height DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 358 of 537

s

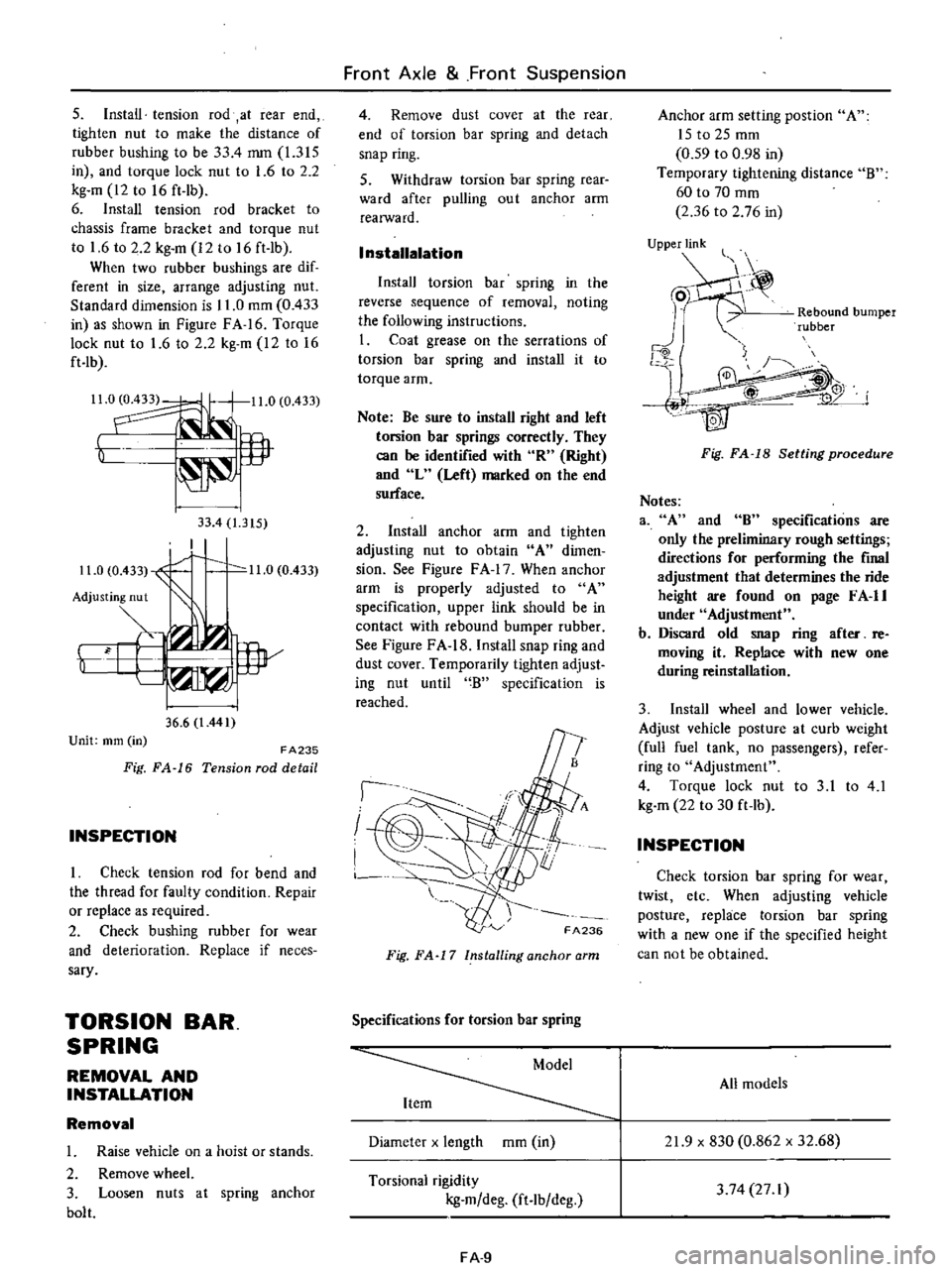

Install

tension

rod

at

rear

end

tighten

nut

to

make

the

distance

of

rubber

bushing

to

be

33

4

mm

1

315

in

and

torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

6

Install

tension

rod

bracket

to

chassis

frame

bracket

and

torque

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

When

two

rubber

bushings

are

dif

ferent

in

size

arrange

adjusting

nut

Standard

dimension

is

11

0

mOl

0

433

in

as

shown

in

Figure

FA

16

Torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

Il

0

11

0

0

433

t

lP

33

4

1

315

I

11

0

0

433

1

0

11

0

0

433

Adjusting

nut

Y

i

w

36

6

l

441

Unit

mm

in

FA235

Fig

FA

16

Tension

rod

detail

INSPECTION

I

Check

tension

rod

for

bend

and

the

thread

for

faulty

condition

Repair

or

replace

as

required

2

Check

bushing

rubber

for

wear

and

deterioration

Replace

if

neces

sary

TORSION

BAR

SPRING

REMOVAL

AND

INSTALLATION

Removal

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

nuts

at

spring

anchor

bolt

Front

Axle

Front

Suspension

4

Remove

dust

cover

at

the

rear

end

of

torsion

bar

spring

and

detach

snap

ring

S

Withdraw

torsion

bar

spring

rear

ward

after

pulling

ou

t

anchor

arm

realWard

I

nstallalation

Install

torsion

bar

spring

in

the

reverse

sequence

of

removal

noting

the

following

instructions

I

Coat

grease

on

the

serrations

of

torsion

bar

spring

and

install

it

to

torque

arm

Note

Be

sure

to

install

right

and

left

torsion

bar

springs

correctly

They

can

be

identified

with

R

Right

and

L

Left

marked

on

the

end

surface

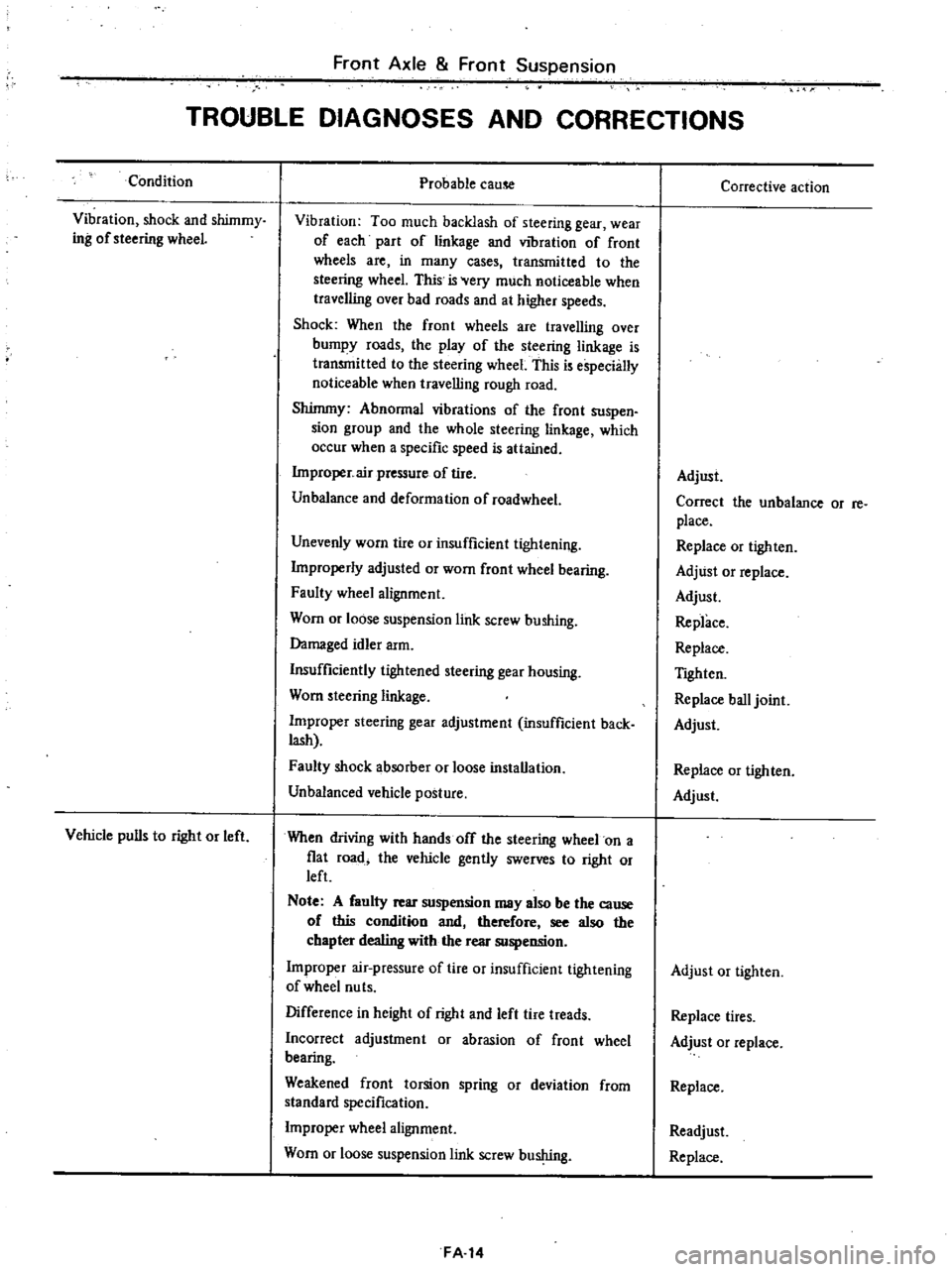

2

Install

anchor

arm

and

tighten

adjusting

nut

to

obtain

A

dimen

sion

See

Figure

F

A

17

When

anchor

arm

is

properly

adjusted

to

A

specification

upper

link

should

be

in

contact

with

rebound

bumper

rubber

See

Figure

FA

18

Install

snap

ring

and

dust

cover

Temporarily

tighten

adjust

ing

nut

until

B

specification

is

reached

I

I

I

FA236

Fig

FA

17

Installing

anchor

arm

Specifications

for

torsion

bar

spring

Diameter

x

length

mOl

in

Torsional

rigidity

kg

m

deg

ft

lb

deg

FA

9

Anchor

arm

setting

post

ion

A

ISt02Smm

0

59

to

0

98

in

Temporary

tightening

distance

B

60

to

70

mOl

2

36

to

2

76

in

UjPPje

Rebound

bumper

rubber

j

4W

Fig

FA

18

Setting

procedure

Notes

3

A

and

8

specifications

are

only

the

preliminary

rough

settings

directions

for

performing

the

final

adjustment

that

determines

the

ride

height

are

found

on

page

F

A

II

under

Adjustment

b

Discard

old

snap

ring

after

re

moving

it

Replace

with

new

one

during

reinstallation

3

Install

wheel

and

lower

vehicle

Adjust

vehicle

posture

at

curb

weight

full

fuel

tank

no

passengers

refer

ring

to

Adjustment

4

Torque

lock

nut

to

3

1

to

4

1

kg

m

22

to

30

ft

lb

INSPECTION

Check

torsion

bar

spring

for

wear

twist

etc

When

adjusting

vehicle

posture

replace

torsion

bar

spring

with

a

new

one

if

the

specified

height

can

not

be

obtained

All

models

21

9

x

830

0

862

x

32

68

3

74

27

I

Page 363 of 537

Front

Axle

Front

Suspension

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Condition

Vibration

shock

and

shimmy

ing

of

steering

wheeL

Vehicle

pulls

to

right

or

left

Probable

cause

Vibration

Too

much

backlash

of

steering

gear

wear

of

each

part

of

linkage

and

vibration

of

front

wheels

are

in

many

cases

transmitted

to

the

steering

wheel

This

is

Very

much

noticeable

when

traveJling

over

bad

roads

and

at

higher

speeds

Shock

When

the

front

wheels

are

travelling

over

bumpy

roads

the

play

of

the

steering

linkage

is

transmitted

to

the

steering

wheel

This

is

especially

noticeable

when

travelling

rough

road

Shimmy

Abnormal

vibrations

of

the

front

suspen

sion

group

and

the

whole

steering

linkage

which

occur

when

a

specific

speed

is

attained

Improper

air

pressure

of

tire

Unbalance

and

deformation

of

roadwheel

Unevenly

worn

tire

or

insufficient

tightening

Improperly

adjusted

or

worn

front

wheel

bearing

Faulty

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

Damaged

idler

arm

Insufficiently

tightened

steering

gear

housing

Worn

steering

linkage

Improper

steering

gear

adjustment

insufficient

back

lash

Faulty

shock

absorber

or

loose

installation

Unbalanced

vehicle

posture

When

driving

with

hands

off

the

steering

wheel

on

a

fiat

road

the

vehicle

gently

swerves

to

right

or

left

Note

A

faulty

rear

suspension

may

also

be

the

cause

of

this

condition

and

therefore

see

also

the

chapter

dealing

with

the

rear

suspension

Improper

air

pressure

of

tire

or

insufficient

tightening

of

wheel

nu

ts

Difference

in

height

of

right

and

left

tire

treads

Incorrect

adjustment

or

abrasion

of

front

wheel

bearing

Weakened

front

torsion

spring

or

deviation

from

standard

specification

Improper

wheel

alignment

Worn

or

loose

suspension

link

screw

bushing

FA

14

Corrective

action

Adjust

Correct

the

unbalance

or

re

place

Replace

or

tighten

Adjust

or

replace

Adjust

Replace

Replace

TIghten

Replace

ball

joint

Adjust

Replace

or

tighten

Adjust

Adjust

or

tighten

Replace

tires

Adjust

or

replace

Replace

Readjust

Replace

Page 377 of 537

The

620

series

vehicles

are

equip

ped

with

hydraulic

brakes

on

the

four

wheels

and

mechanical

hand

brakes

on

the

rear

wheels

The

front

brake

is

the

uni

servo

type

and

the

rear

the

duo

servo

with

the

built

in

hand

BRAKE

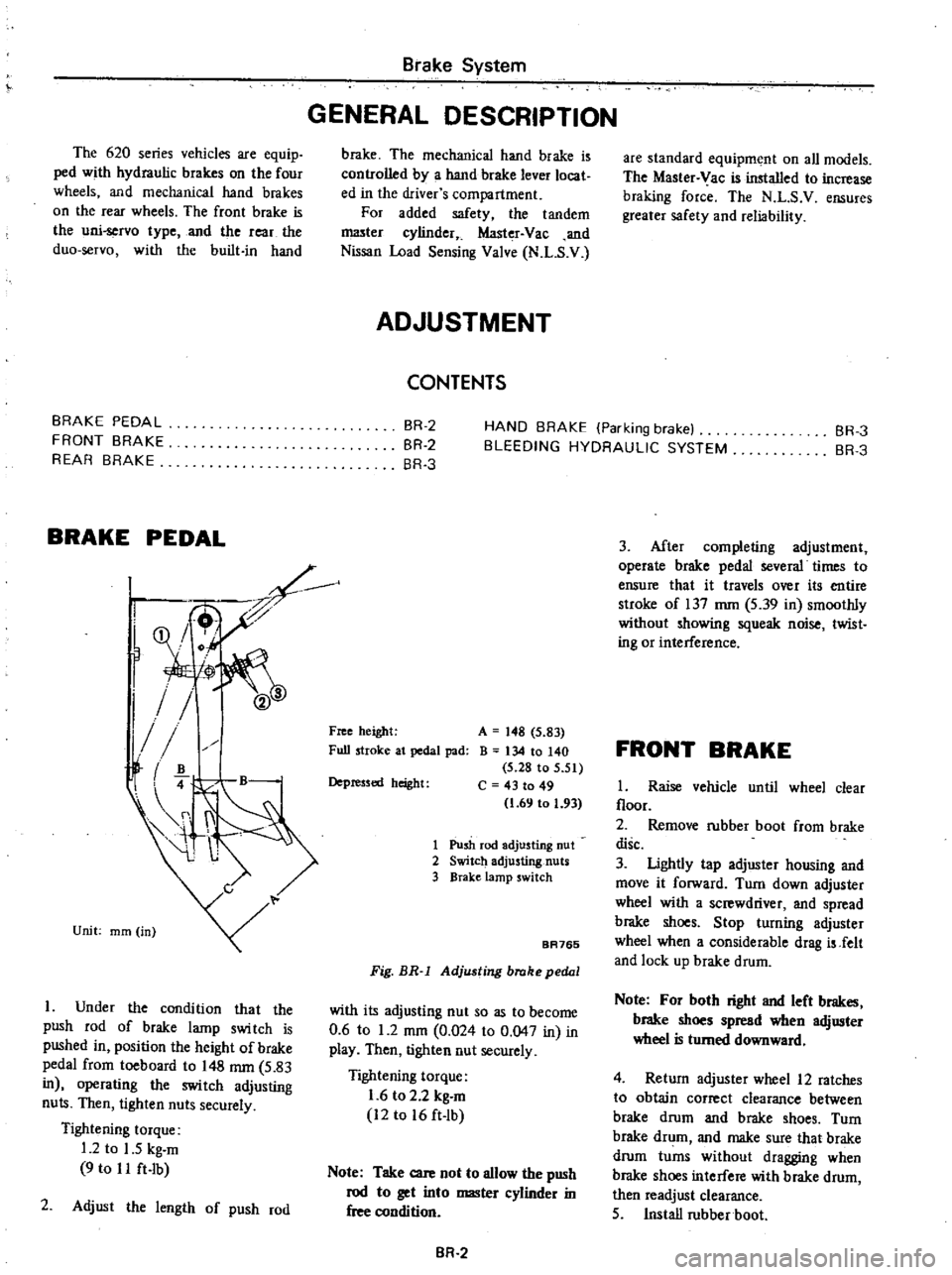

PEDAL

FRONT

BRAKE

REAR

BRAKE

BRAKE

PEDAL

Qi

f

l

II

t

Unit

mm

in

I

Under

the

condition

that

the

push

rod

of

brake

lamp

swi

tch

is

pushed

in

position

the

height

of

brake

pedal

from

toeboard

to

148

mm

5

83

in

operating

the

switch

adjusting

nuts

Then

tighten

nuts

securely

Tightening

torque

1

2

to

1

5

kg

m

9

to

I

I

ft

Ib

2

Adjust

the

length

of

push

rod

Brake

System

GENERAL

DESCRIPTION

brake

The

mechanical

hand

brake

is

controlled

by

a

hand

brake

lever

locat

ed

in

the

driver

s

compartment

For

added

safety

the

tandem

I

1lI3ter

cylinder

Master

Vac

and

Nissan

Load

Sensing

Valve

N

L

S

V

ADJUSTMENT

CONTENTS

are

standard

equipment

on

all

models

The

Master

Vac

is

installed

to

increase

braking

force

The

N

L

S

V

ensures

greater

safety

and

reliability

BR

2

BR

2

BR

3

HAND

BRAKE

Parking

brake

BLEEDING

HYDRAULIC

SYSTEM

BR

3

BR

3

Free

height

Full

stroke

at

pedal

pad

A

148

5

83

B

134

10

140

5

28

to

5

51

C

43

to

49

1

69

to

1

93

Depressed

height

1

Push

rod

adjusting

nut

2

Switch

adjusting

nuts

3

BraKe

lamp

switch

BA765

Fig

BR

l

Adjusting

brake

pedal

with

its

adjusting

nut

so

as

to

become

0

6

to

1

2

mOl

0

024

to

0

047

in

in

play

Then

tigh1en

nut

securely

Tightening

torque

1

6

to

2

2

kg

m

12

to

16

ft

lb

Note

Take

care

not

to

allow

the

push

rod

to

get

into

master

cylinder

in

free

condition

BR

2

3

After

completing

adjustment

operate

brake

pedal

several

times

to

ensure

that

it

travels

over

its

entire

stroke

of

137

mm

5

39

in

smoothly

without

showing

squeak

noise

twist

ing

or

interference

FRONT

BRAKE

1

Raise

vehicle

until

wheel

clear

floor

2

Remove

rubber

boot

from

brake

disc

3

Ughtly

tap

adjuster

housing

and

move

it

forward

Turn

down

adjuster

wheel

with

a

screwdriver

and

spread

brake

shoes

Stop

turning

adjuster

wheel

when

a

considerable

drag

is

Jelt

and

lock

up

brake

drum

Note

For

both

right

and

left

brakes

brake

shoes

spread

when

adjuster

wheel

is

turned

downward

4

Return

adjuster

wheel

12

ratches

to

obtain

correct

clearance

between

brake

drum

and

brake

shoes

Turn

brake

drum

and

make

sure

that

brake

drum

turns

without

dragging

when

brake

shoes

interfere

with

brake

drum

then

readjust

clearance

5

Install

rubber

boot

Page 395 of 537

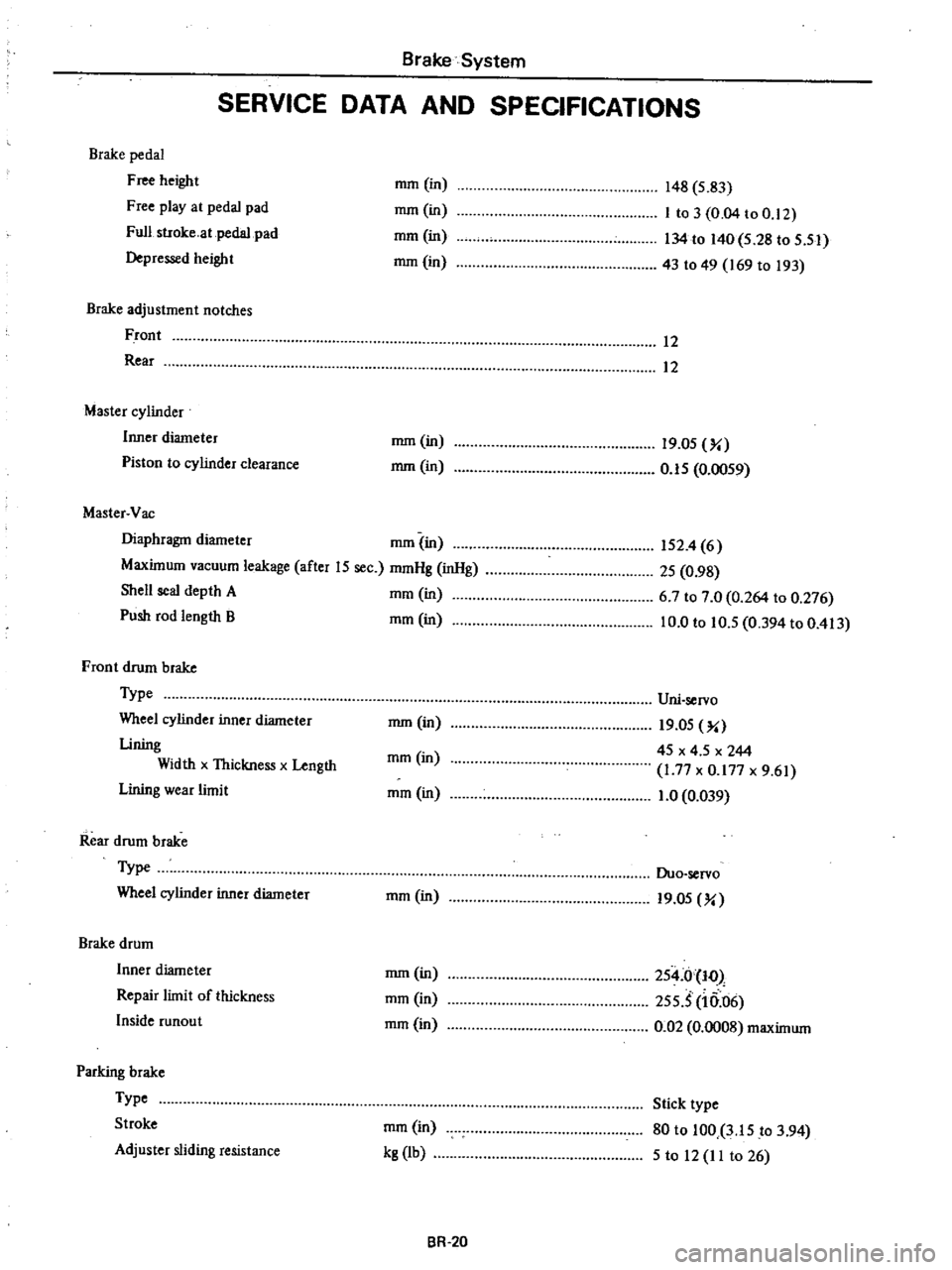

Brake

System

SERVICE

DATA

AND

SPECIFICATIONS

Brake

pedal

Free

height

Free

play

at

pedal

pad

Full

stroke

at

pedal

pad

Depressed

height

mOl

in

mOl

in

mOl

in

mm

in

148

S

83

I

to

3

0

04

to

0

12

134

to

140

5

28

to

S

51

43

to

49

169

to

193

Brake

adjustment

notches

Front

Rear

12

12

Master

cylinder

Inner

diameter

Piston

to

cylinder

deaJance

mm

in

mm

in

19

0S

Yo

O

IS

0

OOS9

Master

Vac

Diaphragm

diameter

mOl

in

Maximum

vacuum

leakage

after

15

sec

mmHg

inHg

Shell

seal

depth

A

mOl

in

Push

rod

length

B

mOl

in

152

4

6

2S

0

98

6

7

to

7

0

0

264

to

0

276

10

0

to

10

5

0

394

to

0

413

Front

drum

brake

Type

Wheel

cylinder

inner

diameter

Lining

Width

x

Thickness

x

Length

Lining

wear

limit

Uni

servo

mm

in

I9

0S

Yo

45

x

4

5

x

244

1

77

x

0

177

x

9

61

1

0

0

039

mm

in

mOl

in

Rear

drum

brake

Type

Wheel

cylinder

inner

diameter

Duo

servo

mOl

in

19

0S

Yo

Brake

drum

Inner

diameter

Repair

limit

of

thickness

Inside

runout

mm

in

mOl

in

mOl

in

254

0

10

2SS

S

10

06

0

02

0

0008

maximum

PaJking

brake

Type

Stroke

Adjuster

sliding

resistance

mm

in

kg

lb

Stick

type

80

to

100

3

lS

to

3

94

S

to

12

11

to

26

BR

20

Page 397 of 537

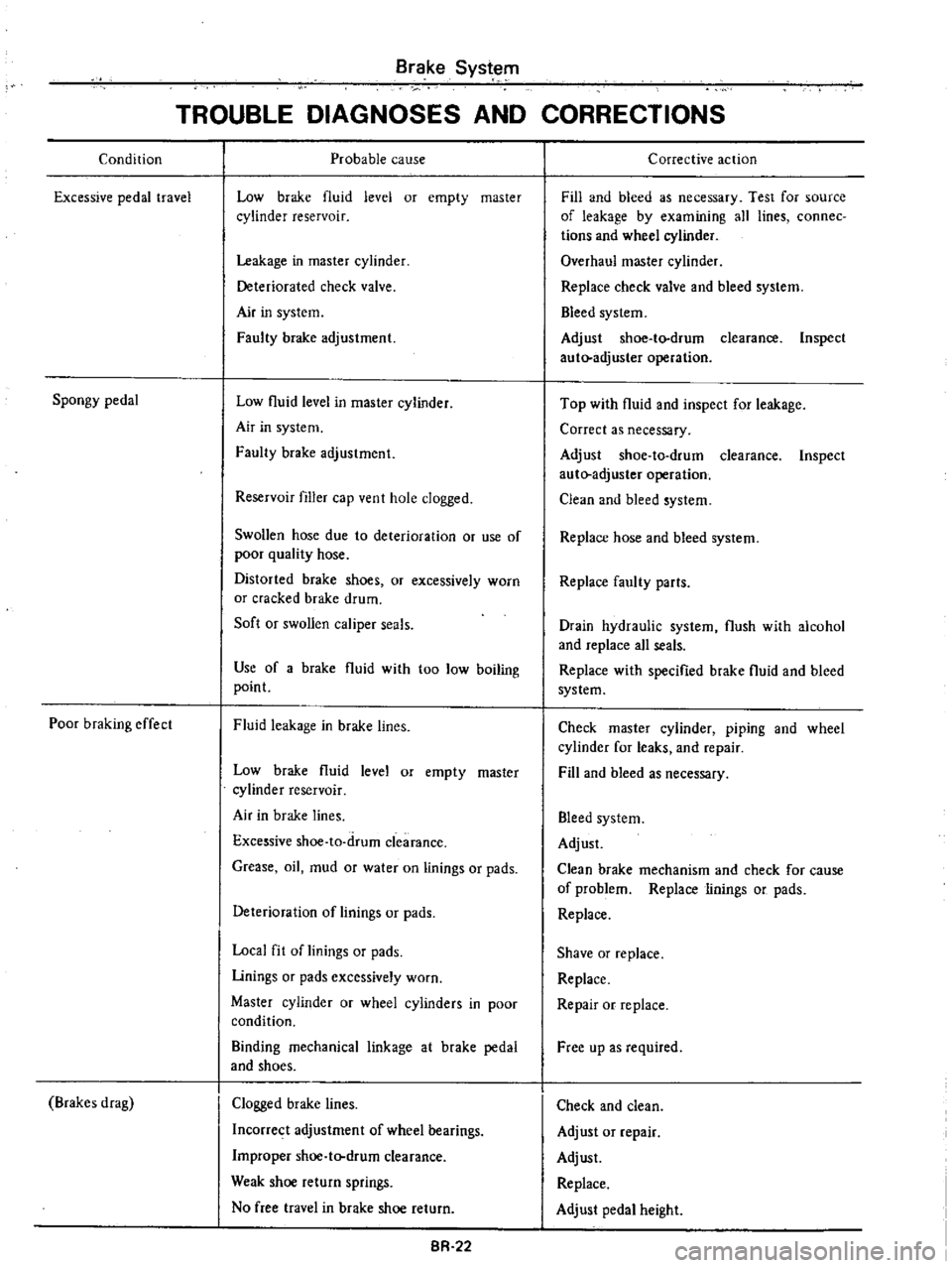

Condition

Excessive

pedal

travel

Spongy

pedal

Poor

braking

effect

Brakes

drag

Brake

Syst

em

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Low

brake

1uid

level

or

empty

master

cylinder

reservoir

Leakage

in

master

cylinder

Deteriorated

check

valve

Air

in

system

Faulty

brake

adjustment

Low

1uid

level

in

master

cylinder

Air

in

system

Faulty

brake

adjustment

Reservoir

filler

cap

vent

hole

clogged

Swollen

hose

due

to

deterioration

or

use

of

poor

quality

hose

Distorted

brake

shoes

or

excessively

worn

or

cracked

brake

drum

Soft

or

swollen

caliper

seals

Use

of

a

brake

1uid

with

too

low

boiling

point

Fluid

leakage

in

brake

lines

Low

brake

1uid

level

or

empty

master

cylinder

reservoir

Air

in

brake

lines

Excessive

shoe

ta

drum

clearance

Grease

oil

mud

or

water

on

linings

or

pads

Deterioration

of

linings

or

pads

Local

fit

of

linings

or

pads

Linings

or

pads

excessively

worn

Master

cylinder

or

wheel

cylinders

in

poor

condition

Binding

mechanical

linkage

at

brake

pedal

and

shoes

Clogged

brake

lines

Incorrect

adjustment

of

wheel

bearings

Improper

shoe

t

drum

clearance

Weak

shoe

return

springs

No

free

travel

in

brake

shoe

return

BR

22

Corrective

action

Fill

and

bleed

as

necessary

Test

for

source

of

leakage

by

examining

all

lines

connec

tions

and

wheel

cylinder

Overhaul

master

cylinder

Replace

check

valve

and

bleed

system

Bleed

system

Adjust

shoe

to

drum

clearance

Inspect

auto

adjuster

operation

Top

with

1uid

and

inspect

for

leakage

Correct

as

necessary

Adjust

shoe

to

drum

clearance

Inspect

aut

adjuster

operation

Clean

and

bleed

system

Replace

hose

and

bleed

system

Replace

faulty

parts

Drain

hydraulic

system

flush

with

alcohol

and

replace

all

seals

Replace

with

specified

brake

1uid

and

bleed

system

Check

master

cylinder

pIpIng

and

wheel

cylinder

for

leaks

and

repair

Fill

and

bleed

as

necessary

Bleed

system

Adjust

Clean

brake

mechanism

and

check

for

cause

of

problem

Replace

linings

or

pads

Replace

Shave

or

replace

Replace

Repair

or

replace

Free

up

as

required

Check

and

clean

Adjust

or

repair

Adjust

Replace

Adjust

pedal

height

Page 418 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

AND

INSTALLATION

Accelerator

wire

I

Remove

air

cleaner

assembly

2

Disconnect

accelerator

wire

from

carburetor

3

Loosen

lock

nut

and

disconnect

accelerator

wire

outer

case

from

wire

holder

See

Figure

FE

I

4

Remove

spring

clamp

and

discon

nect

accelerator

wire

from

accelerator

pedal

arm

S

Remove

two

screws

securing

ac

celerator

wire

outer

case

to

body

and

detach

accelerator

wire

6

To

install

reverse

the

order

of

removal

Apply

recommended

multi

purpose

grease

slightly

to

portion

MG

shown

in

Figure

FE

I

Accelerator

pedal

assembly

I

Remove

spring

clamp

then

dis

connect

accelerator

wire

from

tip

of

pedal

ann

2

Remove

two

screws

securing

ac

celerator

pedal

bracket

to

body

3

Remove

accelerator

pedal

from

dash

panel

See

Figure

FE

I

4

To

install

reverse

the

order

of

removal

INSPECTION

I

Check

accelerator

pedal

return

spring

for

rust

fatigue

or

damage

Replace

if

necessary

2

Check

accelerator

wire

cases

and

fastening

locations

for

rust

damage

or

looseness

Repair

or

replace

if

necessary

ADJUSTMENT

Accelerstor

pedal

and

wire

Adjust

pedal

stopper

bolt

Section

A

so

as

to

obtain

specifi

ed

height

E

as

shown

in

Figure

FE

I

Secure

pedal

stopper

bolt

with

stopper

lock

nut

Refer

to

Figure

FE

I

E

78

mOl

3

07

in

Tightening

torque

01

nut

0

38

to

0

4S

kg

m

2

7

to

3

2

ft

b

2

Release

auto

choke

effect

since

throttle

lever

is

opened

by

fast

idle

earn

until

engine

warms

up

I

Keep

choke

valve

fully

open

with

fingers

2

Pull

throttle

lever

up

by

hand

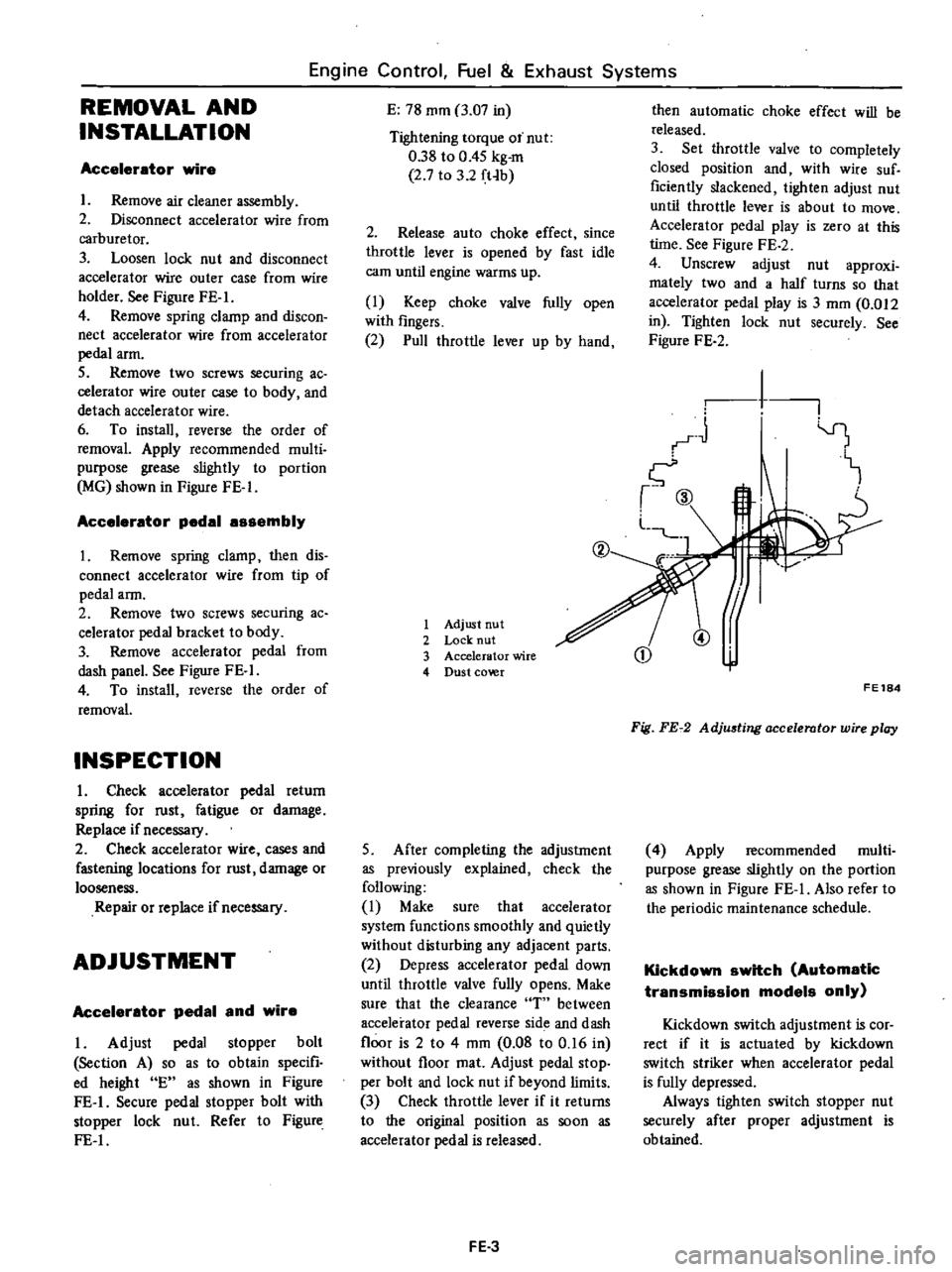

1

Adjust

nut

2

Lock

nut

3

Accelerator

wire

4

Dust

co

r

5

After

completing

the

adjustment

as

previously

explained

check

the

following

I

Make

sure

that

accelerator

system

functions

smoothly

and

quietly

without

disturbing

any

adjacent

parts

2

Depress

accelerator

pedal

down

until

throttle

valve

fully

opens

Make

sure

that

the

clearance

T

between

accelerator

pedal

reverse

side

and

dash

floor

is

2

to

4

mm

0

08

to

0

16

in

without

floor

mat

Adjust

pedal

stop

per

bolt

and

lock

nut

if

beyond

limits

3

Check

throttle

lever

if

it

returns

to

the

original

position

as

soon

as

accelerator

pedal

is

released

FE

3

then

automatic

choke

effect

will

be

released

3

Set

throttle

valve

to

completely

closed

position

and

with

wire

suf

ficiently

slackened

lighten

adjust

nut

until

throttle

lever

is

about

to

move

Accelerator

pedal

play

is

zero

at

this

lime

See

Figure

FE

2

4

Unscrew

adjust

nut

approxi

mately

two

and

a

half

turns

so

that

accelerator

pedal

play

is

3

mOl

0

012

in

Tighten

lock

nut

securely

See

Figure

FE

2

1

I

1

CD

@

FE184

Fig

FE72

AdjU6ting

accelerator

wire

play

4

Apply

recommended

multi

purpose

grease

slightly

on

the

portion

as

shown

in

Figure

FE

I

Also

refer

to

the

periodic

maintenance

schedule

Kickdown

switch

Automatic

transmission

models

only

Kickdown

switch

adjustment

is

cor

rect

if

it

is

actuated

by

kickdown

switch

striker

when

accelerator

pedal

is

fully

depressed

Always

tighten

switch

stopper

nut

securely

after

proper

adjustment

is

obtained

Page 430 of 537

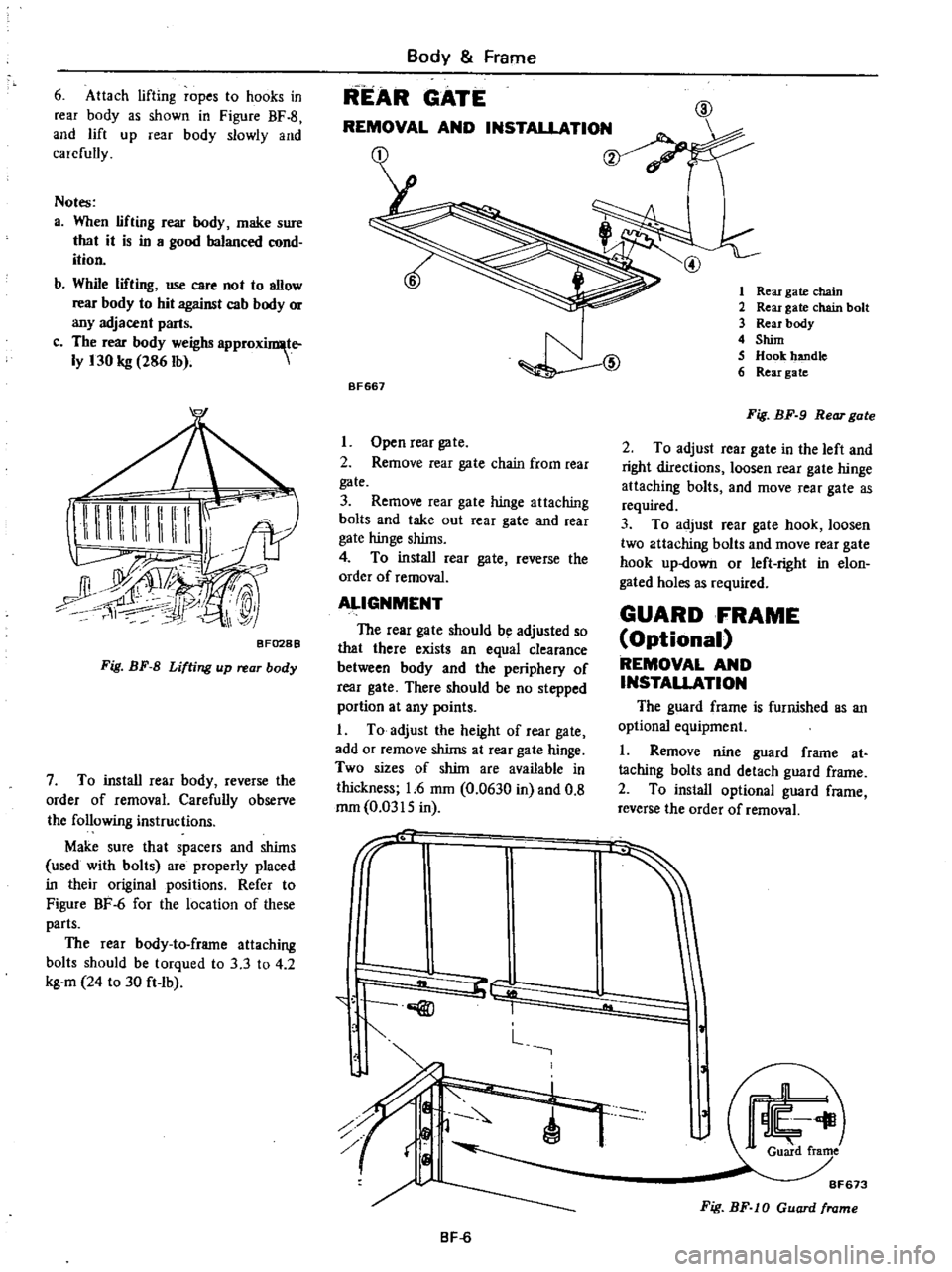

6

Attach

lifting

ropes

to

hooks

in

rear

body

as

shown

in

Figure

BF

8

and

lift

up

rear

body

slowly

and

carefully

Notes

a

When

lifting

rear

body

make

sure

that

it

is

in

a

good

balanced

cond

ition

b

While

lifting

use

care

not

to

allow

rear

body

to

hit

against

cab

body

or

any

adjacent

parts

c

The

rear

body

weighs

approxillll

te

Iy

130

kg

286

Ib

BF0288

Fig

BF

8

Lifting

up

rear

body

7

To

install

rear

body

reverse

the

order

of

removal

Carefully

observe

the

following

instructions

Make

sure

that

spacers

and

shims

used

with

bolts

are

properly

placed

in

their

original

positions

Refer

to

Figure

BF

6

for

the

location

of

these

parts

The

rear

body

to

frame

attaching

bolts

should

be

torqued

to

3

3

to

4

2

kg

m

24

to

30

ft

Ib

Body

Frame

REAR

GATE

00

REMOVAL

AND

INSTAllATION

1

W

@

BF661

I

Open

rear

gate

2

Remove

rear

gate

chain

from

ear

gate

3

Remove

rear

gate

hinge

attaching

bolts

and

take

out

rear

gate

and

rear

gate

hinge

shims

4

To

install

rear

gate

reverse

the

order

of

removal

ALIGNMENT

The

rear

gate

should

be

adjusted

so

that

there

exists

an

equal

clearance

between

body

and

the

periphery

of

rear

gate

There

should

be

no

stepped

portion

at

any

points

I

To

adjust

the

height

of

rear

gate

add

or

remove

shims

at

rear

gate

hinge

Two

sizes

of

shim

are

available

in

thickness

1

6

mm

0

0630

in

and

0

8

rom

0

0315

in

rr

r

f

r

@

C

L

i

BF

6

1

Rear

gate

chain

2

Rear

gate

chain

bolt

3

Rear

body

4

Shim

S

Hook

handle

6

Reargate

Fig

BF

9

Rear

gate

2

To

adjust

rear

gate

in

the

left

and

right

directions

loosen

rear

gate

hinge

attaching

bolts

and

move

rear

gate

as

required

3

To

adjust

rear

gate

hook

loosen

two

attaching

bolts

and

move

rear

gate

hook

up

down

or

left

right

in

elon

gated

holes

as

required

GUARD

FRAME

Optional

REMOVAL

AND

INSTAUATION

The

guard

frame

is

furnished

as

an

optional

equipment

I

Remove

nine

guard

frame

at

taching

bolts

and

detach

guard

frame

2

To

install

optional

guard

frame

reverse

the

order

of

removal

s

SF673

Fig

BF

lO

Guard

frame

Page 432 of 537

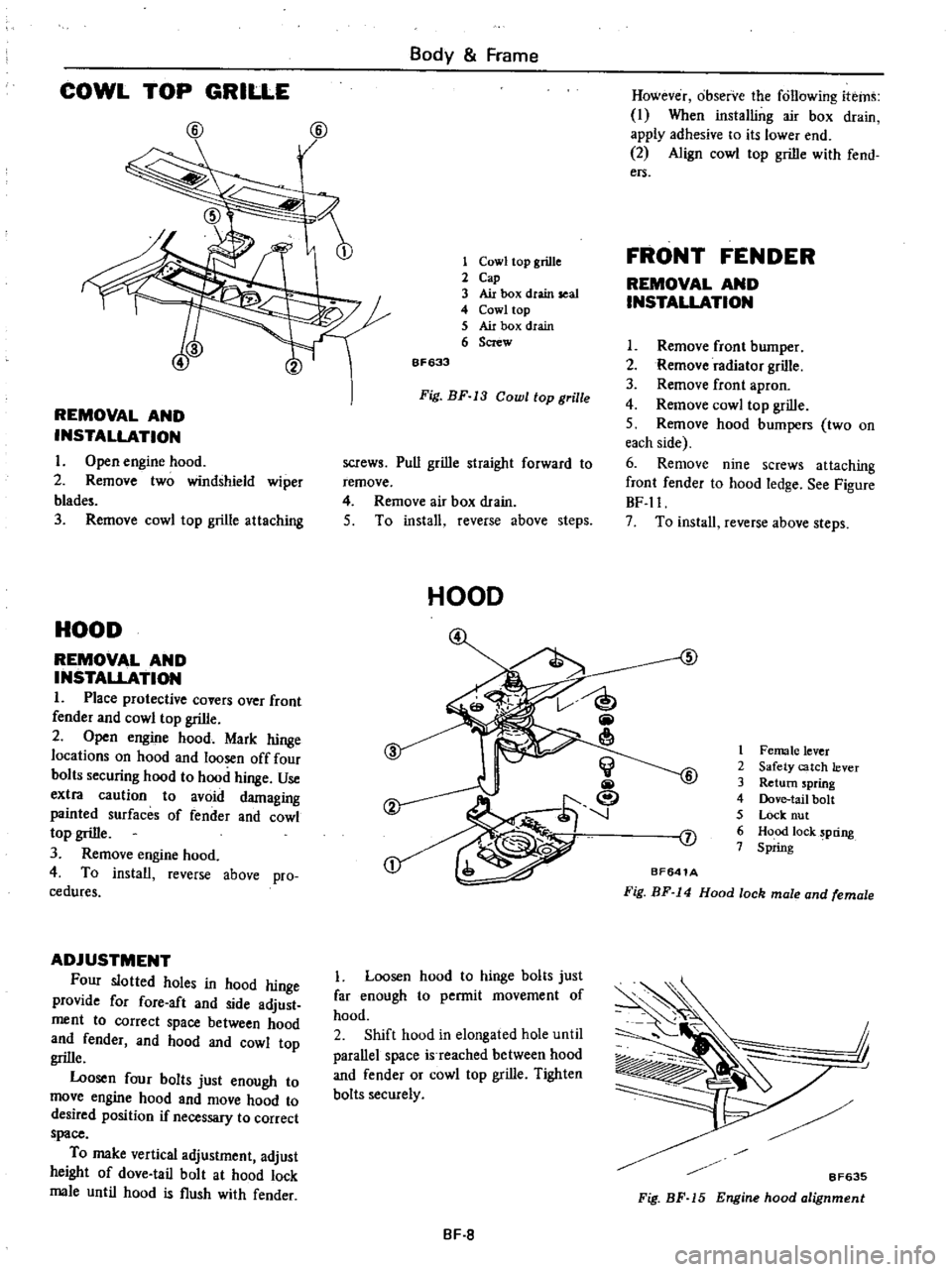

COWL

TOP

GRILLE

@

@

REMOVAL

AND

INSTALLATION

I

Open

engine

hood

2

Remove

two

windshield

wiper

blad

3

Remove

cowl

top

grille

attaching

HOOD

REMOVAL

AND

INSTALLATION

1

Place

protective

covers

over

front

fender

and

cowl

top

grille

2

Open

engine

hood

Mark

hinge

locations

on

hood

and

loosen

off

four

bolts

securing

hood

to

hood

hinge

Use

extra

caution

to

avoid

damaging

painted

surfaces

of

fender

and

cowl

top

grille

3

Remove

engine

hood

4

To

install

reverse

above

pro

cedures

ADJUSTMENT

Four

slotted

holes

in

hood

hinge

provide

for

fore

aft

and

side

adjust

ment

to

correct

space

between

hood

and

fender

and

hood

and

cowl

top

grille

Loosen

four

bolts

just

enough

to

move

engine

hood

and

move

hood

to

desired

position

if

necessary

to

correct

space

To

make

vertical

adjustment

adjust

height

of

dove

tail

bolt

at

hood

lock

male

until

hood

is

flush

with

fender

Body

Frame

1

Cowl

top

grille

2

Cap

3

Air

box

dtain

seal

4

Cowl

top

5

Air

box

drain

6

Screw

6F633

Fig

BF

13

Cowl

top

grille

screws

Pull

grille

straight

forward

to

remove

4

Remove

air

box

drain

5

To

install

reverse

above

steps

HOOD

Loosen

hood

to

hinge

bolts

just

far

enough

to

permit

movement

of

hood

2

Shift

hood

in

elongated

hole

until

parallel

space

is

reached

between

hood

and

fender

or

cowl

top

grille

Tighten

bolts

securely

BF

8

However

observe

the

following

items

I

When

installing

air

box

drain

apply

adhesive

to

its

lower

end

2

Align

cowl

top

grille

with

fend

ers

FRONT

FENDER

REMOVAL

AND

INSTALLATION

I

Remove

front

bumper

2

Remove

radiator

grille

3

Remove

front

apron

4

Remove

cowl

top

grille

S

Remove

hood

bumpers

two

on

each

side

6

Remove

nine

screws

attaching

front

fender

to

hood

ledge

See

Figure

BF

ll

7

To

install

reverse

above

steps

5

1

Female

lever

2

Safety

catch

lever

3

Return

spring

4

Dove

tail

bolt

S

Lock

nut

6

Hood

lock

pring

7

Spring

J

BF641A

Fig

BF

14

Hood

lock

male

and

female

j

I

8F635

Fig

BF

15

Engine

hood

alignment

Page 433 of 537

Body

Frame

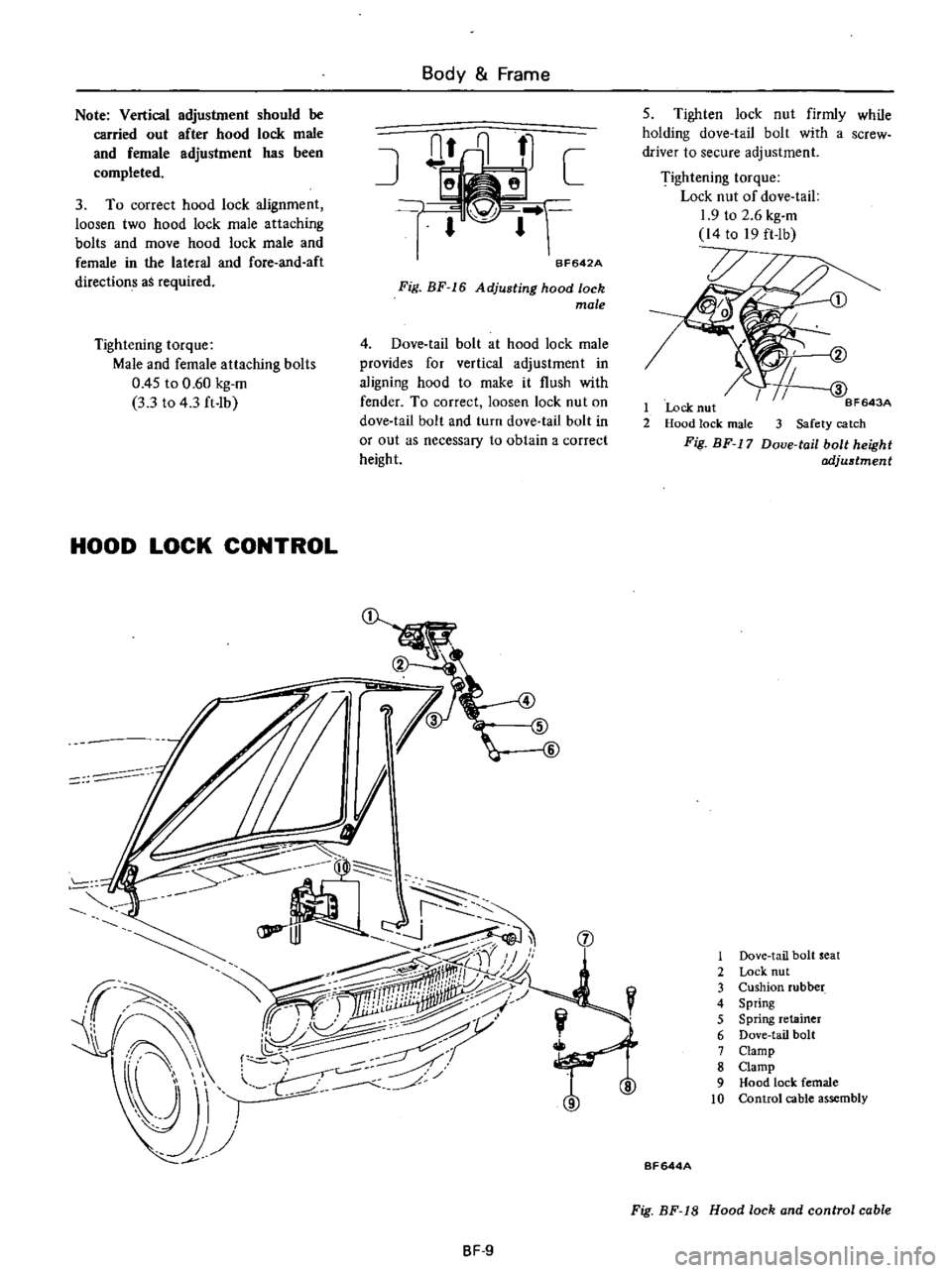

Note

Vertical

adjustment

should

be

carried

out

after

hood

lock

male

and

female

adjustment

has

been

completed

3

To

correct

hood

lock

alignment

loosen

two

hood

lock

male

attaching

bolts

and

move

hood

lock

male

and

female

in

the

lateral

and

fore

and

aft

directions

as

required

D

1r

r

BF642A

Fig

BF

16

Adjusting

hood

lock

male

Tightening

torque

Male

and

female

attaching

bolts

0

45

to

0

60

kg

m

3

3

to

4

3

ft

Ib

4

Dove

tail

bolt

at

hood

lock

male

provides

for

vertical

adjustment

in

aligning

hood

to

make

it

flush

with

fender

To

correct

loosen

lock

nut

on

dove

tail

bolt

and

turn

dove

tail

bolt

in

or

out

as

necessary

to

obtain

a

correct

height

HOOD

LOCK

CONTROL

JI

I

i

I

r

lPP

J

jJ

J

Sr

aj

I

I

I

J

f

ifry

ff

I

ii1iiilliii

j

iW

r

U

I

j

Y

f

7

j

1

JJ

J

8F

9

5

Tighten

lock

nut

firmly

while

holding

dove

tail

bolt

with

a

screw

driver

to

secure

adjustment

Tightening

torque

Lock

nut

of

dove

tail

1

9

to

2

6

kg

m

14

to

19

ft

lb

BF643A

1

Lock

nut

2

Hood

lock

male

3

Safety

catch

Fig

BF

17

Doue

tail

bolt

height

adjustment

1

Dove

tail

bolt

seat

2

Lock

nut

3

Cushion

rubber

4

Spring

5

Spring

retainer

6

Dove

tail

bolt

7

Clamp

8

Clamp

9

Hood

lock

female

10

Control

cable

assembly

BF644A

Fig

BF

18

Hood

lock

and

control

cable

Page 498 of 537

Water

in

the

system

will

ice

the

orifice

when

the

high

pressure

re

frigerant

is

changed

to

low

pressure

refrigerant

by

expansion

valve

etc

and

will

obstruct

the

refrigerant

flow

The

following

items

are

general

instructions

to

be

closely

observed

in

servicing

the

system

I

When

a

system

line

is

discon

nected

plug

the

opening

immediately

This

is

especially

necessary

to

prevent

moisture

condensation

from

forming

in

the

line

and

to

keep

out

dirt

and

dust

It

is

also

necessary

to

keep

the

line

at

and

above

surrounding

air

temperatures

at

all

times

When

con

necting

system

lines

do

not

attempt

to

remove

the

plug

from

the

opening

until

ready

for

immediate

use

2

Always

keep

the

working

place

clean

and

dry

and

free

from

dirt

and

dust

Wipe

water

off

with

a

clean

cloth

3

Have

all

necessary

tools

in

pre

paration

beforehand

and

have

tools

clean

and

dry

4

The

compressor

oil

will

easily

absorb

moisture

when

exposed

to

air

Immediateiy

close

the

opening

of

the

container

after

use

It

is

also

necessary

to

observe

the

following

notes

Notes

a

The

oil

should

not

be

transfused

from

a

container

into

another

as

the

failure

will

possibly

cause

mois

ture

to

mix

with

the

oil

b

The

used

oil

should

not

be

returned

into

a

container

c

The

oil

should

not

be

used

if

its

state

of

preservation

is

not

clear

enough

5

When

connecting

or

disconnect

ing

pipes

from

the

refrigeration

sys

tem

use

two

wrenches

One

wrench

is

used

for

holding

the

fixing

nut

in

place

while

the

other

for

turning

the

mating

flare

nut

Failure

to

do

so

may

result

in

a

twisted

tube

or

may

damage

connection

6

Also

use

care

not

to

give

scratches

to

the

seating

surface

at

connections

A

small

scratch

on

the

seating

surface

Air

Conditioning

may

be

the

cause

of

gas

leakage

Before

connecting

pipes

be

sure

to

give

coating

of

compressor

oil

to

the

sea

ting

surfaces

SAFETY

PRECAUTIONS

I

Since

direct

contact

of

the

liquid

refrigerant

with

your

skin

will

cause

frostbite

always

be

careful

when

handling

the

refrigerant

Wear

gloves

or

wrap

a

piece

of

cloth

around

service

valve

to

protect

your

fingers

against

frostbite

by

refrigerant

If

any

of

the

refrigerant

should

get

into

your

eyes

when

charging

the

refrigerant

splash

your

eyes

with

cool

water

to

raise

the

temperature

gradually

Apply

a

protec

tive

film

to

the

eye

to

avoid

infection

Do

not

rub

your

eyes

Consult

an

eye

specialist

Always

wear

goggles

or

glasses

to

protect

your

eyes

when

working

around

the

system

Should

refrigerant

strikes

your

body

splash

on

cool

water

and

apply

a

protective

film

2

The

refrigerant

service

container

has

a

safe

strength

However

if

han

dled

incorrectiy

it

wili

explode

Therefore

always

follow

the

instruc

tions

on

the

label

In

particular

never

stpre

it

in

a

hot

location

above

S20C

l250F

or

drop

it

from

a

high

height

3

The

refrigerant

gas

is

odorless

and

colorless

and

breathing

may

become

difficult

due

to

the

lack

of

oxygen

Since

the

refrigerant

gas

is

heavier

than

air

and

will

lay

close

to

the

floor

be

especially

careful

when

handling

it

in

small

confined

spaces

4

The

refrigerant

itself

is

nonflam

mable

However

a

toxic

gas

phosgene

gas

is

produced

when

it

contacts

fire

and

special

care

is

therefore

required

when

checking

for

leaks

in

the

system

with

a

halide

torch

5

Do

not

steam

clean

on

the

sys

tern

especially

condenser

since

exces

sively

high

pressure

will

build

up

in

the

system

resulting

in

explosion

of

the

system

The

above

precautions

are

essential

in

handling

of

Refrigerant

l

2

and

their

strict

observation

requires

suffi

AC

9

dent

training

Therefore

it

is

of

first

importance

that

any

other

personnel

than

a

well

trained

serviceman

should

not

be

allowed

to

handle

the

refrig

erant

EVACUATING

AND

CHARGING

SYSTEM

During

servicing

use

caution

to

keep

air

from

getting

into

refrigerant

When

air

enters

the

system

all

refriger

ant

must

be

evacuated

from

system

prior

to

charging

new

refrigerant

Air

in

refrigerant

has

the

following

delete

rious

effects

I

Since

the

condensation

tempera

ture

of

the

air

is

extremely

low

the

air

will

not

be

condensed

when

refrigerant

gas

is

condensed

in

the

condenser

and

the

air

will

thus

remain

in

gaseous

form

Consequently

the

effective

thermal

transmission

area

of

condenser

for

refrigerant

gas

will

be

red

uced

and

refrigerant

gas

to

be

condensed

will

be

red

ueed

The

pressure

rise

will

become

proportional

to

the

volume

of

the

air

in

system

2

When

air

and

refrigerant

are

mixed

in

system

a

chemical

reaction

will

be

produced

and

hydrochloric

acid

which

will

adversely

affect

the

aluminum

copper

iron

and

other

materials

in

system

may

be

generated

HANDLING

MANIFOLD

GAUGE

The

pressure

at

the

high

and

low

sides

of

system

should

be

measured

when

evacuating

and

charging

refrig

erant

and

when

diagnosing

trouble

in

the

system

The

manifold

gauge

is

used

for

these

purposes

A

manifold

gauge

has

two

pressure

gauges

a

low

pressure

gauge

and

a

high

pressure

gauge

These

gauges

are

connected

to

the

high

and

low

side

service

valves

of

system

through

flexible

charging

hoses

The

construction

of

manifold

gauge

is

shown

in

Figure

AC

13

When

valve

stem

is

fully

screwed

the

valve

is

front

seated

and

valve

path

and

the

center

path

are

blocked

When

valve

stem

is

backed

off

the

paths

are

opened