differential DATSUN B110 1973 Service Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 273 of 513

SERVICE

EQUIPMeNT

A12

ENGINE

SPECIAL

SERVICE

TOOL

Tool

number

Tool

name

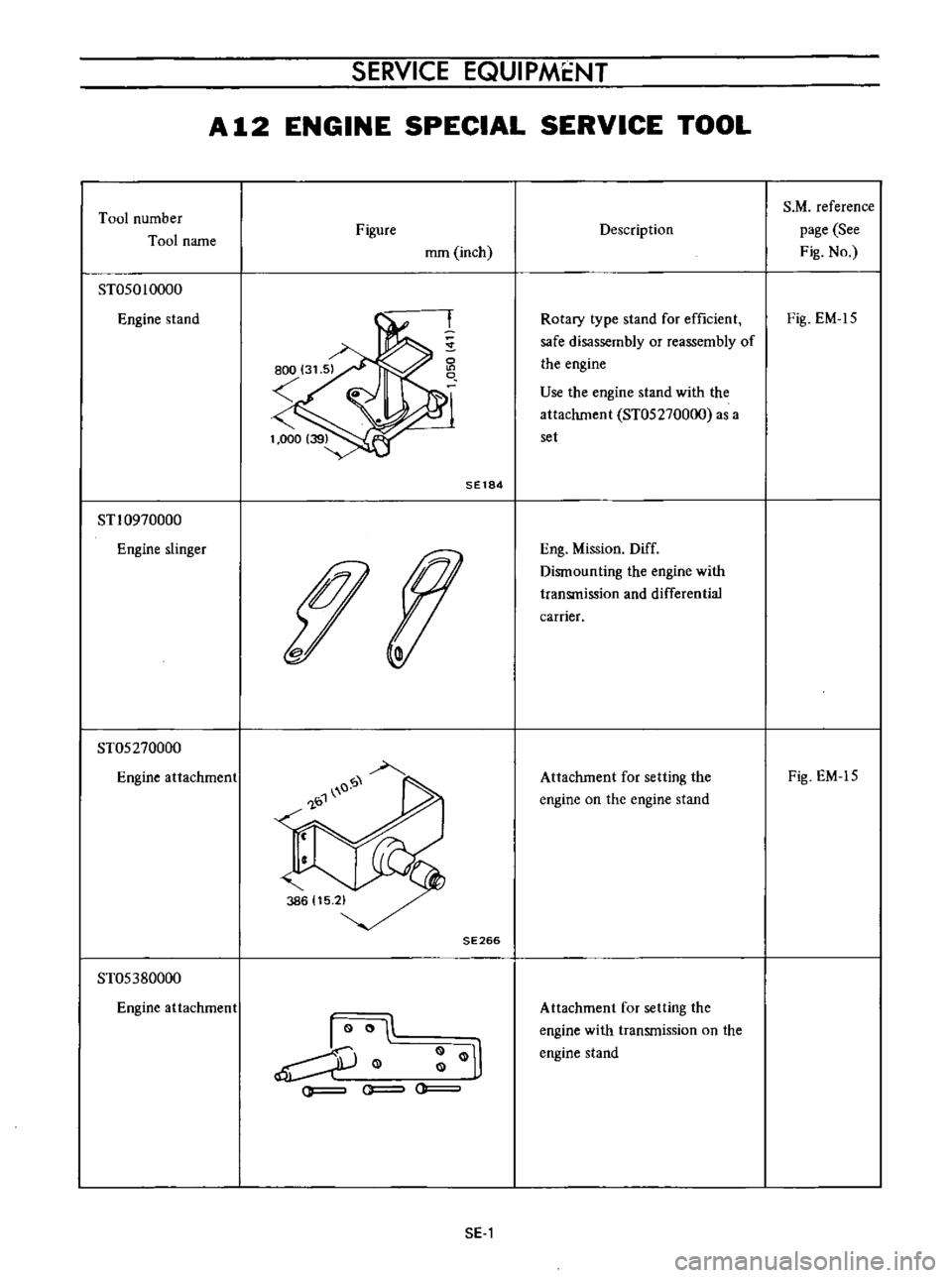

ST050

10000

Engine

stand

STI

0970000

Engine

slinger

ST05270000

Engine

attachment

ST05380000

Engine

attachment

Figure

mm

inch

SE184

0

1

SE266

I

G

0

1

@

@

SE

1

Description

Rotary

type

stand

for

efficient

safe

disassembly

or

reassembly

of

the

engine

Use

the

engine

stand

with

the

attachment

ST05270000

as

a

set

Eng

Mission

Difr

Dismounting

the

engine

with

transmission

and

differential

carrier

Attachment

for

setting

the

engine

on

the

engine

stand

Attachment

for

setting

the

engine

with

transmission

on

the

engine

stand

S

M

reference

page

See

Fig

No

Fig

EM

15

Fig

EM

15

Page 281 of 513

SERVICE

EQUIPMENT

Tool

number

S

M

reference

Tool

name

Figure

Description

page

See

mm

inch

Fig

No

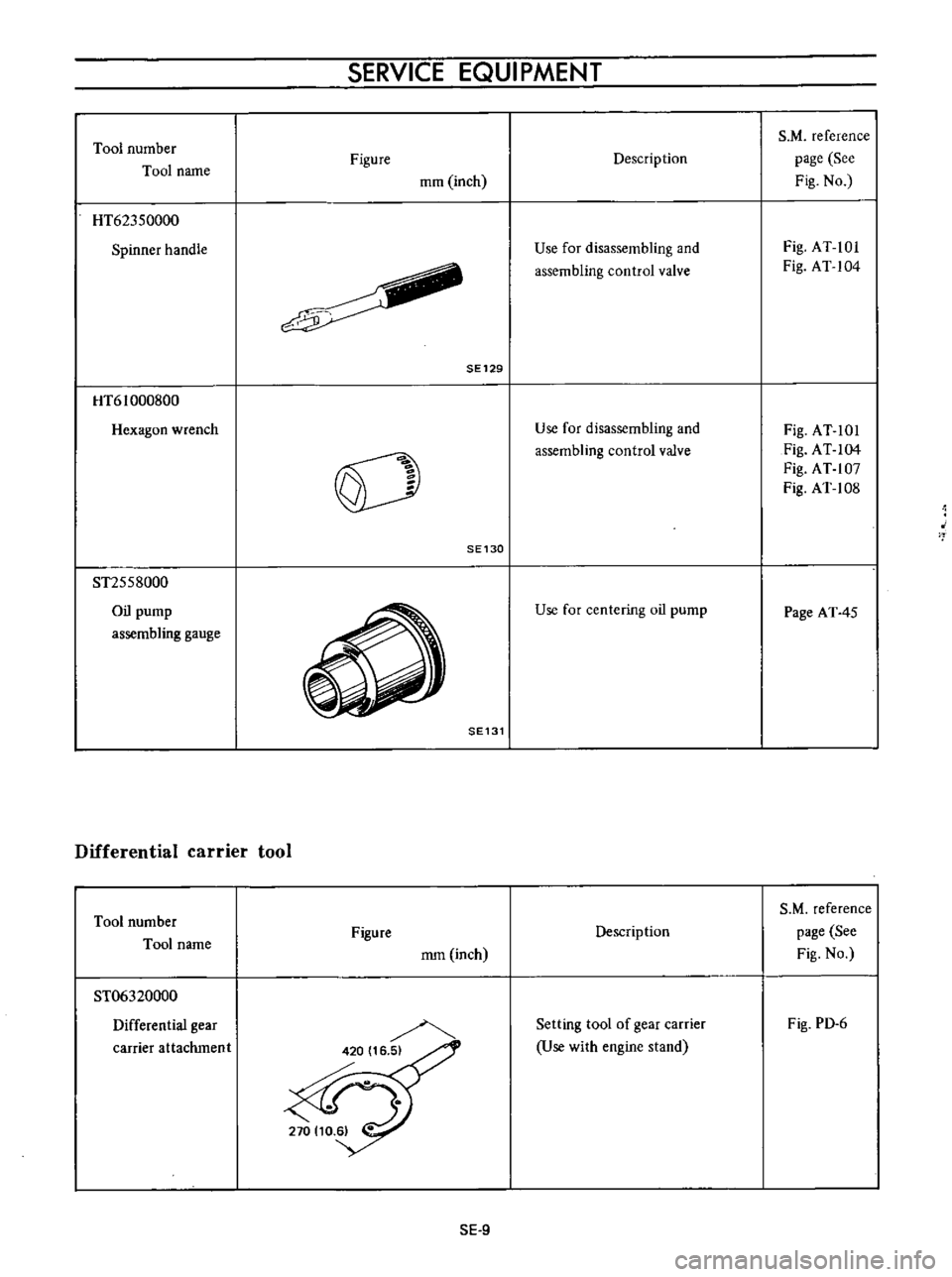

HT62350000

Spinner

handle

Use

for

disassembling

and

Fig

AT

101

assembling

control

valve

Fig

AT

104

SE129

HT61000800

Hexagon

wrench

Use

for

disassembling

and

Fig

AT

101

0

assembling

control

valve

Fig

AT

104

Fig

AT

107

Fig

AT

108

SE130

sT2558000

Oil

pump

Use

for

centering

oil

pump

Page

AT

45

assembling

gauge

SE131

Differential

carrier

tool

Tool

number

Tool

name

Figure

Description

S

M

reference

page

See

Fig

No

rom

inch

sT06320000

Differential

gear

carrier

attachment

Setting

tool

of

gear

carrier

Use

with

engine

stand

Fig

PD

6

sE

9

Page 283 of 513

Tool

number

Tool

name

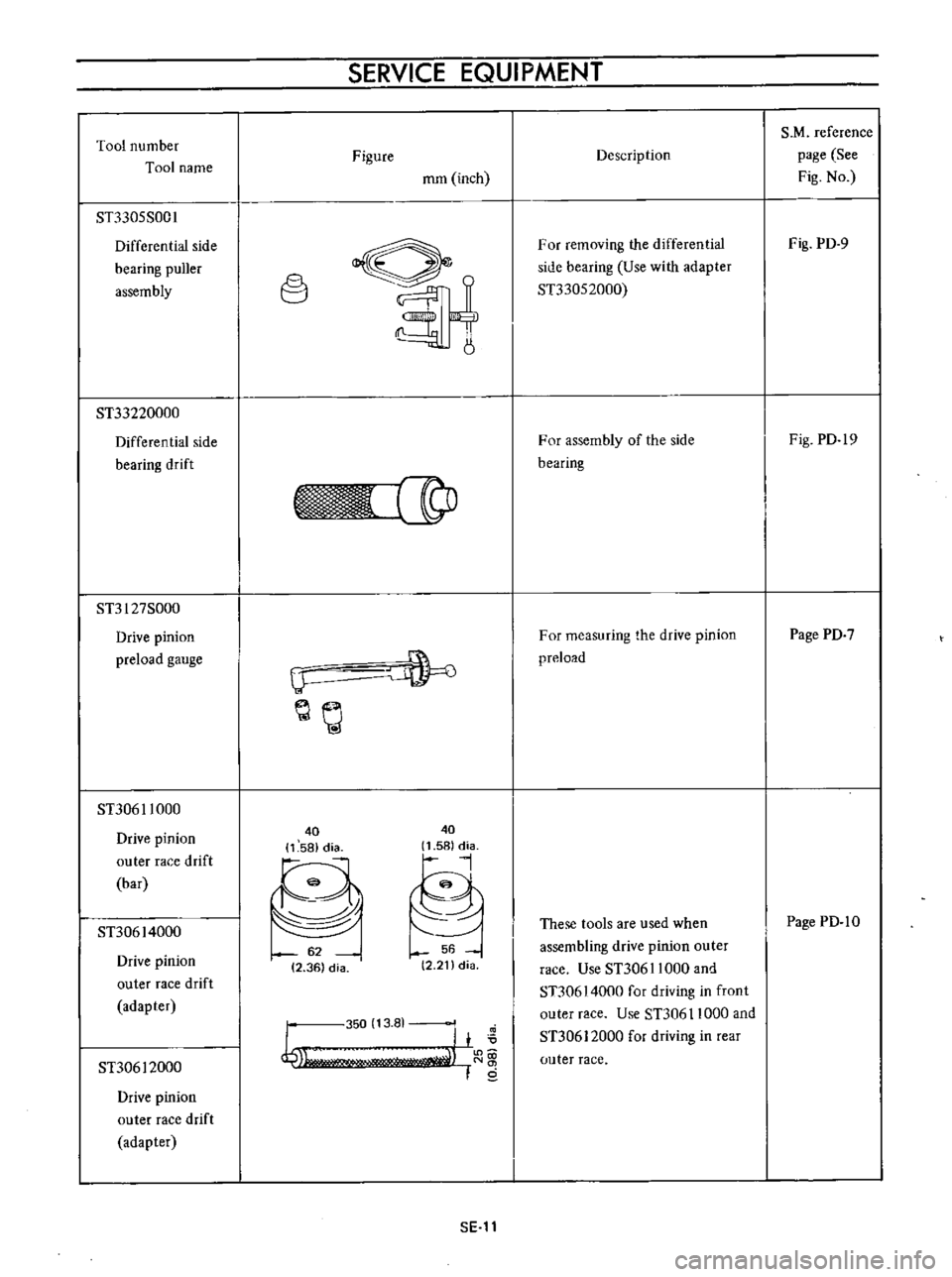

ST3305S001

Differential

side

bearing

puller

assembly

ST33220000

Differential

side

bearing

drift

ST3

I

275000

Drive

pinion

preload

gauge

ST30611000

Drive

pinion

outer

race

drift

bar

ST30614000

Drive

pinion

outer

race

drift

adapter

ST306

I

2000

Drive

pinion

outer

race

drift

adapter

SERVICE

EQUIPMENT

Figure

mm

inch

@

o

a

l

40

1

581

dia

40

1

581

dia

1

56

2

211

dia

62

2

36

dia

5

3

1

I

I

5

wil

N

I

SE

ll

Description

For

removing

the

differential

side

bearing

Use

with

adapter

ST33052000

For

assembly

of

the

side

bearing

For

measuring

the

drive

pinion

preload

The

tools

are

used

when

assembling

drive

pinion

outer

race

Use

ST30611000

and

ST30614000

for

driving

in

front

outer

race

Use

ST30611000

and

ST30612000

for

driving

in

rear

outer

race

S

M

reference

page

See

Fig

No

Fig

PD

9

Fig

PD

19

Page

PD

7

Page

PD

1O

Page 301 of 513

GENERAL

INFORMATION

steering

wheel

should

be

secured

to

maintain

a

straight

ahead

position

TIE

DOWN

The

front

tie

down

hook

is

used

the

both

front

end

of

tension

rod

Do

not

apply

the

hook

at

the

center

of

tension

rod

or

suspension

member

The

rear

tie

down

hook

is

used

the

both

front

shackle

of

rear

spring

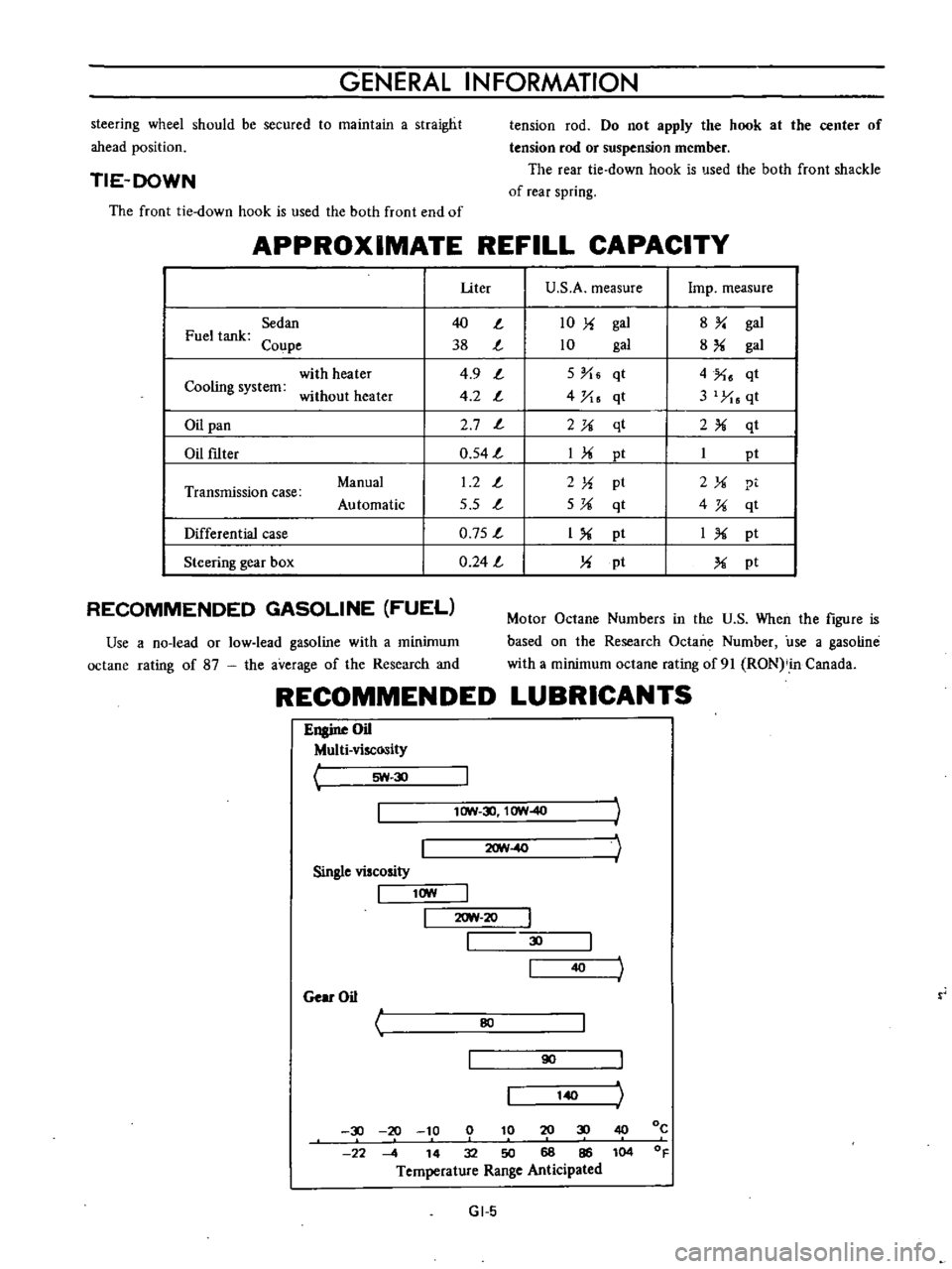

APPROXIMATE

REFILL

CAPACITY

Liter

U

S

A

measure

I

Imp

measure

Sedan

Fuel

tank

Coupe

with

heater

Cooling

system

without

heater

40

L

38

L

4

9

L

4

2

L

2

7

L

0

54

L

1

2

L

5

5

L

0

75

L

0

24

L

Oil

pan

Oilf1lter

Transmission

case

Manual

Automatic

Differential

case

Steering

gear

box

RECOMMENDED

GASOLINE

FUEL

Use

a

no

lead

or

low

lead

gasoline

with

a

minimum

octane

rating

of

87

the

average

of

the

Research

and

1O

gal

8Y

gal

10

gal

8

gal

5

v

qt

4

M

qt

4

Y

6

qt

3

Y

qt

2Ji

qt

2

qt

1

pt

I

pt

2

pt

2

pt

5Ji

qt

4

qt

1

pt

1

pt

pt

pi

Motor

Octane

Numbers

in

the

U

S

When

the

figure

is

based

on

the

Research

Octane

Number

use

a

gasoline

with

a

minimum

octane

rating

of

91

RON

in

Canada

RECOMMENDED

LUBRICANTS

GI

5

r

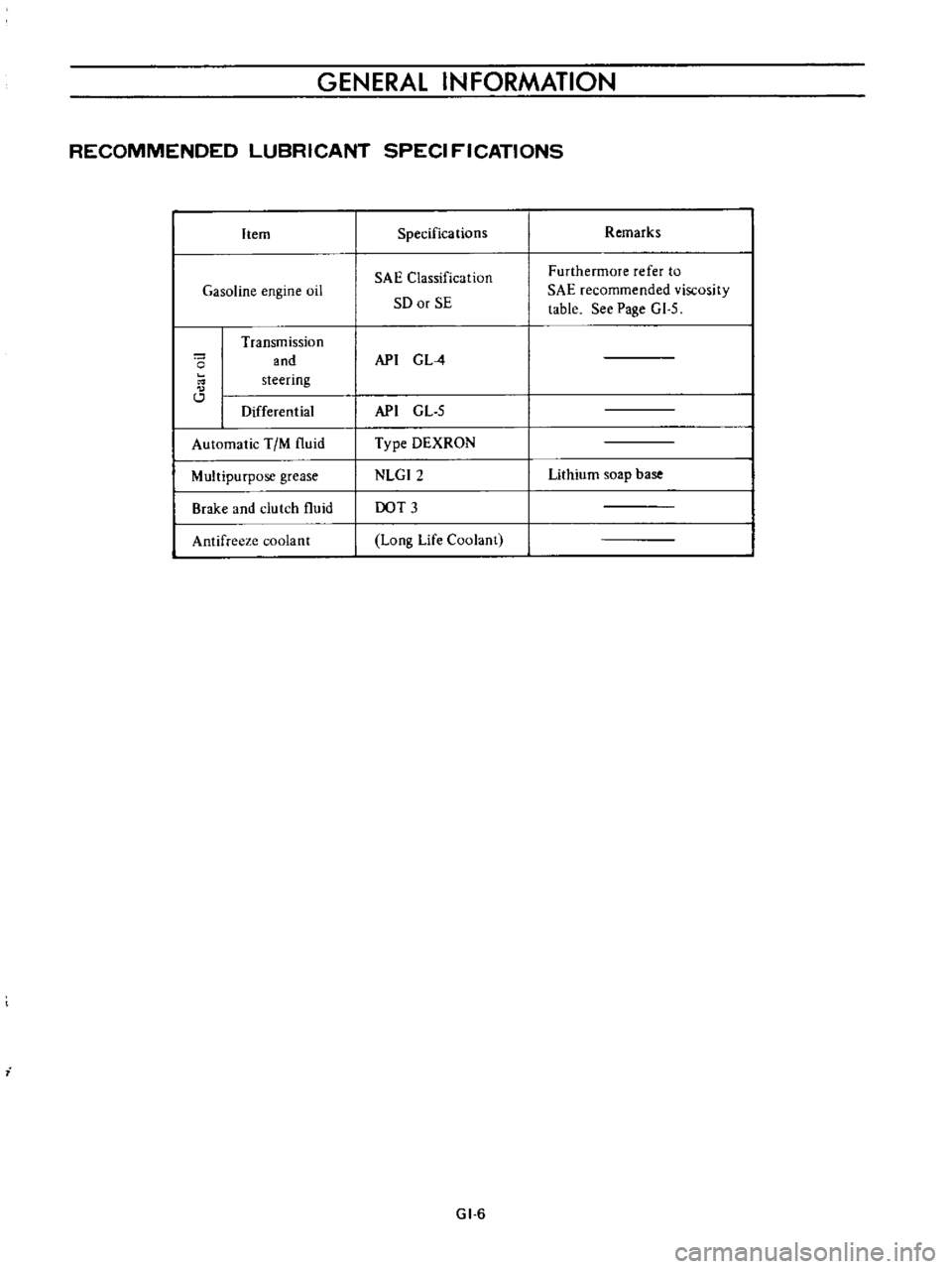

Page 302 of 513

GENERAL

INFORMATION

RECOMMENDED

LUBRICANT

SPECI

FICATIONS

Item

Gasoline

engine

oil

o

Transmission

and

steering

Differential

Automatic

TIM

fluid

Multipurpose

grease

Brake

and

clutch

fluid

Antifreeze

coolant

i

Specifications

SAE

Classification

SO

or

SE

API

G

L

4

API

GL

5

Type

DEXRON

NLGI2

DOT

3

Long

Life

Coolant

GI

6

Remarks

Furthermore

refer

to

SAE

recommended

viscosity

table

See

Page

GI

5

Lithium

soap

base

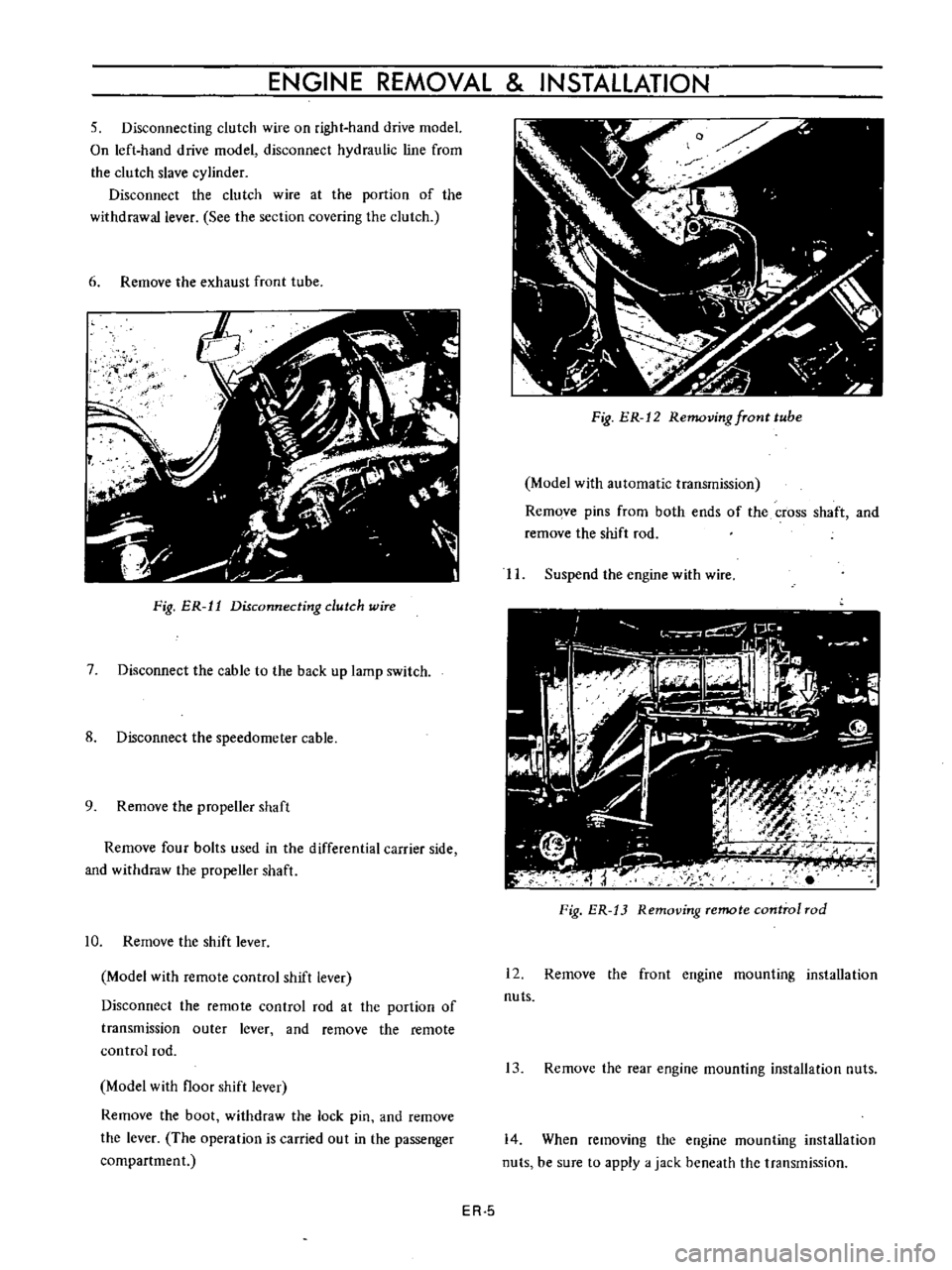

Page 468 of 513

ENGINE

REMOVAL

INSTAllATION

5

Disconnecting

clutch

wire

on

right

hand

drive

model

On

left

hand

drive

model

disconnect

hydraulic

line

from

the

clutch

slave

cylinder

Disconnect

the

clutch

wire

at

the

portion

of

the

withdrawal

lever

See

the

section

covering

the

clutch

6

Remove

the

exhaust

front

tube

ij

f

I

Fig

ER

11

Disconnecting

dutch

wire

7

Disconnect

the

cable

to

the

back

up

lamp

switch

8

Disconnect

the

speedometer

cable

9

Remove

the

propeller

shaft

Remove

four

bolts

used

in

the

differential

carrier

side

and

withdraw

the

propeller

shaft

10

Remove

the

shift

lever

Model

with

remote

control

shift

lever

Disconnect

the

remote

control

rod

at

the

portion

of

transmission

outer

lever

and

remove

the

remote

control

rod

Model

with

floor

shift

lever

Remove

the

boot

withdraw

the

lock

pin

and

remove

the

lever

The

operation

is

carried

out

in

the

passenger

compartment

Fig

ER

12

Removing

fTont

tube

Model

with

automatic

transmission

Remove

pins

from

both

ends

of

the

cross

shaft

and

remove

the

shift

rod

II

Suspend

the

engine

with

wire

Fig

ER

13

Removing

remote

control

rod

12

Remove

the

front

engine

mounting

installation

nuts

13

Remove

the

rear

engine

mounting

installation

nuts

14

When

removing

the

engine

mounting

installation

nuts

be

sure

to

apply

a

jack

beneath

the

transmission

ER

5