Compressor

ST25420000

or

ST2542001

Re

move

snap

ring

@

from

spring

re

tainer

using

Snap

Ring

Remover

ST25320001

See

Figure

AT

79

Note

When

Clutch

Spring

Compres

sor

STIS420000

is

to

be

used

cut

the

toe

tips

of

threeloigs

by

a

grinding

wheel

See

Figure

AT

80

AT

1

Fig

AT

79

RemoL

ing

snap

ring

Page 55 of 513

c

Inspection

and

adJu

Stmenf

trouble

first

check

the

linhge

f

no

1

i

jI

fect

is

found

in

the

lin1

age

check

of

manu

a

l

liiiJ

i

the

inhibitor

switch

Th

d

1F

aI

S

t

th

I

I

f

e

a

JU

i

J

u

epara

e

e

range

se

eet

ever

rom

Iy

important

ii

s3

ns

etion

of

oil

the

lower

shift

rod

and

turn

the

range

1

level

for

the

automatiC

tran

smission

select

lever

to

N

Therefore

great

care

should

be

exer

Note

In

the

position

N

the

slot

of

cised

because

defective

adjustment

will

the

manual

shaft

is

vertical

result

in

the

breakdown

of

the

trans

By

the

use

of

the

tester

check

the

two

bIack

yellow

BY

wires

from

the

inhibitor

switch

in

the

ranges

N

and

P

and

the

two

red

bIack

RB

wires

in

the

range

R

for

continuity

Turn

range

select

lever

to

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

3

0

on

both

sides

from

each

lever

set

line

How

ever

if

its

continuity

range

is

obvi

ously

unequal

on

both

sides

the

adjustment

is

required

f

any

malfunction

is

found

un

screw

the

fastening

nut

of

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

ly

to

the

position

N

by

means

of

the

selector

lever

When

the

slot

of

the

shaft

becomes

vertical

the

detent

works

to

position

the

shaft

correctly

with

a

click

sound

Move

the

switch

slightly

aside

so

that

the

screw

hole

will

be

aligned

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

0101

0

0591

in

diameter

pin

into

the

holes

If

the

alignment

is

made

correct

1

5ten

the

switch

body

with

the

bolts

pull

out

the

pin

and

tighten

up

the

screw

again

into

the

hole

and

fasten

the

selector

lever

as

before

Check

over

again

the

continuity

with

the

tester

If

the

malfunction

still

remains

replace

the

inhibitor

switch

mission

Inspection

Pull

the

selector

lever

toward

you

and

turn

it

so

far

as

p

to

1

range

where

clicks

will

be

felt

by

hand

This

is

the

detent

of

manual

valve

in

the

body

and

indicates

the

correct

posi

tion

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

tion

plate

when

it

is

released

Adjustment

This

procedure

can

be

accom

plished

by

referring

to

Removal

and

nstallation

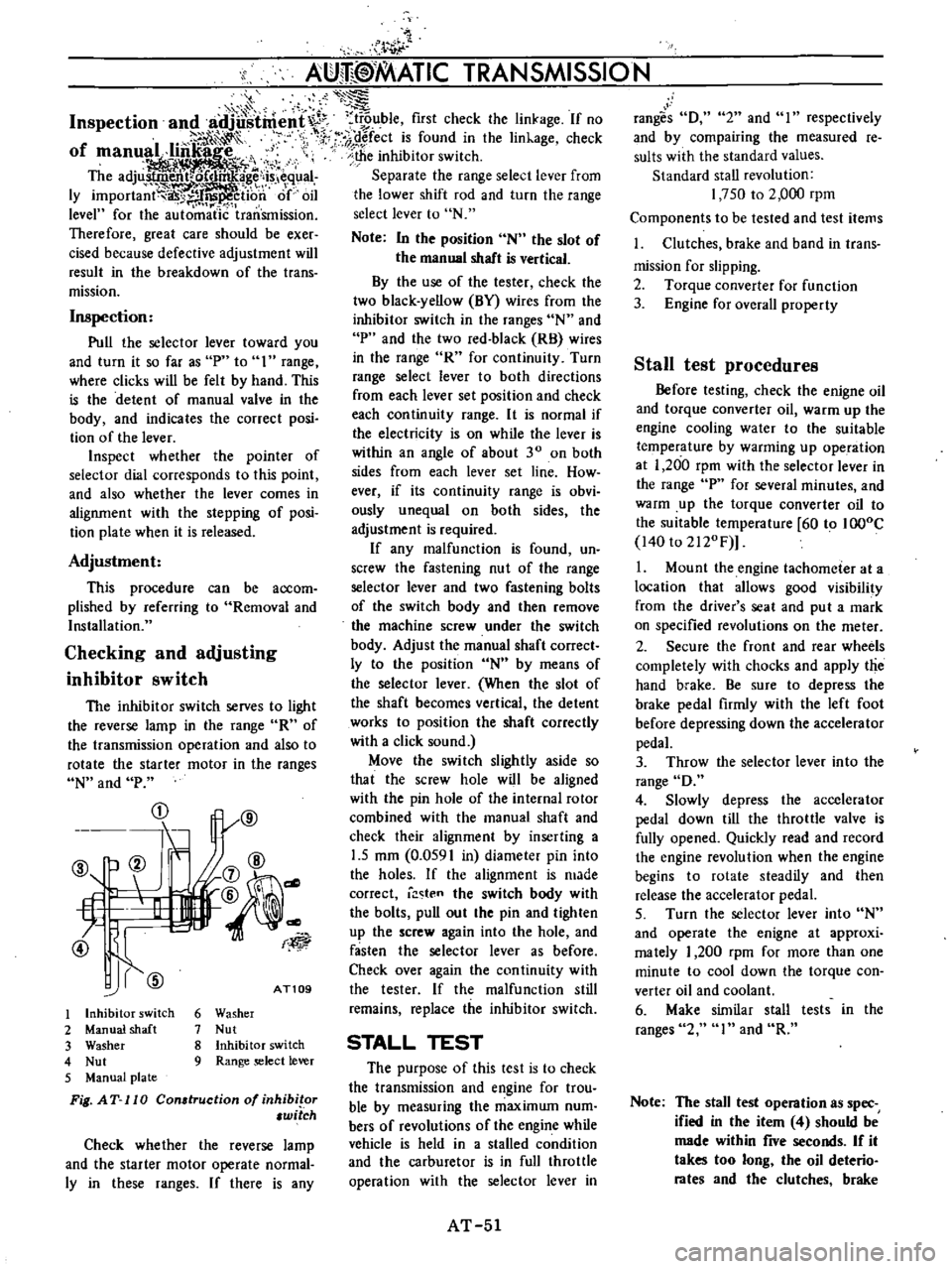

Checking

and

adjusting

inhibitor

switch

The

inhibitor

switch

serves

to

light

the

reverse

lamp

in

the

range

R

of

the

transmission

operation

and

also

to

rotate

the

starter

motor

in

the

ranges

N

and

P

j

r@

I

If

r

f

B

@

I

Jt

@

@

c

v@

i

r

fji

AT109

1

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fig

AT

II

0

Con

truction

of

inhibitor

witch

6

Washer

7

Nut

8

Inhibitor

switch

9

Range

select

lever

Check

whether

the

reverse

lamp

and

the

starter

motor

operate

normal

ly

in

these

ranges

If

there

is

any

t

ki

A

mm

ATIC

TRANSMISSION

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximwn

num

bers

of

revolutions

of

the

engine

while

vehicle

is

held

in

a

stalled

condition

and

the

carburetor

is

in

full

throttle

operation

with

the

selector

lever

in

AT

51

rang

s

D

2

and

I

respectively

and

by

com

pairing

the

measured

re

sults

with

the

standard

values

Standard

stall

revolution

1

750

to

2

000

rpm

Components

to

be

tested

and

test

items

1

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

function

3

Engine

for

overall

property

Stall

test

procedures

Before

testing

check

the

enigne

oil

and

torque

converter

oil

warm

up

the

engine

cooling

water

to

the

suitable

temperature

by

warming

up

ope

ration

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

several

minutes

and

warm

up

the

torque

converter

oil

to

the

suitable

temperature

60

to

IOOoC

140

to

2120F

1

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

from

the

driver

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

completely

with

chocks

and

apply

the

hand

brake

Be

sure

to

depress

the

brake

pedal

firmly

with

the

left

foot

before

depressing

down

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

D

4

Slowly

depress

the

accelerator

pedal

down

till

the

throttle

valve

is

fully

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Turn

the

selector

lever

into

N

and

operate

the

enigne

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

verter

oil

and

coolant

6

Make

similar

stall

tests

in

the

ranges

2

I

and

R

Note

The

stall

test

operation

as

spec

ified

in

the

item

4

should

be

made

within

five

seconds

If

it

takes

too

long

the

oil

deterio

rates

and

the

clutches

brake

Page 56 of 513

and

band

are

adversely

af

fected

Sufficient

cooling

time

should

be

given

between

each

test

for

the

four

ranges

0

2

I

and

R

Judgement

I

High

stall

revolution

more

than

standard

revolution

If

the

engine

revolution

in

staU

condition

is

higher

than

the

standard

values

it

indicates

that

one

or

more

clutches

in

the

transmission

are

slip

ping

and

therefore

nO

further

test

is

required

For

the

following

abnormalities

the

respective

causes

3re

presumed

High

rpm

in

all

ranges

Low

line

pre

ure

High

rpm

in

D

2

and

I

and

normal

rpm

in

R

Rear

clutch

slipping

High

pm

in

D

and

2

and

normal

rpm

in

lOne

way

clutch

slipping

High

rpm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

either

front

clutch

or

low

and

reverse

brake

a

road

test

is

needed

If

while

coasting

after

starting

with

the

lever

in

I

range

engine

braking

does

not

work

properly

it

is

deter

mined

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

The

slipping

of

the

band

brake

is

difficult

to

ascertain

However

if

it

occurs

with

the

lever

in

2

range

the

enigne

revolution

increases

up

to

the

same

level

as

in

1st

speed

and

therefore

it

can

be

found

out

by

careful

observation

It

is

impossible

to

check

it

in

the

stall

test

Z

Standard

stall

revolution

If

the

enigne

revolution

in

stall

condition

is

within

the

standard

values

the

control

elements

are

nor

mally

operating

in

the

ranges

0

2

I

and

R

Also

the

engine

and

one

way

clutch

of

the

torque

converter

are

normal

in

perfonnance

and

operation

The

one

way

clutch

of

the

torque

Gear

shift

Propeller

shaft

rpm

D

D

1

840

to

2

340

D

DJ

3

340

to

3

840

DJ

D

3

460

to

2

960

D

0

1

790

to

1

290

D

D

330

to

830

D

OJ

l

720

to

2

220

DJ

D2

or

1

350

to

850

DJ

D

D

0

700

Max

I

I

1

860

to

1

360

CHASSIS

converter

however

sometimes

sticks

This

should

be

determined

in

the

road

test

3

Low

stall

revolution

less

than

standard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

values

it

indicates

that

the

engine

is

in

abnormal

condition

or

the

torque

con

verter

s

one

way

clutch

is

slipping

4

Other

I

If

the

accelerating

performance

is

poor

until

vehicle

speed

of

approxi

mately

50

km

h

30

MPH

is

attained

and

then

normal

beyond

that

speed

it

can

be

judged

that

the

torque

con

verter

s

one

way

dutch

is

slipping

2

If

the

torque

converter

s

one

way

clutch

sticks

vehicle

speed

can

not

exceed

approximately

80

km

h

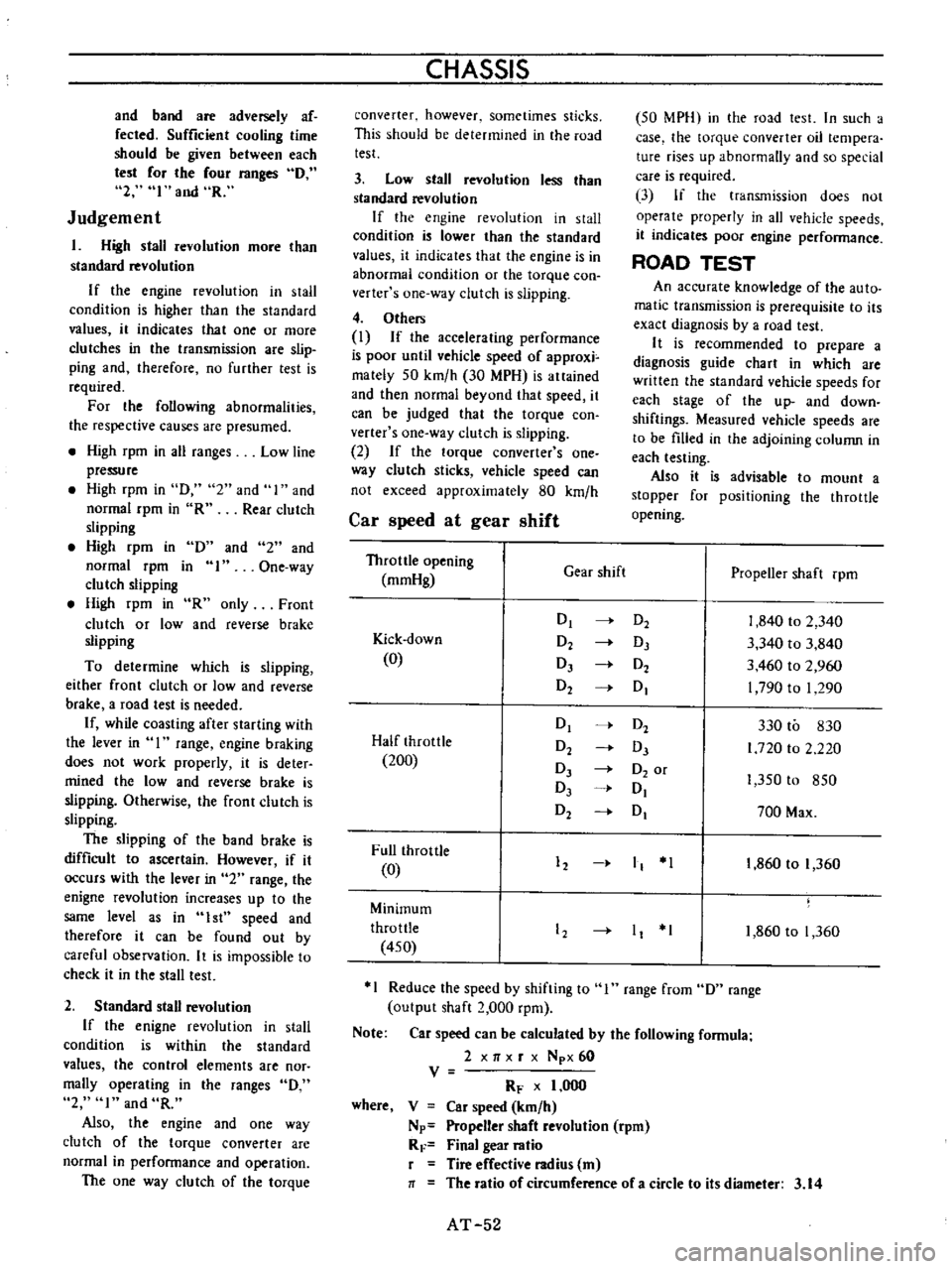

Car

speed

at

gear

shift

Throttle

opening

mmHg

Kick

down

0

Half

throttle

200

Full

throttle

0

Minimum

throttle

450

I

50

MPH

in

the

road

test

In

such

a

case

the

torque

converter

oH

tempera

ture

rises

up

abnormally

and

s

o

s

pecial

care

is

required

13

If

the

transmission

does

not

operate

properly

in

all

vehicle

speeds

it

indicates

poor

engine

perfonnance

ROAD

TEST

An

accurate

knowledge

of

the

auto

matic

transmission

is

prerequisite

to

its

exact

diagnosis

by

a

road

test

It

is

recommended

to

prepare

a

diagnosis

guide

chart

in

which

are

written

the

standard

vehicle

speeds

for

each

stage

of

the

up

and

down

shiftings

Measured

vehicle

speeds

are

to

be

filled

in

the

adjoining

column

in

each

testing

Also

it

is

advisable

to

mount

a

stopper

for

positioning

the

throttle

opening

I

I

1

860

to

1

360

I

Reduce

the

speed

by

shifting

to

range

from

D

range

output

shaft

2

000

rpm

Note

Car

speed

can

be

calculated

by

the

following

fonnula

2

x

7r

x

r

x

Npx

60

v

RF

X

1

000

where

V

Car

speed

km

h

Np

Propeller

shaft

revolution

rpm

RF

Final

gear

ratio

r

Tire

effective

radius

m

11

The

ratio

of

circumference

of

a

circle

to

its

diameter

3

14

AT

52

Page 57 of 513

Checking

speed

changing

condition

The

driver

s

feeling

during

gear

changes

should

also

be

checked

at

tentively

1

A

sharp

shock

or

unsmoothness

are

felt

during

a

gear

change

2

A

gear

change

is

made

with

a

long

and

dragging

feeling

These

indicate

that

the

throttle

pressure

is

too

low

or

some

valve

connected

to

the

throttle

is

defective

Checking

items

during

speed

change

1

In

D

range

gear

changes

DI

o

D2

D3

are

effected

In

R

range

the

speed

does

not

increase

2

The

kick

down

operates

properly

3

By

moving

the

lever

from

D

into

I

gear

changes

D3

2

12

II

are

effected

In

the

ranges

12

and

II

the

engine

braking

works

properly

4

In

the

speed

does

not

in

crease

5

Should

be

quickly

fixed

at

2

range

6

In

P

vehicle

can

be

parked

properly

If

any

malfunction

occurs

in

the

second

gear

during

the

road

test

that

is

if

vehicle

shakes

drags

or

sling

in

shifting

up

from

DI

directly

to

D3

or

in

shifting

up

from

D

to

W

I

r

I

1

1

I

2

31

I

I

I

I

I

t

Lh

I

I

I

I

1000

lsOo

2000

2500

Output

shaft

speed

rpm

AUTOMATIC

TRANSMISSION

D2

the

brake

band

should

be

ad

justed

If

these

troubles

remain

after

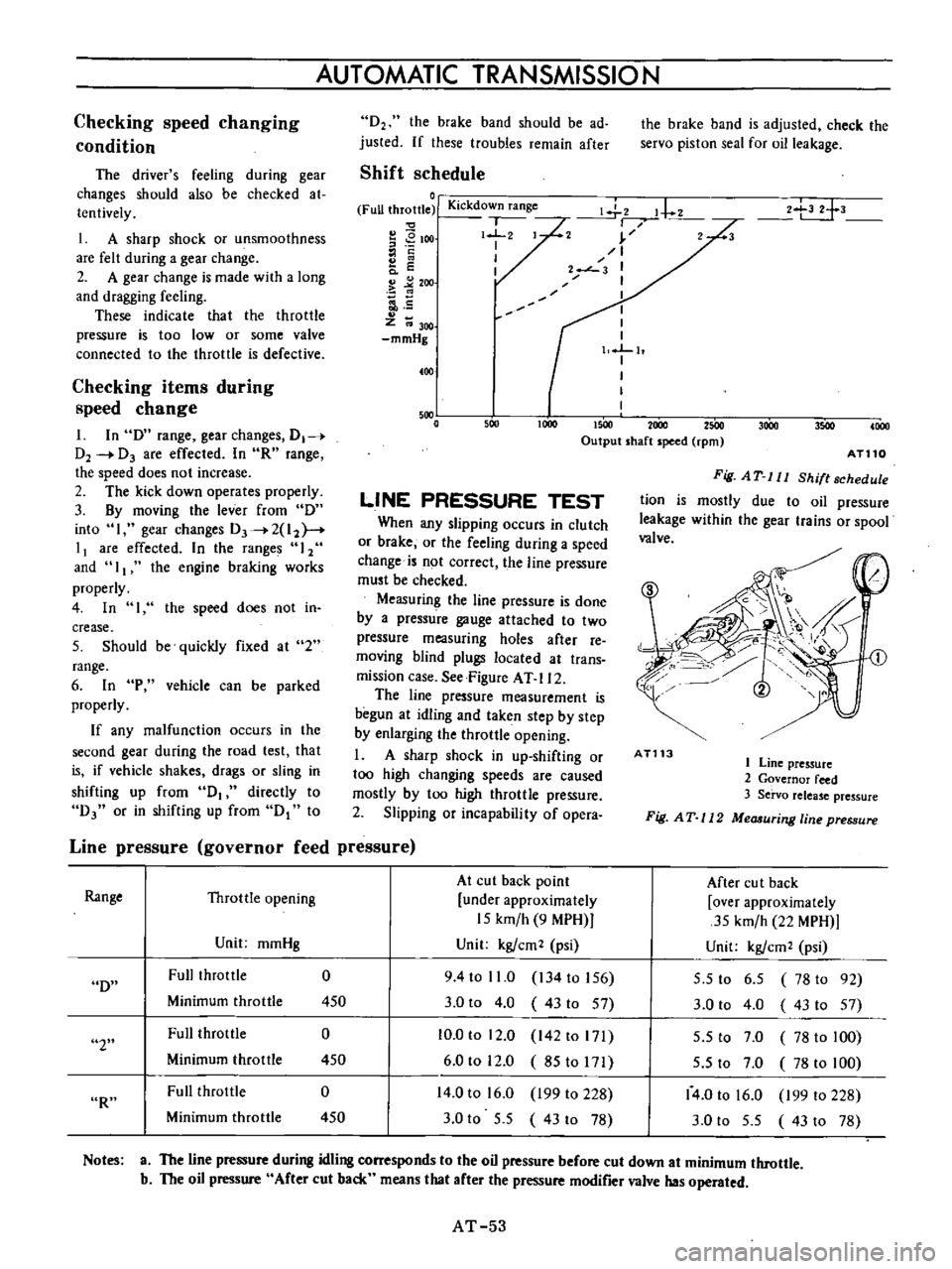

Shift

schedule

o

Full

throttlell

e

2100

E

E

200

is

Z

cu

300

mmHg

soo

o

soo

LINE

PRESSURE

TEST

When

any

slipping

occurs

in

clutch

or

brake

or

the

feeling

during

a

speed

change

is

not

correct

the

line

pressure

must

be

checked

Measuring

the

line

pressure

is

done

by

a

pressu

re

gauge

attached

to

two

pressure

measuring

holes

after

re

moving

blind

plugs

located

at

trans

mission

case

See

Figure

AT

112

The

line

pressure

measurement

is

begun

at

idling

and

taken

step

by

step

by

enlarging

the

throttle

opening

1

A

sharp

shock

in

up

shifting

or

too

high

changing

speeds

are

caused

mostly

by

too

high

throttle

pressure

2

Slipping

or

incapability

of

opera

Line

pressure

governor

feed

pressure

At

cut

back

point

After

cut

back

Throttle

opening

under

approximately

over

approximately

15

kmfh

9

MPH

35

kmfh

22

MPH

Unit

mmHg

Unit

kg

cm2

psi

Unit

kg

cm2

psi

Full

throttle

0

94

to

11

0

134

to

156

5

5

to

6

5

78

to

92

Minimum

throttle

450

3

0

to

4

0

43

to

57

3

0

to

4

0

43

to

57

Full

throttle

0

10

0

to

12

0

142

to

171

5

5

to

7

0

78

to

100

Minimum

throttle

450

6

0

to

12

0

85toI71

5

5

to

7

0

78

to

100

Full

throttle

0

14

0

to

16

0

199

to

228

14

0

to

16

0

199

to

228

Minimum

throttle

450

3

0

to

5

5

4310

78

3

0

to

5

5

43

to

78

Range

D

2

R

the

brake

band

is

adjusted

check

the

servo

piston

seal

for

oil

leakage

3

30ixI

3500

000

AT110

Fig

A

T

llI

Shift

schedule

tion

is

mostly

due

to

oil

pressure

leakage

within

the

gear

trains

or

spool

valve

AT113

I

Line

pressure

2

Governor

reed

3

Servo

release

pressure

Fig

A

T

112

MeCJ8uring

line

pressure

Notes

a

The

line

pressure

during

idling

corresponds

to

the

oil

pressure

before

cut

down

at

minimum

throttle

b

The

oil

pressure

After

cut

back

means

that

after

the

pressure

modifier

valve

has

operated

AT

53