automatic transmission DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 418 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

AND

INSTALLATION

Accelerator

wire

I

Remove

air

cleaner

assembly

2

Disconnect

accelerator

wire

from

carburetor

3

Loosen

lock

nut

and

disconnect

accelerator

wire

outer

case

from

wire

holder

See

Figure

FE

I

4

Remove

spring

clamp

and

discon

nect

accelerator

wire

from

accelerator

pedal

arm

S

Remove

two

screws

securing

ac

celerator

wire

outer

case

to

body

and

detach

accelerator

wire

6

To

install

reverse

the

order

of

removal

Apply

recommended

multi

purpose

grease

slightly

to

portion

MG

shown

in

Figure

FE

I

Accelerator

pedal

assembly

I

Remove

spring

clamp

then

dis

connect

accelerator

wire

from

tip

of

pedal

ann

2

Remove

two

screws

securing

ac

celerator

pedal

bracket

to

body

3

Remove

accelerator

pedal

from

dash

panel

See

Figure

FE

I

4

To

install

reverse

the

order

of

removal

INSPECTION

I

Check

accelerator

pedal

return

spring

for

rust

fatigue

or

damage

Replace

if

necessary

2

Check

accelerator

wire

cases

and

fastening

locations

for

rust

damage

or

looseness

Repair

or

replace

if

necessary

ADJUSTMENT

Accelerstor

pedal

and

wire

Adjust

pedal

stopper

bolt

Section

A

so

as

to

obtain

specifi

ed

height

E

as

shown

in

Figure

FE

I

Secure

pedal

stopper

bolt

with

stopper

lock

nut

Refer

to

Figure

FE

I

E

78

mOl

3

07

in

Tightening

torque

01

nut

0

38

to

0

4S

kg

m

2

7

to

3

2

ft

b

2

Release

auto

choke

effect

since

throttle

lever

is

opened

by

fast

idle

earn

until

engine

warms

up

I

Keep

choke

valve

fully

open

with

fingers

2

Pull

throttle

lever

up

by

hand

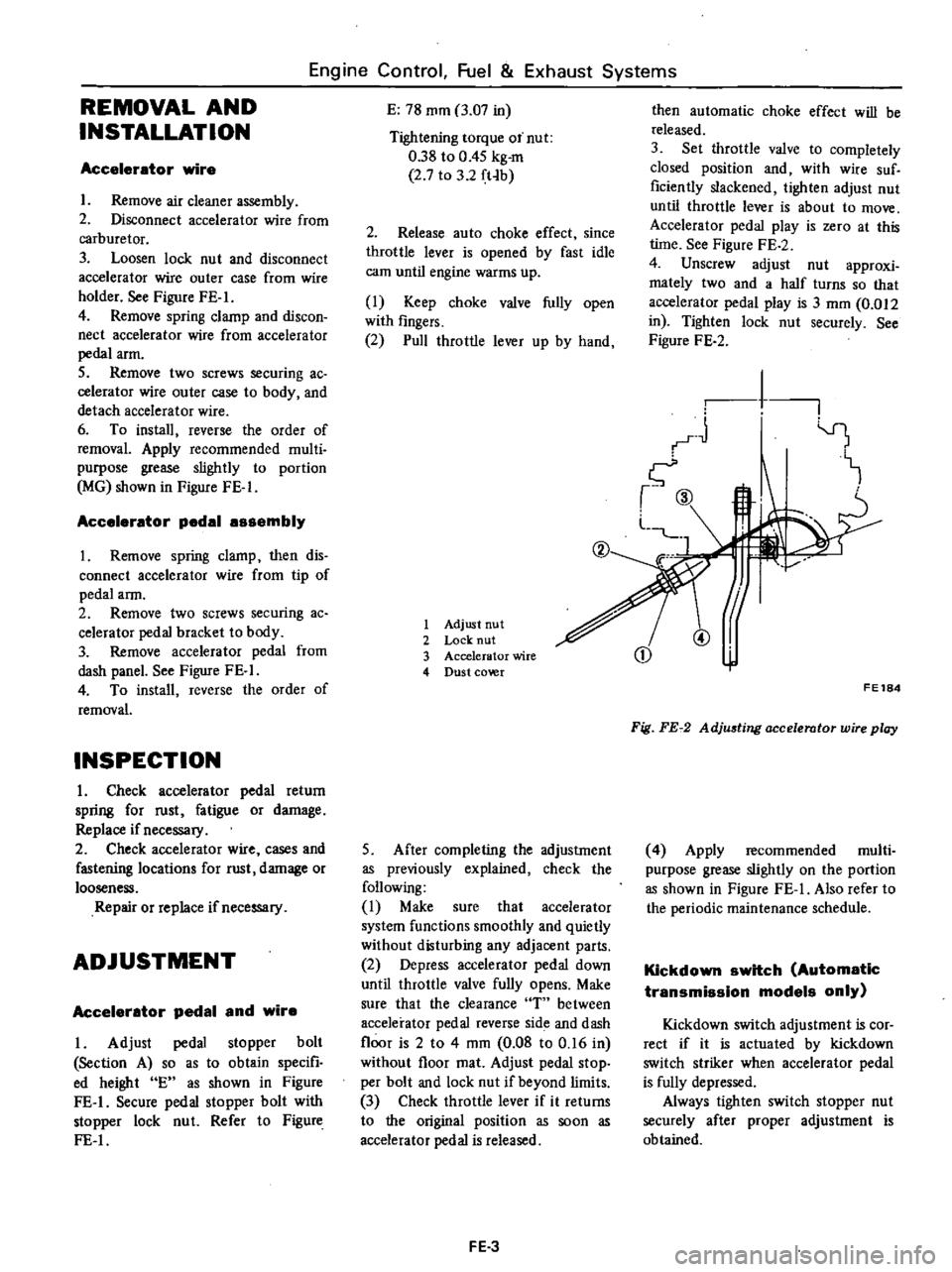

1

Adjust

nut

2

Lock

nut

3

Accelerator

wire

4

Dust

co

r

5

After

completing

the

adjustment

as

previously

explained

check

the

following

I

Make

sure

that

accelerator

system

functions

smoothly

and

quietly

without

disturbing

any

adjacent

parts

2

Depress

accelerator

pedal

down

until

throttle

valve

fully

opens

Make

sure

that

the

clearance

T

between

accelerator

pedal

reverse

side

and

dash

floor

is

2

to

4

mm

0

08

to

0

16

in

without

floor

mat

Adjust

pedal

stop

per

bolt

and

lock

nut

if

beyond

limits

3

Check

throttle

lever

if

it

returns

to

the

original

position

as

soon

as

accelerator

pedal

is

released

FE

3

then

automatic

choke

effect

will

be

released

3

Set

throttle

valve

to

completely

closed

position

and

with

wire

suf

ficiently

slackened

lighten

adjust

nut

until

throttle

lever

is

about

to

move

Accelerator

pedal

play

is

zero

at

this

lime

See

Figure

FE

2

4

Unscrew

adjust

nut

approxi

mately

two

and

a

half

turns

so

that

accelerator

pedal

play

is

3

mOl

0

012

in

Tighten

lock

nut

securely

See

Figure

FE

2

1

I

1

CD

@

FE184

Fig

FE72

AdjU6ting

accelerator

wire

play

4

Apply

recommended

multi

purpose

grease

slightly

on

the

portion

as

shown

in

Figure

FE

I

Also

refer

to

the

periodic

maintenance

schedule

Kickdown

switch

Automatic

transmission

models

only

Kickdown

switch

adjustment

is

cor

rect

if

it

is

actuated

by

kickdown

switch

striker

when

accelerator

pedal

is

fully

depressed

Always

tighten

switch

stopper

nut

securely

after

proper

adjustment

is

obtained

Page 428 of 537

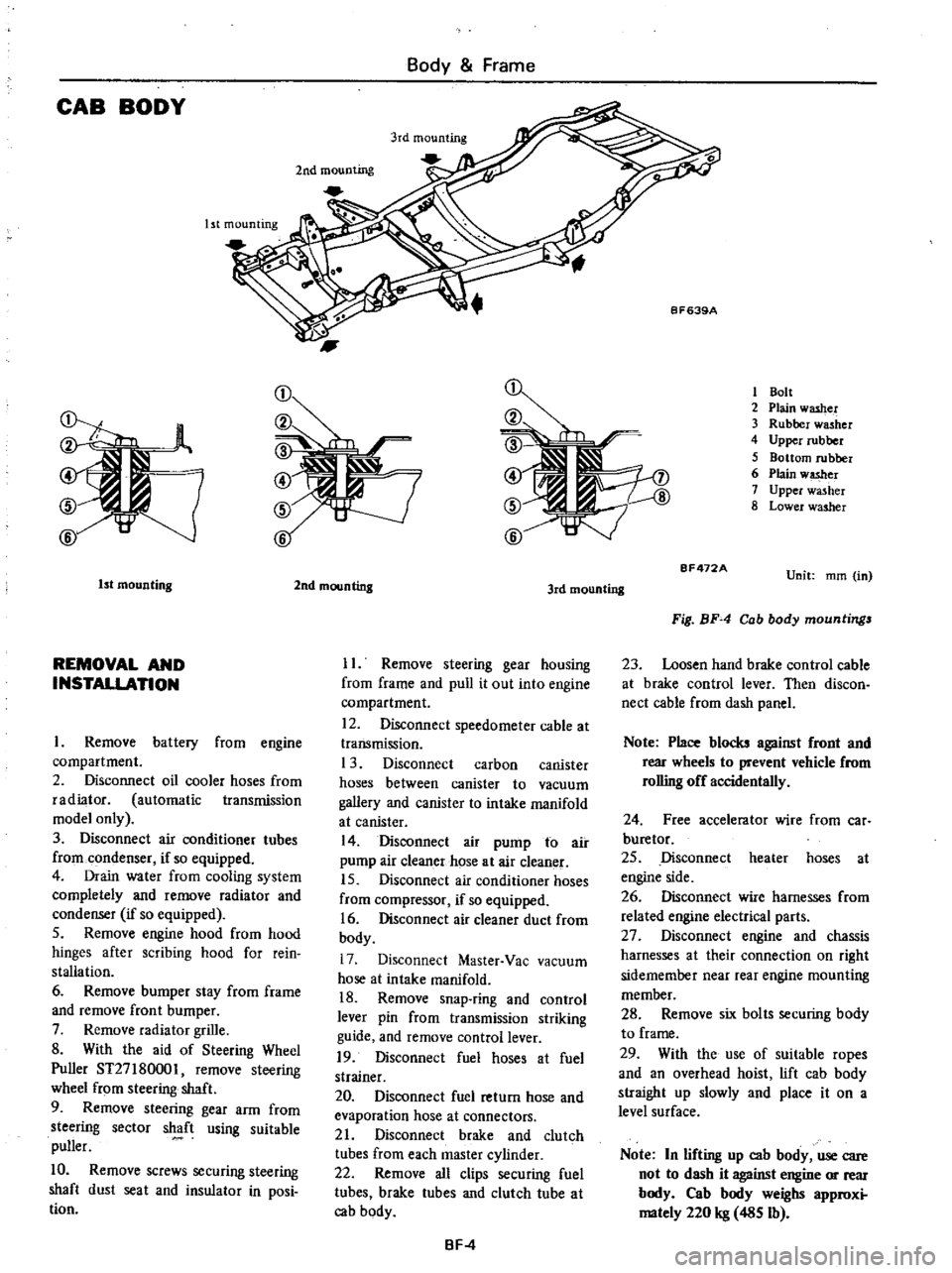

CAB

BODY

Body

Frame

Ist

mounting

2nd

mounting

1

Bolt

2

Plain

washer

3

Rubber

washer

4

Upper

rubber

5

Bottom

rubber

6

Plain

w

er

7

Upper

washer

8

Lower

washer

1st

mounting

REMOVAL

AND

INSTALLATION

Remove

battery

from

engine

compartment

2

Disconnect

oil

cooler

hoses

from

radiator

automatic

transmission

model

only

3

Disconnect

air

conditioner

tubes

from

condenser

if

so

equipped

4

Drain

water

from

cooling

system

completely

and

remove

radiator

and

condenser

if

so

equipped

5

Remove

engine

hood

from

hood

hinges

after

scribing

hood

for

rein

stallation

6

Remove

bumper

stay

from

frame

and

remove

front

bumper

7

Remove

radiator

grille

8

With

the

aid

of

Steering

Wheel

Puller

ST27

180001

remove

steering

wheel

from

steering

shaft

9

Remove

steering

gear

arm

from

steering

sector

shaft

using

suitable

puller

10

Remove

screws

securing

steering

shaft

dust

seat

and

insulator

in

posi

tion

2nd

mounting

3rd

mounting

II

Remove

steering

gear

housing

from

frame

and

pull

it

out

into

engine

compartment

12

Disconnect

speedometer

cable

at

transmission

1

3

Disconnect

carbon

canister

hoses

between

canister

to

vacuum

gallery

and

canister

to

intake

manifold

at

canister

14

Disconnect

air

pump

to

air

pump

air

cleaner

hose

at

air

cleaner

15

Disconnect

air

conditioner

hoses

from

compressor

if

so

equipped

16

Disconnect

air

cleaner

duct

from

body

17

Disconnect

Master

Vac

vacuum

hose

at

intake

manifold

18

Remove

snap

ring

and

control

lever

pin

from

transmission

striking

guide

and

remove

control

lever

19

Disconnect

fuel

hoses

at

fuel

strainer

20

Disconnect

fuel

return

hose

and

evaporation

hose

at

connectors

21

Disconnect

brake

and

clutch

tubes

from

each

master

cylinder

22

Remove

all

clips

securing

fuel

tubes

brake

tubes

and

clutch

tube

at

cab

body

BF

4

BF472A

Unit

mm

in

Fig

BF

4

Cab

body

mountings

23

Loosen

hand

brake

control

cable

at

brake

control

lever

Then

discon

nect

cable

from

dash

panel

Note

Place

blocks

against

front

and

rear

wheels

to

prevent

vehicle

from

rolling

off

accidentally

24

Free

accelerator

wire

from

car

buretor

25

Disconnect

heater

hoses

at

engine

side

26

Disconnect

wire

harnesses

from

related

engine

electrical

parts

27

Disconnect

engine

and

chassis

harnesses

at

their

connection

on

right

sidemember

near

rear

engine

mounting

member

28

Remove

six

bolts

securing

body

to

frame

29

With

the

use

of

suitable

ropes

and

an

overhead

hoist

lift

cab

body

straight

up

slowly

and

place

it

on

a

level

surface

Note

In

lifting

up

cab

body

use

care

not

to

dash

it

against

engine

or

rear

body

Cab

body

weighs

approxi

mately

220

kg

485

Ib

Page 484 of 537

m

W

D

to

l

l

0

c

l

l

s

Q

3

For

Automatic

Transmission

LB

B

For

Manual

Transmission

m

For

Automatic

Transmission

COLOR

CODE

B

Black

BI

Brown

G

Green

L

Blue

Lg

Light

green

R

Red

W

White

Y

Yellow

BW

Black

with

white

stripe

LgR

Light

green

with

red

stripe

BY

RB

RB

B

WB

RB

YB

2

RB

I

B

1

BW

r

BY

LB

For

Automatic

Transmission

to

o

c

m

r0

O

O

Dl

For

Manual

Transmission

@

CJ

lti

3

RB

fB

BY

YB

RB@RB

YB

BY

1

To

kickdown

solenoid

fOT

Automatic

Transmission

2

To

reverse

switch

for

Manual

Tranmission

3

To

inhibitor

switch

for

Automatic

Transmission

4

To

oil

pressure

switch

5

To

starter

motor

6

To

engine

room

harness

for

Manual

Transmission

7

To

engine

room

harness

for

Automatic

Transmission

Page 518 of 537

INSPECTION

Evaporator

Check

evaporator

for

leakage

or

damage

If

damaged

replace

Expansion

valve

Check

expansion

valve

for

leakage

or

clogging

If

clogged

clean

filter

in

expansion

valve

If

damaged

replace

RECEIVER

DRYER

AND

PIPING

REMOVAL

AND

INSTAUATION

Receiver

dryer

I

Disconnect

battery

ground

cable

2

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

3

Disconnect

compressor

lead

wire

at

connector

4

Disconnect

cooling

pipes

at

joints

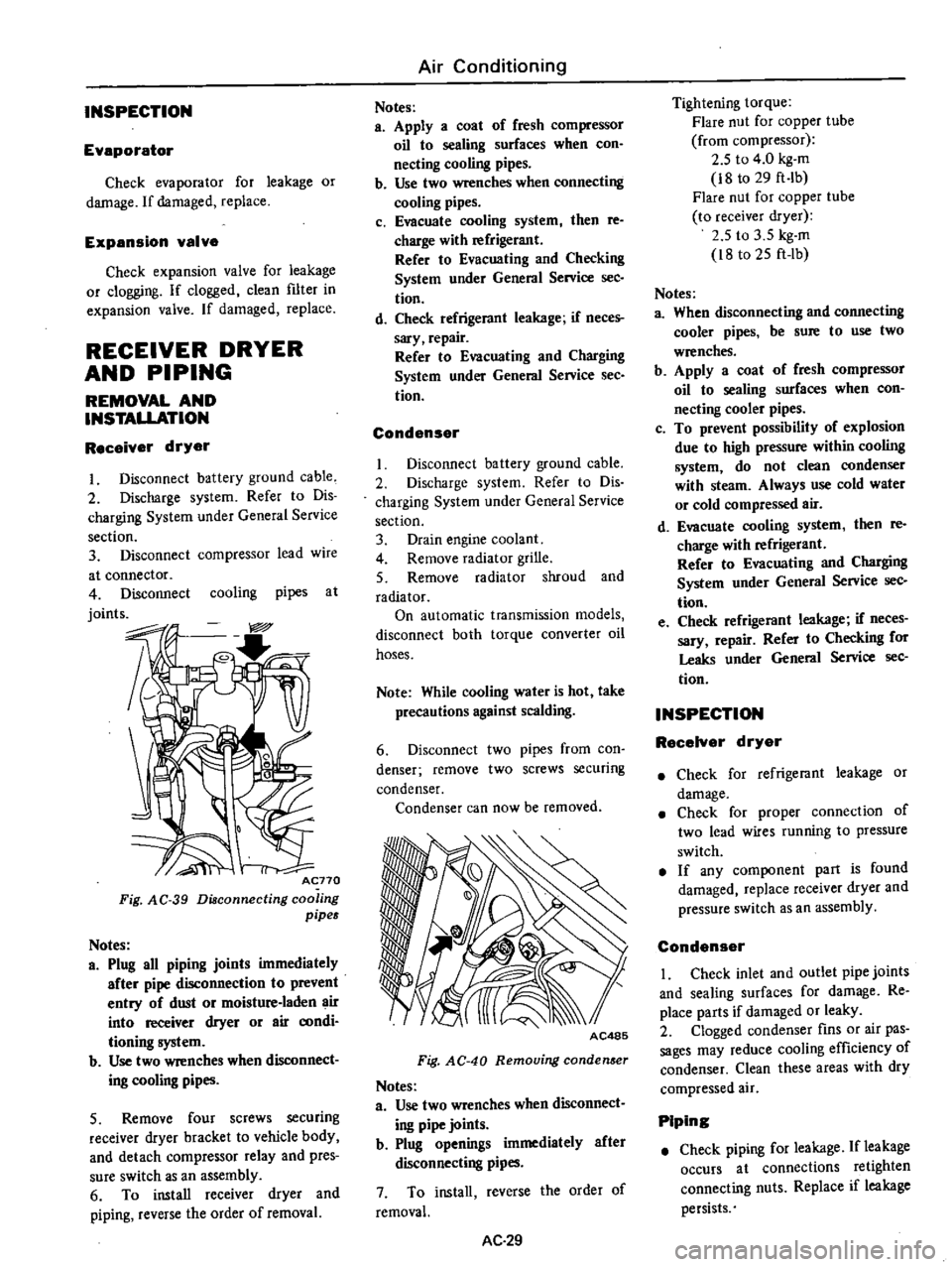

Acno

Fig

AC

39

Diaconnecting

coo

ing

pipes

Notes

a

Plug

all

piping

joints

immediately

after

pipe

disconnection

to

prevent

entry

of

dust

or

moisture

laden

air

into

receiver

dryer

or

air

aJOdi

tioning

system

b

Use

two

wrenches

when

dIsconnect

ing

cooling

pipes

5

Remove

four

screws

securing

receiver

dryer

bracket

to

vehicle

body

and

detach

compressor

relay

and

pres

sure

switch

as

an

assembly

6

To

install

receiver

dryer

and

piping

reverse

the

order

of

removal

Air

Conditioning

Notes

a

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

when

con

necting

cooling

pipes

b

Use

two

wrenches

when

connecting

cooling

pipes

c

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Checking

System

under

General

Service

sec

tion

d

Check

refrigerant

leakage

if

neces

sary

repair

Refer

to

Evacuating

and

Charging

System

under

General

Service

See

tion

Condenser

Disconnect

battery

ground

cable

2

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

3

Drain

engine

coolant

4

Remove

radiator

grille

5

Remove

radiator

shroud

and

radiator

On

automatic

transmission

models

disconnect

both

torque

converter

oil

hoses

Note

While

cooling

water

is

hot

take

precautions

against

scalding

6

Disconnect

two

pipes

from

con

denser

remove

two

screws

securing

condenser

Condenser

can

now

be

removed

AC485

Fig

AC

40

Removing

conden

er

Notes

a

Use

two

wrenches

when

disconnect

ing

pipe

joints

b

Plug

openings

immediately

after

disconnecting

pipes

7

To

install

reverse

the

order

of

removal

AC

29

Tightening

torque

Flare

nut

for

copper

tube

from

compressor

2

5

to

4

0

kg

m

i8

to

29

ft

Ib

Flare

nut

for

copper

tube

to

receiver

dryer

2

5

to

3

5

kg

m

i8

to

25

ft

lb

Notes

a

When

disconnecting

and

connecting

cooler

pipes

be

sure

to

use

two

wrenches

b

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

when

con

necting

cooler

pipes

c

To

prevent

possibility

of

explosion

due

to

high

pressure

within

cooling

system

do

not

clean

condenser

with

steam

Always

use

cold

water

or

cold

compressed

air

d

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Charging

System

under

General

Service

sec

tion

e

Check

refrigerant

leakage

if

neces

sary

repair

Refer

to

Checking

for

Leaks

under

General

Service

sec

tion

INSPECTION

RecelYer

dryer

Check

for

refrigerant

leakage

or

damage

Check

for

proper

connection

of

two

lead

wires

running

to

pressure

switch

If

any

component

part

is

found

damaged

replace

receiver

dryer

and

pressure

switch

as

an

assembly

Condenser

I

Check

inlet

and

outlet

pipe

joints

and

sealing

surfaces

for

damage

Re

place

parts

if

damaged

or

leaky

2

Clogged

condenser

fins

or

air

pas

sages

may

reduce

cooling

efficiency

of

condenser

Clean

these

areas

with

dry

compressed

air

Piping

Check

piping

for

leakage

If

leakage

occurs

at

connections

retighten

connecting

nuts

Replace

if

leakage

persists

Page 531 of 537

GENERAL

DESCRI

PTION

Special

Tools

play

very

important

role

in

the

maintenance

of

vehicles

These

are

essential

to

the

safe

accu

rate

and

speedy

servicing

The

working

times

listed

in

the

col

umn

under

FLAT

RATE

TIME

in

FLAT

RATE

SCHEDULE

are

com

puted

based

on

the

use

of

Special

Tools

The

identification

code

of

mainte

nance

tools

is

made

up

of

2

alpha

betical

letters

and

8

digital

figures

The

heading

two

letters

roughly

classify

tools

or

equipment

as

fol

lows

STOOOOOOOO

KVOOOOOOOO

Special

Tool

Special

Tool

Recently

established

Engine

Overhauling

Machine

General

Gauge

Hand

Tool

EMOOOOOOOO

GGOOOOOOOO

HTOOOOOOOO

HOW

TO

READ

SPECIAL

TOOL

LIST

APPLIED

VEHICLE

OR

UNIT

In

this

column

word

All

is

given

for

tools

applicable

to

all

vehicle

mod

els

and

unit

types

treated

in

this

manu

al

for

tools

applicable

only

to

particu

lar

models

or

units

those

vehicle

models

or

unit

types

are

indicated

NEWLY

ADDED

X

put

in

this

column

shows

newly

added

tools

Service

Equipment

SERVICE

EQUIPMENT

CLASS

Indicated

in

this

column

are

classi

fication

ftg1ll

es

in

accordance

with

Classification

of

Speciai

Tool

REMARKS

As

regards

special

tools

which

are

also

applicable

to

models

other

than

those

dealt

ith

U

this

m

inual

this

coluITUl

names

those

other

models

CLASSIFICATION

OF

SPECIAL

TOOL

I

Inspection

and

minor

repairs

11

General

disassembly

and

assembly

Ill

Special

disassembly

and

assembly

A

Important

a

Exclusive

with

no

alternative

b

Parts

will

be

damaged

if

repaired

without

special

tool

c

Gauges

B

General

To

facilitate

servicing

I

Inspection

and

minor

repairs

a

Inspection

and

maintenance

b

Unit

replacement

c

Minor

unit

disassembly

SPECIAL

TOOL

SET

See

attached

tool

list

The

set

is

available

for

new

and

other

dealers

who

must

go

through

initial

preparation

SET

77

620NA

KV00102000

This

set

is

designed

for

the

chassis

and

body

of

the

620

models

without

regard

to

their

destination

SE

2

Classification

Important

General

2

3

4

5

6

11

General

disassembly

and

assembly

General

disassembly

such

as

engine

transmission

and

differential

111

Special

disassembly

and

assembly

a

Disassembly

of

exclusive

parts

such

as

automatic

transmission

and

electrical

accessories

b

Special

work

such

as

boring

and

welding

c

Work

very

rarely

required

SET

3N71B

KV0010l000

This

set

is

designed

for

use

on

the

3N71B

automatic

transmission

It

con

sists

of

the

same

service

tools

as

those

previously

available

separately

Page 535 of 537

Service

Equipment

AUTOMATIC

TRANSMISSION

TOOL

Applied

Set

3N71B

Newly

Tool

Number

Tool

Name

vehicle

Class

Remarks

added

or

unit

KVOOlO1OOO

ST07870000

Transmission

case

stand

All

X

3

ST2505S001

Oil

pressure

gauge

set

All

X

I

ST25

I

60000

Torque

driver

All

X

3

ST2532000l

Snap

ring

remover

All

X

3

ST25420001

Clutch

spring

compressor

All

X

3

ST25490000

Socket

extension

All

X

3

ST2557000l

Hex

head

extension

All

X

3

8210

610

710

S30

ST25580000

Oil

pump

assembling

gauge

All

X

3

ST25850000

Sliding

hammers

All

X

3

GG930

I

0000

Torque

wrench

All

X

3

HT6

I

000800

Hexagon

wrench

All

X

3

HT62350000

Spinner

handle

All

X

6

HT69860000

Snap

ring

remover

All

X

3

SE

6