oil filter DATSUN B110 1973 Service Repair Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 274 of 513

Tool

number

T

ooJ

name

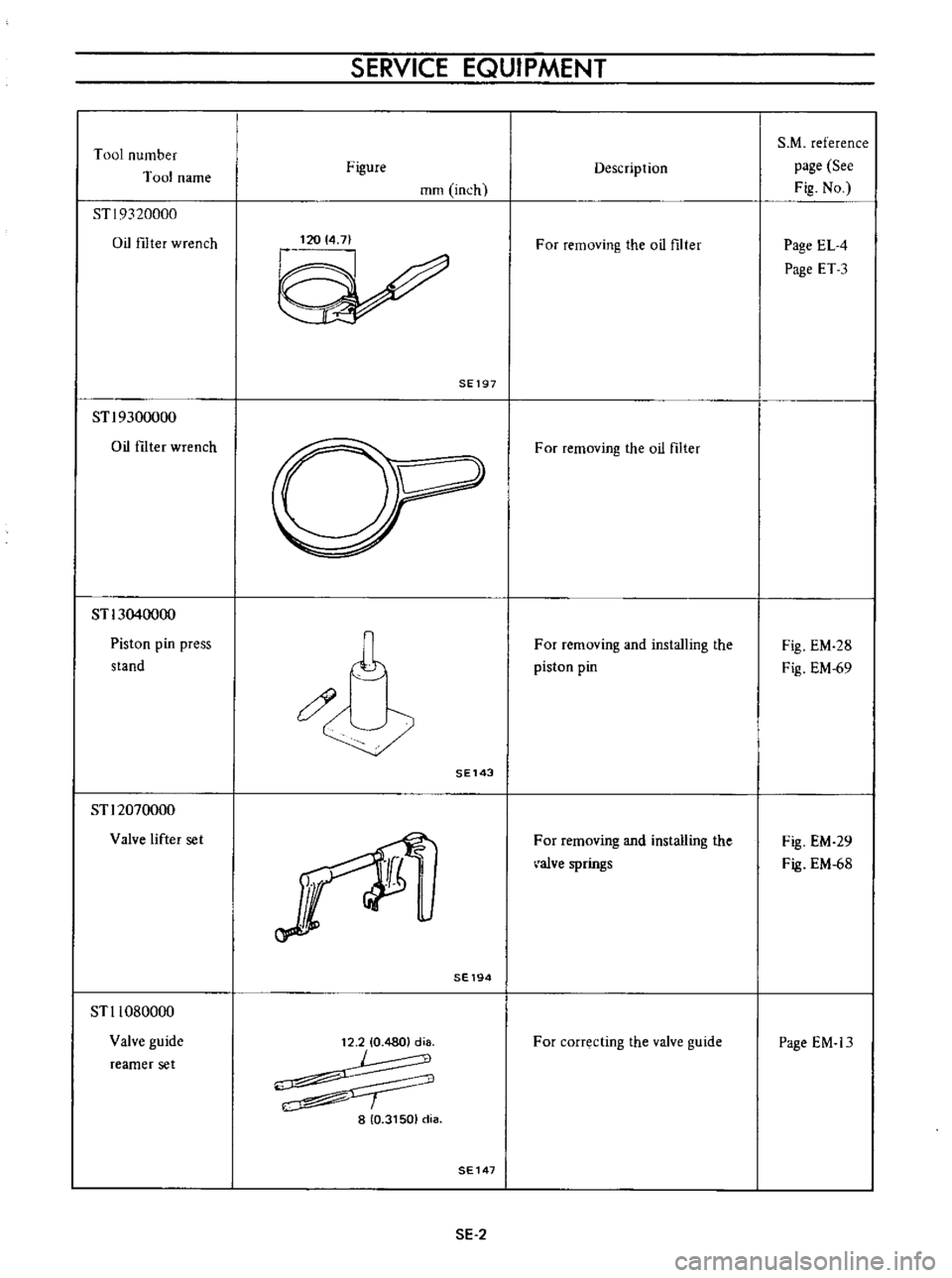

ST

I

9320000

Oil

filter

wrench

STl9300000

Oil

ftIter

wrench

STl3040000

Piston

pin

press

stand

STl2070000

Valve

lifter

set

STl1080000

Valve

guide

reamer

set

SERVICE

EQUIPMENT

Figure

mm

inch

120

14

7

SE197

11

0

SE143

SE194

12

210

4801

d

8

L

8

10

31501

d

a

SE147

SE

2

Description

For

removing

the

oil

filter

For

removing

the

oil

filter

For

removing

and

installing

the

piston

pin

For

removing

and

installing

the

a1ve

springs

For

correcting

the

valve

guide

S

M

reference

page

See

Fig

No

Page

EL

4

Page

ET

3

Fig

EM

28

Fig

EM

69

Fig

EM

29

Fig

EM

68

Page

EM

13

Page 306 of 513

EMISSION

CONTROL

AND

TUNE

UP

EMISSION

CONTROL

SYSTEM

AN

D

ENGINE

TUNE

UP

CONTENTS

BASIC

MECHANICAL

SYSTEM

ET

Checking

and

adjusting

dash

pot

Adjusting

intake

and

exhaust

valve

automatic

transmission

model

only

ET

9

clearances

ET

1

Checking

carburetor

return

spring

ET

9

Checking

and

adjustin9

drive

belt

ET

2

Checking

choke

mechanism

choke

valve

Retightening

cylinder

head

bolts

manifold

and

linkagel

ET

9

nuts

and

carburetor

securing

nuts

ET

2

Checking

anti

dieseling

solenoid

ET

9

Checking

engine

oil

ET

2

Replacing

fuel

filter

ET

10

Replacing

oil

filter

ET

3

Checking

fuel

lines

hoses

pipings

Changing

engine

coolant

L

L

C

ET

3

connections

etc

ET10

Checking

cooling

system

hoses

and

THROTTLE

OPENER

CONTROL

SYSTEM

ET

10

connections

ET

4

Checking

and

adjusting

throttle

opener

ET

13

Checking

vacuum

fittings

hoses

and

TRANSMISSION

CONTROLLED

VACUUM

connections

ET

4

ADVANCE

SYSTEM

ET

17

Checking

engine

compression

ET

4

Checking

electrical

advance

control

system

ET

19

Checking

exhaust

manifold

heat

control

AUTOMATIC

TEMPERATURE

CONTROL

AIR

valve

ET

5

CLEANER

A

T

C

AIR

CLEANER

ET

20

IGNITION

AND

FUEL

SYSTEM

ET

5

Replacing

carburetor

air

cleaner

filter

ET

20

Checking

battery

ET

5

Checking

hot

air

control

valve

ET

20

Checking

and

adjusting

ignition

timing

ET

5

CRANKCASE

EMISSION

CONTROL

Checking

or

replacing

distributor

breaker

SYSTEM

ET

22

point

condenser

and

spark

plugs

ET

6

Checking

or

replacing

PCV

valve

ET

23

Checking

distributor

ignition

wiring

and

Checking

ventilation

hoses

ET

23

ignition

coil

ET

7

EVAPORATIVE

EMISSION

CONTROL

Checking

distributor

cap

and

rotor

ET

7

SYSTEM

ET

23

Adjusting

carburetor

id

Ie

rpm

and

Checking

engine

compartment

hose

mixture

ratio

ET

8

connections

and

fuel

vapor

control

valves

ET

23

Checking

fuel

tank

vacuum

relief

valve

operation

ET

24

BASIC

MECHANICAL

SYSTEM

1

Start

engine

and

run

it

until

it

is

heated

to

operating

temperature

or

at

least

more

than

800C

I760F

of

engine

oil

temperature

then

stop

engine

Adjusting

intake

and

exhaust

valve

clearances

Valve

clearance

adjustment

should

be

made

while

engine

is

stationary

To

adjust

proceed

as

follows

2

Rotate

crankshaft

to

bring

No

1

cylinder

in

top

dead

center

on

its

compression

stroke

3

Remove

valve

rocker

cover

to

gain

access

to

valve

ET

1

Page 307 of 513

ENGINE

operating

mechanism

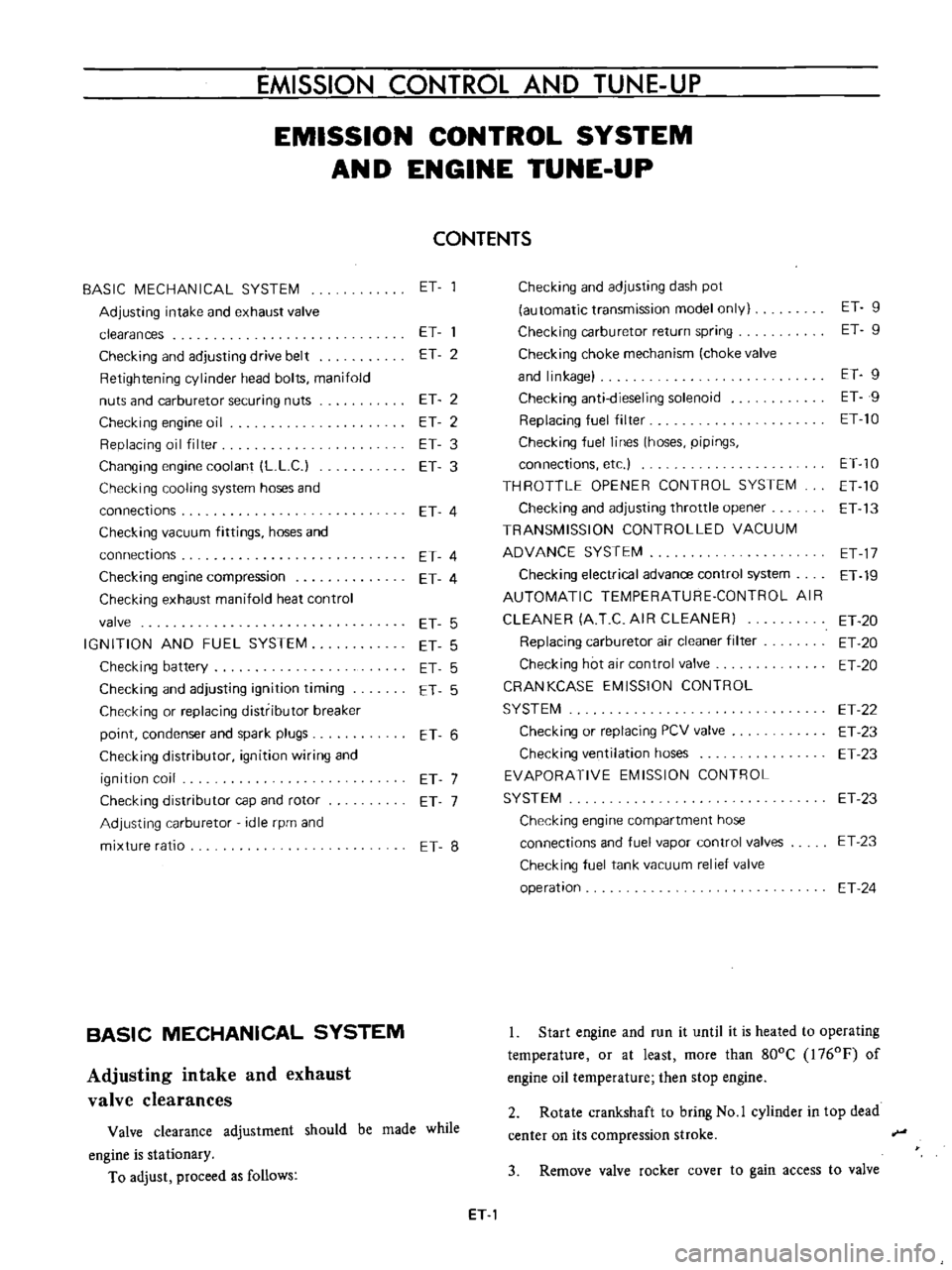

Adjust

valve

clearance

at

following

four

points

while

engine

is

still

hot

G

Exhaust

valve

of

No

1

cylinder

CV

Intake

valve

of

No

1

cylinder

CID

Intake

valve

of

No

2

cylinder

CID

Exhaust

valve

of

No

3

cylinder

Note

Numbers

in

parenthesis

agree

with

those

in

ac

companying

sketch

I

Fig

BY

1

Adjusting

valve

clearance

4

Again

rotate

crankshaft

one

turn

so

that

No

4

piston

is

in

top

dead

ce

lter

on

its

compression

stroke

Adjust

follnwing

valves

@

Exhaust

valve

of

No

2

cylinder

@

Intake

valve

of

No

3

cylinder

f

Intake

valve

of

No

4

cylinder

@

Exhaust

valve

of

No

4

cylinder

Adjustment

should

be

made

while

engine

is

hot

After

all

valves

have

been

adjusted

correctly

tighten

lock

nut

firmly

to

secure

the

adjustment

Vah

e

clearance

Hot

Intake

0

35

mm

0

014

in

Exhaust

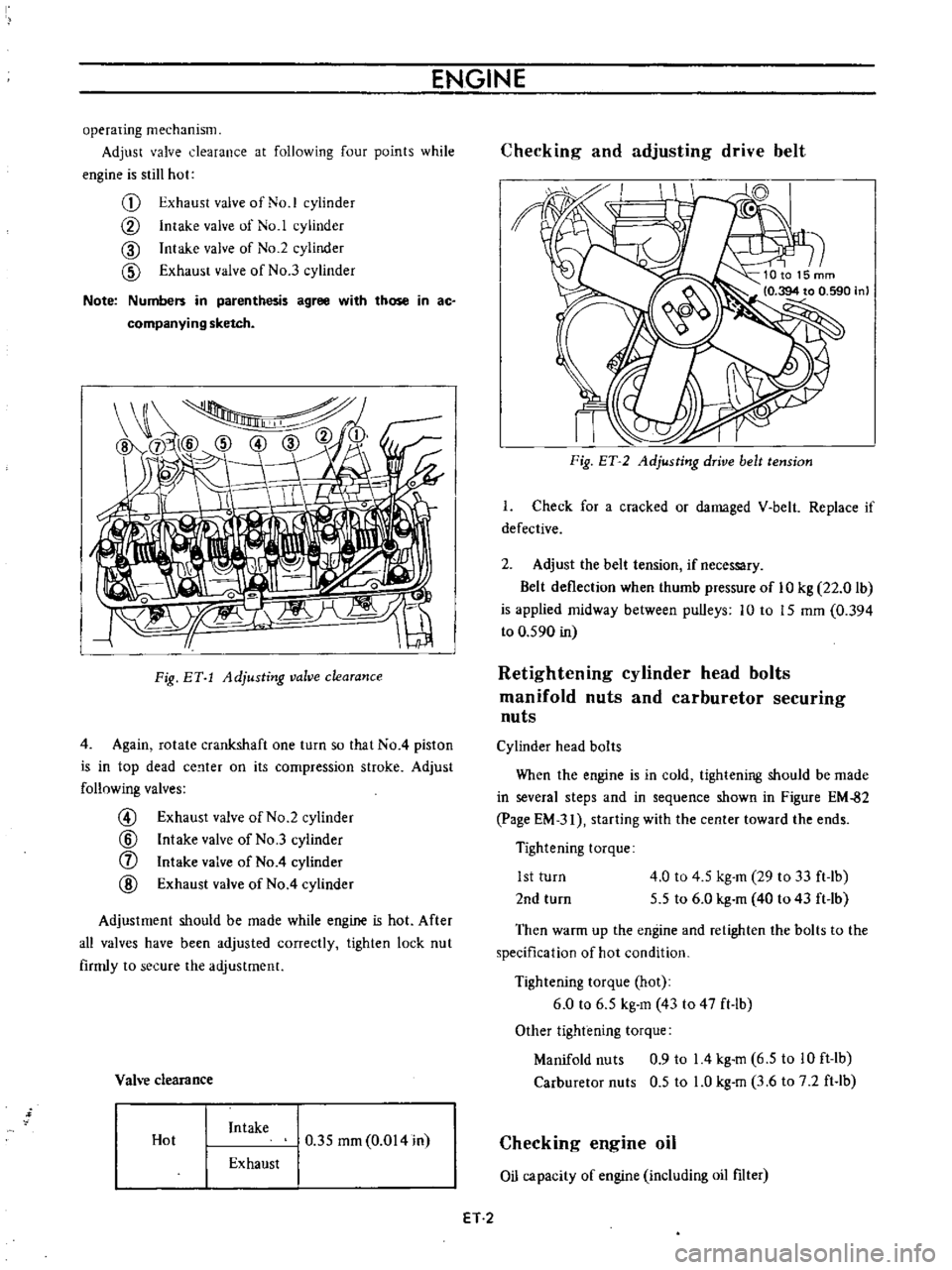

Checking

and

adjusting

drive

belt

II

I

Fig

ET

2

Adjusting

drive

belt

tension

I

Check

for

a

cracked

or

damaged

V

belt

Replace

if

defective

2

Adjust

the

belt

tension

if

necessary

Belt

deflection

when

thumb

pressure

of

10

kg

22

0

lb

is

applied

midway

between

pulleys

10

to

15

mm

0

394

to

0

590

in

Retightening

cylinder

head

bolts

manifold

nuts

and

carburetor

securing

nuts

Cylinder

head

bolts

When

the

engine

is

in

cold

tightening

should

be

made

in

several

steps

and

in

sequence

shown

in

Figure

EM

82

page

EM

31

starting

with

the

center

toward

the

ends

Tightening

torque

1st

turn

2nd

turn

4

0

to

4

5

kg

m

29

to

33

ft

lb

5

5

to

6

0

kg

m

40

to

43

ft

lb

Then

warm

up

the

engine

and

retighten

the

bolts

to

the

specification

of

hot

condition

Tightening

torque

hot

6

0

to

6

5

kg

m

43

to

47

ft

lb

Other

tightening

torque

Manifold

nuts

0

9

to

14

kg

m

6

5

to

10

ft

lb

Carburetor

nuts

0

5

to

LO

kg

m

3

6

to

7

2

ft

lb

Checking

engine

oil

Oil

capacity

of

engine

including

oil

filter

ET

2

Page 308 of 513

EMISSION

CONTROL

AND

TUNE

UP

Capacity

Maximum

3

3

L

X

US

gal

y

Imp

gal

2

3

L

US

gal

f

Imp

gal

Minimum

Make

sure

that

engine

oil

is

not

deteriorated

with

cooling

water

or

gasoline

Drain

and

refill

the

oil

if

necessary

Notes

a

A

milky

oil

indicates

the

presence

of

cooling

water

Find

the

cause

for

necessary

corrective

action

b

Oil

with

extremely

low

viscosity

indicates

dilution

with

gasoline

2

Check

oil

level

If

found

below

L

mark

refill

to

H

mark

on

gauge

Fig

ET

3

Checking

engine

oil

level

Replacing

oil

filter

The

oil

ftIter

is

of

a

cartridge

type

The

oil

filter

can

be

removed

using

oil

ftIter

wrench

STl9320000

Check

for

oil

leaks

through

gasketed

flange

If

any

leakage

is

found

retighten

slightly

If

necessary

replace

filter

as

an

assembly

2

When

installing

an

oil

filter

tighten

by

hand

Note

Do

not

overtighten

oil

filter

or

oil

leakage

way

result

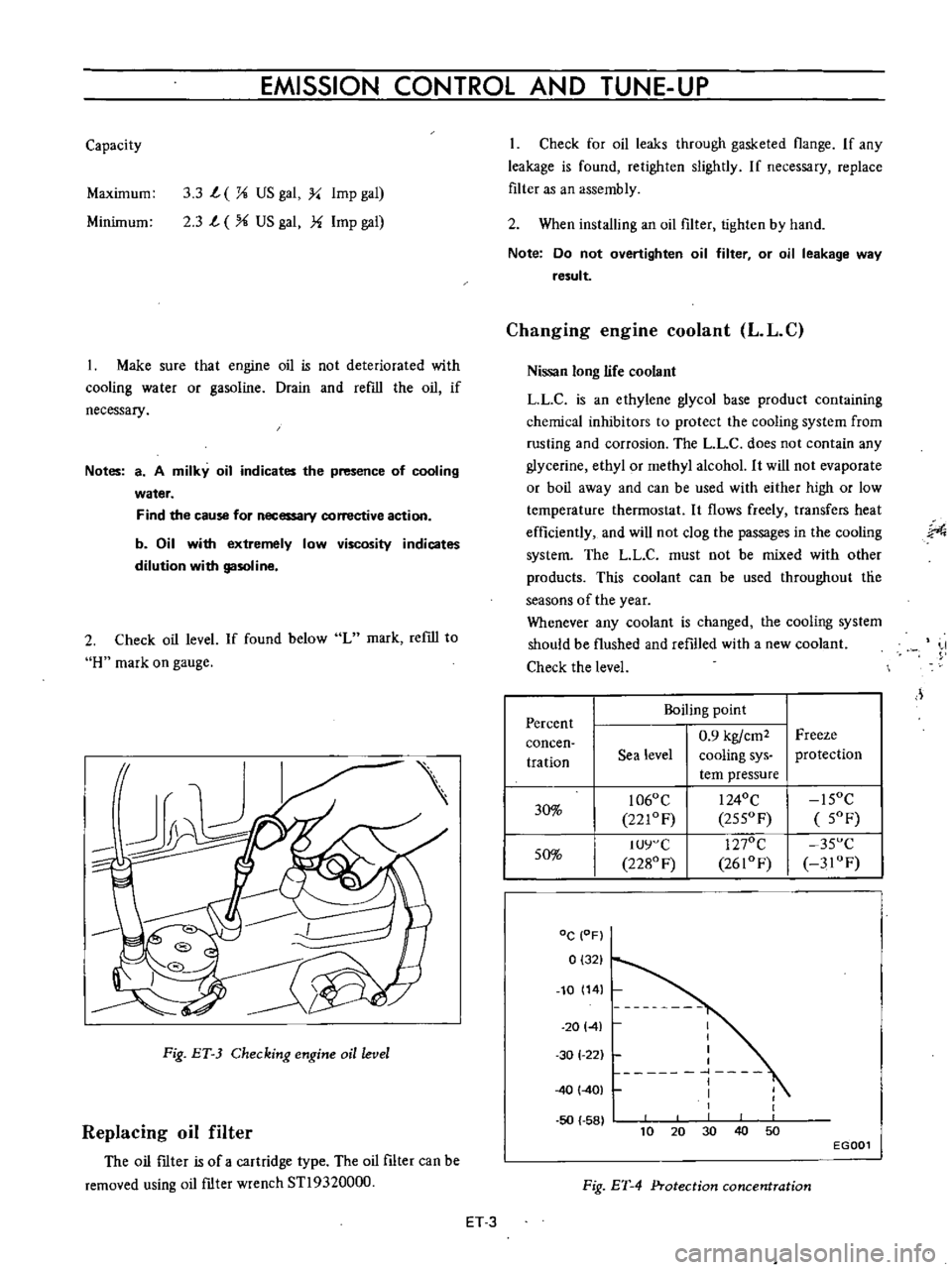

Changing

engine

coolant

L

L

C

Nissan

long

life

coolant

LLC

is

an

ethylene

glycol

base

product

containing

chemical

inhibitors

to

protect

the

cooling

system

from

rusting

and

corrosion

The

L

L

C

does

not

contain

any

glycerine

ethyl

or

methyl

alcohol

It

will

not

evaporate

or

boil

away

and

can

be

used

with

either

high

or

low

temperature

thermostat

It

flows

freely

transfers

heat

efficiently

and

will

not

clog

the

passages

in

the

cooling

system

The

LL

C

must

not

be

mixed

with

other

products

This

coolant

can

be

used

throughout

tlie

seasons

of

the

year

Whenever

any

coolant

is

changed

the

cooling

system

should

be

flushed

and

refilled

with

a

new

coolant

Check

the

level

J

Percent

Boiling

point

0

9

kgfcm2

Freeze

concen

tration

Sea

level

cooling

sys

protection

tern

pressure

30

1060

C

I

240C

15OC

221OF

255OF

5OF

50

IUY

C

1270C

35

C

2280

F

2610F

3IOF

DC

OF

0

321

10

14

20141

50

58

I

I

I

I

1

I

I

1

30

1

22

40

401

40

10

30

50

20

EGOOl

Fig

ET

4

Protection

concentration

ET

3

Page 327 of 513

ENGINE

6

Start

the

engine

and

continue

idling

as

described

under

paragraphs

I

2

and

3

above

When

several

minutes

have

passed

and

the

valve

is

partially

opened

read

the

thermister

indication

It

is

correct

if

the

reading

falls

between

380C

1000

F

and

550C

1300

F

If

the

reading

is

abnormal

replace

the

sensor

7

On

the

engine

equipped

with

an

idle

compensator

as

service

option

do

as

follows

before

replacing

the

sensor

Clog

hose

on

idle

compensator

side

by

twisting

or

clamping

it

and

check

the

temperature

as

given

in

paragraphs

5

and

6

above

If

the

thermometer

shO

vs

correct

temperature

replace

the

idle

compensa

tOf

if

the

reading

is

abnormal

replace

the

sensor

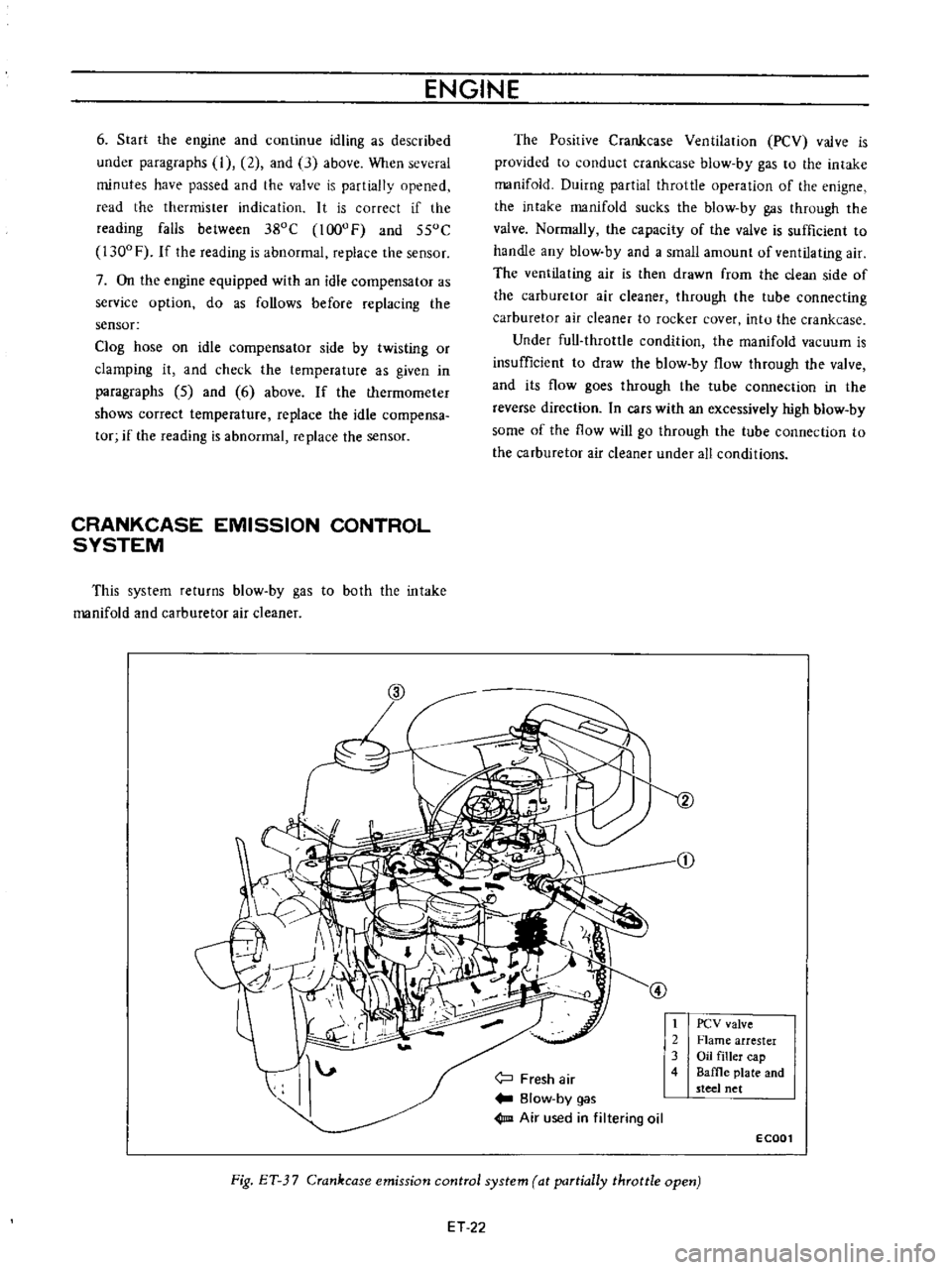

CRANKCASE

EMISSION

CONTROL

SYSTEM

This

system

returns

blow

by

gas

to

both

the

intake

manifold

and

carburetor

air

cleaner

The

Posirive

Crankcase

Ventilation

PCV

valve

is

provided

to

conduct

crankcase

blow

by

gas

to

the

intake

manifold

Duirng

partial

throttle

operation

of

the

enigne

the

intake

manifold

sucks

the

blow

by

gas

through

the

valve

Normally

the

capacity

of

the

valve

is

sufficient

to

handle

any

blow

by

and

a

small

amount

of

ventilating

air

The

ventilating

air

is

then

drawn

from

the

clean

side

of

the

carburetor

air

cleaner

through

the

tube

connecting

carburetor

air

cleaner

to

rocker

cover

intu

the

crankcase

Under

full

throttle

condition

the

manifold

vacuum

is

insufficient

to

draw

the

blow

by

flow

through

the

valve

and

its

flow

goes

through

the

tube

connection

in

the

reverse

direction

In

cars

with

an

excessively

high

blow

by

some

of

the

flow

will

go

through

the

tube

connection

to

the

carburetor

air

cleaner

under

all

conditions

j

Fresh

air

Blow

by

gas

1m

Air

used

in

filtering

oil

t

2

3

4

PCV

valve

Flame

arrester

Oil

filler

cap

Baffle

plate

and

steel

net

ECOOl

Fig

ET

3

7

Crankcase

emission

control

system

at

partially

throttle

open

ET

22

Page 328 of 513

EMISSION

CONTROL

AND

TUNE

UP

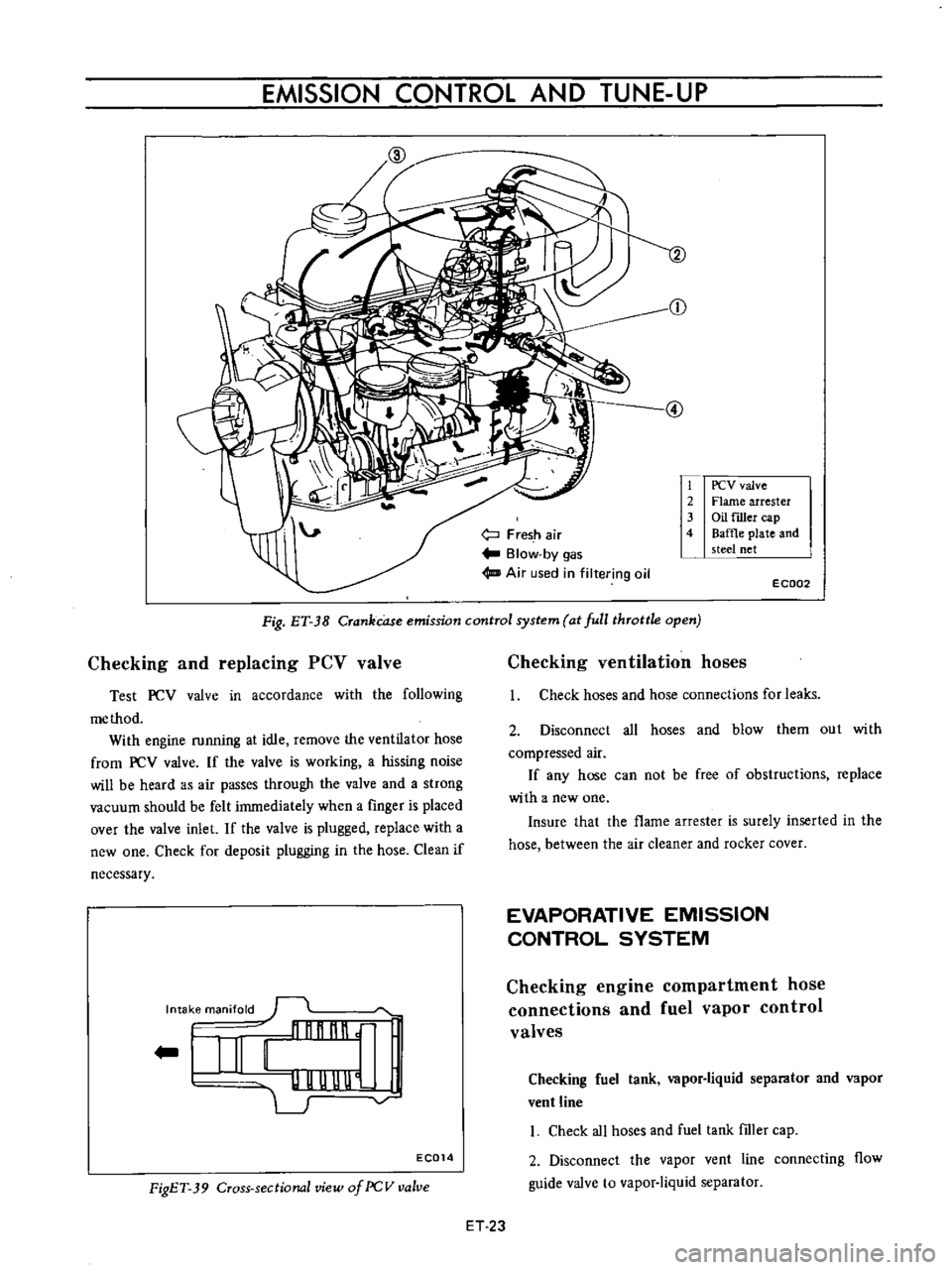

CD

@

Fresh

air

Blow

by

gas

Air

used

in

filtering

oil

1

PCV

valve

2

Flame

arrester

3

Oil

filler

cap

4

Baffle

plate

and

steel

net

E

C002

Fig

ET

J8

Crankcase

emission

control

system

at

full

throttle

open

Checking

and

replacing

PCV

valve

Test

PCV

valve

in

accordance

with

the

following

me

thod

With

engine

running

at

idle

remove

the

ventilator

hose

from

PCV

valve

If

the

valve

is

working

a

hissing

noise

will

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuum

should

be

felt

immediately

when

a

finger

is

placed

over

the

valve

inlet

If

the

valve

is

plugged

replace

with

a

new

one

Check

for

deposit

plugging

in

the

hose

Clean

if

necessary

Intake

manifold

l

illlr

nnnl

UUUU

l

I

G

EC014

FigET

39

Cross

sectional

view

of

PCV

valve

Checking

ventilation

hoses

I

Check

hoses

and

hose

connections

for

leaks

2

Disconnect

all

hoses

and

blow

them

out

with

compressed

air

If

any

hose

can

not

be

free

of

obstructions

replace

with

a

new

one

Insure

that

the

flame

arrester

is

surely

inserted

in

the

hose

between

the

air

cleaner

and

rocker

cover

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

Checking

engine

compartment

hose

connections

and

fuel

vapor

control

valves

Checking

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

I

Check

all

hoses

and

fuel

tank

ftIler

cap

2

Disconnect

the

vapor

vent

line

connecting

flow

guide

valve

to

vapor

liquid

separator

ET

23

Page 337 of 513

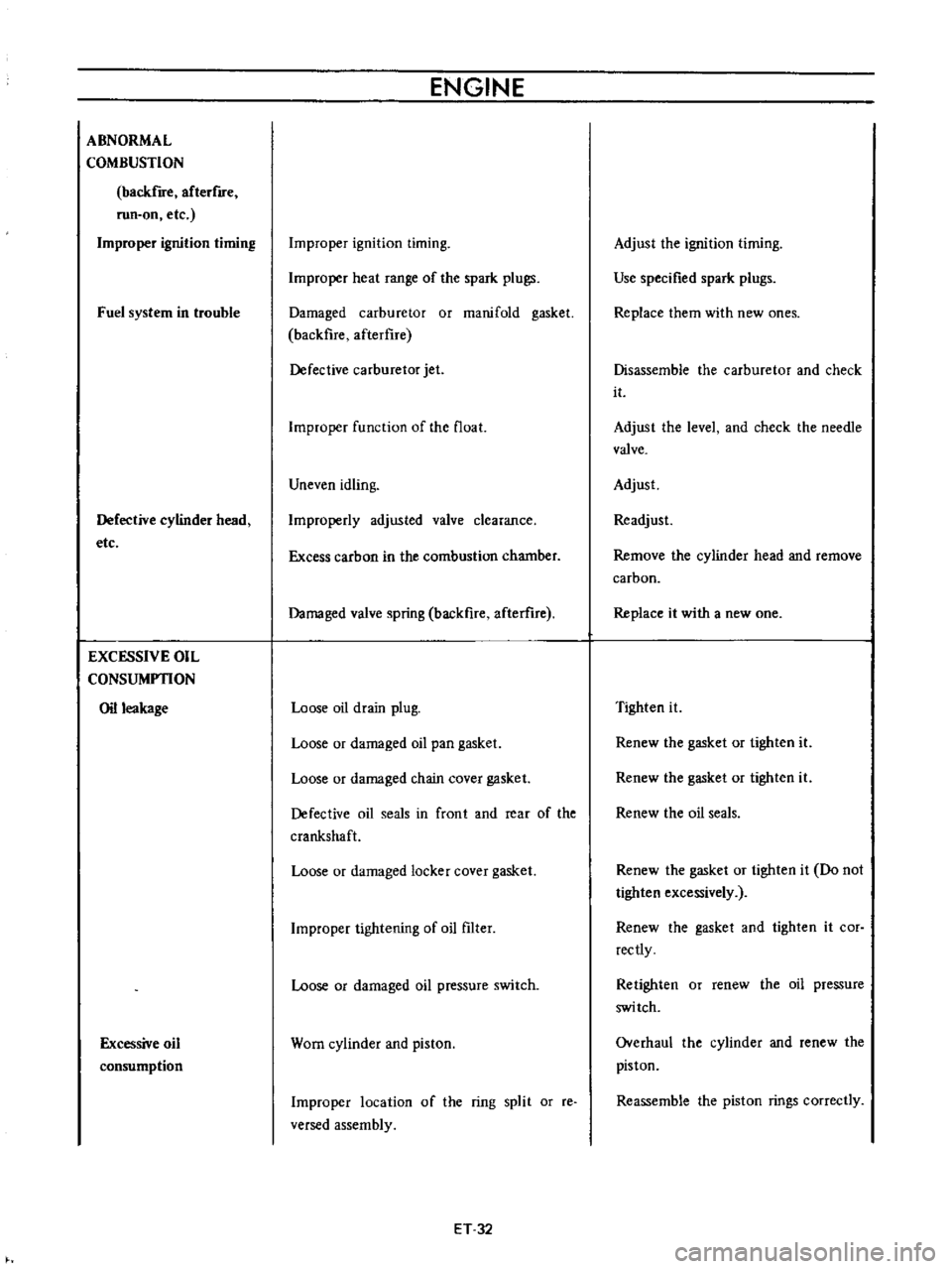

ABNORMAL

COMBUSTION

backfire

afterflfe

run

on

etc

Improper

ignition

timing

Fuel

system

in

trouble

Defective

cylinder

head

etc

EXCESSIVE

OIL

CONSUMPTION

Oil

leakage

Excessive

oil

consumption

ENGINE

Improper

ignition

timing

Improper

heat

range

of

the

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfire

afterflre

Defective

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Improperly

adjusted

valve

clearance

Excess

carbon

in

the

combustion

chamber

Damaged

valve

spring

backfire

afterure

Loose

oil

drain

plug

Loose

or

damaged

oil

pan

gasket

Loose

or

damaged

chain

cover

gasket

Defective

oil

seals

in

front

and

rear

of

the

crankshaft

Loose

or

damaged

locker

cover

gasket

Improper

tightening

of

oil

filter

Loose

or

damaged

oil

pressure

switch

Worn

cylinder

and

piston

Improper

location

of

the

ring

split

or

reo

versed

assembly

ET

32

Adjust

the

ignition

timing

Use

specified

spark

plugs

Replace

them

with

new

ones

Disassemble

the

carburetor

and

check

it

Adjust

the

level

and

check

the

needle

valve

Adjust

Readjust

Remove

the

cylinder

head

and

remove

carbon

Replace

it

with

a

new

one

Tighten

it

Renew

the

gasket

or

tighten

it

Renew

the

gasket

or

tighten

it

Renew

the

oil

seals

Renew

the

gasket

or

tighten

it

Do

not

tighten

excessively

Renew

the

gasket

and

tighten

it

cor

rectly

Retighten

or

renew

the

oil

pressure

switch

Overhaul

the

cylinder

and

renew

the

piston

Reassemble

the

piston

rings

correctly

Page 372 of 513

ENGINE

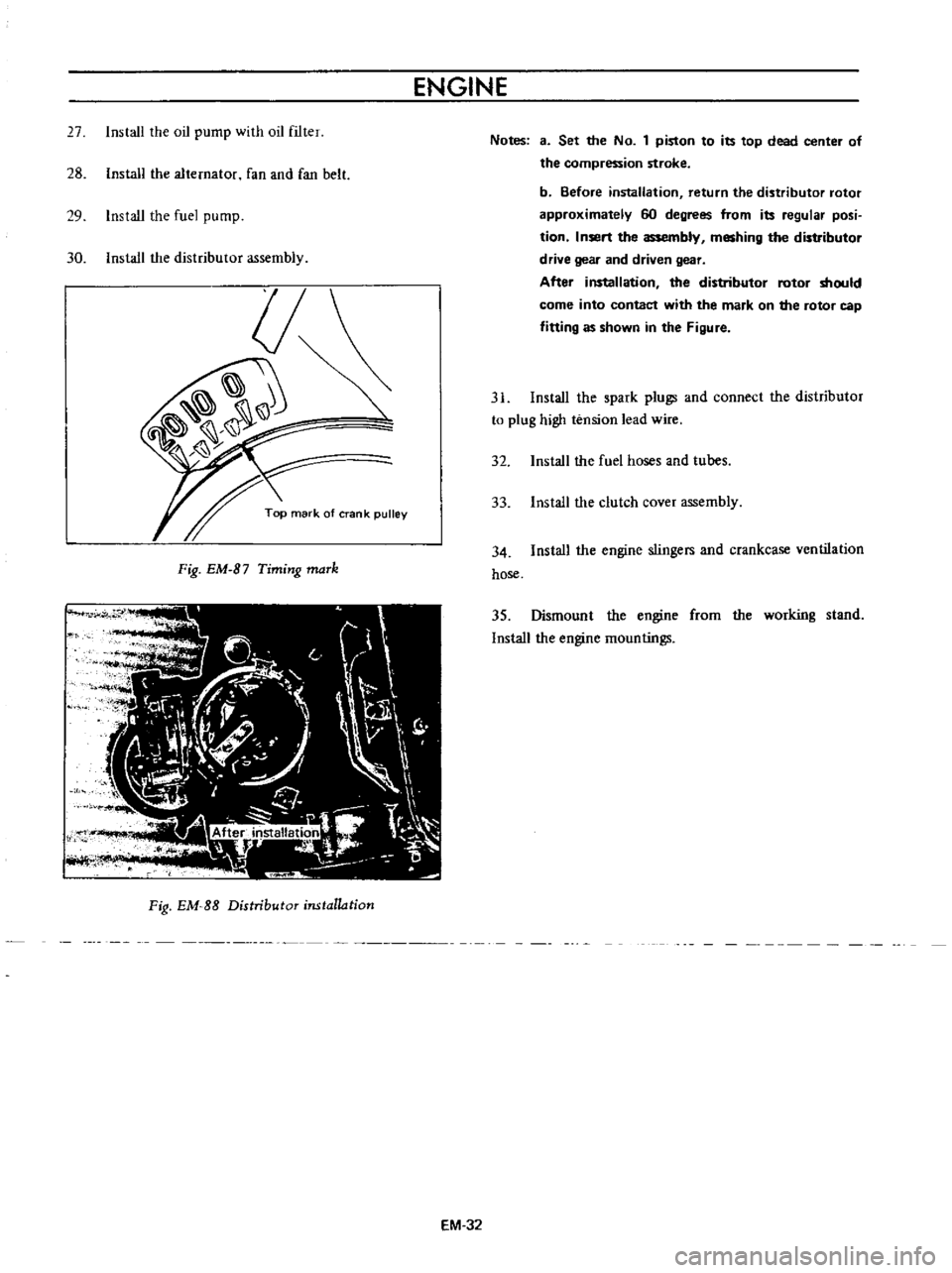

27

Install

the

oil

pump

with

oil

filter

28

Install

the

alternator

fan

and

fan

belt

29

Install

the

fuel

pump

30

Install

the

distributor

assembly

Fig

EM

B7

Timing

maTk

Fig

EM

SS

Distributor

installation

EM

32

Notes

3

Set

the

No

1

piston

to

its

top

dead

center

of

the

compression

stroke

b

Before

installation

return

the

distributor

rotor

approximately

60

degrees

from

its

regular

posi

tion

Insert

the

assembly

meshing

the

distributor

drive

gear

and

driven

gear

After

installation

the

distributor

rotor

should

come

into

contact

with

the

mark

on

the

rotor

cap

fitting

as

shown

in

the

Figure

31

Install

the

spark

plugs

and

connect

the

distributor

to

plug

high

tension

lead

wire

32

Install

the

fuel

hoses

and

tubes

33

Install

the

clutch

cover

assembly

34

Install

the

engine

stingers

and

crankcase

ventilation

hose

35

Dismount

the

engine

from

the

working

stand

Install

the

engine

mountings

Page 379 of 513

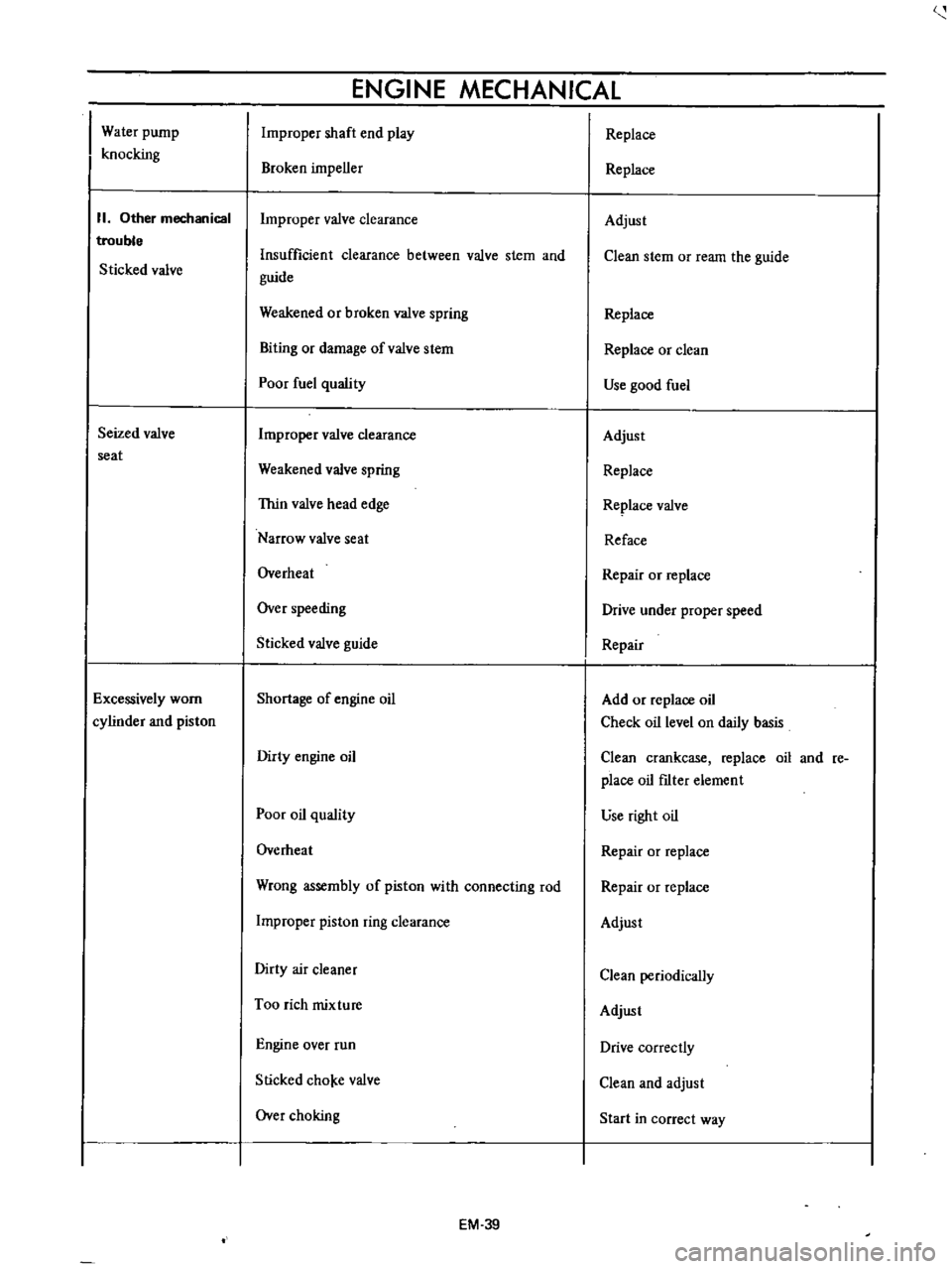

Water

pump

knocking

II

Other

mechanical

trouble

Sticked

valve

Seized

valve

seat

Excessively

worn

cylinder

and

piston

ENGINE

MECHANICAL

Improper

shaft

end

play

Broken

impeller

Improper

valve

clearance

Insufficient

clearance

between

valve

stem

and

guide

Weakened

or

broken

valve

spring

Biting

or

damage

ofvalve

stem

Poor

fuel

quality

Improper

valve

clearance

Weakened

valve

spring

Thin

valve

head

edge

Narrow

valve

seat

Overheat

Over

speeding

Sticked

valve

guide

Shortage

of

engine

oil

Dirty

engine

oil

Poor

oil

quality

Overheat

Wrong

assembly

of

piston

with

connecting

rod

Improper

piston

ring

clearance

Dirty

air

cleaner

Too

rich

mixture

Engine

over

run

Slicked

cho

e

valve

Over

choking

EM

39

Replace

Replace

Adjust

Clean

stem

or

ream

the

guide

Replace

Replace

or

clean

Use

good

fuel

Adjust

Replace

Replace

valve

Reface

Repair

or

replace

Drive

under

proper

speed

Repair

Add

or

replace

oil

Check

oil

level

on

daily

basis

Clean

crankcase

replace

oil

and

re

place

oil

fIlter

element

use

right

oil

Repair

or

replace

Repair

or

replace

Adjust

Clean

periodically

Adjust

Drive

correctly

Clean

and

adjust

Start

in

correct

way

Page 382 of 513

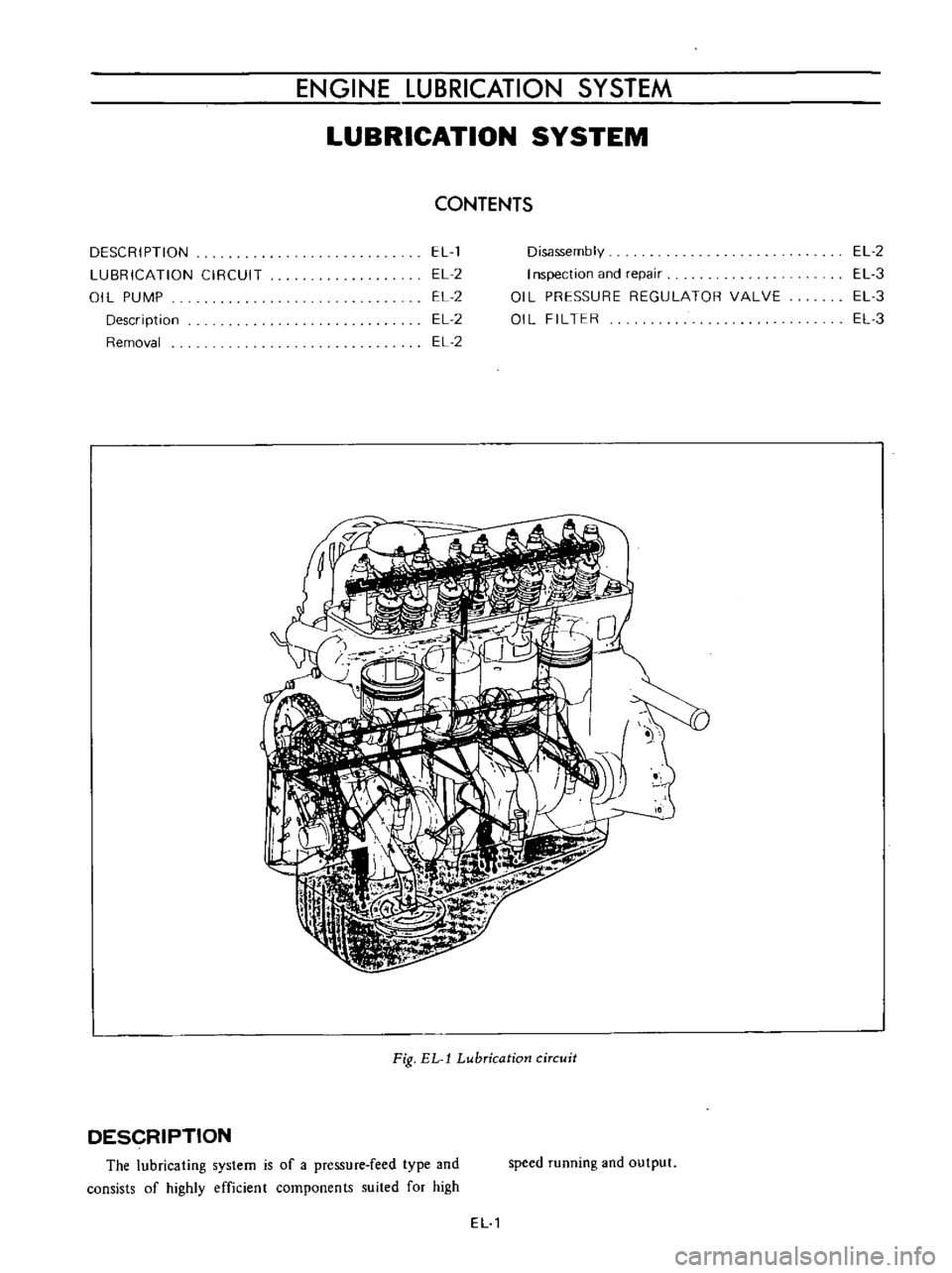

ENGINE

lUBRICATION

SYSTEM

LUBRICATION

SYSTEM

CONTENTS

DESCRIPTION

LUBRICATION

CIRCUIT

OIL

PUMP

Description

Removal

EL

1

EL

2

EL

2

EL

2

EL

2

Disassembly

I

nspection

and

repair

OIL

PRESSURE

REGULATOR

VALVE

OIL

FILTER

EL

2

EL

3

EL

3

EL

3

Fig

EL

l

Lubrication

circuit

DESCRIPTION

The

lubricating

system

is

of

a

pressure

feed

type

and

consists

of

highly

efficient

components

suited

for

high

speed

running

and

output

EL

1