ESP DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 58 of 513

Judgement

in

measurmg

line

pressure

I

Low

idling

line

pressures

in

the

ranges

D

2

loR

and

P

It

can

be

artributed

to

trouble

in

the

pressure

supply

system

or

too

low

output

of

power

caused

by

1

A

worn

oil

pump

2

An

oil

pressure

leakage

in

the

oil

pump

valve

body

or

case

3

A

sticking

regulator

valve

2

Low

idling

line

pressures

in

cer

tain

ranges

only

It

is

caused

pressumabIy

by

an

oil

leakage

in

the

devices

or

circuits

con

nected

to

the

relevant

ranges

1

When

there

is

an

oil

leakage

in

the

rear

clutch

and

governor

the

line

pressures

in

D

2

and

I

are

low

but

the

pressure

is

normal

in

R

2

When

an

oil

leakage

occurs

in

the

low

and

reverse

brake

circuit

the

line

pressures

in

R

and

p

are

low

but

the

pressure

is

normal

in

0

2

and

I

3

High

idling

line

pressures

It

is

presumed

to

be

caused

by

an

increased

vacuum

throttle

pressure

owing

to

a

leakage

in

the

vacuum

tube

or

diaphragm

or

by

an

increased

line

pressure

due

to

a

sticking

regulator

CHASSIS

valve

Vacuum

leakage

is

checked

by

di

reetly

measuring

the

negative

pressure

after

removing

the

vacuum

pipe

A

puncture

of

the

vacuum

dia

phragm

can

be

easily

ascertained

because

the

torque

converter

oil

is

absorbed

into

the

engine

and

the

exhaust

pipe

blows

up

the

white

smoke

4

Checking

items

when

the

line

pressure

is

increasing

In

trJs

checking

the

line

pressure

should

be

measured

with

vacuums

of

450

mmHg

and

0

mmHg

in

accordance

with

the

stall

test

procedure

test

procedure

1

If

the

line

pressures

do

not

increase

despite

the

vacuum

decrease

check

whether

the

vacuum

rod

is

incorporated

2

If

the

line

pressures

do

not

meet

the

standard

it

is

caused

mostly

by

a

sticking

pressure

regulating

valve

pres

sure

regulating

valve

plug

or

amptifier

TROUBLE

SHOOTING

CHART

Inspecting

items

1

Inspection

with

automatic

trans

mission

on

vehicle

J

AT

54

A

Oil

level

B

Range

selecr

linkage

C

Inhibitor

switch

and

wiring

D

Vacuum

diaphragm

and

piping

E

Downshift

solenoid

kick

down

switch

and

wiring

F

Engine

idling

rpm

G

Oil

pressure

throttle

H

Engine

stall

rpm

I

Rear

lubrication

J

Control

valve

manual

K

Governor

valve

L

Band

servo

M

Transmission

air

check

N

Oil

quantity

o

Ignition

switch

and

starter

motor

P

Engine

adjustment

and

brake

in

spection

2

Inspection

after

inspecting

auto

matic

transmission

on

vehicle

m

Rear

clutch

n

Front

clutch

q

Band

brake

r

Low

and

reverse

brake

s

Oil

pump

Leakage

of

oil

passage

u

One

way

clutch

of

torque

converter

v

One

way

clutch

of

transmission

w

Front

clutch

check

ball

x

Parking

linkage

y

Planetary

gear

Page 80 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

C

DMark

Unit

mm

in

Fig

PD

26

Thickness

of

shim

on

left

side

Thickness

of

shim

on

right

side

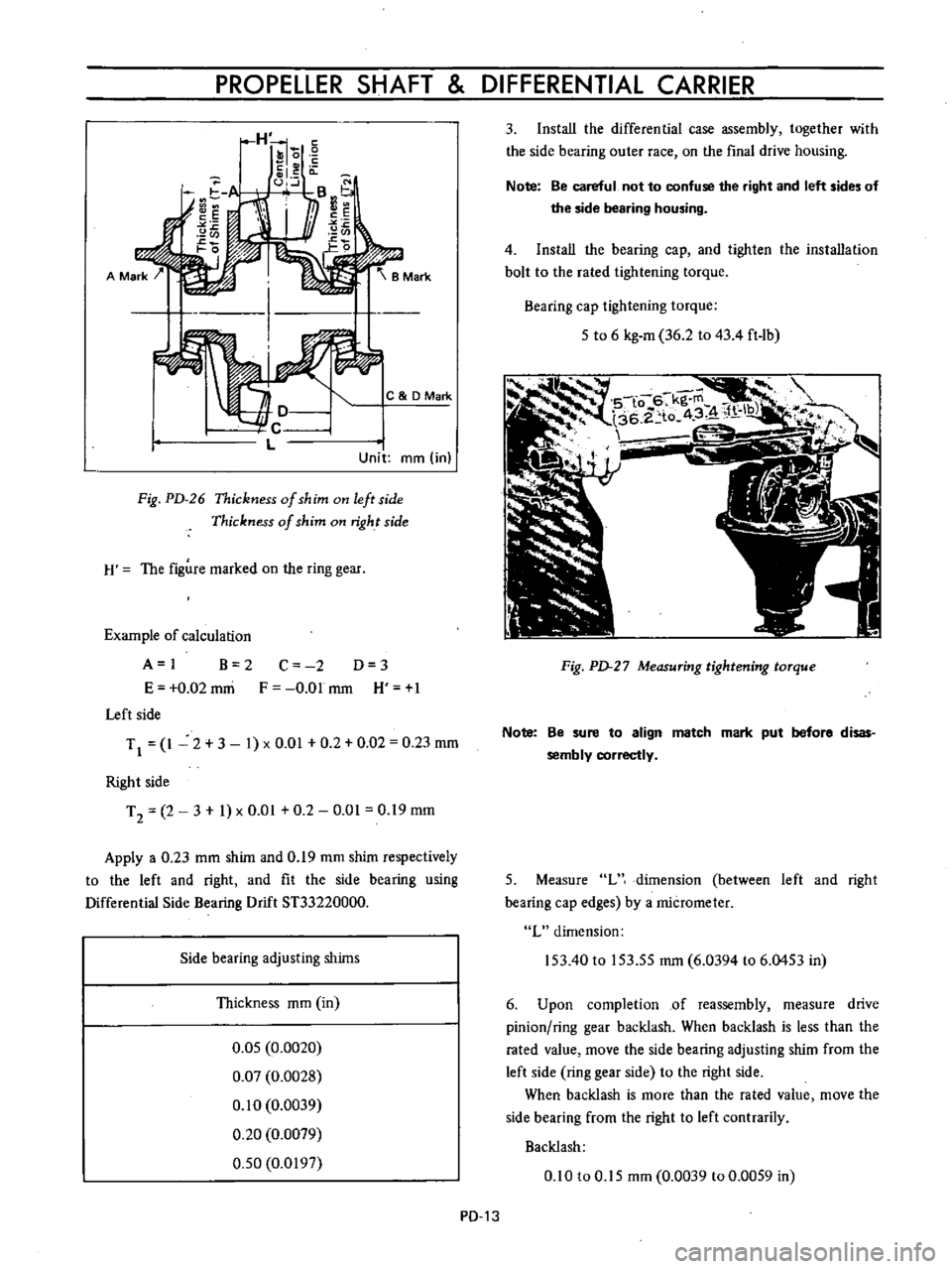

H

The

figure

marked

on

the

ring

gear

Example

of

calculation

A

I

B

2

E

0

02

mni

Left

side

C

2

D

3

F

O

Olmm

H

1

TJ

1

2

3

1

xO

01

0

2

0

02

0

23

mm

Right

side

T

2

2

3

1

x

0

01

0

2

0

01

0

19

mm

Apply

a

0

23

mm

shim

and

0

19

mm

shim

respectively

to

the

left

and

right

and

fit

the

side

bearing

using

Differential

Side

Bearing

Drift

ST33220000

Side

bearing

adjusting

shims

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

PD

13

3

Install

the

differential

case

assembly

together

with

the

side

bearing

outer

race

on

the

final

drive

housing

Note

Be

careful

not

to

confuse

the

right

and

left

sides

of

the

side

bearing

housing

4

Install

the

bearing

cap

and

tighten

the

installation

bolt

to

the

rated

tightening

torque

Bearing

cap

tightening

torque

5

to

6

kg

m

36

2

to

43

4

ft

1b

Fig

PD

27

Measuring

tightening

torque

Note

Be

sure

to

align

match

mark

put

before

disas

sembly

correctly

5

Measure

L

dimension

between

left

and

right

bearing

cap

edges

by

a

micrometer

L

dimension

153

40

to

153

55

mm

6

0394

to

6

0453

in

6

Upon

completion

of

reassembly

measure

drive

pinion

ring

gear

backlash

When

backlash

is

less

than

the

rated

value

move

the

side

bearing

adjusting

shim

from

the

left

side

ring

gear

side

to

the

right

side

When

backlash

is

more

than

the

rated

value

move

the

side

bearing

from

the

right

to

left

contrarily

Backlash

0

10

to

0

15

mm

0

0039

to

0

0059

in

Page 100 of 513

CHASSIS

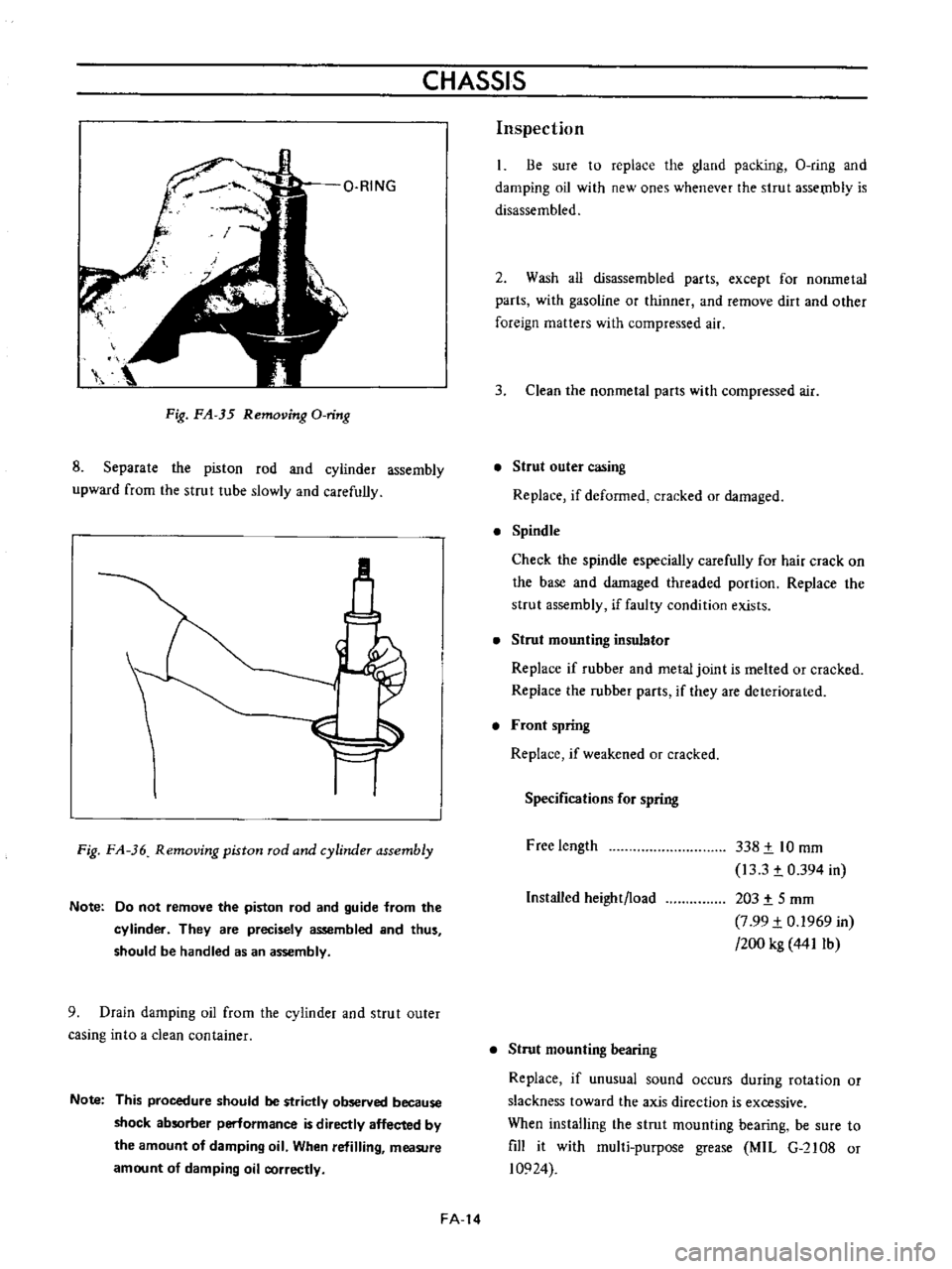

Fig

FA

35

Removing

O

ring

8

Separate

the

piston

rod

and

cyiinder

assembly

upward

from

the

strut

tube

slowly

and

carefully

M

Fig

FA

36

Removing

piston

rod

and

cylinder

assembly

Note

Do

not

remove

the

piston

rod

and

guide

from

the

cylinder

They

are

precisely

assembled

and

thus

should

be

handled

as

an

assembly

9

Drain

damping

oil

from

the

cylinder

and

strut

outer

casing

into

a

clean

container

Note

This

procedure

should

be

strictly

observed

because

shock

absorber

perlormance

is

directly

affected

by

the

amount

of

damping

oil

When

refilling

measure

amount

of

damping

oil

correctly

FA

14

Inspection

Be

sure

to

replace

the

gland

packing

O

ring

and

damping

oil

with

new

ones

whenever

the

strut

assetnb1y

is

disassembled

2

Wash

all

disassembled

parts

except

for

nonmetal

parts

with

gasoline

or

thinner

and

remove

dirt

and

other

foreign

matters

with

compressed

air

3

Clean

the

nonmetal

parts

with

compressed

air

Strut

outer

casing

Replace

if

deformed

cracked

or

damaged

Spindle

Check

the

spindle

especially

carefully

for

hair

crack

on

the

base

and

damaged

threaded

portion

Replace

the

strut

assembly

if

faulty

condition

exists

Strut

mounting

insulator

Replace

if

rubber

and

metal

joint

is

melted

or

cracked

Replace

the

rubber

parts

if

they

are

deteriorated

Front

spring

Replace

if

weakened

or

cracked

Specifications

for

spring

Free

length

338

t

10

mm

13

3

t

0

394

in

203

t

5

mm

7

99

t

0

1969

in

200

kg

441Ib

Installed

height

load

Strut

mounting

bearing

Replace

if

unusual

sound

occurs

during

rotation

or

slackness

toward

the

axis

direction

is

excessive

When

installing

the

strut

mounting

bearing

be

sure

to

fill

it

with

mul1i

purpose

grease

MIL

G

2108

or

10924

Page 111 of 513

FRONT

AXLE

FRONT

SUSPENSION

joint

Transverse

link

mounting

bolt

Tension

rod

Transverse

link

side

Body

side

Stabilizer

bar

Connecting

rod

and

transverse

link

installation

nut

Connecting

rod

and

stabilizer

bar

installation

nut

Stabilizer

bar

and

body

installation

bolt

2

2

to

3

0

15

9

to

21

7

4

0

to

5

0

28

9

to

36

2

2

2

to

3

0

15

9

to

217

5

5

to

6

5

39

7

to

47

0

0

9

to

1

2

6

5

to

8

7

0

9

to

1

2

6

5

to

8

7

0

9

to

1

2

6

5

to

8

7

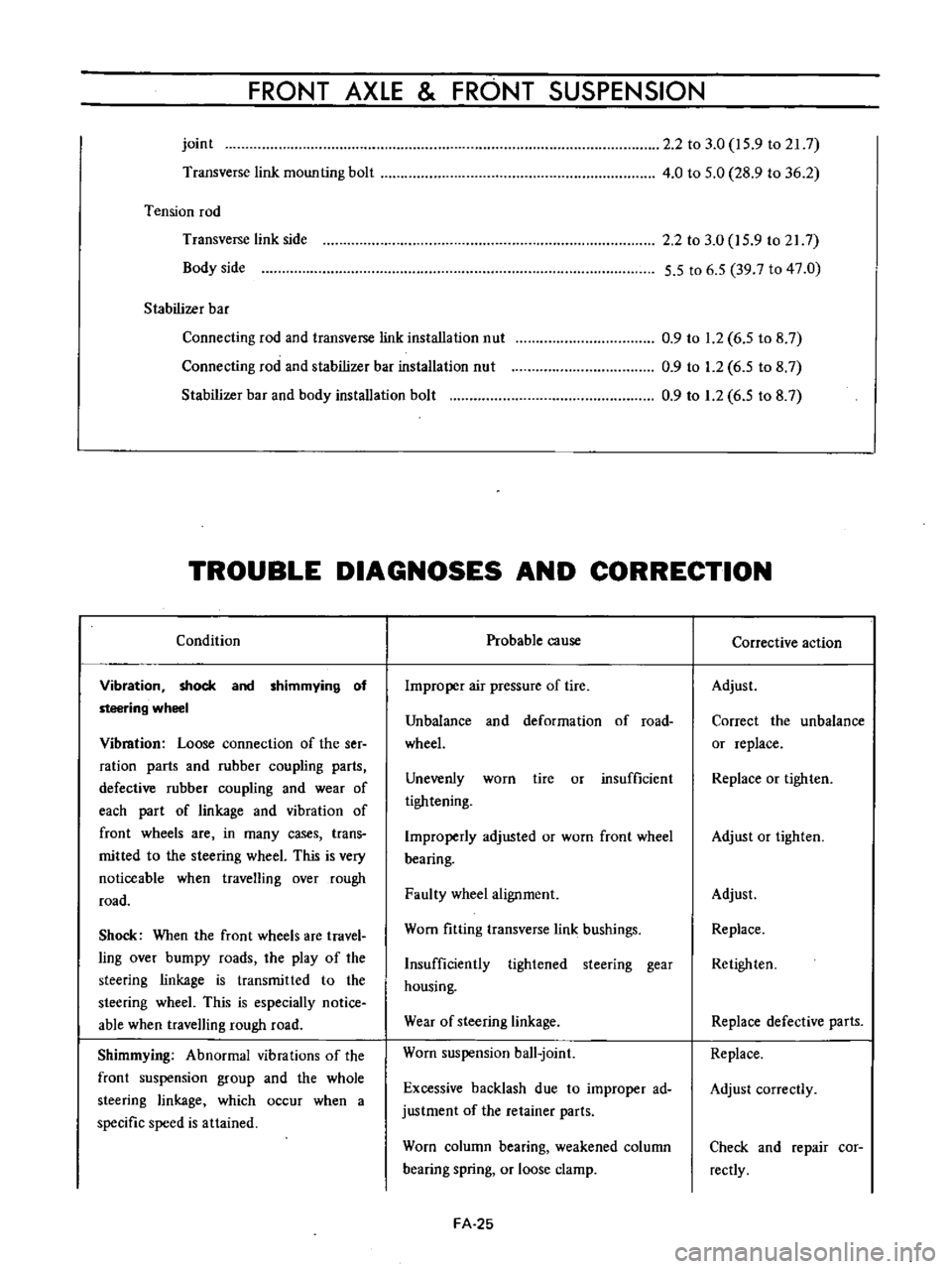

TROUBLE

DIAGNOSES

AND

CORRECTION

Condition

Vibration

shock

and

shimmying

of

steering

wheel

Vibmtion

Loose

connection

of

the

ser

ration

parts

and

rubber

coupling

parts

defective

rubber

coupling

and

wear

of

each

part

of

linkage

and

vibration

of

front

wheels

are

in

many

cases

trans

mitted

to

the

steering

wheeL

This

is

very

noticeable

when

travelling

over

rough

road

Shock

When

the

front

wheels

are

travel

ling

over

bumpy

roads

the

play

of

the

steering

linkage

is

transmitted

to

the

steering

wheeL

This

is

especially

notice

able

when

travelling

rough

road

Shimmying

Abnormal

vibrations

of

the

front

suspension

group

and

the

whole

steering

linkage

which

occur

when

a

specific

speed

is

attained

Probable

cause

Improper

air

pressure

of

tire

Unbalance

and

deformation

of

road

wheeL

Unevenly

worn

tire

or

insufficient

tightening

Improperly

adjusted

or

worn

front

wheel

bearing

Faulty

wheel

alignment

Worn

fitting

transverse

link

bushings

Insufficiently

tightened

steering

gear

housing

Wear

of

steering

linkage

Worn

suspension

ball

joint

Excessive

backlash

due

to

improper

ad

justment

of

the

retainer

parts

Worn

column

bearing

weakened

column

bearing

spring

or

loose

clamp

FA

25

Corrective

action

Adjust

Correct

the

unbalance

or

replace

Replace

or

tighten

Adjust

or

tighten

Adjust

Replace

Retighten

Replace

defective

parts

Replace

Adjust

correctly

Check

and

repair

cor

rectly

Page 157 of 513

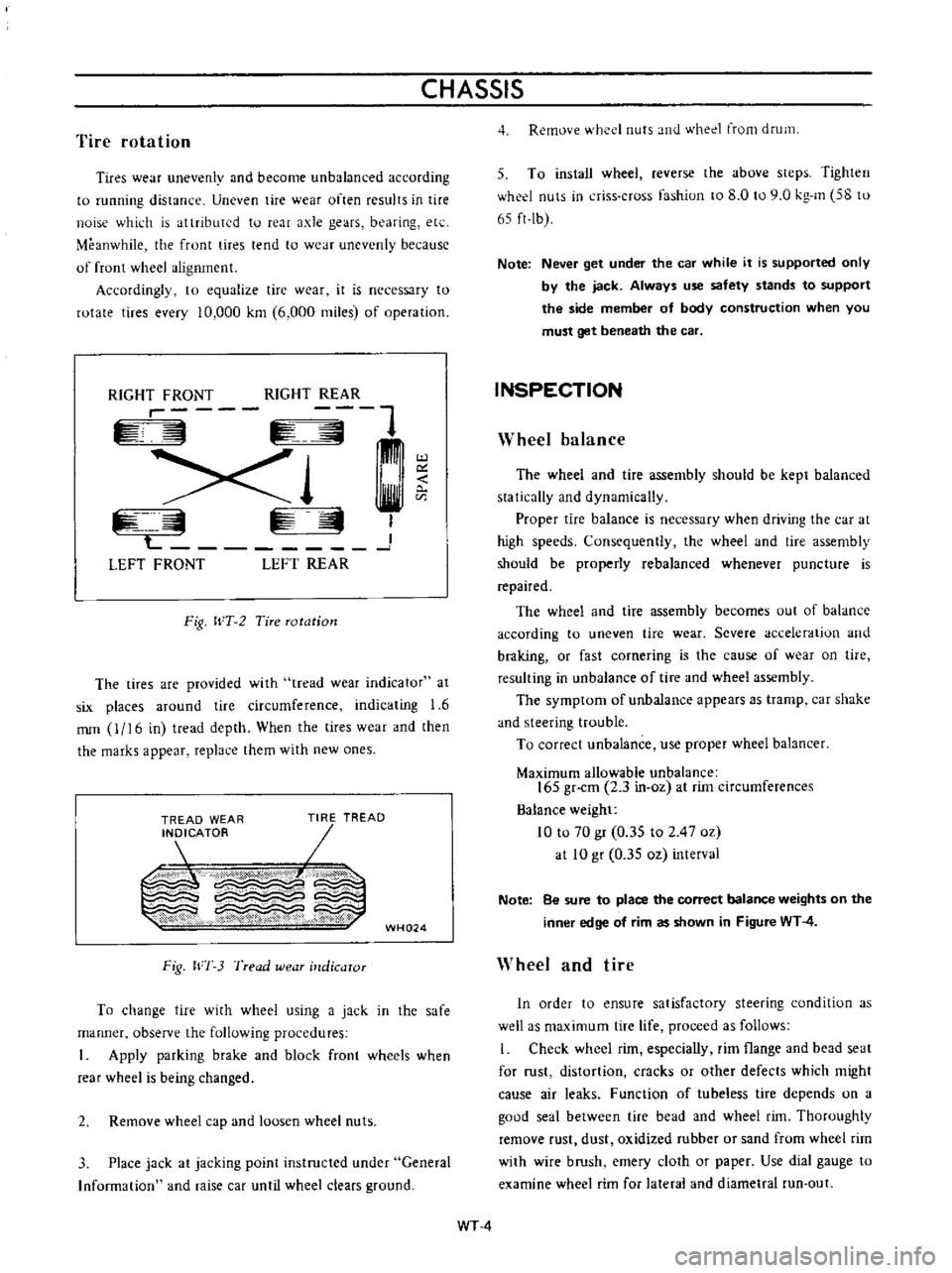

CHASSIS

Tire

rotation

Tires

wear

unevenly

and

become

unbalanced

according

to

running

distance

Uneven

tire

wear

often

results

in

tire

noise

whkh

is

attributed

to

rear

axle

gears

bearing

ell

Meanwhile

the

front

tires

tend

to

wear

unevenly

because

of

front

wheel

alignment

Accordingly

to

equalize

tire

wear

it

is

necessary

to

rotate

tires

every

10

000

km

6

000

miles

of

operation

RIGHT

FRONT

RIGHT

REAR

r

1

Xl

L

J

LEFT

FRONT

LEFT

REAR

Fig

WT

2

Tire

rotation

The

tires

are

provided

with

tread

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

nun

0

16

in

tread

depth

When

the

tires

wear

and

then

the

marks

a

ppear

replace

them

with

new

ones

TREAD

WEAR

INDICATOR

7

TREAD

m

Y

X

W

X

v

w

WH024

Fig

WI

3

Tread

wear

illdicator

To

change

tire

with

wheel

using

a

jack

in

the

safe

manner

observe

the

following

procedures

I

Apply

parking

brake

and

block

front

wheels

when

rear

wheel

is

being

changed

2

Remove

wheel

cap

and

loosen

wheel

nuts

3

Place

jack

at

jacking

point

instructed

under

General

Information

and

raise

car

until

wheel

clears

ground

4

Remove

wheel

nuts

and

whed

from

drum

5

To

install

wheel

reverse

the

above

steps

Tighten

whed

nuts

in

criss

cross

fashion

to

8

0

to

9

0

kg

m

58

to

65

ft

lb

Note

Never

get

under

the

car

while

it

is

supported

only

by

the

jack

Always

use

safety

stands

to

support

the

side

member

of

body

construction

when

you

must

get

beneath

the

car

INSPECTION

Wheel

balance

The

wheel

and

tire

assembly

should

be

kept

balanced

statically

and

dynamically

Proper

tire

balance

is

necessary

when

driving

the

car

at

high

speeds

Consequently

the

wheel

and

tire

assembly

should

be

properly

rebalanced

whenever

puncture

is

repaired

The

wheel

and

tire

assembly

becomes

out

of

balance

according

to

uneven

tire

wear

Severe

acceleration

and

braking

or

fast

cornering

is

the

cause

of

wear

on

tire

resulting

in

unbalance

of

tire

and

wheel

assembly

The

symptom

of

unbalance

appears

as

tramp

car

shake

and

steering

trouble

To

correct

unbalance

use

proper

wheel

balancer

Maximum

allowable

unbalance

165

gr

cm

2

3

in

ol

at

rim

circumferences

Balance

weight

10

to

70

gr

0

35

to

2

47

Ol

at

10

gr

0

35

Ol

interval

Note

Be

sure

to

place

the

correct

balance

weights

on

the

inner

edge

of

rim

as

shown

in

Figure

WT

4

Wheel

and

tire

In

order

to

ensure

satisfactory

steering

condition

as

well

as

maximum

tire

life

proceed

as

follows

I

Check

wheel

rim

especially

rim

flange

and

bead

seat

for

rust

distortion

cracks

or

other

defects

which

might

cause

air

leaks

Function

of

tubeless

tire

depends

on

a

good

seal

between

tire

bead

and

wheel

rim

Thoroughly

remove

rust

dust

oxidized

rubber

or

sand

from

wheel

rim

with

wire

brush

emery

cloth

or

paper

Use

dial

gauge

to

examine

wheel

rim

for

lateral

and

diametral

run

out

WT

4

Page 161 of 513

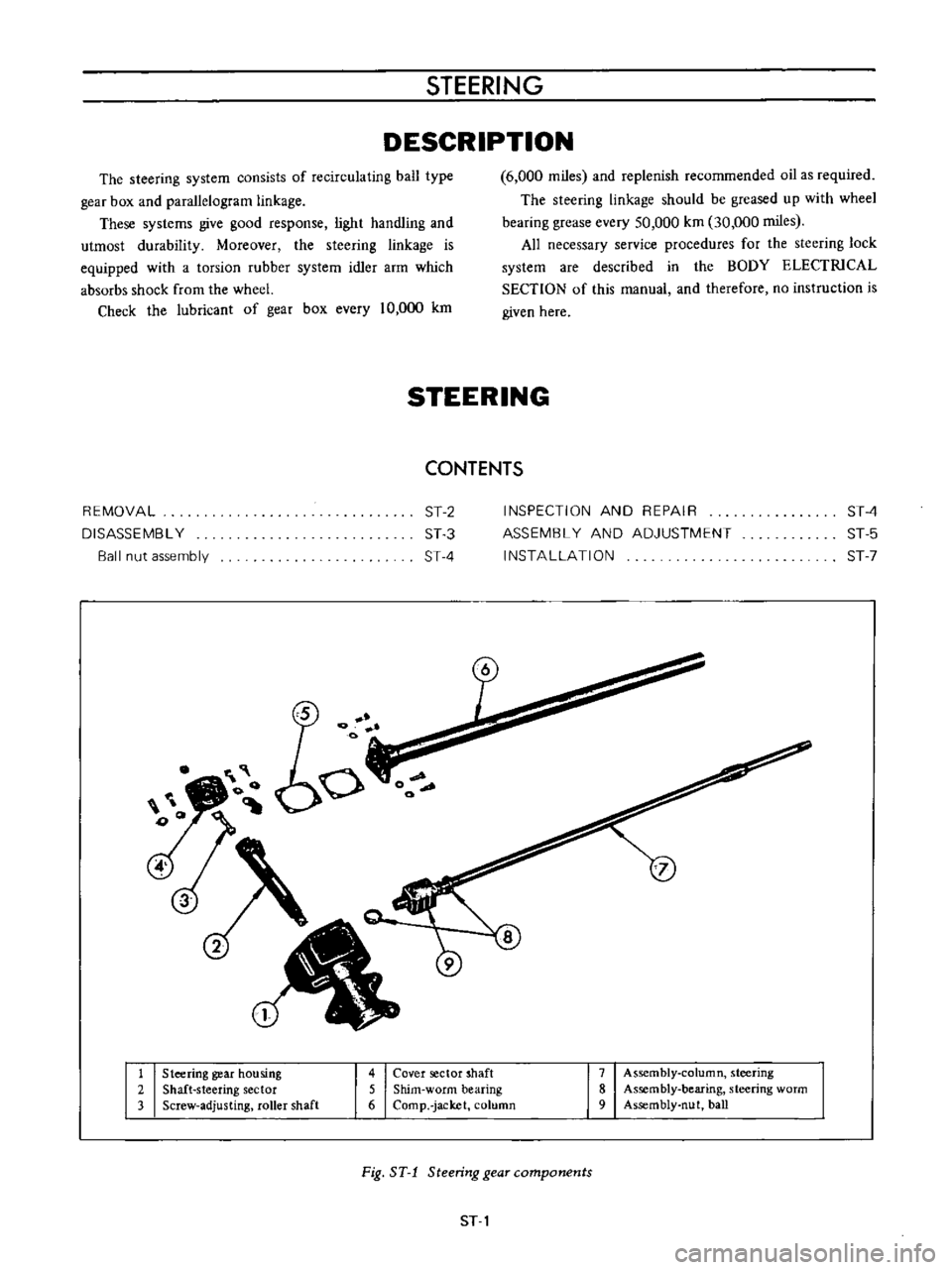

STEERING

DESCRIPTION

The

steering

system

consists

of

recirculating

ball

type

gear

box

and

parallelogram

linkage

These

systems

give

good

response

light

handling

and

utmost

durability

Moreover

the

steering

linkage

is

equipped

with

a

torsion

rubber

system

idler

arm

which

absorbs

shock

from

the

wheel

Check

the

lubricant

of

gear

box

every

10

000

km

6

000

miles

and

replenish

recommended

oil

as

required

The

steering

linkage

should

be

greased

up

with

wheel

bearing

grease

every

50

000

km

30

000

miles

All

necessary

service

procedures

for

the

steering

lock

system

are

described

in

the

BODY

ELECTRICAL

SECTION

of

this

manual

and

therefore

no

instruction

is

given

here

STEERING

CONTENTS

REMOVAL

DISASSEMBL

Y

Ball

nut

assembly

ST

2

ST

3

ST

4

INSPECTION

AND

REPAIR

ASSEMBL

Y

AND

ADJUSTMENT

INSTALLATION

ST

4

ST

5

ST

7

1

Steering

gear

housing

2

Shaft

steering

sector

3

Screw

adjusting

roller

shaft

4

Cover

sector

shaft

5

Shim

worm

bearing

6

Comp

jacket

column

7

Assembly

column

steering

8

Assembly

bearing

steering

worm

9

Assembly

nut

ball

Fig

ST

1

Steering

gear

components

ST

1

Page 168 of 513

CHASSIS

I

l

I

I

2

fa

r

o

Fig

ST

14

Collapsible

steering

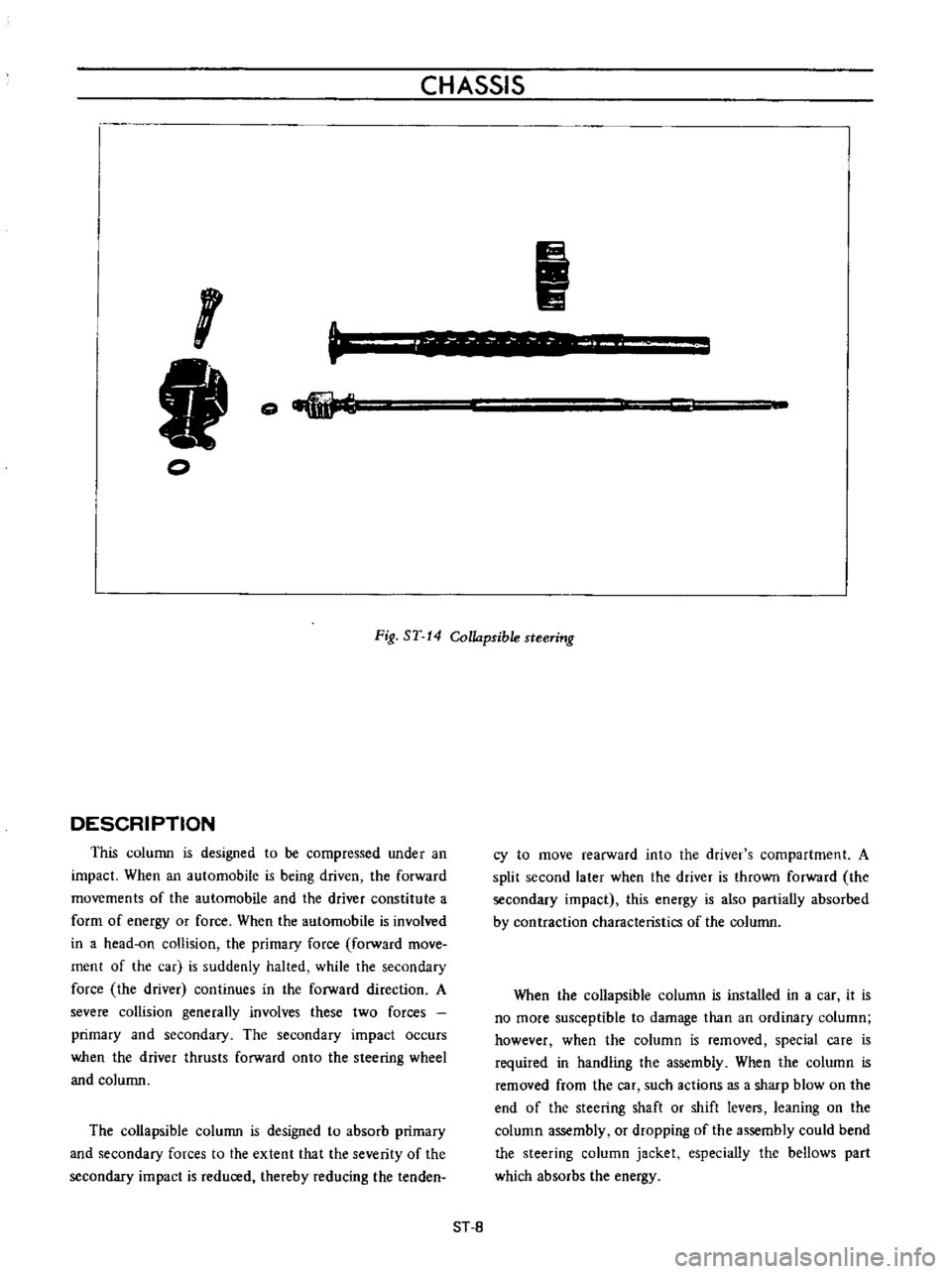

DESCRIPTION

This

column

is

designed

to

be

compressed

under

an

impact

When

an

automobile

is

being

driven

the

forward

movements

of

the

automobile

and

the

driver

constitute

a

form

of

energy

or

force

When

the

automobile

is

involved

in

a

head

on

collision

the

primary

force

forward

move

ment

of

the

car

is

suddenly

halted

while

the

secondary

force

the

driver

continues

in

the

forward

direction

A

severe

collision

generally

involves

these

two

forces

primary

and

secondary

The

secondary

impact

occurs

when

the

driver

thrusts

forward

onto

the

steering

wheel

and

column

The

collapsible

column

is

designed

to

absorb

primary

and

secondary

forces

to

the

extent

that

the

severity

of

the

secondary

impact

is

reduced

thereby

reducing

the

tenden

cy

to

move

rearward

into

the

driver

s

compartment

A

split

second

later

when

the

driver

is

thrown

forward

the

secondary

impact

this

energy

is

also

partially

absorbed

by

contraction

characteristics

of

the

column

When

the

collapsible

column

is

installed

in

a

car

it

is

no

more

susceptible

to

damage

than

an

ordinary

column

however

when

the

column

is

removed

special

care

is

required

in

handling

the

assembly

When

the

column

is

removed

from

the

car

such

actions

as

a

sharp

blow

on

the

end

of

the

steering

shaft

or

shift

levers

leaning

on

the

column

assembly

or

dropping

of

the

assembly

could

bend

the

steering

column

jacket

especially

the

bellows

part

which

absorbs

the

energy

ST

8

Page 170 of 513

CHASSIS

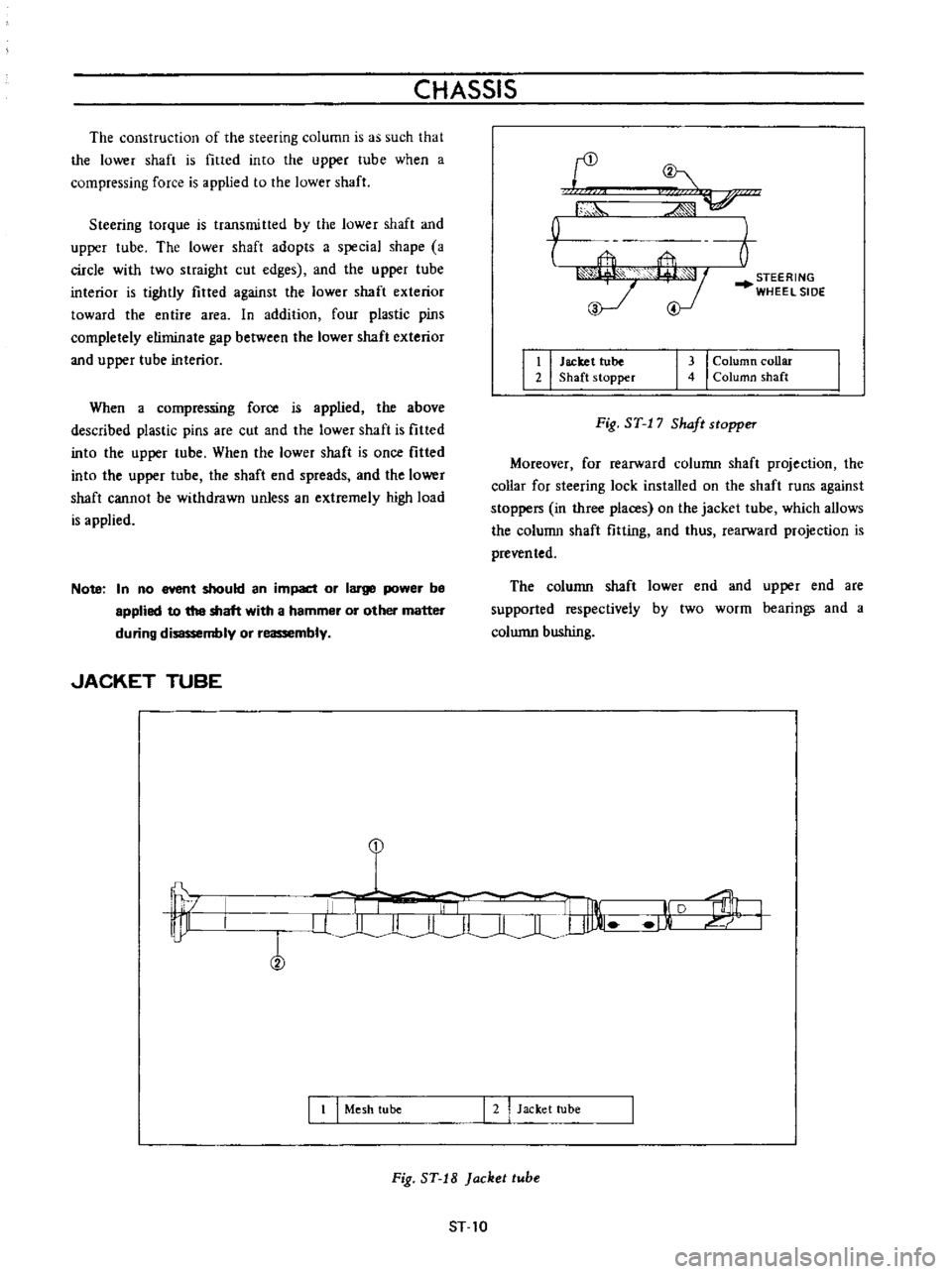

The

construction

of

the

steering

column

is

as

such

that

the

lower

shaft

is

fitted

into

the

upper

tube

when

a

compressing

force

is

applied

to

the

lower

shaft

r

I

1

V

f

7

Steering

torque

is

transmitted

by

the

lower

shaft

and

upper

tube

The

lower

shaft

adopts

a

special

shape

a

circle

with

two

straight

cut

edges

and

the

upper

tube

interior

is

tightly

fitted

against

the

lower

shaft

exterior

toward

the

entire

area

In

addition

four

plastic

pins

completely

eliminate

gap

between

the

lower

shaft

exterior

and

upper

tube

interior

I

I

Jacket

lube

2

Shaft

stopper

I

3

I

Column

coUar

4

Column

shaft

When

a

compressing

force

is

applied

the

above

described

plastic

pins

are

cut

and

the

lower

shaft

is

fitted

into

the

upper

tube

When

the

lower

shaft

is

once

fitted

into

the

upper

tube

the

shaft

end

spreads

and

the

lower

shaft

cannot

be

withdrawn

unless

an

extremely

high

load

is

applied

Fig

ST

1

7

Shaft

stopper

Moreover

for

rearward

column

shaft

projection

the

collar

for

steering

lock

installed

on

the

shaft

runs

against

stoppers

in

three

places

on

the

jacket

tube

which

allows

the

column

shaft

fitting

and

thus

reaIWard

projection

is

prevented

Note

In

no

event

should

an

impact

or

large

power

be

applied

to

the

shaft

with

a

hammer

or

other

matter

during

disassembly

or

reassembly

The

column

shaft

lower

end

and

upper

end

are

supported

respectively

by

two

worm

hearings

and

a

colwnn

bushing

JACKET

TUBE

w

1

U

II

I

II

I

r

liJl

I

I

D

I

1

1

Mesh

tube

I

2

Jacket

tube

Fig

ST

18

Jacket

tube

ST

10

Page 176 of 513

CHASSIS

The

following

tightening

torque

of

nuts

shall

be

adopted

Ball

stud

nut

3

0

to

5

0

kg

m

21

7

to

36

2

ft

lb

Gear

arm

nut

14

kg

m

101

ft

lb

Idler

arm

nut

57

to

6

3

kg

m

41

2

to

45

6

ft

lb

2

Assembly

of

the

idler

assembly

is

accomplished

as

follows

I

Apply

soap

water

on

the

outer

circumference

of

bushing

Press

the

bushing

into

the

idler

arm

carefully

until

the

bushing

protrudes

equally

at

the

both

sides

2

Fit

idler

arm

body

in

the

rubber

bushing

Keep

the

idler

arm

center

line

in

parallel

with

the

chassis

center

line

INSTALLATION

Installation

can

be

accomplished

in

the

reverse

order

of

removal

Pay

attention

to

the

following

points

Set

the

length

of

both

side

rods

to

296

8

mm

11

69

in

It

should

be

done

between

the

ball

stud

centers

2

Check

wheel

alignment

and

if

necessary

adjust

it

ACCIDENT

COLLISION

When

accident

collision

occurs

unfortunately

and

the

vehicle

especially

its

front

unit

is

damaged

conduct

inspection

in

accordance

with

the

following

instruction

Inspect

the

steering

system

particularly

carefully

because

it

is

a

very

important

unit

for

driving

I

Check

both

side

steering

angles

for

correct

balance

2

With

the

tires

positioned

at

neutral

steering

wheel

bar

for

correct

position

check

the

l

3

Operate

the

steering

system

and

check

it

for

sliding

noise

4

Check

the

operation

for

smoothness

l

5

Check

the

side

rod

and

cross

rod

for

bending

6

Check

the

gear

arm

for

crack

7

Check

the

gear

housing

tiglltening

bolt

for

slackness

and

installation

boss

for

crack

8

Check

the

sector

shaft

serration

for

twisting

9

Check

the

sector

gear

for

crack

10

Check

the

ball

screw

for

pitting

II

Check

the

column

shaft

for

bending

crack

and

sliding

scar

12

Check

the

jacket

tube

for

bending

13

Check

the

steering

post

clamp

for

existance

of

column

offset

14

Check

the

side

member

gear

housing

installation

unit

for

deformation

IS

Check

the

portion

of

the

steering

post

bracket

installed

on

the

steering

post

clamp

for

correct

installation

AD

JUSTMENT

I

Toe

in

The

procedure

of

toe

in

adjustment

is

outlined

in

section

FRONT

AXLE

AND

FRONT

SUSPENSION

2

Steering

angle

Under

the

specified

load

4

passengers

adjust

the

stopper

bolt

of

the

knuckle

arm

so

that

the

inner

wheel

has

an

angle

of

430

Note

Specified

steering

angle

of

wheel

is

430

for

inner

wheel

and

36005

for

outer

wheel

ST

16

Page 184 of 513

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

For

all

models

fuel

tank

capacity

has

been

increased

in

response

to

the

increased

engine

output

Location

and

mounting

strength

are

improved

for

improvement

of

safety

Sedan

40

l

101

2

US

gal

8

3

4

Imp

gal

Van

38

l

10

US

gal

8

3

8

Imp

gal

Coupe

38

l

10

US

gal

8

3

8

Imp

gal

and

completely

drain

fuel

2

Remove

the

fuel

line

connector

3

Remove

the

luggage

compartment

finishing

4

Remove

four

bolts

used

to

secure

the

fuel

tank

5

Loosen

the

hose

clamp

f

r

II

J

y

I

0

I

V

Ii

i

iJb

Also

for

piping

consideration

has

been

given

on

the

safety

To

be

more

specifically

the

fuel

line

coming

out

from

the

fuel

tank

is

laid

inside

the

rear

side

member

so

that

the

fuel

line

is

protected

from

gravel

and

other

interferences

from

road

In

the

front

floor

section

the

fuel

line

is

laid

inside

a

tunnel

and

thus

fuel

line

reaches

the

engine

compartment

In

addition

the

fuel

strainer

and

fuel

tank

outlet

units

connect

the

fuel

line

with

rubber

hoses

and

for

aU

other

sections

bandy

tube

is

used

Fig

FE

9

Drain

plug

position

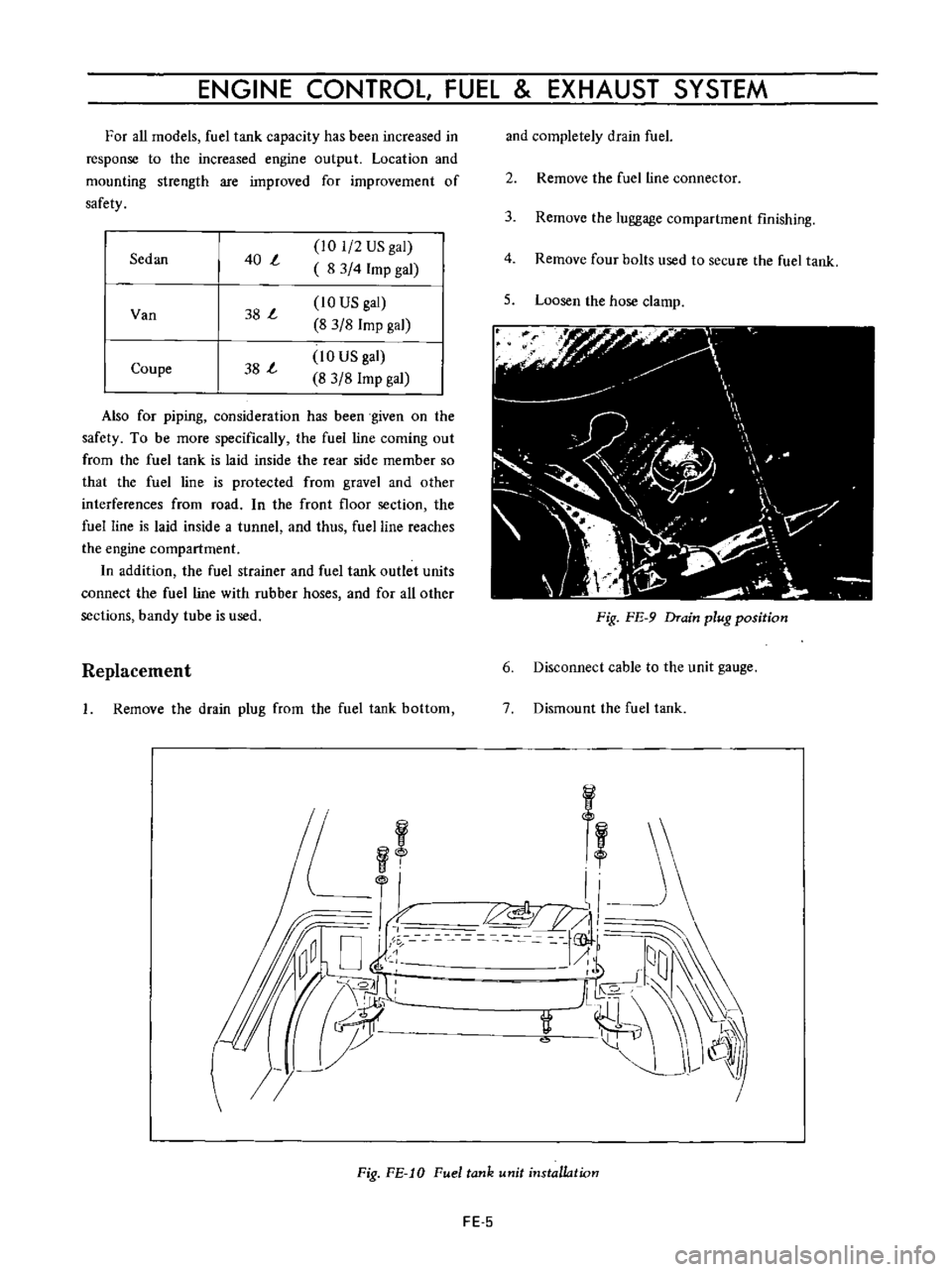

Replacement

Remove

the

drain

plug

from

the

fuel

tank

bottom

6

Disconnect

cable

to

the

unit

gauge

7

Dismount

the

fuel

tank

f

I

Y

L

ll

C

jjhrr

@

Fig

FE

10

Fuel

tank

14nit

installation

FE

5