fuse DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 462 of 537

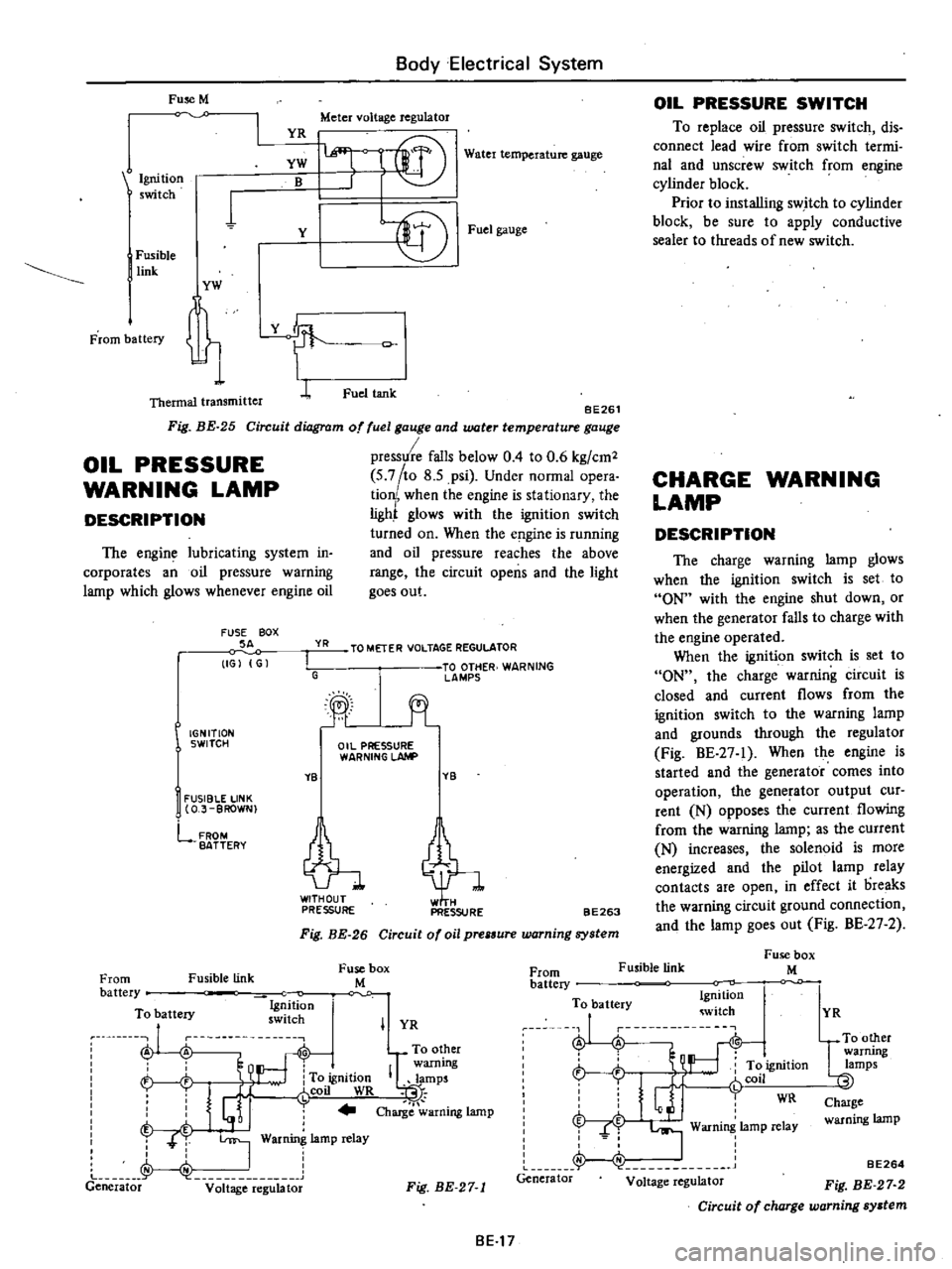

Fuse

M

Body

Electrical

System

YR

Meter

voltage

regulator

Water

temperature

gauge

BE261

Circuit

diagram

of

fuel

gauge

and

water

temperature

gauge

pressure

falls

below

0

4

to

0

6

kg

cm2

5

7

to

8

5

psi

Under

normal

opera

tion

when

the

engine

is

stationary

the

ligh

glows

with

the

ignition

switch

turned

on

When

the

e

gine

is

running

and

oil

pressure

reaches

the

above

range

the

circuit

opens

and

the

light

goes

out

Ignition

switch

YW

B

1

Y

I

Fusible

link

YW

t

Thermal

transmitter

L

Fig

BE

25

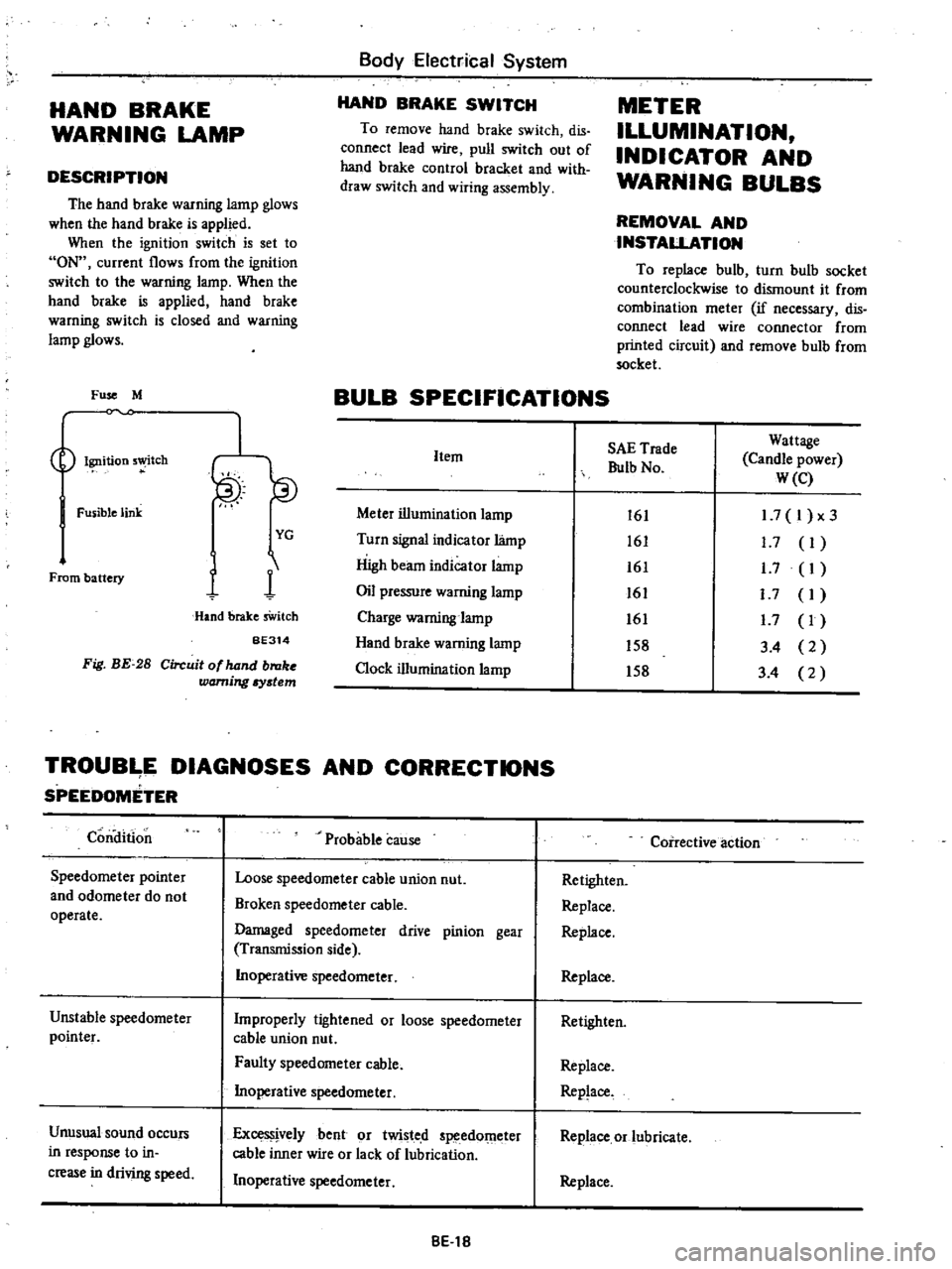

OIL

PRESSURE

WARNING

LAMP

DESCRIPTION

The

engine

lubricating

system

in

corporates

an

oil

pressure

warning

lamp

which

glows

whenever

engine

oil

FUSE

BOX

SA

IGJ

G

YR

I

G

IGNITION

SWITCH

YB

I

FUSIBLE

LINK

O

J

BROWN

lffi

l

f

r@

Fuel

gauge

Fuel

tank

TO

METER

VOLTAGE

REGULATOR

TO

OTHER

WARNING

lAMPS

jt

Oil

PRESSURE

WARNING

LAhlP

YB

tl

PRESSURE

PRESSURE

FROM

BATTERY

BE263

Fig

BE

26

Circuit

of

oil

prelSure

warning

system

Fusible

link

Fuse

box

M

OIL

PRESSURE

SWITCH

To

replace

oil

pressure

switch

dis

connect

lead

wire

from

switch

termi

nal

and

unscrew

switch

from

engine

cylinder

block

Prior

to

installing

switch

to

cylinder

block

be

sure

to

apply

conductive

sealer

to

threads

of

new

switch

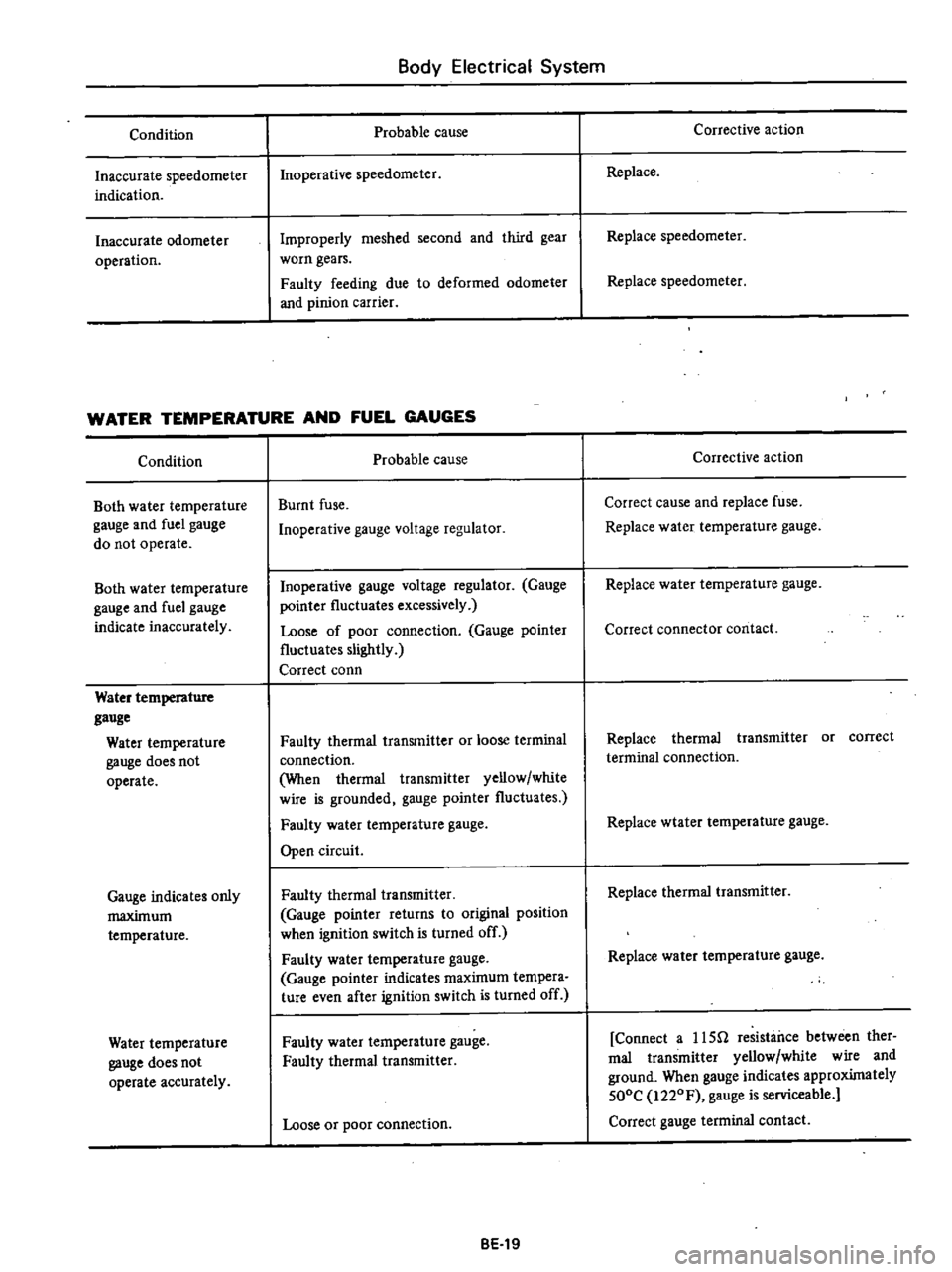

CHARGE

WARNING

LAMP

DESCRIPTION

The

charge

warning

lamp

glows

when

the

ignition

switch

is

set

to

ON

with

the

engine

shut

down

or

when

the

generator

falls

to

charge

with

the

engine

operated

When

the

ignition

switch

is

set

to

ON

the

charge

warning

circuit

is

closed

and

current

flows

from

the

ignition

switch

to

the

warning

lamp

and

grounds

through

the

regulator

Fig

BE

27

1

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

cur

rent

N

opposes

th

current

flowing

from

the

warning

lamp

as

the

current

N

increases

the

solenoid

is

more

energized

and

the

pilot

lamp

relay

contacts

are

open

in

effect

it

oreaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

Fig

BE

27

2

Fusible

link

Fuse

box

M

From

battery

To

battery

Ig

ition

ru

nu

swllch

A

A

To

other

warning

h

To

ignition

IQlamps

i

J

r

coil

WR

t

I

j

Charge

warning

lamp

T

T

I

War

lamp

relay

J

I

Generator

v

it

ge

e

g

bt

From

battery

To

battery

Ignition

witch

J

i

L

r

t

ft

ignition

r

Glj

fCOil

WR

f

I

Warning

lamp

relay

Generator

Voltage

regulator

I

YR

Fig

BE

27

1

BE17

YR

UTO

other

warrung

lamps

Charge

warning

lamp

BE264

Fig

BE

27

2

Circuit

of

charge

warning

system

Page 463 of 537

HAND

BRAKE

WARNING

LAMP

DESCRIPTION

The

hand

brake

warning

lamp

glows

when

the

hand

brake

is

applied

When

the

ignition

switch

is

set

to

ON

current

flows

from

the

ignition

switch

to

the

warning

lamp

When

the

hand

brake

is

applied

hand

brake

warning

switch

is

closed

and

warning

lamp

glows

Fuse

M

Ignition

5

tch

Fusible

link

From

battery

I

YG

1

1

Hand

brake

sWitch

BE314

Fig

BE

28

Circuit

of

hand

broke

warning

Iystem

Body

Electrical

System

HAND

BRAKE

SWITCH

To

remove

hand

brake

switch

dis

connect

lead

wire

pull

switch

out

of

hand

brake

control

bracket

and

with

draw

switch

and

wiring

assembly

METER

ILLUMINATION

INDICATOR

AND

WARNING

BULBS

REMOVAL

AND

INSTALLATION

To

replace

bulb

turn

bulb

socket

counterclockwise

to

dismount

it

from

combination

meter

if

necessary

dis

connect

lead

wire

connector

from

printed

circuit

and

remove

bulb

from

socket

BULB

SPECIFICATIONS

Item

Meter

illumination

lamp

Turn

signal

indicator

lamp

High

beam

indicator

lamp

Oil

pressure

warning

lamp

Charge

warning

lamp

Hand

brake

warning

lamp

Clock

illumination

lamp

SAE

Trade

Bulb

No

Wattage

Candle

power

W

e

161

161

161

161

161

158

158

1

7

I

x3

1

7

I

1

7

I

I

7

I

1

7

I

3

4

2

3

4

2

TROUB

E

DIAGNOSES

AND

CORRECTIONS

SPEEDOMETER

Condition

Speedometer

pointer

and

odometer

do

not

operate

Unstable

speedometer

pointer

Unusual

sound

occurs

in

response

to

in

crease

in

driving

speed

Probable

cause

Loose

speedometer

cable

union

nut

Broken

speedometer

cable

Damaged

speedometer

drive

pinion

gear

Transmission

side

Inoperative

speedometer

Improperly

tightened

or

loose

speedometer

cable

union

nut

Faulty

speedometer

cable

Inoperative

speedometer

ExceS

jvelybent

or

twisted

speedOmeter

cable

inner

wire

or

lack

of

lubrication

Inoperative

speedometer

8El8

Coirective

action

Retighten

Replace

Replace

Replace

Retighten

Replace

Replace

Replace

or

lubricate

Replace

Page 464 of 537

Condition

Inaccurate

speedometer

indication

Inaccurate

odometer

operation

Body

Electrical

System

Probable

cause

Inoperative

speedometer

Improperly

meshed

second

and

third

gear

worn

gears

Faulty

feeding

due

to

deformed

odometer

and

pinion

carrier

WATER

TEMPERATURE

AND

FUEL

GAUGES

Condition

Both

water

temperature

gauge

and

fuel

gauge

do

not

operate

Both

water

temperature

gauge

and

fuel

gauge

indicate

inaccurately

Water

temperature

gauge

Water

temperature

gauge

does

not

operate

Gauge

indicates

only

maximum

temperature

Water

temperature

gauge

does

not

operate

accurately

Probable

cause

Burnt

fuse

Inoperative

gauge

voltage

regulator

Inoperative

gauge

voltage

regulator

Gauge

pointer

fluctuates

excessively

Loose

of

poor

connection

Gauge

pointer

fluctuates

slightly

Correct

conn

Faulty

thermal

transmitter

or

loose

terminal

connection

When

thermal

transmitter

yellow

white

wire

is

grounded

gauge

pointer

fluctuates

Faulty

water

temperature

gauge

Open

circuit

Faulty

thermal

transmitter

Gauge

pointer

returns

to

original

position

when

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Gauge

pointer

indicates

maximum

tempera

ture

even

after

ignition

switch

is

turned

off

Faulty

water

temperature

gauge

Faulty

thermal

transmitter

Loose

or

poor

connection

BE

19

Corrective

action

Replace

Replace

speedometer

Replace

speedometer

Corrective

action

Correct

cause

and

replace

fuse

Replace

water

temperature

gauge

Replace

water

temperature

gauge

Correct

connector

contact

Replace

thermal

transmitter

or

correct

terminal

connection

Replace

wtater

temperature

gauge

Replace

thermal

transmitter

Replace

water

temperature

gauge

Connect

a

usn

resistance

between

ther

mal

transmitter

yellow

white

wire

and

ground

When

gauge

indicates

approximately

500C

i220F

gauge

is

serviceable

Correct

gauge

terminal

contact

Page 466 of 537

Body

Electrical

System

ELECTRICAL

ACCESSORIES

CONTENTS

HORN

DESCRIPTION

REMOVAL

AND

INSTALLATION

IGNITION

SWITCH

REMOVAL

AND

INSTALLATION

INSPECTION

WINDSHIELD

WIPER

AND

WASHER

REMOVAL

AND

INSTALLATION

INSPECTION

RADIO

REMOVAL

AND

INSTALLATION

ADJUSTMENT

CLOCK

REMOVAL

I

NST

ALLA

TION

HEATER

DESCRIPTION

AIRFLOW

HEATER

UNIT

ASSEMBLY

BE

21

BE

21

BE

21

8E

n

BE

22

BE

22

BE

23

BE

23

BE

23

BE

25

BE

25

BE

25

BE

25

BE

25

BE

26

BE

26

BE

26

BE

28

BE

29

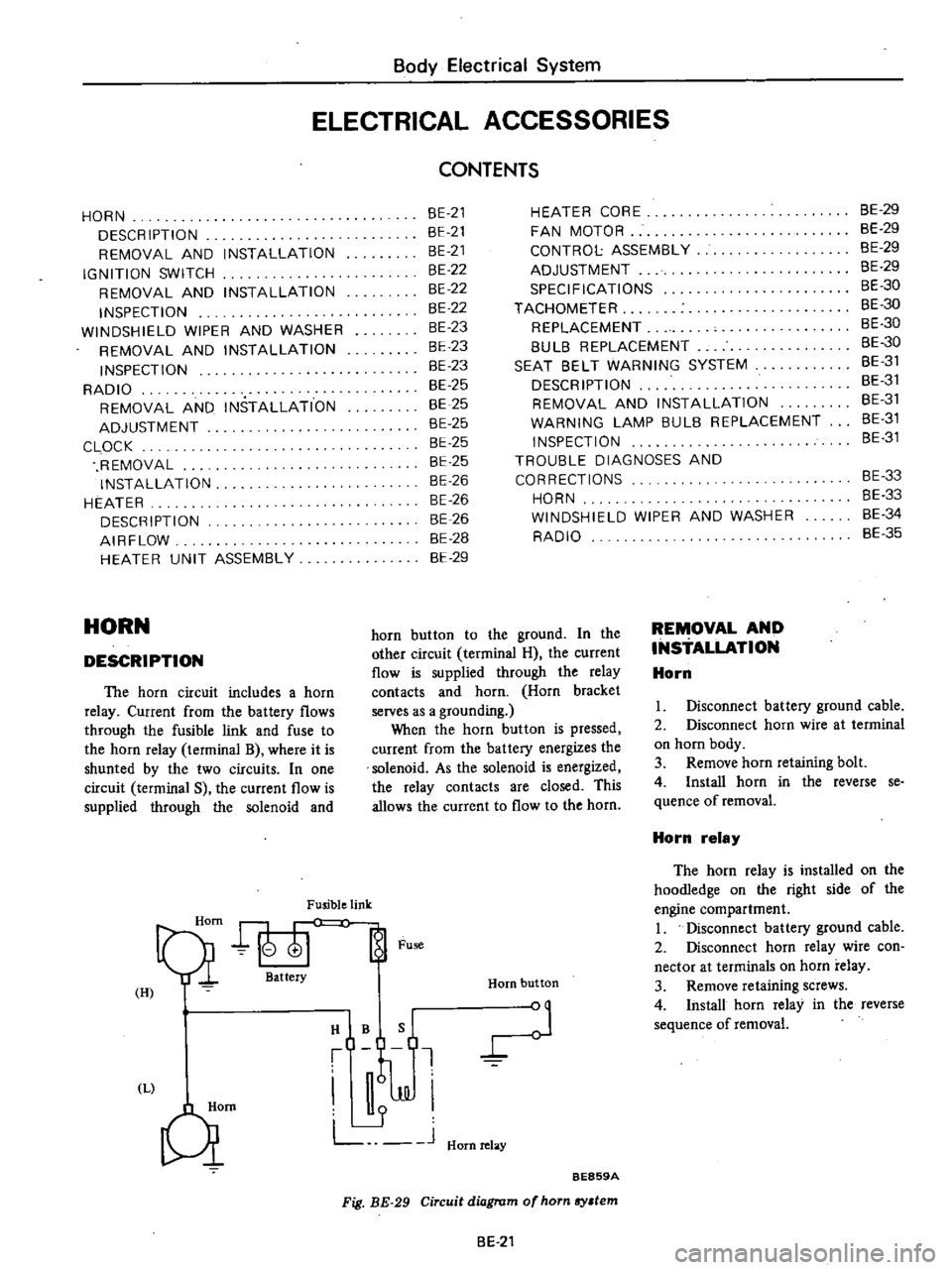

HORN

DESCRIPTION

The

horn

circuit

includes

a

horn

relay

Current

from

the

battery

flows

through

the

fusible

link

and

fuse

to

the

horn

relay

terminal

B

where

it

is

shunted

by

the

two

circuits

In

one

circuit

terminal

S

the

current

flow

is

supplied

through

the

solenoid

and

Fusible

link

Qi

att

Fu

H

I

HIBQ

t

J

JJI

L

J

Hornrelay

Qm

HEATER

CORE

FAN

MOTOR

CONTROL

ASSEMBLY

ADJUSTMENT

SPECIFICATIONS

TACHOMETER

REPLACEMENT

8UL8

REPLACEMENT

SEAT

8ELT

WARNING

SYSTEM

DESCRIPTION

REMOVAL

AND

INSTALLATION

WARNING

LAMP

BULB

REPLACEMENT

INSPECTION

TROUBLE

DIAGNOSES

AND

CORRECTIONS

HORN

WINDSHIELD

WIPER

AND

WASHER

RADIO

Horn

button

BE859A

Fig

BE

29

Circuit

diagram

of

horn

sy

tem

horn

button

to

the

ground

In

the

other

circuit

terminal

H

the

current

flow

is

supplied

through

the

relay

contacts

and

horn

Horn

bracket

serves

as

a

grounding

When

the

horn

button

is

pressed

current

from

the

battery

energizes

the

solenoid

As

the

solenoid

is

energized

the

relay

contacts

are

closed

This

allows

the

current

to

flow

to

the

horn

BE

21

REMOVAL

AND

INSTALLATION

Horn

8E

29

BE

29

BE

29

8E

29

BE

30

BE

30

BE

30

8E

30

8E

31

BE

31

BE

31

8E

31

8E

31

BE

33

8E

33

8E

34

BE

35

I

Disconnect

battery

ground

cable

2

Disconnect

horn

wire

at

terminal

on

horn

body

3

Remove

horn

retaining

bolt

4

Install

horn

in

the

reverse

se

quence

of

removal

Horn

relay

The

horn

relay

is

installed

on

the

hoodIedge

on

the

right

side

of

the

engine

compartment

I

Disconnect

battery

ground

cable

2

Disconnect

horn

relay

wire

con

nector

at

terminals

on

horn

relay

3

Remove

retaining

screws

4

Install

horn

relay

in

the

reverse

sequence

of

removal

Page 469 of 537

Body

Electrical

System

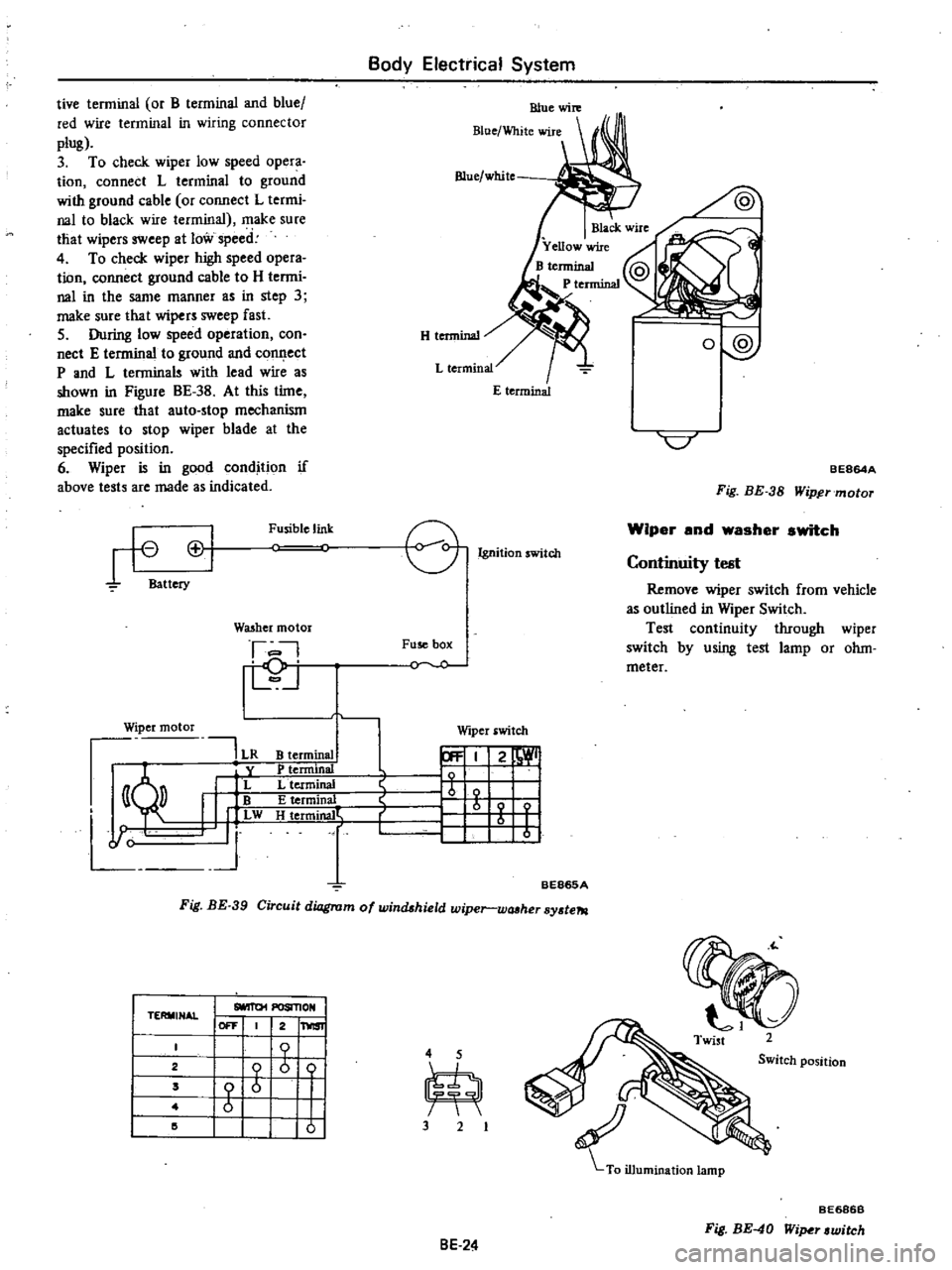

tive

terminal

or

B

terminal

and

blue

red

wire

terminal

in

wiring

connector

plug

3

To

check

wiper

low

speed

opera

tion

connect

L

terminal

to

ground

with

ground

cable

or

connect

L

termi

nal

to

black

wire

terminal

make

sure

that

wipers

sweep

at

low

speed

4

To

check

wiper

high

speed

opera

tion

connect

ground

cable

to

H

termi

nal

in

the

same

manner

as

in

step

3

make

sure

that

wipers

sweep

fast

5

During

low

speed

operation

con

nect

E

terminal

to

ground

and

conl

ect

P

and

L

terminals

with

lead

wire

as

shown

in

Figure

BE

38

At

this

time

make

sure

that

auto

stop

mechanism

actuates

to

stop

wiper

blade

at

the

specified

position

6

Wiper

is

in

good

condition

if

above

tests

are

made

as

indicated

H

tenninal

Blue

white

o

@

C

BE864A

Fig

BE

38

Wipftrmotor

rt

Cl

Battery

Fusible

link

e

Ignition

witch

Wiper

and

washer

switch

I

D

j

Fuse

box

Y

O

Continuity

test

Remove

wiper

switch

from

vehicle

as

outlined

in

Wiper

Switch

Test

continuity

through

wiper

switch

by

using

test

lamp

or

ohm

meter

WQ5hcr

motor

Wiper

motor

191

LR

y

I

L

I

w

J

Wiper

switch

B

terminal

P

tenninal

L

terminal

E

terminal

H

t

rmjrW

r

21

1

b

I

r

1

I

I

BE865A

Fig

BE

39

Circuit

diagram

of

windshield

wiper

wtUher

sy

te7tl

TERMINAL

I

SlOIT01

POSIl10N

I

I

OFF

2

1

1

2

I

b

ii

4

5

Switch

position

2

I

Z

m

Z

I

I

I

I

I

I

I

10

I

3

2

BE686B

Fig

BE

40

Wi

r

witch

8E

24

Page 472 of 537

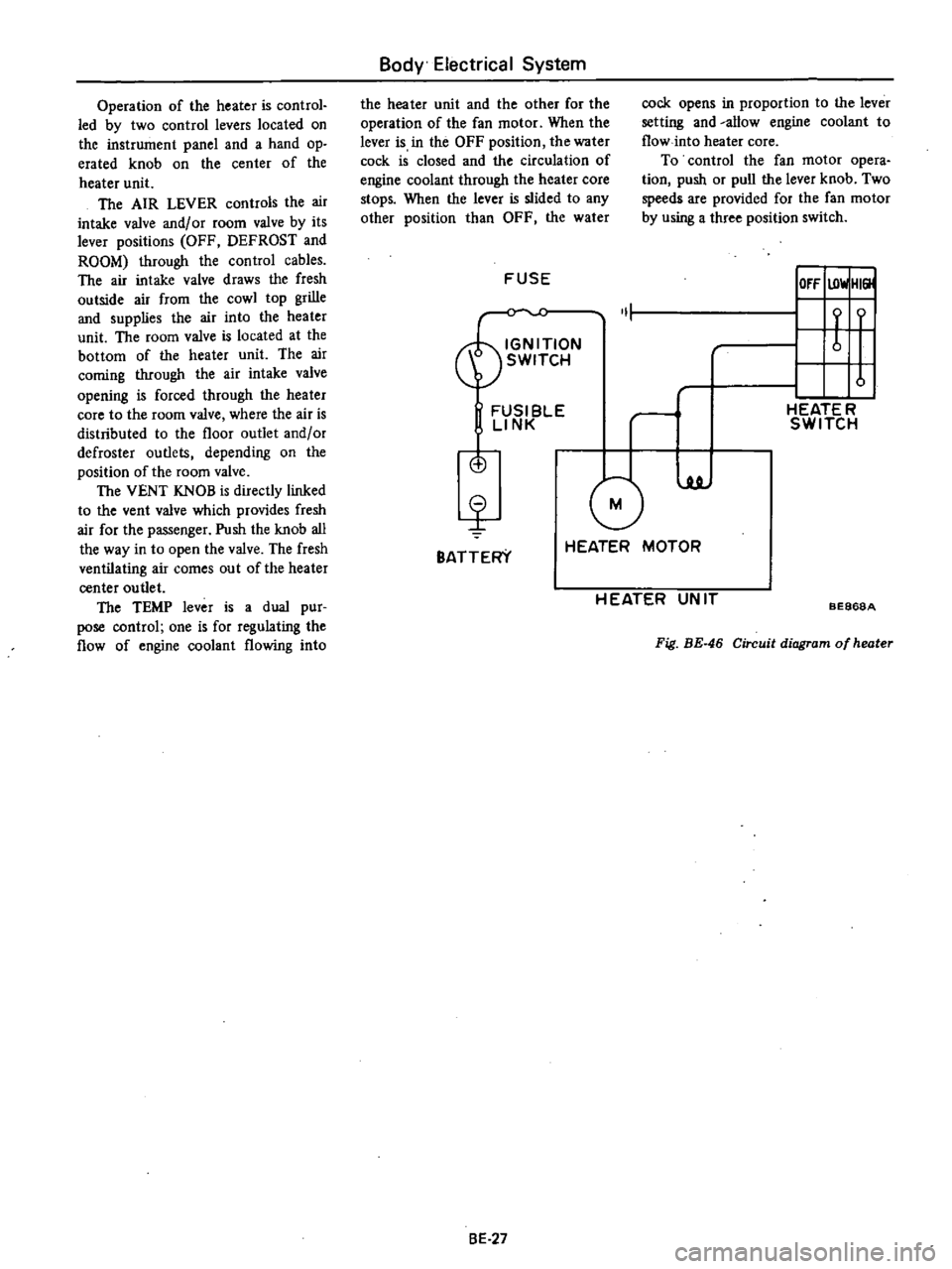

Operation

of

the

heater

is

control

led

by

two

control

levers

located

on

the

instrument

panel

and

a

hand

op

erated

knob

on

the

center

of

the

heater

unit

The

AIR

LEVER

controls

the

air

intake

valve

and

or

room

valve

by

its

lever

positions

OFF

DEFROST

and

ROOM

through

the

control

cables

The

air

intake

valve

draws

the

fresh

outside

air

from

the

cowl

top

grille

and

supplies

the

air

into

the

heater

unit

The

room

valve

is

located

at

the

bottom

of

the

heater

unit

The

air

coming

through

the

air

intake

valve

opening

is

forced

through

the

heater

core

to

the

room

valve

where

the

air

is

distributed

to

the

floor

outlet

and

or

defroster

outlets

depending

on

the

position

of

the

room

valve

The

VENT

KNOB

is

directly

linked

to

the

vent

valve

which

provides

fresh

air

for

the

passenger

Push

the

knob

all

the

way

in

to

open

the

valve

The

fresh

ventilating

air

comes

out

of

the

heater

center

outlet

The

TEMP

lever

is

a

dual

pur

pose

control

one

is

for

regulating

the

flow

of

engine

coolant

flowing

into

Body

Electrical

System

the

heater

unit

and

the

other

for

the

operation

of

the

fan

motor

When

the

lever

is

in

the

OFF

position

the

water

cock

is

closed

and

the

circulation

of

engine

coolant

through

the

heater

core

stops

When

the

lever

is

slided

to

any

other

position

than

OFF

the

water

cock

opens

in

proportion

to

the

lever

setting

and

allow

engine

coolant

to

flow

into

heater

core

To

control

the

fan

motor

opera

tion

push

or

pull

the

lever

knob

Two

speeds

are

provided

for

the

fan

motor

by

using

a

three

position

switch

FUSE

IOfF

UlwlHI

ON

1

t

f

SWITCH

u

FUSI

BlE

rl

HEATE

R

LINK

SWITCH

is

G

luJ

BATTERY

HEATER

MOTOR

H

EATER

UN

IT

BE868A

Fig

BE

46

Circuit

diagram

of

heater

8E

27

Page 477 of 537

Body

Electrical

System

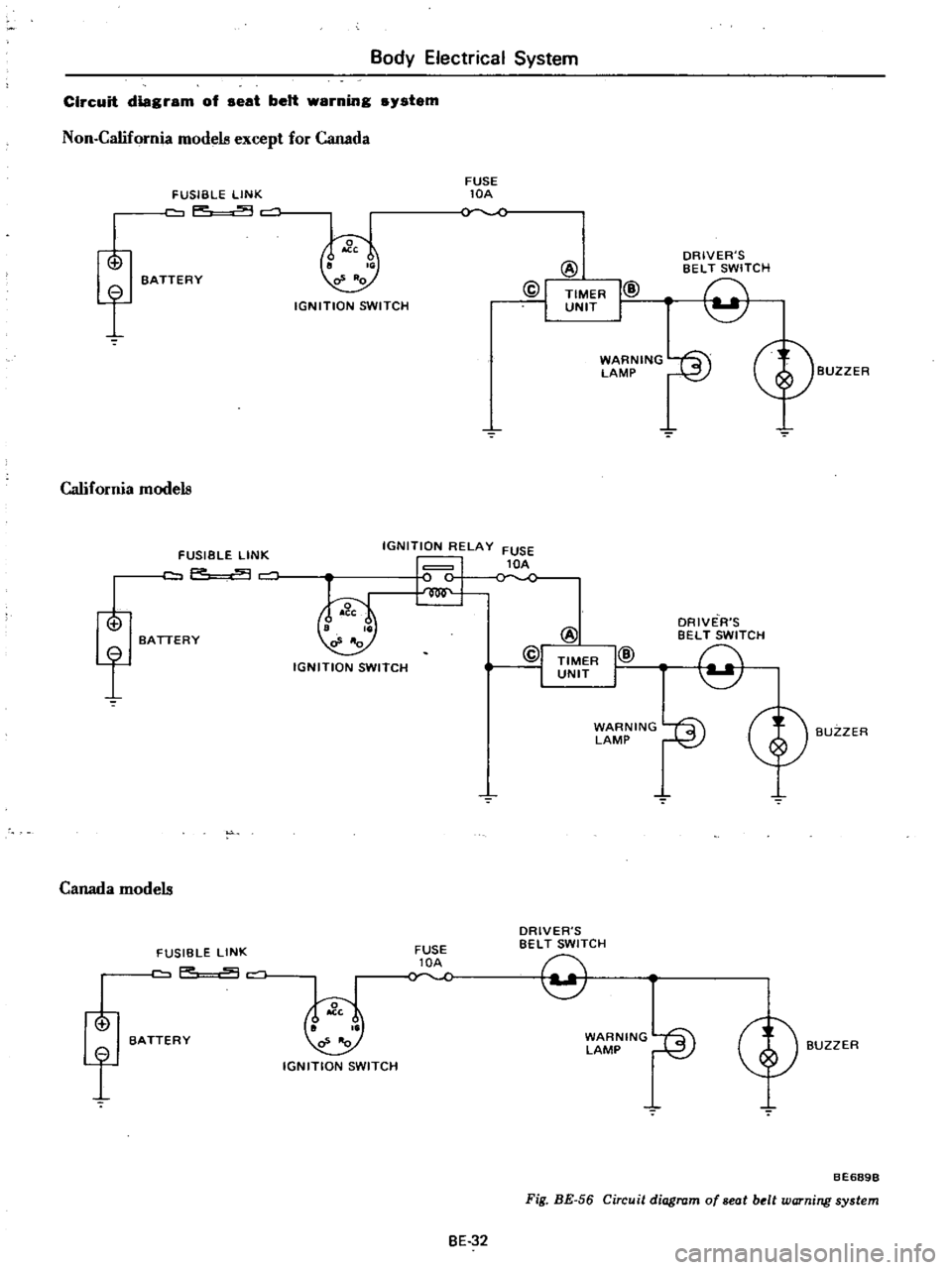

Circuit

diagram

of

seat

belt

warning

system

Non

California

modela

except

for

Canada

f

FUSIBLE

LINK

p

c

o

BATTERY

California

modela

f

Canada

modela

o

f

FUSIBLE

LINK

F

9

BATTERY

FUSIBLE

LINK

aP

c

BATTERY

IGNITION

SWITCH

FUSE

lOA

@

@I

TIMER

UNIT

I@

I

WARNING

fS

LAMP

l

2

IGNITION

RELAY

FUSE

1

lC

1

lOA

IGNITION

SWITCH

N

IGN

ITION

SWITCH

FUSE

lOA

BE

32

DRIVER

S

BELT

SWITCH

9

ORIVE

R

S

BELT

SWITCH

9

WARNING

r

i

LAMP

I

2

J

DRIVER

S

BELT

SWITCH

9

WARNING

fS

LAMP

I

2

J

Cf

BUZZER

BUZZER

BUZZER

BE689B

Fig

BE

56

Circuit

diagram

of

seat

belt

warning

system

Page 478 of 537

Body

Electrical

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

HORN

Condition

Horn

does

not

operate

Horn

sounds

continuously

Reduced

volume

and

or

tone

quality

Probable

cause

Discharged

battery

Measure

specific

gravity

of

electrolyte

Burnt

fuse

Faulty

horn

button

contact

Horn

sounds

when

horn

relay

terminal

s

is

grounded

Inoperative

horn

relay

Horn

sounds

when

B

and

H

horn

relay

tenninals

are

connected

with

a

test

lead

Damaged

horn

or

loose

horn

terminal

con

nection

Short

circuited

horn

button

and

or

horn

button

lead

wire

When

light

green

lead

wire

is

disconnected

from

horn

relay

terminal

s

horn

stops

to

sound

Inoperative

horn

relay

Loose

or

poor

connector

contact

Fuse

relay

horn

and

or

horn

button

Damaged

horn

BE

33

Corrective

action

Recharge

or

replace

battery

Correct

cause

and

replace

fuse

Repair

horn

button

Replace

horn

relay

Correct

horn

te

inal

onnection

or

replace

horn

Repair

horn

button

or

its

wiring

Replace

horn

relay

Repair

Replace

Page 479 of 537

Body

Electrical

System

WINDSHIELD

WIPER

AND

WASHER

Condition

Windshield

wiper

motor

does

not

operate

Wiper

operating

speed

is

too

slow

Wiper

speed

cannot

be

changed

correctly

Wiper

motor

continues

to

run

after

switch

is

turned

off

or

wiper

blades

do

not

return

to

correct

position

Probable

cause

Burnt

fuse

Damaged

motor

Check

wiper

motor

as

outlined

in

Inspec

tion

Loose

connection

Faulty

wiper

and

washer

switch

Test

continuity

through

switch

as

outlined

in

Inspection

Open

power

circuit

or

ground

circuit

Damaged

motor

Loose

or

poor

connection

Seized

or

rusted

wiper

linkage

Humming

occurs

on

motor

in

wiper

blade

operating

cycle

Wiper

blades

stick

on

windshield

glass

Raise

arm

and

operate

wiper

without

load

Faulty

wiper

switch

Damaged

motor

Faulty

auto

stop

operation

Poor

connection

Faulty

switch

BE

34

Corrective

action

Correct

cause

and

replace

fuse

Replace

wiper

motor

Repair

Replace

Repair

Replace

motor

Repair

Lubricate

or

replace

Clean

windshield

glass

and

or

replace

wiper

blade

Replace

Replace

Remove

auto

stop

device

cover

and

check

relay

contacts

Clean

dirty

contacts

or

repair

relay

plate

bending

if

necessary

Repair

Replace

Page 485 of 537

m

J

c

@

@

r

1

I

I

I

II

U

j

J

r

U

I

IT

L

U

L

L

@

Qj

flll

I

1

I

I

1

lL

to

t

l

Q

1

To

room

Jamp

cable

2

To

light

switch

3

To

fuse

4

To

tachometer

or

clock

5

To

hazard

flasher

unit

6

To

stop

lamp

switch

7

To

ignition

switch

8

To

hazard

switch

9

To

tU

and

dimmer

switch

10

To

check

connector

11

To

AMP

M

T

only

11

To

combination

instrument

Non

California

mode15

except

for

Canada

13

To

combination

meter

14

To

flasher

unit

IS

To

kickdown

switch

AfT

only

16

To

hand

brake

switch

17

To

heater

motor

18

To

illumination

control

rheostat

19

To

wiper

switch

light

switch

illumination

lamp

20

To

wiper

switch

21

To

cigar

lighter

22

To

heater

control

illumination

lamp

23

To

radio

24

To

heater

control

25

To

belt

and

E

G

R

warning

lamp

Non

California

models

or

floor

te

peratuJe

California

models

26

To

heater

control

illumination

lamp

27

To

buzzer

28

To

belt

warning

timer

U

S

A

Olodels

29

To

indicator

lamp

AfT

only

30

To

cooler

harness

31

To

wiptr

motor

32

To

door

switch

R

H

33

To

engine

compartment

harness

34

To

floor

harness

E

m

S

@

o

J

o

Q

m

CD

n

Ql

en

I

i

3