height DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 227 of 537

Stroke

30

mm

Jt

i

I

1

18

in

Sj

1

i

J

o

Fig

CL

15

Non

adj

table

operating

cylinder

CLUTCH

PEDAL

Removal

and

installation

Removal

See

Figure

CL

16

1

Pry

off

cotter

pin

and

take

out

clevis

pin

disconnect

push

rod

from

pedal

assembly

2

Unhook

return

spring

Loosen

off

fulcrum

pin

and

remove

pedal

as

sembly

CfJ

W5

6

3

ch

fD

ij

ll

i

A

1

aevis

pin

2

Cotter

pin

3

Return

spring

4

Pedal

boss

S

Pedal

assembly

6

Bush

7

Nut

8

Push

rod

9

Fulcrum

pin

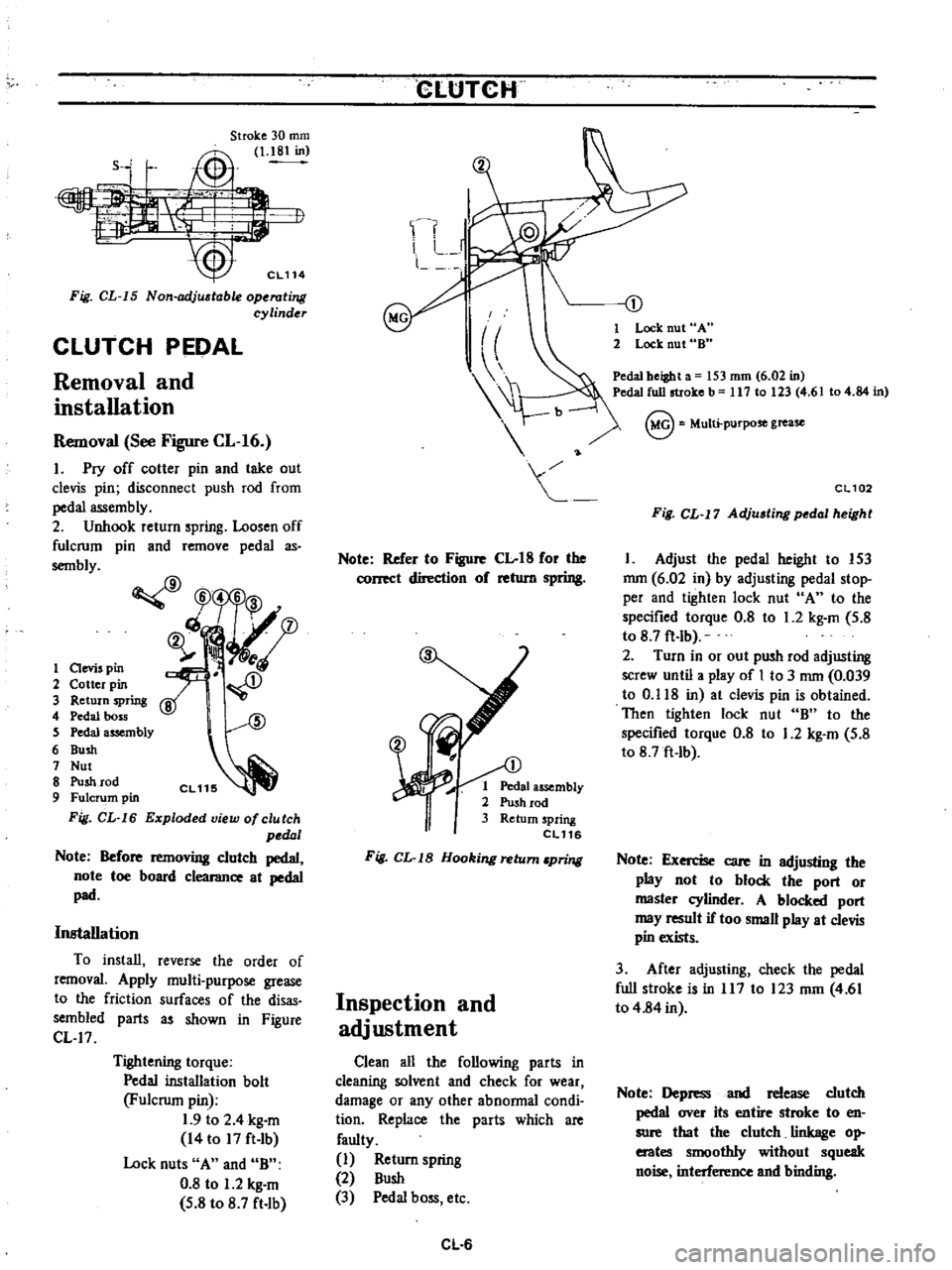

Fig

CL

16

Exploded

view

of

clutch

pedal

Note

Before

removing

clutch

pedal

note

toe

board

clearance

at

pedal

pad

Installation

To

install

reverse

the

order

of

removal

Apply

multi

purpose

grease

to

the

friction

surfaces

of

the

disas

sembled

parts

as

shown

in

Figure

CL

17

Tightening

torque

Pedal

installation

bolt

Fulcrum

pin

1

9

to

2

4

kg

m

14

to

17

ft

Ib

Lock

nuts

A

and

B

0

8

to

1

2

kg

m

5

8

to

8

7

ft

lb

CLtJTCH

Note

Refer

to

Figure

Clot8

for

the

correct

direction

of

return

spring

1

Pedal

assembly

2

Push

rod

3

Return

spring

eL116

Fig

CL

1B

Hooking

return

pring

Inspection

and

adjustment

Clean

all

the

following

parts

in

cleaning

solvent

and

check

for

wear

damage

or

any

other

abnormal

condi

tion

Replace

the

parts

which

are

faulty

1

Return

spring

2

Bush

3

Pedal

boss

etc

CL

6

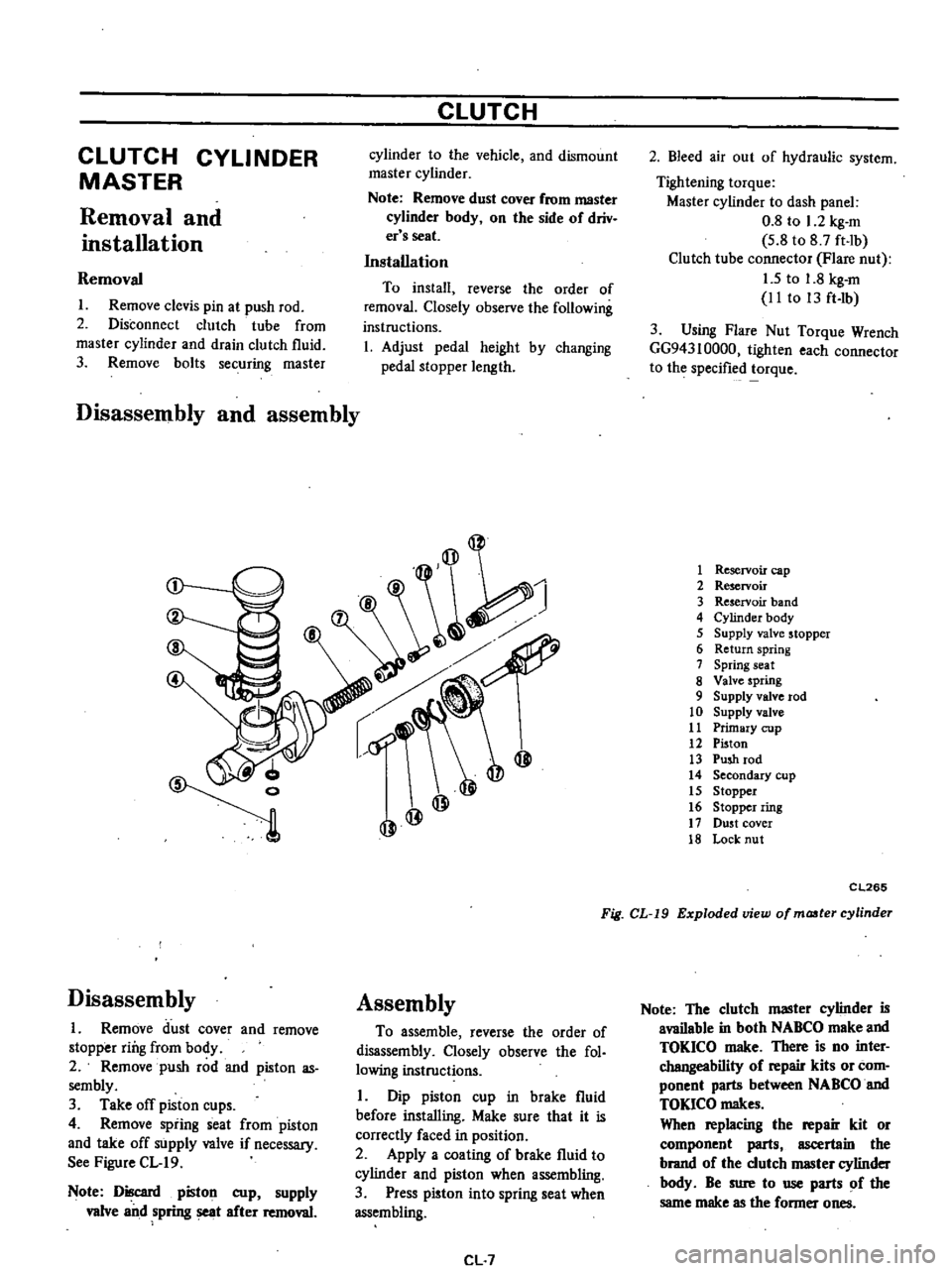

1

Lock

nut

A

2

Lock

nut

8

Pedal

beiBht

a

53

mm

6

02

in

Pedal

full

stroke

b

117

10

23

4

6

104

84

in

@

Multi

purpose

grease

CL102

Fig

CL

17

Adju

ting

pedal

height

1

Adjust

the

pedal

height

to

153

mm

6

02

in

by

adjusting

pedal

stop

per

and

tighten

lock

nut

A

to

the

specified

torque

0

8

to

1

2

kg

m

5

8

to

8

7

ft

lb

2

Turn

in

or

out

push

rod

adjusting

screw

until

a

play

of

I

to

3

mm

0

039

to

0

118

in

at

clevis

pin

is

obtained

Then

tighten

lock

nut

B

to

the

specified

torque

0

8

to

1

2

kg

m

5

8

to

8

7ft

Ib

Note

Exercise

care

in

adjusting

the

play

not

to

block

the

port

or

master

cylinder

A

blocked

port

may

result

if

too

small

play

at

clevis

pin

exists

3

After

adjusting

check

the

pedal

full

stroke

is

in

117

to

123

mm

4

61

to

4

84

in

Note

Depress

and

release

clutch

pedal

over

its

entire

stroke

to

en

sure

that

the

clutch

linkage

op

erates

smoothly

without

squeak

noise

interference

and

binding

Page 228 of 537

CLUTCH

CYLINDER

MASTER

Removal

and

installation

Removal

I

Remove

clcvis

pin

at

push

rod

2

Disconnect

clutch

tube

from

master

cylinder

and

drain

clutch

fluid

3

Remove

bolts

securing

master

Disassembly

and

assembly

CLUTCH

cylinder

to

the

vehicle

and

dismount

master

cylinder

Note

Remove

dust

cover

from

master

cylinder

body

on

the

side

of

driv

er

s

seat

Installation

To

install

reverse

the

order

of

removal

Closely

observe

the

following

instructions

1

Adjust

pedal

height

by

changing

pedal

stopper

length

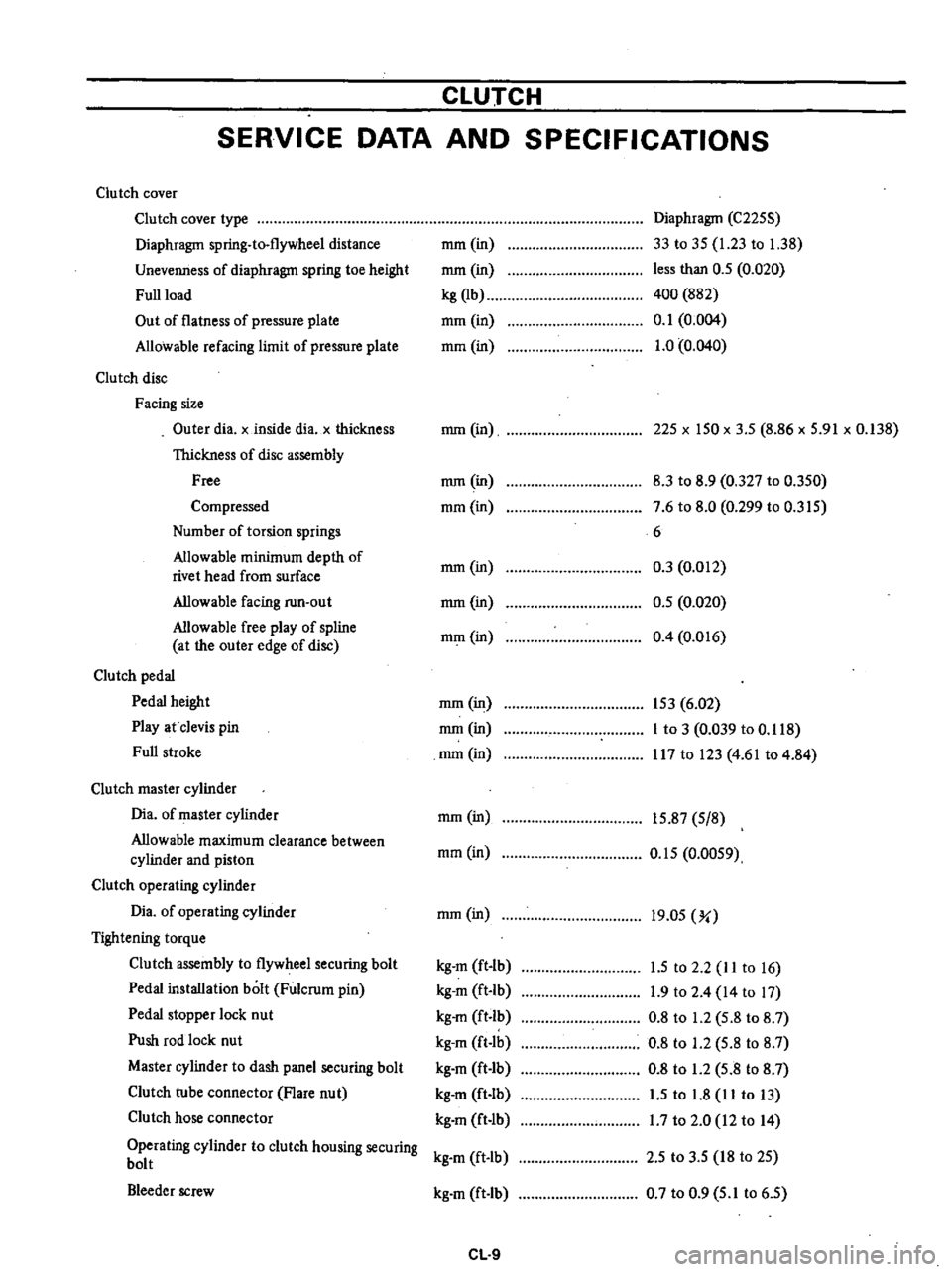

Disassembly

1

Remove

dust

cover

and

remove

stopper

ring

from

body

2

Remove

push

rod

and

piston

as

sembly

3

Take

off

piston

cups

4

Remove

spiing

seat

from

piston

and

take

off

supply

valve

if

necessary

See

Figure

CL

19

Note

Discard

piston

cup

supply

valve

and

spring

seat

after

removal

Assembly

To

assemble

reverse

the

order

of

disassembly

Closely

observe

the

fol

lowing

instructions

I

Dip

piston

cup

in

brake

fluid

before

installing

Make

sure

that

it

is

correctly

faced

in

position

2

Apply

a

coating

of

brake

fluid

to

cylinder

and

piston

when

assembling

3

Press

piston

into

spring

seat

when

assembling

CL

7

2

Bleed

air

out

of

hydraulic

system

Tightening

torque

Master

cylinder

to

dash

panel

0

8

to

1

2

kg

m

5

8

to

8

7

ft

lb

Clutch

tube

connector

Flare

nut

1

5

to

1

8

kg

m

II

to

13

ft

lb

3

Using

Flare

Nut

Torque

Wrench

GG94310000

tighten

each

connector

to

the

specified

torque

1

Reservoir

cap

2

Reservoir

3

Reservoir

band

4

Cylinder

body

5

Supply

valve

stopper

6

Return

spring

7

Spring

seat

8

Valve

spring

9

Supply

valve

rod

10

Supply

valve

11

Primary

cup

12

Piston

13

Push

rod

14

Secondary

cup

15

Stopper

16

Stopper

ring

17

DU5t

cover

18

Lock

nut

CL265

Fig

CL

19

Exploded

view

of

maater

cylinder

Note

The

clutch

master

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKlCO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

clutch

IIIBSter

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

Page 230 of 537

CLUTCH

SERVICE

DATA

AND

SPECIFICATIONS

Clutch

cover

Clu

tch

cover

type

Diaphragm

spring

to

flywheel

distance

Unevenness

of

diaphragm

spring

toe

height

Full

load

Out

of

flatness

of

pressure

plate

Allowable

refacing

limit

of

pressure

plate

Clutch

disc

Facing

size

Outer

dia

x

inside

dia

x

thickness

Thickness

of

disc

assembly

Free

Compressed

Number

of

torsion

springs

Allowable

minimum

depth

of

rivet

head

from

surface

Allowable

facing

run

out

Allowable

free

play

of

spline

at

the

outer

edge

of

disc

Clutch

pedal

Pedal

height

Play

at

clevis

pin

Full

stroke

Clutch

master

cylinder

Dia

of

master

cylinder

Allowable

maximum

clearance

between

cylinder

and

piston

Clutch

operating

cylinder

Dia

of

operating

cylinder

Tightening

torque

Clutch

assembly

to

flywheel

securing

bolt

Pedal

installation

bolt

Fulcrum

pin

Pedal

stopper

lock

nut

Push

rod

lock

nut

Master

cylinder

to

dash

panel

securing

bolt

Clutch

tube

connector

Flare

nut

Clutch

hose

connector

Operating

cylinder

to

clutch

housing

securing

bolt

Bleeder

screw

mm

in

mm

in

kg

Qb

mm

in

mm

in

Diaphragm

C225S

33

to

35

1

23

to

1

38

less

than

0

5

0

020

400

882

0

1

0

004

1

0

0

040

mm

in

225

x

150

x

3

5

8

86

x

5

91

x

0

138

mm

in

mm

in

8

3

to

8

9

0

327

to

0

350

7

6

to

8

0

0

299

to

0

315

6

0

3

0

012

0

5

0

020

0

4

0

016

mm

in

mm

in

mm

in

mm

in

153

6

02

mm

in

I

to

3

0

039

to

0

118

mm

in

117

to

123

4

61

to

4

84

mm

in

15

87

5

8

mm

in

0

15

0

0059

mm

in

19

05

Yo

kg

m

ft

lb

1

5

to

2

2

lito

16

kg

m

ft

Ib

1

9

to

2

4

14

to

17

kg

m

ft

b

0

8

to

1

2

5

8

to

8

7

kg

m

ft

lb

0

8

to

1

2

5

8

to

8

7

kg

m

ft

Ib

0

8

to

1

2

5

8

to

8

7

kg

m

ft

lb

1

5

to

1

8

11

to

13

kg

m

ft

lb

1

7

to

2

0

12

to

14

kg

m

ft

lb

2

5

to

3

5

18

to

25

kg

m

ft

Ib

0

7

to

0

9

5

1

to

6

5

CL

9

Page 231 of 537

CLUTCH

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Probable

cause

and

testing

Clutch

slips

Corrective

action

Slipping

of

the

clutch

may

be

noticeable

when

any

of

the

following

symptoms

is

encountered

during

operation

I

Vehicle

will

not

respond

to

engine

speed

during

acceleration

2

Insufficient

vehicle

speed

3

Lack

of

power

during

uphill

driving

Some

of

the

above

conditions

are

also

experienced

when

engine

problem

is

oc

urring

First

de

tennine

whether

engine

or

clutch

is

causing

the

problem

If

slipping

clutch

is

left

unheeded

wear

and

or

overheating

will

occur

on

clutch

facing

until

it

is

no

longer

serviceable

TO

TEST

FOR

SLIPPING

CLlJfCH

proceed

as

follows

During

upgrade

travelling

run

engine

at

about

40

to

50

km

h

25

to

31

MPH

with

gear

shift

lever

in

3rd

speed

position

shift

into

highest

gear

and

at

the

same

time

rev

up

engine

If

clutch

is

slipping

vehicle

will

not

readily

respond

to

depression

of

accelerator

pedal

Clutch

facing

worn

excessively

Oil

or

grease

on

clutch

facing

W

r

d

clut

h

cov

r

pressure

plat

Replace

Replace

tpa

o

e

lace

Dragging

clutch

is

particularly

noticeable

when

shifting

gears

especially

into

low

gear

TO

TEST

FOR

DRAGGING

CLlJfCH

proceed

as

follows

I

Start

engine

Disengage

clutch

Shift

into

reverse

gear

and

then

into

Neutral

Gradually

increase

engine

speed

and

again

shift

into

reverse

gear

If

clutch

is

dragging

gear

grating

is

heard

when

shifting

from

Neutral

into

Reverse

Clutch

drags

2

Stop

engine

and

shift

gear

Conduct

this

test

at

each

gear

position

3

Gears

are

smoothly

shifted

in

step

2

but

drag

when

shifting

to

1st

speed

position

at

idling

a

If

dragging

is

encountered

at

the

end

of

shifting

check

condition

of

synchro

mechanism

in

transmission

b

If

dragging

is

encountered

at

the

beginning

of

shifting

proceed

to

step

4

below

4

Push

change

lever

toward

Reverse

side

depress

pedal

to

check

for

free

travel

a

If

pedal

can

be

depressed

further

check

clutch

condition

b

If

pedal

cannot

be

depressed

further

proceed

to

step

5

below

5

Check

clutch

control

pedal

height

pedal

free

travel

withdrawal

lever

play

etc

If

no

abnonnal

condition

exists

and

if

pedal

cannot

be

depressed

further

check

clutch

condition

Clutch

disc

runout

or

warped

Wear

or

rust

on

hub

splines

in

clutch

disc

Diaphragm

spring

toe

height

out

of

ad

justment

or

toe

tip

worn

Worn

or

improperly

installed

parts

CL10

Repair

or

replace

Clean

and

lubricate

with

grease

or

replace

Adjust

or

replace

Repair

or

replace

Page 232 of 537

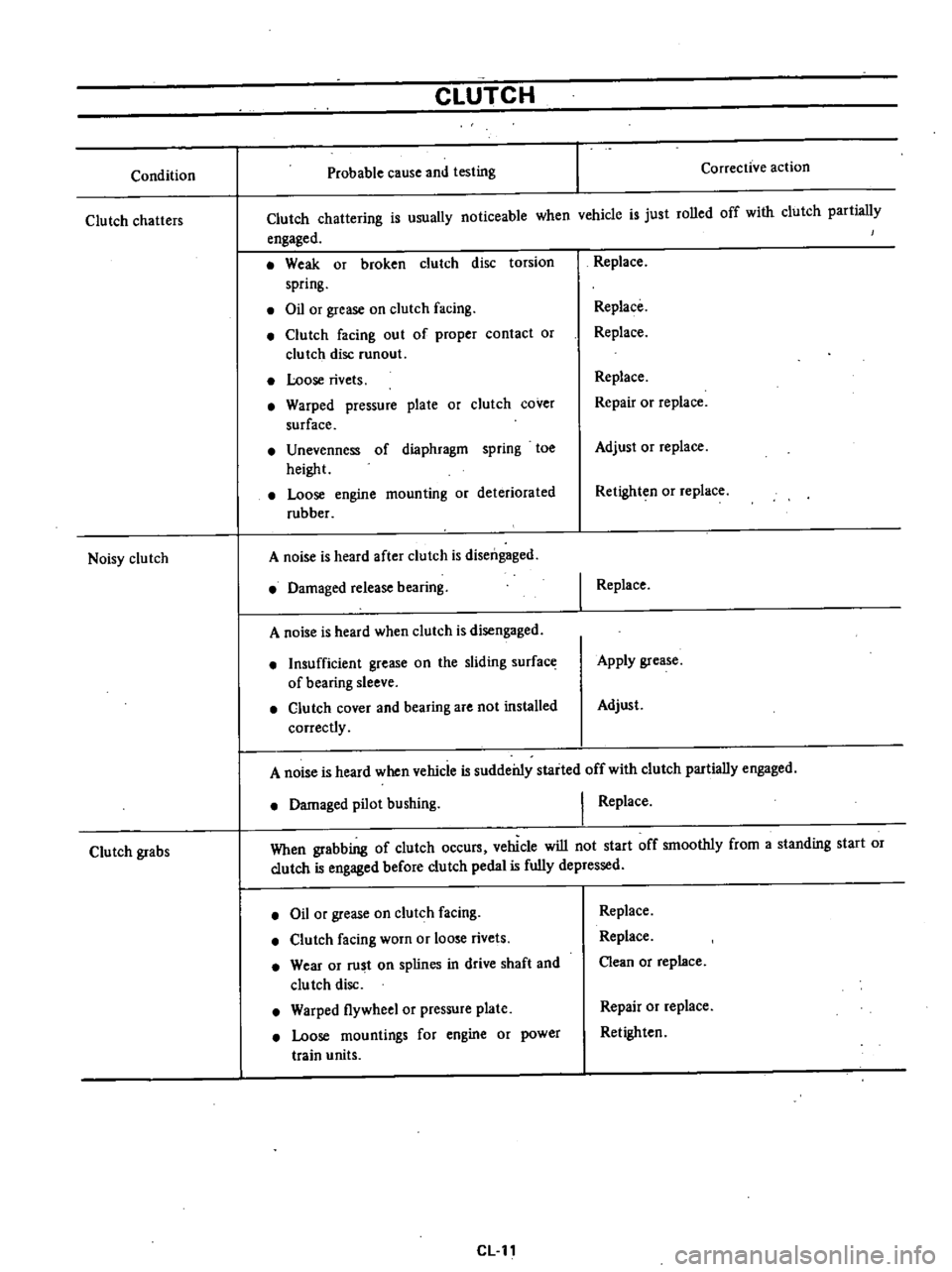

Condition

Clutch

chatters

Noisy

clutch

Clutch

grabs

CLUTCH

Probable

cause

and

testing

Corrective

action

Clutch

chattering

is

usually

noticeable

when

vchicle

is

just

rolled

off

with

clutch

partially

engaged

Weak

or

broken

clutch

disc

torsion

spring

Oil

or

grease

on

clutch

facing

Clutch

facing

out

of

proper

contact

or

clutch

disc

runout

Loose

rivets

Warped

pressure

plate

or

clutch

cover

surface

Unevenness

of

diaphragm

spring

toe

height

Loose

engine

mounting

or

deteriorated

rubber

A

noise

is

heard

after

clutch

is

disengaged

Damaged

release

bearing

A

noise

is

heard

when

clutch

is

disengaged

Insufficient

grease

on

the

sliding

surface

of

bearing

sleeve

Clutch

cover

and

bearing

are

not

installed

correctly

Replace

Replace

Replace

Replace

Repair

or

replace

Adjust

or

replace

Retighten

or

replace

I

Replace

Apply

grease

Adjust

A

noise

is

heard

when

vehicle

is

suddei11y

staited

off

with

clutch

partially

engaged

Damaged

pilot

bushing

I

Replace

When

grabbing

of

clutch

occurs

vehicle

will

not

start

off

smoothly

from

a

standing

start

or

clutch

is

engaged

before

clutch

pedal

is

fully

depressed

Oil

or

grease

on

clutch

facing

Clutch

facing

worn

or

loose

rivets

Wear

or

rust

on

splines

in

drive

shaft

and

clu

tch

disc

Warped

flywheel

or

pressure

plate

Loose

mountings

for

engine

or

power

train

units

CLll

Replace

Replace

Clean

or

replace

Repair

or

replace

Retighten

Page 292 of 537

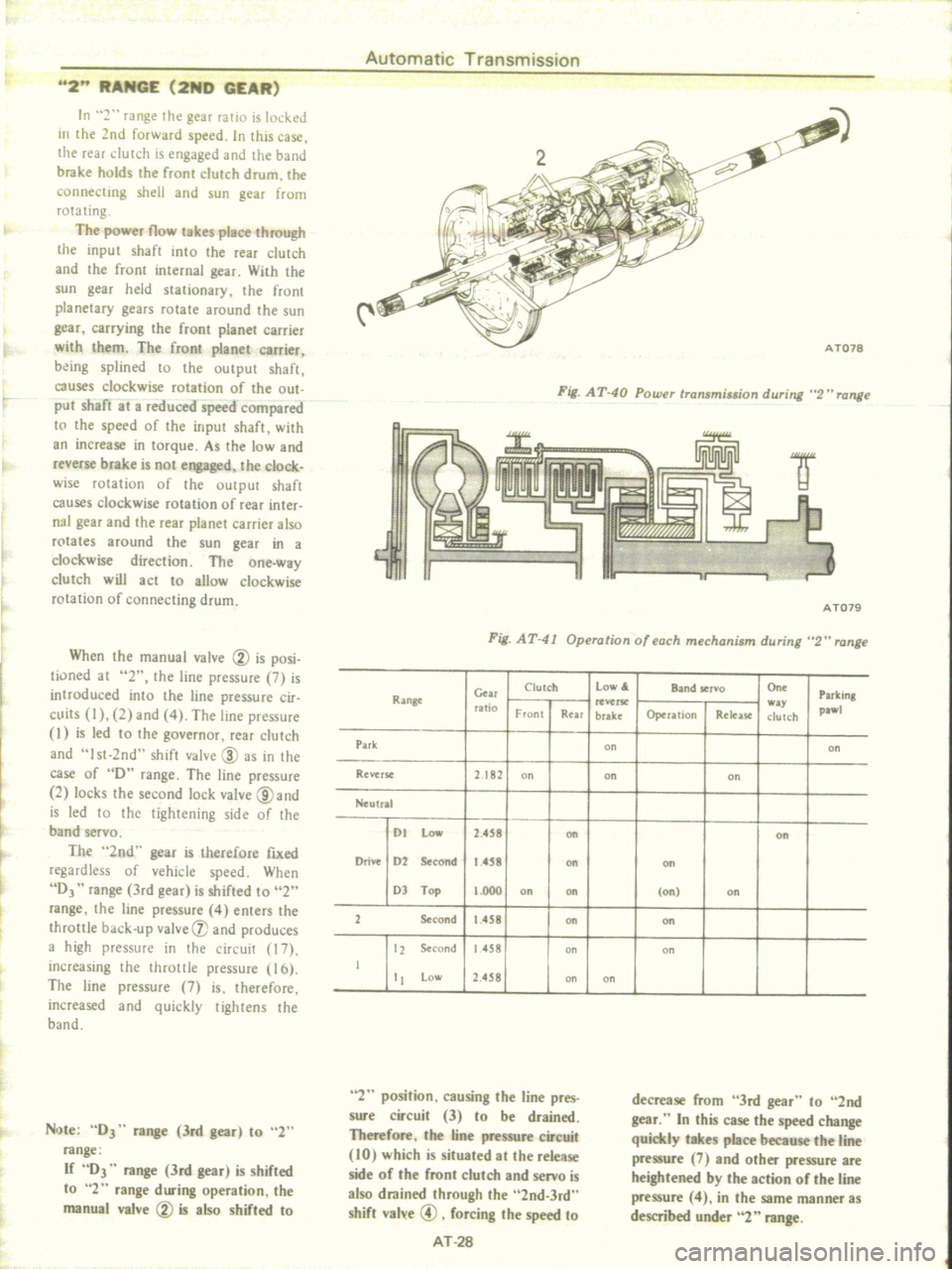

2

RANGE

2ND

GEAR

Automatic

Transmission

In

2

range

the

gear

rario

is

IOI

keJ

III

the

2nd

forward

speed

In

this

case

the

rear

dutch

is

engaged

and

the

band

brake

holds

the

front

clutch

drum

the

connecting

shell

and

sun

gear

from

rotating

The

power

flow

takes

place

through

the

input

shaft

inlo

the

rear

clutch

and

the

front

internal

gear

With

Ihe

sun

gear

held

stationary

the

front

planetary

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

front

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

OUI

put

shaft

at

a

reduced

speed

compared

to

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

engaged

the

clock

wise

rotation

of

the

output

shaft

causes

clockwise

rotation

of

fear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

clutch

will

act

to

allow

clockwise

rotation

of

connecting

drum

When

the

manual

valve

V

is

posi

tioned

at

2

the

line

pressure

7

is

introduced

into

the

line

pressure

cir

cuits

I

2

and

4

The

line

pressure

I

is

led

to

the

governor

rear

clutch

and

I

st

2nd

shift

valve

CID

as

in

the

case

of

D

range

The

line

pressure

2

locks

the

second

lock

valve

@and

is

led

to

thc

tightening

side

of

Ihe

band

servo

The

2nd

gear

is

therefore

fixed

regardless

of

vehicle

speed

When

DJ

range

3rd

gear

is

shifted

to

2

range

the

line

pressure

4

enters

Ihe

throttle

back

up

valve

V

and

produces

a

high

pressure

in

the

circuit

17

increasing

thc

throttle

pressure

li

6

The

line

pressure

7

is

therefore

increased

and

quickly

tightens

the

band

N

e

DJ

range

3rd

gear

to

2

range

If

DJ

range

3rd

gear

is

shifled

to

2

range

during

operation

the

manual

valve

V

is

also

shifted

to

A

T078

Fig

AT

40

Powu

tTansminion

during

2

H

range

A

1079

Fig

AT

41

Operation

of

each

mechanism

during

2

range

Clutch

Low

Band

ser

o

On

Parking

Gw

Ran8t

utio

w

pa

Front

Rear

brake

Operalion

Release

dutch

Pui

on

on

Revtrs

e

2

182

on

on

on

Neutral

01

Low

2

458

on

on

Drive

02

Second

1

458

Oft

Oft

OJ

Top

1

000

on

on

on

on

1

Second

1

458

on

Oft

12

tocond

1458

on

on

J

tt

Low

2

458

on

on

2

position

causing

the

line

pres

sure

circuit

3

to

be

drained

Therefore

the

line

pressure

circuit

10

which

is

situated

at

the

release

side

of

the

front

clutch

and

servo

is

also

drained

through

the

2nd

3rd

shift

val

e

@

forcing

the

speed

to

AT

28

decrease

from

3rd

gear

to

2nd

gear

In

this

case

the

speed

change

quickly

takes

place

because

the

line

pressure

7

and

other

pressure

are

heightened

by

the

action

of

the

line

pressure

4

in

the

same

manner

as

described

under

2

range

Page 333 of 537

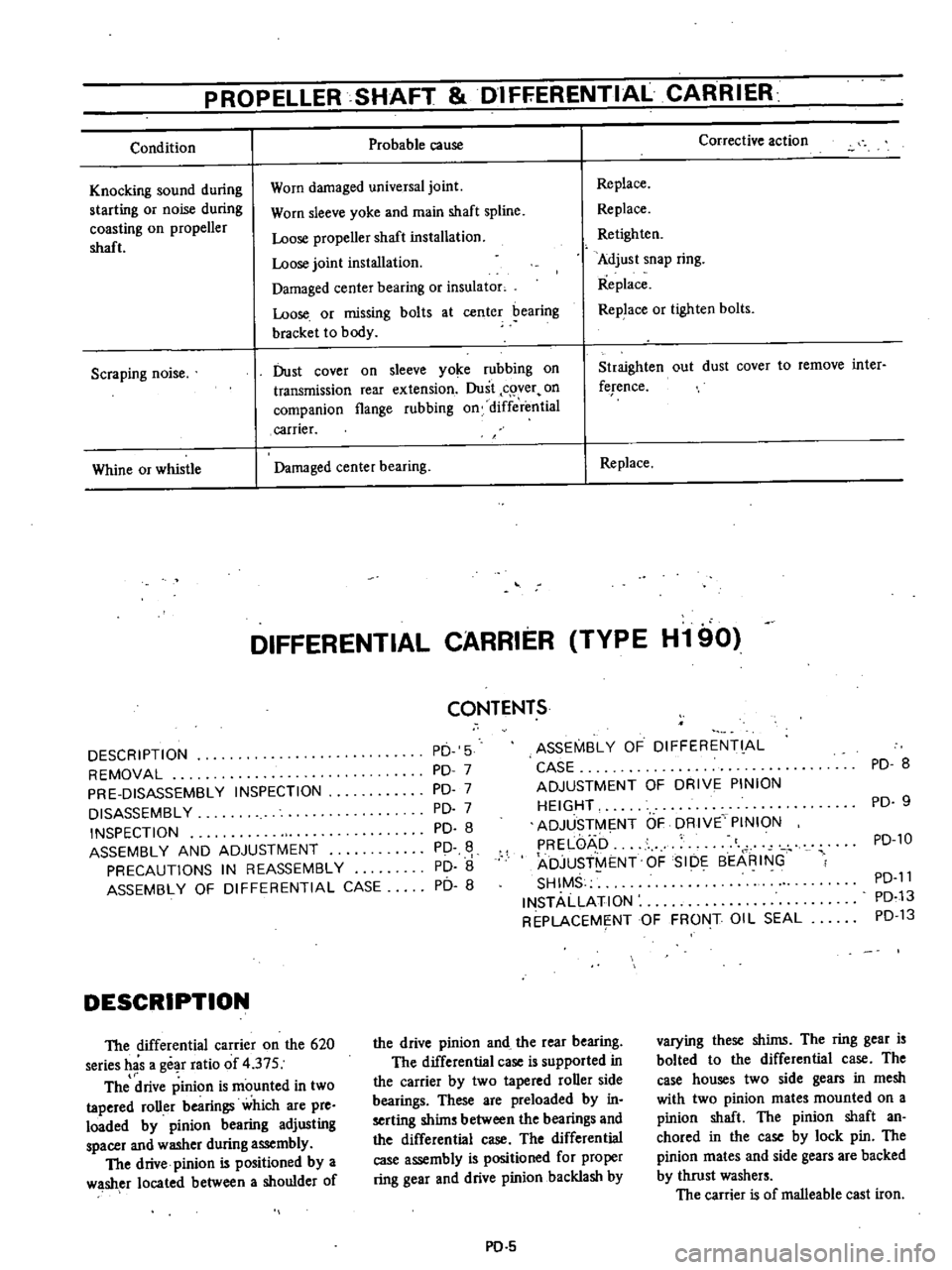

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Condition

Probable

cause

Knocking

sound

during

starting

or

noise

during

coasting

on

propeller

shaft

Worn

damaged

universal

joint

Worn

sleeve

yoke

and

main

shaft

spline

Loose

propeller

shaft

installation

Loose

joint

installation

Damaged

center

bearing

or

insulator

Loose

or

missing

bolts

at

center

bearing

bracket

to

body

Scraping

noise

Dust

cover

on

sleeve

yoke

rubbing

on

transmission

rear

extension

Dust

c

ver

on

companion

flange

rubbing

on

differ

mtial

carrier

Whine

or

whistle

Damaged

center

bearing

Corrective

action

Replace

Replace

Retighten

Adjust

snap

ring

Replace

Replace

or

tighten

bolts

Straighten

out

dust

cover

to

remove

inter

ference

Replace

DIFFERENTIAL

CARRIER

TYPE

H190

CONTENTS

DESCRIPTION

REMOVAL

PRE

DISASSEMBLY

INSPECTION

DISASSEMBLY

INSPECTION

ASSEMBLY

AND

ADJUSTMENT

PRECAUTIONS

IN

REASSEMBLY

ASSEMBLY

OF

DIFFERENTIAL

CASE

PD

5

PD

7

PD

7

PD

7

PD

8

PD

PD

8

PD

8

DESCRIPTION

The

differential

carrier

on

the

620

series

has

a

gear

ratio

of

4

37S

The

drive

pinion

is

rnounted

in

two

tapered

roUer

bearings

which

are

pre

loaded

by

pinion

bearing

adjusting

spacer

and

washer

during

assembly

The

drive

pinion

is

positioned

by

a

washer

located

between

a

shoulder

of

ASSEMBl

Y

OF

DIFFERENT

Al

CASE

ADJUSTMENT

OF

DRIVE

PINION

HEIGHT

ADJUSTME

NT

OF

DRIVE

PINION

PRELOAD

t

ADJUST

ENT

OF

SIDE

8EARING

SHIMS

INSTAllATION

REPLACEME

NTOF

FRONT

Oil

SEAL

the

drive

pinion

and

the

rear

bearing

The

differential

case

is

supported

in

the

carrier

by

two

tapered

roller

side

bearings

These

are

preloaded

by

in

serting

shims

between

the

bearings

and

the

differential

case

The

differential

case

assembly

is

positioned

for

proper

ring

gear

and

drive

pinion

backlash

by

PO

5

PD

8

PD

9

PD

lO

PD

11

PD

13

PD

13

varying

these

shims

The

ring

gear

is

bolted

to

the

differential

case

The

case

houses

two

side

gears

in

mesh

with

two

pinion

mates

mounted

on

a

pinion

shaft

The

pinion

shaft

an

chored

in

the

case

by

lock

pin

The

pinion

mates

and

side

gears

are

backed

by

thrust

washers

The

carrier

is

of

malleable

cast

iron

Page 337 of 537

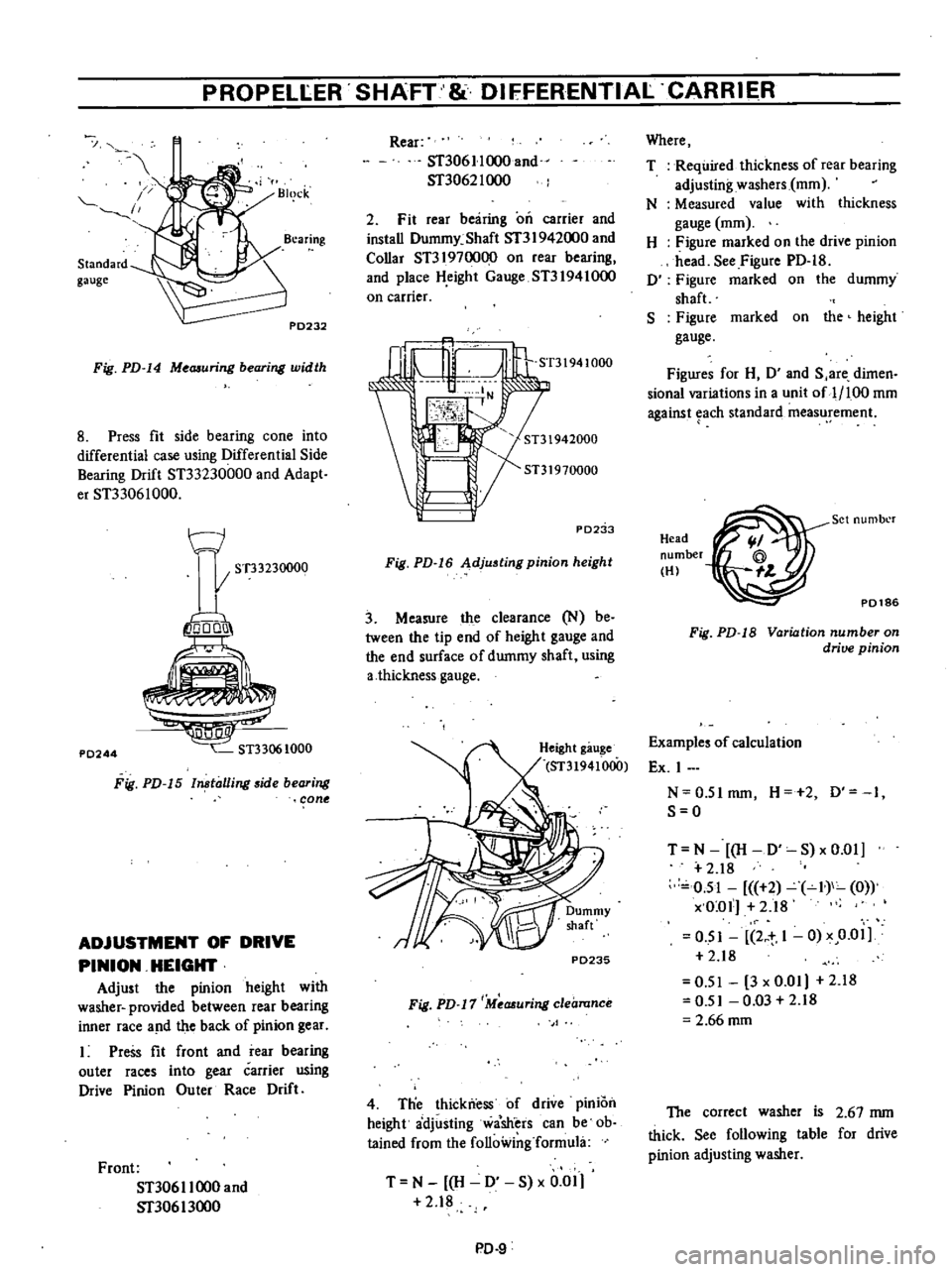

PROPELLER

SHAFT

DifFERENTIAL

CARRIER

Standard

gauge

I

1

Fig

PD

14

Me

uring

bearing

width

8

Press

fit

side

bearing

cone

into

differential

case

using

Differential

Side

Bearing

Drift

ST33230000

and

Adapt

er

ST33061000

t

J

I

ST33230000

io

o1

P0244

Fig

PD

15

ln

talling

side

bearing

cone

ADJUSTMENT

OF

DRIVE

PINION

HEIGHT

Adjust

the

pinion

height

with

washer

provided

between

rear

bearing

inner

race

a

ld

the

back

of

pinion

gear

Press

fit

front

and

rear

bearing

outer

races

into

gear

carrier

using

Drive

Pinion

Ou

ter

Race

Drift

Front

ST306

I

1000

and

Sf30613oo0

Rear

ST306

II

000

and

ST3062I

000

2

Fit

rear

bearing

on

carrier

and

install

Dummy

Shaft

Sf3

I

942000

and

Collar

ST3197oo00

on

rear

bearing

and

place

H

eight

Gauge

ST31941000

on

carrier

ST31941000

PD2

b

Fig

PD

16

Adjusting

pinion

height

3

Measure

the

clearance

N

be

tween

the

tip

end

of

height

gauge

and

the

end

surface

of

dummy

shaft

using

a

thickness

gauge

P0235

Fig

PD

17

Measuring

clearance

4

Tlie

thickness

of

drive

pInIOn

height

adjusting

wa

sh

ers

can

be

ob

tained

from

the

following

formula

T

N

H

0

S

x

0

01

2

18

PD

9

Where

T

Required

thickness

of

rear

bearing

adjusting

washers

mOl

N

Measured

value

with

thickness

gauge

mOl

H

Figure

marked

on

the

drive

pinion

head

See

Figure

PD

18

0

Figure

marked

on

the

dummy

shaft

S

Figure

marked

on

the

height

gauge

Figures

for

H

0

and

S

are

dimen

sional

variations

in

a

unit

of

1

100

mOl

against

each

standard

measurement

Head

number

HI

P0186

Set

numbl

r

Fig

PD

18

Variation

number

on

drive

pinion

Examples

of

calculation

Ex

I

N

0

5Imm

H

2

0

1

S

O

T

N

H

D

S

xO

01

2

18

0

51

2

I

0

x

O

ol

2

18

O

SI

2

t

1

0

x

0

01

2

18

0

51

3

x

0

01

2

18

0

51

0

03

2

18

2

66

mOl

The

correct

washer

is

2

67

mm

thick

See

following

table

for

drive

pinion

adjusting

washer

Page 340 of 537

PROPELLER

SHAFf

DIFFERENTIAL

CARR

IER

Ex

2

A

0

B

3

C

I

0

0

E

0

20

mOl

F

0

17

mOl

H

2

Left

side

T

I

A

C

D

H

x

om

0

17S

E

0

I

0

2

x

0

01

0

I7S

0

20

0

I

0

2

x

0

01

0

17S

0

20

3

Om

0

17S

0

20

0

03

0

17S

0

20

O

34S

mrn

The

correct

shinjs

are

O

OS

plus

0

10

plus

0

20

mrn

thick

Right

side

T2

B

D

H

xO

0l

O

ISO

F

3

0

2

x

om

O

ISO

0

17

3

0

2

x

om

0

150

0

17

S

x

0

01

0

ISO

0

I7

O

OS

0

1S0

0

17

0

37

mrn

The

correct

shims

are

0

07

plus

0

1

0

plus

0

20

mm

thick

Note

If

w1ues

signifying

A

B

C

0

and

H

are

not

given

regard

them

as

zero

and

compute

Aft

assembly

check

to

see

that

preload

and

backlash

are

correct

If

not

readjust

Side

bearing

adjusting

shim

Thickness

mm

in

O

OS

0

0020

0

07

0

0028

0

1

0

0

0039

0

20

0

0079

0

50

0

0197

2

Fit

determined

side

bearing

adjusting

shim

on

differential

case

and

press

fit

left

and

right

side

bearing

inner

races

on

it

using

Side

Bearing

Drift

ST33230000

and

Adapter

ST33061000

3

Install

differential

case

assembly

into

gear

carrie

tapping

with

a

rubber

mallet

4

Align

mark

on

bearing

cap

with

that

on

gear

carrier

and

install

bearing

cap

on

carrier

And

tight

n

bolts

to

specified

torque

Tightening

torque

4

0

to

S

O

kg

m

29

to

36

fHb

S

Measure

ring

gear

to

drive

pinion

backlash

If

backlash

is

too

small

remove

shims

from

left

side

and

add

them

to

right

side

To

reduce

backlash

remove

shims

from

right

side

and

add

them

to

left

side

Backlash

O

1S

to

0

20

mrn

0

00S9

to

0

0079

in

Fig

PD

22

Mccuuring

back1aah

6

At

the

same

time

check

side

bearing

preload

Bearing

preload

should

read

12

0

to

20

0

kg

cm

10

to

17

in

lb

of

rotating

torque

3

S

to

S

8

kg

7

7

to

12

8

Ib

at

ring

gear

bolt

hole

PD

12

If

preload

does

not

accord

with

this

specification

adjust

it

with

side

bear

ing

shims

7

Check

and

adjust

the

tooth

con

tact

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

ferric

oxide

and

gear

oil

to

produce

a

contact

pattern

3

Rotate

pinion

through

several

revolutions

in

the

forward

and

reverse

directions

until

a

defmite

contact

pat

tern

is

developed

on

ring

gear

4

When

contact

pattern

is

incor

rect

readjust

thickness

of

adjusting

washer

S

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

following

manner

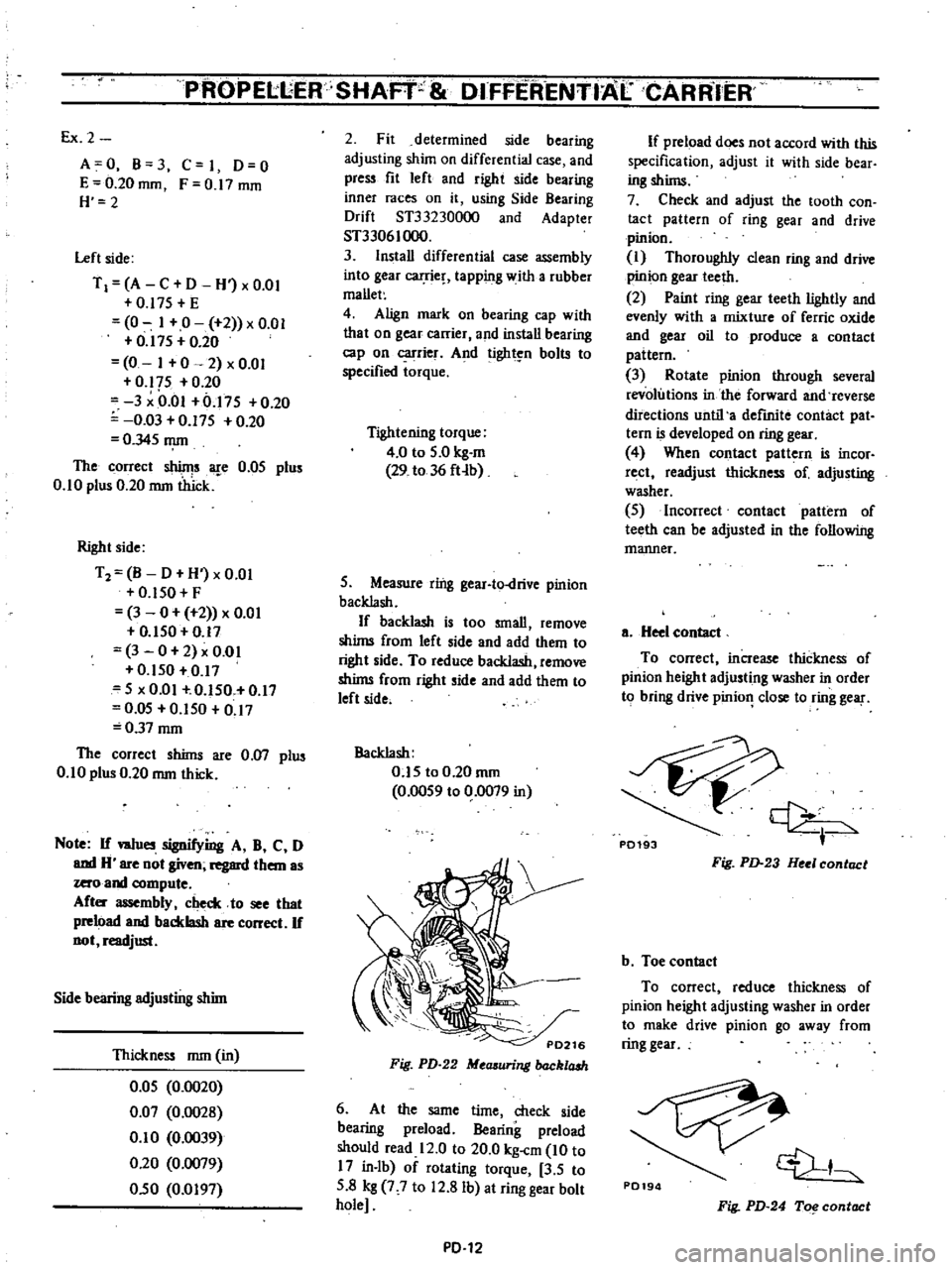

a

Heel

contact

To

correct

increase

thickness

of

pinion

height

adjusting

washer

in

order

to

bring

drive

pinio

close

to

ring

gear

P0193

Fig

PD

23

Hul

contact

b

Toe

contact

To

correct

reduce

thickness

of

pinion

height

adjusting

washer

in

order

to

make

drive

pinion

go

away

from

ring

gear

P0194

1

Fig

PD

24

To

contact

Page 347 of 537

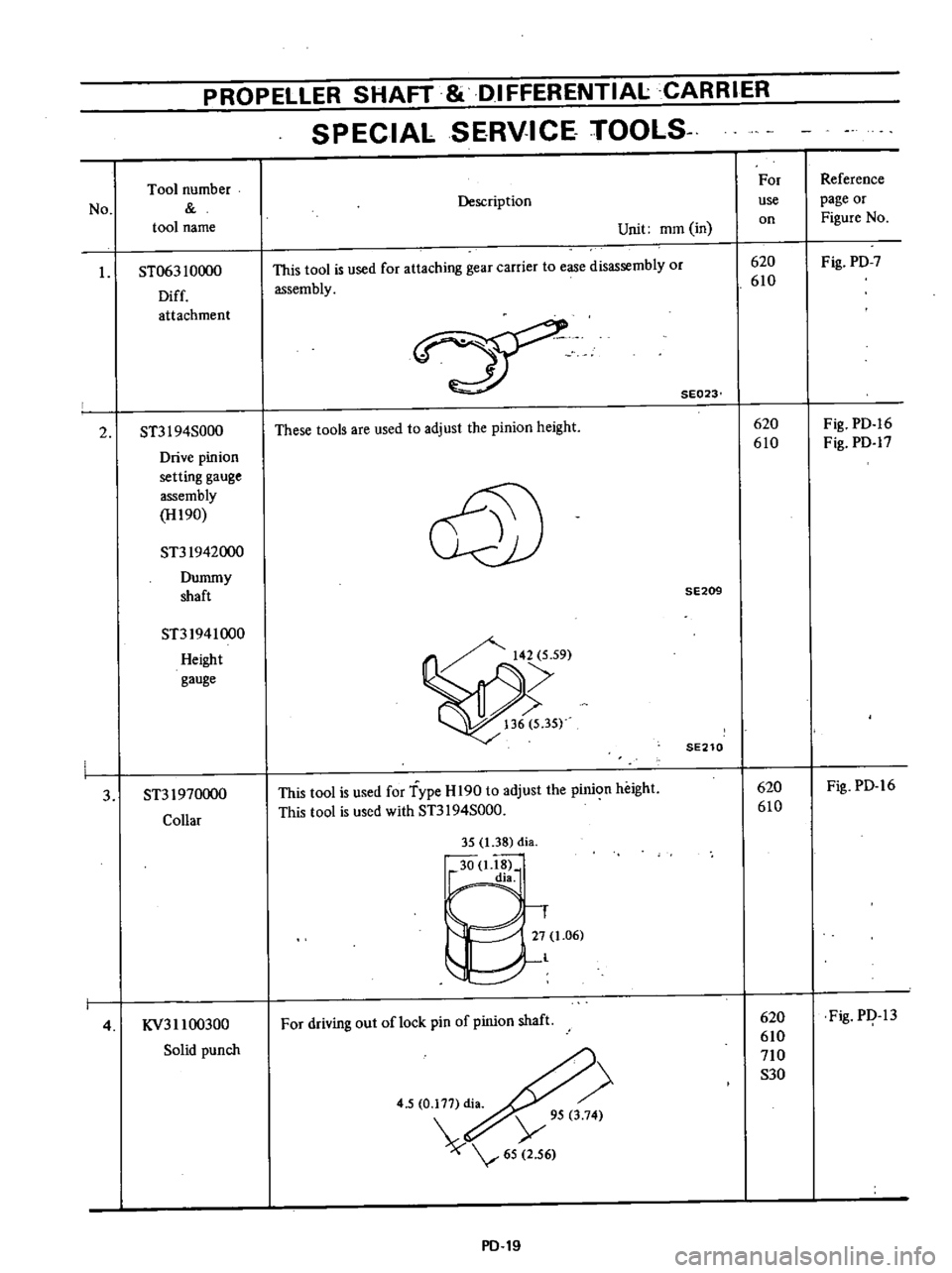

PROPELLER

SHAFT

8i

DIFFERENTIALCARRIER

SPECIAL

SERVICE

TOOlS

No

Tool

number

tool

name

I

ST063

10000

Diff

attachment

2

ST3I

94S000

Drive

pinion

setting

gauge

assembly

H190

ST31942000

Dummy

shaft

ST31941000

Height

gauge

3

ST31970000

Collar

4

KV311

00300

Solid

punch

Description

Unit

mOl

in

This

tool

is

used

for

attaching

gear

carrier

to

ease

disassembly

or

assembly

SE023

These

tools

are

used

to

adjust

the

pinion

height

@

SE209

SE210

This

tool

is

used

for

Type

H

190

to

adjust

the

pinion

height

This

tool

is

used

with

ST3I

94S000

35

1

38

di

30

1

18

dia

1

27

1

06

l

For

driving

out

oflock

pin

of

pinion

shaft

4

5

0

177

di

Y

95

3

74

65

2

56

PD

19

For

use

on

620

610

620

610

620

610

620

610

710

S30

Reference

page

or

Figure

No

Fig

PD

7

Fig

PD

16

Fig

PD

17

Fig

PD

16

Fig

PI

13