ESP DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 404 of 513

FUEl

SYSTEM

l

I

@

1J

w

I

I

I

I

1

1

1

t

2

3

4

5

6

7

8

9

10

tt

12

Hi

metal

Heater

Bi

metal

cover

Fast

idle

earn

Bi

metal

Bi

metal

index

mark

Choke

shaft

lever

Choke

valve

Unloader

tang

Vacuum

diaphragm

Throttle

valve

Fast

idle

adjusting

screw

j

@

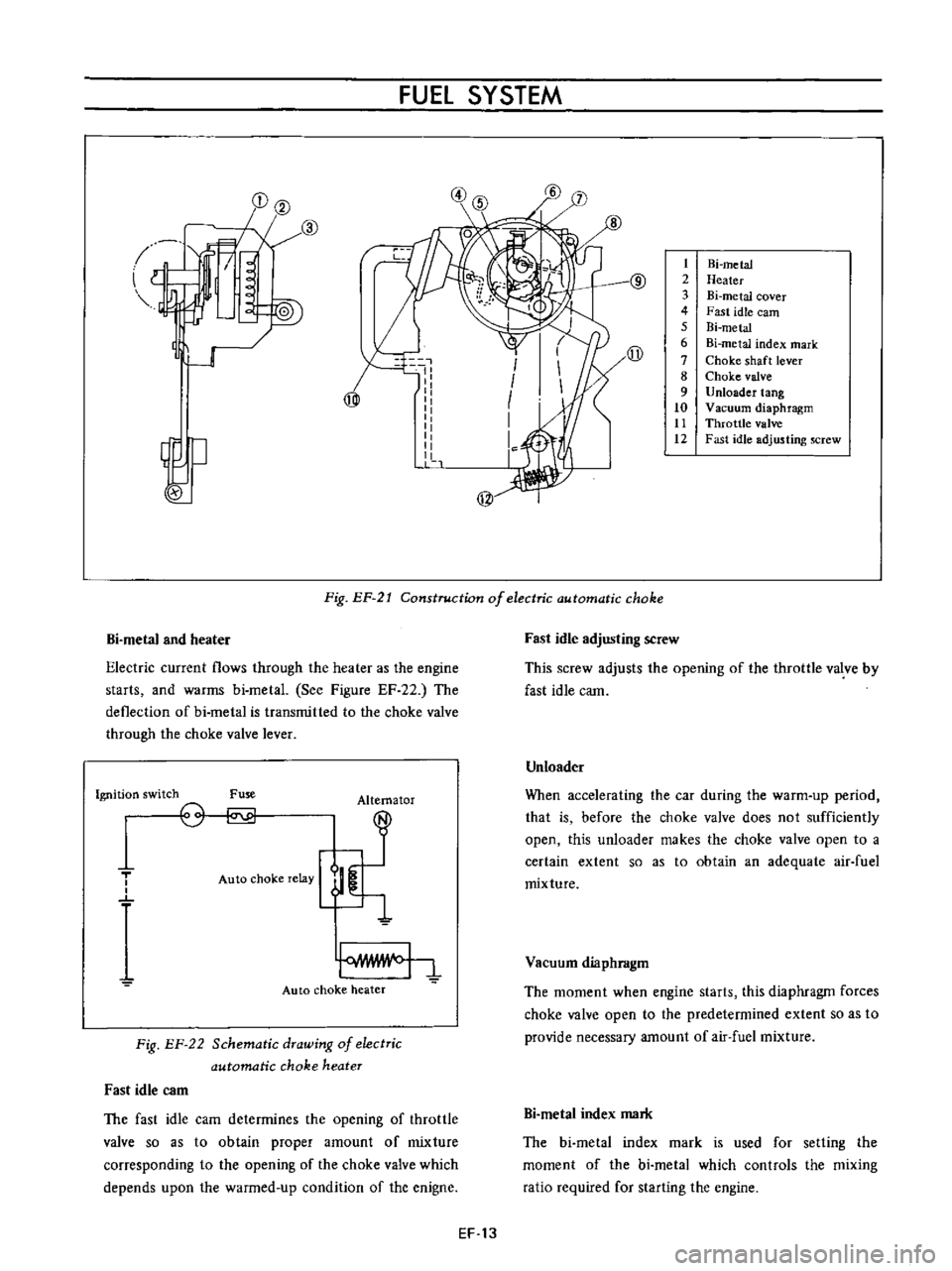

Fig

EP

21

Construction

of

electric

automatic

choke

Bi

metal

and

heater

Electric

current

flows

through

the

heater

as

the

engine

starts

and

warms

bi

metal

See

Figure

EF

22

The

deflection

of

bi

metal

is

transmitted

to

the

choke

valve

through

the

choke

valve

lever

Ignition

switch

Fuse

Alternator

T

o

o

Auto

choke

relay

Auto

choke

heater

Fig

EF

22

Schematic

drawing

of

electric

automatic

choke

heater

Fast

idle

C3m

The

fast

idle

cam

determines

the

opening

of

throttle

valve

so

as

to

obtain

proper

amount

of

mixture

corresponding

to

the

opening

of

the

choke

valve

which

depends

upon

the

warmed

up

condition

of

the

enigne

Fast

idle

adjusting

screw

This

screw

adjusts

the

opening

of

the

throttle

valve

by

fast

idle

cam

Unloader

When

accelerating

the

car

during

the

warm

up

period

that

is

before

the

choke

valve

does

not

sufficiently

open

this

unloader

makes

the

choke

valve

open

to

a

certain

extent

so

as

to

obtain

an

adequate

air

fuel

mixture

Vacuum

diaphragm

The

moment

when

engine

starts

this

diaphragm

forces

choke

valve

open

to

the

predetermined

extent

so

as

to

provide

necessary

amount

of

air

fuel

mixture

Bi

metaI

index

mark

The

bi

metal

index

mark

is

used

for

setting

the

moment

of

the

bi

metal

which

controls

the

mixing

ratio

required

for

starting

the

engine

EF

13

Page 411 of 513

ENGINE

Y

Q

0

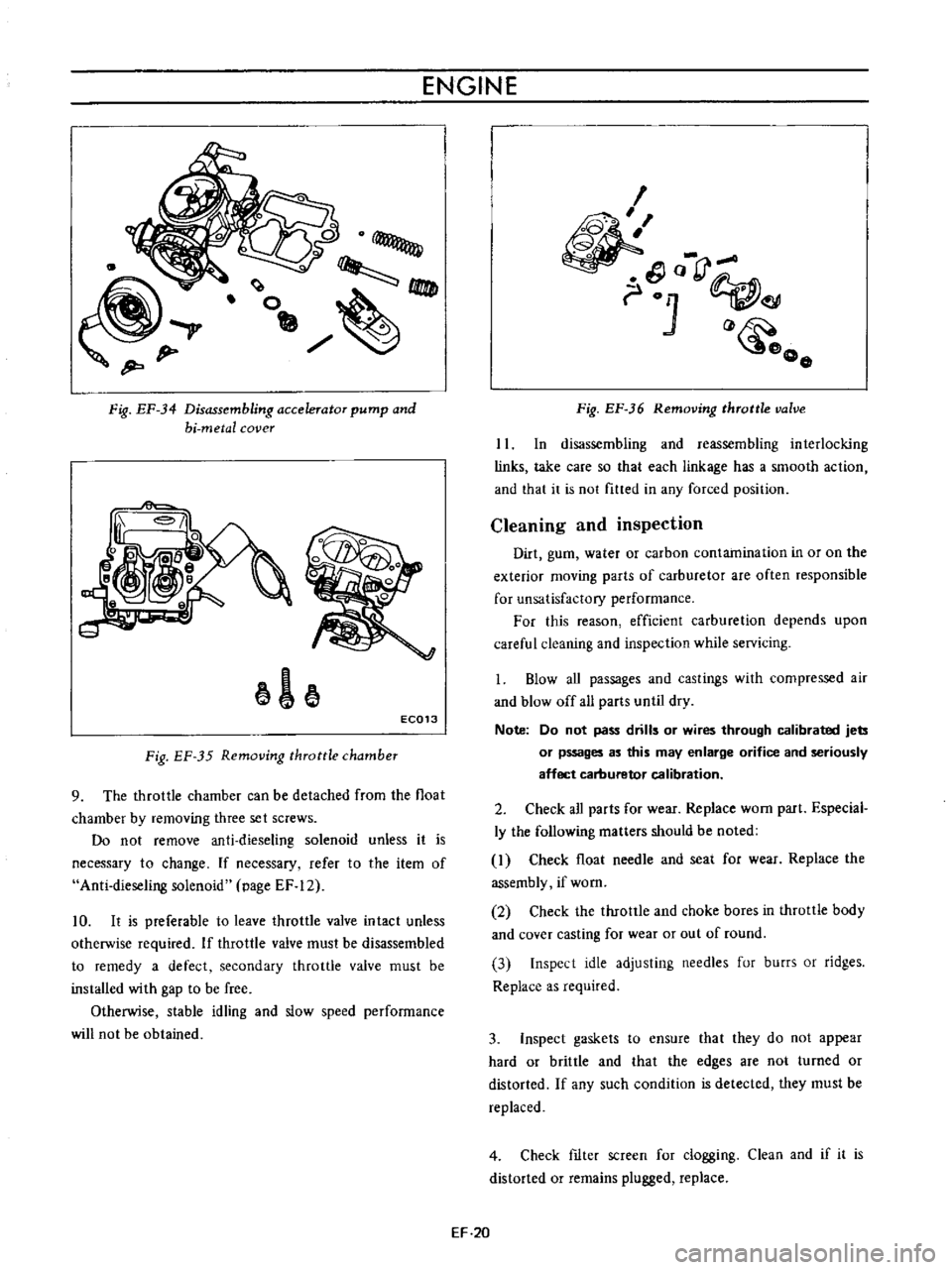

Fig

EF

34

Disassembling

accelerator

pump

and

hi

metal

cover

1

EC013

Fig

EF

35

Removing

throttle

chamber

9

The

throttle

chamber

can

be

detached

from

the

float

chamber

by

removing

three

set

screws

Do

not

remove

anti

dieseling

solenoid

unless

it

is

necessary

to

change

If

necessary

refer

to

the

item

of

Anti

dieseling

solenoid

page

EF

12

10

It

is

preferable

to

leave

throttle

valve

intact

unless

otherwise

required

If

throttle

valve

must

be

disassembled

to

remedy

a

defect

secondary

throttle

valve

must

be

installed

with

gap

to

be

free

Otherwise

stable

idling

and

slow

speed

performance

will

not

be

obtained

I

o

rJ

01

o

o

Fig

EF

36

Removing

throttle

valve

II

In

disassembling

and

reassembling

interlocking

links

take

care

so

that

each

linkage

has

a

smooth

action

and

that

it

is

not

fitted

in

any

forced

position

Cleaning

and

inspection

Dirt

gum

water

or

carbon

contamination

in

or

on

the

exterior

moving

parts

of

carburetor

are

often

responsible

for

unsatisfactory

performance

For

this

reason

efficient

carburetion

depends

upon

careful

cleaning

and

inspection

while

servicing

1

Blow

aU

passages

and

castings

with

compressed

air

and

blow

off

all

parts

until

dry

Note

Do

not

pass

drills

or

wires

through

calibrated

jets

or

pssages

as

this

may

enlarge

orifice

and

seriously

affect

carburetor

calibration

2

Check

all

parts

for

wear

Replace

worn

part

Especial

ly

the

following

matters

should

be

noted

I

Check

float

needle

and

seat

for

wear

Replace

the

assembly

if

worn

2

Check

the

throttle

and

choke

bores

in

throttle

body

and

cover

casting

for

wear

or

out

of

round

3

Inspect

idle

adjusting

needles

fur

burrs

or

ridges

Replace

as

required

3

Inspect

gaskets

to

ensure

that

they

do

not

appear

hard

or

brittle

and

that

the

edges

are

not

turned

or

distorted

If

any

such

condition

is

detected

they

must

be

replaced

4

Check

fIlter

screen

for

clogging

Clean

and

if

it

is

distorted

or

remains

plugged

replace

EF

20

Page 464 of 513

ENGINE

REMOVAL

INSTAllATION

ENGINE

MOUNTING

CONTENTS

FRONT

ENGINE

MOUNTING

Removal

Reinstallation

ER

1

ER

1

ER

2

REAR

ENGINE

MOUNTING

Removal

Reinstallation

ER

2

ER

2

ER

3

r

0

iQ

@

q

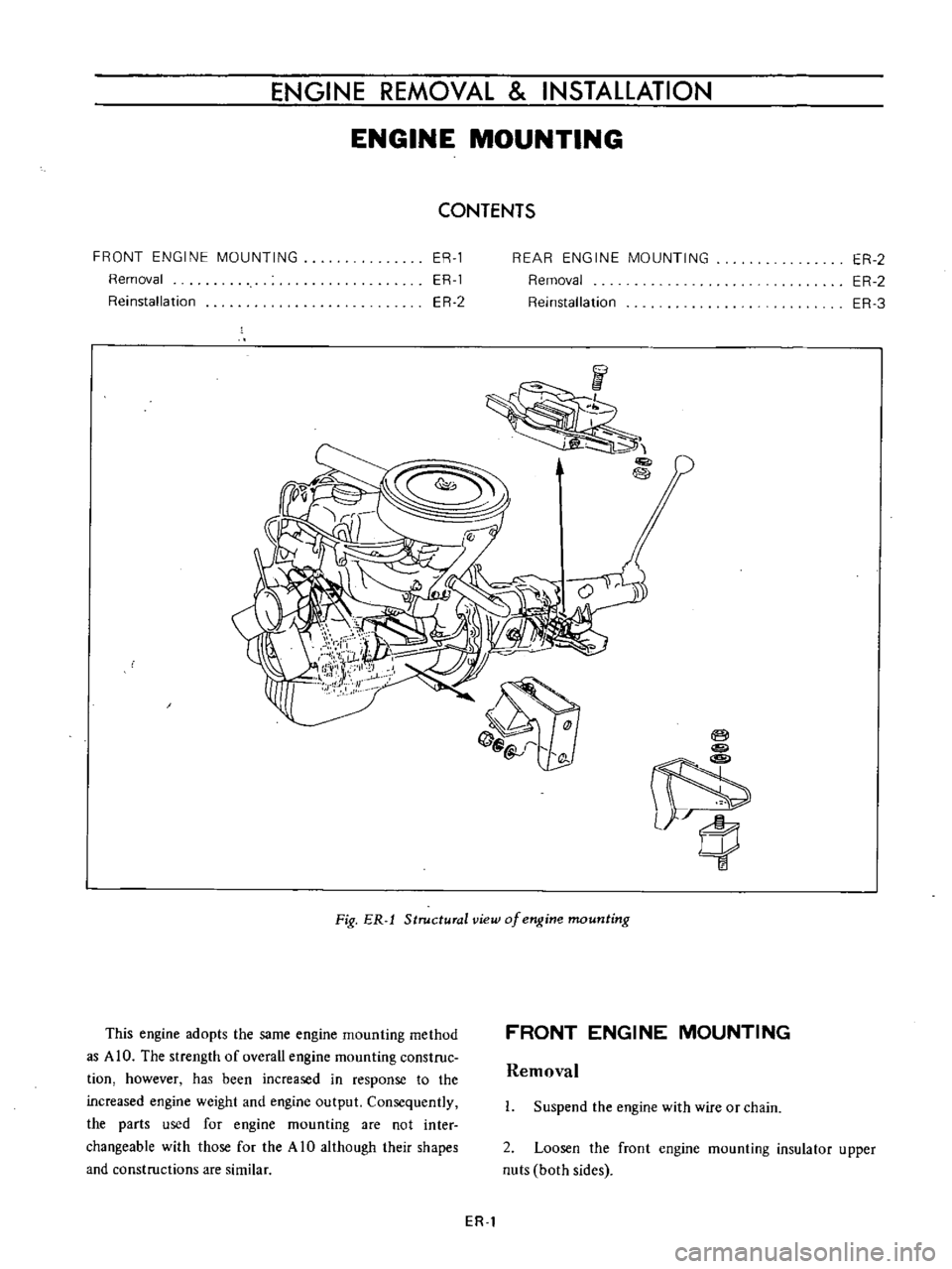

Fig

ER

1

Structural

view

of

engine

mounting

This

engine

adopts

the

same

engine

mounting

method

as

AIO

The

strength

of

overall

engine

mounting

construc

tion

however

has

been

increased

in

response

to

the

increased

engine

weight

and

engine

output

Consequently

the

parts

used

for

engine

mounting

arc

not

inter

changeable

with

those

for

the

A

10

although

their

shapes

and

constructions

are

similar

FRONT

ENGINE

MOUNTING

Removal

I

Suspend

the

engine

with

wire

or

chain

2

Loosen

the

front

engine

mounting

insulator

upper

nuts

both

sides

ER

1

Page 475 of 513

CLUTCH

J

I

I

Withdrawal

lever

2

Return

spring

I

31

Release

bearing

ST20610000

iwn

rm

hj

sf

W

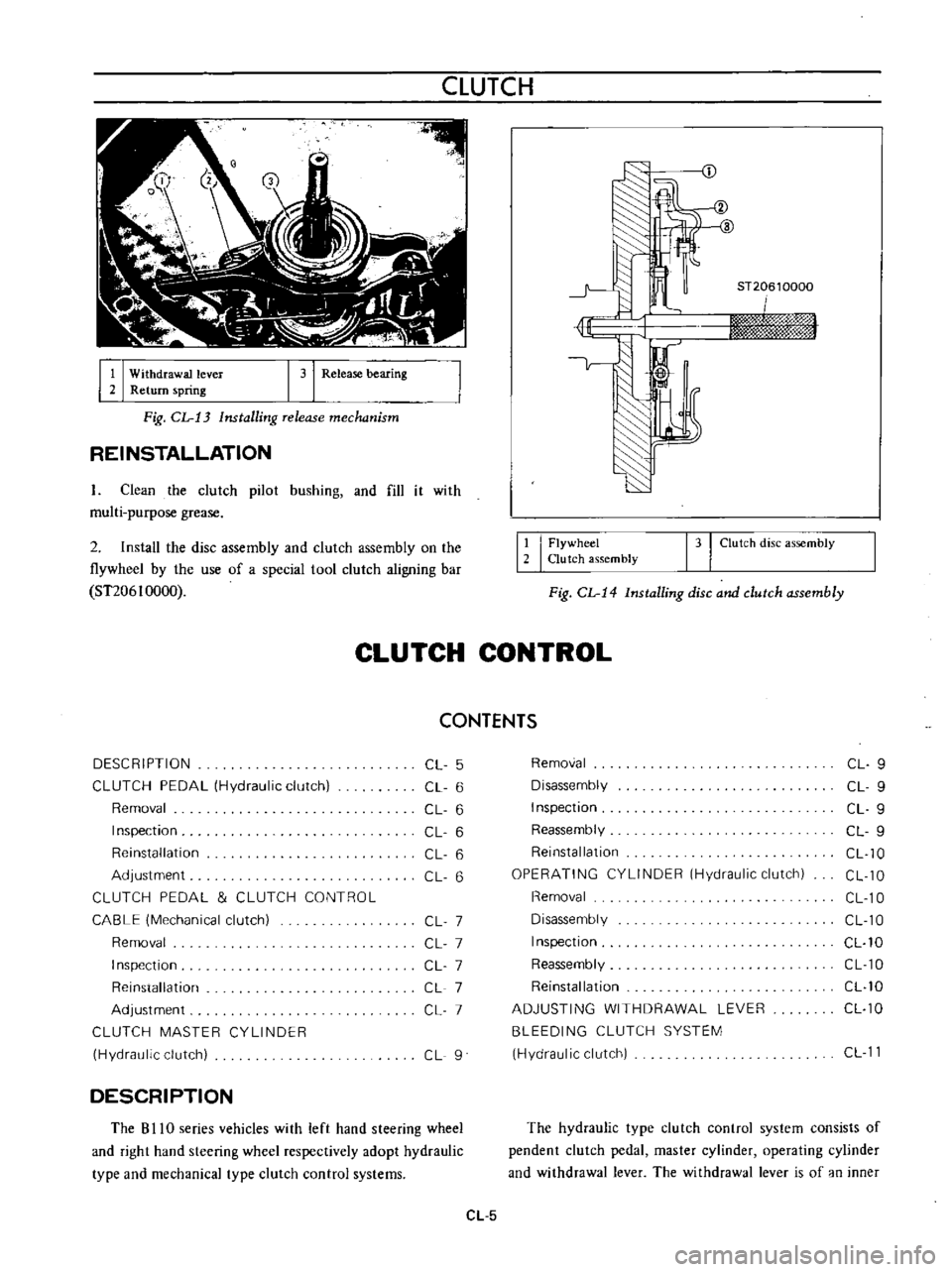

Fig

CL

13

Installing

release

mechanism

REINSTALLATION

L

Clean

the

clutch

pilot

bushing

and

fill

it

with

multi

purpose

grease

2

Install

the

disc

assembly

and

clutch

assembly

on

the

flywheel

by

the

use

of

a

special

tool

clutch

aligning

bar

ST206

I

0000

12

I

Flywheel

Clutch

assembly

131

Clutch

disc

assembly

Fig

CL

14

Installing

disc

and

clutch

assembly

CLUTCH

CONTROL

CONTENTS

DESCRIPTION

CL

5

Removal

CL

9

CLUTCH

PEDAL

Hydraulic

clutch

CL

6

Disassembly

CL

9

Removal

CL

6

Inspection

CL

9

Inspection

CL

6

Reassembly

CL

9

Reinstallation

CL

6

Reinstallation

CL

10

Adjustment

CL

6

OPERATING

CYLINDER

Hydraulic

clutch

CL

10

CLUTCH

PEDAL

CLUTCH

CONTROL

Removal

CL

10

CABLE

Mechanical

clutch

CL

7

Disassembly

CL

10

Removal

CL

7

Inspection

CL

10

Inspection

CL

7

Reassembly

CL

10

Reinstallation

CL

7

Reinstallation

CL

10

Adjustment

CL

7

ADJUSTING

WITHDRAWAL

LEVER

CL

10

CLUTCH

MASTER

CYLINDER

BLEEDING

CLUTCH

SYSTEM

Hydraulic

clutch

CL

9

Hydraulic

clutch

CL

11

DESCRIPTION

The

B

I

IO

series

vehicles

with

left

hand

steering

wheel

and

right

hand

steering

wheel

respectively

adopt

hydraulic

type

and

mechanical

type

clutch

control

systems

The

hydraulic

type

clutch

control

system

consists

of

pendent

clutch

pedal

master

cylinder

operating

cylinder

and

withdrawal

lever

The

withdrawal

lever

is

of

an

inner

CL

5

Page 480 of 513

CHASSIS

2

Apply

brake

fluid

sufficiently

to

the

cylinder

and

piston

and

assemble

them

Reinstallation

Reinstall

the

master

cylinder

assembly

in

reverse

sequence

of

removal

and

adjust

as

follows

I

Adjust

the

pedal

height

by

changing

the

push

rod

length

2

B

eed

air

out

of

the

hydraulic

system

OPERATING

CYLINDER

Hydraulic

clutch

Removal

Remove

the

return

spring

2

Disconnect

the

clutch

line

from

the

operating

cyl

inder

3

Disconnect

the

push

rod

from

the

withdrawal

lever

4

Release

two

bolts

used

to

mount

the

operating

cylinder

to

the

clutch

housing

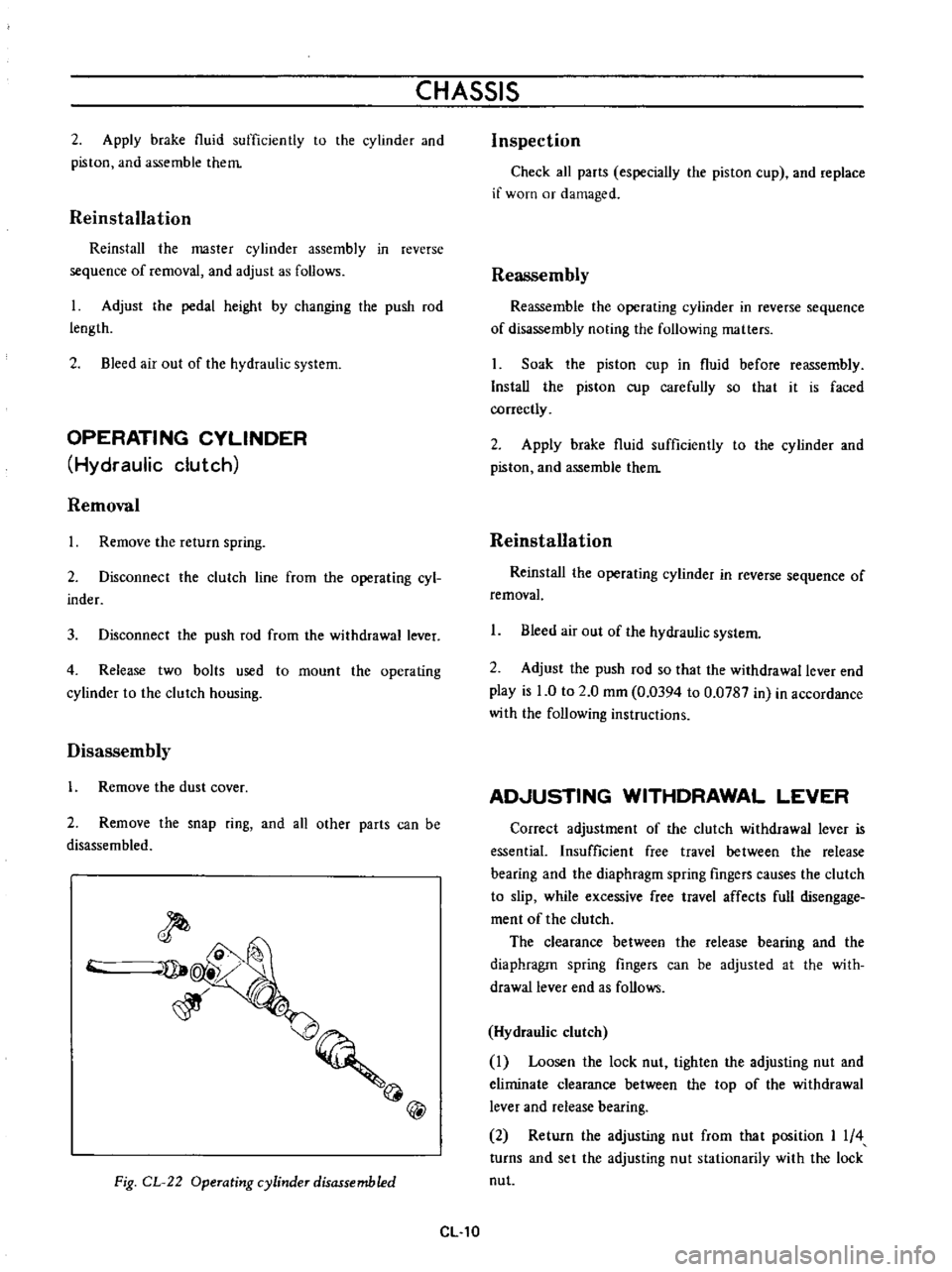

Disassembly

1

Remove

the

dust

cover

2

Remove

the

snap

ring

and

all

other

parts

can

be

disassembled

@

Fig

CL

22

Operating

cylinder

disassembled

CL

10

Inspection

Check

all

parts

especially

the

piston

cup

and

replace

if

worn

or

damaged

Reassembly

Reassemble

the

operating

cylinder

in

reverse

sequence

of

disassembly

noting

the

following

matters

Soak

the

piston

cup

in

fluid

before

reassembly

Install

the

piston

cup

carefully

so

that

it

is

faced

correctly

2

Apply

brake

fluid

sufficiently

to

the

cylinder

and

piston

and

assemble

them

Reinstallation

Reinstal

the

operating

cylinder

in

reverse

sequence

of

removal

1

Bleed

air

out

of

the

hydraulic

system

2

Adjust

the

push

rod

so

that

the

withdrawal

lever

end

play

is

0

to

2

0

mm

0

0394

to

0

0787

in

in

accordance

with

the

following

instructions

AD

USTING

WITHDRAWAL

LEVER

Correct

adjustment

of

the

clutch

withdrawal

lever

is

essential

Insufficient

free

travel

between

the

release

bearing

and

the

diaphragm

spring

fingers

causes

the

clutch

to

slip

while

excessive

free

travel

affects

full

disengage

ment

of

the

clutch

The

clearance

between

the

release

bearing

and

the

diaphragm

spring

fingers

can

be

adjusted

at

the

with

drawallever

end

as

follows

Hydraulic

clutch

Loosen

the

lock

nut

tighten

the

adjusting

nut

and

eliminate

clearance

between

the

top

of

the

withdrawal

lever

and

release

bearing

2

Return

the

adjusting

nut

from

that

position

I

4

turns

and

set

the

adjusting

nut

stationarily

with

the

lock

nut

Page 483 of 513

CLUTCH

Operating

cylinder

clutch

Operating

cylinder

diameter

T

Ilhtening

torque

19

05

mm

0

750

in

Clutch

assembly

securing

bolt

1

5

to

2

2

kg

m

10

8

to

15

9

ft

Ib

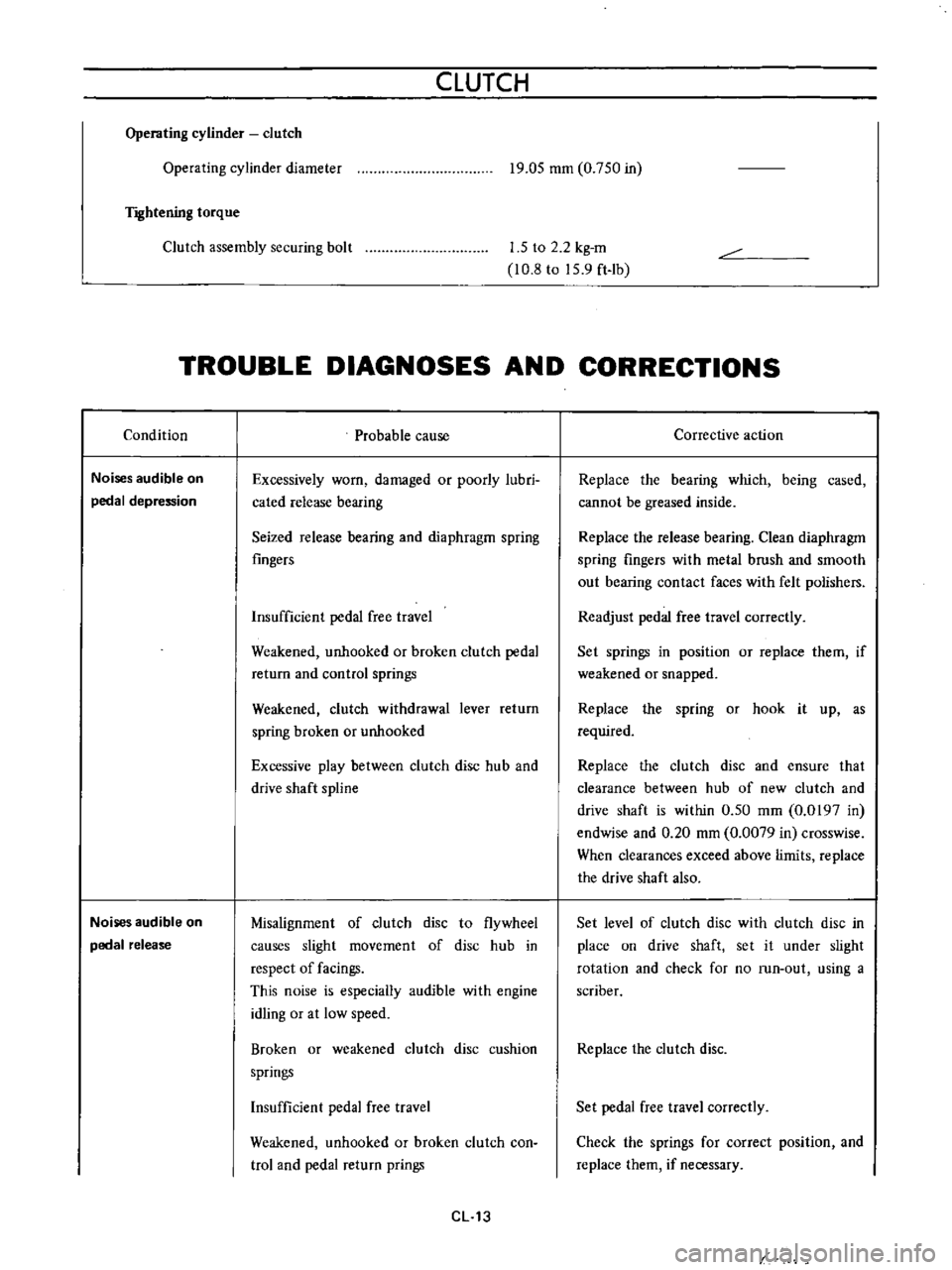

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Noises

audible

on

pedal

depression

Noises

audible

on

pedal

release

Probable

cause

Excessively

worn

damaged

or

poorly

lubri

cated

release

bearing

Seized

release

bearing

and

diaphragm

spring

fingers

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

pedal

return

and

control

springs

Weakened

clutch

withdrawal

lever

return

spring

broken

or

unhooked

Excessive

play

between

clutch

disc

hub

and

drive

shaft

spline

Misalignment

of

clutch

disc

to

flywheel

causes

slight

movement

of

disc

hub

in

respect

of

facings

This

noise

is

especially

audible

with

engine

idling

or

at

low

speed

Broken

or

weakened

clutch

disc

cushion

springs

Insufficient

pedal

free

travel

Weakened

unhooked

or

broken

clutch

con

trol

and

pedal

return

prings

CL

13

Corrective

action

Replace

the

bearing

which

being

cased

cannot

be

greased

inside

Replace

the

release

bearing

Clean

diaphragm

spring

fingers

with

metal

brush

and

smooth

out

bearing

contact

faces

with

felt

polishers

Readjust

pedal

free

travel

correctly

Set

springs

in

position

or

replace

them

if

weakened

or

snapped

Replace

the

spring

or

hook

it

up

as

required

Replace

the

clutch

disc

and

ensure

that

clearance

between

hub

of

new

clutch

and

drive

shaft

is

within

0

50

mm

0

0197

in

endwise

and

0

20

mm

0

0079

in

crosswise

When

clearances

exceed

above

limits

replace

the

drive

shaft

also

Set

level

of

clutch

disc

with

clutch

disc

in

place

on

drive

shaft

set

it

under

slight

rotation

and

check

for

no

run

out

using

a

scriber

Replace

the

clutch

disc

Set

pedal

free

travel

correctly

Check

the

springs

for

correct

position

and

replace

them

if

necessary

Page 505 of 513

CHASSIS

5

Remove

the

speed

change

retainer

bolt

I

6

Remove

the

speed

change

retainer

2

7

Remove

the

2nd

top

change

lever

and

bush

13

from

the

control

rod

4

8

Lower

the

control

rod

so

that

the

control

lever

pin

comes

out

from

the

lower

bracket

5

and

withdraw

the

control

lever

pin

Note

low

the

control

rod

to

such

an

extent

that

the

con

b

ol

lever

pin

does

not

interfere

the

lower

bracket

9

Withdraw

the

control

rod

from

the

passenger

com

partment

10

Remove

the

cotter

pins

and

disconnect

the

speed

change

rods

Remove

the

cross

shaft

from

the

side

member

and

withdraw

the

cross

shaft

assembly

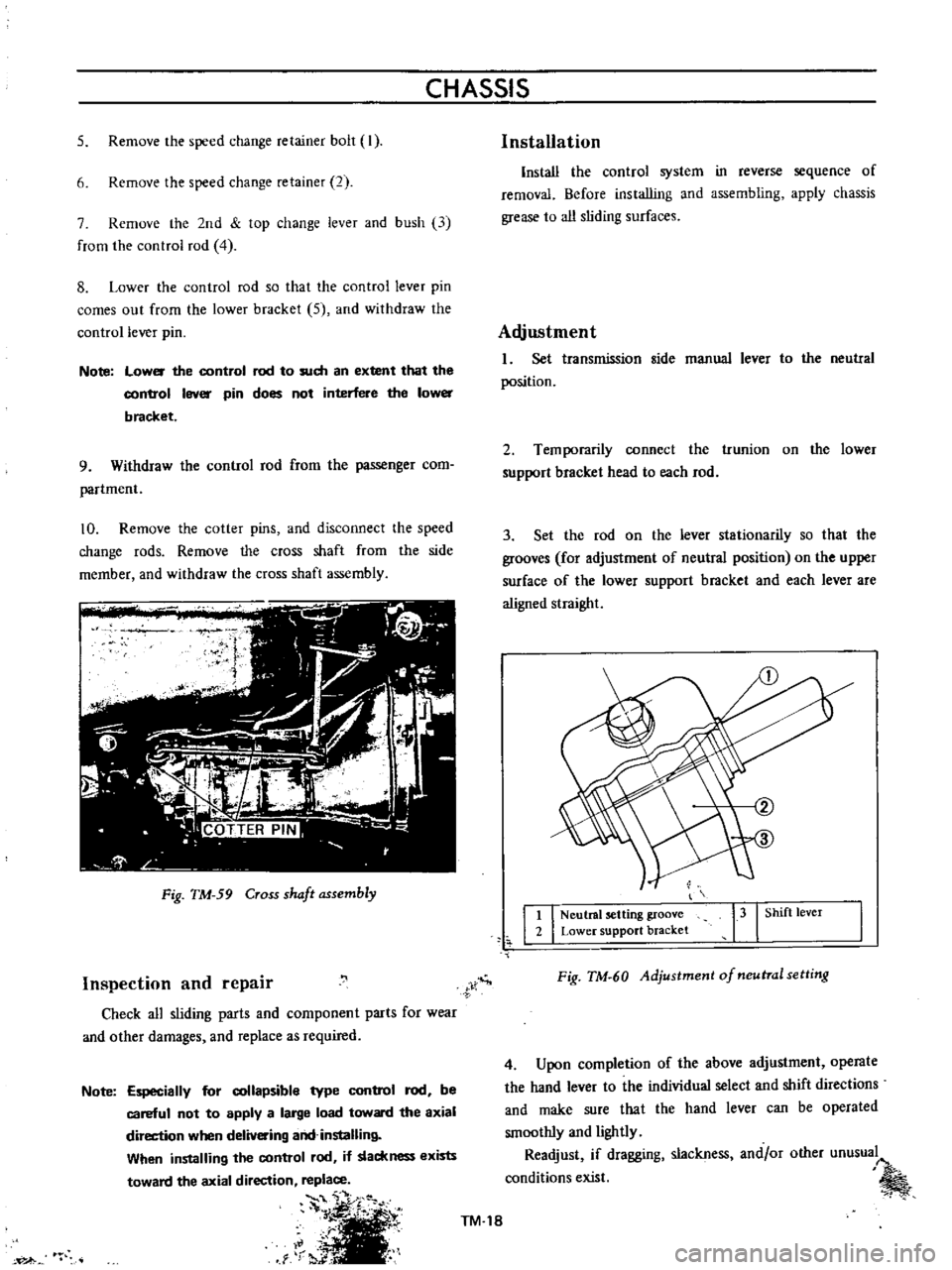

Fig

TM

59

Cross

shaft

assembly

Inspection

and

repair

Check

all

sliding

parts

and

component

parts

for

wear

and

other

damages

and

replace

as

required

Note

Especially

for

collapsible

type

control

rod

be

careful

not

to

apply

a

large

load

toward

the

axial

direction

when

delivering

and

installing

When

installing

the

control

rod

if

slackness

exists

toward

the

axial

direction

replace

S

i

TM

18

C

1

rr

i

Al

Installation

Install

the

control

system

in

reverse

sequence

of

removal

Before

installing

and

assembling

apply

chassis

grease

to

all

sliding

surfaces

Adjustment

I

Set

transmission

side

manual

lever

to

the

neutral

position

2

Temporarily

connect

the

trunion

on

the

lower

support

bracket

head

to

each

rod

3

Set

the

rod

on

the

lever

stationarily

so

that

the

grooves

for

adjustment

of

neutral

position

on

the

upper

surface

of

the

lower

support

bracket

and

each

lever

are

aligned

straight

t

I

Neutral

setting

groove

2

Lower

support

bracket

13

I

Shift

lever

Fig

TM

60

Adjustment

of

neutral

setting

4

Upon

completion

of

the

above

adjustment

operate

the

hand

lever

to

the

individual

select

and

shift

directions

and

make

sure

that

the

hand

lever

can

be

operated

smoothly

and

lightly

Readjust

if

dragging

slackness

and

or

other

unusual

conditions

exist