ABS DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 471 of 513

CLUTCH

CLUTCH

CONTENTS

DESCRIPTION

REMOVAL

DISASSEMBL

Y

INSPECTION

AND

ADJUSTMENT

Clutch

assembly

Cll

CL

2

CL

2

CL

2

CL

2

DESCRIPTION

The

clutch

is

a

single

dty

disc

diaphragm

spring

type

clutch

The

major

components

are

clutch

cover

pressure

plate

diaphragm

spring

and

wire

rings

The

clutch

disc

is

provided

with

riveted

pia

tes

on

both

surfaces

and

coil

springs

arranged

in

a

link

The

coil

springs

absorb

shock

while

engaging

the

clutch

softening

and

smoothing

clutch

30

1181

I

4J

I

m

I

I

5

O

N

l

l

9

p

1L

oz

l

t

O

Ii

N

lt

o

O

Vf

I

1

I

t

I

0

tN

00

f

M

g

1

co

0

00

U

N

N

y

Disc

assembly

Release

bearing

and

sleeve

REASSEMBL

Y

CL

3

CL

4

CL

4

CL

4

CL

5

Release

mechanism

REINSTALLATION

engagement

Release

bearing

sleeve

and

withdrawal

lever

are

used

to

control

clutch

engagement

and

disengagement

Each

part

of

the

clutch

assembly

is

secured

with

rivets

Therefore

when

a

trouble

is

uncorrectable

replace

the

clutch

assembly

wHh

J

new

assembly

93

53

3

682

JOOD4

33

Unit

mm

in

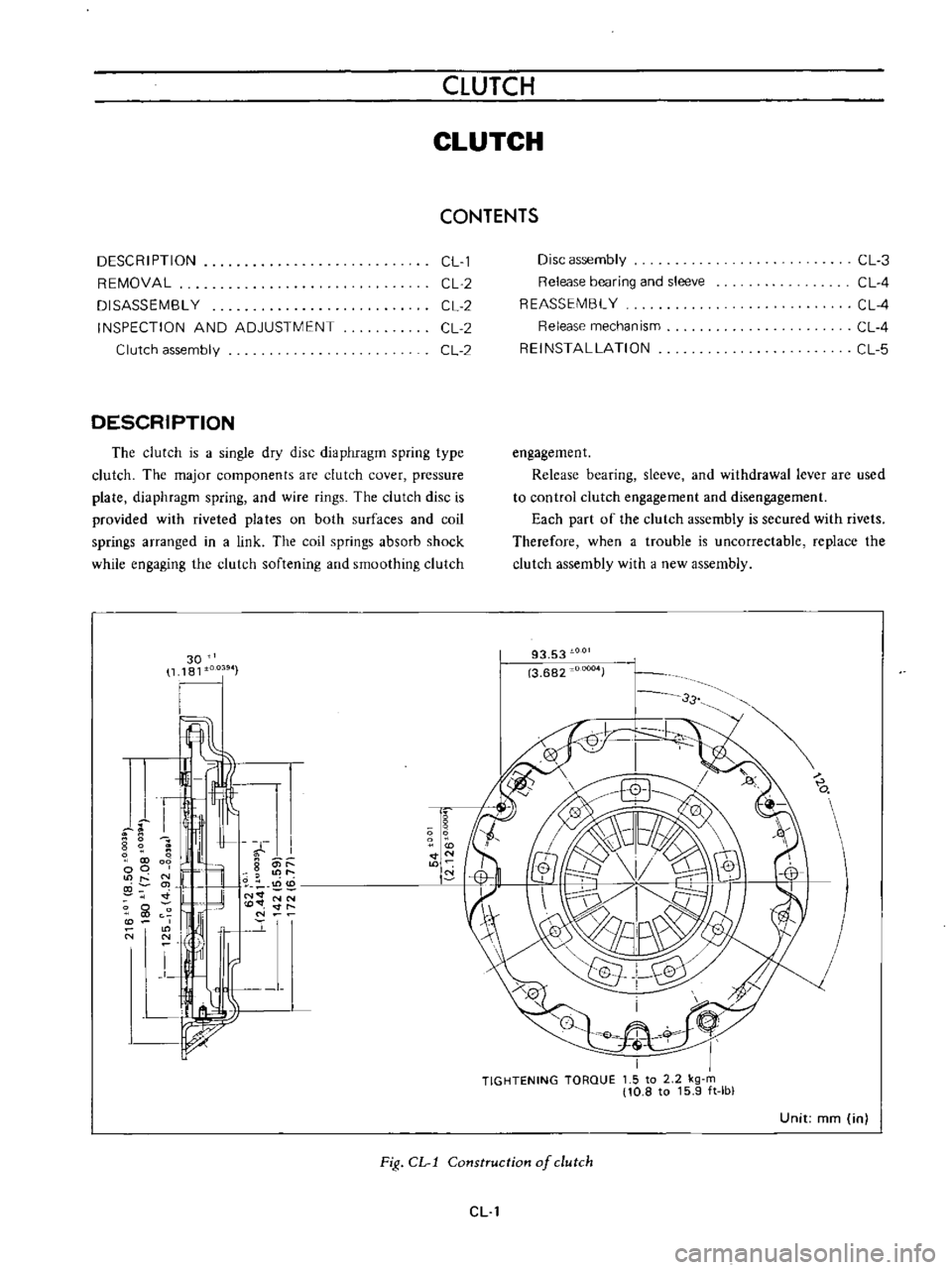

Fig

CL

l

Construction

of

clutch

ell

Page 485 of 513

CLUTCH

Clogged

vent

hole

in

reservoir

cap

promotes

vacuum

in

master

cylinder

allowing

air

to

inf1ltrate

past

the

seal

Abnormal

lining

wear

Insufficient

pedal

free

travel

The

clutch

grabs

The

clutch

slips

Driver

steps

unnecessarily

on

pedal

this

causes

lin

jog

wear

and

damage

to

release

bearing

Weakened

or

snapped

pressure

springs

Incorrectly

installed

linings

Oil

or

grease

on

flywheel

pressure

plate

and

linings

Loose

disc

linings

due

to

poor

rivet

tightness

Clutch

disc

hub

does

not

slide

freely

on

drive

shaft

spline

Warped

or

cracked

pressure

plate

Misalignment

Stiffened

hydraulic

control

mechanism

Wom

out

lining

Insufficient

clutch

pedal

return

travel

due

to

the

control

and

pedal

return

springs

being

weak

or

misadjusted

Weakened

or

broken

diaphragm

spring

Oil

or

grease

on

linings

eLl5

Clean

reservoir

cap

unclog

the

vent

hole

and

bleed

the

system

Adjust

clutch

pedal

free

travel

correctly

Advise

driver

to

discontinue

wrong

practice

and

step

on

clutch

pedal

only

when

ne

cessary

Check

pressure

springs

for

tension

as

speci

fied

and

replace

springs

if

they

are

unserviceable

Replace

linings

with

new

ones

and

install

them

correctly

Check

clutch

disc

for

center

alignment

Remove

cause

of

leakage

clean

flywheel

and

pressure

plate

thoroughly

replace

linings

If

linings

are

not

worn

replace

defective

rivets

Otherwise

replace

linings

and

clench

rivets

securely

Remove

any

foreign

matter

or

dirt

deposits

from

shaft

splines

When

trouble

is

still

present

replace

damaged

parts

Replace

pressure

plate

Locate

the

defective

point

and

if

possible

adjust

alignment

or

replace

distorted

parts

Check

spring

tension

If

necessary

take

down

pedal

and

lubricate

components

Install

new

linings

and

make

sure

tha

t

the

clutch

disc

pressure

plate

and

flywheel

are

not

damaged

Locate

cause

of

failure

and

replace

defective

springs

Overhaul

clutch

and

replace

springs

Remove

cause

of

leakage

and

replace

linings

if

cleaning

is

ineffective

Page 503 of 513

CHASSIS

REINSTALLATION

Remount

the

transmission

in

reverse

sequence

of

dismounting

TRANSMISSION

GEAR

CONTROL

CONTENTS

DESCRIPTION

COLUMN

SHIFT

CONTROL

SYSTEM

Removal

TM

16

TM

17

TM

17

DESCRIPTION

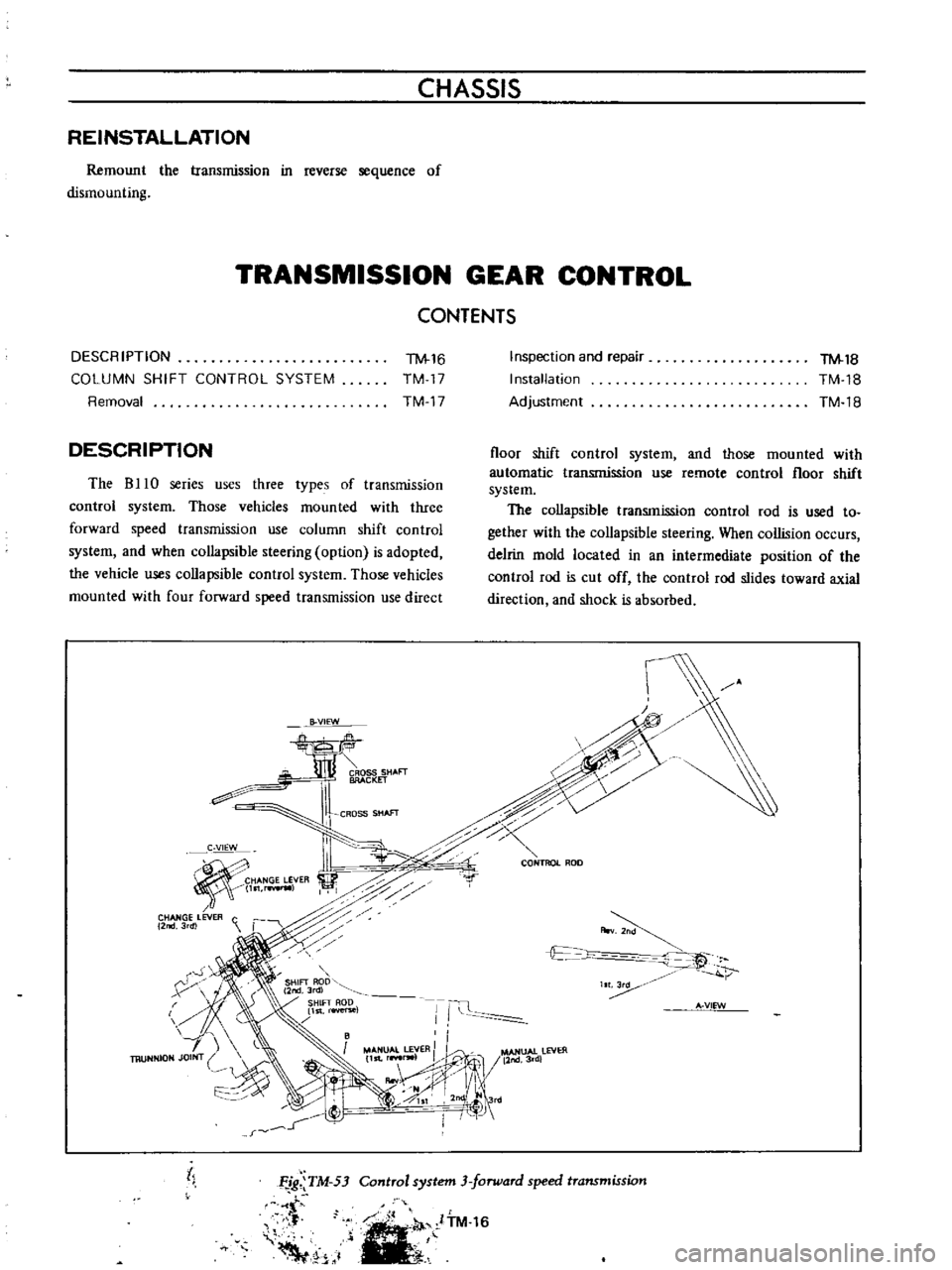

The

B

10

series

uses

three

types

of

transmission

control

system

Those

vehicles

mounted

with

three

forward

speed

transmission

use

column

shift

control

system

and

when

collapsible

steering

option

is

adopted

the

vehicle

uses

collapsible

control

system

Those

vehicles

mounted

with

four

forward

speed

transmission

use

direct

B

VIEW

CROSS

SHAFT

BRACKET

CROSS

SHAfT

C

VIEW

HANGE

LEVER

l

rwIl

CHANGE

LEVER

C

2

3rdl

r

X

h

Inspection

and

repair

Installation

Adjustment

TM

18

TM

18

TM

18

floor

shift

control

system

and

those

mounted

with

automatic

transmission

use

remote

control

floor

shift

system

The

collapsible

transmission

control

rod

is

used

to

gether

with

the

collapsible

steering

When

collision

occurs

delrin

mold

located

in

an

intermediate

position

of

the

control

rod

is

cut

off

the

control

rod

slides

toward

axial

direction

and

shock

is

absorbed

c

0

CONTROL

ROD

r

A

v

t

c

t

IT

Ii

A

VIEW

MANUAL

LEVER

II

l

MANUAl

lEVER

11st

r

lW1

11nd3rd

IIooV

j

II

1

0SI

2nd

Jrd

I

I

j

tl

Control

system

3

forward

speed

transmission

Ffg

TM

53

t

f

Voo

1

ITM

16