ground clearance DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 428 of 513

ENGINE

EE022

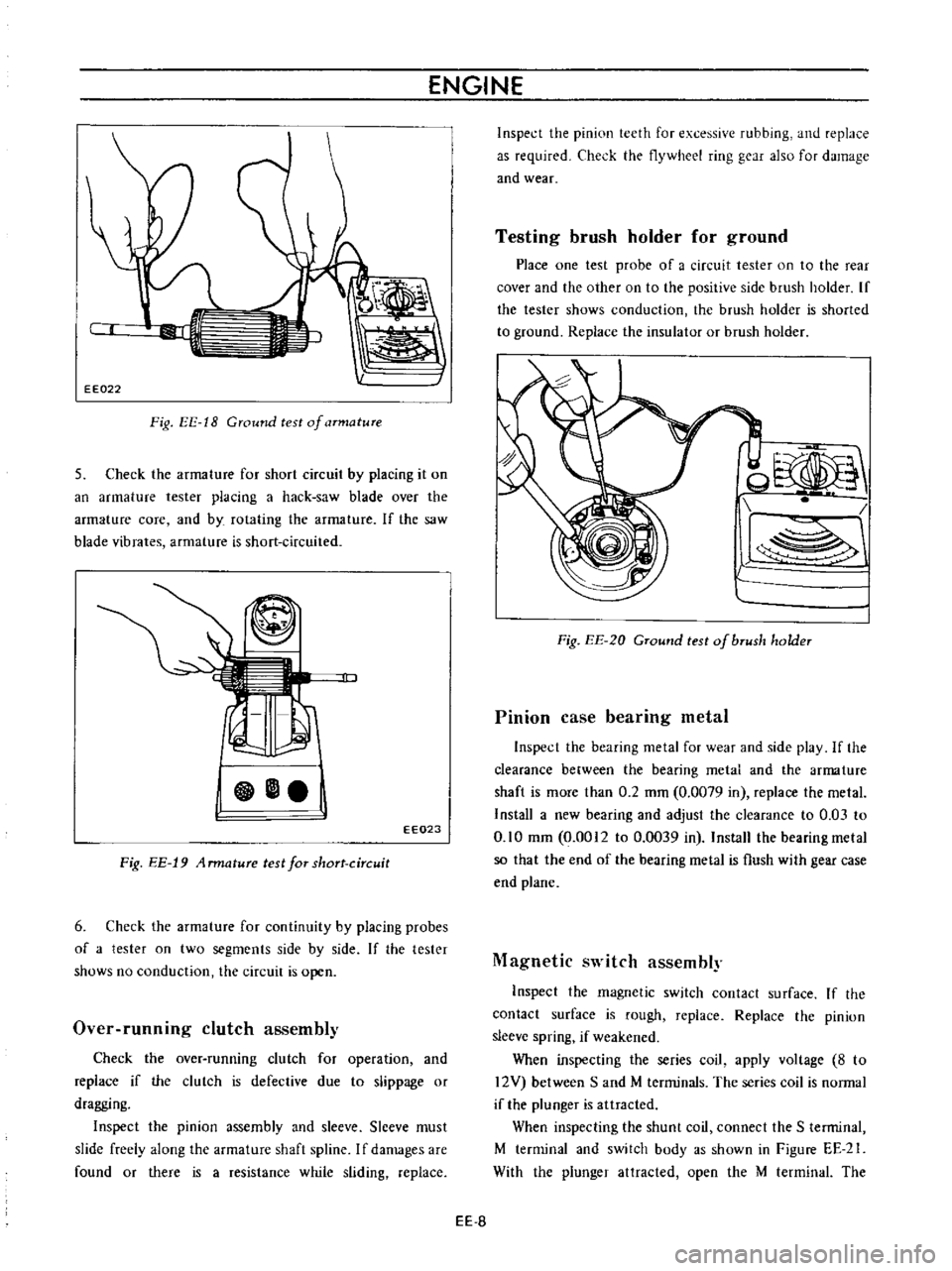

Fig

EE

18

Ground

test

of

armature

5

Check

the

armature

for

short

circuit

by

placing

it

on

an

armature

tester

placing

a

hack

saw

blade

over

the

armature

core

and

by

rotating

the

armature

If

the

saw

blade

vibrates

armature

is

short

circuited

EE023

Fig

EE

19

4

rmature

test

for

short

circuit

6

Check

the

armature

for

continuity

by

placing

probes

of

a

tester

on

two

segments

side

by

side

If

the

tester

shows

no

conduction

the

circuit

is

open

Over

runnmg

clutch

assembly

Check

the

over

running

clutch

for

operation

and

replace

if

the

clutch

is

defective

due

to

slippage

or

dragging

Inspect

the

pinion

assembly

and

sleeve

Slceve

must

slide

freely

along

the

armature

shaft

spline

I

f

damages

are

found

or

there

is

a

resistance

while

sliding

replace

Inspect

the

pinion

teeth

for

excessive

rubbing

and

replace

as

required

Check

the

flywheel

ring

gear

also

for

damage

and

wear

Testing

brush

holder

for

ground

Place

one

test

probe

of

a

circuit

tester

on

to

the

rear

cover

and

the

other

on

to

the

positive

side

brush

holder

If

the

tester

shows

conduction

the

brush

holdcr

is

shorted

to

ground

Replace

the

insulator

or

brush

holder

od

l

Fig

EE

20

GTound

test

of

bTush

holder

Pinion

case

bearing

metal

Inspect

the

bearing

metal

for

wear

and

sidc

play

If

the

clearance

between

the

bearing

metal

and

the

arma

ture

shaft

is

mOTe

than

0

2

mm

0

0079

in

replace

the

metal

Install

a

new

bearing

and

adjust

the

clearance

to

0

03

to

0

10

mm

0

0012

to

0

0039

in

Install

the

bearing

metal

so

that

the

end

of

the

bearing

metal

is

flush

with

gear

case

end

plane

Magnetic

switch

assembly

Inspect

the

magnetic

switch

contact

surface

If

the

contact

surface

is

rough

replace

Replace

the

pinion

sleeve

spring

if

weakened

When

inspecting

the

series

coil

apply

voltagc

8

to

12V

between

Sand

M

terminals

The

series

coil

is

normal

if

the

plunger

is

attracted

When

inspecting

the

shunt

coil

connect

the

S

terminal

M

terminal

and

switch

body

as

shown

in

Figure

EE

21

With

the

plunger

attracted

open

the

M

terminal

The

EE

S