air filter DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 164 of 537

J

1

Fuel

tank

2

Fuel

f1l1er

cap

with

vacuum

relief

valve

3

Liquid

vapor

separator

4

Vapor

vent

line

5

Vacuum

signalUne

As

the

throttle

valve

opens

and

vehicle

speed

increases

vacuum

pres

sure

in

the

vacuum

signal

line

forces

rHL

JL

I

EC785

INSPECTION

FUEL

TANK

VAPOR

LIQUID

SEPARATOR

AND

VAPOR

VENT

LINE

I

Check

all

hoses

and

fuel

tank

mler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

vapor

liquid

separator

3

Connect

a

3

way

connector

a

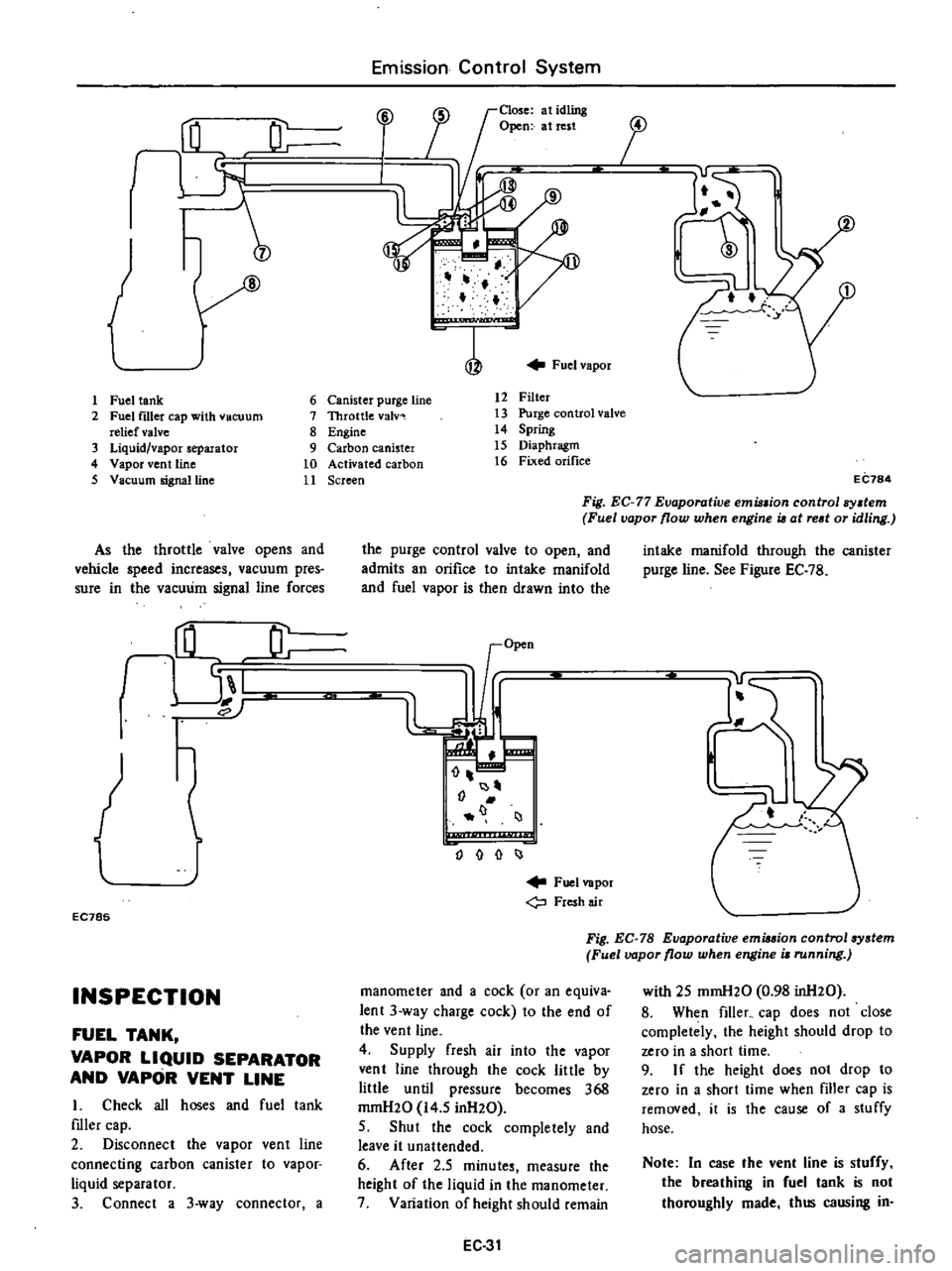

Emission

Control

System

Close

at

idling

Open

at

rest

i

J

17

f

Fuel

vapor

6

Canister

purge

line

7

Throttle

valv

8

Engine

9

Carbon

canister

10

Activated

carbon

11

Screen

12

Filter

13

Purge

control

valve

14

Spring

15

Diaphragm

16

Fixed

orifice

i

j

EC784

Fig

EC

77

Evaporative

emu

ion

control

sy

tem

Fuel

vapor

flow

when

engine

i6

at

red

or

idling

the

purge

control

valve

to

open

and

admits

an

orifice

to

intake

manifold

and

fuel

vapor

is

then

drawn

into

the

I

J

o

I

Fuel

vapor

Fresh

air

intake

manifold

through

the

canister

purge

line

See

Figure

EC

7B

Fig

EC

78

Evaporative

emiuion

control

system

Fuel

vapor

flow

when

engine

i

running

manometer

and

a

cock

or

an

equiva

lent

3

way

charge

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mrnH20

14

5

inH20

5

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

EC

31

with

25

mmH20

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

removed

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thus

causing

in

Page 165 of 537

sufficient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

1

3

connectur

COCk

Air

Manometer

Emission

Control

System

repaired

or

replaced

368

mmH20

14

5

inH20

LL

IPO

liqUid

epo

o

36

r

@

Carbon

canister

EC786

Fig

EC

79

Checking

evaporative

emmion

control

syatem

CARBON

CANISTER

PURGE

CONTROL

VALVE

Check

for

fuel

vapor

leakage

in

the

distributor

vacuum

line

at

diaphragm

of

carbon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

I

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

vacuum

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET349

Fig

EC

so

Checking

carbon

canuter

purge

control

valve

3

If

there

is

a

leak

remove

top

cover

from

purge

control

valve

and

check

for

dislocated

or

cracked

dia

phragm

If

necessary

replace

dia

phragm

kit

which

is

made

up

of

a

retainer

a

diaphragm

and

a

spring

@

@

1

Cover

2

Diaphragm

3

Retainer

4

Spring

ET350

Fig

EC

81

Carbon

catU

ter

purge

control

valve

CARBON

CANISTER

FILTER

Check

for

a

contaminated

element

Element

can

be

removed

at

the

bottom

of

canister

installed

on

vehicle

body

EC

32

ET37Q

Fig

EC

s2

Replacing

carbon

canuter

filter

FUEL

TANK

VACUUM

RELIEF

VALVE

Remove

fuel

filler

cap

and

see

it

functions

properly

I

Wipe

clean

valve

housing

and

have

it

in

your

mouth

2

Inhale

air

A

slight

resistance

ac

companied

by

valve

indicates

that

valve

is

in

good

mechanical

condition

Note

also

that

by

further

inhaling

air

the

resistance

should

be

disappeared

with

valve

clicks

3

If

valve

is

clogged

or

if

no

resist

ance

is

felt

replace

cap

as

an

assem

bled

uni

t

l

u

ET369

Fig

EC

83

Fuel

filler

cap

Page 381 of 537

DISASSEMBLY

AND

ASSEMBLY

1

00

11I

1

Reservoir

cap

2

Oil

mter

3

Oil

reservoir

4

Packing

5

Valve

cap

Brake

System

00

oC

1

O

b

0

1

r

r

L

BA927

6

Secondary

piston

stopper

7

Bleeder

screw

8

Secondary

return

spring

9

Secondary

piston

10

Primary

return

spring

11

Primary

piston

12

Piston

stopper

13

Piston

stopper

ring

1

Remove

reservoir

cap

and

filter

and

drain

out

brake

fluid

2

Pry

off

stopper

ring

using

a

screwdriver

3

Remove

stopper

screw

and

take

out

stopper

primary

piston

assembly

spring

and

secondary

piston

assembly

in

the

order

shown

Note

Discard

piston

cup

if

it

is

re

moved

from

piston

sembly

and

use

a

new

one

4

Unscrew

plugs

to

gain

access

to

check

valve

for

disassembling

Note

Never

detach

reservoir

tank

U

it

is

removed

for

any

reason

dis

canI

it

and

install

a

new

one

S

Assemble

master

cylinder

in

the

reverse

sequence

of

disassembly

pay

ing

particular

attention

to

the

follow

ing

notes

Fig

BR

10

Master

cylinder

Tightening

torque

Valve

cap

T

okico

8

t09

kg

m

S8

to

6S

ft

Ib

Nabco

2

5

to

3

S

kg

m

18

to

2S

ft

Ib

Bleeder

0

7

to

0

9

kg

m

S

to

7

ft

lb

Notes

a

Replace

gaskets

and

packings

with

new

ones

b

Apply

brake

fluid

or

rubber

grease

to

sliding

contact

surfaces

of

parts

to

facilitate

assembly

of

master

cylinder

c

The

blllke

master

cylinder

is

avail

able

in

both

NABCO

make

and

TOKlCO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKlCO

JIIlkes

When

replacing

the

repair

kit

or

component

parts

BR

6

ascertain

the

brand

of

the

brake

master

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

INSPECTION

Thoroughly

clean

all

parts

in

a

suitable

solvent

and

check

for

WOol

or

damaged

parts

Replace

any

part

that

is

faulty

Note

Do

not

clean

robber

parts

with

minerai

oil

since

this

will

be

the

sure

way

of

deteriolllting

parts

Use

brake

fluid

or

alcohoL

When

alco

hol

is

used

for

leaning

these

parts

do

not

immerse

them

in

it

longer

than

30

seconds

After

parts

are

cIeaned

dry

with

compressed

air

I

Check

cylinder

and

position

for

evidence

of

abnonnaI

wear

or

damage

Replace

if

found

faulty

2

Check

piston

to

cylinder

clear

ance

If

it

is

more

than

O

IS

mm

0

OOS9

in

replace

either

piston

or

cylinder

Master

cylinder

inner

diameter

19

0S

mm

Yoin

3

Check

for

weakened

fatigued

or

damaged

springs

and

replace

if

neces

sary

4

When

master

cylioder

is

disassem

bled

be

sure

to

discard

cups

and

valves

Replace

any

other

part

which

shows

evidence

of

deformation

wear

or

damage

S

Replace

damaged

oil

reservoirs

and

caps

INSTALLATION

Install

master

cylinder

in

the

re

verse

sequence

of

removal

Bleed

air

out

of

master

cylinder

by

loosening

bleeder

screw

after

it

is

installed

in

its

original

position

Tightening

torque

Brake

master

cylinder

attaching

nut

0

8

to

1

1

kg

m

6

to

8

ft

Ib

Brake

tube

connector

I

S

to

1

8

kg

m

II

to

13

ft

Ib

Page 389 of 537

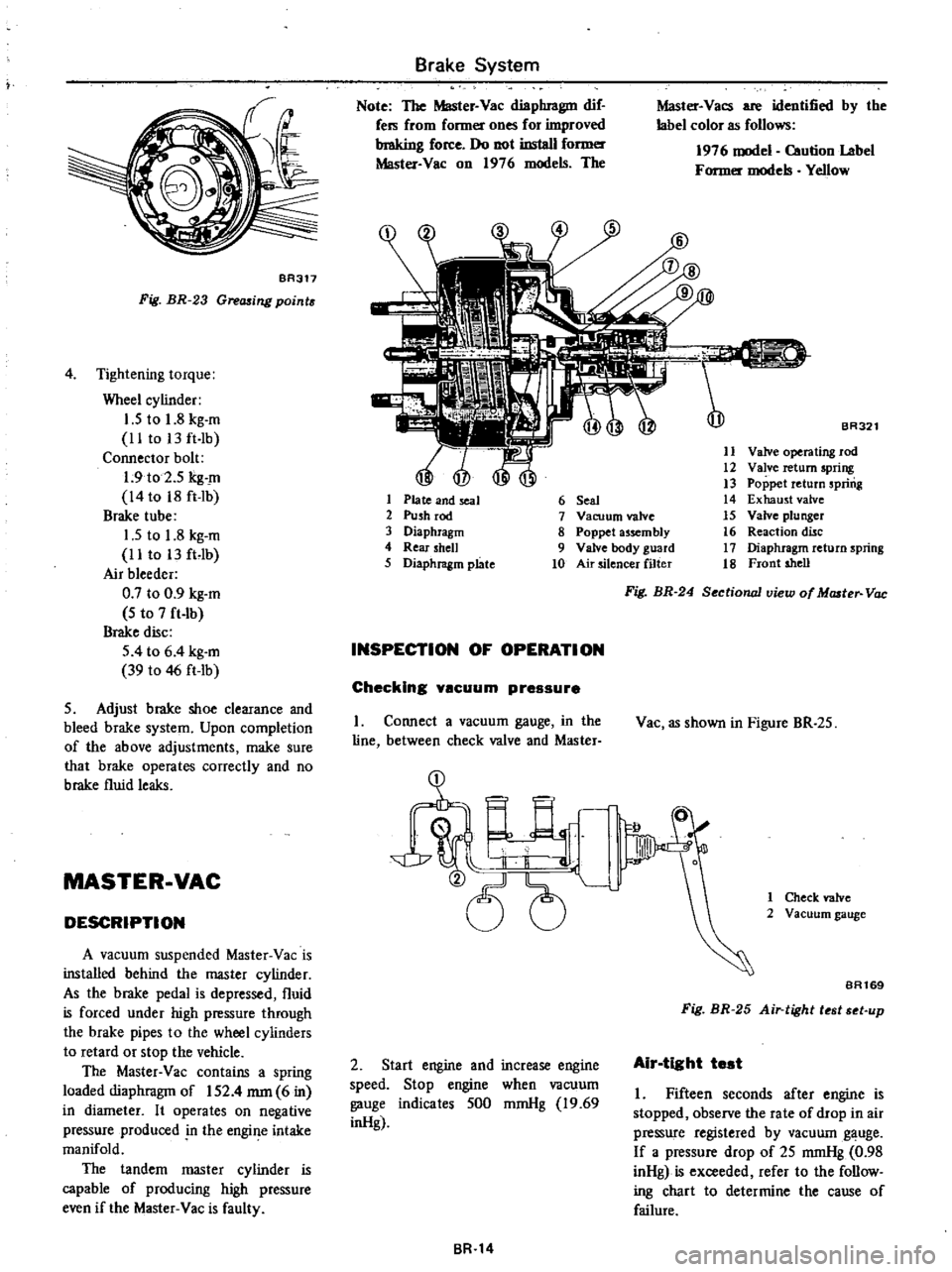

f

BR317

Fig

BR

23

Gre

ing

point

4

Tightening

torque

Wheel

cylinder

J

S

to

1

8

kg

m

II

to

13ft

Ib

Connector

bolt

1

9

to

2

5

kg

m

14

to

18

ft

Ib

Brake

tube

1

5

to

1

8

kg

m

II

to

13

ft

Ib

Air

bleeder

0

7

to

0

9

kg

m

S

to

7

ft

Ib

Brake

disc

5

4

to

6

4

kg

m

39

to

46

ft

Ib

S

Adjust

brake

shoe

clearance

and

bleed

brake

system

Upon

completion

of

the

above

adjustments

make

sure

that

brake

operates

correctly

and

no

brake

fluid

leaks

MASTER

VAC

DESCRIPTION

A

vacuum

suspended

Master

Vac

is

installed

behind

the

master

cylinder

As

the

brake

pedal

is

depressed

fluid

is

forced

under

high

pressure

through

the

brake

pipes

to

the

wheel

cylinders

to

retard

or

stop

the

vehicle

The

Master

Vac

contains

a

spring

loaded

diaphragm

of

IS2

4

mm

6

in

in

diameter

It

operates

on

negative

pressure

produced

n

the

engine

intake

manifold

The

tandem

master

cylinder

is

capable

of

producing

high

pressure

even

if

the

Master

Vac

is

faulty

Brake

System

Note

The

Master

Vac

diaphragm

dif

fers

from

fonner

ones

for

improved

braking

force

Do

not

install

fonner

Master

Vac

on

1976

models

The

1

Plate

and

seal

2

Push

rod

3

Diaphragm

4

Rear

shell

5

Diaphragm

plate

Master

Vacs

are

identified

by

the

label

color

as

follows

1976

model

Caution

Label

Former

models

YeJlow

BR321

11

Valve

operating

rod

12

Valve

return

spring

13

Poppet

return

spring

14

Exhaust

valve

15

Valve

plunger

16

Reaction

disc

17

Diaphragm

return

spring

18

Front

shell

6

Seal

7

Vacuum

valve

8

Poppet

assembly

9

Valve

body

guard

10

Air

silencer

filter

INSPECTION

OF

OPERATION

Checking

yscuum

pressure

I

Connect

a

vacuum

gauge

in

the

line

between

check

valve

and

Master

2

Start

engine

and

increase

engine

speed

Stop

engine

when

vacuum

gauge

indicates

SOO

mmHg

19

69

inHg

BR

14

Fig

BR

24

Sectionall1iew

of

Master

Vac

Vac

as

shown

in

Figure

BR

25

1

Check

valve

2

Vacuum

gauge

BA169

Fig

BR

25

Air

tight

t

t

t

up

Air

tight

test

I

Fifteen

seconds

after

engine

is

stopped

observe

the

rate

of

drop

in

air

pressure

registered

by

vacuum

gauge

If

a

pressure

drop

of

25

mmHg

0

98

inHg

is

exceeded

refer

to

the

follow

ing

chart

to

determine

the

cause

of

failure

Page 518 of 537

INSPECTION

Evaporator

Check

evaporator

for

leakage

or

damage

If

damaged

replace

Expansion

valve

Check

expansion

valve

for

leakage

or

clogging

If

clogged

clean

filter

in

expansion

valve

If

damaged

replace

RECEIVER

DRYER

AND

PIPING

REMOVAL

AND

INSTAUATION

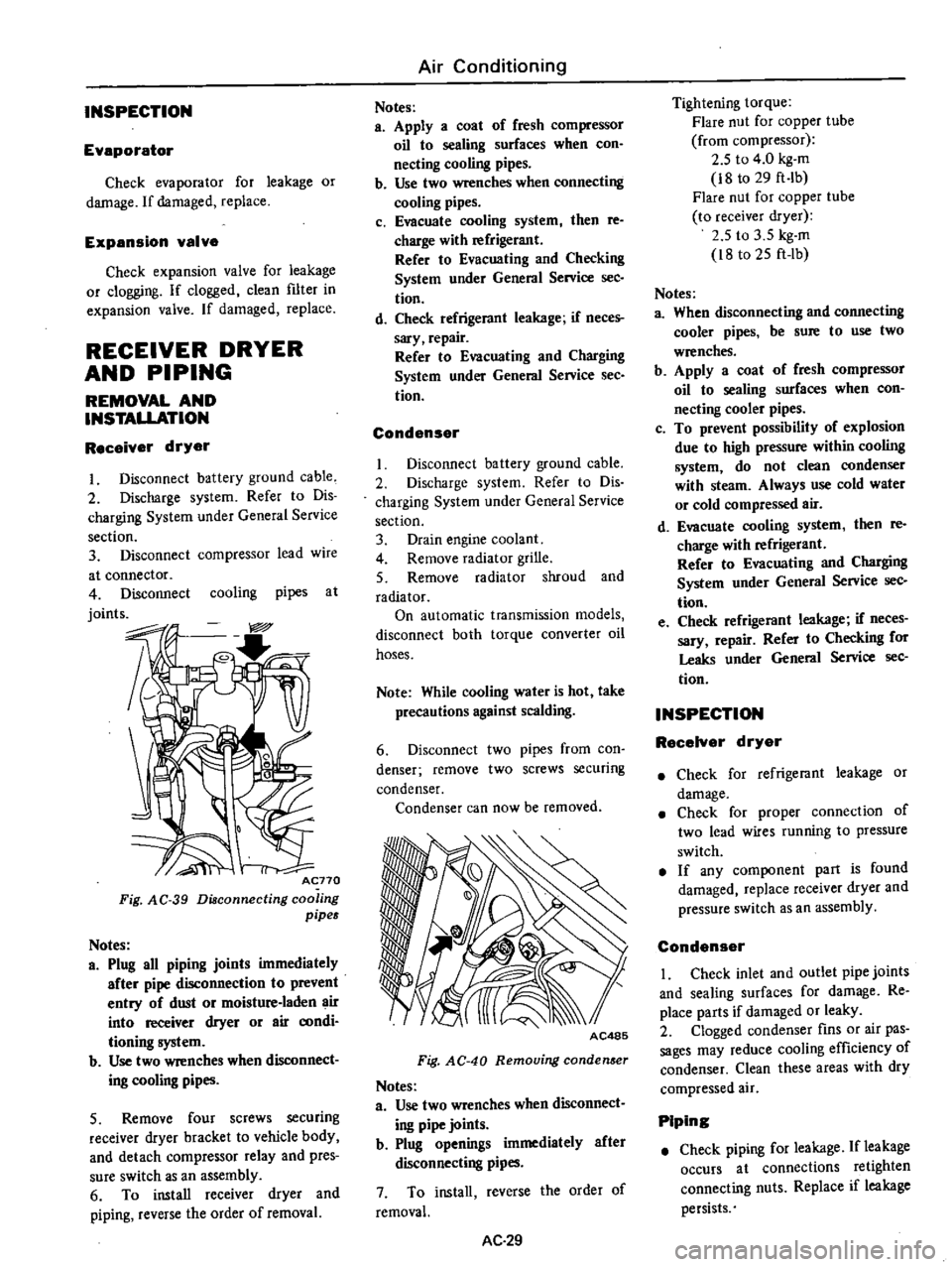

Receiver

dryer

I

Disconnect

battery

ground

cable

2

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

3

Disconnect

compressor

lead

wire

at

connector

4

Disconnect

cooling

pipes

at

joints

Acno

Fig

AC

39

Diaconnecting

coo

ing

pipes

Notes

a

Plug

all

piping

joints

immediately

after

pipe

disconnection

to

prevent

entry

of

dust

or

moisture

laden

air

into

receiver

dryer

or

air

aJOdi

tioning

system

b

Use

two

wrenches

when

dIsconnect

ing

cooling

pipes

5

Remove

four

screws

securing

receiver

dryer

bracket

to

vehicle

body

and

detach

compressor

relay

and

pres

sure

switch

as

an

assembly

6

To

install

receiver

dryer

and

piping

reverse

the

order

of

removal

Air

Conditioning

Notes

a

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

when

con

necting

cooling

pipes

b

Use

two

wrenches

when

connecting

cooling

pipes

c

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Checking

System

under

General

Service

sec

tion

d

Check

refrigerant

leakage

if

neces

sary

repair

Refer

to

Evacuating

and

Charging

System

under

General

Service

See

tion

Condenser

Disconnect

battery

ground

cable

2

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

3

Drain

engine

coolant

4

Remove

radiator

grille

5

Remove

radiator

shroud

and

radiator

On

automatic

transmission

models

disconnect

both

torque

converter

oil

hoses

Note

While

cooling

water

is

hot

take

precautions

against

scalding

6

Disconnect

two

pipes

from

con

denser

remove

two

screws

securing

condenser

Condenser

can

now

be

removed

AC485

Fig

AC

40

Removing

conden

er

Notes

a

Use

two

wrenches

when

disconnect

ing

pipe

joints

b

Plug

openings

immediately

after

disconnecting

pipes

7

To

install

reverse

the

order

of

removal

AC

29

Tightening

torque

Flare

nut

for

copper

tube

from

compressor

2

5

to

4

0

kg

m

i8

to

29

ft

Ib

Flare

nut

for

copper

tube

to

receiver

dryer

2

5

to

3

5

kg

m

i8

to

25

ft

lb

Notes

a

When

disconnecting

and

connecting

cooler

pipes

be

sure

to

use

two

wrenches

b

Apply

a

coat

of

fresh

compressor

oil

to

sealing

surfaces

when

con

necting

cooler

pipes

c

To

prevent

possibility

of

explosion

due

to

high

pressure

within

cooling

system

do

not

clean

condenser

with

steam

Always

use

cold

water

or

cold

compressed

air

d

Evacuate

cooling

system

then

re

charge

with

refrigerant

Refer

to

Evacuating

and

Charging

System

under

General

Service

sec

tion

e

Check

refrigerant

leakage

if

neces

sary

repair

Refer

to

Checking

for

Leaks

under

General

Service

sec

tion

INSPECTION

RecelYer

dryer

Check

for

refrigerant

leakage

or

damage

Check

for

proper

connection

of

two

lead

wires

running

to

pressure

switch

If

any

component

part

is

found

damaged

replace

receiver

dryer

and

pressure

switch

as

an

assembly

Condenser

I

Check

inlet

and

outlet

pipe

joints

and

sealing

surfaces

for

damage

Re

place

parts

if

damaged

or

leaky

2

Clogged

condenser

fins

or

air

pas

sages

may

reduce

cooling

efficiency

of

condenser

Clean

these

areas

with

dry

compressed

air

Piping

Check

piping

for

leakage

If

leakage

occurs

at

connections

retighten

connecting

nuts

Replace

if

leakage

persists

Page 532 of 537

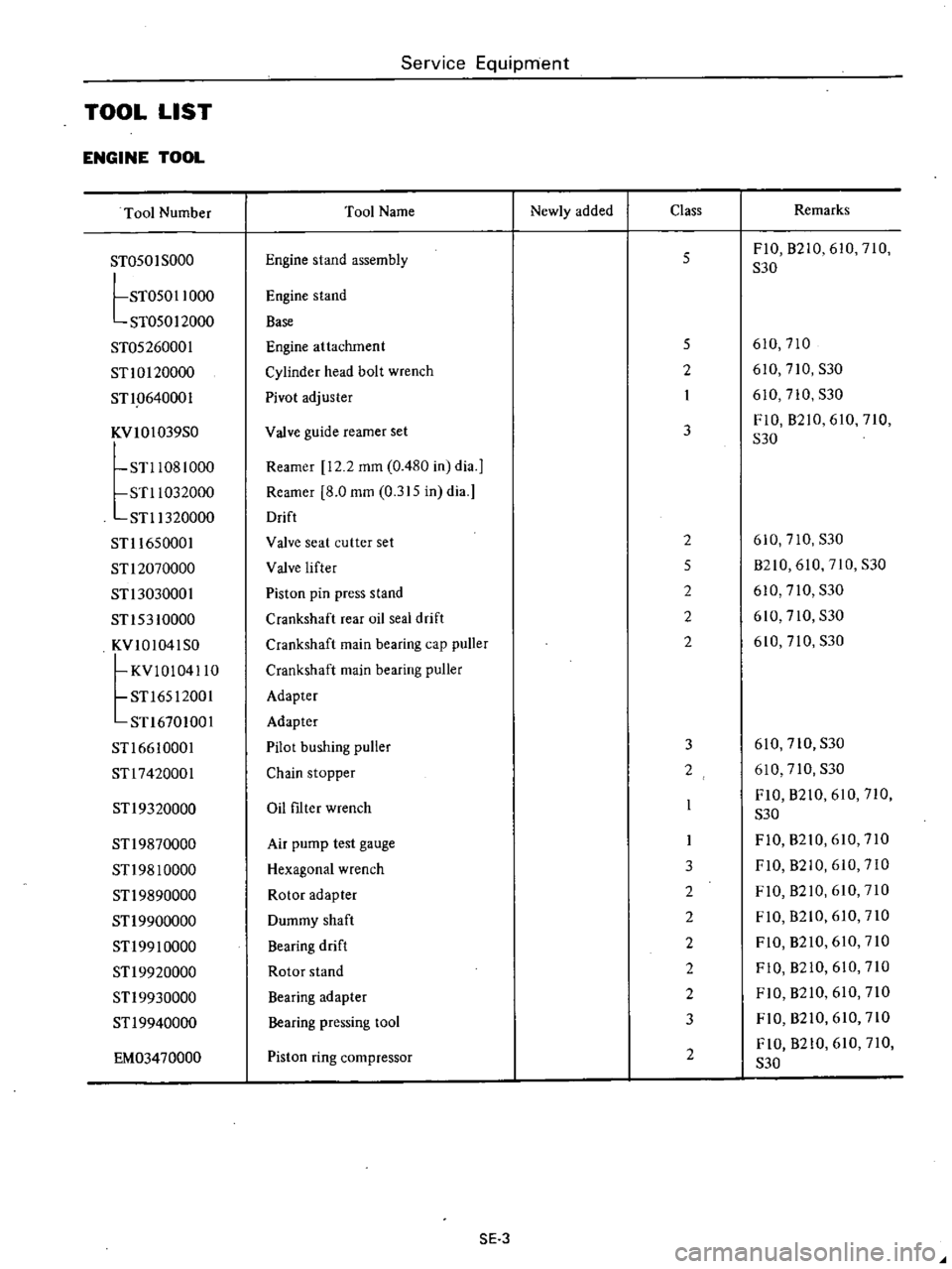

Service

Equipment

TOOL

LIST

ENGINE

TOOL

Tool

Number

Tool

Name

Newly

added

Class

Remarks

ST050

I

SODa

Engine

stand

assembly

5

FIO

B2iO

610

710

S30

tST05011000

Engine

stand

ST050

I

2000

Base

ST05260001

Engine

attachment

5

610

710

STlOl20000

Cylinder

head

bolt

wrench

2

610

710

S30

STl

0640001

Pivot

adjuster

I

610

710

S30

KVIOI039S0

Valve

guide

reamer

set

3

FiO

B210

610

710

S30

STl1081

000

Reamer

12

2

mffi

0

480

in

dia

J

STl1032000

Reamer

8

0

mffi

0

315

in

dia

STl1320000

Drift

STll650001

Valve

seat

cutter

set

2

610

710

S30

STl2070000

Valve

lifter

5

B210

610

710

S30

STl3030001

Piston

pin

press

stand

2

610

710

S30

STl53

10000

Crankshaft

rear

oil

seal

drift

2

610

710

S30

KVI01041S0

Crankshaft

main

bearing

cap

puller

2

610

710

S30

KVIOI04110

Crankshaft

main

bearing

puller

STl6512001

Adapter

STl6701001

Adapter

STl6610001

Pilot

bushing

puller

3

610

710

S30

STl7420001

Chain

stopper

2

610

710

S30

STl9320000

Oil

filter

wrench

FIO

B210

610

710

S30

STl9870000

Air

pump

test

gauge

FI0

B210

610

710

STl98

10000

Hexagonal

wrench

3

FIO

B2iO

610

710

STl9890000

Rotor

adapter

2

FIO

B210

610

710

STl9900000

Dummy

shaft

2

FIO

B210

610

710

STl99

10000

Bearing

drift

2

FIO

B210

610

710

STl9920000

Rotor

stand

2

FIO

B210

610

710

STl9930000

Bearing

adapter

2

FIO

B210

610

710

ST

I

9940000

Bearing

pressing

tool

3

FIO

B210

610

710

EM03470000

Piston

ring

compressor

2

FIO

B210

610

710

S30

SE

3