fuel tank removal DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 182 of 513

ENGINE

CONTROL

FUEL

EXHAUST

SYSTEM

R

H

drive

L

H

drive

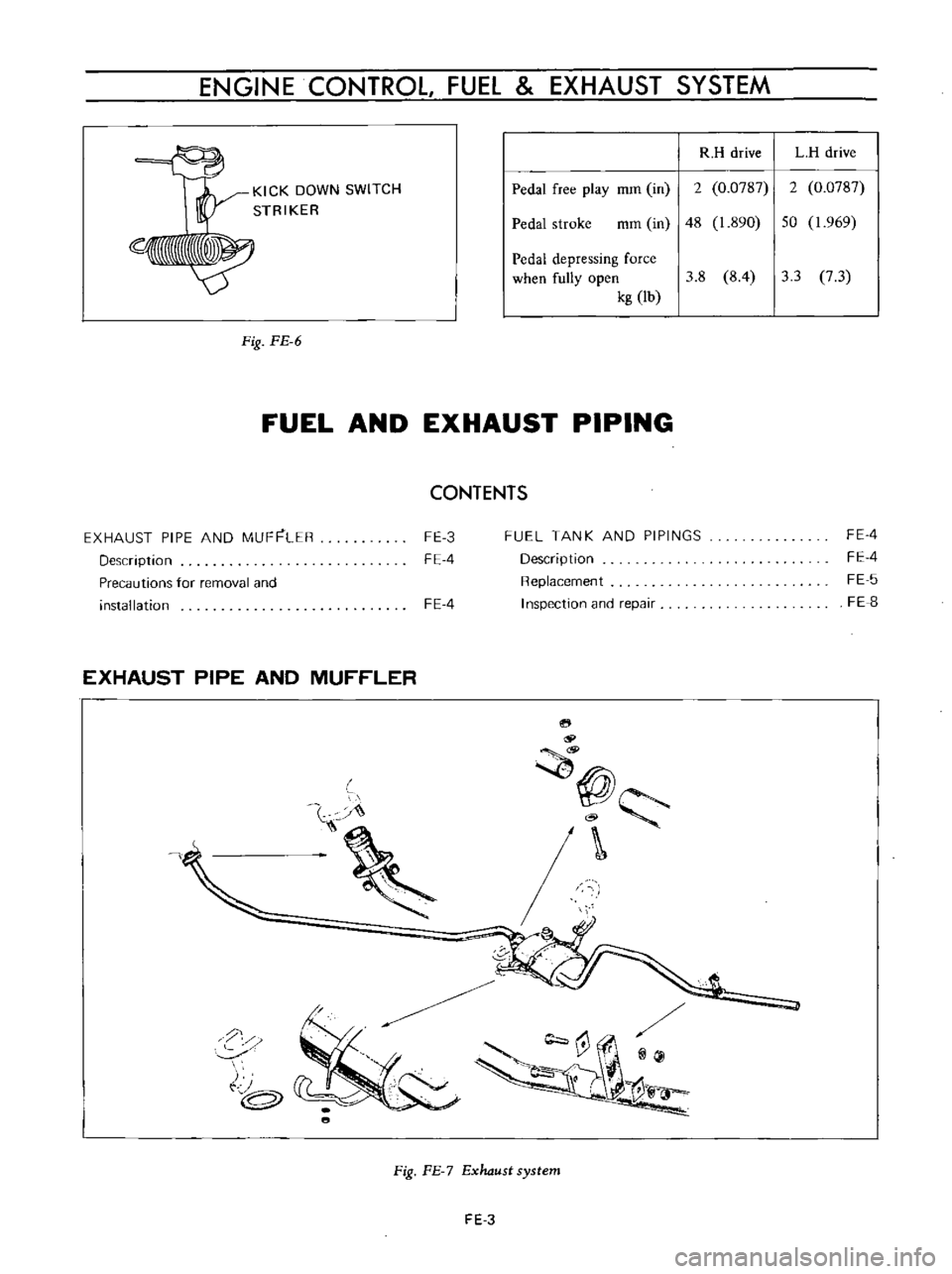

KICK

DOWN

SWITCH

STRIKER

Pedal

free

play

mrn

in

2

0

0787

2

0

0787

Pedal

stroke

mm

in

48

1

890

50

1

969

Pedal

depressing

force

when

fully

open

3

8

8

4

3

3

7

3

kg

lb

Fig

FE

6

FUEL

AND

EXHAUST

PIPING

CONTENTS

EXHAUST

PIPE

AND

MUF

LER

Description

Precautions

for

removal

and

installation

FE

3

FE

4

FUEL

TANK

AND

PIPINGS

Description

Replacement

I

nspection

and

repair

FE

4

FE

4

FE

5

FE

S

FE

4

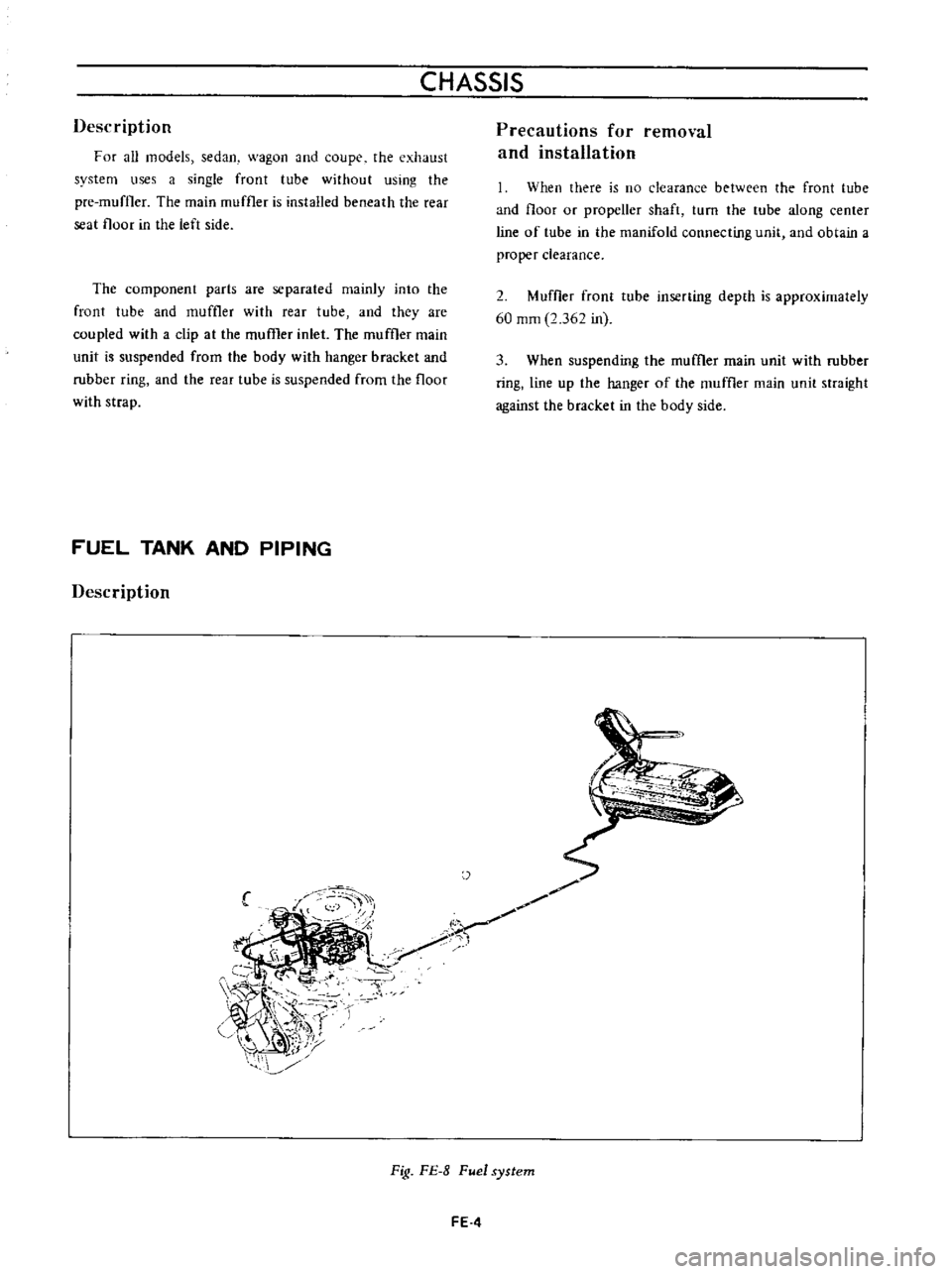

EXHAUST

PIPE

AND

MUFFLER

i

@

@

@

Fig

FE

Exhaust

system

FE

3

Page 183 of 513

CHASSIS

Description

F

Of

aU

models

sedan

wagon

and

coupe

the

exhaust

system

uses

a

single

front

tube

without

using

the

pre

muffler

The

main

muffler

is

installed

beneath

the

rear

seat

floor

in

the

left

side

The

component

parts

are

separated

mainly

into

the

front

tube

and

muffler

with

rear

tube

and

they

are

coupled

with

a

dip

at

the

muffler

inlet

The

rnuffler

main

unit

is

suspended

from

the

body

with

hanger

bracket

and

rubber

ring

and

the

rear

tube

is

suspended

from

the

floor

with

strap

FUEL

TANK

AND

PIPING

Description

Precautions

for

removal

and

installation

When

there

is

no

clearance

between

the

front

tube

and

floor

or

propeller

shaft

turn

the

tube

along

center

line

of

tube

in

the

manifold

connecting

unil

and

obtain

a

proper

clearance

2

Muffler

front

tube

inserting

depth

is

approximately

60

mm

2

362

in

3

When

suspending

the

muffler

rnain

unit

with

rubber

ring

line

up

the

hanger

of

the

muffler

main

unit

straight

against

the

bracket

in

the

body

side

OJ

f

r

ii

7

0

i

i

c

5t

r

t5j

n

jJ

I

L

Fig

FE

8

Fuel

system

FE

4

Page 254 of 513

BODY

ELECTRICAL

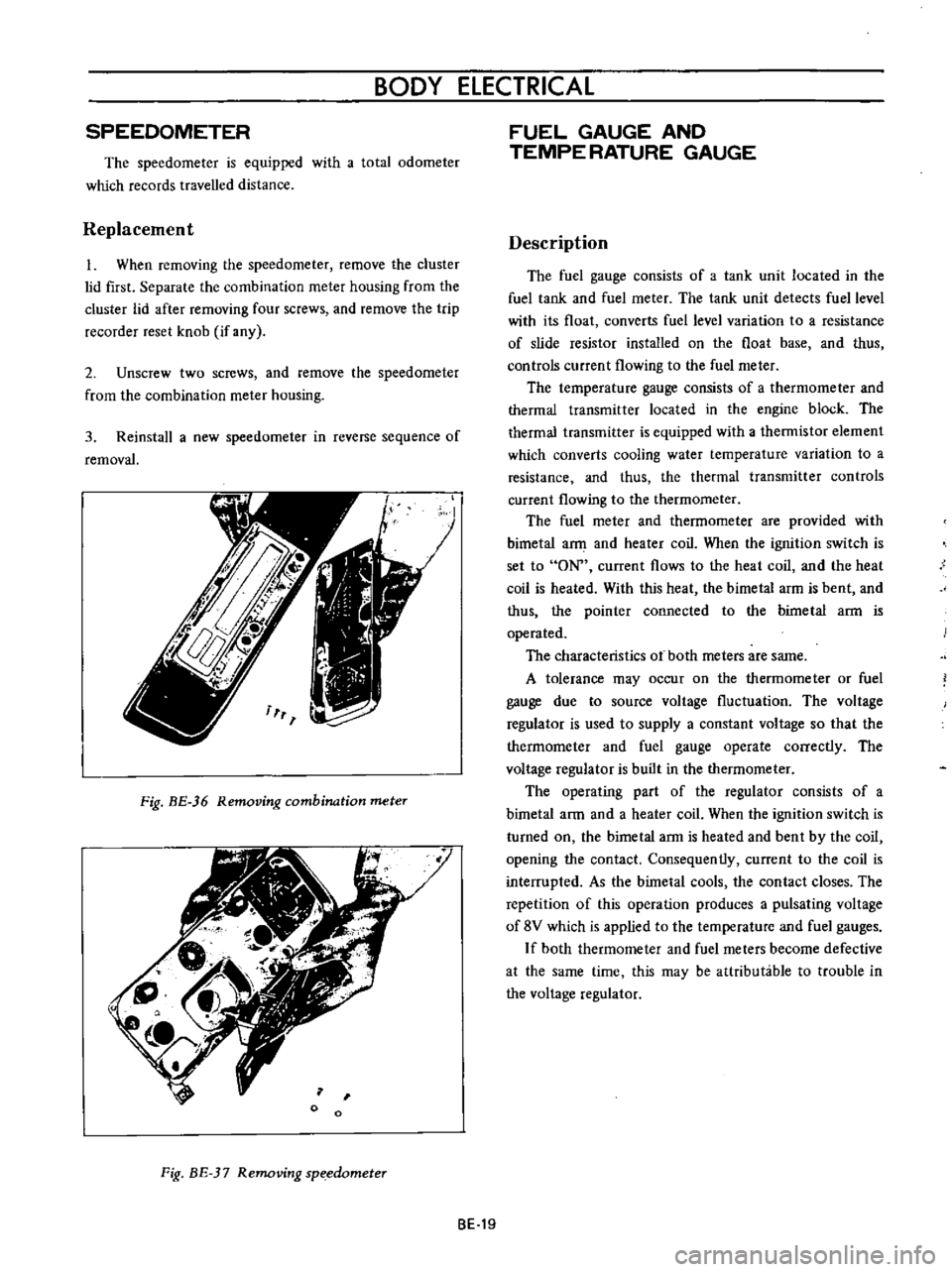

SPEEDOMETER

The

speedometer

is

equipped

with

a

total

odometer

which

records

travelled

distance

Replacement

1

When

removing

the

speedometer

remove

the

cluster

lid

first

Separate

the

combination

meter

housing

from

the

cluster

lid

after

removing

four

screws

and

remove

the

trip

recorder

reset

knob

if

any

2

Unscrew

two

screws

and

remove

the

speedometer

from

the

combination

meter

housing

3

Reinstall

a

new

speedometer

in

reverse

sequence

of

removal

Fig

BE

36

Removing

combination

meter

o

Fig

BE

37

Removing

sp

edometer

FUEL

GAUGE

AND

TEMPE

RATURE

GAUGE

Description

The

fuel

gauge

consists

of

a

tank

unit

located

in

the

fuel

tank

and

fuel

meter

The

tank

unit

detects

fuel

level

with

its

float

converts

fuel

level

variation

to

a

resistance

of

slide

resistor

installed

on

the

float

base

and

thus

controls

current

flowing

to

the

fuel

meter

The

temperature

gauge

consists

of

a

thermorneter

and

thermal

transmitter

located

in

the

engine

block

The

thermal

transmitter

is

equipped

with

a

thermistor

element

which

converts

cooling

water

temperature

variation

to

a

resistance

and

thus

the

thermal

transmitter

controls

current

flowing

to

the

thermometer

The

fuel

rneter

and

thermometer

are

provided

with

bimetal

a

and

heater

coil

When

the

ignition

switch

is

set

to

ON

current

flows

to

the

heat

coil

and

the

heat

coil

is

heated

With

this

heat

the

bimetal

arm

is

bent

and

thus

the

pointer

connected

to

the

bimetal

ann

is

operated

The

characteristics

ot

both

meters

are

same

A

tolerance

may

occur

on

the

thermometer

or

fuel

gauge

due

to

source

voltage

fluctuation

The

voltage

regulator

is

used

to

supply

a

constant

voltage

so

that

the

therrnorneter

and

fuel

gauge

operate

correctly

The

voltage

regulator

is

built

in

the

thermometer

The

operating

part

of

the

regulator

consists

of

a

bimetal

arm

and

a

heater

coil

When

the

ignition

switch

is

turned

on

the

birnetal

arm

is

heated

and

bent

by

the

coil

opening

the

contact

Consequently

current

to

the

coil

is

interrupted

As

the

bimetal

cools

the

contact

closes

The

repetition

of

this

operation

produces

a

pulsating

voltage

of

8V

which

is

applied

to

the

ternperature

and

fuel

gauges

If

both

thermometer

and

fuel

meters

become

defective

at

the

same

time

this

may

be

attributable

to

trouble

in

the

voltage

regulator

BE

19

Page 255 of 513

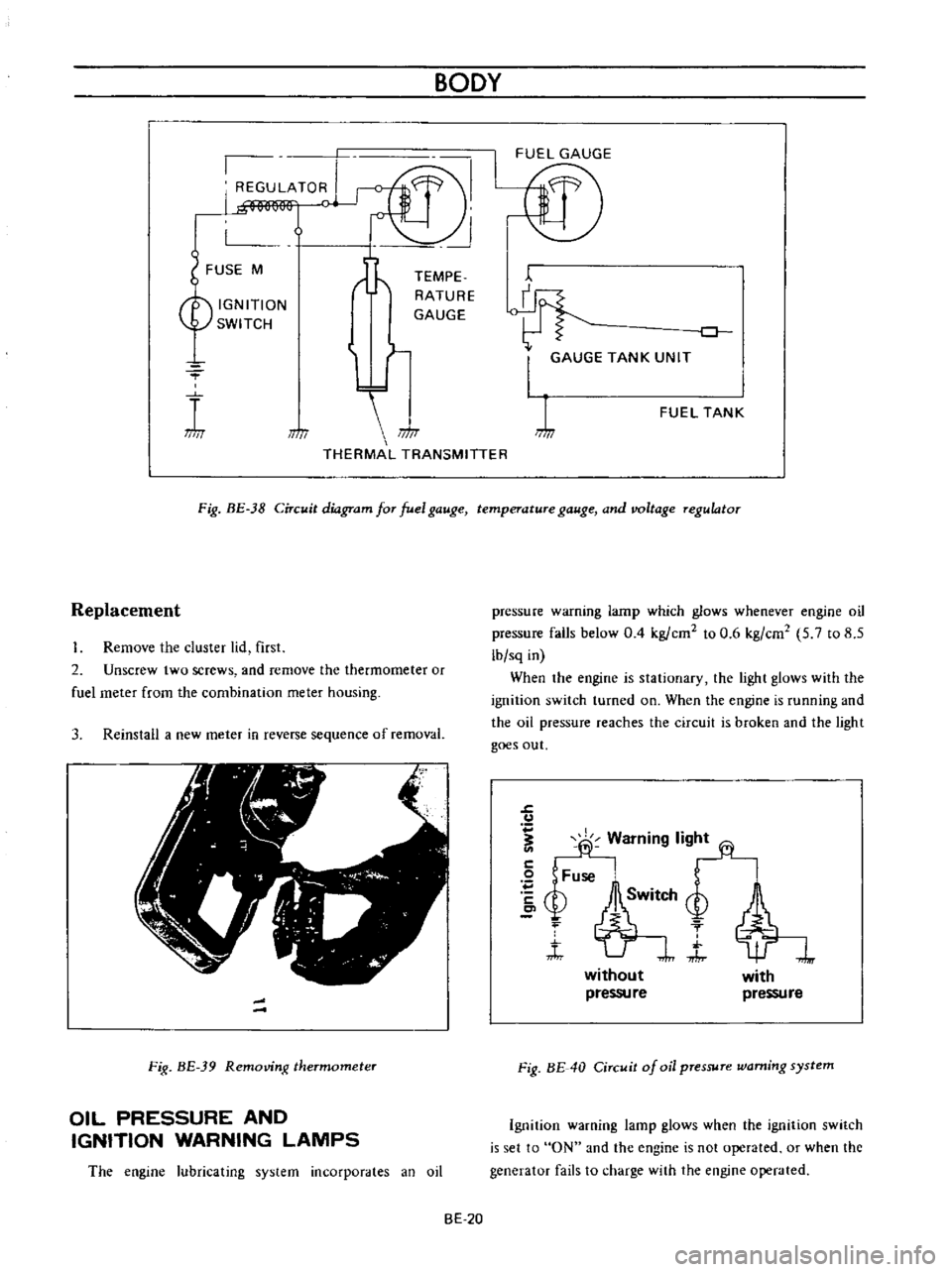

BODY

REGULATOR

FUSE

M

TEMPE

RATURE

GAUGE

IGNITION

SWITCH

Lf

I

iT

Ji

1M

THERMAL

TRANSMITTER

I

J

0

I

GAUGE

TANK

UNIT

FUEL

TANK

Fig

BE

38

Circuit

diagram

for

fuel

gauge

temperature

gauge

and

voltage

regulator

Replacement

Remove

the

cluster

lid

first

2

Unscrew

two

screws

and

remove

the

thermometer

or

fuel

meter

from

the

combination

meter

housing

3

Reinstall

a

new

meter

in

reverse

sequence

of

removal

Fig

BE

39

Removing

thermometer

OIL

PRESSURE

AND

IGNITION

WARNING

LAMPS

The

engine

lubricating

system

incorporates

an

oil

pressure

warning

lamp

which

glows

whenever

engine

oil

pressure

falls

below

0

4

kg

ern

to

0

6

kg

em

5

7

to

8

5

lb

sq

in

When

the

engine

is

stationary

the

light

glows

with

the

ignition

switch

turned

on

When

the

engine

is

running

and

the

oil

pressure

reaches

the

circuit

is

broken

and

the

light

goes

out

J

u

fj

Warning

lig

2

Fuse

bSM

Q

f

t

J

without

pressu

re

with

pressure

Fig

BE

40

Circuit

of

oil

pressure

warning

system

Ignition

warning

lamp

glows

when

the

ignition

switch

is

set

to

ON

and

the

engine

is

not

operated

or

when

the

generator

fails

to

charge

with

the

engine

operated

BE

20

Page 396 of 513

FUEl

SYSTEM

FUEL

STRAINER

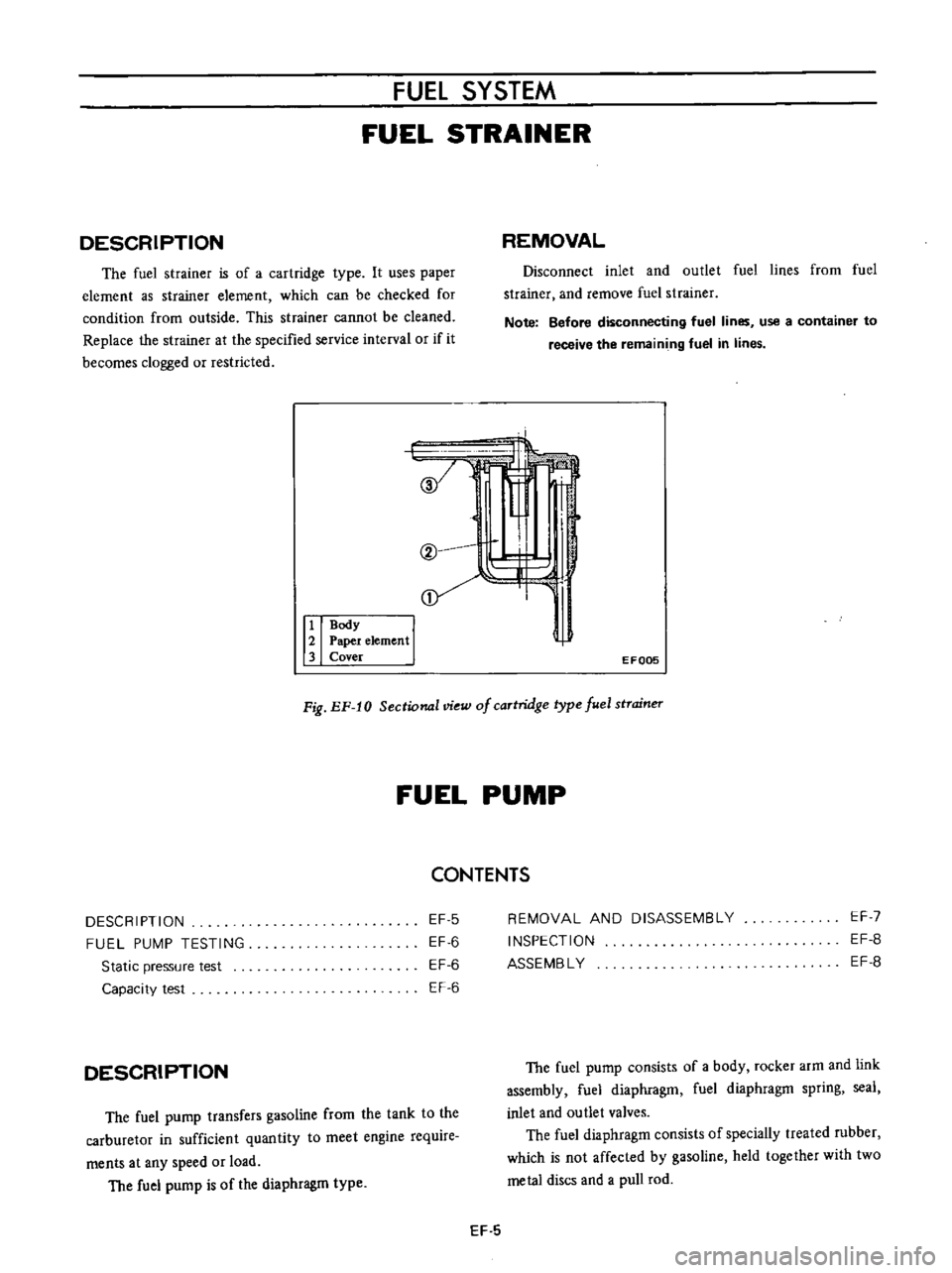

DESCRIPTION

The

fuel

strainer

is

of

a

cartridge

type

It

uses

paper

element

as

strainer

element

which

can

be

checked

for

condition

from

outside

This

strainer

cannot

be

cleaned

Replace

the

strainer

at

the

specified

service

interval

or

if

it

becomes

clogged

or

restricted

REMOVAL

Disconnect

inlet

and

outlet

fuel

lines

from

fuel

strainer

and

remove

fuel

strainer

Note

Before

disconnecting

fuel

lines

use

a

container

to

receive

the

remaining

fuel

in

lines

r

@

I

I

Il

QY

I

I

I

elementl

3

Cover

@

EF005

Fig

EF

10

Sectional

view

of

caTtridge

type

fuel

stTaineT

FUEL

PUMP

CONTENTS

DESCRIPTION

FUEL

PUMP

TESTING

Static

pressure

test

Capacity

test

EF

5

EF

6

EF

6

EF

6

DESCRIPTION

The

fuel

pump

transfers

gasoline

from

the

tank

to

the

carburetor

in

sufficient

quantity

to

meet

engine

require

ments

at

any

speed

or

load

The

fuel

pump

is

of

the

diaphragm

type

REMOVAL

AND

DISASSEMBLY

INSPECTION

ASSEMBLY

EF

7

EF

B

EF

B

The

fuel

pump

consists

of

a

body

rocker

arm

and

link

assembly

fuel

diaphragm

fuel

diaphragm

spring

seal

inlet

and

outlet

valves

The

fuel

diaphragm

consists

of

specially

treated

rubber

which

is

not

affected

by

gasoline

held

together

with

two

metal

discs

and

a

pull

rod

EF

5

Page 397 of 513

ENGINE

FUEL

PUMP

TESTING

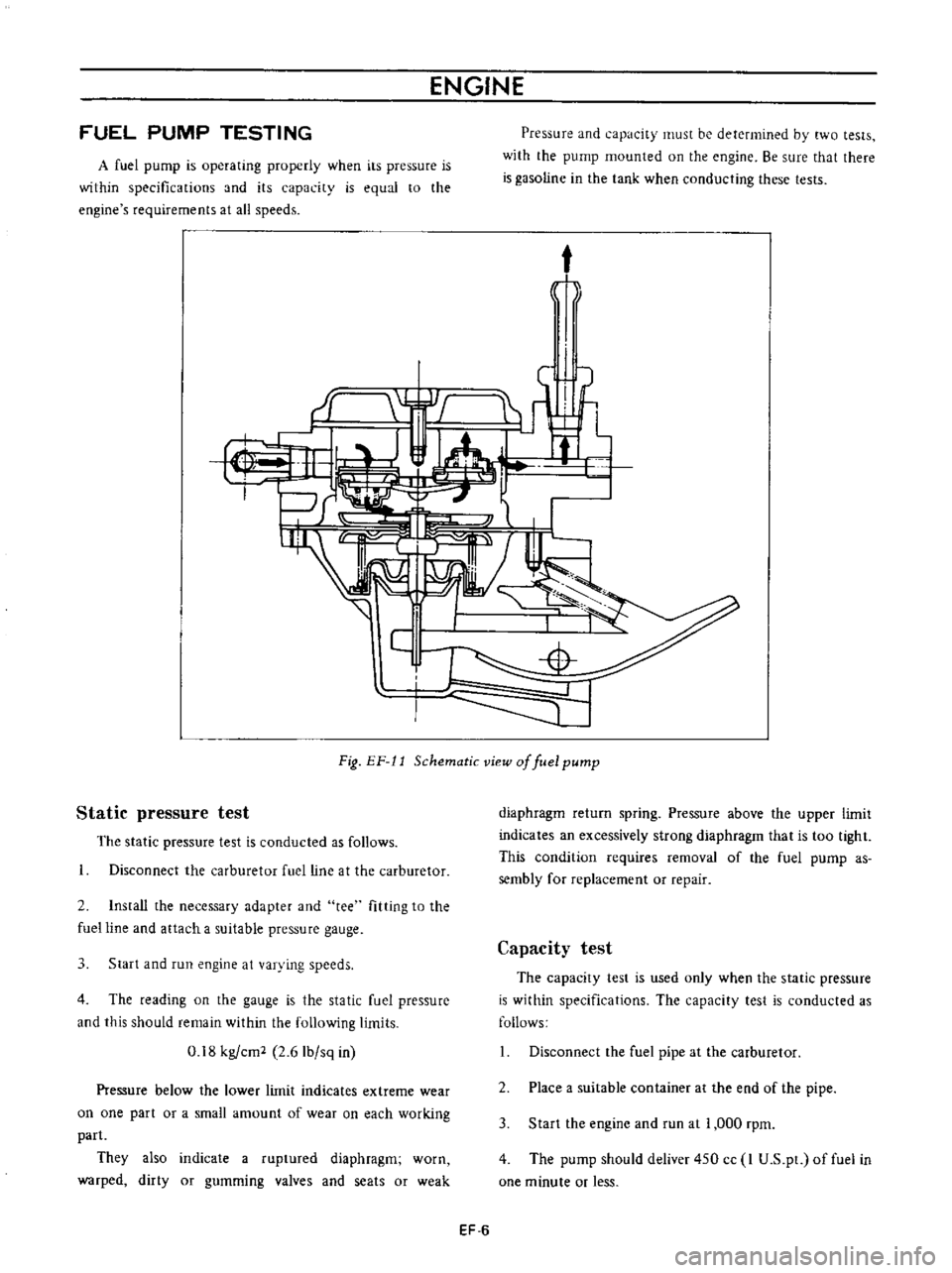

A

fuel

pump

is

operating

properly

when

its

pressure

is

within

specifications

and

its

capacity

is

equal

to

the

engine

5

requirements

at

all

speeds

Pressure

and

cap

lcity

must

be

determined

by

two

tests

with

the

pump

mounted

on

the

engine

Be

sure

that

there

is

gasoline

in

the

tank

when

conducting

these

tests

Fig

EF

11

Schematic

view

of

fuel

pump

Static

pressure

test

The

static

pressure

test

is

conducted

as

follows

Disconnect

the

carburetor

fuel

line

at

the

carburetor

2

Install

the

necessary

adapter

and

tee

fitting

to

the

fuel

line

and

attach

a

suitable

pressure

gauge

Start

and

run

engine

at

varying

speeds

4

The

reading

on

the

gauge

is

the

static

fuel

pressure

and

this

should

remain

within

the

following

limits

0

18

kgJcm2

2

61b

sq

in

Pressure

below

the

lower

limit

indicates

extreme

wear

on

one

part

or

a

small

amount

of

wear

on

each

working

part

They

also

indicate

a

ruptured

diaphragm

worn

warped

dirty

or

gumming

valves

and

seats

or

weak

diaphragm

return

spring

Pressure

above

the

upper

limit

indicates

an

excessively

strong

diaphragm

that

is

too

tight

This

condition

requires

removal

of

the

fuel

pump

as

sembly

for

replacement

or

repair

Capacity

test

The

capacity

test

is

used

only

when

the

static

pressure

is

within

specifications

The

capacity

test

is

conducted

as

follows

1

Disconnect

the

fuel

pipe

at

the

carburetor

2

Place

a

suitable

container

at

the

end

of

the

pipe

3

Start

the

engine

and

run

at

1

000

rpm

4

The

pump

should

deliver

450

cc

I

V

S

p

of

fuel

in

one

minute

or

less

EF

6

Page 398 of 513

FUEL

SYSTEM

If

no

gasoline

or

only

a

little

flows

from

open

end

of

pipe

the

fuel

pipe

is

clogged

or

the

pump

is

malfunction

ing

Before

removing

the

pump

remove

the

gas

tank

cap

disconnect

both

inlet

and

outlet

pipes

and

blow

through

them

with

an

air

hose

to

make

sure

that

they

are

clear

This

will

eliminate

possible

clogged

gas

strainer

in

the

fuel

tank

Reconnect

the

pipes

to

the

pump

and

retest

flow

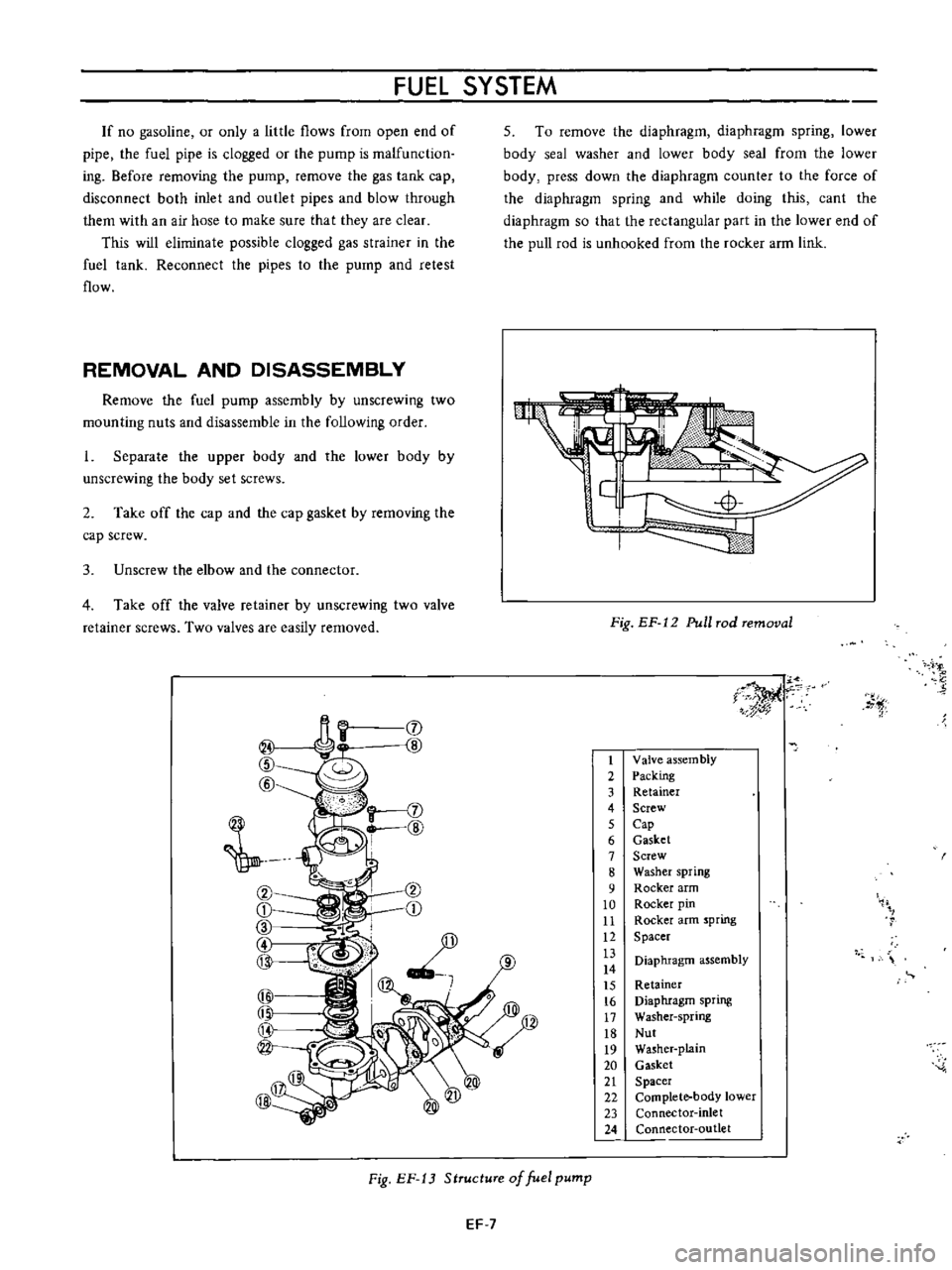

REMOVAL

AND

DISASSEMBLY

Remove

the

fuel

pump

assembly

by

unscrewing

two

mounting

nuts

and

disassemble

in

the

following

order

1

Separate

the

upper

body

and

the

lower

body

by

unscrewing

the

body

set

screws

2

Take

off

the

cap

and

the

cap

gasket

by

removing

the

cap

screw

3

Unscrew

the

elbow

and

the

connector

4

Take

off

the

valve

retainer

by

unscrewing

two

valve

retainer

screws

Two

valves

are

easily

removed

@

@

GS

5

To

remove

the

diaphragm

diaphragm

spring

lower

body

seal

washer

and

lower

body

seal

from

the

lower

body

press

down

the

diaphragm

counter

to

the

force

of

the

diaphragm

spring

and

while

doing

this

cant

the

diaphragm

so

that

the

rectangular

part

in

the

lower

end

of

the

pull

rod

is

unhooked

from

the

rocker

arm

link

Fig

EF

jJ

StructuTe

of

fuel

pump

EF

7

j

i

I

of

4

Fig

EF

12

Pull

Tad

Temoval

r1

r

f

i

t

1

2

3

4

5

6

7

B

9

10

tt

t2

t3

t4

15

t6

t7

tB

t9

20

2t

22

23

24

Valve

assem

bly

Packing

Retainer

Screw

Cap

Gasket

Screw

Washer

spring

Rocker

arm

Rocker

pin

Rocker

arm

spring

Spacer

Diaphragm

assembly

Retainer

Diaphragm

spring

Washer

spring

Nut

Washer

plain

Gasket

Spacer

Complete

body

lower

Connector

inlet

Connector

outlet