brake DATSUN PICK-UP 1977 Workshop Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 324 of 537

Specifications

and

adjustment

AfT

Automatic

transmission

assembly

Model

code

number

Torque

converter

assembly

Stamped

mark

on

th

e

TiC

Front

clutch

Number

of

drive

plate

Number

of

driven

plates

Clearance

Thickness

of

retainin

g

plate

Rear

clutch

Number

of

drive

plates

Number

of

driven

plates

Clearance

Thickness

of

retaining

plate

Low

reverse

brake

Number

of

drive

plates

Number

f

driven

pla

es

Clearance

Thickness

of

retaining

plaie

Brake

band

Piston

size

Big

dia

S

all

dia

Control

valve

assembly

Stamped

mark

on

slraine

Governor

assembly

Stamped

mark

on

governor

body

Automatic

Transmission

mOl

in

mm

in

mOl

inJ

mOl

in

mOl

in

mOl

in

mOl

in

AT

60

X2402

16

B

3

3

1

6

to

1

8

0

063

to

0

071

10

6

0

417

10

8

0

42S

11

0

0

433

11

2

0

441

11

4

0

449

11

6

0

4S7

4

4

1

0

to

1

5

0

039

to

0

OS9

4

8

0

189

4

4

0

80

to

1

0S

0

0315

to

0

0413

11

8

0

46S

12

0

0

472

12

2

0

480

12

4

0

488

12

6

0

496

12

8

O

S04

64

2

S2

40

1

57

E

35

Page 325 of 537

Automatic

Transmission

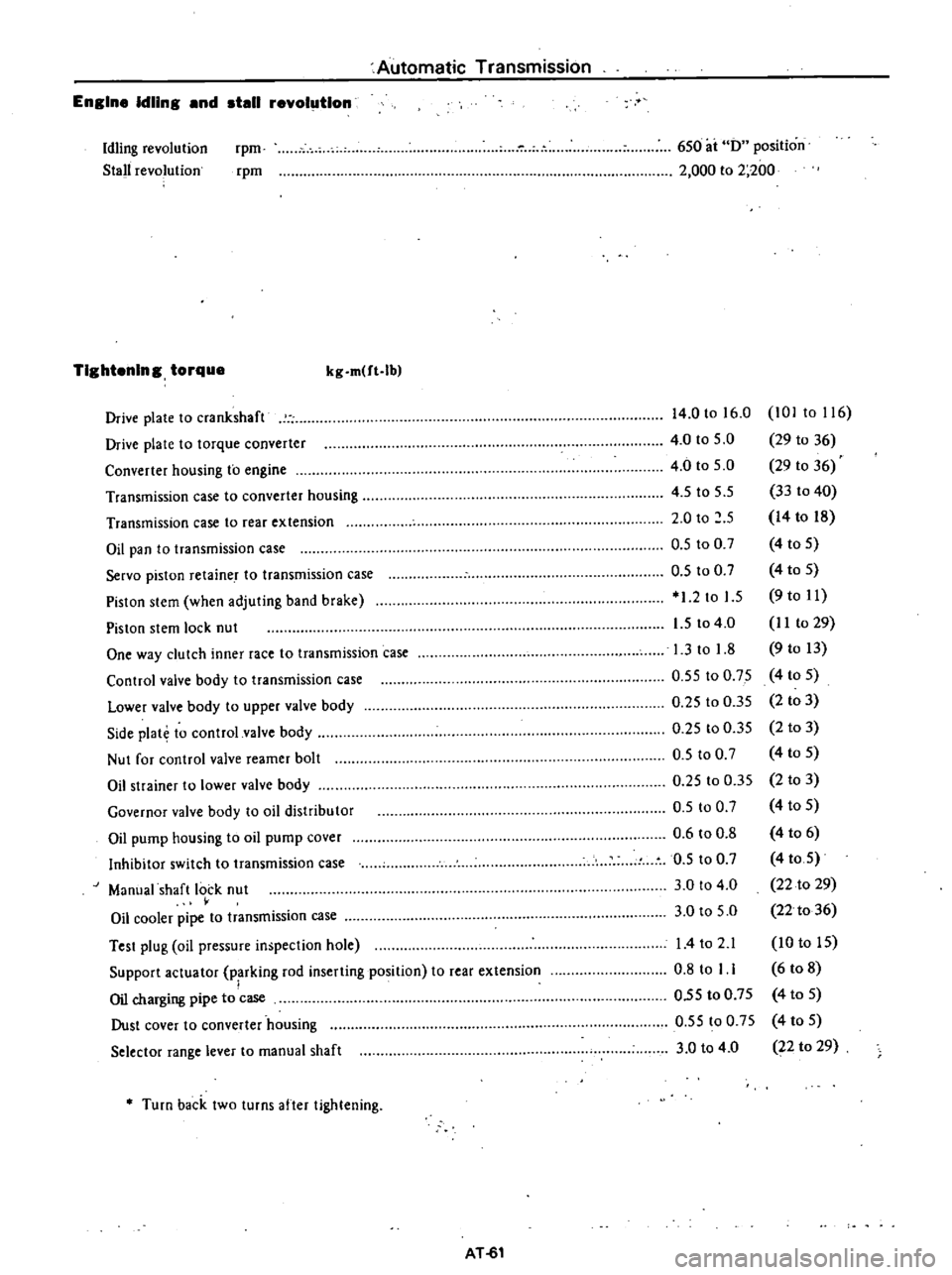

Engine

Idling

and

stall

revolution

Idling

revolution

Stall

revolution

rpm

rpm

6S0

ai

0

position

2

000

to

2

200

TIghtening

torque

kg

m

ft

lb

Drive

plate

to

crankshaft

Drive

plate

to

torque

converter

Converter

housing

to

engine

Transmission

case

to

converter

housing

Transmission

case

to

rear

extension

Oil

pan

to

transmission

case

Servo

piston

retaine

T

to

transmission

case

Pislon

slem

when

adjuting

band

brake

Piston

stem

lock

nut

One

way

clutch

inner

race

to

transmission

case

Control

valve

body

to

transmission

case

Lower

valve

body

to

upper

valve

body

Side

plat

to

control

valve

body

Nut

for

control

valve

reamer

bolt

Oil

strainer

to

lower

valve

body

Governor

valve

body

to

oil

distribu

tor

Oil

pump

housing

to

oil

pump

cover

Inhibitor

switch

to

transmission

case

Manual

shaft

lock

nut

Oil

cooler

pipe

to

transmission

case

Test

plug

oil

pressure

inspection

hole

Support

actuator

parking

rod

inserting

position

to

rear

extension

I

Oil

charging

pipe

to

case

Dust

cover

to

converter

housing

Selector

range

lever

to

manual

shaft

14

0

to

16

0

101

to

116

4

0

to

5

0

29

to

36

4

0

to

S

O

29

10

36

4

S

to

5

5

33

to

40

2

0

to

S

14

to

18

O

S

to

0

7

4

to

S

O

S

to

0

7

4

to

S

1

2

to

1

5

9

to

11

1

5

to

4

0

I

I

to

29

1

3

to

1

8

9

to

13

0

5S

to

0

75

4

to

S

0

25

to

O

3S

2

to

3

0

25

to

0

35

2

to

3

O

S

to

0

7

4

to

S

0

25

to

0

35

2

to

3

D

S

100

7

4

to

5

0

6

to

0

8

4

to

6

0

5

to

0

7

4

toS

3

0

to

4

0

22

to

29

3

0

to

S

O

22

to

36

I

4to

2

1

10

to

IS

0

8

to

I

1

6

to

8

O

5S

to

0

7S

4

to

S

O

5S

to

0

75

4

to

S

3

0

to

4

0

22

to

29

Turn

back

two

turns

after

tightening

AT

61

Page 352 of 537

The

design

of

the

front

suspension

adopts

the

independent

double

wishbone

type

suspension

used

the

torsion

bar

spring

Both

the

upper

and

lower

links

are

installed

on

the

bracket

which

is

welded

on

the

frame

A

1d

the

above

links

swing

to

allow

the

knuckle

spindle

to

move

freely

in

a

vertical

dimension

The

top

and

bottom

of

the

knuckle

spindle

support

are

connected

to

the

upper

link

through

rubber

bushing

and

to

the

lower

lick

through

screw

bushing

The

tension

rod

held

by

the

brack

ets

on

the

chassis

frame

and

lower

lick

wiih

rubber

bushings

bears

the

force

of

fore

and

aft

direction

The

front

end

of

the

torsion

bar

spring

is

installed

to

the

torque

arm

which

attaches

to

the

lower

link

The

opposite

end

is

installed

to

the

spring

anchor

that

secures

to

chassis

frame

firmly

The

both

ends

of

the

torsion

bar

spring

are

serrated

The

shock

absorber

is

double

action

telescopic

hydraulic

type

The

upper

stem

is

attached

to

the

bracket

of

the

chassis

frame

The

lower

insulated

bracket

is

bolted

to

the

lower

lick

The

bumper

rubber

secured

to

the

bracket

Of

the

frame

limits

the

verti

cal

motion

of

the

suspension

lick

The

knuckle

spindle

is

connecied

to

the

k

ufkle

spindle

arm

by

the

king

pin

The

king

pin

bushings

are

fitted

to

the

upper

and

lower

arm

portIOns

of

the

knuckle

spindle

and

seals

are

provided

at

the

portions

mentioned

to

keep

water

and

dirt

from

enteri

g

The

knuckle

arm

is

connected

to

the

lower

end

of

the

knuckle

spindle

to

transmit

ttLe

movement

of

the

steering

wheel

to

the

knuckle

spindle

The

wheel

hub

is

supported

by

two

taper

roller

bearings

on

the

knuckle

spindle

Tlie

brake

drum

and

wheel

are

secured

to

ihe

hub

by

the

hub

bolts

Front

Axle

Front

Suspension

FRONT

AXLE

REMOVAL

AND

INSTALLATION

Removal

I

Jack

up

and

support

vehicle

on

the

stands

at

the

frame

in

a

safe

manner

2

Remove

front

wheel

3

Re

ove

brake

hose

together

with

connector

from

wheel

cylinder

4

Remove

brake

drum

S

Remove

hub

cap

and

then

remove

cotter

pin

adjusting

cap

and

spindle

nut

from

knuckle

spindle

6

Remove

wheel

hub

outer

and

inner

wheel

bearings

bearing

washer

and

grease

seal

from

knuckle

spindle

7

Remove

brake

disc

assembly

from

the

flange

of

knuckle

spindle

8

Remove

knuckle

arm

from

knuckle

spindle

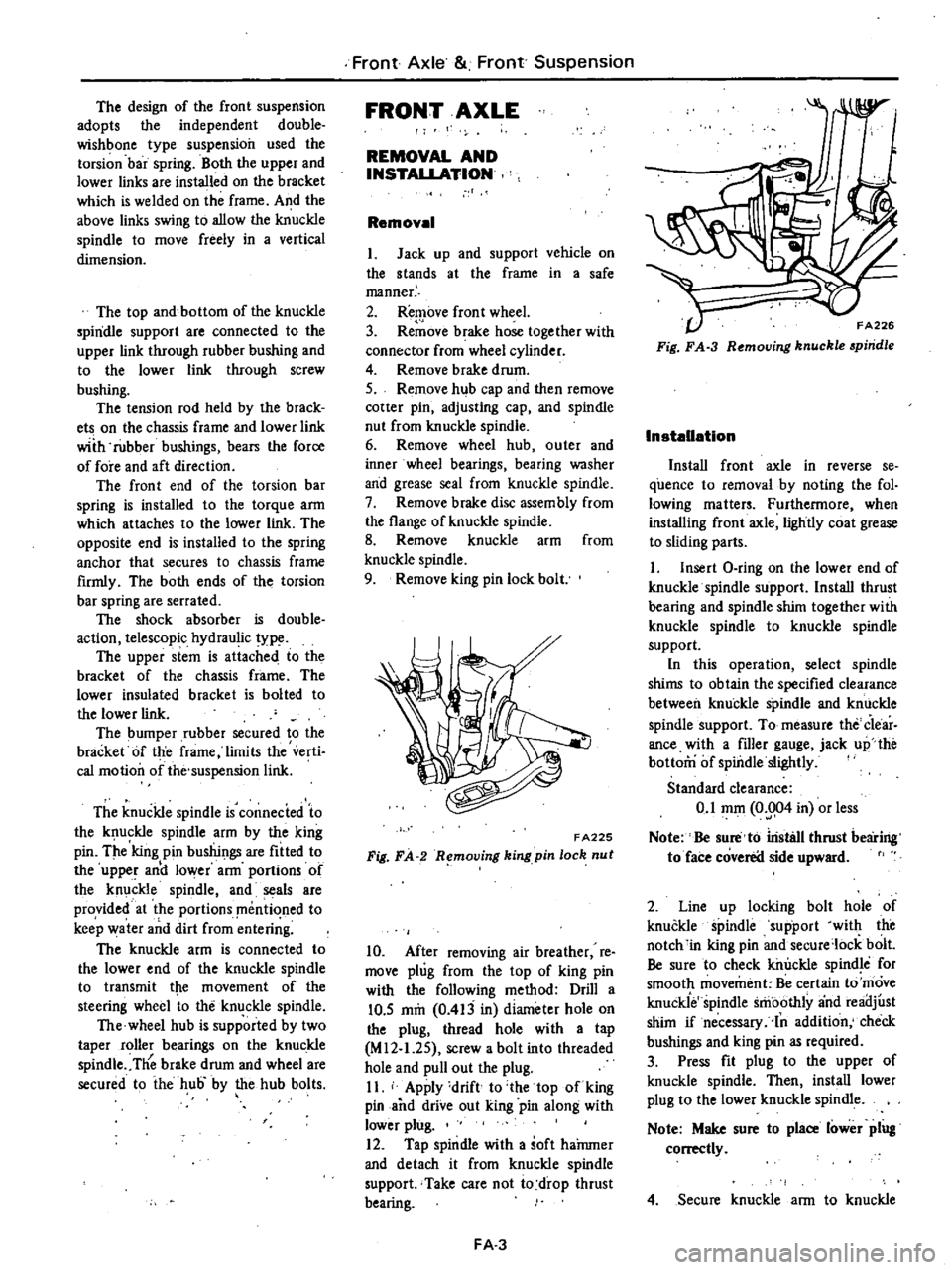

9

Remove

king

pin

lock

bolt

FA225

Fig

FA

R

mol1ing

king

pin

loch

nut

10

After

removing

air

breather

re

move

plug

from

the

top

of

king

pin

with

the

following

method

Drill

a

10

5

mm

0

413

in

diameter

hole

on

the

plug

thread

hole

with

a

tap

M

12

1

2S

screw

a

bolt

into

threaded

hole

and

pull

out

the

plug

II

Apply

drift

to

the

top

of

king

pin

and

drive

out

king

pin

along

with

lower

plug

12

Tap

spindle

with

a

soft

haJnmer

and

detach

it

from

knuckle

spindle

support

Take

care

not

io

drop

thrust

bearing

FA

3

FA226

Fig

FA

3

R

moving

knuckle

piridle

Installation

Install

front

axle

in

reverse

se

quence

to

removal

by

noting

the

fol

lowing

matters

Furthermore

when

installing

front

axle

lightly

coat

grease

to

sliding

parts

I

Insert

O

ring

on

the

lower

end

of

knuckle

spindle

support

Install

thrust

bearing

and

spindle

shim

together

with

knuckle

spindle

to

knuckle

spindle

support

In

this

operation

select

spindle

shims

to

obtain

the

specified

clearance

between

knuckle

spindle

and

knuckle

spindle

support

To

measure

the

Clear

ance

with

a

filler

gauge

jack

up

the

bottom

of

spindle

slightly

Standard

clearance

0

1

mOl

0

004

in

or

less

Note

Be

sure

to

iristsll

thrust

bearing

to

face

coverea

side

upward

2

Line

up

locking

bolt

hole

of

knuckle

spindle

support

with

the

notch

in

king

pin

and

secure

lock

bolt

Be

sure

to

check

killJckle

spindle

for

smooth

movement

Be

certain

to

move

knuckie

spindle

smoothly

and

reailjust

shim

if

necessary

In

addition

check

bushings

and

king

pin

as

required

3

Press

fit

plug

to

the

upper

of

knuckle

spindle

Then

install

lower

plug

to

the

lower

knuckle

spindle

Note

Make

sure

to

place

lower

plug

conectly

4

Secure

knuckle

arm

to

knuckle

Page 359 of 537

UPPER

AND

LOWER

LINKS

REMOVAL

AND

INSTALLATION

Removal

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

and

brake

drum

as

an

assembly

3

Remove

wheel

hub

Refer

to

see

tion

Front

Axle

4

Loosen

bolts

retaining

brake

disc

to

knuckle

spindle

and

remove

brake

disc

5

Remove

knuckle

arm

torsion

bar

spimgJ

stabilizer

shock

absorber

and

tension

rod

in

t

ili

order

referring

the

related

sections

6

Remove

upper

fulcrum

bolt

se

curing

knuckle

spindle

support

to

upper

link

assembly

and

disassemble

them

7

Remove

upper

link

bushings

from

knuckle

spindle

support

8

Remove

screw

bushings

from

both

ends

of

lower

link

fulcrum

pin

9

Loosen

nut

at

lower

portion

of

knuckle

spindle

support

from

inside

and

pull

out

cotter

pin

retaining

ful

crum

pin

10

Pull

out

fulcrum

pin

with

drift

and

remove

knuckle

spindle

support

with

knuckle

spindle

from

lower

link

Then

detach

dust

cover

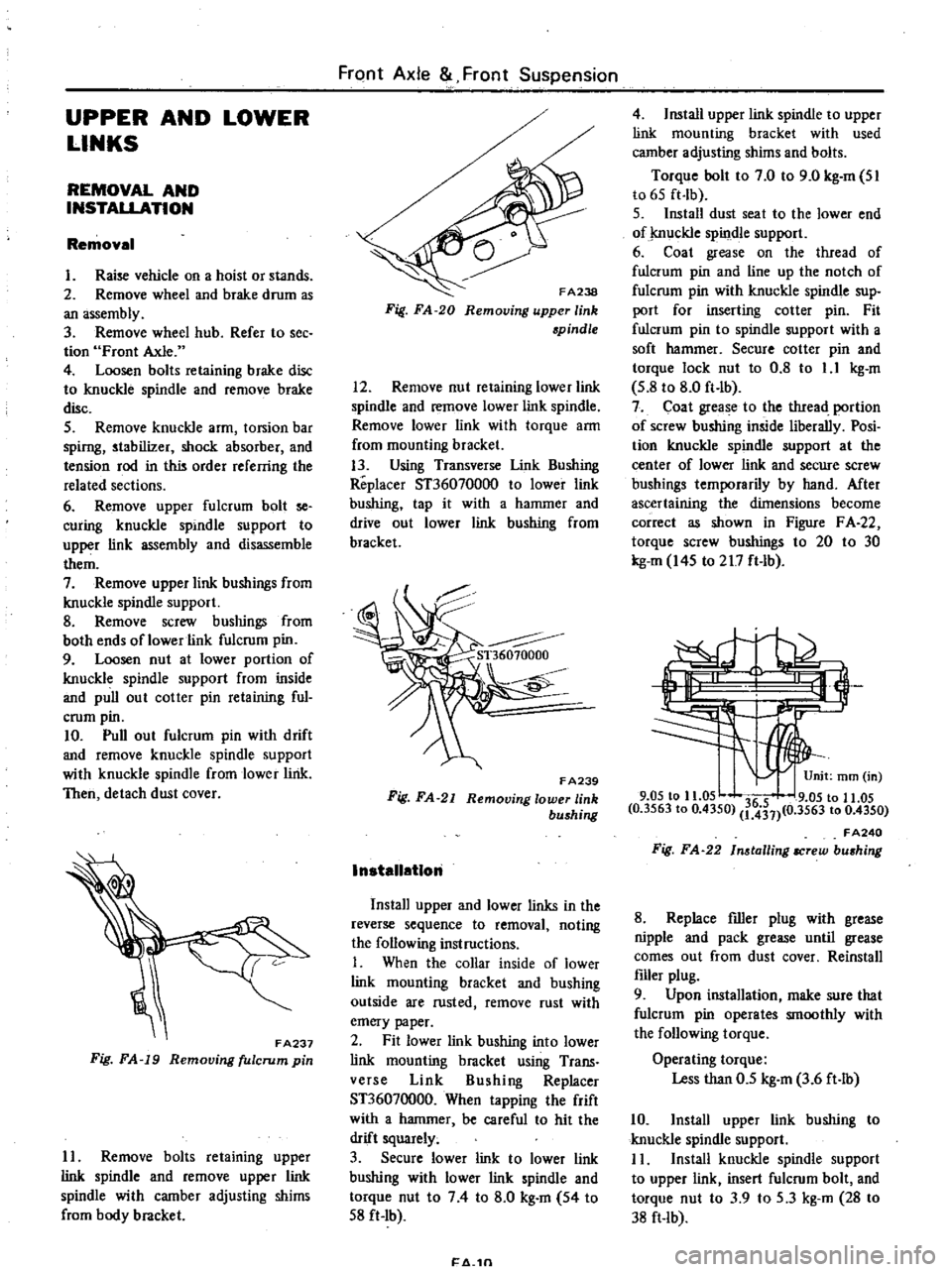

FA237

Fig

FA

19

Removing

fulcrum

pin

II

Remove

bolts

retaining

upper

link

spindle

and

remove

upper

link

spindle

with

camber

adjusting

shims

from

body

bracket

FrClnt

Axle

Front

Suspension

FA238

Fig

FA

20

Removing

upper

link

spindle

12

Remove

nut

retaining

lower

link

spindle

and

remove

lower

link

spindle

Remove

lower

link

with

torque

arm

from

mounting

bracket

13

Using

Transverse

Unk

Bushing

Replacer

ST36070000

to

lower

link

bushing

tap

it

with

a

hammer

and

drive

out

lower

link

bushing

from

bracket

F

A239

Fig

FA

21

Removing

lower

link

bushing

InstallatIon

Install

upper

and

lower

links

in

the

reverse

sequence

to

removal

noting

the

following

instructions

I

When

the

collar

inside

of

lower

link

mounting

bracket

and

bushing

outside

are

rusted

remove

rust

with

emery

paper

2

Fit

lower

link

bushing

into

lower

link

mounting

bracket

using

Trans

verse

Link

Bushing

Replacer

ST36070000

When

tapping

the

frift

with

a

hammer

be

careful

to

hit

the

drift

squarely

3

Secure

lower

link

to

lower

link

bushing

with

lower

link

spindle

and

torque

nut

to

74

to

8

0

kg

m

54

to

S8

ft

Ib

1

4

1n

4

Install

upper

link

spindle

to

upper

link

mounting

bracket

with

used

camber

adjusting

shims

and

bolts

Torque

bolt

to

7

0

to

9

0

kg

m

SI

to

6S

ft

lb

S

Install

dust

seat

to

the

lower

end

of

j

nuckle

spindle

support

6

Coat

grease

on

the

thread

of

fulcrum

pin

and

line

up

the

notch

of

fulcrum

pin

with

knuckle

spindle

sup

port

for

inserting

cotter

pin

Fit

fulcrum

pin

to

spindle

support

with

a

soft

hammer

Secure

cotter

pin

and

torque

lock

nut

to

0

8

to

1

1

kg

m

S

8

to

8

0

ft

lb

7

Coat

grease

to

the

tIuead

portion

of

screw

bushing

inside

liberally

Posi

tion

knuckle

spindle

support

at

the

center

of

lower

link

and

secure

screw

bushings

temporarily

by

hand

Mter

ascertaining

the

dimensions

become

correct

as

shown

in

Figure

F

A

22

torque

screw

bushings

to

20

to

30

kg

m

I4S

to

217

ft

lb

3

9

05

to

11

05

36

5

9

05

to

11

05

0

3563

to

0

4350

1

431

0

3563

to

0

4350

FA240

Fig

FA

22

In

tailing

IICrew

bu

hing

8

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

filler

plug

9

Upon

installation

make

sure

that

fulcrum

pin

operates

smoothly

with

the

following

torque

Operating

torque

Less

than

0

5

kg

m

3

6

ft

lb

10

Install

upper

link

bushing

to

knuckle

spindle

support

I

I

Install

knuckle

spindle

support

to

upper

link

insert

fulcrum

bolt

and

torque

nut

to

3

9

to

S

3

kg

m

28

to

38

ft

lb

Page 360 of 537

Note

When

installing

fulcrum

pin

insert

it

from

rearward

of

vehicle

12

Install

tension

rod

shock

ab

sorber

I

stabilizer

torsion

bar

spring

and

knuckle

arm

referring

to

the

related

paragraphs

13

Install

brake

disc

to

knuckle

spindle

and

torque

securing

bolt

to

4

2

to

5

0

kg

m

30

to

36

ft

Ib

14

Install

wheel

and

brake

drum

as

an

assembly

and

torque

knuckle

spin

dle

nut

to

8

0

to

9

0

kg

m

58

to

65

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Upper

link

I

Detach

upper

link

spindle

from

upper

links

and

remove

clamp

dust

cover

and

dust

seal

Secure

upper

link

in

a

vise

and

loosen

screw

bushing

Assemble

link

spindle

in

reverse

sequence

to

disassembling

noting

the

following

instructions

2

Torque

screw

bushing

on

upper

link

to

3S

to

55

kg

m

253

to

398

ft

Ib

Install

new

dust

seal

and

dust

cover

and

secure

them

with

clamp

3

Coat

grease

to

screw

bushing

in

side

and

the

thread

portion

of

upper

link

spindle

liberally

Screw

front

and

rear

links

to

upper

link

spindle

in

the

same

length

so

as

to

obtain

the

speci

fied

figures

as

shown

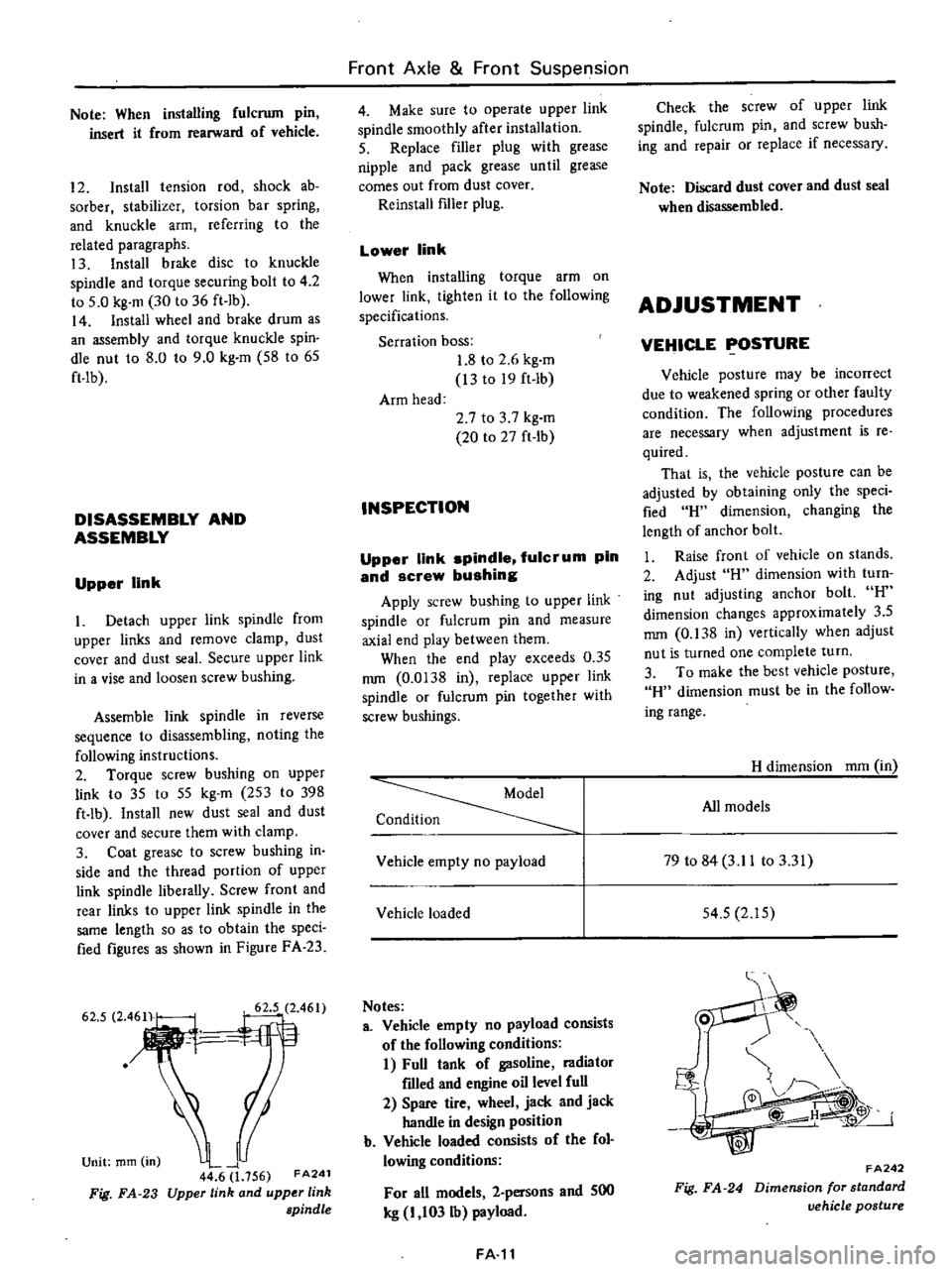

in

Figure

FA

23

Unit

mm

in

I

44

6

1

156

FA2

Upper

link

and

upper

link

spindle

Fig

FA

23

Front

Axle

Front

Suspension

4

Make

sure

to

operate

upper

link

spindle

smoothly

after

installation

5

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

f1ller

plug

Lower

link

When

installing

torque

arm

on

lower

link

tighten

it

to

the

following

specifications

Serration

boss

1

8

to

2

6

kg

m

13

to

19

ft

Ib

Arm

head

2

7

to

3

7

kg

m

20

to

27

ft

tb

INSPECTION

Upper

link

spindle

fulcrum

pin

and

screw

bushing

Apply

screw

bushing

to

upper

link

spindle

or

fulcrum

pin

and

measure

axial

end

play

between

them

When

the

end

play

exceeds

0

35

mm

0

0138

in

replace

upper

link

spindle

or

fulcrum

pin

together

with

screw

bushings

Condition

Vehicle

empty

no

payload

Vehicle

loaded

Notes

a

Vehicle

empty

no

payload

consists

of

the

following

conditions

I

Full

tank

of

gasoline

radiator

f1lled

and

engine

oil

level

full

2

Spare

tire

wheel

jack

and

jack

handle

in

design

position

b

Vehicle

loaded

consists

of

the

fol

lowing

conditions

For

all

models

2

persons

and

SIlO

leg

I

103lb

payload

FA

Check

the

screw

of

upper

link

spindle

fulcrum

pin

and

screw

bush

ing

and

repair

or

replace

if

necessary

Note

Discard

dust

cover

and

dust

seal

when

disassembled

ADJUSTMENT

VEHICLE

POSTURE

Vehicle

posture

may

be

incorrect

due

to

weakened

spring

or

other

faulty

condition

The

following

procedures

are

necessary

when

adjustment

is

Ie

quired

That

is

the

vehicle

posture

can

be

adjusted

by

obtaining

only

the

speci

fied

H

dimension

changing

the

length

of

anchor

bolt

I

Raise

front

of

vehicle

on

stands

2

Adjust

H

dimension

with

turn

ing

nut

adjusting

anchor

bolt

H

dimension

changes

approximately

3

5

mm

0

J38

in

vertically

when

adjust

nut

is

turned

one

complete

turn

3

To

make

the

best

vehicle

posture

H

dimension

must

be

in

the

follow

ing

range

H

dimension

mOl

in

All

models

79

to

84

3

11

to

3

31

54

5

2

15

o

i

Fig

FA

24

FA242

Dimension

for

standard

vehicle

postl4re

Page 362 of 537

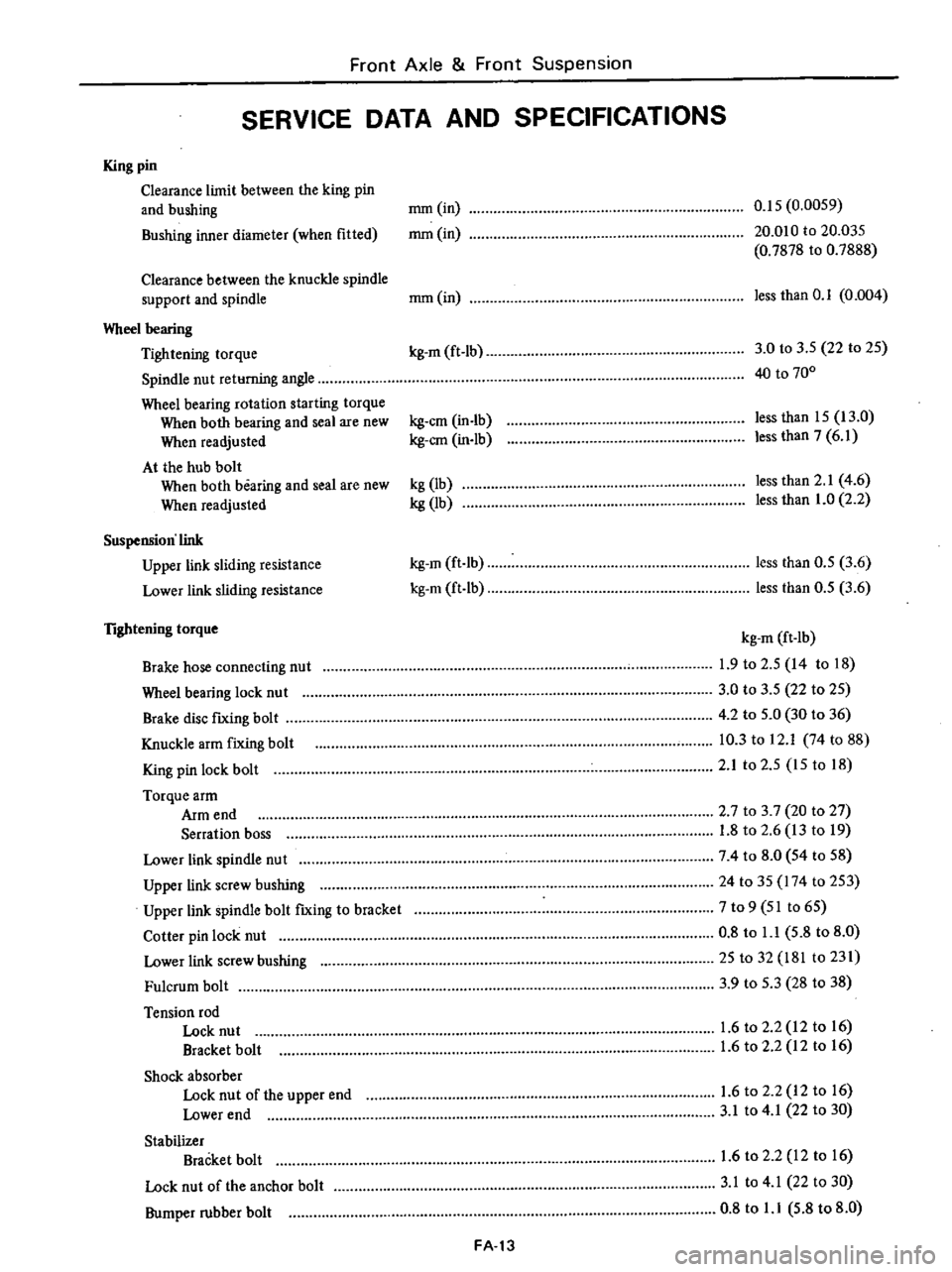

Front

Axle

Front

Suspension

SERVICE

DATA

AND

SPECIFICATIONS

King

pin

Clearance

limit

between

the

king

pin

and

bushing

mm

in

0

15

0

0059

Bushing

inner

diameter

when

fitted

mm

in

20

010

to

20

035

0

7878

to

0

7888

Clearance

between

the

knuckle

spindle

support

and

spindle

mm

in

less

than

0

1

0

004

Wheel

bearing

Tightening

torque

kg

m

ft

Ib

3

0

to

3

S

22

to

2S

Spindle

nut

returning

angle

40

to

700

Wheel

bearing

rotation

starting

torque

When

both

bearing

and

seal

are

new

kg

em

in

Ib

less

than

IS

13

0

When

readjusted

kg

em

in

lb

less

than

7

6

1

At

the

hub

bolt

When

both

bearing

and

seal

are

new

kg

lb

less

than

2

1

4

6

When

readjusted

kg

lb

less

than

1

0

2

2

Suspension

link

Upper

link

sliding

resistance

kg

m

ft

Ib

less

than

O

S

3

6

Lower

link

sliding

resistance

kg

m

ft

lb

less

than

O

S

3

6

lightening

torque

kg

m

ft

Ib

Brake

hose

connecting

nut

1

9

to

2

S

14

to

18

Wheel

bearing

lock

nu

t

3

0

to

3

5

22

to

2S

Brake

disc

fIXing

bolt

4

2

to

S

O

30

to

36

Knuckle

arm

fixing

bolt

10

3

to

12

1

74

to

88

King

pin

lock

bolt

2

1

to

2

S

IS

to

18

Torque

arm

Arm

end

2

7

to

3

7

20

to

27

Serration

boss

1

8

to

2

6

13

to

19

Lower

link

spindle

nut

74

to

8

0

S4

to

58

Upper

link

screw

bushing

24

to

35

174

to

2S3

Upper

link

spindle

bolt

fIXing

to

bracket

7

to

9

51

to

6S

Cotter

pin

lock

nut

0

8

to

l

l

5

8

to

8

0

Lower

link

screw

bushing

25

to

32

181

to

231

Fulcrum

bolt

3

9

to

S

3

28

to

38

Tension

rod

Lock

nut

1

6

to

2

2

12

to

16

Bracket

bolt

1

6

to

2

2

12

to

16

Shock

absorber

Lock

nut

of

the

upper

end

1

6

to

2

2

12

to

16

Lower

end

3

1

to

4

1

22

to

30

Stabilizer

Bracket

bolt

1

6

to

2

2

12

to

16

Lock

nut

of

the

anchor

bolt

3

1

to

4

1

22

to

30

Bumper

rubber

bolt

0

8

to

l

l

5

8

to

8

0

FA

13

Page 365 of 537

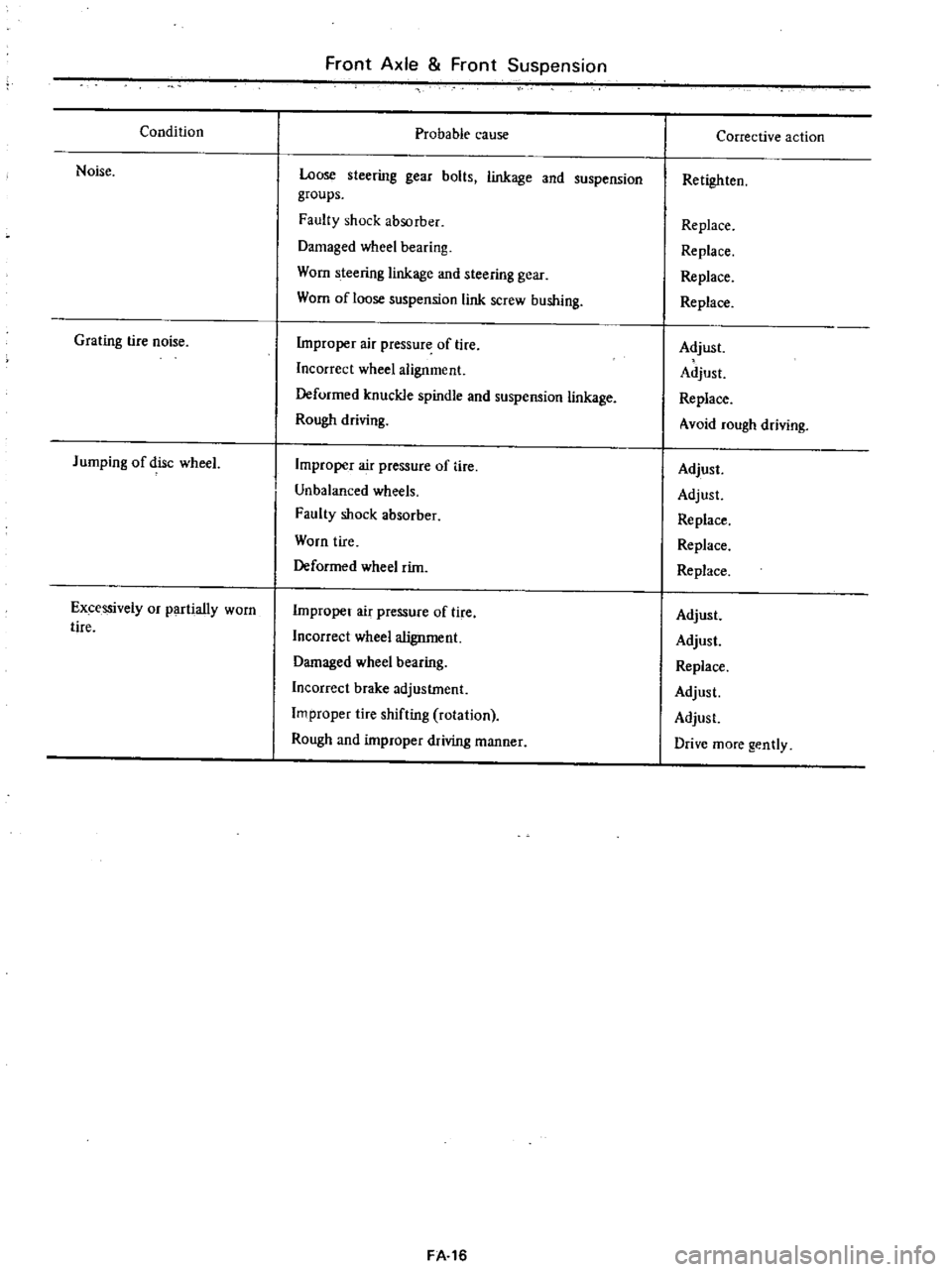

Condition

Noise

Grating

tire

noise

Jumping

of

disc

wheeL

Excessively

or

partially

worn

tire

Front

Axle

Front

Suspension

Probable

cause

Loose

steering

gear

bolts

linkage

and

suspension

groups

Faulty

shock

absorber

Damaged

wheel

bearing

Worn

steering

linkage

and

steering

gear

Worn

of

loose

suspension

link

screw

bushing

Improper

air

pressure

of

lire

Incorrect

wheel

alignment

Deformed

knuckle

spindle

and

suspension

linkage

Rough

driving

Improper

air

pressure

of

tire

Unbalanced

wheels

Faulty

shock

absorber

Worn

tire

Deformed

wheel

rim

Improper

air

pressure

of

tire

Incorrect

wheel

alignment

Damaged

wheel

bearing

Incorrect

brake

adjustment

Improper

tire

shifting

rotation

Rough

and

improper

wiving

manner

FA

16

Corrective

action

Retighten

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Avoid

rough

driving

Adjust

Adjust

Replace

Replace

Replace

Adjust

Adjust

Replace

Adjust

Adjust

Drive

more

gently

Page 369 of 537

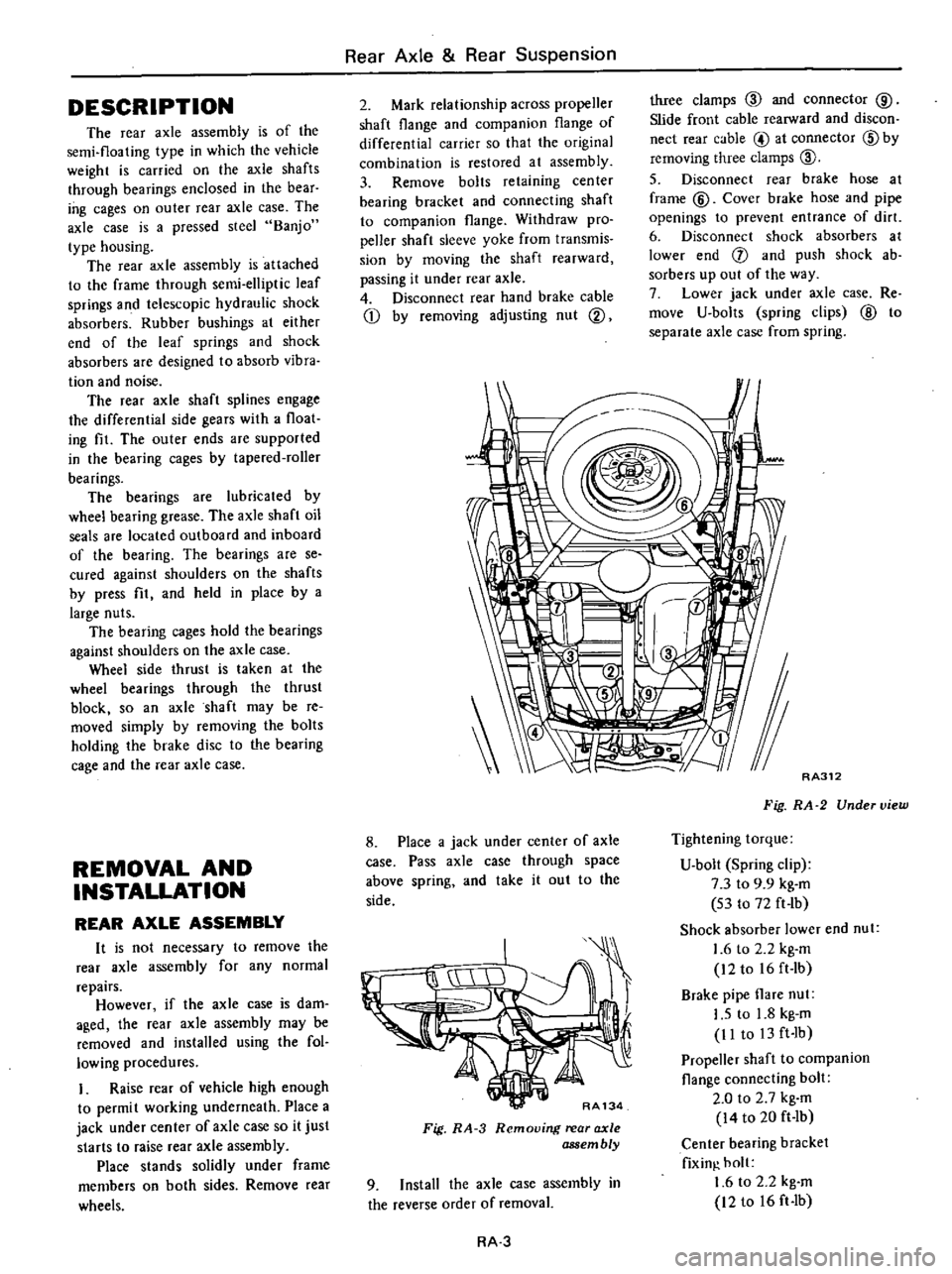

DESCRIPTION

The

rear

axle

assembly

is

of

the

semi

floating

type

in

which

the

vehicle

weight

is

carried

on

the

axle

shafts

through

bearings

enclosed

in

the

bear

ing

cages

on

outer

rear

axle

case

The

axle

case

is

a

pressed

steeJ

Banjo

type

housing

The

rear

axle

assembly

is

attached

to

the

frame

through

semi

elliptic

leaf

springs

and

telescopic

hydraulic

shock

absorbers

Rubber

bushings

at

either

end

of

the

leaf

springs

and

shock

absorbers

are

designed

to

absorb

vibra

tion

and

noise

The

rear

axle

shaft

splines

engage

the

differential

side

gears

with

a

float

ing

fit

The

outer

ends

are

supported

in

the

bearing

cages

by

tapered

roller

bearings

The

bearings

are

lubricated

by

wheel

bearing

grease

The

axle

shaft

oil

seals

are

located

outboard

and

inboard

of

the

bearing

The

bearings

are

se

cured

against

shoulders

on

the

shafts

by

press

fit

and

held

in

place

by

a

large

nuts

The

bearing

cages

hold

the

bearings

against

shoulders

on

the

axle

case

Whee

side

thrust

is

taken

at

the

wheel

bearings

through

the

thrust

block

so

an

axle

shaft

may

be

re

moved

simply

by

removing

the

bolts

holding

the

brake

disc

to

the

bearing

cage

and

the

rear

axle

case

REMOVAL

AND

INSTALLATION

REAR

AXLE

ASSEMBLY

It

is

not

necessary

to

remove

the

reaT

axle

assembly

for

any

normal

repairs

However

if

the

axle

case

is

dam

aged

the

rear

axle

assembly

may

be

removed

and

installed

using

the

fol

lowing

procedures

I

Raise

rear

of

vehicle

high

enough

to

permi

t

working

underneath

Place

a

jack

under

center

of

axle

case

so

it

just

starts

to

raise

rear

axle

assembly

Place

stands

solidly

under

frame

members

on

both

sides

Remove

rear

wheels

Rear

Axle

Rear

Suspension

2

Mark

relationship

across

propeller

shaft

flange

and

companion

flange

of

differential

carrier

so

that

the

original

combination

is

restored

at

assembly

3

Remove

bolts

retaining

center

bearing

bracket

and

connecting

shaft

to

companion

flange

Withdraw

pro

peller

shaft

sleeve

yoke

from

transmis

sion

by

moving

the

shaft

rearward

passing

it

under

rear

axle

4

Disconnect

rear

hand

brake

cable

Q

by

removing

adjusting

nut

@

three

clamps

ID

and

connector

@

Slide

front

cable

rearward

and

discon

nect

rear

cable

@

at

connector

ID

by

removing

three

clamps

ID

5

Disconnect

rear

brake

hose

at

frame

@

Cover

brake

hose

and

pipe

openings

to

prevent

entrance

of

dirt

6

Disconnect

shock

absorbers

at

lower

end

f

and

push

shock

ab

sorbers

up

out

of

the

way

7

Lower

jack

under

axle

case

Re

move

U

bolts

spring

clips

@

to

separate

axle

case

from

spring

8

Place

a

jack

under

center

of

axle

case

Pass

axle

case

through

space

above

spring

and

take

it

out

to

the

side

RA134

Fig

RA

3

Removing

rear

axle

assembly

9

Install

the

axle

case

assembly

in

the

reverse

order

of

removal

RA

3

RA312

Fig

RA

2

Under

view

Tightening

torque

U

bolt

Spring

clip

7

3

to

9

9

kg

m

53

to

72

ft

lb

Shock

absorber

lower

end

nut

1

6

to

2

2

kg

m

12to

16ft

Ib

Brake

pipe

flare

nut

I

S

to

1

8

kg

m

II

to

13

ft

Ib

Propeller

shaft

to

companion

flange

connecting

bolt

2

0

to

2

7

kg

m

14

to

20

ft

Ib

Center

bearing

bracket

fixin

holt

1

6

to

2

2

kg

m

12

to

16

ft

Ib

Page 370 of 537

REAR

AXLE

SHAFT

AND

WHEEL

BEARING

I

Raise

rear

of

vehicle

and

support

under

axle

case

on

stands

Remove

rear

wheel

2

Disconnect

rear

hand

brake

cable

by

removing

adjusting

nut

and

clamps

3

Disconnect

brake

tube

at

rear

wheel

cylinder

Cover

brake

tube

and

wheel

cylinder

openings

to

prevent

entrance

of

dirt

4

Remove

brake

drum

Not

If

brake

drum

cannot

be

easily

removed

return

brake

adjuster

install

two

bolts

M8

x

I

2S

in

holes

on

the

flange

face

of

brake

drum

and

tighten

bolts

evenly

until

brake

drum

is

driven

out

5

Remove

nuts

retaining

wheel

bearing

cage

to

brake

disc

I

Jq

AA135

Fig

RA

4

Removing

nuts

AA418

Fig

RA

5

Removing

rear

axle

shaft

assem

bly

7

Remove

oil

seal

in

axle

case

if

necessary

and

install

new

seal

Insure

against

damaging

the

seal

lip

Rear

Axle

Rear

Suspension

8

Position

axle

shaft

in

vise

with

Rear

Axle

Stand

ST07630000

9

Unbend

lock

washer

with

a

screw

driver

Note

Do

not

use

used

lock

washer

again

RAl38

Fig

RA

6

Unbending

lock

washer

10

Remove

lock

nut

using

Rear

Axle

Bearing

Lock

Nut

Wrench

ST38020000

I

AA139

Fig

RA

7

R

mouing

lock

nut

II

Withdraw

wheel

bearing

to

gether

with

bearing

cage

and

brake

disc

using

Rear

Axle

Shaft

Bearing

Puller

HT72480000

HT72480000

r

t

Rvr

G

l

AA343

Fig

RA

8

Removing

bearing

o

12

Remove

oil

seal

in

bearing

cage

if

necessary

13

To

remove

wheel

bearing

outer

race

after

removed

oil

seal

apply

a

brass

drift

to

race

side

surface

and

withdraw

it

by

tapping

the

lop

of

drift

with

a

hammer

Installing

can

be

proceeded

in

the

reverse

order

of

removal

procedure

as

follows

RA

4

I

Fit

wheel

bearing

outer

race

by

tapping

with

a

brass

hammer

evenly

while

fitting

2

Install

a

new

oil

seal

in

bearing

cage

Lubricate

cavity

between

seal

lips

with

wheel

bearing

grease

after

fitting

seal

3

Place

bearing

cage

with

brake

disc

and

bearing

spacer

on

axle

shaft

and

fit

bearing

cone

To

install

bearing

cone

apply

a

brass

drift

to

race

side

surface

and

tapping

the

top

of

drift

with

a

hammer

AA141

Fig

RA

9

Installing

whetl

bearing

4

Place

bearing

lock

washer

Q

and

bearing

nut

lock

washer

@

on

axle

shaft

and

tighten

lock

nut

@

using

Rear

AJde

Bearing

Lock

Nut

Wrench

ST38020000

and

bend

up

lock

wash

er

Notes

a

Be

careful

to

place

the

faced

side

of

nut

to

washer

side

so

that

washer

is

not

damaged

b

Coincide

washer

lip

with

nut

groove

correc

ly

by

tightening

nul

and

bend

washer

carefuljy

so

that

lip

will

nol

be

damaged

Tightening

torque

IS

to

20

kg

m

J08

to

14S

ft

Ib

t

i

i

f

ifii

itf

L

4

S

11

iI

i

j

pu

y

J

t

Mf

i

I

AA142

Fig

RA

IO

Layout

of

ock

nut

Page 376 of 537

DATSUN

PICK

UP

MODEL

620

SERIES

l

4ISSAN

I

NISSAN

MOTOR

CO

LTD

TOKYO

JAPAN

SECTION

BR

BRAKE

SYSTEM

GENERAL

DESCRIPTIDN

BR

2

ADJUSTMENT

BR

2

SERVICE

BRAKE

BR

4

HAND

BRAKE

BR

18

SERVICE

DATA

AND

BR

2D

SPECIFICATlDNS

TROUBLE

DIAGNDSES

BR

22

AND

CORRECTIONS

SPECIAL

SERVICE

TOOLS

BR

25