ABS DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 119 of 513

CHASSIS

4

Tighten

he

brake

back

plate

to

housing

nunge

bults

and

nuts

with

a

torque

of

1

5

to

2

0

kg

m

10

8

to

145

ft

Ibl

Check

the

rear

axle

shaft

end

playas

shown

in

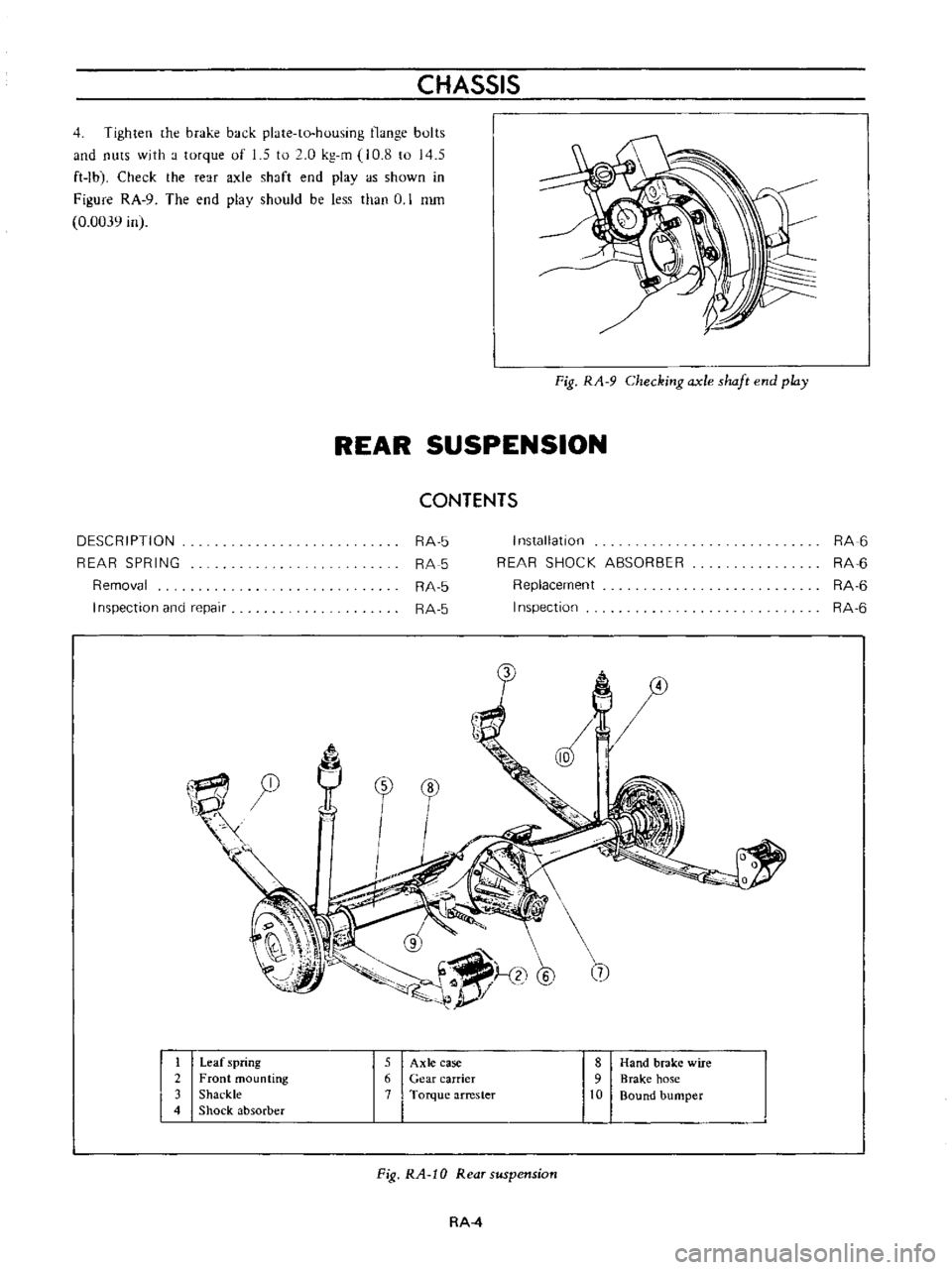

Figure

RA

9

The

end

plav

should

be

less

than

U

I

nun

0

0039

in

Fig

RA

9

Checking

axle

shaft

end

play

REAR

SUSPENSION

CONTENTS

DESCRIPTION

REAR

SPRING

Removal

I

nspection

and

repair

RA

5

RA

5

RA

5

RA

5

I

n5tallatlon

REAR

SHOCK

ABSORBER

Replacement

Inspection

RA

6

RA

6

RA

6

RA

6

0

tr

1

1

@

5

@

7

I

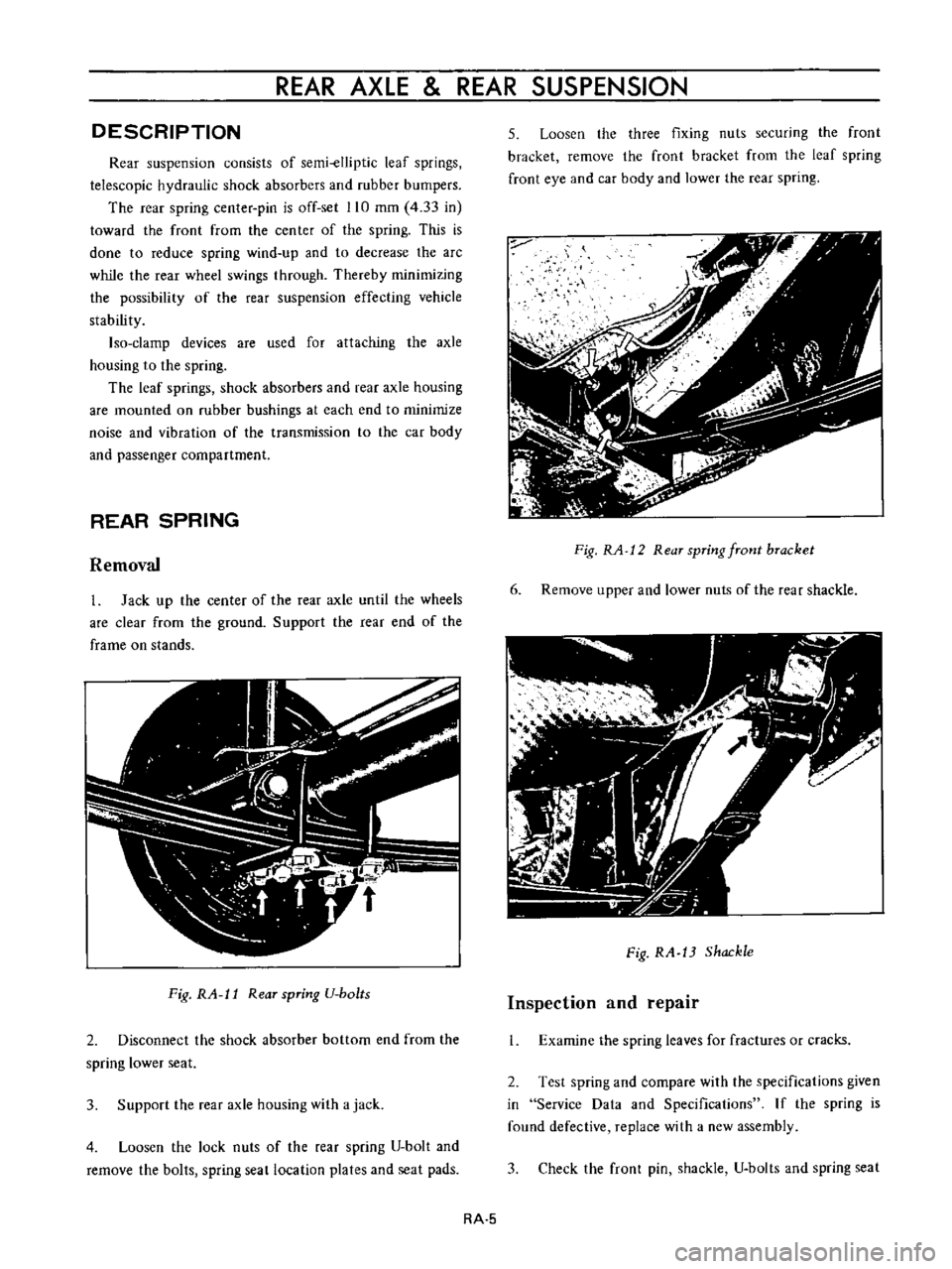

Leaf

spring

5

Axle

case

8

Hand

brake

wire

2

Front

mounting

6

Gear

carrier

9

Brake

hose

3

Shackle

7

Torque

arrester

10

Bound

bumper

4

Shock

absorber

Fig

RA

10

Rear

suspension

RA

4

Page 120 of 513

REAR

AXLE

REAR

SUSPENSION

DESCRIPTION

Rear

suspension

consists

of

semi

elliptic

leaf

springs

telescopic

hydraulic

shock

absorbers

and

rubber

bumpers

The

rear

spring

center

pin

is

off

set

110

mm

4

33

in

toward

the

front

from

the

center

of

the

spring

This

is

done

to

reduce

spring

wind

up

and

to

decrease

the

arc

while

the

rear

wheel

swings

through

Thereby

minimizing

the

possibility

of

the

rear

suspension

effecting

vehicle

stability

Iso

clamp

devices

are

used

for

attaching

the

axle

housing

to

the

spring

The

leaf

springs

shock

absorbers

and

rear

axle

housing

are

mounted

on

rubber

bushings

at

each

end

to

minimize

noise

and

vibration

of

the

transmission

to

the

car

body

and

passenger

compartment

REAR

SPRING

Removal

1

Jack

up

the

center

of

the

rear

axle

until

the

wheels

are

clear

from

the

ground

Support

the

rear

end

of

the

frame

on

stands

Fig

RA

l1

Rear

spring

U

bo

ts

2

Disconnect

the

shock

absorber

bottom

end

from

the

spring

lower

seat

3

Support

the

rear

axle

housing

with

a

jack

4

Loosen

the

lock

nuts

of

the

rear

spring

U

bolt

and

remove

the

bolts

spring

seat

location

plates

and

seat

pads

5

Loosen

the

three

fixing

nuts

securing

the

front

bracket

remove

the

front

bracket

from

the

leaf

spring

front

eye

and

car

body

and

lower

the

rear

spring

Fig

RA

12

Rear

spring

front

bracket

6

Remove

upper

and

lower

nuts

of

the

rear

shackle

Fig

RA

13

Shackle

Inspection

and

repair

1

Examine

the

spring

leaves

for

fractures

or

cracks

2

Test

spring

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

If

the

spring

is

found

defective

replace

with

a

new

assembly

3

Check

the

front

pin

shackle

U

bolts

and

spring

seat

RA

5

Page 121 of 513

CHASSIS

for

wear

cra

ks

straightness

and

damaged

thread

s

If

defective

parts

are

found

replace

with

new

ones

4

Inspect

all

rubber

pans

for

wear

damage

separation

and

deformation

Replace

them

if

necessary

Installation

Install

the

rear

spring

in

reverse

sequence

of

removal

noting

the

following

matters

Coat

the

front

bracket

pin

front

bracket

bushing

shackle

pin

and

shackle

bushing

with

a

soap

solution

prior

to

assembly

2

The

front

pin

securing

nut

and

shock

absorber

lower

end

securing

nut

should

be

tightened

with

the

vehicle

unladen

Note

Make

sure

that

the

flange

of

the

shackle

bushing

is

clamped

evenly

on

both

sides

REAR

SHOCK

ABSORBER

Replacement

lack

up

the

center

of

the

rear

axle

and

support

the

axle

housing

with

stands

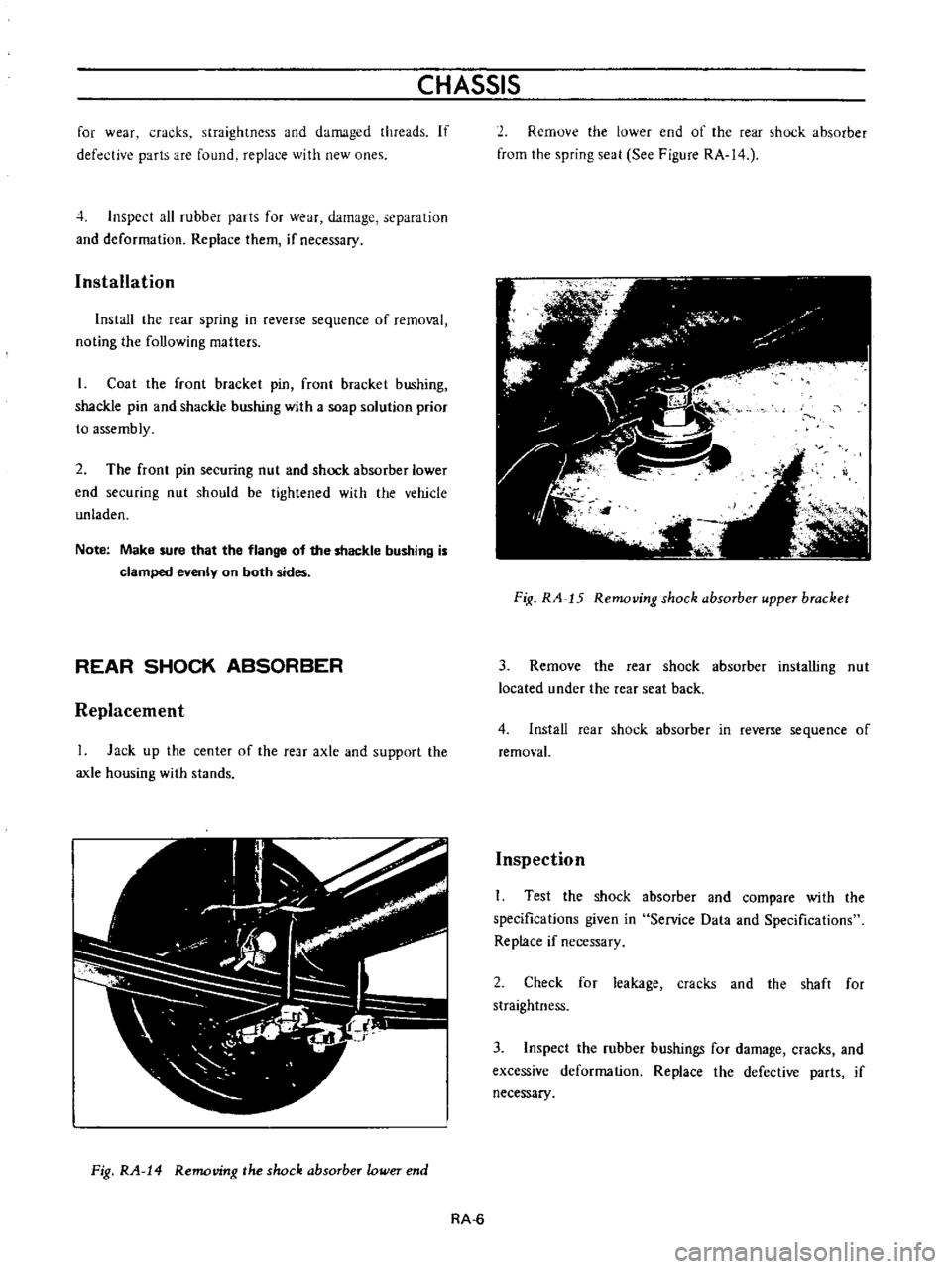

Fig

RA

14

Removing

the

shock

absorber

ower

end

2

Remove

the

lower

end

of

the

rear

shock

absorber

from

the

spring

seat

See

Figure

RA

14

FiK

RA

15

Removing

shock

absorber

upper

bracket

3

Remove

the

rear

shock

absorber

installing

nut

located

under

the

rear

seat

back

4

Install

rear

shock

absorber

in

reverse

sequence

of

removal

Inspection

Test

the

shock

absorber

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

Replace

if

necessary

2

Check

for

leakage

cracks

and

the

shafl

for

straightness

3

Inspect

the

rubber

bushings

for

damage

cracks

and

excessive

deformation

Replace

the

defective

parts

jf

necessary

RA

6

Page 122 of 513

REAR

AXLE

REAR

SUSPENSION

SERVICE

DATA

AN

D

SPECIFICATIONS

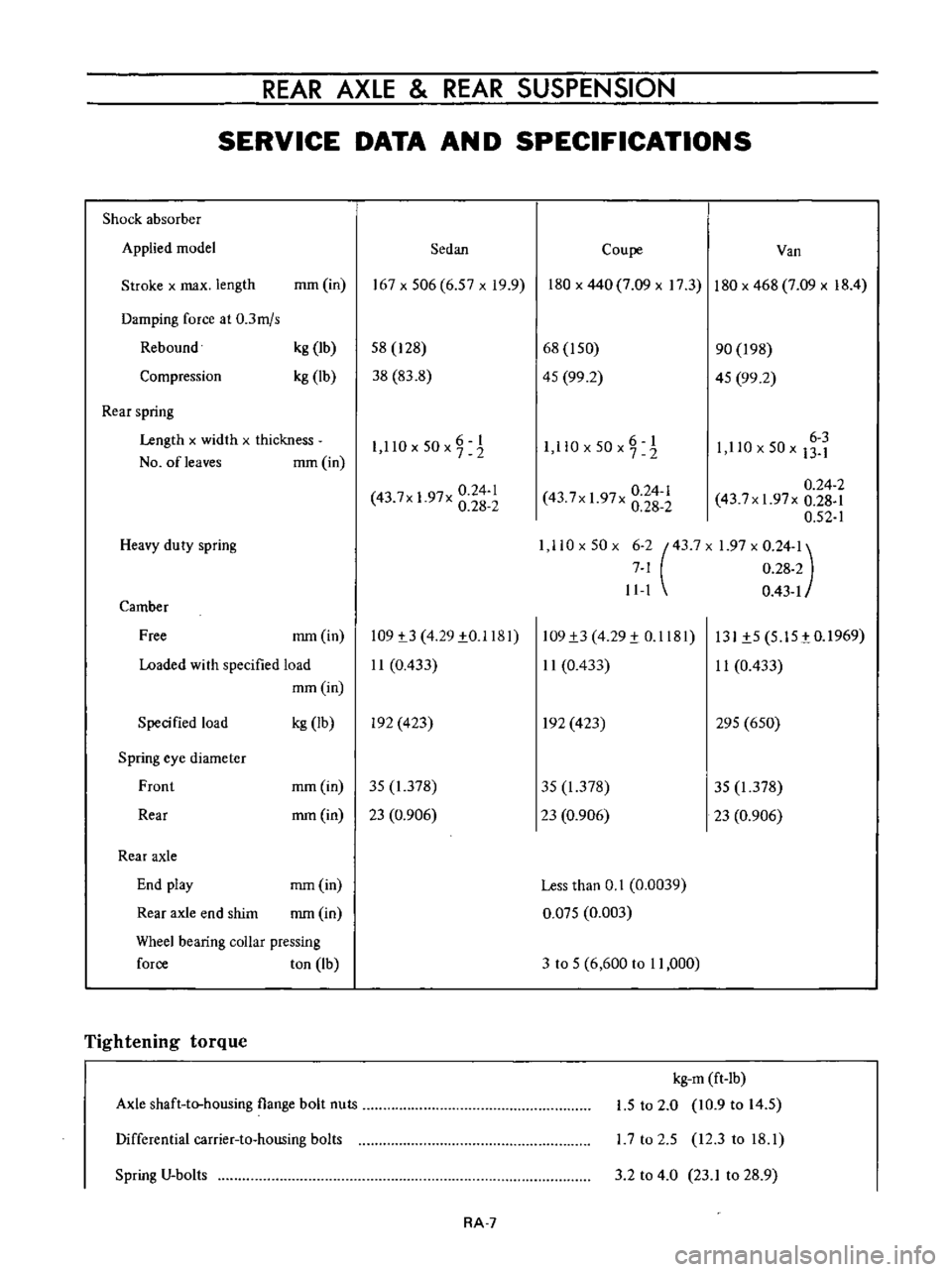

Shock

absorber

Applied

model

Sedan

Coupe

Van

Stroke

x

max

length

mm

in

167x506

6

57xI9

9

180

x

440

7

09

x

17

3

180

x

468

7

09

x

18

4

Damping

force

at

0

3mjs

Rebound

Compression

kg

Ib

kg

lb

58

128

38

83

8

68

I

50

45

99

2

90

198

45

99

2

Rear

spring

Length

x

widlh

x

thickness

NO

ofleaves

mm

in

6

I

1

llOx50x72

O

6

1

I

ll

x50x7

2

6

3

1

110

x

50

x

13

1

0

24

1

43

7x

1

97x

0

28

2

0

24

2

43

7xI

97x

0

28

1

0

52

1

1

110x50x

6

2

43

7X

1

97

x

0

24

1

7

1

0

28

2

11

1

0

43

1

0

24

1

43

7x

1

97x

0

28

2

Heavy

duty

spring

Camber

Free

mm

in

109

t3

4

29

1

0

1181

11

0

433

109

1

3

4

29

1

0

1181

11

0

433

131

1

5

5

15

tO

1969

11

0

433

Loaded

wi

th

specified

load

mm

in

Specified

load

kg

Ib

In

423

In

423

295

650

Spring

eye

diameter

Front

mm

in

35

1

378

35

1

378

35

1

378

Rear

mm

in

23

0

906

23

0

906

23

0

906

Rear

axle

End

play

mm

in

Less

than

0

1

0

0039

Rear

axle

end

shim

mm

in

0

Q75

0

003

Wheel

bearing

coUar

pressing

force

ton

Ib

3

to

5

6

600

to

11

000

Tightening

torque

Axle

shaft

to

housing

flange

bolt

nuts

kg

m

ft

lb

1

5

to

2

0

10

9

to

14

5

L7

to

2

5

12

3

to

18

1

Differential

carrier

to

housing

bolts

Spring

V

bolts

3

2

to

4

0

23

1

to

28

9

RA

7

Page 123 of 513

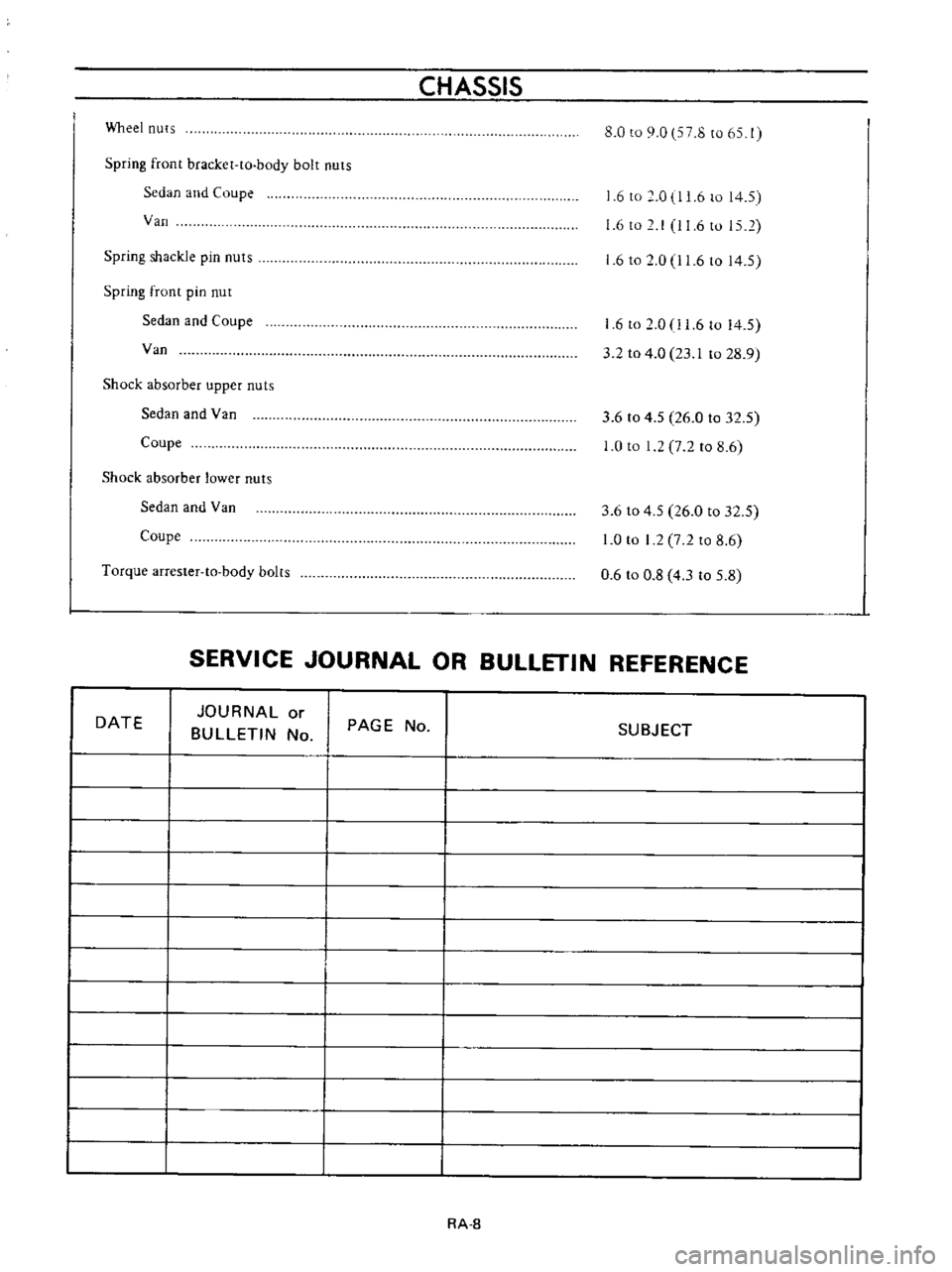

CHASSIS

Wheel

nuts

8

0

to

9

0

7

8

to

65

1

Spring

front

bracket

to

body

bolt

nuts

Sedan

and

Coupe

Van

6

to

0

1

6

to

14

5

6

to

I

11

6

to

15

2

Spring

shackle

pin

nuts

1

6

to

0

11

6

to

14

5

Spring

front

pin

nut

Sedan

and

Coupe

Van

6

to

2

0

1

6

to

14

5

3

2

to

4

0

23

1

to

28

9

Shock

absorber

upper

nuts

Sedan

and

Van

Coupe

3

6

to

4

5

26

0

to

32

5

0

to

1

7

2

to

8

6

Shock

absorber

lower

nuts

Sedan

and

Van

Coupe

3

6

to

4

5

26

0

to

32

5

0

to

I

2

7

2

to

8

6

0

6

to

0

8

4

3

to

5

8

Torque

arrester

to

body

bolts

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

PAGE

No

SUBJECT

RA

8

Page 158 of 513

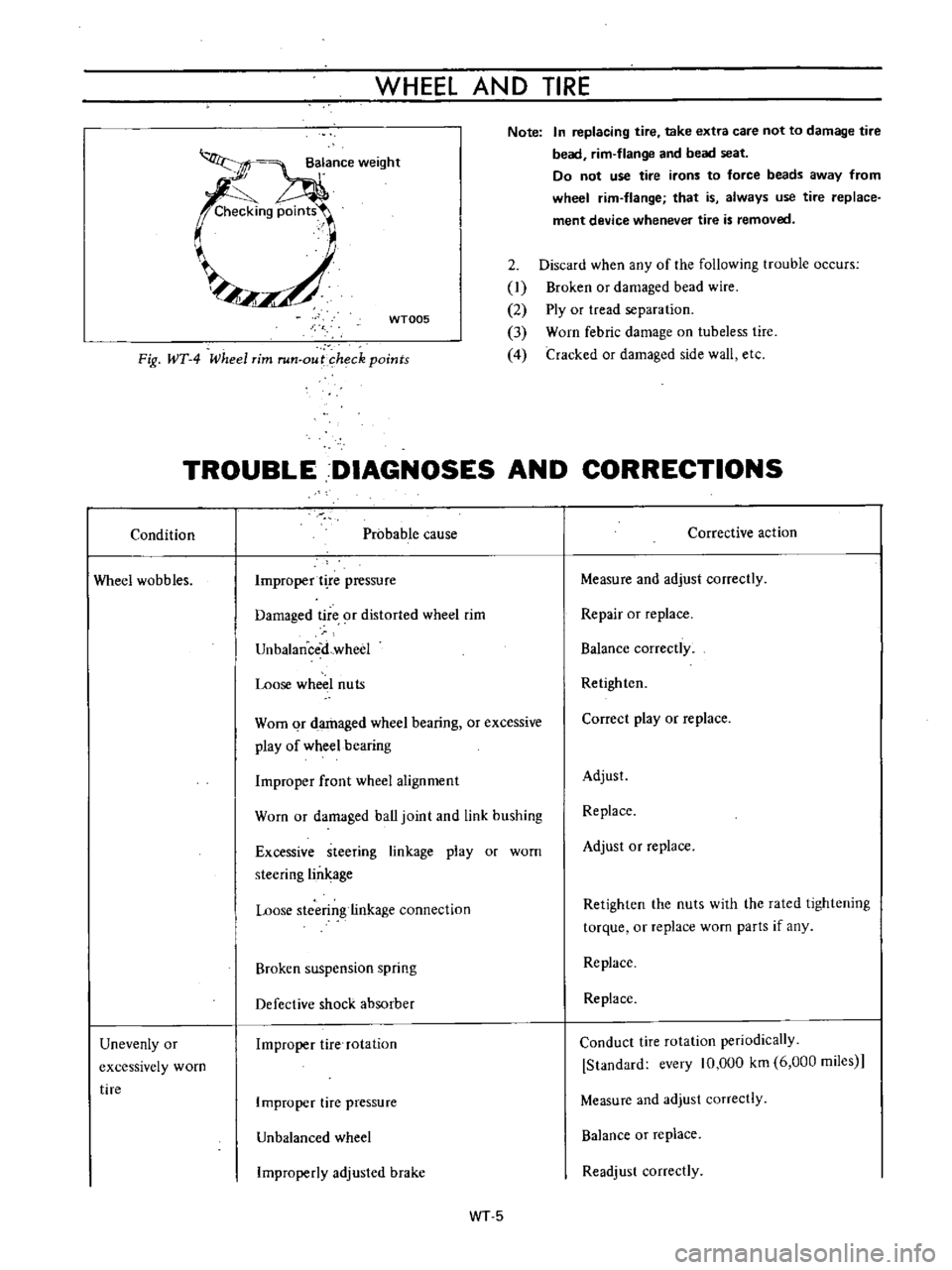

WHEEL

AND

TIRE

Note

In

replacing

tire

take

extra

care

not

to

damage

tire

bead

rim

flange

and

bead

seat

Do

not

use

tire

irons

to

force

beads

away

from

wheel

rim

flange

that

is

always

use

tire

replace

ment

device

whenever

tire

is

removed

WT005

2

Discard

when

any

of

the

following

trouble

occurs

I

Broken

or

damaged

bead

wire

2

Ply

or

tread

separation

3

Worn

febric

damage

on

tubeless

tire

4

Cracked

or

damaged

side

wall

etc

Fig

WT

4

Wheel

rim

run

out

heck

points

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

Corrective

action

Wheel

wobbles

Improper

t

re

pressure

Measure

and

adjust

correctly

Damaged

tire

9f

distorted

wheel

rim

Repair

or

replace

UnbalanceiLwheel

Balance

correctly

Loose

wheel

nuts

Retighten

Worn

qr

damaged

wheel

bearing

or

excessive

play

of

wheel

bearing

Correct

play

or

replace

Improper

front

wheel

alignment

Adjust

Worn

or

damaged

ball

joint

and

link

bushing

Replace

Excessive

steering

linkage

play

or

worn

steering

lin

age

Adjust

or

replace

Loose

stcerin

linkage

connection

Retighten

the

nuts

with

the

rated

lightening

torque

or

replace

worn

parts

if

any

Broken

suspension

spring

Replace

Defective

shock

absorber

Replace

Unevenly

or

excessively

worn

tire

Improper

tire

rotation

Conduct

tire

rotation

periodically

Standard

every

10

000

km

6

000

miies

Improper

tire

pressure

Measure

and

adjust

correctly

Unbalanced

wheel

Balance

or

replace

Improperly

adjusled

brake

Readjust

correctly

WT5

Page 161 of 513

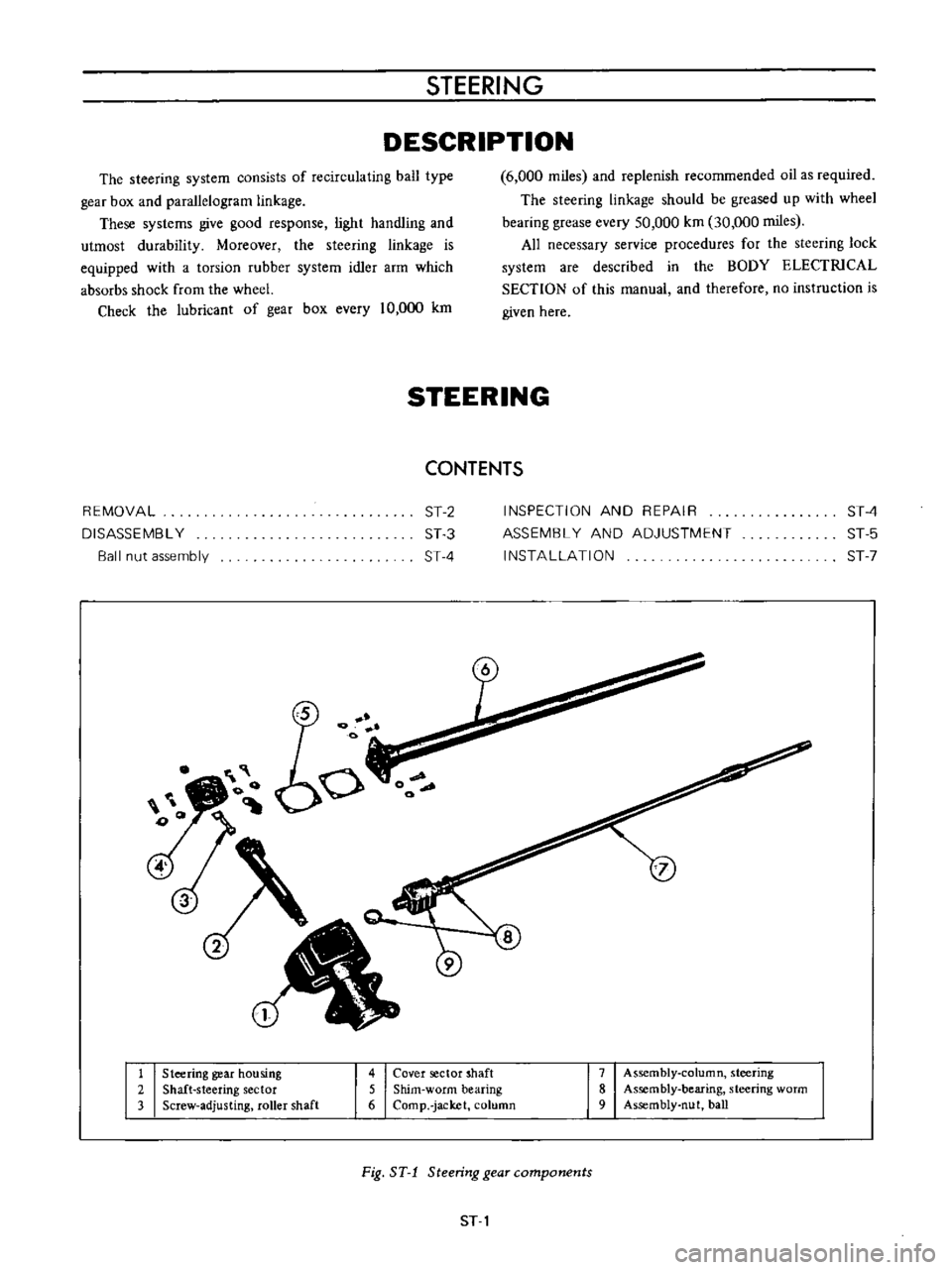

STEERING

DESCRIPTION

The

steering

system

consists

of

recirculating

ball

type

gear

box

and

parallelogram

linkage

These

systems

give

good

response

light

handling

and

utmost

durability

Moreover

the

steering

linkage

is

equipped

with

a

torsion

rubber

system

idler

arm

which

absorbs

shock

from

the

wheel

Check

the

lubricant

of

gear

box

every

10

000

km

6

000

miles

and

replenish

recommended

oil

as

required

The

steering

linkage

should

be

greased

up

with

wheel

bearing

grease

every

50

000

km

30

000

miles

All

necessary

service

procedures

for

the

steering

lock

system

are

described

in

the

BODY

ELECTRICAL

SECTION

of

this

manual

and

therefore

no

instruction

is

given

here

STEERING

CONTENTS

REMOVAL

DISASSEMBL

Y

Ball

nut

assembly

ST

2

ST

3

ST

4

INSPECTION

AND

REPAIR

ASSEMBL

Y

AND

ADJUSTMENT

INSTALLATION

ST

4

ST

5

ST

7

1

Steering

gear

housing

2

Shaft

steering

sector

3

Screw

adjusting

roller

shaft

4

Cover

sector

shaft

5

Shim

worm

bearing

6

Comp

jacket

column

7

Assembly

column

steering

8

Assembly

bearing

steering

worm

9

Assembly

nut

ball

Fig

ST

1

Steering

gear

components

ST

1

Page 168 of 513

CHASSIS

I

l

I

I

2

fa

r

o

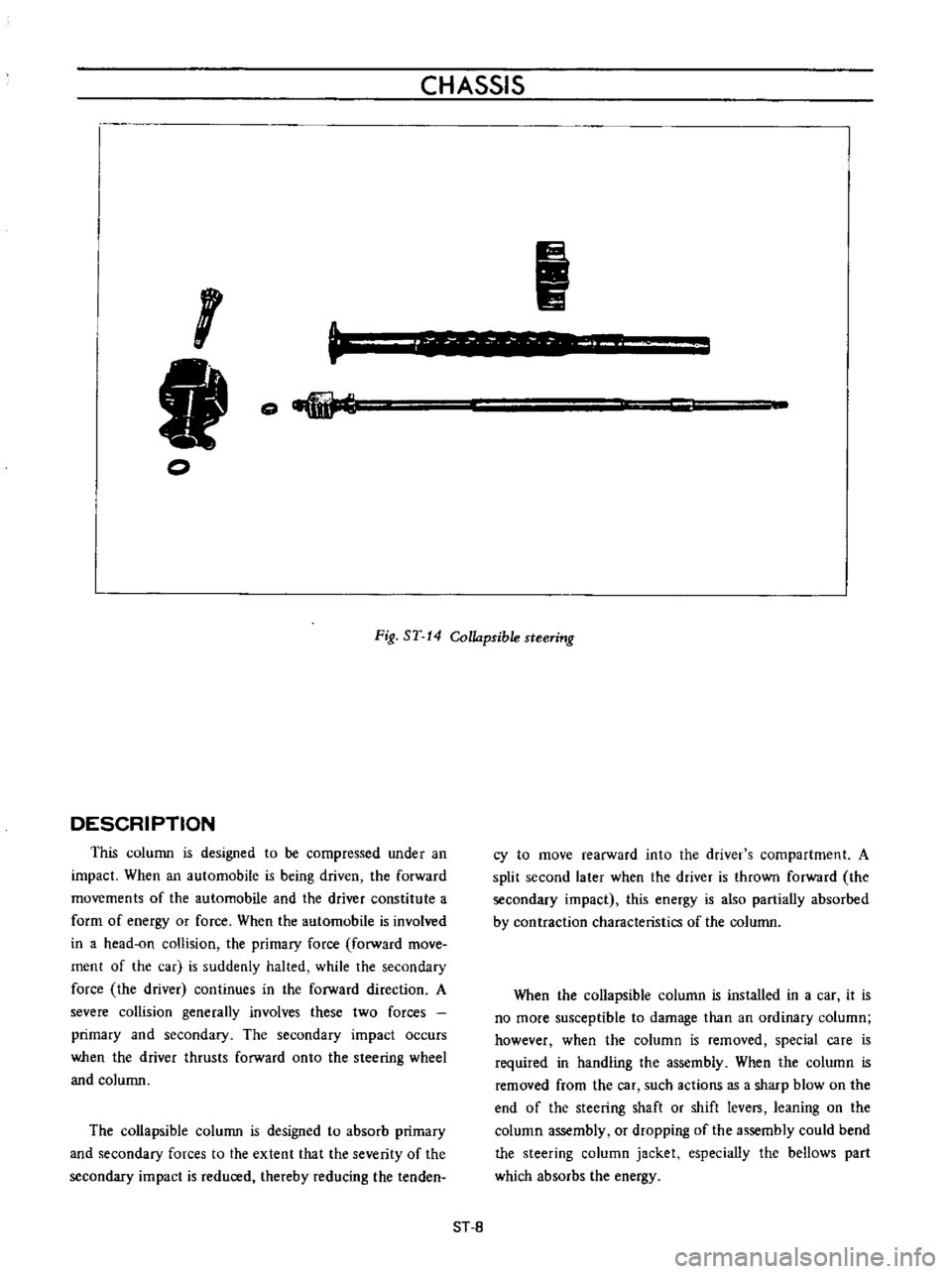

Fig

ST

14

Collapsible

steering

DESCRIPTION

This

column

is

designed

to

be

compressed

under

an

impact

When

an

automobile

is

being

driven

the

forward

movements

of

the

automobile

and

the

driver

constitute

a

form

of

energy

or

force

When

the

automobile

is

involved

in

a

head

on

collision

the

primary

force

forward

move

ment

of

the

car

is

suddenly

halted

while

the

secondary

force

the

driver

continues

in

the

forward

direction

A

severe

collision

generally

involves

these

two

forces

primary

and

secondary

The

secondary

impact

occurs

when

the

driver

thrusts

forward

onto

the

steering

wheel

and

column

The

collapsible

column

is

designed

to

absorb

primary

and

secondary

forces

to

the

extent

that

the

severity

of

the

secondary

impact

is

reduced

thereby

reducing

the

tenden

cy

to

move

rearward

into

the

driver

s

compartment

A

split

second

later

when

the

driver

is

thrown

forward

the

secondary

impact

this

energy

is

also

partially

absorbed

by

contraction

characteristics

of

the

column

When

the

collapsible

column

is

installed

in

a

car

it

is

no

more

susceptible

to

damage

than

an

ordinary

column

however

when

the

column

is

removed

special

care

is

required

in

handling

the

assembly

When

the

column

is

removed

from

the

car

such

actions

as

a

sharp

blow

on

the

end

of

the

steering

shaft

or

shift

levers

leaning

on

the

column

assembly

or

dropping

of

the

assembly

could

bend

the

steering

column

jacket

especially

the

bellows

part

which

absorbs

the

energy

ST

8

Page 171 of 513

STEERING

The

jacket

tube

is

of

a

mesh

and

a

part

of

which

is

punched

in

rhombus

forming

an

energy

absorbing

part

of

the

collapsible

steering

Upper

and

lower

guide

tubes

two

guide

tubes

joined

with

polyacetal

resin

are

inserted

into

the

mesh

tube

so

STEERING

POST

CLAMP

that

an

energy

generated

by

collision

can

be

absorbed

as

smoothly

as

possible

with

a

low

load

The

guide

tubes

function

as

a

guide

for

mesh

tube

while

the

mesh

tube

is

collapsed

and

improve

bending

rigidity

of

the

entire

jacket

tube

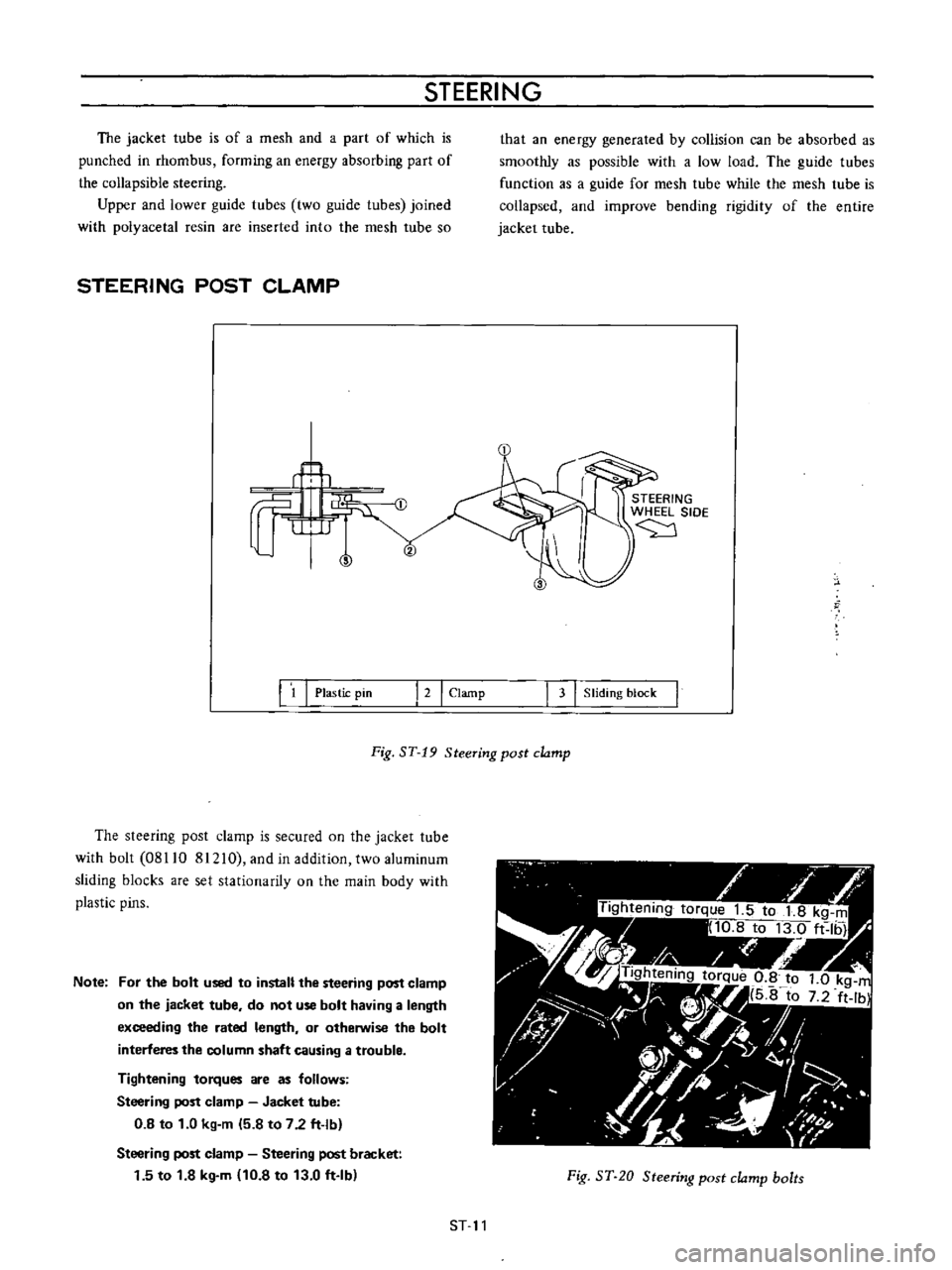

1

1

Plastic

pin

I

2

I

Clamp

1

3

I

Sliding

block

Fig

ST

19

Steering

post

clamp

The

steering

post

clamp

is

secured

on

the

jacket

tube

with

bolt

08110

81210

and

in

addition

two

aluminum

sliding

blocks

are

set

stationarity

on

the

main

body

with

plastic

pins

Note

For

the

bolt

used

to

install

the

steering

post

clamp

on

the

jacket

tube

do

not

use

bolt

having

a

length

exceeding

the

rated

length

or

otherwise

the

bolt

interferes

the

column

shaft

causing

a

trouble

Tightening

torques

are

as

follows

Steering

post

clamp

Jacket

tube

0

8

to

1

0

kg

m

5

8

to

7

2

ft

lb

Steering

post

clamp

Steering

post

bracket

1

5

to

1

8

kg

m

10

8

to

13

0

ft

Ib

Fig

ST

20

Steering

post

clamp

bolts

ST

11

Page 172 of 513

CHASSIS

The

sliding

block

is

secured

on

the

steering

post

bracket

with

bolts

upper

half

of

the

steering

column

is

supported

on

the

bracket

and

thus

the

steering

post

clamp

is

installed

on

the

body

When

a

large

impact

is

applied

from

the

driver

side

the

plastic

pins

are

cut

off

and

leaving

the

sliding

block

in

the

steering

post

bracket

side

the

clamp

proper

is

disengaged

downward

together

with

the

jacket

tube

For

any

force

applied

from

front

direction

of

the

vehicle

the

steering

post

clamp

sliding

block

does

not

move

rearward

This

construction

is

called

One

way

slide

system

and

with

this

construction

projection

of

the

column

shaft

toward

the

driver

is

prevented

completely

COLUMN

BEARING

b

ciJ

STEERING

WHEEL

SIDE

1

Jacket

tube

2

Washer

3

Snap

ring

4

Column

bush

5

ColurtlO

shaft

Fig

ST

21

Column

bearing

Construction

of

the

column

shaft

upper

bearing

is

as

such

that

both

radial

and

thrust

forces

are

absorbed

DISASSEMBLY

First

remove

the

snap

ring

from

the

upper

surface

of

the

column

bushing

Thereafter

general

instructions

for

ordinary

steering

apply

Inspect

and

adjust

the

sector

shaft

worm

ball

nut

unit

adjust

screw

unit

worm

bearing

and

other

relative

parts

in

accordance

with

the

instructions

for

ordinary

type

steering

INSPECTION

Inspect

the

parts

such

as

column

shaft

jacket

tube

etc

which

are

used

to

absorb

energy

in

accordance

with

the

following

instructions

Check

the

column

shaft

plastic

pin

for

breakdown

2

Check

the

steering

lock

collar

for

warping

and

screw

for

breakdown

3

Measure

tolal

length

of

the

jacket

tube

Replace

if

contracted

However

when

tube

collapse

is

within

3

mm

0

1181

in

adjustmenl

by

means

of

bushing

is

also

possible

4

Check

the

steering

post

clamp

sliding

block

for

tightness

5

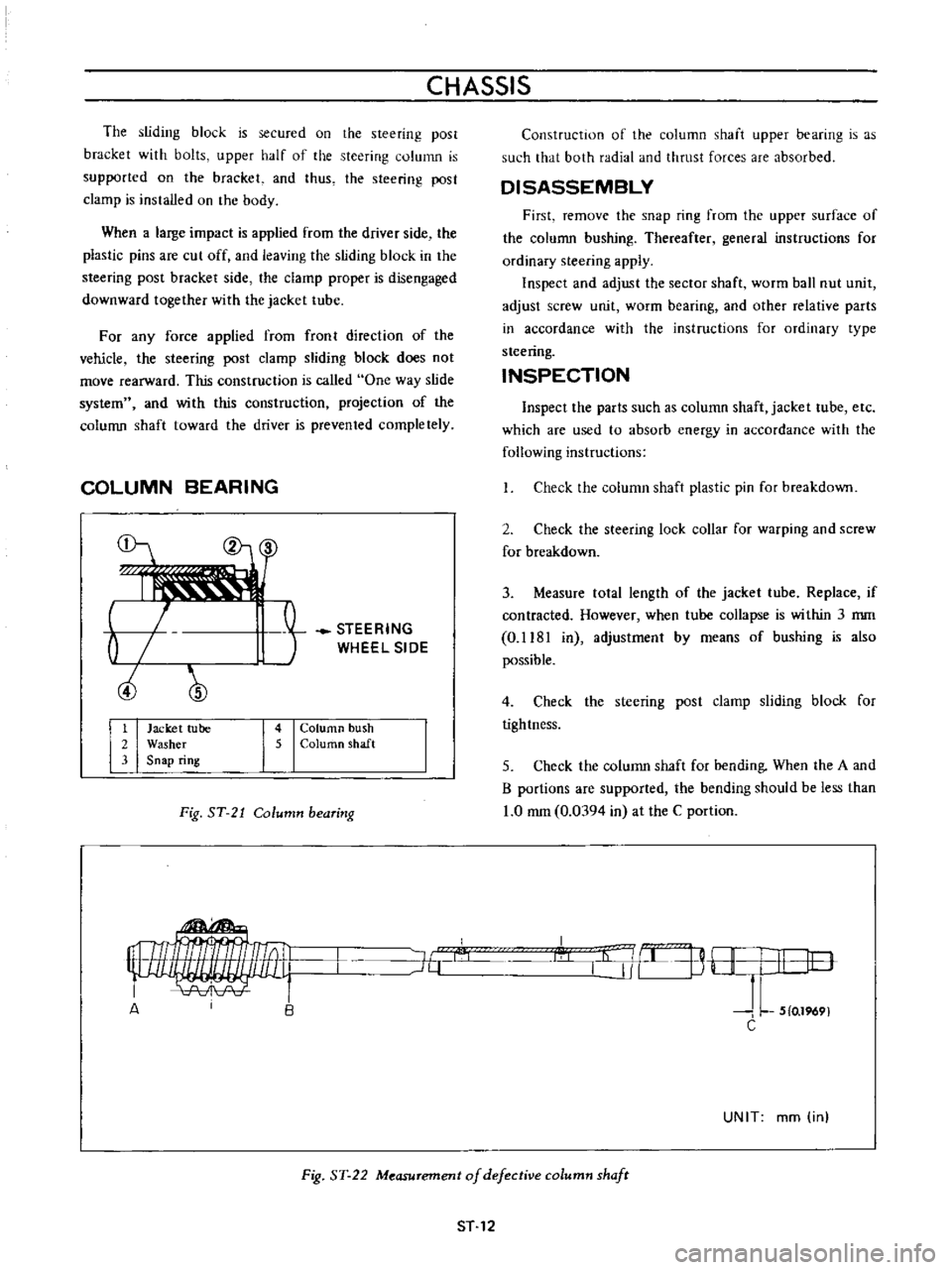

Check

the

column

shaft

for

bending

When

the

A

and

B

portions

are

supported

the

bending

should

be

less

than

1

0

mm

0

0394

in

at

the

C

portion

I

l

j

B

H

I

I

lO

J

L

5

0

1969

C

J6

A

UNIT

mm

in

Fig

ST

22

Measurement

of

defective

column

shafr

ST

12