height DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 9 of 537

Fig

GI

9

Manual

trammiuion

number

location

Automatic

transmission

number

The

transmission

serial

number

is

attached

to

the

right

hand

side

of

transmission

case

Numbering

system

X

XXXXX

I

Serial

number

monthly

Month

of

manufacture

I

2

9

X

Y

Z

last

figure

of

year

of

manufacture

AT344

Fig

01

10

Automatic

trammi

sion

number

location

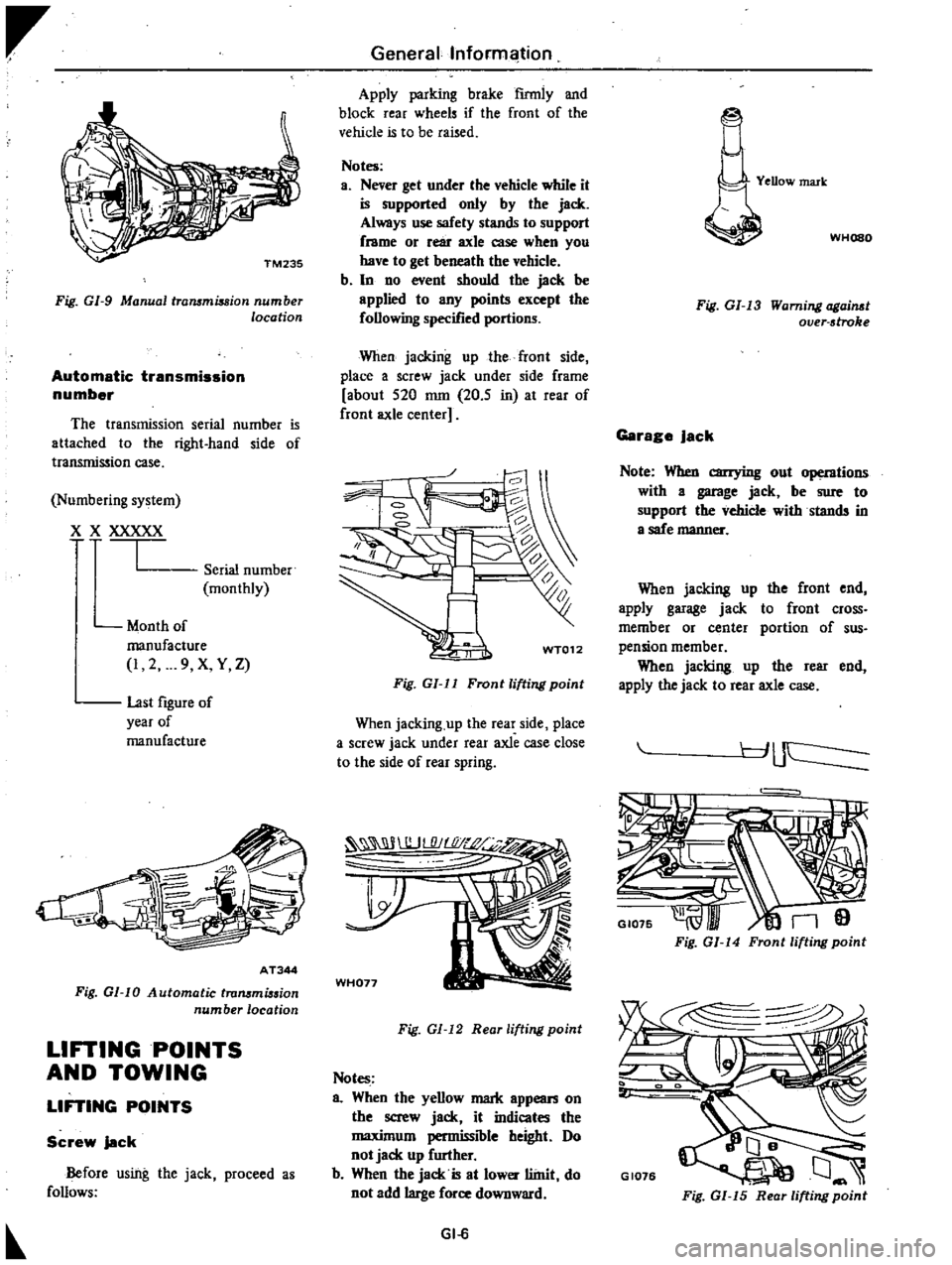

LIFTING

POINTS

AND

TOWING

LIFTING

POINTS

Screw

jack

Before

using

the

jack

proceed

a

follows

Generallnforml

ition

Apply

parking

brake

firmly

and

block

rear

wheels

if

the

front

of

the

vehicle

is

to

be

raised

Notes

a

Never

get

under

the

vehicle

while

it

is

supported

only

by

the

jack

Always

use

safety

stands

to

support

frame

or

rear

axle

case

when

you

have

to

get

beneath

the

vehicle

b

In

no

event

should

the

jack

be

applied

to

any

points

except

the

following

specified

portions

When

jacking

up

the

front

side

place

a

screw

jack

under

side

frame

about

520

nun

20

5

in

at

rear

of

front

axle

center

WT012

Fig

GI

ll

Front

lifting

point

When

jacking

up

the

rear

side

place

a

screw

jack

under

rear

axle

case

close

to

the

side

of

rear

spring

WH077

Fig

GI

12

Reor

lifting

point

Notes

a

When

the

yellow

mark

appean

on

the

screw

jack

it

indicates

the

maximum

permissible

height

Do

not

jack

up

further

b

When

the

jack

is

at

lower

llinit

do

not

add

large

force

downward

GI

6

YeDow

mark

WHOSO

Fig

GI

13

Warning

ogai

t

over

stroke

Garage

Jack

Note

When

carrying

out

operntions

with

a

garage

jack

be

sure

to

support

the

vehicle

withstands

in

a

safe

manner

When

jacking

up

the

front

end

apply

garage

jack

to

front

cross

member

or

center

portion

of

sus

pension

member

When

jacking

up

the

rear

end

apply

the

jack

to

rear

axle

case

r

J

uc

I

GI075

n9

Fig

GI

14

Front

lifting

point

GI076

Fig

GI

15

Rear

lifting

point

Page 34 of 537

r

EC350

Fig

ET

43

Cleanill

l

E

G

R

control

lJ

Jlue

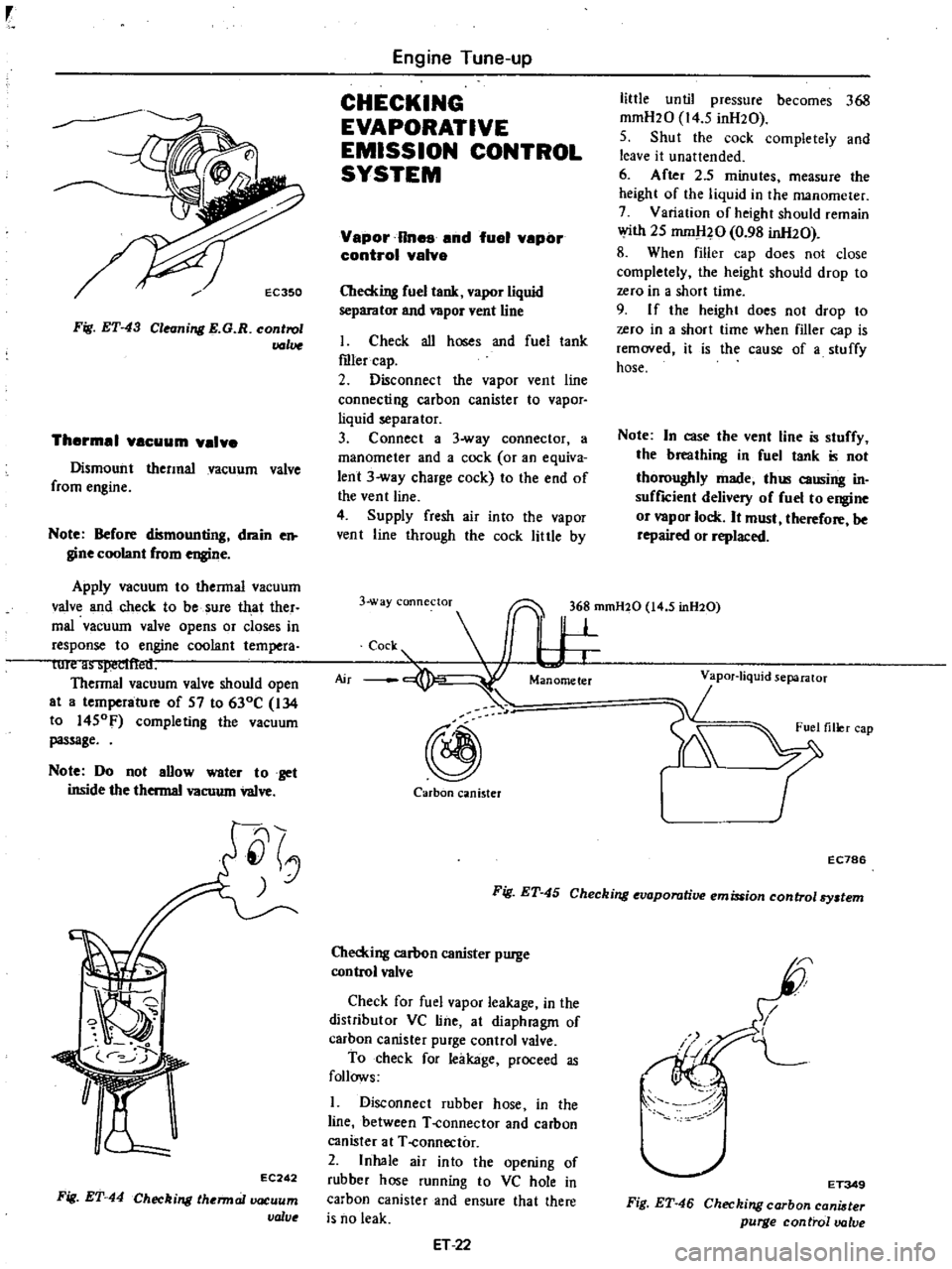

Thermal

VBCuum

valve

Dismount

thermal

vacuum

valve

from

engine

Note

Before

dismounting

drain

e

gine

coolant

from

engine

Apply

vacuum

to

thermal

vacuum

valve

and

check

to

be

sure

that

ther

mal

vacuum

valve

opens

or

closes

in

response

to

engine

coolant

tempera

lurt

i1

i

iYCl

lt

lt

U

Thermal

vacuum

valve

should

open

at

a

temperature

of

57

to

630C

134

to

1450F

completing

the

vacuum

passage

Note

Do

not

aUow

water

to

get

inside

the

thermal

vacuum

valve

EC

242

Fig

ET

44

Checkill

lthermallXlCuum

valve

Engine

Tune

up

CHECKING

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

Vapor

Rnes

and

fuel

vepor

control

valve

Checking

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

I

Check

all

hoses

and

fuel

tank

roler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

vapor

liquid

separator

3

Connect

a

3

way

connector

a

manometer

and

a

cock

or

an

equiva

lent

3

way

charge

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mmH20

14

5

inH20

5

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

with

25

mm

l20

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

removed

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thl

causing

in

suffICient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

3

way

connectoT

36

mmH20

14

5

inH20

c

s

I

W

@

Carbon

canister

r

EC786

Fig

ET

45

Checking

evaporative

emission

control

By

tem

Checking

carbon

canister

purge

control

valve

Check

for

fuel

vapor

leakage

in

the

distributor

VC

line

at

diaphragm

of

carhon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

1

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

VC

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET

22

I

I

L

I

ET349

Fig

ET

46

Checking

carbon

cani

ter

purge

control

valve

Page 54 of 537

Engine

Mechanical

Valve

head

diameter

I

In

42

0

to

42

2

1

654

to

1

661

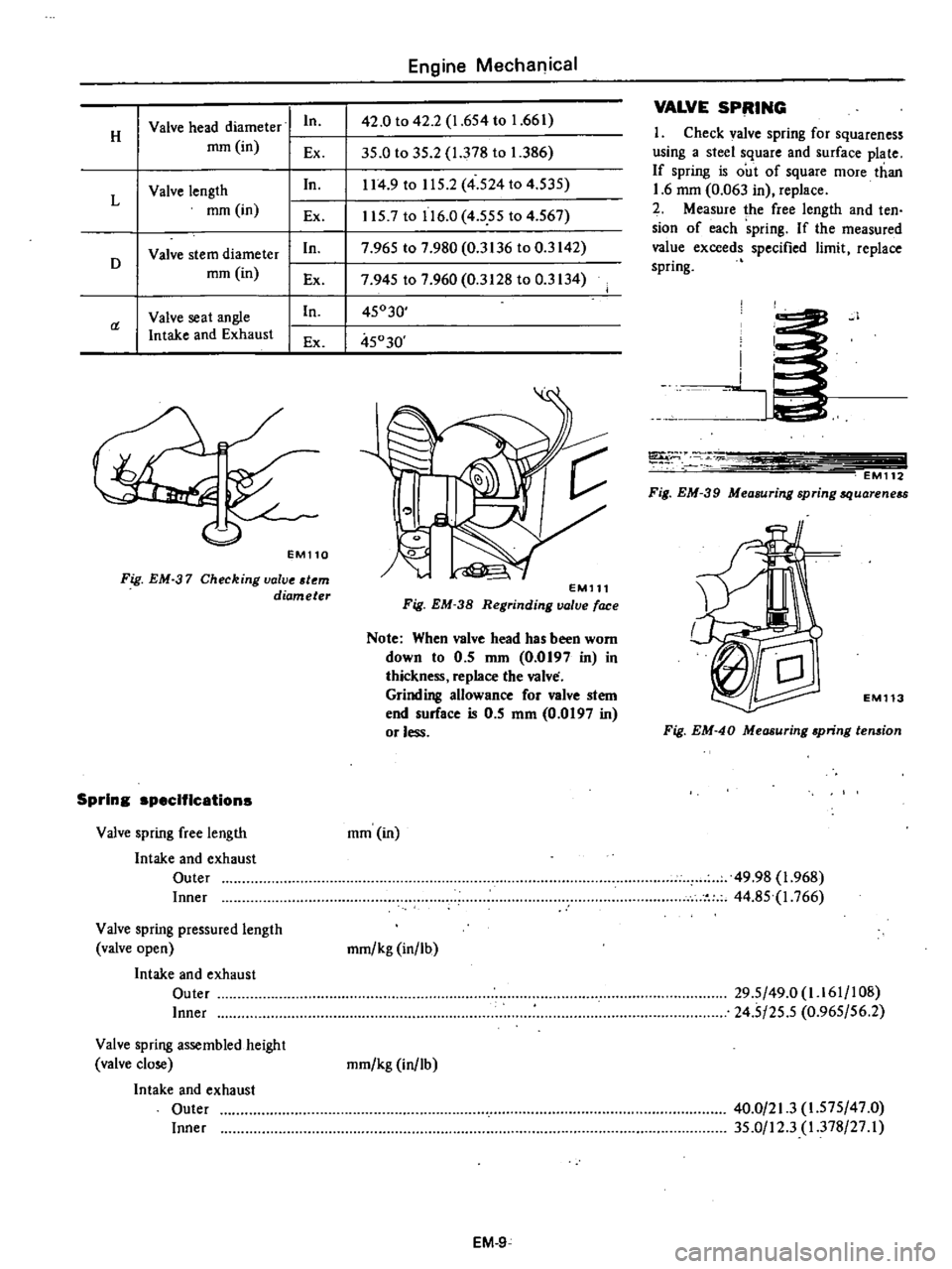

VALVE

SPRING

H

1

Check

valve

spring

for

squareness

mm

in

Ex

35

0

to

35

2

1

378

to

1

386

using

a

steel

square

and

surface

plate

In

114

9

to

115

2

4

524

to

4

535

If

spring

is

out

of

square

more

than

Valve

length

1

6

mm

0

063

in

replace

L

mm

in

2

Measure

lhe

free

length

and

ten

Ex

1157

to

116

0

4

555

to

4

567

sion

of

each

spring

If

the

measured

Valve

stem

diameter

In

7

965

to

7

980

0

3136

to

0

3142

value

exceeds

specified

limit

replace

D

mm

in

spring

Ex

7

945

to

7

960

0

3128

to

0

3134

Valve

seat

angle

In

45030

a

Intake

and

Exhaust

Ex

45030

EM110

Fig

EM

37

Checking

valve

tern

diameter

Spring

specifications

Valve

spring

free

length

Intake

and

exhaust

Outer

Inner

Valve

spring

pressured

length

valve

open

Intake

and

exhaust

Outer

Inner

Valve

spring

assembled

height

valve

close

Intake

and

exhaust

Outer

Inner

EMll1

Fig

EM

38

Regrinding

valve

face

Note

When

valve

head

has

been

worn

down

to

0

5

nun

0

0197

in

in

thickness

replace

the

valve

Grinding

allowance

for

valve

stem

end

surface

is

0

5

mm

0

0197

in

or

less

mm

in

mmlkg

in

lb

mmlkg

in

lb

EM

9

I

i

J

T

EM112

Fig

EM

39

Measuring

spring

quareneu

1

EM113

Fig

EM

40

Measuring

apring

ten

ion

49

98

1

968

44

85

1

766

29

5

49

0

1

161

108

24

5

25

5

0

965156

2

40

0

21

3

1

575

47

0

35

0

12

3

1

378

27

I

Page 58 of 537

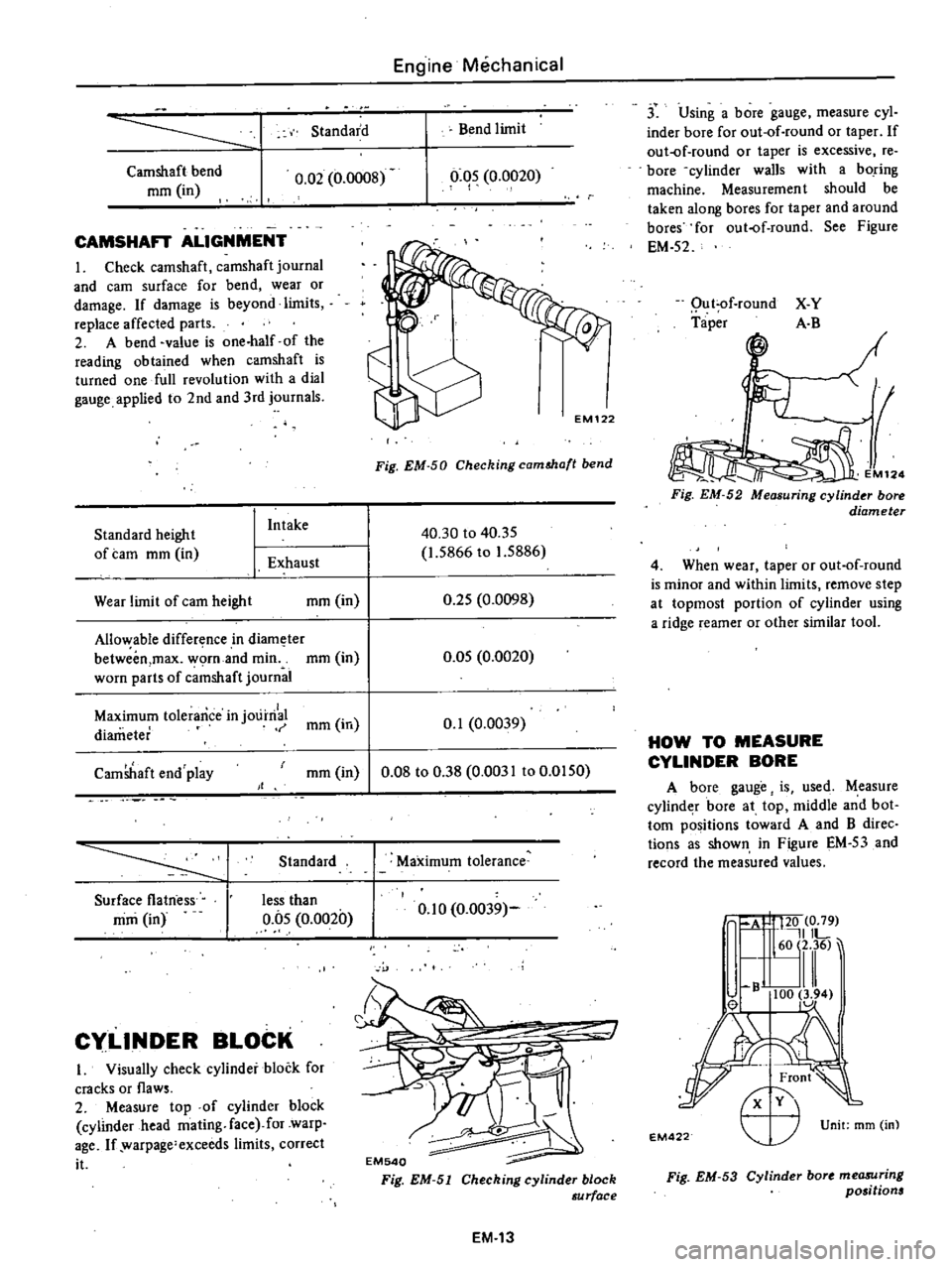

Standard

Camshaft

bend

mm

in

0

02

0

0008

CAMSHAFT

ALIGNMENT

I

Check

camshaft

camshaft

journal

and

earn

surface

for

bend

wear

or

damage

If

damage

is

beyond

limits

replace

affected

parts

2

A

bend

value

is

one

half

of

the

reading

obtained

when

camshaft

is

turned

one

full

revolution

with

a

dial

gauge

applied

to

2nd

and

3rd

journals

Standard

height

of

tam

mm

in

I

Intake

1

Exhaust

Wear

limit

of

earn

height

mm

in

Allo

able

difference

in

diam

ter

betweim

max

worn

and

min

mm

in

worn

parts

of

c

mshaft

journal

Engine

Mechanical

Bend

limit

0

05

0

0020

I

Fig

EM

50

Checking

camMa

t

bend

40

30

to

40

35

1

5866

to

1

5886

0

25

0

0098

0

05

0

0020

Maximum

tolerance

in

j01

irri

mm

in

0

1

0

0039

diameter

CamShaft

end

play

mm

in

0

08

to

0

38

0

0031

to

0

0150

Standard

Surface

flatness

mm

in

less

than

0

05

0

0020

Cy

LlNDER

BLOCK

I

Visually

check

cylinder

block

for

cracks

or

flaws

2

Measure

top

of

cylinder

block

cylinder

head

mating

face

for

warp

age

If

warpage

exceeds

limits

correct

it

Maximum

tolerance

0

10

0

0039

EM540

Fig

EM

51

Cheching

cylinder

block

au

rface

EM

13

j

Using

a

bore

gauge

measure

cyl

inder

bore

for

out

of

round

or

taper

If

out

of

round

or

taper

is

excessive

re

bore

cylinder

walls

with

a

boring

machine

Measuremen

t

should

be

taken

along

bores

for

taper

and

around

bores

for

out

of

round

See

Figure

EM

52

Qu

t

of

round

Taper

X

Y

A

B

M12

Fig

EM

52

Measuring

cylinder

bore

diameter

4

When

wear

taper

or

out

of

round

is

minor

and

within

limits

remove

step

at

topmost

portion

of

cylinder

using

a

ridge

reamer

or

other

similar

tool

HOW

TO

MEASURE

CYLINDER

BORE

A

bore

gauge

is

used

Measure

cylind

r

bore

at

top

middle

and

bot

tom

positions

toward

A

and

B

direc

tions

as

shown

in

Figure

EM

53

and

record

the

measured

values

A

I

120

0

79

IlL

60

2

36

lll

B

100

3

94

el

1

Unit

mm

m

EM

22

r

Fig

EM

53

Cylinder

bort

me08Uring

positions

Page 62 of 537

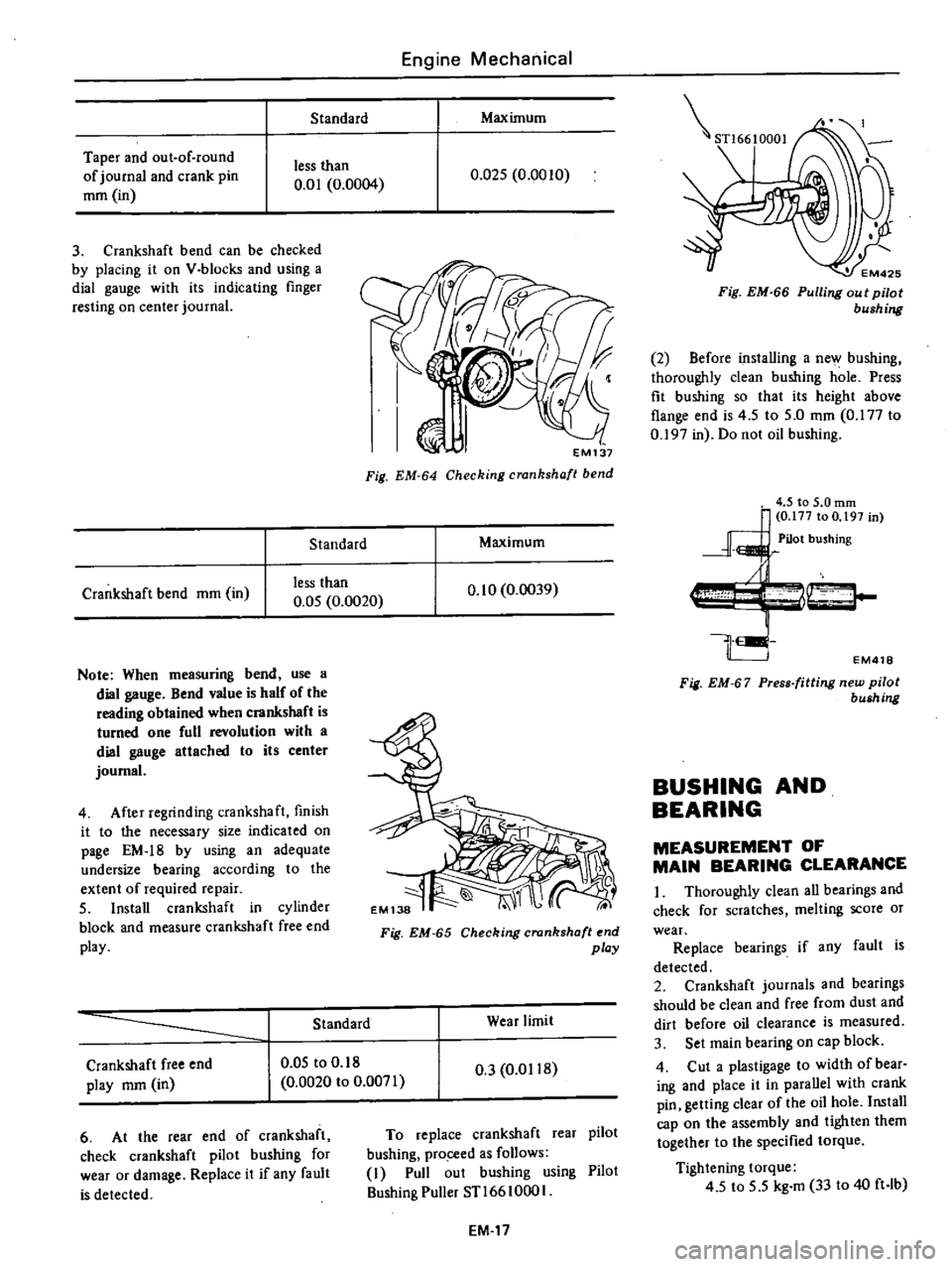

Standard

Taper

and

out

of

round

of

journal

and

crank

pin

mm

in

less

than

0

01

0

0004

3

Crankshaft

bend

can

be

checked

by

placing

it

on

V

blocks

and

using

a

dial

gauge

with

its

indicating

finger

resting

on

center

journal

Standard

Crankshaft

bend

mm

in

less

than

0

05

0

0020

Note

When

measuring

bend

use

a

dial

gauge

Bend

value

is

half

of

the

reading

obtained

when

crankshaft

is

turned

one

full

revolution

with

a

dial

gauge

attached

to

its

center

journal

4

After

regrinding

crankshaft

finish

it

to

the

necessary

size

indicated

on

page

EM

18

by

using

an

adequate

undersize

bearing

according

to

the

extent

of

required

repair

5

Install

crankshaft

in

cylinder

block

and

measure

crankshaft

free

end

play

Engine

Mechanical

Maximum

0

Q25

0

0010

EM137

Fig

EM

64

Checking

crankshaft

bend

Maximum

0

10

0

0039

Fig

EM

65

Checking

crankshaft

end

play

Standard

Wear

limit

Crankshaft

free

end

play

mm

in

0

05

to

0

18

0

0020

to

0

0071

0

3

0

0118

6

At

the

rear

end

of

crankshaft

check

crankshaft

pilot

bushing

for

wear

or

damage

Replace

it

if

any

fault

is

detected

To

replace

crankshaft

rear

pilot

bushing

pro

ceed

as

follows

I

Pull

out

bushing

using

Pilot

Bushing

Puller

STl66

1000

I

EM

17

STl6610001

EM425

Fig

EM

66

Pulling

out

pilot

bushing

2

Before

installing

a

new

bushing

thoroughly

clean

bushing

hole

Press

fit

bushing

so

that

its

height

above

flange

end

is

4

5

to

5

0

mm

0

177

to

0

197

in

Do

not

oil

bushing

EM418

Fig

EM

67

Press

fitting

new

pilot

bush

ng

BUSHING

AND

BEARING

MEASUREMENT

OF

MAIN

BEARING

CLEARANCE

I

Thoroughly

clean

all

bearings

and

check

for

scratches

melting

score

or

wear

Replace

bearings

if

any

fault

is

detected

2

Crankshaft

journals

and

bearings

should

be

clean

and

free

from

dust

and

dirt

before

oil

clearance

is

measured

3

Set

main

bearing

on

cap

block

4

Cut

a

plastigage

to

width

of

bear

ing

and

place

it

in

parallel

with

crank

pin

getting

clear

of

the

oil

hole

Install

cap

on

the

assembly

and

tighten

them

together

to

the

specified

torque

Tightening

torque

4

5

to

5

5

kg

m

33

to

40

ft

lb

Page 69 of 537

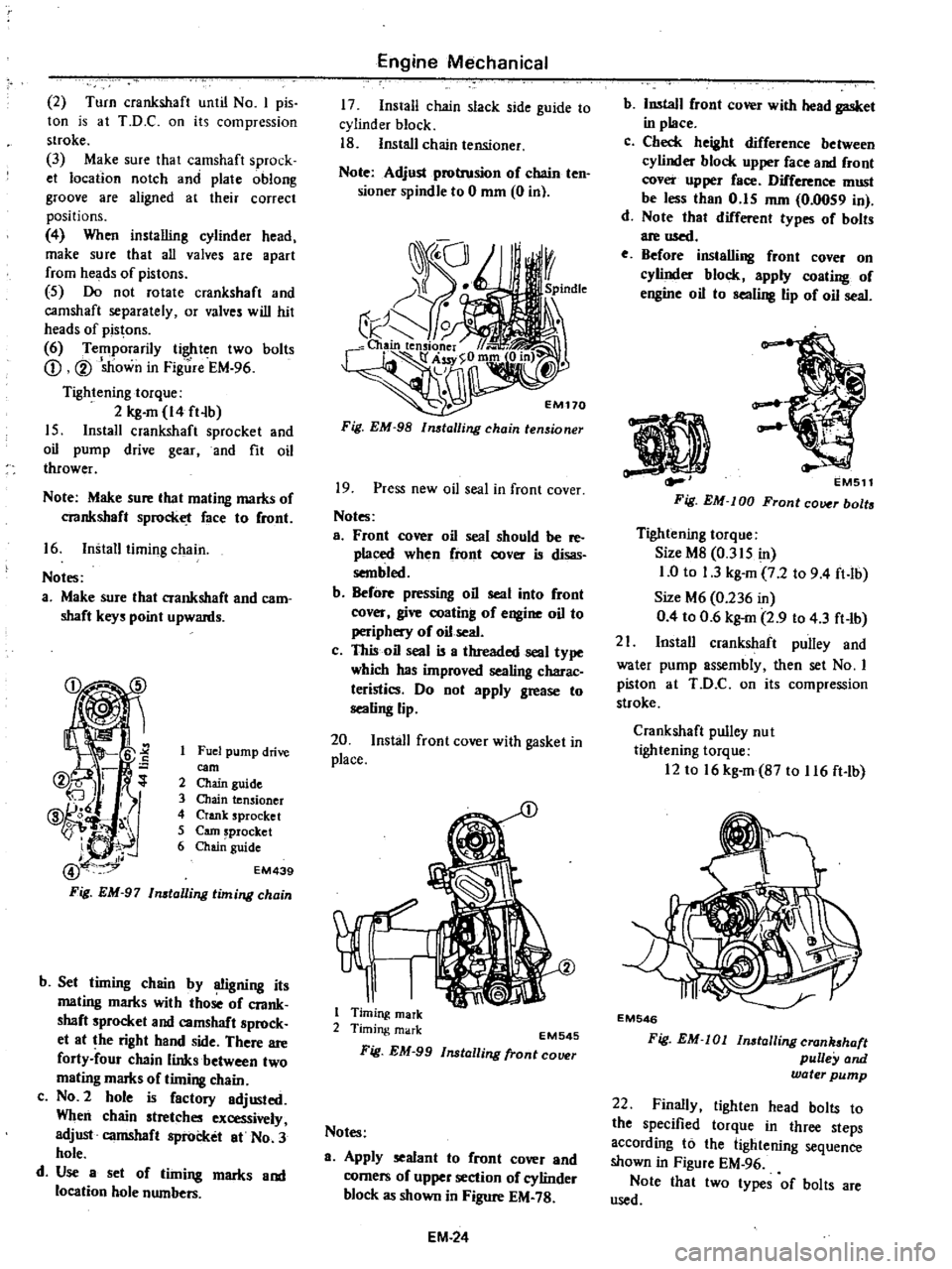

2

Turn

crankshaft

until

No

I

pis

ton

is

at

T

D

C

on

its

compression

stroke

3

Make

sure

thai

camshaft

sprock

et

location

notch

and

plate

oblong

groove

are

aligned

at

their

correct

positions

4

When

installing

cylinder

head

make

sure

that

all

valves

are

apart

from

heads

of

pistons

5

Do

not

rotate

crankshaft

and

camshaft

separately

or

valves

will

hit

heads

of

pistons

6

Temporarily

tighten

two

bolts

CD

V

sJiown

in

Fig

re

EM

96

Tightening

torque

2

kg

m

14

ft

b

15

Install

crankshaft

sprocket

and

oil

pump

drive

gear

and

fit

oil

thrower

Note

Make

sure

lhat

maling

marks

of

crankshaft

sprocket

face

10

Cront

16

Install

timing

chain

Noles

a

Make

sure

that

crankshaft

and

cam

shaft

keys

point

upwards

Fuel

pump

drive

earn

2

Chain

guide

3

Chain

tensioner

4

Crank

sprocket

5

earn

sprocket

6

Chai

guide

EM439

b

Set

timing

chain

by

OOgning

its

mating

marks

with

those

oC

crank

shaft

sprocket

and

camshaft

sprock

et

at

the

right

hand

side

There

are

forty

four

chain

links

between

two

mating

marks

of

timing

chain

c

NO

2

hole

is

Cactory

adjusted

When

chain

stretches

excessively

adjust

camshaft

sprocket

at

No

3

hole

d

Use

a

set

of

timing

marks

and

location

hole

numbers

Engine

Mechanical

17

Install

chain

slack

side

guide

to

cylinder

block

18

Install

chain

tensioner

Note

Adjust

protrusion

oC

chain

ten

sioner

spindle

to

0

mm

0

in

Fig

EM

98

lmtalling

chain

tensioner

19

Press

new

oil

seal

in

front

cover

Notes

a

Front

cover

oil

seal

should

be

reo

placed

when

Cront

cover

is

disas

sembled

b

BeCore

pressing

oil

seal

into

Cront

cover

give

coating

of

engine

oil

to

periphery

of

oil

seal

c

This

oil

seal

is

a

threaded

seal

type

which

has

improved

sealing

charac

teristics

Do

not

apply

grease

to

sealing

lip

20

Install

front

cover

with

gasket

in

place

1

Timing

mark

2

Timing

mark

EM545

Fig

EM

99

Installing

fronl

COlHlr

Notes

a

Apply

sealant

to

Cront

cover

and

corners

oC

upper

section

of

cylinder

block

as

shown

in

Figure

EM

78

EM

24

b

Install

Cront

cover

with

head

gasket

in

place

c

Check

height

diCCerence

between

cylinder

block

upper

Cace

and

Cront

cover

upper

Cace

DifCerence

must

be

less

than

0

15

mm

0

0059

in

d

Note

that

difCerent

types

oC

bolts

are

used

e

Before

installing

front

cover

on

cylinder

block

apply

coating

oC

engine

oil

10

sealing

lip

of

oil

seal

EMS11

Fig

EM

lOD

Front

cover

bolts

Tightening

torque

Size

M8

0

315

in

1

0

to

1

3

kg

m

7

2

to

9

4

ft

lb

Size

M6

0

236

in

0

4

to

0

6

kg

m

2

9

to

4

3

ft

lb

21

Install

crankshaft

pulley

and

water

pump

assembly

then

set

No

I

piston

at

ToO

C

on

its

compression

stloke

Crankshaft

pulley

nu

I

tightening

torque

12

to

16

kg

m

B7

to

116

ft

lb

EM546

Fig

EM

Ol

lnstallingcran

haft

pulley

and

water

pump

22

Finally

tighten

head

bolts

to

the

specified

torque

in

three

steps

according

to

the

lightening

sequence

shown

in

Figure

EM

96

Note

thai

Iwo

types

of

bolts

are

used

Page 73 of 537

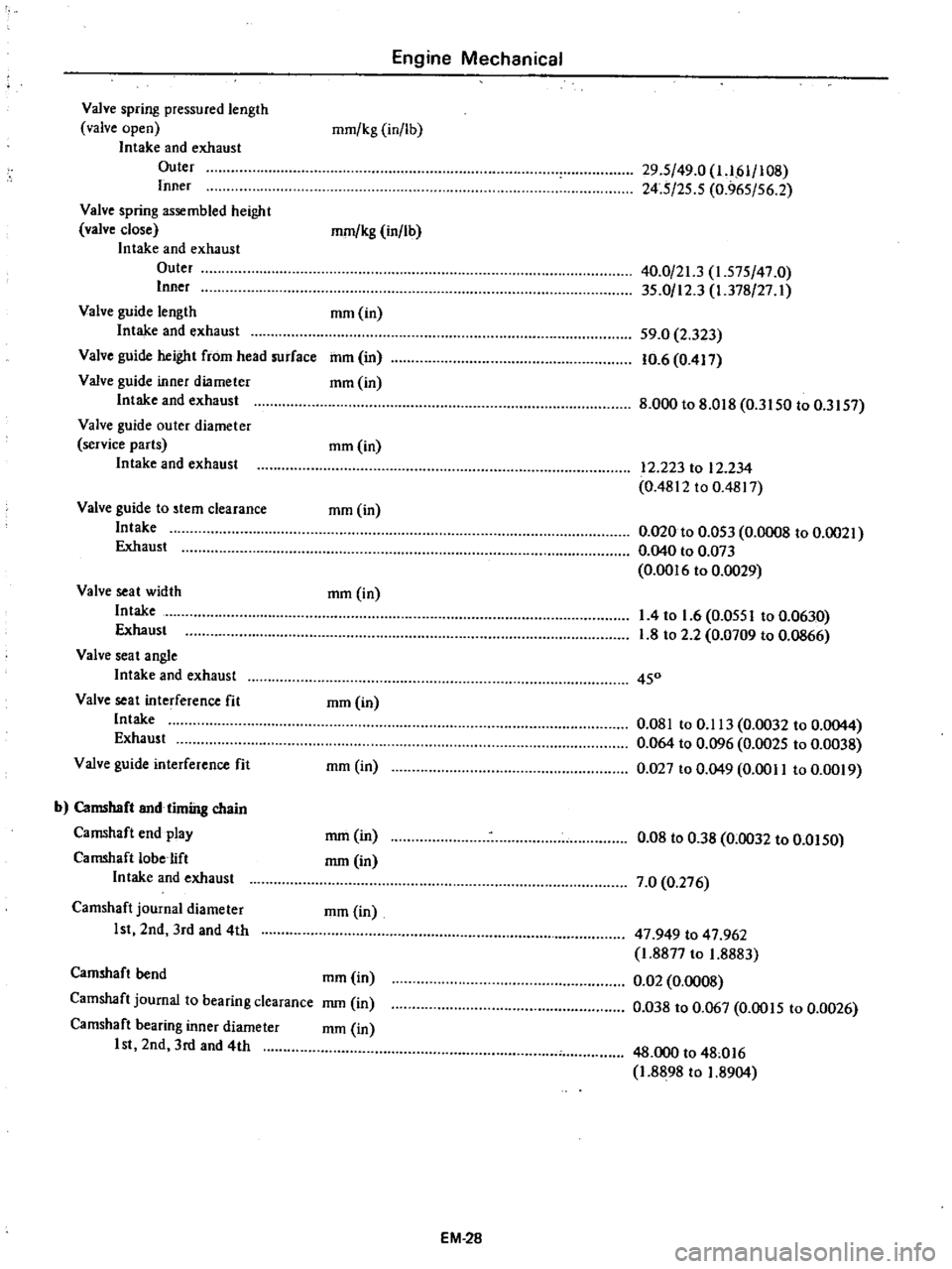

Valve

spring

pressured

length

valve

open

Intake

and

exhaust

Outer

Inner

Valve

spring

assembled

height

valve

close

Intake

and

exhaust

Outer

Inner

Valve

guide

length

Intake

and

exhaust

Valve

guide

height

from

head

surface

Valve

guide

inner

diameter

Intake

and

exhaust

Valve

guide

outer

diameter

service

parts

Intake

and

exhaust

Valve

guide

to

stem

clearance

Intake

Exhaust

Valve

seat

width

Intake

Exhaust

Valve

seat

angle

Intake

and

exhaust

Valve

seat

interference

fit

Intake

Exhaust

Valve

guide

interference

fit

b

Camshaft

and

timing

chain

Camshaft

end

play

Camshaft

lobe

ift

Intake

and

exhaust

Camshaft

joumal

diameter

1st

2nd

3rd

and

4th

Engine

Mechanical

mm

kg

in

lb

mm

kg

in

lb

mm

in

mIll

in

mm

in

mm

in

mm

in

mm

in

mm

in

mm

in

rnm

in

rnm

in

mm

in

Camshaft

bend

mm

in

Camshaft

journal

to

bearing

clearance

mm

in

Camshaft

bearing

inner

diameter

rnm

in

1st

2nd

3rd

and

4th

29

5

49

0

1

IM

108

24

5

25

5

0

965

56

2

40

0

21

3

1

575

47

0

35

0

12

3

1

378

27

I

59

0

2

323

10

6

0

417

8

000

to

8

018

0

3150

to

0

3157

12

223

to

12

234

0

4812

to

0

4817

0

020

to

0

053

0

0008

to

0

0021

0

040

to

0

073

0

0016

to

0

0029

1

4

to

1

6

0

0551

to

0

0630

1

8

to

2

2

0

0709

to

0

0866

450

0

081

to

0

113

0

0032

to

0

0044

0

064

to

0

096

0

0025

to

0

0038

0

027

to

0

049

0

0011

to

0

0019

0

08

to

038

0

0032

to

0

0150

7

0

0

276

47

949

to

47

962

1

8877

to

1

8883

0

02

0

0008

0

Q38

to

0

067

0

00

I

5

to

0

0026

48

000

to

48

016

1

8898

to

1

8904

EM

28

Page 75 of 537

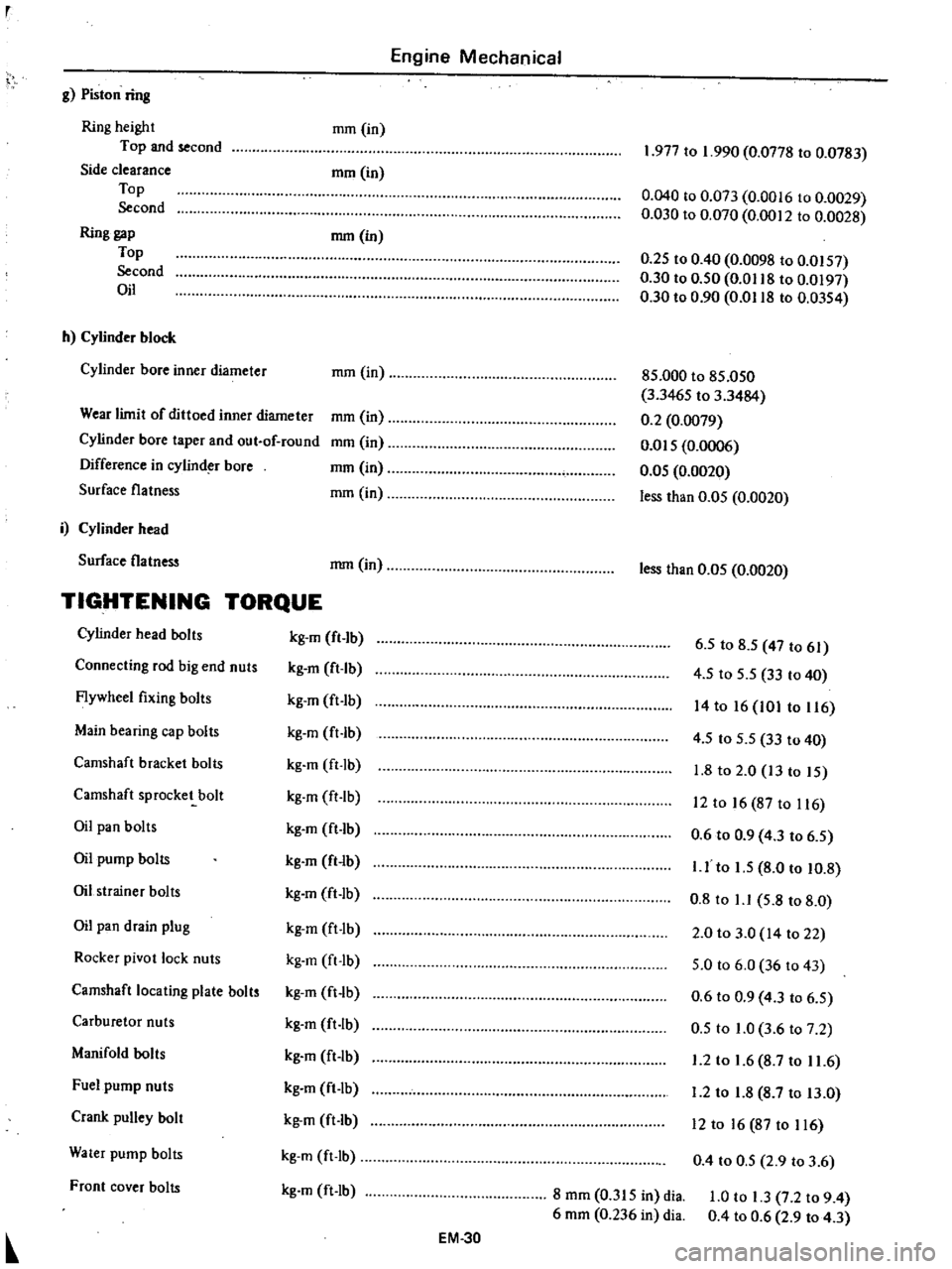

Engine

Mechanical

g

Piston

ring

Ring

height

Top

and

second

Side

clearance

Top

Second

Ring

gap

Top

Second

Oil

mm

in

mrn

in

mm

in

h

Cylinder

block

Cylinder

bore

inner

diameter

mm

in

Wear

limit

of

dittoed

inner

diameter

Cylinder

bore

taper

and

out

of

round

Difference

in

cylind

bore

Surface

flatness

mm

in

mm

in

mm

in

mm

in

i

Cylinder

head

Surface

flatness

mm

in

TIGHTENING

TORQUE

Cylinder

head

bolts

kg

m

fl

lb

Connecting

rod

big

end

nuts

kg

m

ft

Ib

Flywheel

fixing

bolts

kg

m

ft

Ib

Main

bearing

cap

bolts

kg

m

ft

lb

Camshaft

bracket

bolts

kg

m

ft

lb

Camshaft

sprocket

bolt

kg

m

ft

lb

Oil

pan

bolts

kg

m

ft

1b

Oil

pump

bolts

kg

m

ft

lb

Oil

strainer

bolts

kg

m

ft

lb

Oil

pan

drain

plug

kg

m

ft

lb

Rocker

pivot

lock

nuts

kg

m

ft

Ib

Camshaft

locating

plate

bolts

kg

m

ft

lb

Carburetor

nuts

kg

m

ft

lb

Manifold

bolts

kg

m

ft

lb

Fuel

pump

nuts

kg

m

ft

lb

Crank

pulley

bolt

kg

m

ft

lb

Water

pump

bolts

kg

m

ft

Ib

Front

cover

bolts

kg

m

ft

lb

EM

30

1

977

to

1

990

0

0778

to

0

0783

0

040

to

0

073

0

0016

to

0

0029

0

030

to

0

070

0

0012

to

0

0028

0

25

to

0

40

0

0098

to

0

0157

0

30

to

0

50

0

0118

to

0

0197

0

30

to

0

90

0

0118

to

0

0354

85

000

to

85

050

3

3465

to

3

3484

0

2

0

0079

om

5

0

0006

0

05

0

0020

less

than

0

05

0

0020

less

than

0

05

0

0020

6

5

to

8

5

47

to

61

4

5

to

5

5

33

to

40

14

to

16

101

to

116

4

5

to

5

5

33

to

40

1

8

to

2

0

13

to

15

12

to

16

87

to

116

0

6

to

0

9

4

3

to

6

5

I

J

to

1

5

8

0

to

10

8

0

8

to

1

1

5

8

to

8

0

2

0

to

3

0

14

to

22

5

0

to

6

0

36

to

43

0

6

to

0

9

4

3

to

6

5

0

5

to

1

0

3

6

to

7

2

1

2

to

1

6

8

7

to

11

6

1

2

to

1

8

8

7

to

13

0

12

to

16

87

to

116

0

4

to

0

5

2

9

to

3

6

8

mm

0

315

in

dia

6

mm

0

236

in

dia

1

0

to

1

3

7

2

to

9

4

0

4

to

0

6

2

9

to

4

3

Page 164 of 537

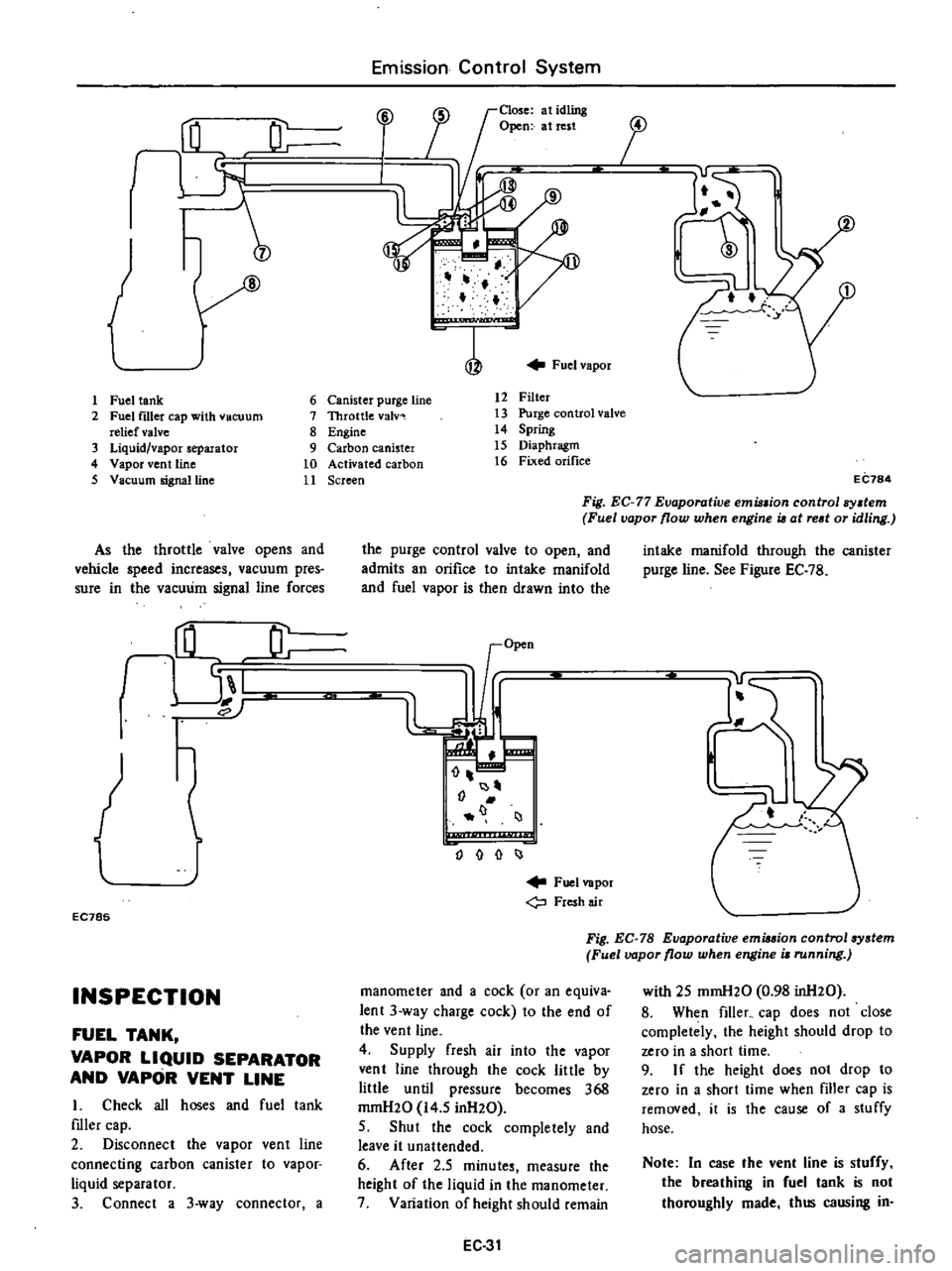

J

1

Fuel

tank

2

Fuel

f1l1er

cap

with

vacuum

relief

valve

3

Liquid

vapor

separator

4

Vapor

vent

line

5

Vacuum

signalUne

As

the

throttle

valve

opens

and

vehicle

speed

increases

vacuum

pres

sure

in

the

vacuum

signal

line

forces

rHL

JL

I

EC785

INSPECTION

FUEL

TANK

VAPOR

LIQUID

SEPARATOR

AND

VAPOR

VENT

LINE

I

Check

all

hoses

and

fuel

tank

mler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

vapor

liquid

separator

3

Connect

a

3

way

connector

a

Emission

Control

System

Close

at

idling

Open

at

rest

i

J

17

f

Fuel

vapor

6

Canister

purge

line

7

Throttle

valv

8

Engine

9

Carbon

canister

10

Activated

carbon

11

Screen

12

Filter

13

Purge

control

valve

14

Spring

15

Diaphragm

16

Fixed

orifice

i

j

EC784

Fig

EC

77

Evaporative

emu

ion

control

sy

tem

Fuel

vapor

flow

when

engine

i6

at

red

or

idling

the

purge

control

valve

to

open

and

admits

an

orifice

to

intake

manifold

and

fuel

vapor

is

then

drawn

into

the

I

J

o

I

Fuel

vapor

Fresh

air

intake

manifold

through

the

canister

purge

line

See

Figure

EC

7B

Fig

EC

78

Evaporative

emiuion

control

system

Fuel

vapor

flow

when

engine

i

running

manometer

and

a

cock

or

an

equiva

lent

3

way

charge

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mrnH20

14

5

inH20

5

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

EC

31

with

25

mmH20

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

removed

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thus

causing

in

Page 225 of 537

l

t

tJ

I

P

o

CUll

Fig

CL

9

Lubricating

poinu

of

withdrawal

lever

and

front

cover

4

Contact

surfaces

of

transmission

main

drive

gear

splines

lithium

base

grease

including

molybdenum

disul

phide

Note

Very

IIIIJllII

amount

of

grease

should

be

ated

to

the

above

points

If

too

much

iubricant

is

applied

it

will

run

out

on

the

friction

plates

when

hot

resulting

in

d

gi

dutch

disc

facings

3

Install

retainer

spring

to

with

drawal

lever

Fit

holder

spring

to

release

bearing

and

sleeve

assembly

then

assemble

withdrawal

Iever

and

bearing

sleeve

as

a

unit

Install

this

assembly

on

transmission

case

Then

install

dust

cover

Pilot

bushing

Before

installing

a

new

bushing

thoroughly

clean

bushing

hole

Install

bushing

in

crankshaft

using

a

soft

hammer

Bushing

need

not

be

oiled

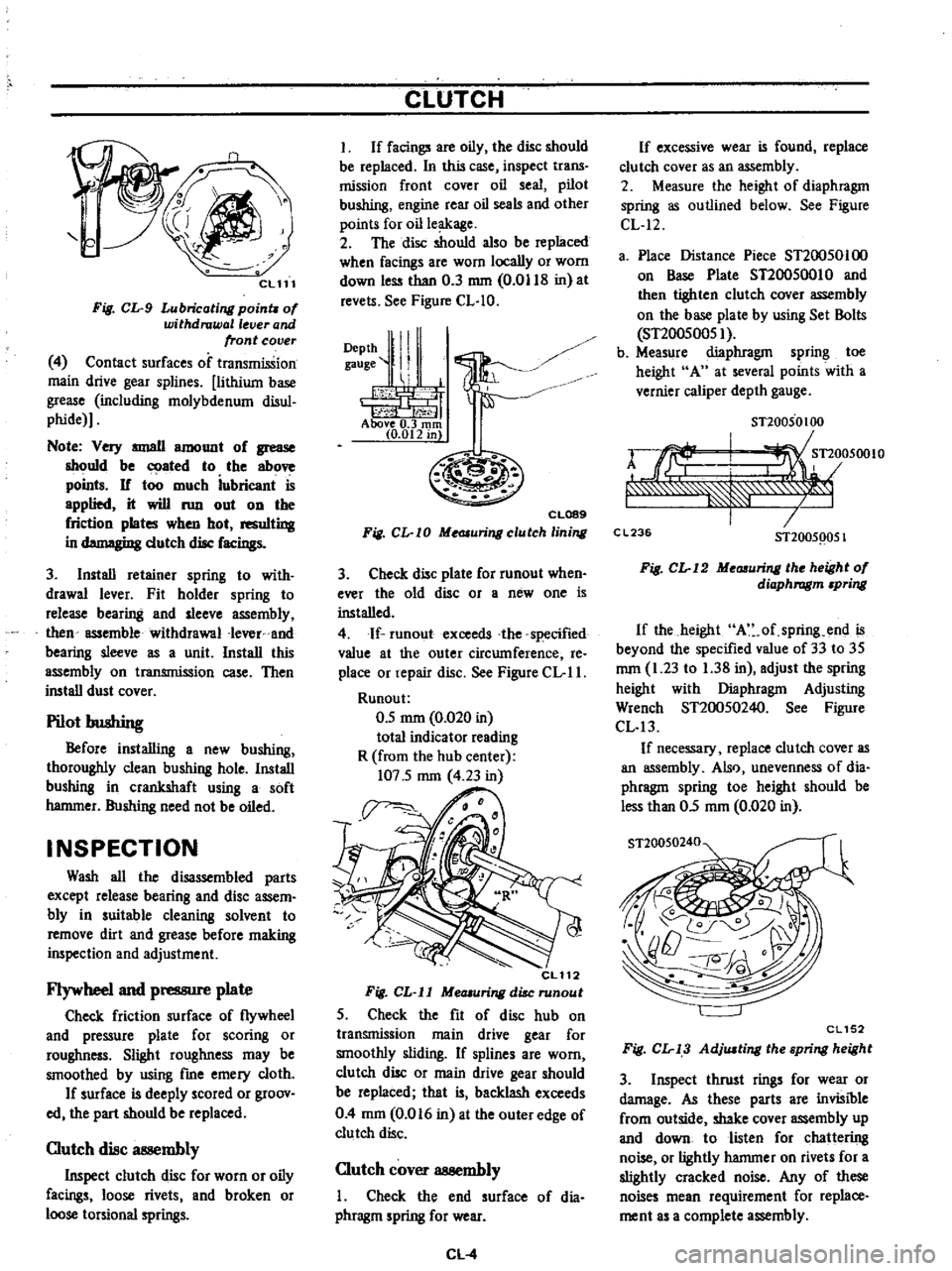

INSPECTION

Wash

all

the

disassembled

parts

except

release

bearing

and

disc

assem

bly

in

suitable

cleaning

solvent

to

remove

dirt

and

grease

before

making

inspection

and

adjustment

Flywheel

and

pressure

plate

Check

friction

surface

of

flywheel

and

pressure

plate

for

scoring

or

roughness

Slight

roughness

may

be

smoothed

by

using

fme

emery

cloth

If

surface

is

deeply

scored

or

groov

ed

the

part

should

be

replaced

Clutch

disc

at

llembly

Inspect

clutch

disc

for

worn

or

oily

facings

loose

rivets

and

broken

or

loose

torsional

springs

CLUTCH

I

If

facings

are

oily

the

disc

should

be

replaced

In

this

case

inspect

trans

mission

front

cover

oil

seal

pilot

bushing

engine

rear

oil

seals

and

other

points

for

oil

leakage

2

The

disc

should

also

be

replaced

when

facings

are

worn

locally

or

worn

down

less

than

0

3

mm

0

0118

in

at

revels

See

Figure

CL

IO

DePth

ll

I

gauge

II

1

i

h

1

j1

t

f

Above

0

3

rom

10

012

in

CL089

Fig

CL

I0

Me

JIuringclutch

lining

3

Check

disc

plate

for

runout

when

ever

the

old

disc

or

a

new

one

is

installed

4

If

runoutexceeds

the

specified

value

at

the

outer

circumference

Ie

place

or

repair

disc

See

Figure

CL

II

Runou

t

0

5

mm

0

020

in

total

indicator

reading

R

from

the

hub

center

107

5

mm

4

23

in

CL112

Fig

CL

ll

MeOlUring

disc

runout

5

Check

the

fit

of

disc

hub

on

transmission

main

drive

gear

for

smoothly

sliding

If

splines

are

worn

clutch

disc

or

main

drive

gear

should

be

replaced

that

is

backlash

exceeds

0

4

mm

0

016

in

at

the

outer

edge

of

clutch

disc

Clutch

cover

assembly

I

Check

the

end

surface

of

dia

phragm

spring

for

wear

CL

4

If

excessive

wear

is

found

replace

clu

tch

cover

as

an

assembly

2

Measure

the

height

of

diaphragm

spring

as

outlined

below

See

Figure

CL

12

a

Place

Distance

Piece

ST20050100

on

Base

Plate

ST20050010

and

then

tighten

clutch

cover

assembly

on

the

base

plate

by

using

Set

Bolls

ST20050051

b

Measure

diaphragm

spring

toe

height

A

at

several

points

with

a

vernier

caliper

depth

gauge

STl0050100

rJrf

I

Tl

05001O

f

7

C

L23

STl005Q051

Fig

CL

12

Me

uring

the

height

of

diaphragm

pring

If

the

height

A

of

spring

end

is

beyond

the

specified

value

of

33

to

35

mm

1

23

to

1

38

in

adjust

the

spring

height

with

Diaphragm

Adjusting

Wrench

ST20050240

See

Figure

CL

13

If

necessary

replace

clutch

cover

as

an

assembly

Also

unevenness

of

dia

phragm

spring

toe

height

should

be

less

than

05

mm

0

020

in

ST20050240

CL152

Fig

CL

13

AdjlUting

the

spring

height

3

Inspect

thrust

rings

for

wear

or

damage

As

these

parts

are

invisible

from

outside

shake

cover

assembly

up

and

down

to

listen

for

chattering

noise

or

lightly

hammer

on

rivets

for

a

slightly

cracked

noise

Any

of

these

noises

mean

requirement

for

replace

ment

as

a

complete

assembly