brake DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 266 of 537

the

space

from

I

to

IS

increases

space

from

15

to

the

drain

port

simultaneously

decreases

As

a

resull

governor

pressure

of

15

increases

and

the

governor

pressure

is

balanced

with

the

sum

of

centrifugal

force

and

spring

force

The

governor

pressure

thus

changes

in

response

to

the

vehicle

speed

change

centrifugal

force

Operation

of

prlmar

governor

valve

The

valve

is

an

ON

OFF

valve

which

closes

the

governor

pressure

IS

regulated

by

the

secondary

gover

nor

valve

when

the

vehicle

reaches

the

minimum

speed

and

when

the

vehicle

speed

exceeds

a

certain

level

the

governor

opens

and

forwards

the

gov

ernor

pressure

15

to

the

control

valve

When

the

vehicle

is

stopped

the

governor

pressure

is

zero

However

when

the

vehicle

is

running

slowly

this

valve

is

depressed

to

Ihe

center

and

the

groove

to

15

is

closed

since

the

governor

pressure

applied

to

the

ring

shaped

area

is

higher

than

the

centrifugal

force

of

this

valve

When

the

governor

speed

exceeds

a

certain

revolution

the

governor

pressure

in

the

circuit

15

also

increases

How

ever

as

the

centrifugal

force

increases

and

exceeds

the

governor

pressure

this

valve

moves

toward

the

outside

and

the

governor

pressure

is

transmitted

to

the

circuil

5

Two

different

valves

are

employed

in

the

governor

so

that

it

will

inde

pendently

control

the

speed

at

high

and

low

speeds

That

is

within

the

low

speed

range

the

governor

pressure

is

not

generated

because

of

the

primary

valve

whereas

at

the

high

speed

range

above

the

breaking

point

governor

pressure

is

regulated

by

the

secondary

valve

The

breaking

point

is

the

point

at

which

the

function

of

one

of

the

governor

is

transferred

to

the

other

as

the

speed

changes

from

the

low

speed

to

the

high

speed

range

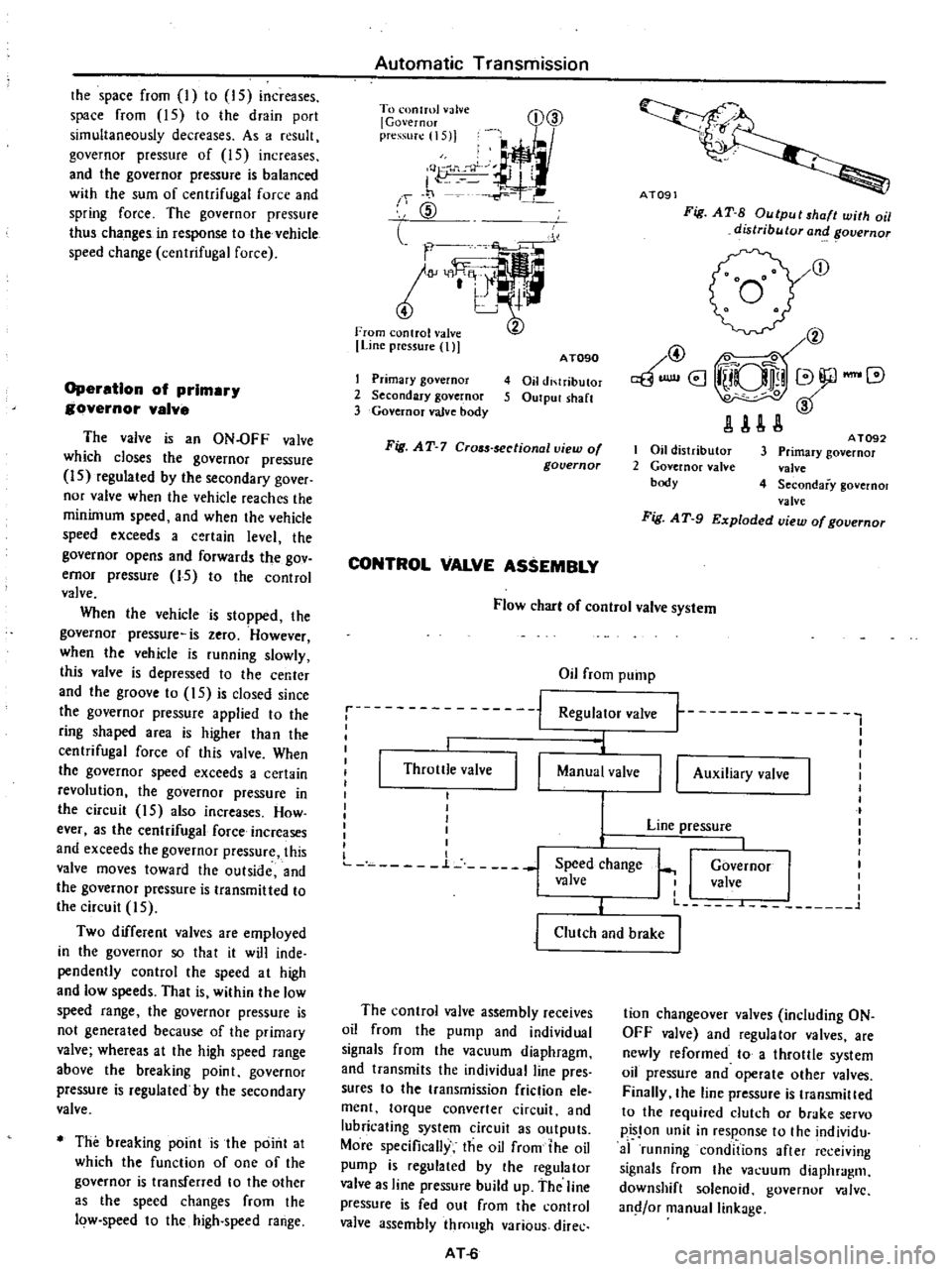

Automatic

Transmission

To

onlml

valve

l

Governor

pre

S1I

1I5

j

I

Q

J

J

f

1

1

CID

l

l

m

Line

pressure

t

D@

I

Primary

governor

2

Secondary

governor

3

Governor

valve

body

AT090

4

Oil

di

lributor

5

Output

sh

lft

Fig

AT

7

Cr05s

sectionallliew

of

governor

CONTROL

VALVE

ASSEMBLY

Ai09

Fig

AT

S

Output

shaft

with

oil

distributor

and

overnor

r

@

@

0

aBUlllI8

iUQlli

V

JlAU

I

Oil

distributor

2

Governor

nlve

body

A

T092

3

Primary

governor

valve

4

Secondary

governol

valve

Fig

A

T

9

Exploded

view

of

governor

Flow

cbar

of

control

valve

system

Oil

from

pump

Regulator

valve

1

I

i

j

Throttle

valve

I

I

l

Manual

valve

I

I

I

I

I

I

I

L

n

L

j

Speed

change

valve

I

I

t

t

I

I

I

I

I

I

Governor

I

I

valve

I

I

I

L

L

1

II

Auxiliary

valve

Line

pressure

j

Clutch

and

brake

The

control

valve

assembly

receives

oil

from

the

pump

and

individual

signals

from

the

vacuum

diaphragm

and

transmits

the

individual

line

pres

sures

to

the

transmission

friction

ele

ment

torque

converter

circuit

and

lubricating

system

circuit

as

outputs

More

specifically

the

oil

from

the

oil

pump

is

regulated

by

the

regulator

valve

as

line

pressure

build

up

the

line

pressure

is

fed

out

from

the

control

valve

assembly

through

various

direc

AT

6

tion

changeover

valves

including

ON

OFF

valve

and

regulator

valves

are

newly

reformed

to

a

throllle

system

oil

pressure

and

operate

other

valves

Finally

the

line

pressure

is

transmilled

to

the

required

dutch

or

brake

servo

pisJon

unit

in

response

to

the

individu

af

running

conditions

after

re

ejving

signals

from

the

va

uum

diaphragm

downshift

solenoid

governor

V

dlvc

and

or

manual

linkage

Page 267 of 537

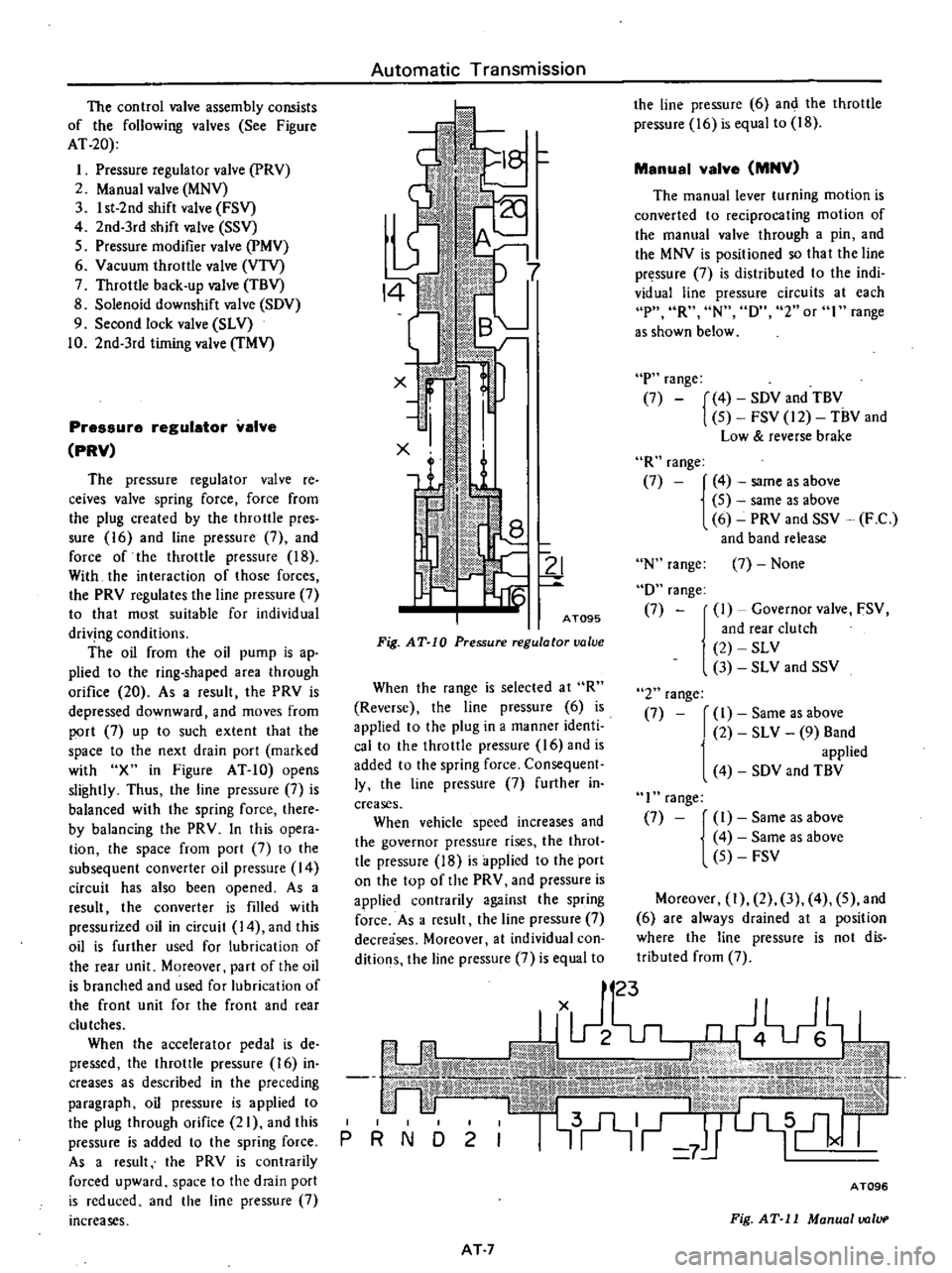

The

control

valve

assembly

consists

of

the

following

valves

See

Figure

AT

20

I

Pressure

regulator

valve

PRV

2

Manual

valve

MNV

3

I

st

2nd

shift

valve

FSV

4

2nd

3rd

shift

valve

SSV

5

Pressure

modifier

valve

PMV

6

Vacuum

throttle

valve

VTV

7

Throttle

back

up

valve

TBV

8

Solenoid

downshift

valve

SDV

9

Second

lock

valve

SL

V

10

2nd

3rd

timing

valve

TMV

Pressure

regulator

valve

PRV

The

pressure

regulator

valve

re

ceives

valve

spring

force

force

from

the

plug

created

by

the

throttle

pres

sure

16

and

line

pressure

7

and

force

of

the

throttle

pressure

18

With

the

interaction

of

those

forces

the

PRY

regulates

the

line

pressure

7

to

that

most

suitable

for

individual

driving

conditions

The

oil

from

the

oil

pump

is

ap

plied

to

the

ring

shaped

area

through

orifice

20

As

a

result

the

PRV

is

depressed

downward

and

moves

from

port

7

up

to

such

extent

that

the

space

to

the

next

drain

port

marked

with

X

in

Figure

AT

10

opens

slightly

Thus

the

line

pressure

7

is

balanced

with

the

spring

force

there

by

balancing

the

PRV

In

this

opera

tion

Ihe

space

from

port

7

to

the

subsequent

converter

oil

pressure

14

circuit

has

also

been

opened

As

a

result

the

converter

is

filled

with

pressurized

oil

in

circuit

14

and

this

oil

is

further

used

for

lubrication

of

the

rear

unit

Moreover

part

of

the

oil

is

branched

and

used

for

lubrication

of

the

front

unit

for

the

front

and

rear

clutches

When

Ihe

accelerator

pedal

is

de

presscd

the

throttle

pressure

16

in

creases

as

described

in

the

preceding

paragraph

oil

pressure

is

applied

to

the

plug

through

orifice

21

and

this

pressure

is

added

to

the

spring

force

As

a

result

the

PRV

is

contrarily

forced

upward

space

to

the

drain

port

is

reduced

and

Ihe

line

pressure

7

increases

Automatic

Transmission

11

AT095

Fig

AT

10

Pressure

regulator

ualue

When

the

range

is

selected

at

R

Reverse

the

line

pressure

6

is

applied

10

the

plug

in

a

manner

identi

caito

the

throttle

pressure

16

and

is

added

10

the

spring

force

Consequent

ly

the

line

pressure

7

further

in

creases

When

vehicle

speed

increases

and

the

governor

pressure

rises

the

theot

tle

pressure

18

is

applied

to

the

port

on

the

top

of

the

PRV

and

pressure

is

applied

contrarily

against

the

spring

force

As

a

result

the

line

pressure

7

decreases

Moreover

at

individual

con

ditions

the

line

pressure

7

is

equal

to

the

line

pressure

6

and

the

throttle

pressure

16

is

equal

to

18

Manual

valve

MNV

The

manual

lever

turning

motion

is

converted

to

reciprocating

motion

of

the

manual

valve

through

a

pin

and

the

MNV

is

positioned

so

that

the

line

pressure

7

is

distributed

to

the

indi

vidual

line

pressure

circuits

at

each

P

R

N

D

2

or

I

range

as

shown

below

P

range

7

4

SDV

and

TBV

5

FSV

12

TBV

and

Low

reverse

brake

R

range

7

4

same

as

above

5

same

as

above

6

PRY

and

SSV

F

C

and

band

release

N

range

D

range

7

7

None

I

Governor

valve

FSV

and

rear

clutch

2

SLY

3

SL

V

and

SSV

2

range

7

I

Same

as

above

2

SL

V

9

Band

applied

4

SDV

and

TBV

I

range

7

I

Same

as

above

4

Same

as

above

5

FSV

Moreover

1

2

3

4

5

and

6

are

always

drained

at

a

position

where

the

line

pressure

is

not

dis

tributed

from

7

u

JJX

g4Vhl

dIillillt

1

dlMIi

W

ld

IiIb

It

i

B

J

jd

l

tJj

fitMi

td

j

L@

x

x

j

j

P

R

N

17

l

AT7

AT096

Fig

AT

11

Manual

ualvp

Page 273 of 537

HYDRAULIC

SYSTEM

AND

MECHANICAL

OPERATION

The

operating

system

of

oil

pres

sure

in

each

range

is

described

below

The

oil

pressure

in

each

circuit

shown

in

the

illustration

is

classified

as

follows

according

to

the

function

fhe

numeraJs

show

the

circuit

num

bers

Pressure

source

of

the

line

7

Operating

Iinc

prcssure

for

friction

elements

123456

8910

1112

Auxiliary

line

pressurc

13

Throttle

system

pressure

16

17

18

19

Others

14

15

Oil

pump

discharge

hole

7

Cd

Torque

converter

pressure

14

Rear

iutch

prc

surc

1

FTOOI

c1

tL

h

prc

ur

It

J

1

011

pump

Sllctlon

hole

M

IIJ1iIII

Automatic

Transmission

Fig

AT

21

Identification

of

oil

channels

in

oil

pump

AT105

Oil

pump

suction

hole

ATl06

Fig

AT

22

Identification

of

oil

channels

in

case

front

face

I

o

Oil

pump

dischar

hole

7

I9JM

c

Torque

converter

f

Os

I

1L

0

ervo

Ie

ease

pressure

14

0

pressure

10

Rear

clutch

Servo

t

ightening

ho

L

pressure

l

0

1

pressure

9

lJ

L

I

c

I

Front

clutch

IT

0

LIO

reverse

brake

pressure

12

U

r

FT

II

pressure

11

rrOil

pump

suction

hol

J

C

Jf

JC

O

Governor

pressure

15

Governor

feed

pressure

l

An07

Fig

AT

23

Identification

of

oil

channels

in

case

face

AT

13

Page 274 of 537

Automatic

Transmission

P

RANGE

PARK

The

operation

of

clutches

and

band

are

functionally

the

same

as

in

Neu

tral

In

parking

however

when

the

parking

pawl

meshes

in

a

gear

which

is

splined

to

the

output

shaft

the

output

shaft

is

mechanically

locked

from

rotating

Free

Lock

AT086

Fig

AT

24

Parlling

mechanum

The

oil

discharged

from

the

oil

Low

Band

ervo

On

pump

is

fed

to

each

part

in

a

similar

Gw

Clutch

Parkin

Range

atia

Il

Yer5e

r

pawl

manner

to

that

of

the

N

range

The

Fron

Rear

brakt

Operation

Release

clutch

oil

having

the

line

pressure

7

which

Park

on

has

been

introduced

into

the

manual

valve

Il

reaches

the

I

st

2nd

shift

Re

er

2

132

on

on

on

valve

CID

through

the

line

pressure

circuit

5

As

the

1st

2nd

shift

Neutral

valve

s

force

to

th

right

hand

ide

PI

L

w

2

3

on

by

the

spring

the

line

pressure

5

and

Drive

P2

Second

14S3

on

on

12

actuates

the

low

and

reverse

brake

through

the

groove

Also

Ihe

03

Top

1

000

on

on

parking

pawl

engages

with

the

outer

2

Second

1

458

teeth

of

the

oil

distributor

by

means

of

the

manual

lever

mechanically

12

Second

1458

on

on

locking

the

output

shaft

II

Low

2

453

on

AT

14

Page 276 of 537

R

RANGE

REVERSE

In

R

range

the

front

clutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

stationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

Automatic

Transmission

R

Fig

AT

26

Power

tranamis

ion

during

R

range

m

i

1

A

TOBS

Fig

A

T

21

Optrationof

each

mechanism

during

R

range

When

the

manual

valve

V

is

posi

Clutch

Low

Band

servo

One

tioned

at

R

range

the

oil

having

the

Gear

Partina

Ranae

re

ne

way

line

pressure

7

is

directed

to

line

ralio

Front

Rear

brake

Openlion

Relulie

clutch

plwl

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

Park

on

on

low

and

reverse

brake

after

being

Ruene

2

182

on

on

on

introduced

into

line

pressure

circuit

Neutral

12

through

the

I

st

2nd

shift

valve

ID

The

pressure

in

the

circuit

op

DI

Low

2

458

on

on

erates

the

release

side

of

the

band

servo

and

the

front

c1u

tch

after

being

Driowe

D2

Second

1

458

on

on

led

to

line

pressure

circuit

0

D3

Top

1

000

on

on

on

through

the

2nd

3rd

shift

valve

@

2

Second

1

458

The

throttle

pressure

I

6

and

the

line

on

on

pressure

6

which

vary

with

the

12

Second

S8

on

on

degree

of

accelerator

pedal

depression

II

Low

2

458

both

act

the

pressure

regulator

on

on

on

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

Rn

range

the

governor

pressure

is

absent

making

all

such

valves

as

the

1st

2nd

shift

valve

ID

lnd

3rd

shift

valvc

@

and

pressurc

modifier

valve

inoperative

AT16

Page 278 of 537

N

RANGE

NEUTRAL

In

N

range

none

of

the

clutches

and

band

are

applied

thus

no

power

is

transmitted

to

the

output

shaft

The

pressure

of

oil

discharged

from

the

oil

pump

is

regulated

by

the

pressure

regulator

valve

Dto

maintain

the

line

pressure

7

and

the

oil

is

led

to

the

manual

valve

@

vacuum

throt

tie

valve

@

and

solenoid

down

shift

valve

@

The

oil

is

further

introduced

into

the

torque

converter

at

its

op

erating

pressure

14

and

a

portion

of

this

oil

is

distributed

to

each

part

as

the

front

lubricant

The

oil

which

has

been

discharged

from

the

torque

con

verter

is

also

distributed

to

eacn

part

as

the

rear

lubricant

As

the

oil

pump

rotates

at

the

same

speed

as

the

engine

the

oil

pump

discharge

increases

with

engine

speed

But

the

surplus

oil

is

returned

to

the

oil

pan

by

the

pressure

regula

tor

valve

D

Automatic

Transmission

Geu

Clutch

Low

4

Band

crvo

One

Pultin

R

atio

WI

pawl

Front

Rear

brake

Operation

Release

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

Dt

Low

2

458

on

on

Drive

D2

Second

1

458

on

on

m

Top

1

000

on

on

on

on

2

Second

1

458

on

on

12

Sec

ond

1

458

on

on

II

Low

2

458

on

on

AT

la

Page 280 of 537

Automatic

Transmission

R

RANGE

REVERSE

R

In

R

range

the

front

dutch

and

the

low

and

reverse

brake

are

applied

The

power

flow

is

through

the

input

shaft

front

clutch

and

connecting

shell

to

the

sun

gear

Clockwise

rota

tion

of

the

sun

gear

causes

counter

clockwise

rotation

of

the

rear

planeta

ry

gears

With

the

connecting

drum

held

Slationary

by

the

low

and

reverse

brake

the

rear

planetary

gears

rotate

the

rear

internal

gear

and

drive

the

flange

counterclockwise

The

rear

drive

flange

splined

to

the

output

shaft

rotates

the

output

shaft

counterclock

wise

at

a

reduced

speed

with

an

increase

in

torque

for

reverse

gear

f

When

Ihe

manual

valve

CV

is

posi

tioned

at

R

range

Ihe

oil

having

Ihe

line

pressure

7

is

directed

to

line

pressure

circuits

5

and

6

The

pressure

in

the

circuit

5

actuates

the

low

and

reverse

brake

after

being

introduced

into

line

pressure

circuit

12

through

the

I

st

2nd

shift

valve

@

The

pressure

in

Ihe

circuit

op

erates

the

release

side

of

the

band

servo

and

the

front

clutch

after

being

led

to

line

pressure

circuit

10

through

the

2nd

3rd

shift

valve

@

The

throtlle

pressure

16

and

the

line

pressure

6

which

vary

with

the

degree

of

acceJerator

pedal

depression

both

act

on

the

prcssure

regulator

valve

CD

and

press

against

its

valve

CD

increasing

line

pressure

7

In

R

range

the

governor

pressure

is

absent

making

all

slldl

valves

as

the

J

SI

2nd

shift

valve

@

2nd

3rd

shift

valvc

@

and

pressure

modifier

valve

j

inoperative

C

Fig

AT

26

Power

transmi

ion

during

R

range

A

TOS5

Fig

AT

27

Operation

attach

mechanism

during

R

range

G

Clutch

Low

A

Band

servo

One

Parkin

Ran

no

wa

plwl

ratio

Front

Rear

brake

Operllioo

Rdr

ue

clutch

k

on

on

Revctte

1

181

on

on

on

Neutnl

DI

Low

1

418

on

on

Driw

D2

Second

1

458

on

on

DJ

Top

1

000

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

I

II

Low

2

458

on

on

AT

16

Page 284 of 537

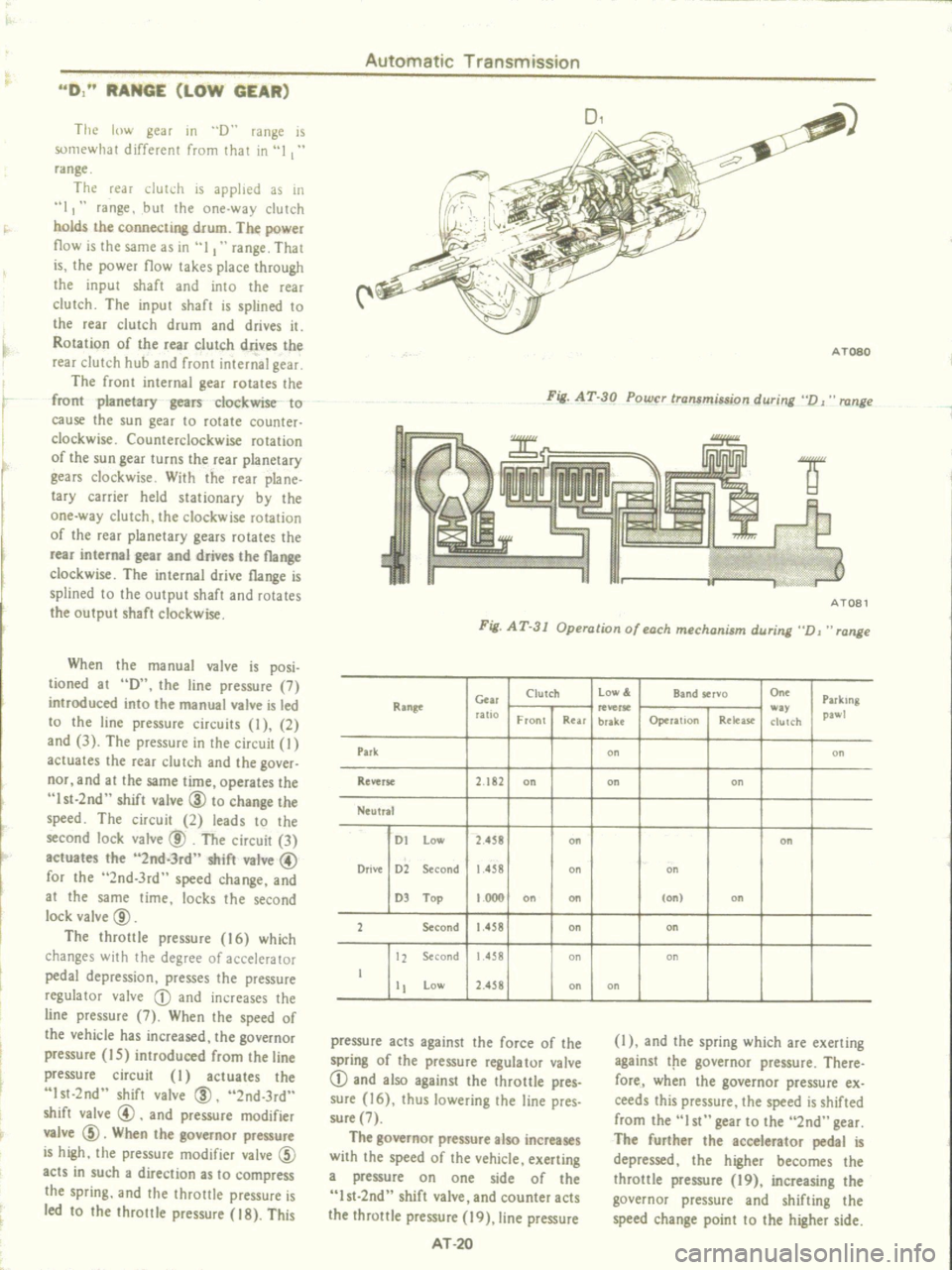

D

RANGE

LOW

GEAR

Automatic

Transmission

The

low

gear

in

D

range

is

somewhat

different

from

that

in

I

range

The

rear

c1utdl

is

applied

as

III

I

range

but

the

one

way

clutch

holds

the

connecting

drum

The

power

now

is

the

same

as

in

1

J

range

That

is

the

power

now

takes

place

through

Ihe

input

shaft

and

into

the

rear

clutch

The

input

shaft

is

splined

to

the

rear

clutch

drum

and

drives

it

Rotation

of

Ihe

rear

clutch

drives

the

rear

clutch

hub

and

front

internal

gear

The

front

internal

gear

rotales

the

front

planetary

gears

clockwise

to

cause

the

sun

gear

to

rotate

counter

clockwise

Counterclockwise

rotation

of

the

sun

gear

turns

the

rear

planetary

gears

clockwise

With

the

rear

plane

tary

carrier

held

stationary

by

the

one

way

clutch

the

clockwise

rotation

of

the

rear

planetary

gears

rotates

the

rear

internal

gear

and

drives

the

flange

clockwise

The

internal

drive

flange

is

splined

to

the

outpul

shaft

and

rotates

the

output

shaft

clockwise

When

the

manual

valve

is

posi

tioned

at

D

the

line

pressure

7

introduced

into

the

manual

valve

is

led

to

the

line

pressure

circuits

l

2

and

3

The

pressure

in

the

circuit

I

acluates

the

rear

clutch

and

the

gover

nor

and

al

the

same

time

operates

the

1st

2nd

shift

valve

CID

to

change

the

speed

The

circuit

2

leads

to

the

second

lock

valve

@

The

circuit

3

actuates

the

2nd

3rd

shift

valve

@

for

the

2nd

3rd

speed

change

and

at

the

same

lime

locks

the

second

lock

valve

@

The

throttle

pressure

16

which

changes

with

the

degree

of

accelerator

pedal

depression

presses

Ihe

pressure

regulator

valve

CD

and

increases

the

line

pressure

7

When

Ihe

speed

of

the

vehicle

has

increased

the

governor

pressure

15

introduced

from

the

line

pressure

circuit

I

actuates

the

I

SI

2nd

shift

valve

CID

2nd

3rd

shift

valve

@

and

pressure

modifier

valve

ID

When

the

governor

pressure

is

high

the

pressure

modifier

valve

ID

acls

in

such

a

direction

as

to

compress

the

spring

and

the

throttle

pressure

is

led

to

the

throttle

pressure

18

This

ATOSO

Fig

AT

30

Power

transmission

during

D

J

range

liIIl

I

IW

L

AT08l

Fig

AT

31

Operation

of

each

mechanism

during

VJ

range

Clutch

low

Band

servo

On

Parking

Cur

Ran

Rllelle

way

pawl

ratio

Front

Rur

brake

Operation

Rekase

ch

lch

Park

on

on

RellerK

2

t82

on

on

on

Neutral

01

low

2

S8

on

on

Orivt

02

Second

1

458

on

on

OJ

Top

1000

on

on

on

on

2

Second

1

458

on

00

t2

Second

1

458

on

on

t

tt

low

2

458

on

on

pressure

acts

against

the

force

of

the

spring

of

the

pressure

regulator

valve

CD

and

also

against

the

throttle

pres

sure

16

thus

lowering

the

line

pres

sure

7

The

governor

pressure

also

increases

with

the

speed

of

Ihe

vehicle

exerting

a

pressure

on

one

side

of

the

lst

2nd

shift

valve

and

counter

acts

the

Ihrottle

pressure

19

line

pressure

AT

20

l

and

the

spring

which

are

exerting

against

t

1e

governor

pressure

There

fore

when

the

governor

pressure

ex

ceeds

Ihis

pressure

the

speed

is

shifted

from

the

I

st

gear

to

the

2nd

gear

The

further

the

accelerator

pedal

is

depressed

the

higher

becomes

the

throttle

pressure

19

increasing

the

governor

pressure

and

shifting

the

speed

change

point

to

the

higher

side

Page 286 of 537

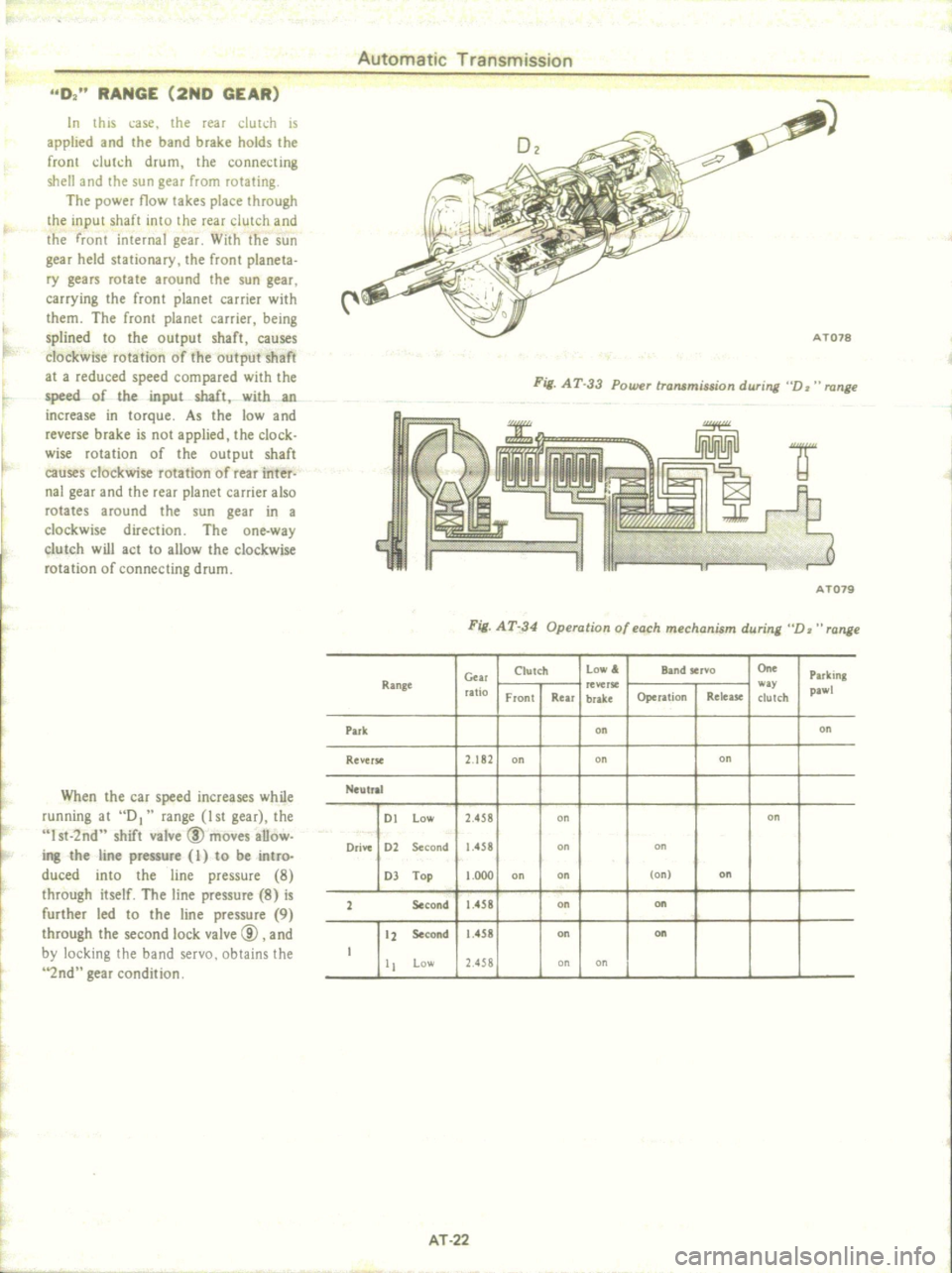

D

RANGE

2ND

GEAR

Automatic

Transmission

t

In

this

case

the

rear

c1ut

h

IS

applied

and

the

band

brake

holds

the

fronl

dUh

h

drum

the

connecting

shell

and

the

sun

gear

from

rotating

The

power

flow

lakes

place

through

the

input

shaft

into

the

rear

clutch

and

the

front

internal

gear

With

the

sun

gear

held

stationary

the

front

planeta

ry

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

fronl

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

output

shaft

at

a

reduced

speed

compared

with

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

applied

the

clock

wise

rotation

of

the

output

shaft

causes

clockwise

rotation

of

rear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

clutch

will

act

to

allow

the

clockwise

rotation

of

connecting

drum

When

the

car

speed

increases

while

running

at

D

range

I

st

gear

the

st

2nd

shift

valve

ID

moves

allow

ing

the

line

pressure

I

to

be

intro

duced

into

the

line

pressure

8

Ihrough

itself

The

line

pressure

8

is

further

led

to

the

line

pressure

9

through

the

second

lock

valve

@

and

by

locking

the

band

servo

obtains

the

2nd

gear

condition

Fig

AT

33

Power

transmission

during

Dz

range

A

T079

Fig

AT

34

Operation

of

each

mechanism

during

D

range

Clutch

Low

Band

servo

On

Patking

G

Range

reverse

w

pawl

ratio

Fronl

Rur

brake

Optrltion

Release

clutch

PlIk

on

on

Revtne

2

182

on

on

on

Neutral

01

Low

2

4S8

on

on

Drive

02

Second

1

4S8

on

on

OJ

Top

1

000

on

on

on

on

2

Second

1

4S8

on

on

12

Second

1

4S8

on

on

1

II

Low

2

4S8

on

on

AT

22

Page 288 of 537

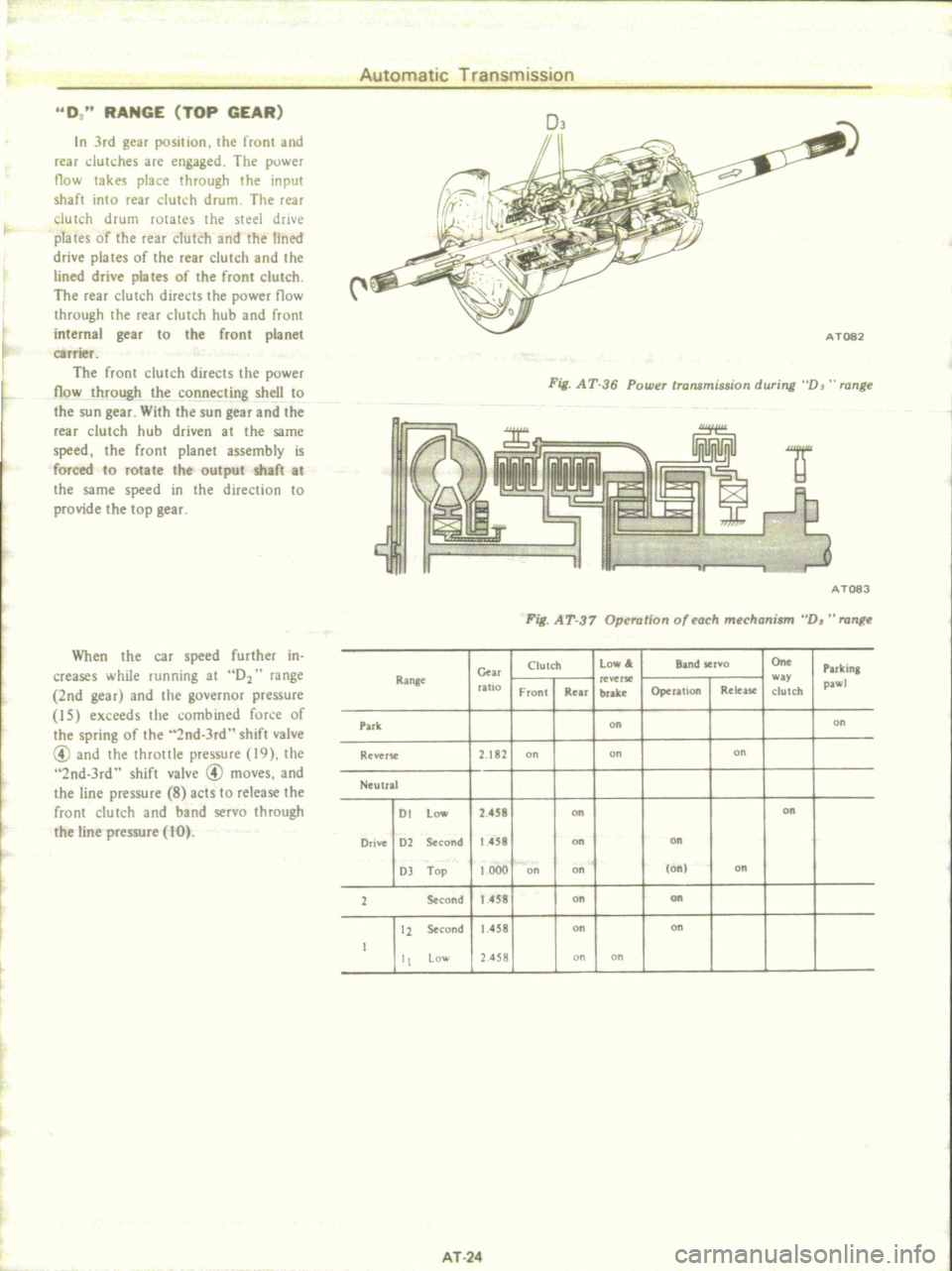

D

RANGE

TOP

GEAR

Automatic

Transmission

In

3rd

gear

position

the

front

and

rear

dUlches

are

engaged

The

power

now

takes

place

through

the

input

shaft

into

rear

clutch

drum

The

rear

clutch

drum

rotates

the

steel

drive

plates

of

the

rear

clutch

and

the

lined

drive

plates

of

the

rear

clutch

and

the

lined

drive

plates

of

the

front

clutch

The

rear

clutch

directs

the

power

flow

through

the

rear

clutch

hub

and

front

internal

gear

to

the

front

pl

net

carrier

The

front

clutch

directs

Ihe

power

now

through

the

connecting

shell

to

the

sun

gear

Wilh

the

sun

gear

and

the

rear

clutch

hub

driven

at

the

same

speed

the

front

planet

assembly

is

forced

to

rotate

the

output

shaft

at

the

same

speed

in

the

direction

to

provide

the

top

gear

When

the

car

speed

further

in

creases

while

running

at

D2

range

2nd

gear

and

the

governor

pressure

15

exceeds

the

combined

force

of

the

spring

of

the

2nd

3rd

shift

valve

@

and

the

throttle

pressure

19

the

2nd

3rd

shift

valve

@

moves

and

the

line

pressure

8

acts

to

release

the

front

clutch

and

band

servo

through

the

line

pressure

10

OJ

a

Fig

AT

36

Power

transmission

during

DJ

range

A

T083

Fig

AT

3

Operation

of

aeh

mf

hani5m

UDJ

range

Clulch

Low

Band

KrVO

One

Parking

em

Ral

8t

reverK

w

pawl

ratio

Front

Rear

brake

Operation

Rdene

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

01

Low

24S8

on

on

Drive

02

Second

1

4S8

on

on

03

Top

1

000

on

on

on

on

1

Second

t

4S8

on

on

12

Second

1

458

on

on

t

I

Lo

2

458

on

on

AT

24