ABS DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 191 of 513

BODY

GENERAL

DESCRIPTION

CONTENTS

DESCRIPTION

BF

1

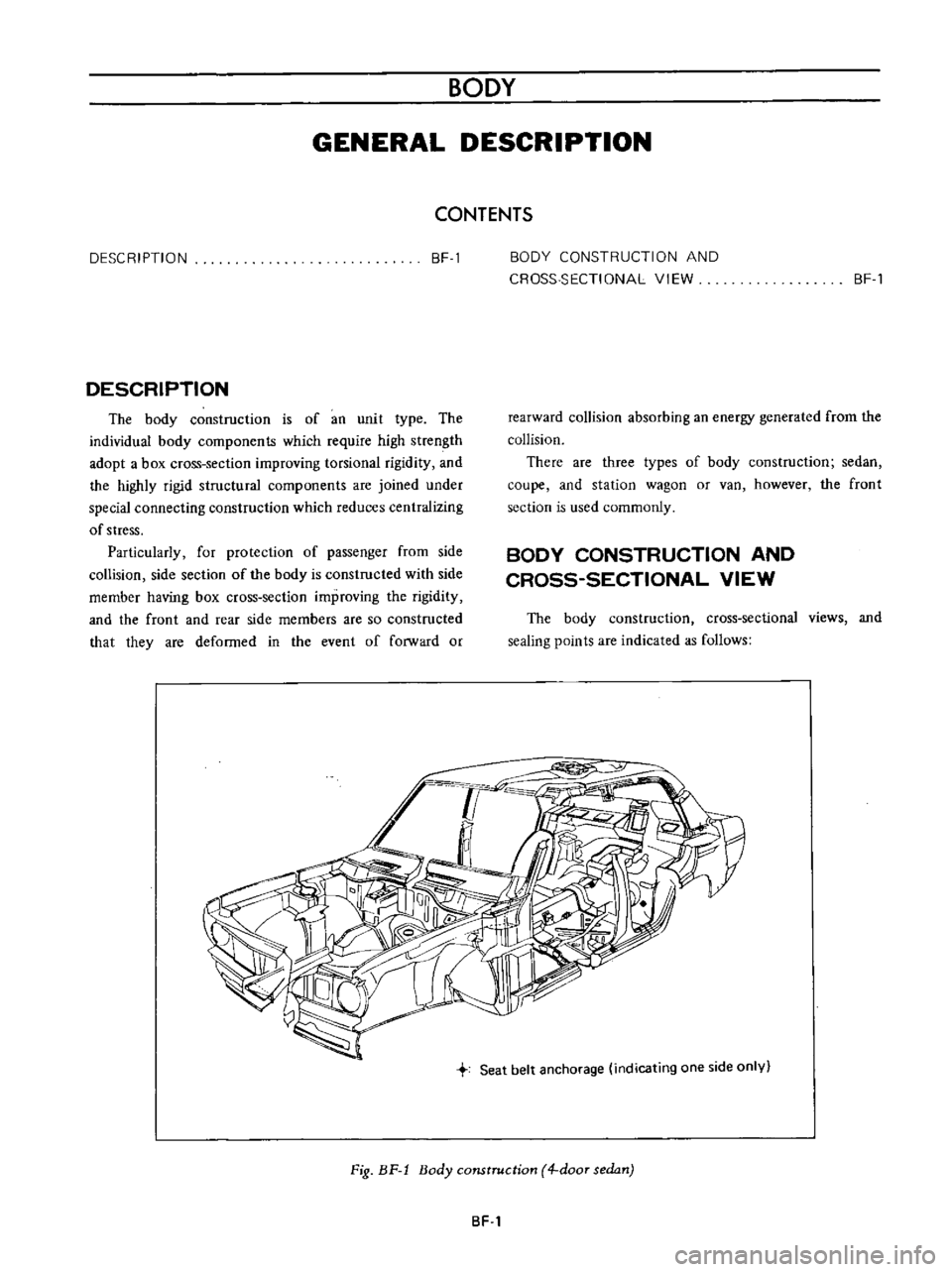

DESCRIPTION

The

body

construction

is

of

an

unit

type

The

individual

body

components

which

require

high

strength

adopt

a

box

cross

section

improving

torsional

rigidity

and

the

highly

rigid

structural

components

are

joined

under

special

connecting

construction

which

reduces

centralizing

of

stress

Particularly

for

protection

of

passenger

from

side

collision

side

section

of

the

body

is

constructed

with

side

member

having

box

cross

section

improving

the

rigidity

and

the

front

and

rear

side

members

are

so

constructed

that

they

are

deformed

in

the

event

of

forward

or

BODY

CONSTRUCTION

AND

CROSS

SECTIONAL

VIEW

BF

1

rearward

collision

absorbing

an

energy

generated

from

the

collision

There

are

three

types

of

body

construction

sedan

coupe

and

station

wagon

or

van

however

the

front

section

is

used

commonly

BODY

CONSTRUCTION

AND

CROSS

SECTIONAL

VIEW

The

body

construction

cross

sectional

views

and

sealing

points

are

indicated

as

follows

Seat

belt

anchorage

indicating

one

side

only

Fig

BF

1

Body

construction

4

door

sedan

BF

1

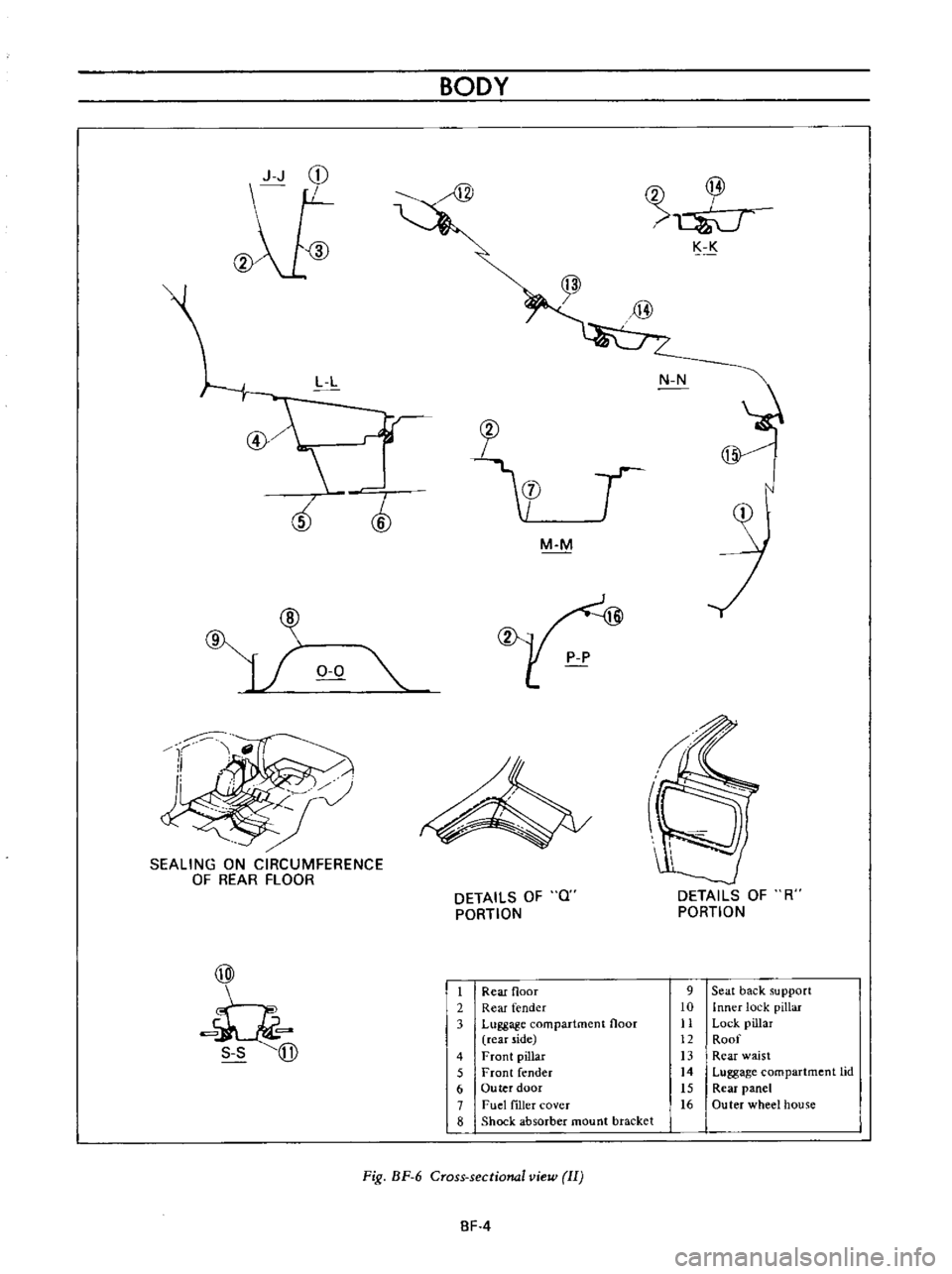

Page 194 of 513

J

J

CD

11

BODY

I

K

L

L

N

N

@

r

T

I

c

cb

I

cp

M

M

J

Ii

0

0

SEALING

ON

CIRCUMFERENCE

OF

REAR

FLOOR

@

Ii

DETAILS

OF

Q

PORTION

DETAILS

OF

R

PORTION

1

Rear

floor

2

Rear

fender

3

Luggage

compartment

floor

rear

side

4

Front

pillar

5

Front

fender

6

Ou

tee

door

7

Fue

filler

cover

8

Shock

absorber

mount

bracket

9

Seat

back

support

10

Inner

lock

pillar

11

Lock

pillar

12

Roof

13

Rear

waist

14

Luggage

compartment

lid

15

Rear

panel

16

Outer

wheel

house

Fig

BF

6

Cross

sectional

view

II

BF

4

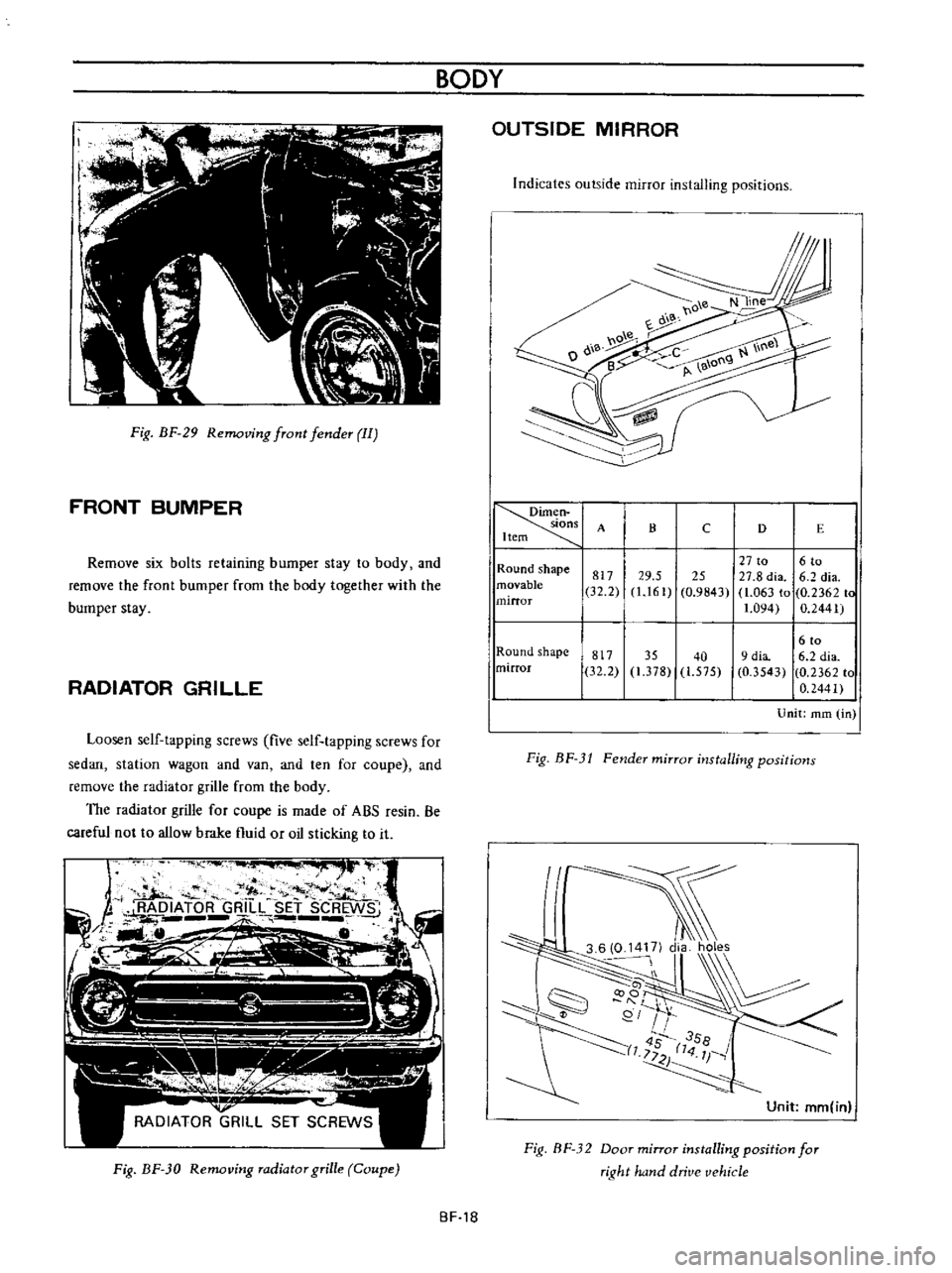

Page 208 of 513

BODY

Fig

BF

29

Removing

front

fender

II

FRONT

BUMPER

Remove

six

bolts

retaining

bumper

stay

to

body

and

remove

the

front

bumper

from

the

body

together

with

the

bumper

stay

RADIATOR

GRILLE

Loosen

self

tapping

screws

five

self

tapping

screws

for

sedan

station

wagon

and

van

and

ten

for

coupe

and

remove

the

radiator

grille

frorn

the

body

The

radiator

grille

for

coupe

is

made

of

ABS

resin

Be

careful

not

to

allow

brake

fluid

or

oil

slicking

to

it

7

7f

rl4

o

j

j

iiA

i

DIATIJR

GR

L

SEt

SC

8N

S

i

e

t

II

L

T

RADIATOR

GRill

SET

SCREWS

Fig

BF

30

Removing

radiator

grille

Coupe

OUTSIDE

MIRROR

Indicates

outside

mirror

installing

positions

liMA

t

o

e

O

I

I

Dimen

sIons

Item

A

B

c

D

E

27

to

6

to

Round

shape

817

29

5

25

27

8

dia

6

2

dia

movable

32

2

1

161

0

98431

1

063

to

0

2362

te

mirror

1

094

0

2441

6

to

Round

shape

817

35

40

9

dia

6

2

dia

mirror

32

2

1

378

l

575

0

3543

0

2362

to

0

2441

Unit

mm

in

Fig

BF

31

Fender

mirror

installing

positions

IW

36

l

71

Ta

h

Le

O

II

coo

c

l

2

f

4

5

358

17

77

74

7

Unit

mm

inl

Fig

RF

32

Door

mirror

installing

position

for

right

hand

drive

vehicle

SF

18

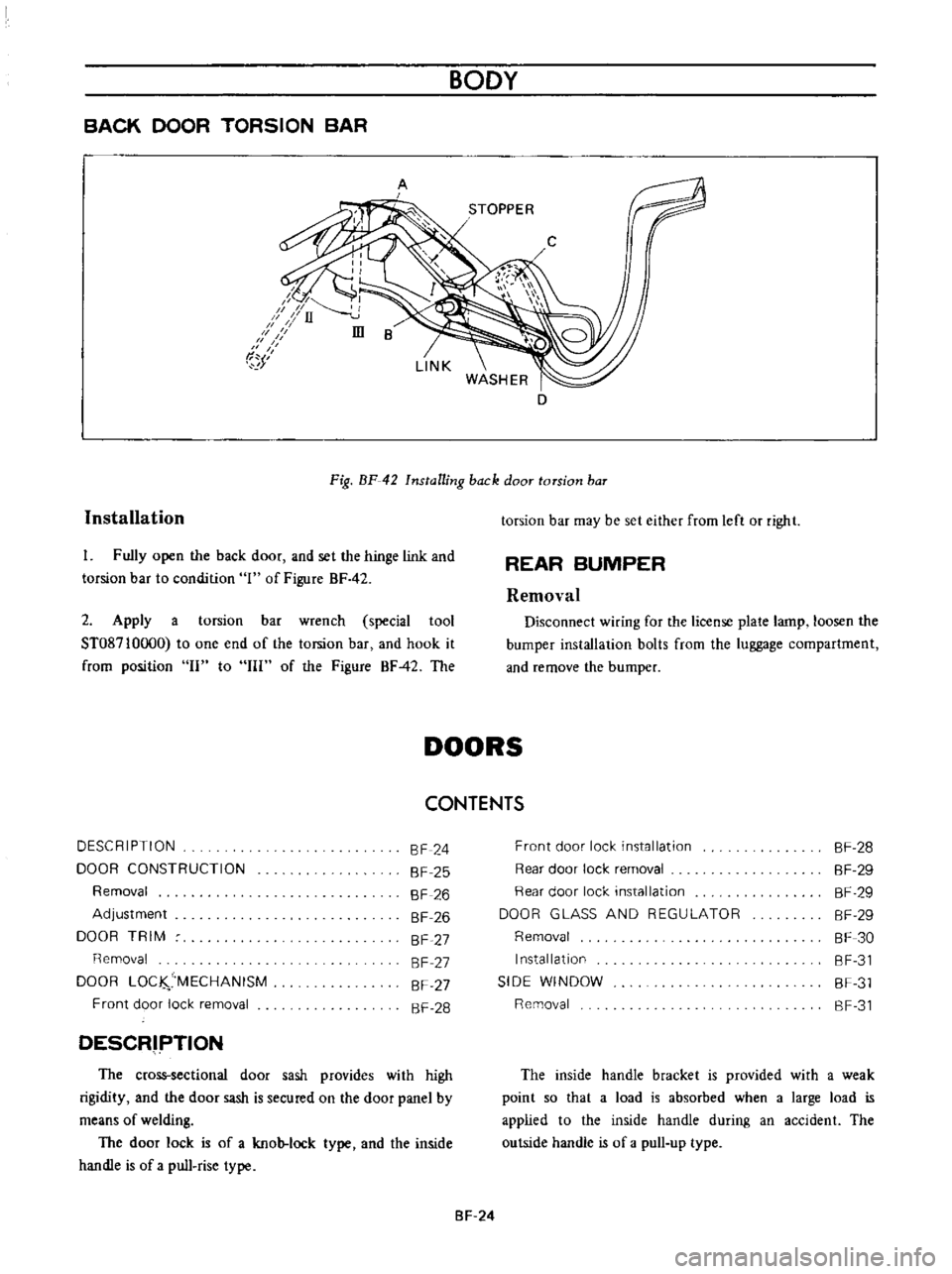

Page 214 of 513

BACK

DOOR

TORSION

BAR

BODY

A

D

Installation

Fig

BF

42

Installing

back

door

torsion

baT

I

Fully

open

the

back

door

and

set

the

hinge

link

and

torsion

bar

to

condition

1

of

Figure

BF

42

2

Apply

a

torsion

bar

wrench

special

tool

ST08710oo0

to

one

end

of

the

torsion

bar

and

hook

it

from

position

II

to

III

of

the

Figure

BF42

The

torsion

bar

may

be

set

either

from

left

or

right

REAR

BUMPER

Removal

Disconnect

wiring

for

the

license

plate

lamp

loosen

the

bumper

installation

bolts

from

the

luggage

compartment

and

remove

the

bumper

DOORS

CONTENTS

DESCRIPTION

DOOR

CONSTRUCTION

Removal

Adjustment

DOOR

TRIM

Removal

DOOR

LOC

MECHANISM

Front

door

lock

removal

SF

24

SF

25

SF

26

SF

26

SF

27

SF

27

SF

27

SF

28

DESCRIPTION

The

cross

sectional

door

sash

provides

with

high

rigidity

and

the

door

sash

is

secured

on

the

door

panel

by

means

of

welding

The

door

lock

is

of

a

knob

lock

type

and

the

inside

handle

is

of

a

pull

rise

type

Front

door

lock

installation

Rear

door

lock

removal

Rear

door

lock

installation

DOOR

GLASS

AND

REGULATOR

Removal

Installation

SIDE

WINDOW

Removal

SF

28

SF

29

SF

29

SF

29

SF

30

SF

31

SF

31

SF

31

The

inside

handle

bracket

is

provided

with

a

weak

point

so

that

a

load

is

absorbed

when

a

large

load

is

applied

to

the

inside

handle

during

an

accident

The

outside

handle

is

of

a

pull

up

type

SF

24

Page 223 of 513

BODY

REAR

WINDOW

ELECTRIC

DEFROSTER

Option

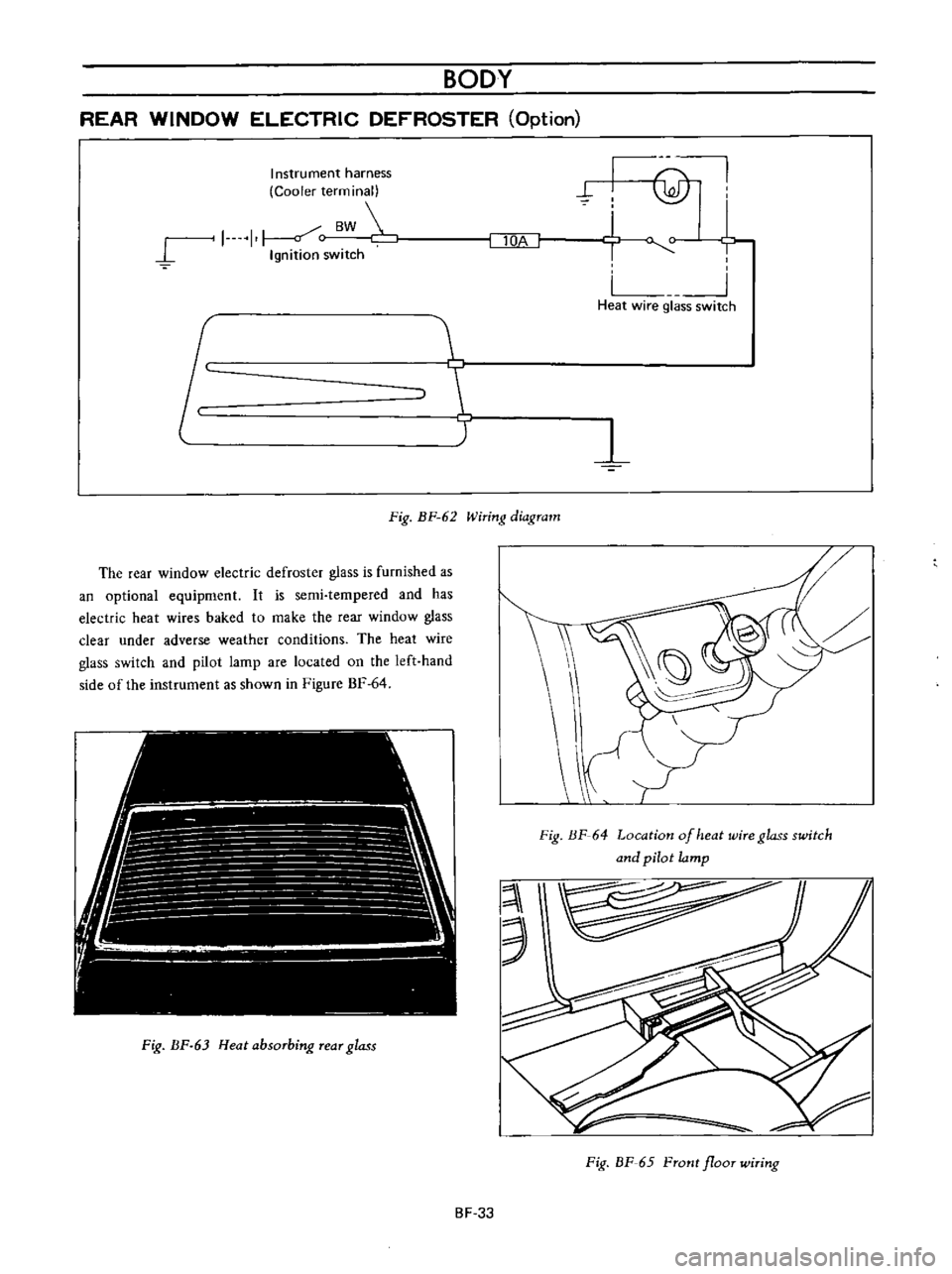

J

Instrument

harness

Cooler

terminal

J

1

1

c

BW

Ignition

switch

I

lOA

@

hi

u

Heat

wire

glass

switch

T

Fig

BF

62

Wiring

diagram

The

rear

window

electric

defroster

glass

is

furnished

as

an

optional

equipment

It

is

semi

tempered

and

has

electric

heat

wires

baked

to

make

the

rear

window

glass

clear

under

adverse

weather

conditions

The

heat

wire

glass

switch

and

pilot

larnp

are

located

on

the

left

hand

side

of

the

instrument

as

shown

in

Figure

BF

64

Fig

BF

63

Heat

absorbing

rear

glass

Fig

HF

64

Location

of

heat

wire

glass

switch

and

pilot

lamp

3

Fig

BF

65

Front

floor

wiring

BF

33

Page 224 of 513

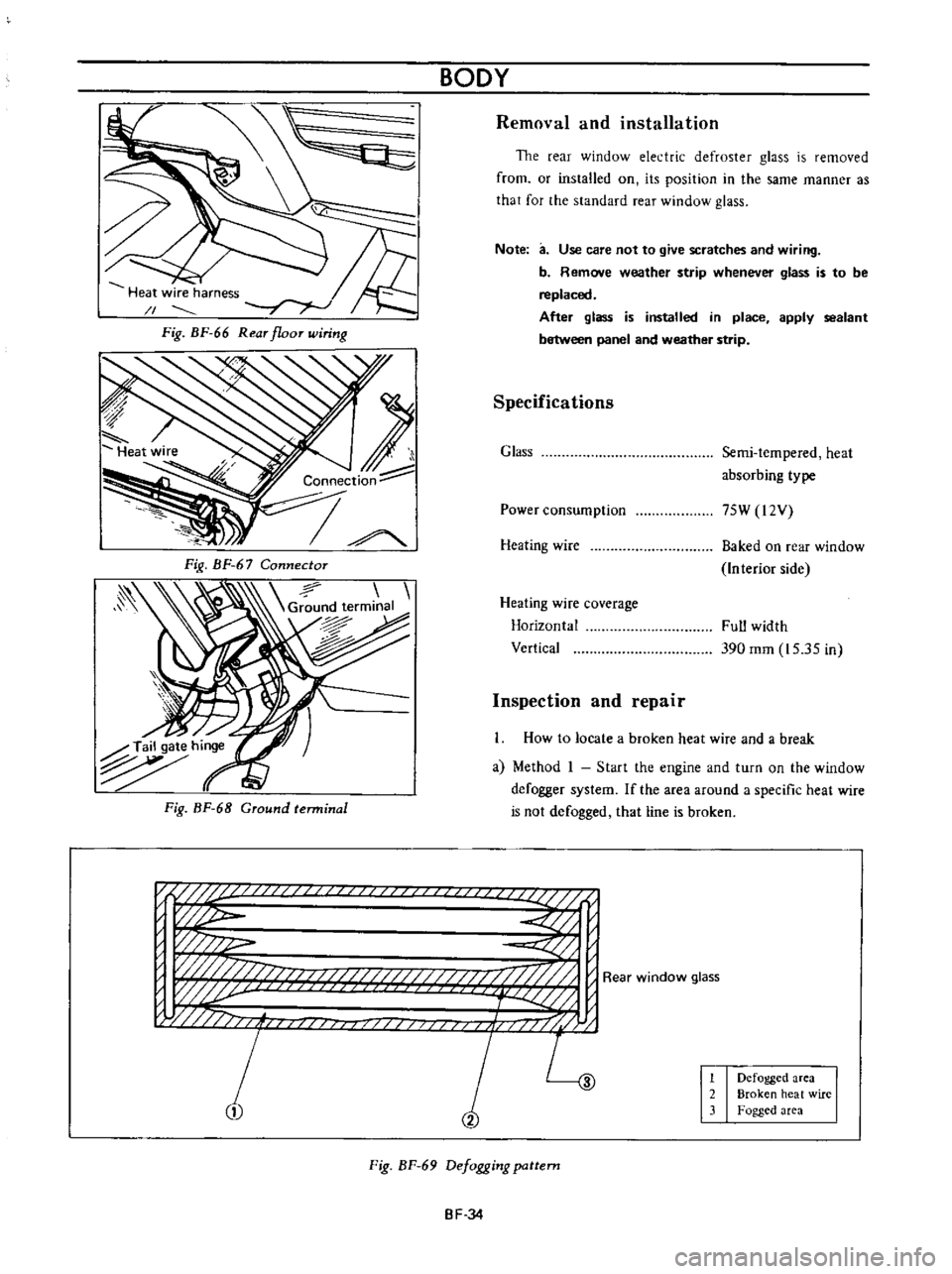

BODY

Removal

and

installation

The

rear

window

electric

defroster

glass

is

removed

from

or

installed

on

its

position

in

the

same

manner

as

that

for

the

standard

rear

window

glass

Heat

wire

harness

1

Fig

BF

66

Rear

floor

wiring

Note

a

Use

care

not

to

give

scratches

and

wiring

b

Remove

weather

strip

whenever

glass

is

to

be

replaced

After

glass

is

installed

in

place

apply

sealant

between

panel

and

weather

strip

1

Connection

Specifications

Glass

Semi

tempered

heat

absorbing

type

Power

consumption

75W

l2V

Heating

wire

Baked

on

rear

window

Interior

side

Heating

wire

coverage

Horizontal

Vertical

Full

width

390

mm

15

35

in

Inspection

and

repair

Ground

terminal

How

to

locate

a

broken

heat

wire

and

a

break

a

Method

I

Start

the

engine

and

turn

on

the

window

defogger

system

If

the

area

around

a

specific

heat

wire

is

not

defogged

that

line

is

broken

n

if

U

i

p

w

w

j

w

j

fj

f

i

j

L

1

2

Defogged

area

Broken

heat

wire

Fogged

area

Fig

BF

69

Defogging

pattern

BF

34

Page 228 of 513

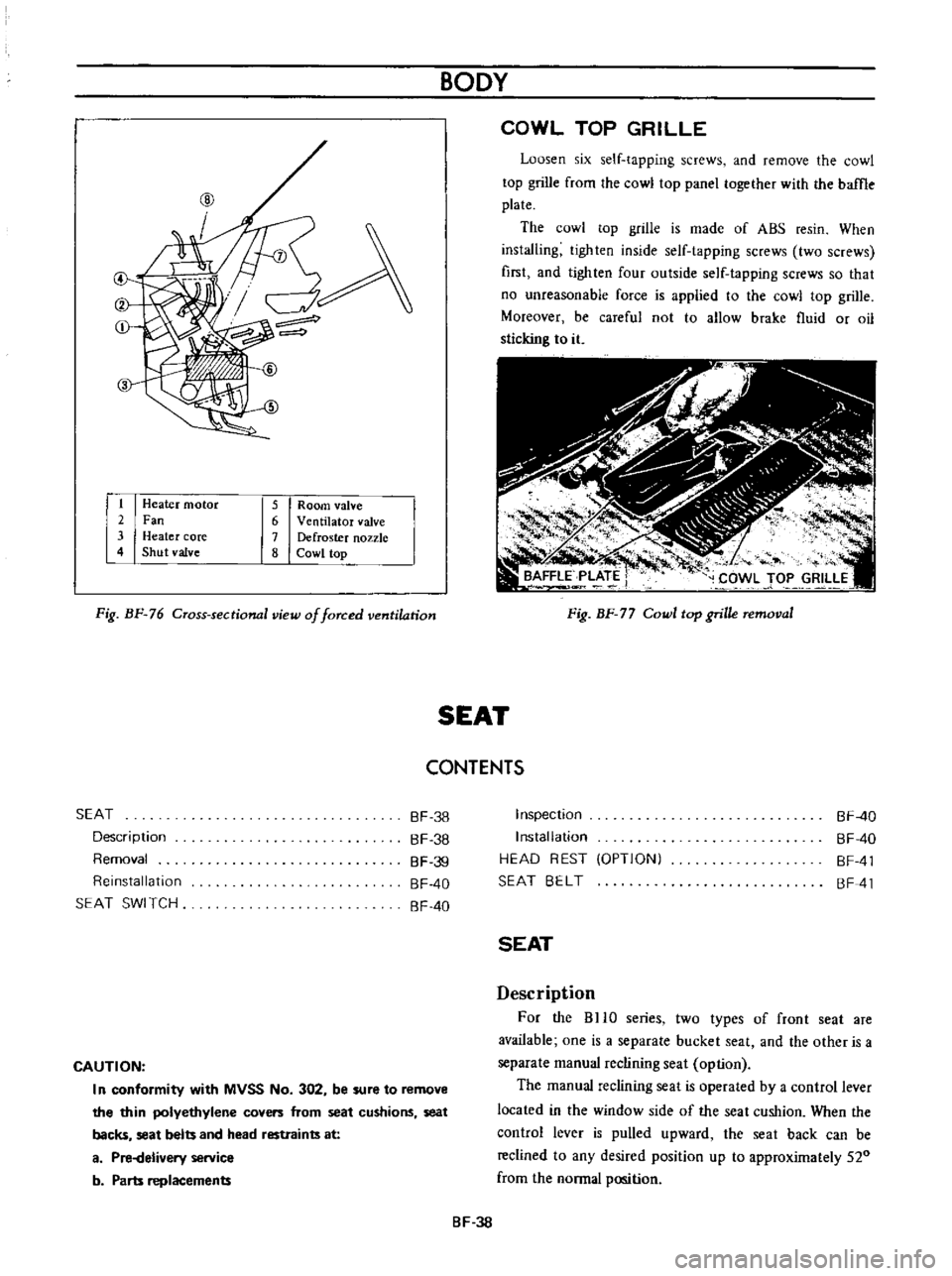

@

c

@

CD

w

1

Heater

motor

2

Fan

3

Heater

core

4

Shut

valve

5

Room

valve

6

Ventilator

valve

7

Defroster

nozzle

8

Cowl

top

Fig

BF

76

Cross

sectional

view

of

forced

ventilation

BODY

COWL

TOP

GRILLE

Loosen

six

self

tapping

screws

and

remove

the

cowl

top

grille

from

the

cowl

top

panel

together

with

the

baffle

plate

The

cowl

top

grille

is

made

of

ABS

resin

When

installing

tighten

inside

self

tapping

screws

two

screws

first

and

lighten

four

outside

self

tapping

screws

so

that

no

unreasonable

force

is

applied

to

the

cowl

top

grille

Moreover

be

careful

not

to

allow

brake

fluid

or

oil

sticking

to

it

Fig

BF

77

Cowl

top

grille

removal

SEAT

CONTENTS

SEAT

Description

Removal

Reinstallation

SEAT

SWI

TCH

BF

38

BF

38

BF

39

BF

40

BF

40

CAUTION

I

n

conformity

with

MVSS

No

302

be

sure

to

remove

the

thin

polyethylene

covers

from

seat

cushions

seat

backs

seat

belts

and

head

restraints

at

a

Pi

Helivery

service

b

Parts

replacements

Inspection

Installation

HEAD

REST

OPTIONI

SEAT

BELT

BF

40

BF

40

BF

41

BF

41

SEAT

Description

For

the

BHO

series

two

types

of

front

seat

are

available

one

is

a

separate

bucket

seat

and

the

other

is

a

separate

manual

reclining

seat

option

The

manual

reclining

seat

is

operated

by

a

control

lever

located

in

the

window

side

of

the

seat

cushion

When

the

control

lever

is

pulled

upward

the

seat

back

can

be

reclined

to

any

desired

position

up

to

approximately

520

from

the

normal

position

BF

38

Page 290 of 513

III

r

AJ

r

oll

t

1

J

1

J

ti

i

1

tl

FOREWORD

This

scrviee

manual

has

been

prepared

lor

the

purpose

of

assistinf

service

persunnel

of

authorized

NISSAN

DA

TSUN

dealers

in

providing

effective

service

and

maintenance

of

the

1973

Datsun

1200

I

il

Since

proper

maintenance

and

serVIce

are

absolutely

essential

in

satisfying

the

owners

of

DatSlLn

this

manual

should

be

kept

in

a

handy

place

for

ready

reference

and

should

be

mrefully

studied

This

nUl

wal

indudes

procedures

for

maintenance

adjustments

mmor

service

operations

renwval

and

installation

IInd

for

disassembly

and

assembly

of

ram

ponents

The

Quick

Reference

lndex

on

the

first

page

enable

the

user

to

quickly

locate

and

desired

tion

4t

the

beginning

of

each

individual

section

is

a

table

of

contents

which

gives

the

page

number

on

which

each

major

subject

begins

An

index

is

placed

at

the

beginning

of

each

major

subject

withill

the

sectioll

The

Special

Tools

when

required

presented

at

the

Sf

section

411

information

illustrations

and

specificatiolls

contained

in

this

manual

are

based

Oll

the

latest

product

inJormation

available

at

the

time

of

publication

approval

Rights

for

tIltl

rnali

11

of

specificatiuns

llnd

mpthods

at

lilY

time

are

reserved

I

I

I

I

NISSAN

MOTOR

CO

TOKYO

APAN

LTD

f

t

I

I

t

J

1972

NlSSAN

MOTOR

CO

LTD

i

t

r

f

i

o

c

1

I

I

l

1

10

I

It

r

f

K

I

1

I

i

I

r

I

i

i

t

j

I

r

7

T

l

1

r

i

i

t

Llo

tff

t

I

1

O

I

trr

rd

I

At

4

rei

1

0

Ii

0

cll

I

f

I

J

i

J

iF

U

y

tn

1

I

I

I

I

i

t

If

tij

1

li

I

J

H

a

r

1

i

I

V

j

lio

4

l

j

i

y

o

J

A

co

L

i

I

I

I

Jil

iLl4

j

l

t1

J

1

i

t

Page 295 of 513

r

FOREWORD

This

service

manual

has

been

prepared

for

the

pnrpose

uf

assisling

service

personnel

of

llllthurized

NISSAN

DATSUN

dealers

in

pruviding

e

feetive

service

and

maintenance

uf

the

973

Datsun

2VV

inee

proper

maintenance

and

scroice

arc

absolutely

essential

ill

satisfying

the

uwners

of

Datsun

Ihis

manual

should

be

kepi

in

a

handy

place

fur

ready

reference

and

shollld

be

carefully

studied

This

manual

indudes

procedures

fnr

maintenance

adjlU

tments

mInor

serVice

ofJf

raliun

mmoval

and

inslallation

and

for

disassl

mbly

and

asscmlJl

of

com

ponents

TIle

Ouick

Reji

ence

Index

on

the

jirst

page

enable

the

user

to

quickly

locale

and

de

ired

sed

ion

AI

Ihe

beginning

of

each

individual

see

ion

is

a

lable

of

contents

which

gives

the

page

number

on

which

each

majur

subject

begins

4n

index

is

placed

at

Ihe

beginning

of

each

majur

subject

within

the

section

1

1

Special

Tools

when

required

presented

at

the

SF

sedion

4ll

informatiun

illustrations

arid

specifications

cOlliaifwd

in

this

manual

are

Jw

ed

on

the

latest

product

infurmation

available

at

Ihe

time

of

publication

appruval

Rights

fur

alternatiun

of

specifications

and

methods

at

uny

time

are

reserved

NISSAN

MOTOR

CO

TOKYO

JAPAN

LTD

@

1972

NISSAN

IOTOR

co

LTD

Page 395 of 513

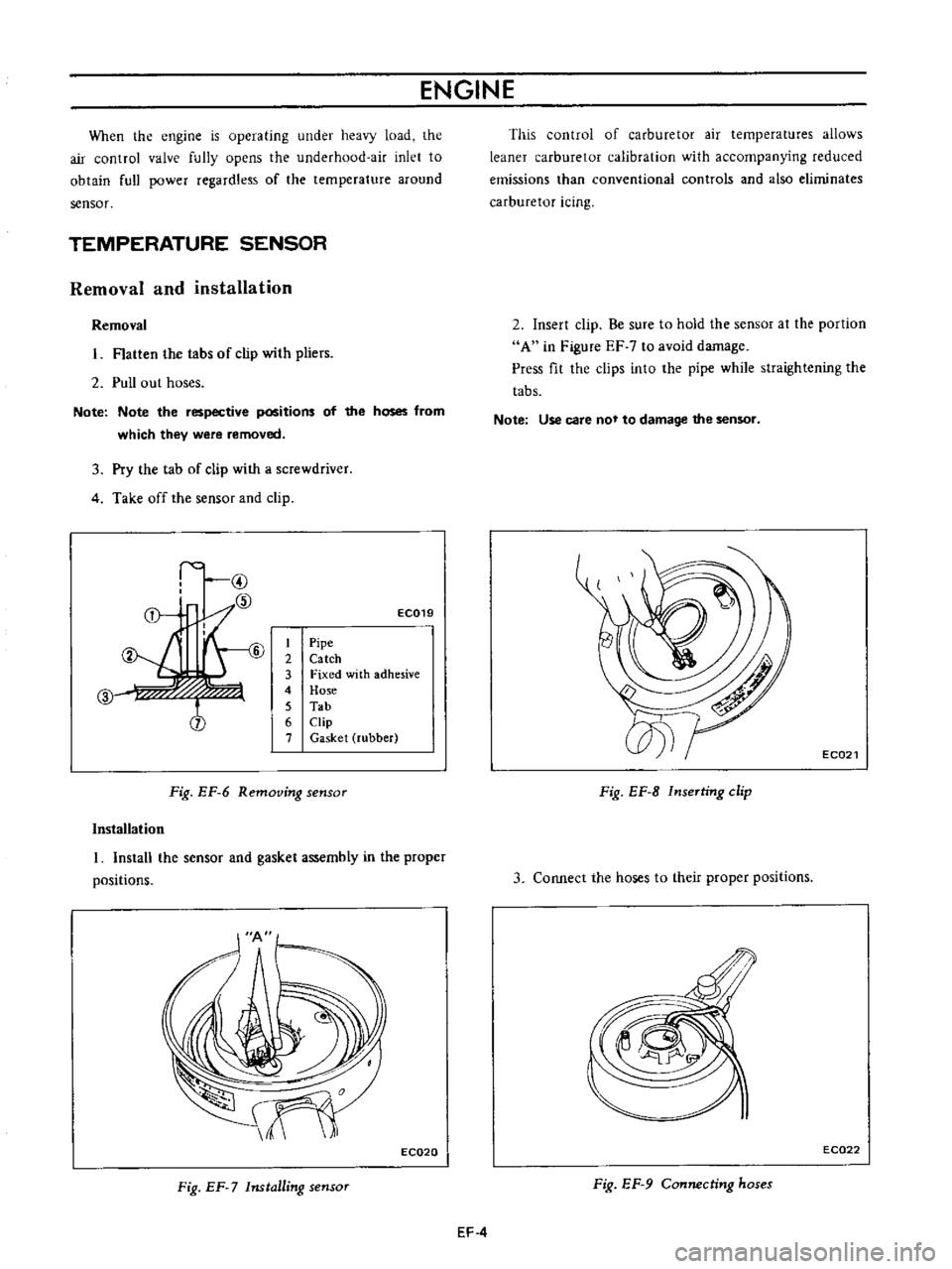

ENGINE

When

the

engine

is

operating

under

heavy

load

the

air

control

valve

fully

opens

the

underhood

air

inlet

to

obtain

full

power

regardless

of

the

temperature

around

sensor

TEMPERATURE

SENSOR

Removal

and

installation

Removal

Hatten

the

tabs

of

clip

with

pliers

2

Pull

out

hoses

Note

Note

the

respective

positions

of

the

hoses

from

which

they

were

removed

3

Pry

the

tab

of

clip

with

a

screwdriver

4

Take

off

the

sensor

and

clip

I

@

f

6

7

CID

f

j

EC019

1

Pipe

2

Catch

3

Fixed

with

adhesive

4

Hose

5

Tab

6

Clip

7

Gasket

rubber

Fig

EF

6

Removing

sensor

Installation

I

Install

the

sensor

and

gasket

assembly

in

the

proper

positions

EC020

Fig

EF

7

Installing

sensor

This

control

of

carburetor

air

temperatures

allows

leaner

carburetor

calibration

with

accompanying

reduced

emissions

than

conventional

controls

and

also

eliminates

carburetor

icing

2

Insert

clip

Be

sure

to

hold

the

sensor

at

the

portion

A

in

Figure

EF

7

to

avoid

damage

Press

fit

the

clips

into

the

pipe

while

straightening

the

tabs

Note

Use

care

not

to

damage

the

sensor

EC021

Fig

EF

B

InseTting

clip

3

COIUlect

the

hoses

to

their

proper

positions

EC022

Fig

EF

9

Connecting

hoses

EF

4