differential DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 79 of 513

CHASSIS

7

Turn

drive

pinion

in

both

directions

several

times

to

set

bearing

rollers

And

adjust

bearing

preload

to

specifi

cations

Drive

pinion

bearing

preload

with

oil

seal

7

to

9

kg

cm

6

1

to

7

8

in

1b

At

companion

flange

bolt

hole

2

25

to

2

95

kg

4

96

to

6

50

1b

Pinion

nut

tightening

torque

12

to

17

kg

m

86

8

to

122

9

ft

1b

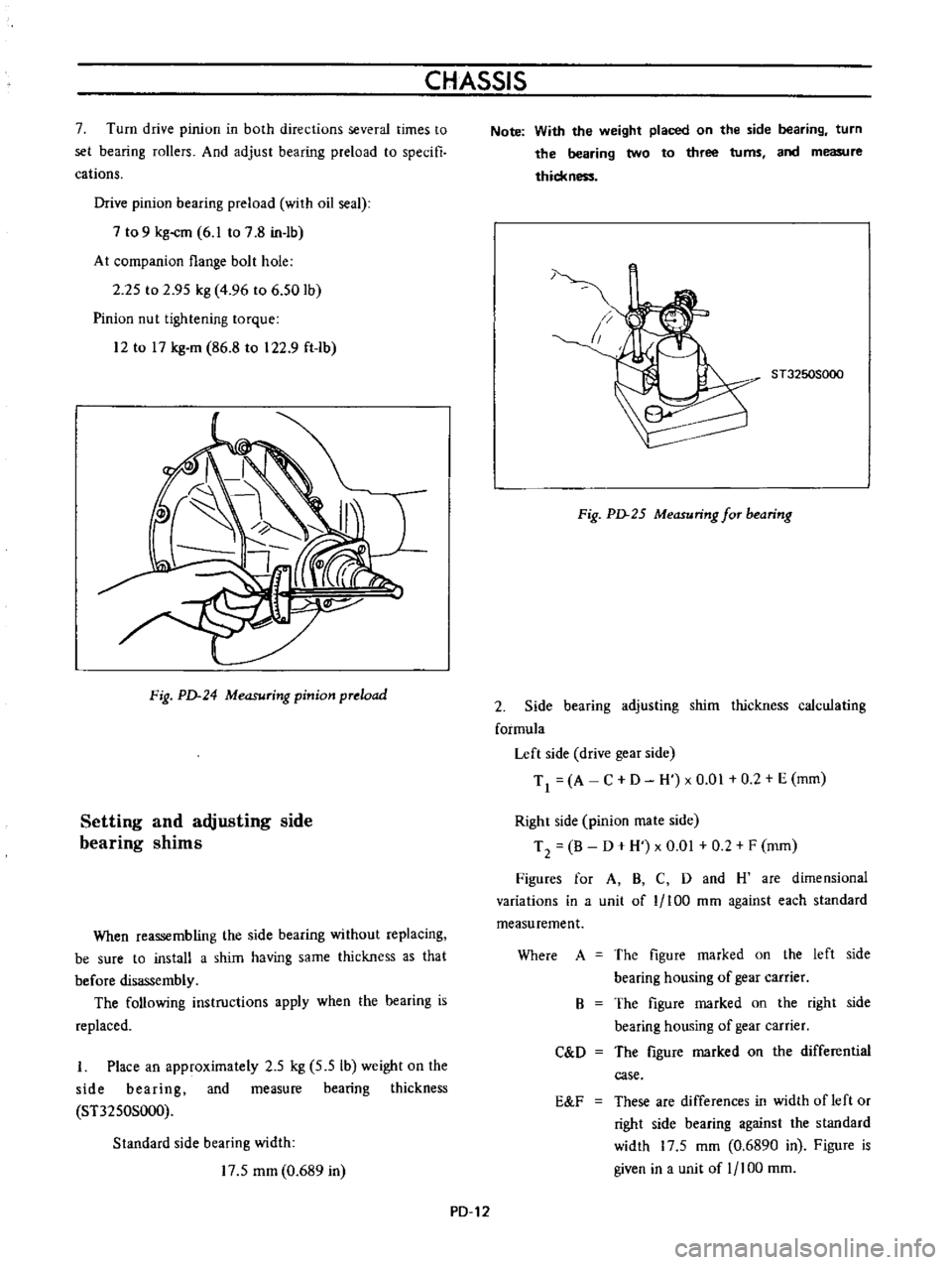

Fig

PD

24

Measuring

pinion

preload

Setting

and

adjusting

side

bearing

shims

When

reassembling

the

side

bearing

without

replacing

be

sure

to

install

a

shim

having

same

thickness

as

that

before

disassembly

The

following

instructions

apply

when

the

hearing

is

replaced

I

Place

an

approximately

2

5

kg

5

5

Ib

weight

on

the

side

bearing

and

measure

bearing

thickness

ST3250S000

Standard

side

bearing

width

17

5

mm

0

689

in

Note

With

the

weight

placed

on

the

side

bearing

turn

the

bearing

two

to

three

turns

and

measure

thickn

1

ST3250S000

Fig

PD

25

Measuring

for

bearing

2

Side

bearing

adjusting

shim

thickness

calculating

formula

Left

side

drive

gear

side

Tl

A

C

D

H

xO

01

0

2

E

mm

Right

side

pinion

mate

side

T

2

B

D

H

x

0

01

0

2

F

mm

Figures

for

A

B

C

D

and

H

are

dimensional

variations

in

a

unit

of

1

100

mm

against

each

standard

measurement

Where

A

The

figure

marked

on

the

left

side

bearing

housing

of

gear

carrier

The

figure

marked

on

the

right

side

bearing

housing

of

gear

carrier

The

figure

marked

on

the

differential

case

B

C

D

E

F

These

are

differences

in

width

of

left

or

right

side

bearing

against

the

standard

width

17

5

mm

0

6890

in

Figure

is

given

in

a

unit

of

1

100

mm

PD

12

Page 80 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

C

DMark

Unit

mm

in

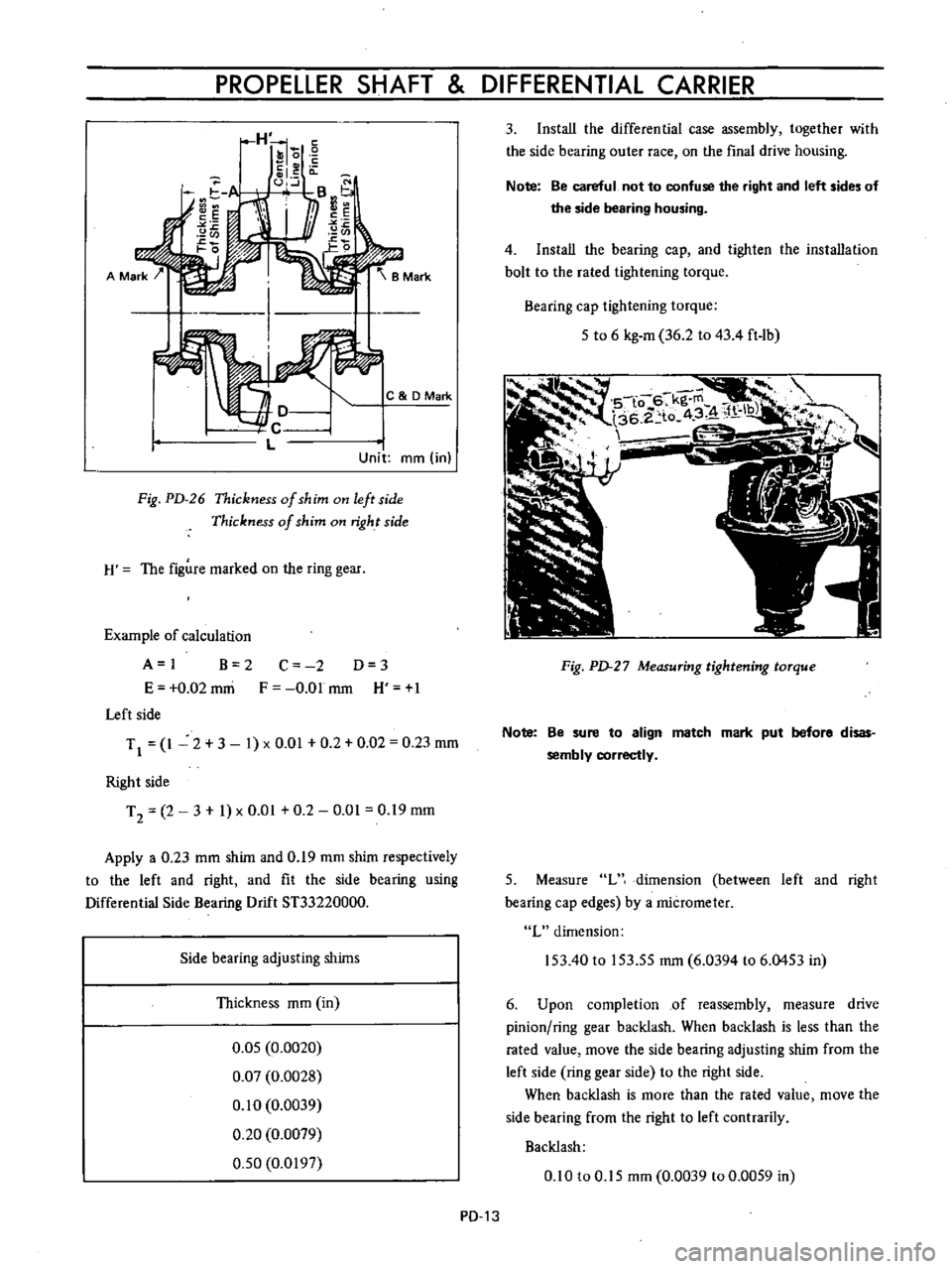

Fig

PD

26

Thickness

of

shim

on

left

side

Thickness

of

shim

on

right

side

H

The

figure

marked

on

the

ring

gear

Example

of

calculation

A

I

B

2

E

0

02

mni

Left

side

C

2

D

3

F

O

Olmm

H

1

TJ

1

2

3

1

xO

01

0

2

0

02

0

23

mm

Right

side

T

2

2

3

1

x

0

01

0

2

0

01

0

19

mm

Apply

a

0

23

mm

shim

and

0

19

mm

shim

respectively

to

the

left

and

right

and

fit

the

side

bearing

using

Differential

Side

Bearing

Drift

ST33220000

Side

bearing

adjusting

shims

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

PD

13

3

Install

the

differential

case

assembly

together

with

the

side

bearing

outer

race

on

the

final

drive

housing

Note

Be

careful

not

to

confuse

the

right

and

left

sides

of

the

side

bearing

housing

4

Install

the

bearing

cap

and

tighten

the

installation

bolt

to

the

rated

tightening

torque

Bearing

cap

tightening

torque

5

to

6

kg

m

36

2

to

43

4

ft

1b

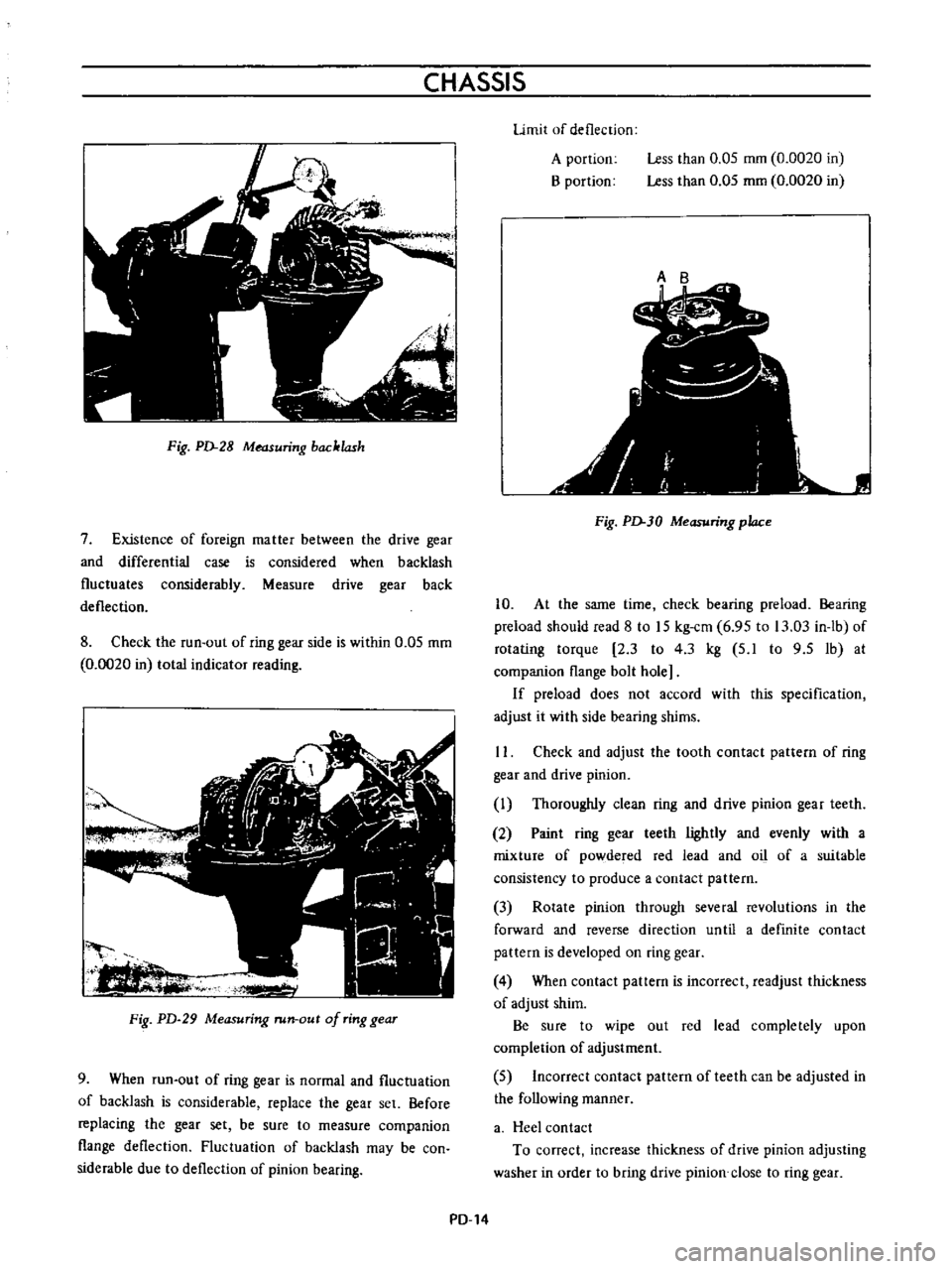

Fig

PD

27

Measuring

tightening

torque

Note

Be

sure

to

align

match

mark

put

before

disas

sembly

correctly

5

Measure

L

dimension

between

left

and

right

bearing

cap

edges

by

a

micrometer

L

dimension

153

40

to

153

55

mm

6

0394

to

6

0453

in

6

Upon

completion

of

reassembly

measure

drive

pinion

ring

gear

backlash

When

backlash

is

less

than

the

rated

value

move

the

side

bearing

adjusting

shim

from

the

left

side

ring

gear

side

to

the

right

side

When

backlash

is

more

than

the

rated

value

move

the

side

bearing

from

the

right

to

left

contrarily

Backlash

0

10

to

0

15

mm

0

0039

to

0

0059

in

Page 81 of 513

CHASSIS

Fig

PD

28

Measuring

backlash

7

Existence

of

foreign

matter

between

the

drive

gear

and

differential

case

is

considered

when

backlash

fluctuates

considerably

Measure

drive

gear

back

deflection

8

Check

the

run

out

of

ring

gear

side

is

within

0

05

mm

0

0020

in

total

indicator

reading

ot

Fig

PD

29

Measuring

run

out

of

ring

gear

9

When

run

out

of

ring

gear

is

normal

and

fluctuation

of

backlash

is

considerable

replace

the

gear

set

Before

replacing

the

gear

set

be

sure

to

measure

companion

flange

deflection

Fluctuation

of

backlash

may

be

con

siderable

due

to

deflection

of

pinion

bearing

Limit

of

deflection

A

portioo

B

portion

Less

than

0

05

mm

0

0020

in

Less

than

0

05

mm

0

0020

in

Ct

r

r

f

1

I

f

i

r

I

oj

j

12

r

Fig

PD

30

Measuring

place

10

At

the

same

time

check

bearing

preload

Bearing

preload

should

read

8

to

15

kg

cm

6

95

to

13

03

in

lb

of

rotating

torque

2

3

to

4

3

kg

5

1

to

9

5

1b

at

companion

flange

bolt

hole

If

preload

does

not

accord

with

this

specification

adjust

it

with

side

bearing

shims

II

Check

and

adjust

the

tooth

contact

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

powdered

red

lead

and

oil

of

a

suitable

consistency

to

produce

a

contact

pattern

3

Rorate

pinion

through

several

revolutions

in

the

forward

and

reverse

direction

until

a

definite

contact

pattern

is

developed

on

ring

gear

4

When

contact

pattern

is

incorrect

readjust

thickness

of

adjust

shim

Be

sure

to

wipe

out

red

lead

completely

upon

completion

of

adjustment

5

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

following

manner

a

Heel

contact

To

correct

increase

thickness

of

drive

pinion

adjusting

washer

in

order

to

bring

drive

pinion

close

to

ring

gear

PD

14

Page 82 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

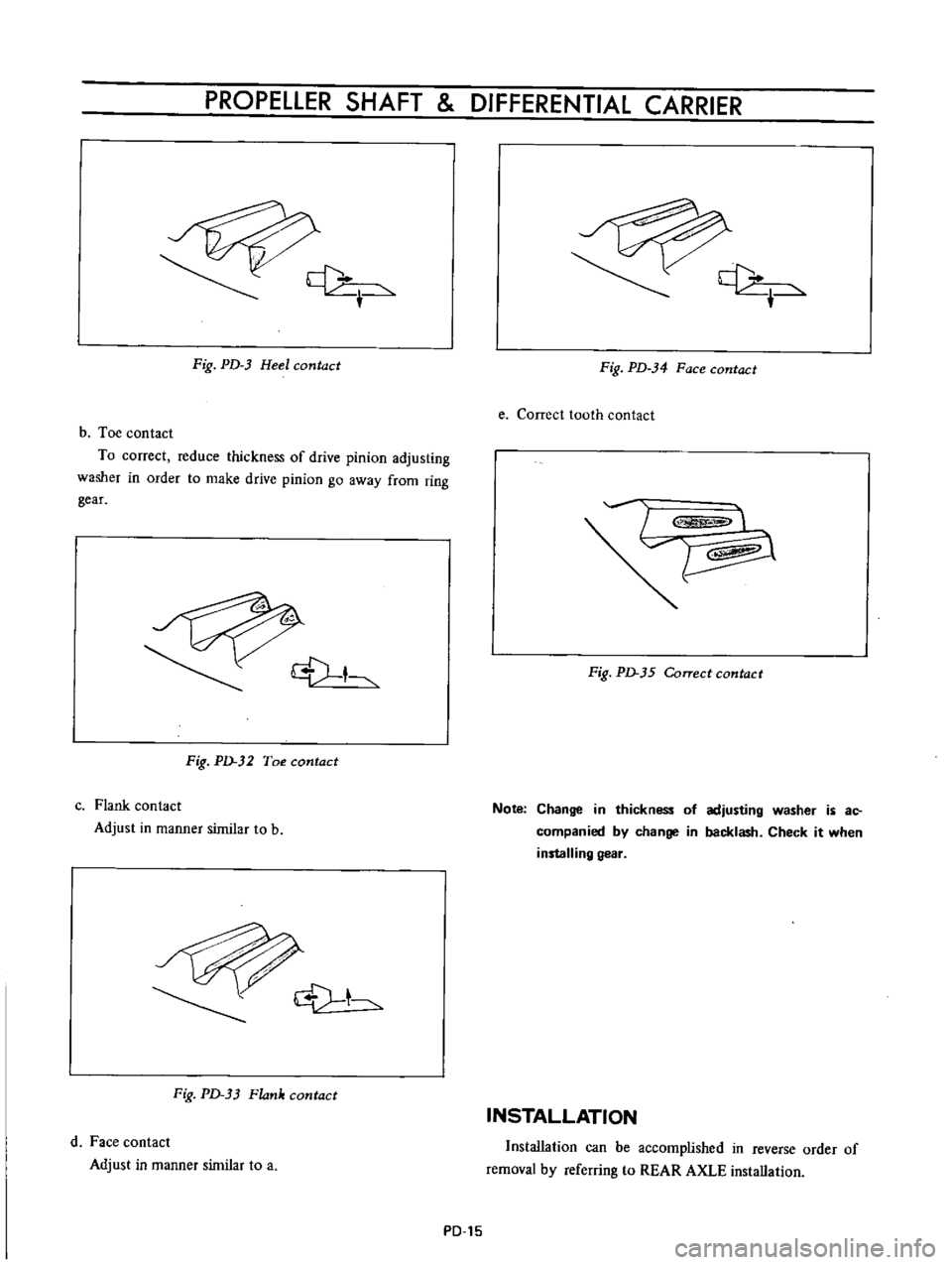

Fig

PD

J

Heel

contact

Fig

PD

34

Face

contact

e

Correct

tooth

contact

b

Toe

contact

To

correct

reduce

thickness

of

drive

pinion

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

L

a

Fig

PD

35

Correct

contact

Fig

PD

J2

Toe

contact

c

Flank

contact

Adjust

in

manner

similar

to

b

Note

Change

in

thickness

of

adjusting

washer

is

ac

companied

by

change

in

backlash

Check

it

when

installing

gear

t

Fig

PD

3J

Flank

contact

INSTALLATION

d

Face

contact

Adjust

in

manner

similar

to

a

Installation

can

be

accomplished

in

reverse

order

of

removal

by

referring

to

REAR

AXLE

installation

PO

15

Page 84 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Incorrect

adjustment

of

bearings

or

gears

Severe

service

due

to

an

excessive

loading

improper

use

of

clutch

Loosened

bolts

and

nuts

such

as

ring

gear

clamp

bolts

Oil

leakage

Worn

out

damaged

or

improperly

driven

front

oil

seal

or

bruised

dented

or

abnormally

worn

slide

face

of

companion

flange

Loosened

bolts

holding

gear

carrier

Defective

gasket

Loosen

filler

or

drain

plug

Clogged

or

damaged

breather

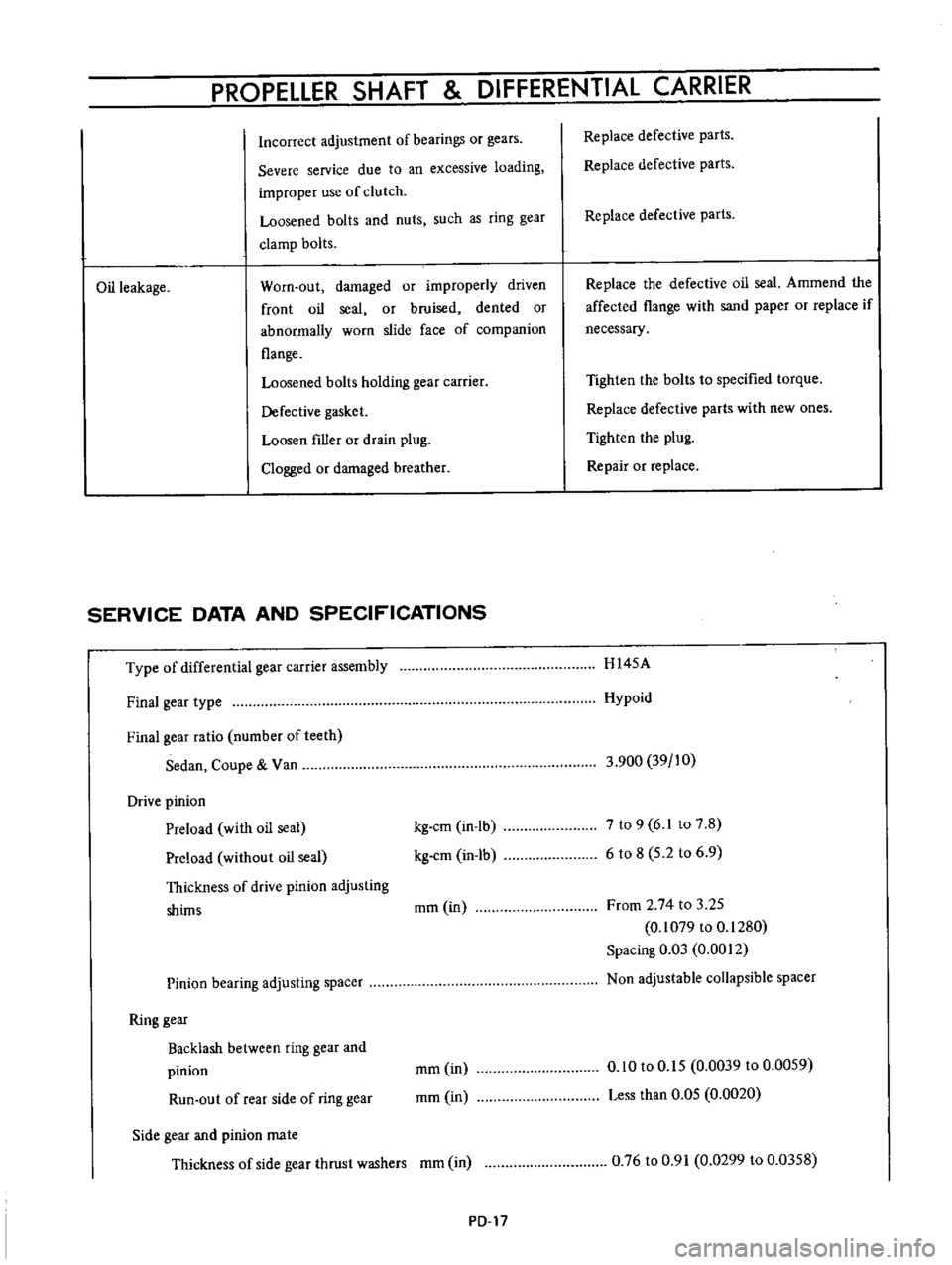

SERVICE

DATA

AND

SPECIFICATIONS

Type

of

differential

gear

carrier

assembly

Final

gear

type

Final

gear

ratio

number

of

teeth

Sedan

Coupe

Van

Drive

pinion

Preload

with

oil

seal

Preload

without

oil

seal

Thickness

of

drive

pinion

adjusting

shims

kg

cm

in

lb

kg

cm

in

lb

mm

in

Pinion

bearing

adjusting

spacer

Ring

gear

Backlash

between

ring

gear

and

pinion

Run

out

of

rear

side

of

ring

gear

mm

in

mm

in

Side

gear

and

pinion

mate

Thickness

of

side

gear

thrust

washers

mm

in

PD

17

Replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Replace

the

defective

oil

seal

Ammend

the

affected

flange

with

sand

paper

or

replace

if

necessary

Tighten

the

bolts

to

specified

torque

Replace

defective

parts

with

new

ones

Tighten

the

plug

Repair

or

replace

H145A

Hypoid

3

900

39

10

7

to

9

6

1

to

7

8

6

to

8

5

2

to

6

9

From

2

74

to

3

25

0

1079

to

0

1280

Spacing

0

Q3

0

0012

Non

adjustable

collapsible

spacer

0

10

to

0

15

0

0039

to

0

0059

Less

than

0

05

0

0020

0

76

to

0

91

0

0299

to

0

0358

Page 85 of 513

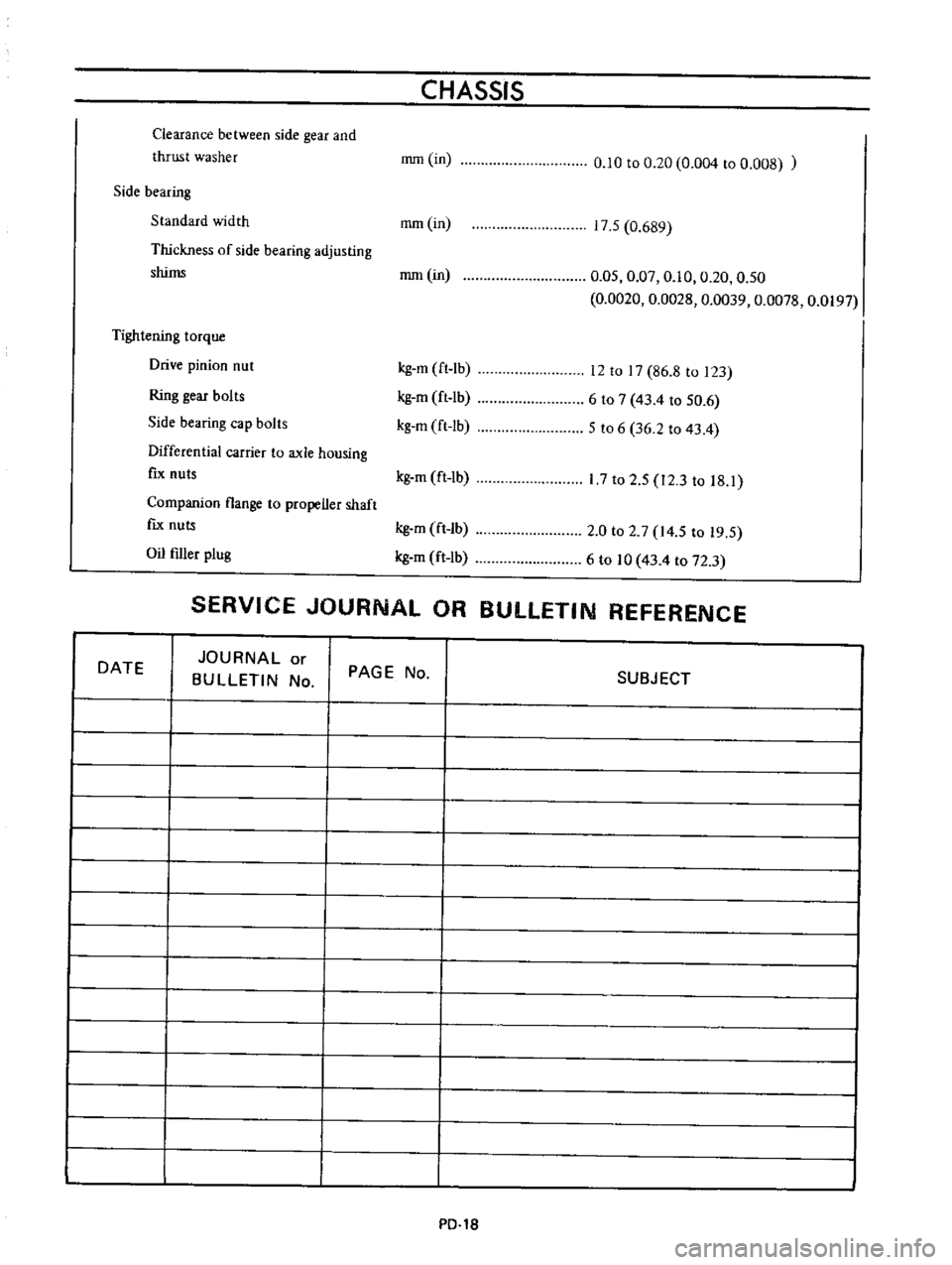

Clearance

between

side

gear

and

thrust

washer

CHASSIS

rrun

in

0

10

to

0

20

0

004

to

0

008

Side

bearing

Standard

width

rom

in

Thickness

of

side

bearing

adjusting

shims

rom

in

Tightening

torque

Drive

pinion

nut

Ring

gear

bolts

Side

bearing

cap

bolts

Differential

carrier

to

axle

housing

fIx

nuts

Companion

flange

to

propeller

shaft

fIx

nuts

Oil

filler

plug

17

5

0

689

0

05

0

07

0

10

0

20

0

50

0

0020

0

0028

0

0039

0

0078

0

0197

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

12

to

17

86

8

to

123

6

to

7

43

4

to

50

6

5

to

6

36

2

to

43

4

kg

m

ft

1b

17

to

2

5

12

3

to

18

1

kg

m

ft

lb

kg

m

ft

lb

2

0

to

2

7

14

5

to

19

5

6

to

10

43

4

to

72

3

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

I

I

I

I

PAGE

No

SUBJECT

PO

1S

Page 122 of 513

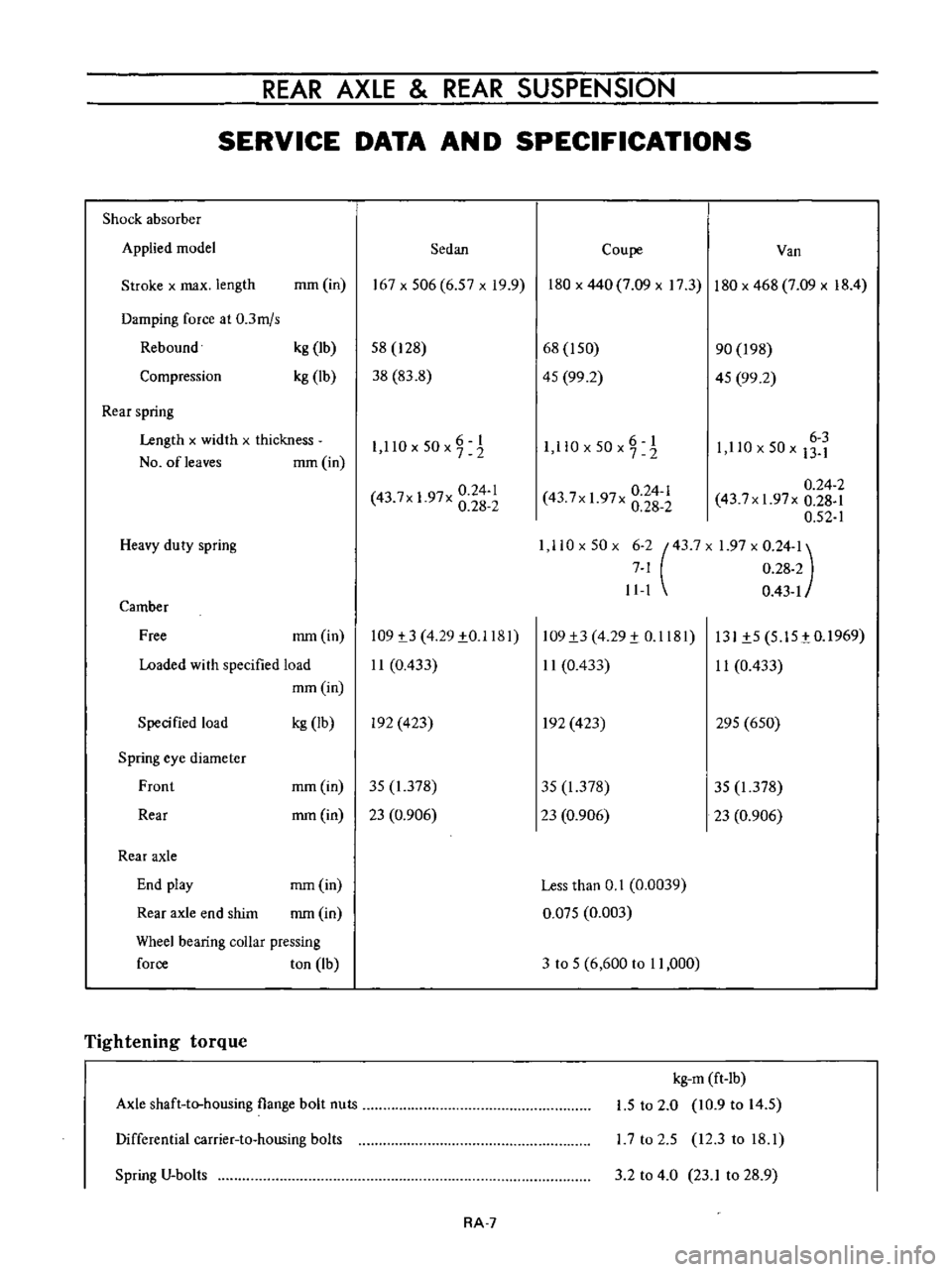

REAR

AXLE

REAR

SUSPENSION

SERVICE

DATA

AN

D

SPECIFICATIONS

Shock

absorber

Applied

model

Sedan

Coupe

Van

Stroke

x

max

length

mm

in

167x506

6

57xI9

9

180

x

440

7

09

x

17

3

180

x

468

7

09

x

18

4

Damping

force

at

0

3mjs

Rebound

Compression

kg

Ib

kg

lb

58

128

38

83

8

68

I

50

45

99

2

90

198

45

99

2

Rear

spring

Length

x

widlh

x

thickness

NO

ofleaves

mm

in

6

I

1

llOx50x72

O

6

1

I

ll

x50x7

2

6

3

1

110

x

50

x

13

1

0

24

1

43

7x

1

97x

0

28

2

0

24

2

43

7xI

97x

0

28

1

0

52

1

1

110x50x

6

2

43

7X

1

97

x

0

24

1

7

1

0

28

2

11

1

0

43

1

0

24

1

43

7x

1

97x

0

28

2

Heavy

duty

spring

Camber

Free

mm

in

109

t3

4

29

1

0

1181

11

0

433

109

1

3

4

29

1

0

1181

11

0

433

131

1

5

5

15

tO

1969

11

0

433

Loaded

wi

th

specified

load

mm

in

Specified

load

kg

Ib

In

423

In

423

295

650

Spring

eye

diameter

Front

mm

in

35

1

378

35

1

378

35

1

378

Rear

mm

in

23

0

906

23

0

906

23

0

906

Rear

axle

End

play

mm

in

Less

than

0

1

0

0039

Rear

axle

end

shim

mm

in

0

Q75

0

003

Wheel

bearing

coUar

pressing

force

ton

Ib

3

to

5

6

600

to

11

000

Tightening

torque

Axle

shaft

to

housing

flange

bolt

nuts

kg

m

ft

lb

1

5

to

2

0

10

9

to

14

5

L7

to

2

5

12

3

to

18

1

Differential

carrier

to

housing

bolts

Spring

V

bolts

3

2

to

4

0

23

1

to

28

9

RA

7

Page 125 of 513

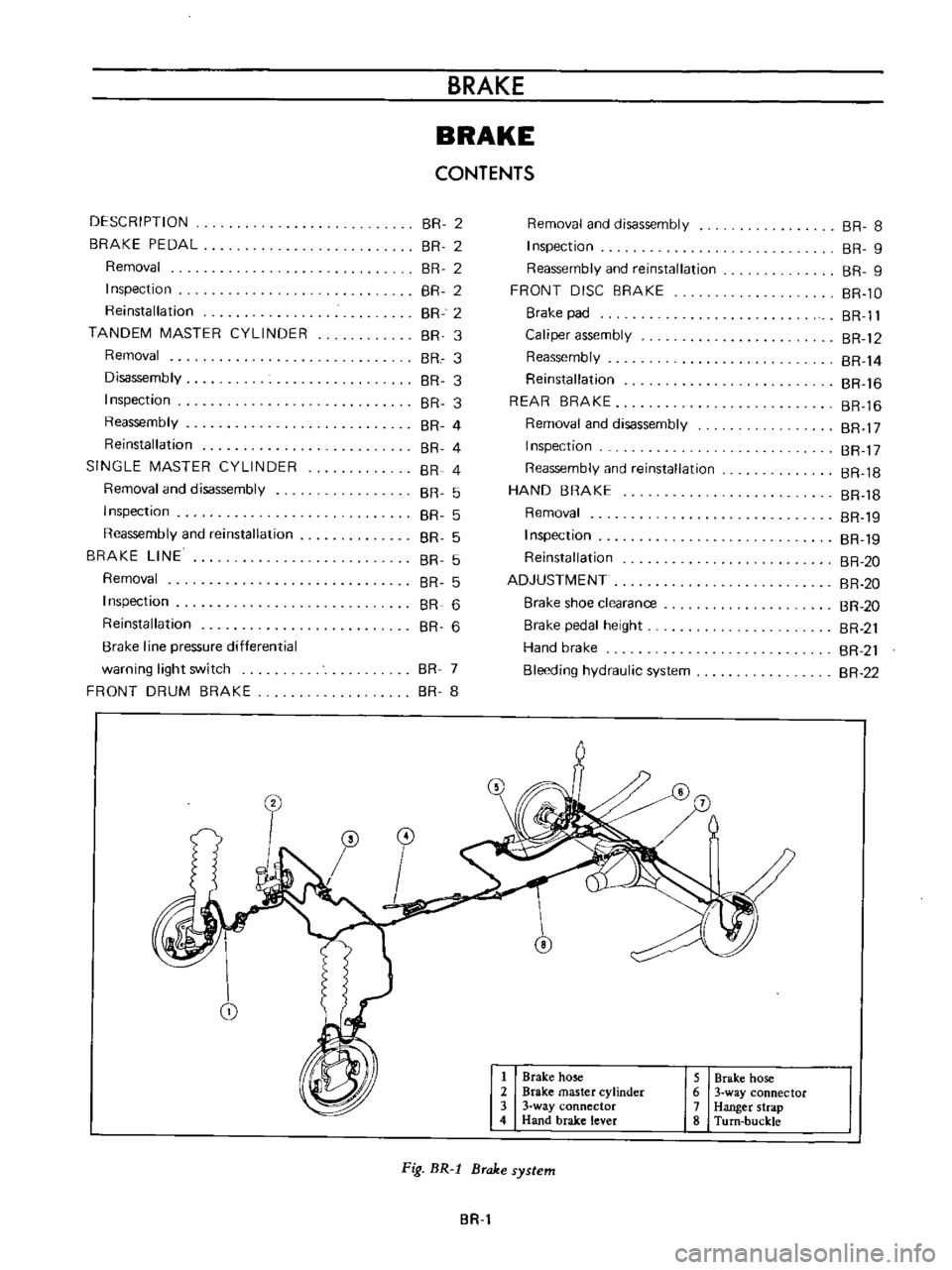

DESCRIPTION

BRAKE

PEDAL

Removal

Inspection

Reinstallation

TANDEM

MASTER

CYLINDER

Removal

Disassembly

Inspection

Reassembly

Reinstallation

SINGLE

MASTER

CYLINDER

Removal

and

disassembly

Inspection

Reassembly

and

reinstallation

BRAKE

LINE

Removal

Inspection

Reinstallation

Brake

line

pressure

differential

warning

light

switch

FRONT

DRUM

BRAKE

cr

I

1

0

I

I

CD

BRAKE

BRAKE

CONTENTS

BR

2

BR

2

BR

2

BR

2

BR

2

BR

3

BR

3

BR

3

BR

3

BR

4

BR

4

BR

4

BR

5

BR

5

BR

5

BR

5

BR

5

BR

6

BR

6

BR

7

BR

8

Removal

and

disassembly

Inspection

Reassembly

and

reinstallation

FRONT

DISC

BRAKE

Brake

pad

Caliper

assembly

Reassembly

Reinstallation

REAR

BRAKE

Removal

and

disassembly

Inspection

Reassembly

and

reinstallation

HAND

8RAKE

Removal

Inspection

Reinstallation

ADJUSTMENT

Brake

shoe

clearance

Brake

pedal

height

Hand

brake

Bleeding

hydraulic

system

@

7

o

i

1

Brake

hose

2

Brake

master

cylinder

3

3

way

connector

4

Hand

brake

lever

5

Brake

hose

6

3

way

connector

7

Hanger

strap

8

Turn

buckle

Fig

BR

l

Brake

system

BR

BR

8

BR

9

BR

9

BR

lO

BR

Il

BR

12

BR

14

BR

16

BR

16

BR

17

BR

17

BR

18

BR

18

BR

19

BR

19

BR

20

BR

20

BR

20

BR

21

BR

21

BR

22

Page 131 of 513

Tightening

torque

3

way

connector

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lh

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lh

1

5

to

1

8

kg

m

10

8

to

13

0

ft

lb

0

7

to

0

9

kg

m

5

1

to

6

5

ft

1b

Master

cylinder

Brake

hose

Air

bleeder

5

Fill

the

master

cylinder

brake

fluid

reservoir

with

brake

fluid

and

perform

air

bleeding

complele1y

Note

a

Do

not

use

brake

fluid

other

than

specified

b

The

specified

brake

fluid

is

used

for

both

single

and

tandem

type

master

cylinders

6

Upon

completion

of

air

bleeding

make

sure

that

the

brake

operates

correctly

and

check

the

brake

tube

and

hose

connectors

for

fluid

leaking

Fully

depress

the

brake

pedal

continue

to

depress

the

brake

pedal

for

several

seconds

and

make

sure

that

no

brake

fluid

leaks

from

any

part

of

the

brake

line

Replace

defective

part

if

required

Brake

line

pressure

differential

warning

light

switch

A

warning

light

is

located

on

the

instrument

panel

to

warn

the

driver

when

a

pressure

difference

of

13

to

17

kg

cm2

185

to

2421bJsq

in

exists

between

the

front

and

rear

b

rake

systems

A

hydraulically

actuated

warning

light

switch

is

located

in

the

engine

compartment

Both

front

and

rear

brake

systems

are

connected

to

this

switch

assembly

When

a

pressure

difference

of

13

to

17

kgJcm2

185

to

242

lbJsq

in

occurs

between

the

front

and

rear

brake

systems

the

valves

will

shuttle

toward

the

side

with

the

low

pressure

The

valve

contacts

with

the

switch

terminal

BRAKE

the

ground

circuit

for

the

warning

light

is

completed

and

thus

the

warning

light

lights

In

this

case

correct

the

hydraulic

brake

problem

and

bleed

the

brakes

Check

the

warning

light

switch

assembly

for

a

proper

operation

Check

the

switch

assembly

for

fluid

leakage

Note

Do

not

attempt

to

repair

switch

for

any

reason

replace

switch

assembly

completely

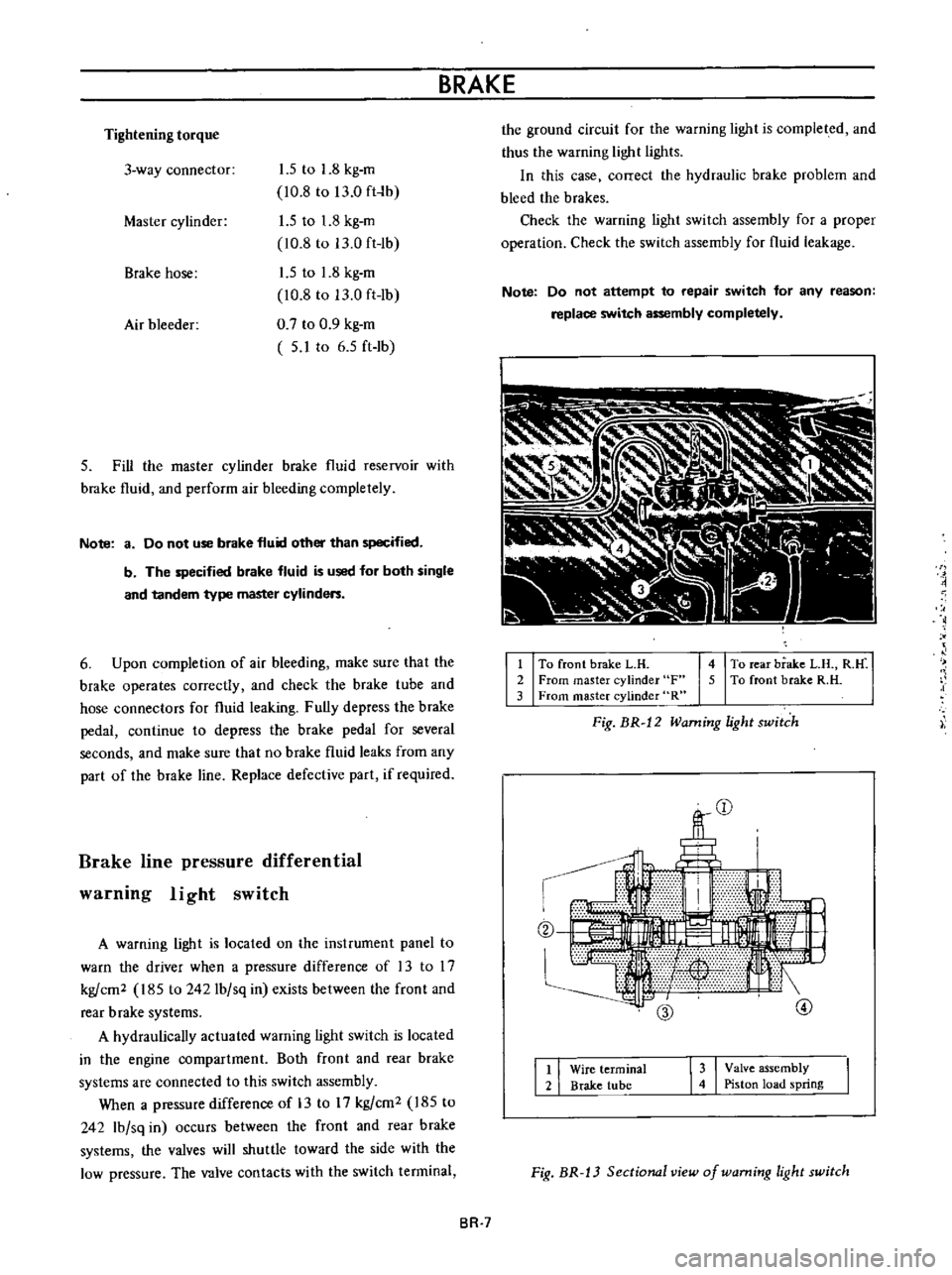

1

To

front

brake

L

H

2

From

master

cylinder

F

3

From

master

cylinder

R

4

To

rear

brake

L

B

R

M

5

To

front

brake

R

H

Fig

BR

12

Warning

light

switch

r

I

@

I

I

3

I

Valve

assembly

4

Piston

load

spring

Wire

terminal

Brake

tube

Fig

BR

13

Sectional

view

of

warning

light

switch

BR

7

Page 256 of 513

BODY

ElECTRICAL

When

the

ignition

switch

is

set

to

ON

the

ignition

wa

rning

circuit

is

closed

and

current

flows

flows

from

the

ignition

switch

to

the

warning

lamp

bulb

and

ground

through

the

regulator

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

current

opposes

the

current

flowing

from

the

warning

lamp

in

effect

it

breaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

l

r

hffi

u

z

Ignition

switch

I

Q

6

I

0

c

M

1

E

8

ca

i

L

g

PI

lot

c

P

I

j

co

rt

0

relay

E

0

5

y

y

1

N

N

3

Alternator

Regulator

Fig

BE

41

Circuit

of

ignition

warning

system

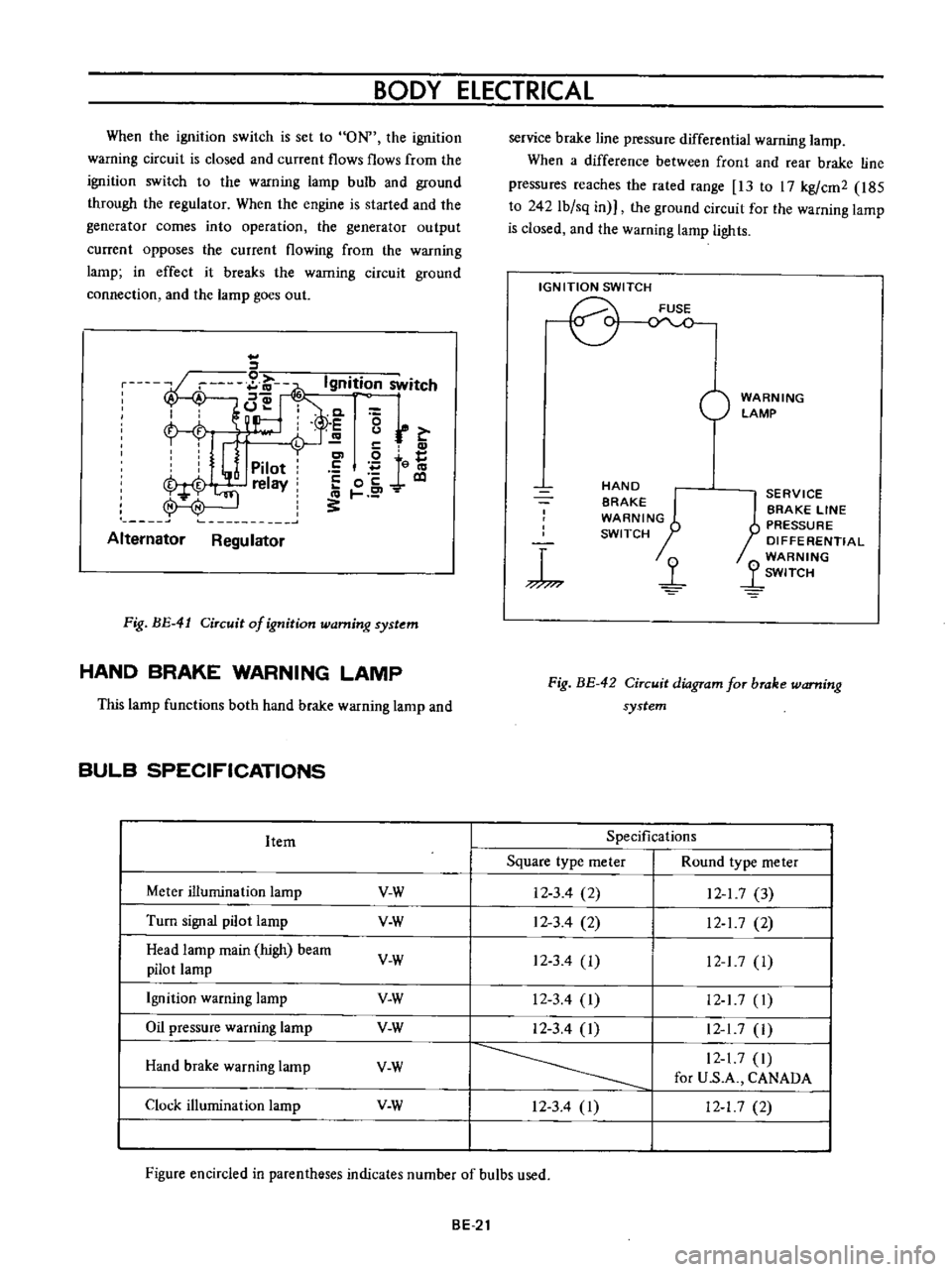

HAND

BRAKE

WARNING

LAMP

This

lamp

functions

both

hand

brake

warning

larnp

and

BULB

SPECIFICATIONS

service

brake

line

pressure

differential

warning

lamp

When

a

difference

between

front

and

rear

brake

line

pressures

reaches

the

rated

range

13

to

17

kgfcm2

185

to

242

lb

sq

in

the

ground

circuit

for

the

warning

lamp

is

closed

and

the

warning

lamp

lights

IGNITION

SWITCH

WARNING

LAMP

L

E

WARNING

SWITCH

1

SERVICE

BRAKE

LINE

PRESSU

R

E

DIFFERENTIAL

WARNING

J

SWITCH

Fig

BE

42

Circuit

diagram

for

brake

warning

system

tern

Specifications

Square

type

meter

Round

type

meter

Meter

illumination

larnp

VoW

12

3

4

2

12

1

7

3

Turn

signal

pilot

lamp

VoW

12

3

4

2

12

1

7

2

Head

lamp

main

high

beam

VoW

12

3

4

I

12

17

1

pilot

lamp

Ignition

warning

lamp

VoW

123

4

I

12

17

1

Oil

pressure

warning

lamp

VoW

12

3

4

1

12

1

7

1

Hand

brake

warning

lamp

VoW

12

1

7

1

for

U

S

A

CANADA

Clock

illumination

lamp

VoW

123

4

I

12

17

2

Figure

encircled

in

parentheses

indicates

number

of

bulbs

used

BE

21