length DATSUN B110 1973 Service Owner's Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 459 of 513

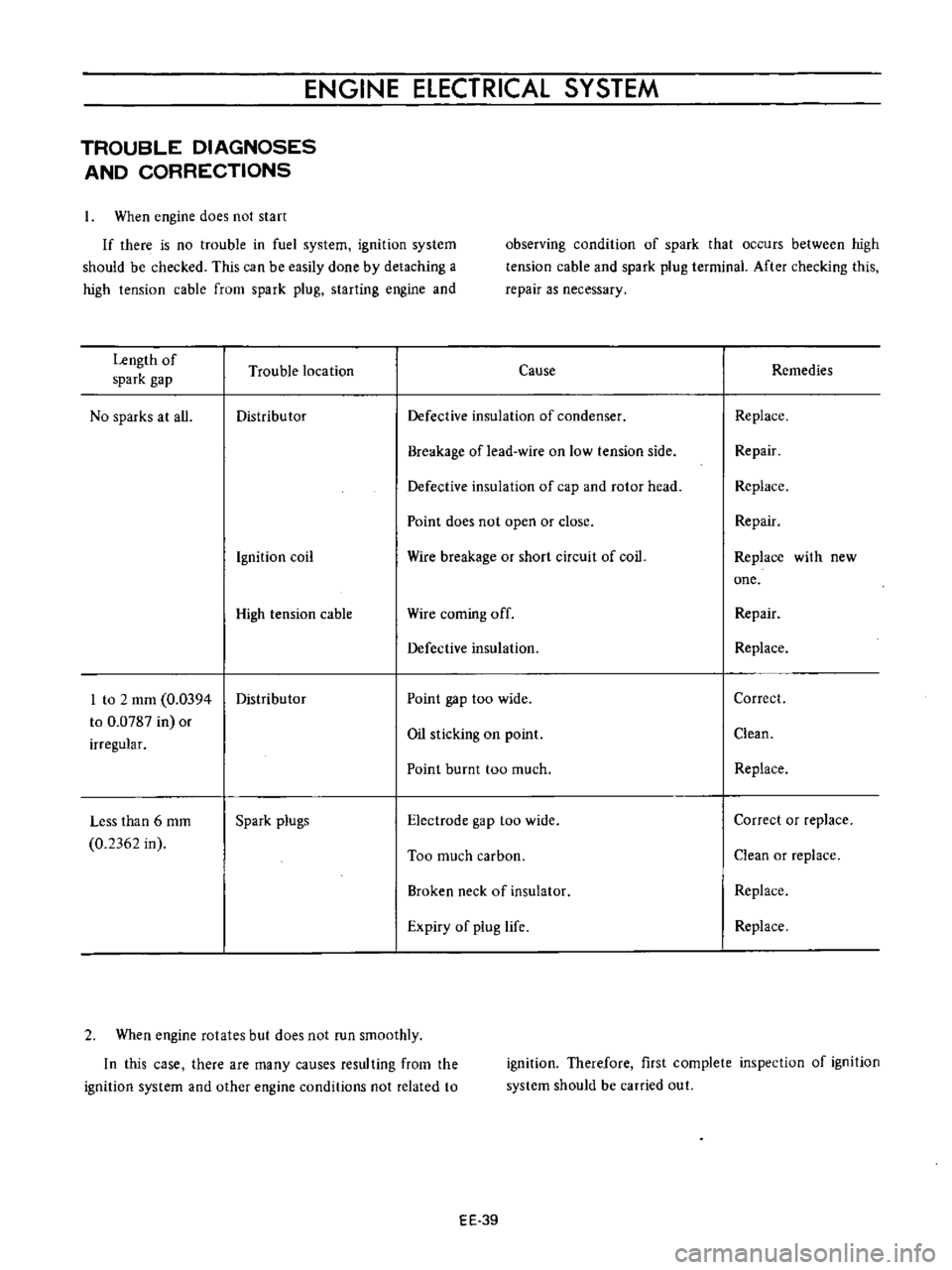

ENGINE

ELECTRICAL

SYSTEM

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

engine

does

not

start

If

there

is

no

trouble

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

cable

from

spark

plug

starting

engine

and

observing

condition

of

spark

that

occurs

between

high

tension

cable

and

spark

plug

terminal

After

checking

this

repair

as

necessary

Length

of

Trouble

location

Cause

Remedies

spark

gap

No

sparks

at

all

Distributor

Defective

insulation

of

condenser

Replace

Breakage

of

lead

wire

on

low

tension

side

Repair

Defective

insulation

of

cap

and

rotor

head

Replace

Point

does

not

open

or

close

Repair

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

cable

Wire

coming

off

Repair

Defective

insulation

Replace

I

to

2

mm

0

0394

Distributor

Point

gap

too

wide

Correct

to

0

0787

in

or

Oil

sticking

on

point

Clean

irregular

Point

burnt

too

much

Replace

Less

than

6

mm

Spark

plugs

Electrode

gap

too

wide

Correct

or

replace

0

2362

in

Too

much

carbon

Clean

or

replace

Broken

neck

of

insulator

Replace

Expiry

of

plug

life

Replace

2

When

engine

rotates

but

does

not

run

smoothly

In

this

case

there

are

many

causes

resulting

from

the

ignition

system

and

other

engine

conditions

not

related

to

ignition

Therefore

first

complete

inspection

of

ignition

system

should

be

carried

out

EE

39

Page 480 of 513

CHASSIS

2

Apply

brake

fluid

sufficiently

to

the

cylinder

and

piston

and

assemble

them

Reinstallation

Reinstall

the

master

cylinder

assembly

in

reverse

sequence

of

removal

and

adjust

as

follows

I

Adjust

the

pedal

height

by

changing

the

push

rod

length

2

B

eed

air

out

of

the

hydraulic

system

OPERATING

CYLINDER

Hydraulic

clutch

Removal

Remove

the

return

spring

2

Disconnect

the

clutch

line

from

the

operating

cyl

inder

3

Disconnect

the

push

rod

from

the

withdrawal

lever

4

Release

two

bolts

used

to

mount

the

operating

cylinder

to

the

clutch

housing

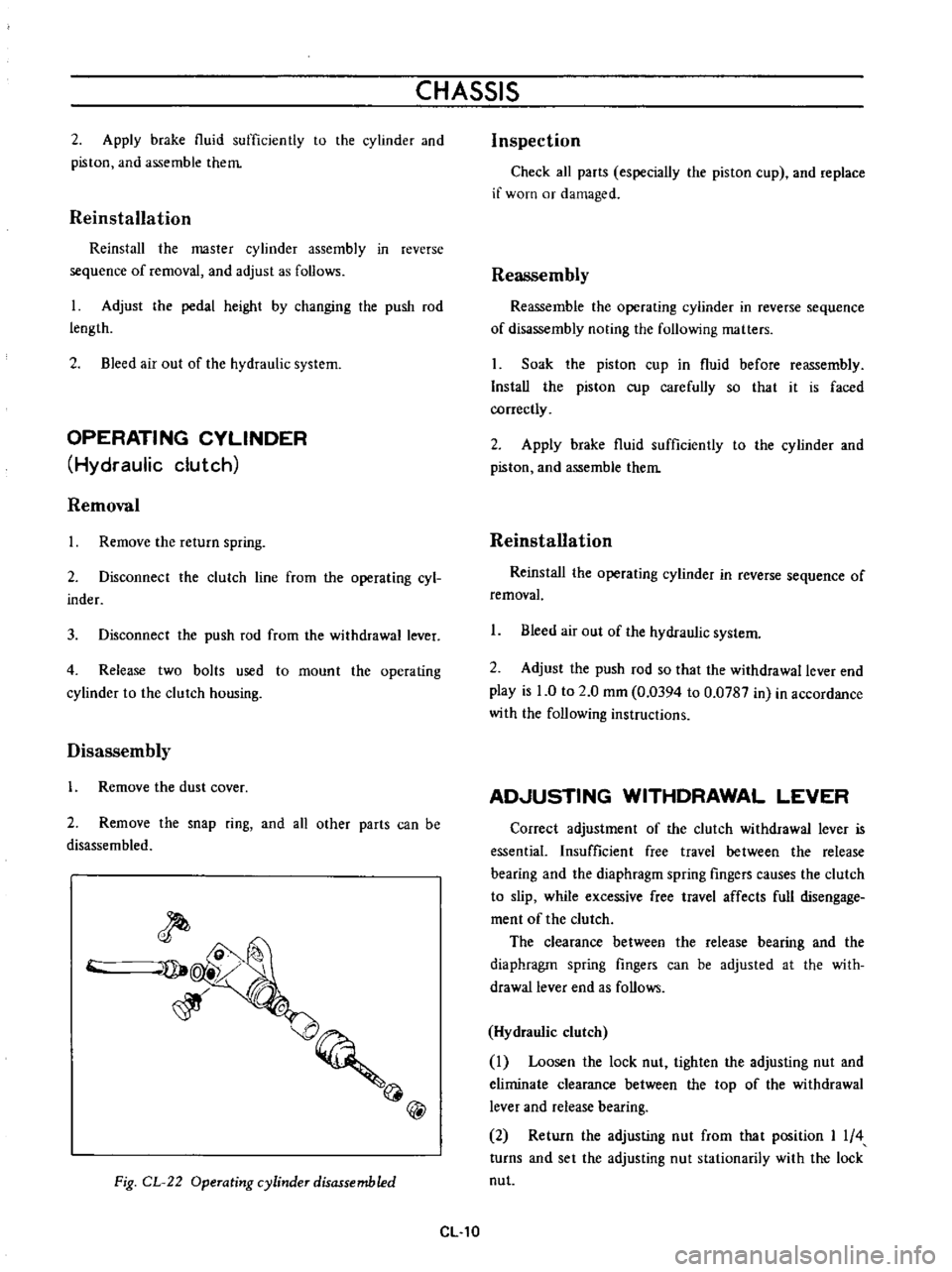

Disassembly

1

Remove

the

dust

cover

2

Remove

the

snap

ring

and

all

other

parts

can

be

disassembled

@

Fig

CL

22

Operating

cylinder

disassembled

CL

10

Inspection

Check

all

parts

especially

the

piston

cup

and

replace

if

worn

or

damaged

Reassembly

Reassemble

the

operating

cylinder

in

reverse

sequence

of

disassembly

noting

the

following

matters

Soak

the

piston

cup

in

fluid

before

reassembly

Install

the

piston

cup

carefully

so

that

it

is

faced

correctly

2

Apply

brake

fluid

sufficiently

to

the

cylinder

and

piston

and

assemble

them

Reinstallation

Reinstal

the

operating

cylinder

in

reverse

sequence

of

removal

1

Bleed

air

out

of

the

hydraulic

system

2

Adjust

the

push

rod

so

that

the

withdrawal

lever

end

play

is

0

to

2

0

mm

0

0394

to

0

0787

in

in

accordance

with

the

following

instructions

AD

USTING

WITHDRAWAL

LEVER

Correct

adjustment

of

the

clutch

withdrawal

lever

is

essential

Insufficient

free

travel

between

the

release

bearing

and

the

diaphragm

spring

fingers

causes

the

clutch

to

slip

while

excessive

free

travel

affects

full

disengage

ment

of

the

clutch

The

clearance

between

the

release

bearing

and

the

diaphragm

spring

fingers

can

be

adjusted

at

the

with

drawallever

end

as

follows

Hydraulic

clutch

Loosen

the

lock

nut

tighten

the

adjusting

nut

and

eliminate

clearance

between

the

top

of

the

withdrawal

lever

and

release

bearing

2

Return

the

adjusting

nut

from

that

position

I

4

turns

and

set

the

adjusting

nut

stationarily

with

the

lock

nut

Page 484 of 513

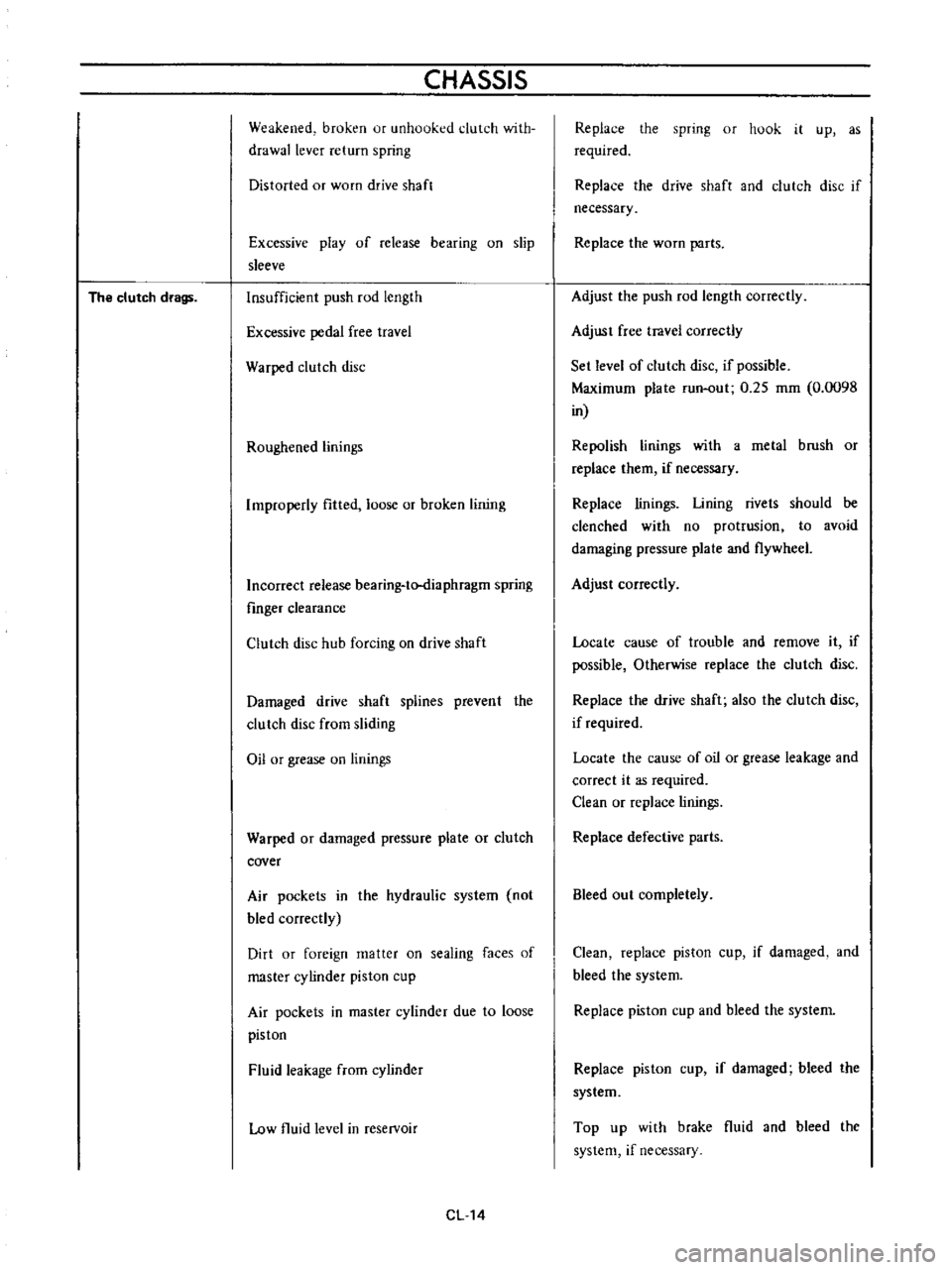

The

clutch

drags

CHASSIS

Weakened

broken

ur

unhooked

clutch

with

drawallever

return

spring

Distorted

or

worn

drive

shaft

Excessive

play

of

release

bearing

on

slip

sleeve

Insufficient

push

rod

length

Excessive

pedal

free

travel

Warped

clutch

disc

Roughened

linings

Improperly

fitted

loose

or

broken

lining

Incorrect

release

bearing

to

diaphragm

spring

fmger

clearance

Clutch

disc

hub

forcing

on

drive

shaft

Damaged

drive

shaft

splines

prevent

the

clutch

disc

from

sliding

Oil

or

grease

on

linings

Warped

or

damaged

pressure

plate

or

clutch

cover

Air

pockets

in

the

hydraulic

system

not

bled

correctly

Dirt

or

foreign

matter

on

sealing

faces

of

master

cylinder

piston

cup

Air

pockets

in

master

cylinder

due

to

loose

piston

Fluid

leakage

from

cylinder

Low

fluid

level

in

reservoir

CL14

Replace

the

spring

or

hook

it

up

as

required

Replace

the

drive

shaft

and

clutch

disc

if

necessary

Replace

the

worn

parts

Adjust

the

push

rod

length

correctly

Adjust

free

travel

correctly

Set

level

of

clutch

disc

if

possible

Maximum

plate

run

out

0

25

mm

0

0098

in

Repolish

linings

with

a

metal

brush

or

replace

them

if

necessary

Replace

linings

Lining

rivets

should

be

clenched

with

no

protrusion

to

avoid

damaging

pressure

plate

and

flywheel

Adjust

correctly

Locate

cause

of

trouble

and

remove

it

if

possible

Otherwise

replace

the

clutch

disc

Replace

the

drive

shaft

also

the

clutch

disc

if

required

Locate

the

cause

of

oil

or

grease

leakage

and

correct

it

as

required

Clean

or

replace

linings

Replace

defective

parts

Bleed

out

completely

Clean

replace

piston

cup

if

damaged

and

bleed

the

system

Replace

piston

cup

and

bleed

the

system

Replace

piston

cup

if

damaged

bleed

the

system

Top

up

with

brake

fluid

and

bleed

the

system

if

necessary