coolant level DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 20 of 537

r

ManifolJ

nuts

I

2

to

1

6

kg

m

8

7

to

I

6

ft

lb

Carburelor

nuls

0

5

to

1

0

kg

m

3

6

to

7

2

fl

tb

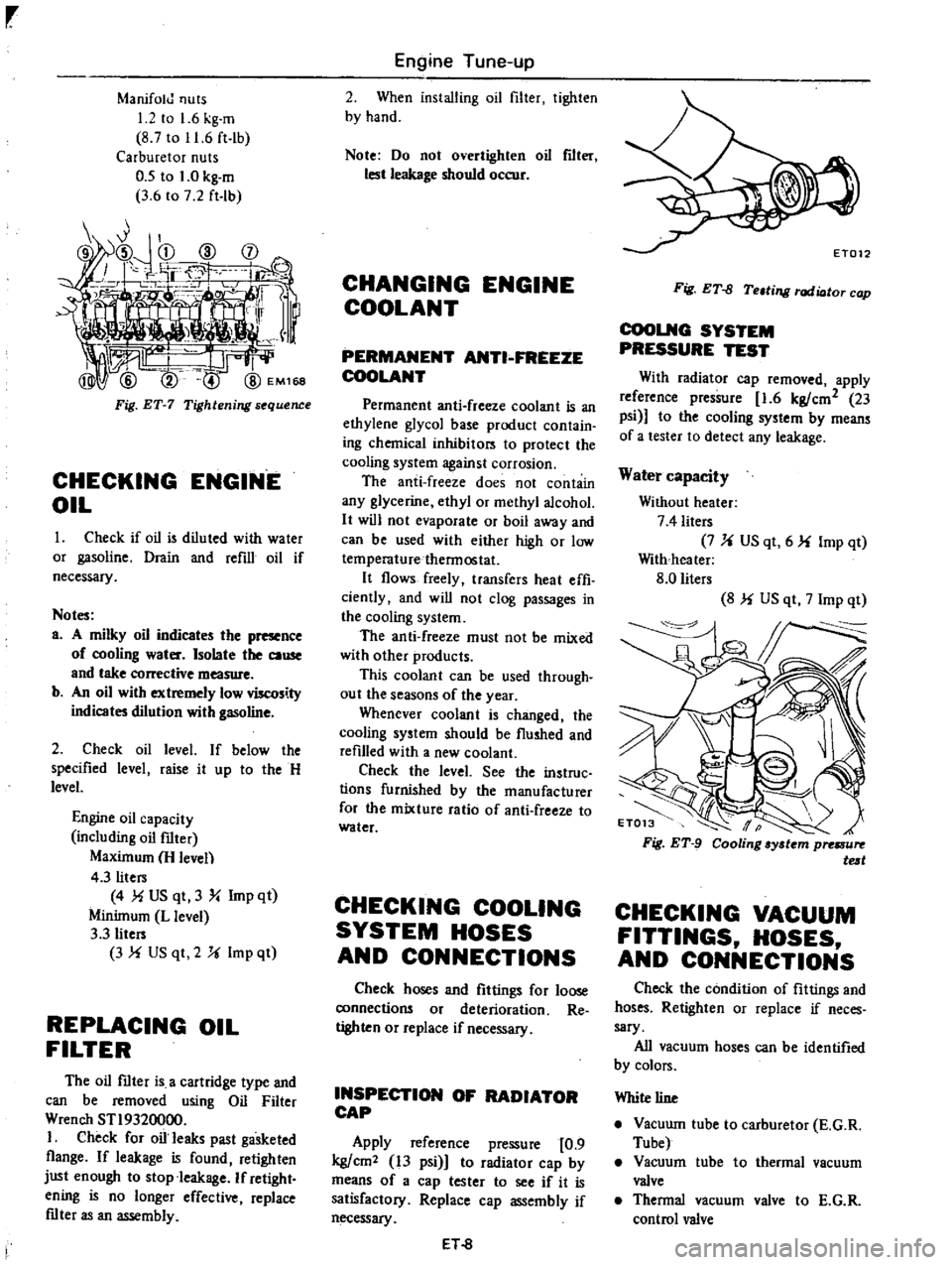

Fig

ET

7

Tightening

s

quence

CHECKING

ENGINE

OIL

Check

if

oil

is

diluled

with

water

or

gasoline

Drain

and

refill

oil

if

necessary

Notes

a

A

milky

oil

indicates

the

presence

of

cooling

water

Isolate

the

cause

and

take

corrective

measure

b

An

oil

with

extremely

low

viscosity

indicates

dilution

with

gasoline

2

Check

oil

level

If

below

the

specified

level

raise

it

up

10

the

H

level

Engine

oil

capacity

including

oil

filter

Maximum

H

leven

4

3

liters

4

MUS

qt

3

Y

Imp

qt

Minimum

L

level

3

3

liters

3

f

US

qt

2

U

Imp

ql

REPLACING

OIL

FILTER

The

oil

mter

is

a

cartridge

type

and

can

be

removed

using

Oil

Filter

Wrench

STI9320000

I

Check

for

oil

leaks

past

gasketed

flange

If

leakage

is

found

retighten

just

enough

to

stop

leakage

If

retight

ening

is

no

longer

effective

replace

mter

as

an

assembly

Engine

Tune

up

2

When

installing

oil

filter

tighlen

by

hand

Note

Do

not

overtighten

oil

flIt

lest

leakage

should

occur

CHANGING

ENGINE

COOLANT

PERMANENT

ANTI

FREEZE

COOLANT

Permanent

anti

freeze

coolant

is

an

ethylene

glycol

base

producl

conlain

ing

chemical

inhibilors

10

protect

the

cooling

system

against

corrosion

The

anti

freeze

does

not

contain

any

glycerine

ethyl

or

methyl

alcohol

It

will

not

evaporate

or

boil

away

and

can

be

used

with

either

high

or

low

temperaturethennoslat

It

flows

freely

transfers

heat

effi

ciently

and

will

not

clog

passages

in

the

cooling

system

The

anti

freeze

must

not

be

mixed

with

other

products

This

coolant

can

be

used

through

out

the

seasons

of

the

year

Whenever

coolant

is

changed

the

cooling

syslem

should

be

flushed

and

refilled

with

a

new

coolant

Check

the

level

See

the

instruc

lions

furnished

by

the

manufacturer

for

the

mixture

ratio

of

anti

freeze

10

water

CHECKING

COOLING

SYSTEM

HOSES

AND

CONNECTIONS

Check

hoses

and

fittings

for

loose

connections

or

deterioration

Re

tighten

or

replace

if

necessary

INSPECTION

OF

RADIATOR

CAP

Apply

reference

pressure

0

9

kg

cm2

13

psi

1

to

radiator

cap

by

means

of

a

cap

tester

to

see

if

it

is

satisfactory

Replace

cap

assembly

if

necessary

ET

8

Fig

ET

fJ

Teltill

l

rod

ioto

cop

COOLNG

SYSTEM

PRESSURE

TEST

With

radiator

cap

removed

apply

reference

pressure

1

6

kg

cm2

23

psi

to

the

cooling

system

by

means

of

a

lesler

to

detect

any

leakage

Water

capacity

Without

heater

7

4

liters

7

U

US

qt

6

f

Imp

qt

With

heater

8

0

liters

8

f

US

qt

7

Imp

qt

CHECKING

VACUUM

FITTINGS

HOSES

AND

CONNECTIONS

Check

the

condition

of

filtings

and

hoses

Retighten

or

replace

if

neces

sary

All

vacuum

hoses

can

be

identified

by

colors

White

line

Vacuwn

tube

to

carburetor

E

G

R

Tube

Vacuum

tube

to

thermal

vacuum

valve

Thennal

vacuum

valve

to

E

G

R

control

valve

Page 91 of 537

DESCRIPTION

COOLANT

LEVEL

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

WATER

PUMP

REMOVAL

AND

INSTALLATION

DISASSEMBLY

INSPECTION

AND

ADJUSTMENT

TORQUE

COUPLING

REMOVAL

AND

INSTALLATION

DESCRIPTION

The

cooling

system

is

of

the

con

ventional

pressure

type

A

centrifugal

pump

installed

on

the

timing

chain

cover

serves

to

circulate

the

coolant

The

pressure

type

radiator

filler

cap

installed

on

the

radiator

operates

the

cooling

system

at

higher

than

atmos

pheric

pressure

The

higher

pressure

raises

the

boiling

point

of

the

coolant

and

in

Cooling

System

COOLING

SYSTEM

CONTENTS

CO

2

CO

2

OISASSEMBL

Y

INSPECTION

TEM

COUPLlNG

INSPECTION

THERMOSTAT

REMOVAL

AND

INSTALLATION

INSPECTION

RADIATOR

REMOVAL

AND

INSTALLATION

INSPECTION

CO

2

CO

2

CO

3

CO

3

CO

3

CO

3

CO

4

creases

the

cooling

efficiency

of

the

radiator

When

the

thermostat

is

closed

the

coolant

remains

in

the

cylinder

head

and

block

for

swift

warming

up

of

the

engine

After

it

reaches

normal

oper

ating

temperature

the

coolant

circu

lates

through

the

radiator

The

cooling

fan

drive

is

of

a

coupling

type

COOLANT

LEVEL

The

coolant

level

should

be

check

ed

and

maintained

at

SO

mm

1

97

in

below

the

upper

face

of

filler

neck

when

the

engine

is

cold

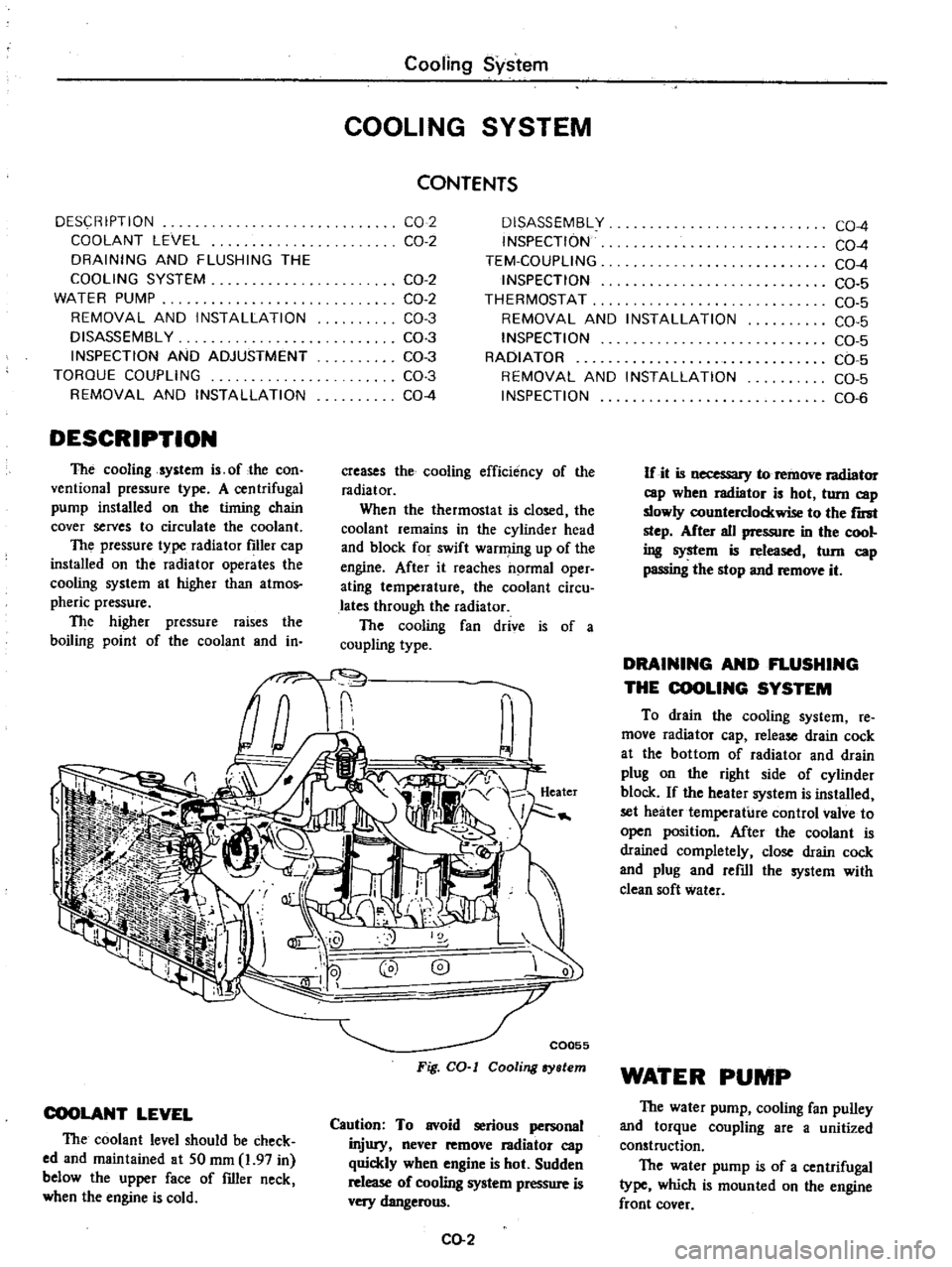

C0055

Fig

CO

I

Cooling

ry

lem

Caution

To

avoid

serious

personal

injury

never

remove

I3diator

cap

quickly

when

engine

is

hot

Sudden

release

of

cooling

system

pressure

is

very

dangerous

CO

2

CO

4

CO

4

CO

4

CO

5

CO

5

CO

5

CO

5

CO

5

CO

5

CO

6

If

it

is

necessary

to

remove

radiator

cap

wben

radiator

is

hot

turn

cap

slowly

counterclockwise

to

the

r

step

After

all

pressure

in

the

cool

ing

system

is

released

tom

cap

passing

the

stop

and

remove

it

DRAINING

AND

FLUSHING

THE

COOLING

SYSTEM

To

drain

the

cooling

system

re

move

radiator

cap

release

drain

cock

at

the

bottom

of

radiator

and

drain

plug

on

the

right

side

of

cylinder

block

If

the

heater

system

is

installed

set

heater

temperature

control

valve

to

open

position

After

the

coolant

is

drained

completely

close

drain

cock

and

plug

and

refill

the

system

with

clean

soft

water

WATER

PUMP

The

water

pump

cooling

fan

pulley

and

torque

coupling

are

a

unitized

construction

The

water

pump

is

of

a

centrifugal

type

which

is

mounted

on

the

engine

front

cover

Page 96 of 537

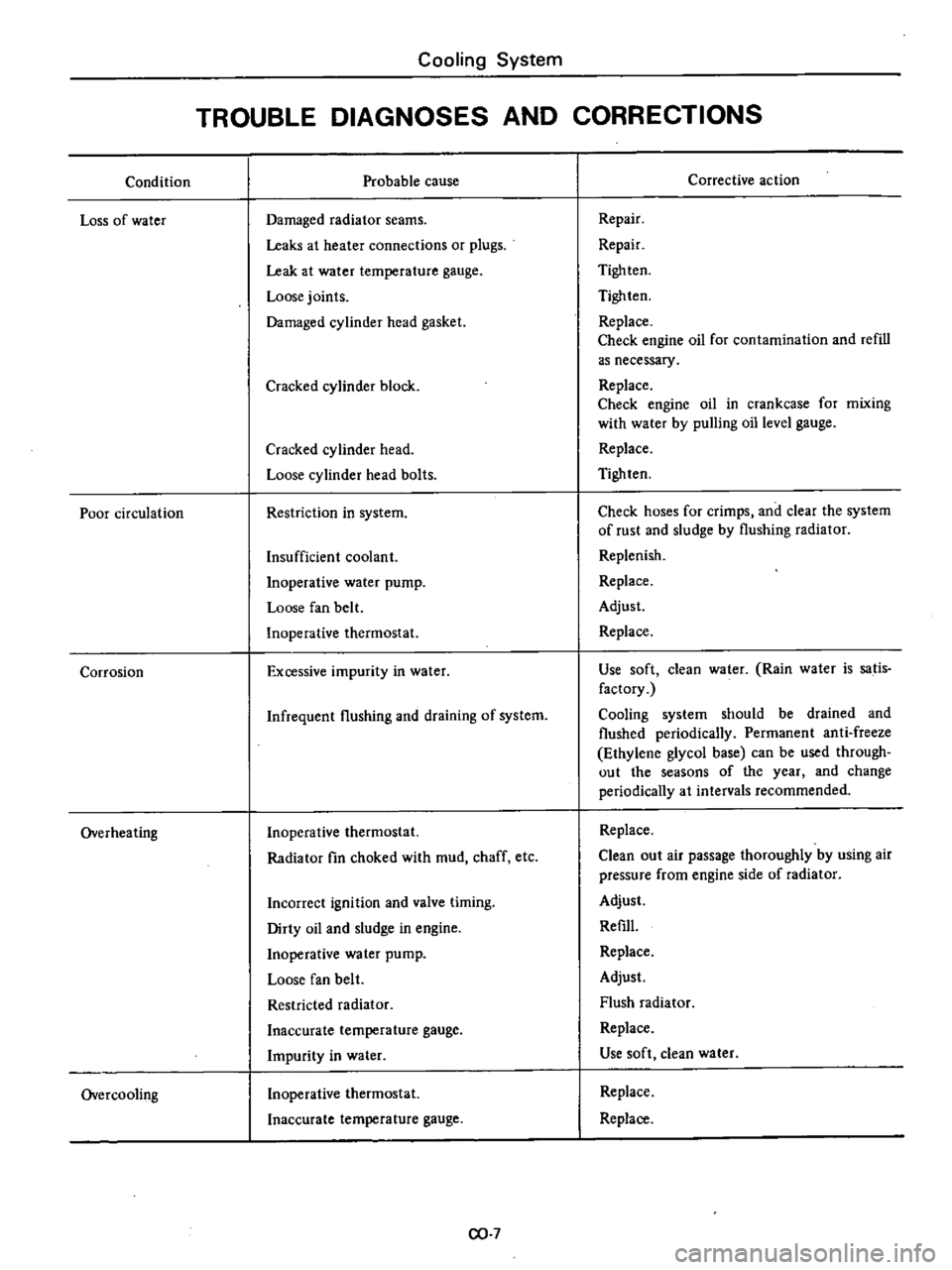

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Overcooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tigh

ten

Tighten

Replace

Check

engine

oil

for

contamination

and

refill

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

Rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flushed

periodically

Permanent

anti

freeze

Ethylene

glycol

base

can

be

used

through

out

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Adjust

Flush

radiator

Replace

Use

soft

clean

water

Replace

Replace

Page 314 of 537

Using

the

tester

check

the

two

black

yellow

BY

wires

from

the

in

hibitor

switch

in

the

ranges

N

and

I

and

the

tw

re

d

black

RBj

wir

s

in

the

range

R

for

continuity

Turn

range

select

lever

in

both

directions

from

each

lever

set

position

and

check

each

continuity

range

It

is

normal

if

the

electricity

is

on

while

the

lever

is

within

an

angle

of

about

30

on

both

sides

from

each

lever

set

line

How

ever

if

its

continl

ity

range

is

obvious

ly

unequal

on

both

sides

adjustment

is

required

If

any

malfunction

is

found

un

screw

the

fastening

nut

of

the

range

selector

lever

and

two

fastening

bolts

of

the

switch

body

and

then

remove

the

machine

screw

under

the

switch

body

Adjust

the

manual

shaft

correct

ly

to

the

position

N

by

means

of

the

selector

lever

When

the

slot

of

the

shaft

becomes

vertical

the

detent

works

to

position

the

shaft

correctly

with

a

clicking

sound

MSlVe

the

switch

slightly

asj

Je

so

that

the

screw

hole

will

be

aligned

with

the

pin

hole

of

the

internal

rotor

combined

with

the

manual

shaft

and

check

their

alignment

by

inserting

a

1

5

mm

0

059

in

diameter

pin

into

the

holes

If

the

alignment

is

correct

fasten

the

switch

body

with

the

bolts

pull

out

the

pin

tighten

up

the

screw

in

the

hole

and

fasten

the

selector

lever

as

before

Check

the

continuity

again

with

the

tester

If

the

malfunc

tion

still

remains

replace

the

inhibitor

switch

Chcck

whether

the

reverse

lamp

and

the

starter

motor

operate

normal

ly

in

these

ranges

If

Ihere

is

any

lrouble

first

check

the

linkage

If

no

fault

is

found

in

the

linkage

check

the

inhibitor

switch

Separate

the

manual

lever

from

Ihe

remote

control

selector

rod

and

turn

the

range

selcct

lever

to

N

Note

In

the

position

N

the

slot

of

the

manual

shaft

is

vertical

STALL

TEST

The

purpose

of

this

test

is

to

check

the

transmission

and

engine

for

trou

ble

by

measuring

the

maximum

num

bers

of

revolutions

of

the

engine

while

Automatic

Transmission

vehicle

is

held

in

a

stalled

condition

The

carburctor

is

in

full

throttle

opera

tion

with

the

selector

lever

in

ranges

f

2

and

I

respectively

Com

pare

the

measured

results

with

the

slandard

values

Components

to

be

tested

and

test

items

I

Clutches

brake

and

band

in

trans

mission

for

slipping

2

Torque

converter

for

proper

fune

tioning

3

Engine

for

overall

properly

STALL

TEST

PROCEDURES

Before

Icsting

c

heck

the

engine

oil

and

torque

converter

oil

warm

up

the

engine

cooling

water

to

suitable

tem

perature

by

running

at

1

200

rpm

with

the

selector

lever

in

the

range

P

for

several

minutes

Warm

up

the

torque

converter

oil

to

suitable

temperature

6010

1000C

140

to

2l20F

I

Mount

the

engine

tachometer

at

a

location

that

allows

good

visibility

fro

the

dri

er

s

seat

and

put

a

mark

on

specified

revolutions

on

the

meter

2

Secure

the

front

and

rear

wheels

with

chocks

and

apply

the

hand

brake

Be

sure

to

depress

the

brake

pedal

fumly

with

the

left

foot

before

de

pressing

the

accelerator

pedal

3

Throw

the

selector

lever

into

the

range

1

4

Slowly

depress

the

accelerator

pedal

until

the

throttle

valvc

is

fully

opened

Quickly

read

and

record

the

engine

revolution

when

the

engine

begins

to

rotate

steadily

and

then

release

the

accelerator

pedal

5

Shift

the

selector

lever

to

N

and

operate

the

engine

at

approxi

mately

1

200

rpm

for

more

than

one

minute

to

cool

down

the

torque

con

ver

ter

oil

and

coolant

6

Make

similar

stall

tests

in

ranges

2

I

and

RIO

Note

The

stall

test

operation

as

speci

f

d

in

item

4

should

be

I

l3de

wiihin

five

seconds

If

it

takes

too

long

the

oil

deteriorates

an

the

clutches

brake

and

band

are

ad

versely

affected

Sufficient

cooling

time

should

be

given

between

each

AT

5O

test

for

the

four

ranges

0

2

I

and

R

JUDGEMENT

High

stall

revolution

more

than

standard

revolution

If

the

engine

revolution

in

stall

condition

is

higher

than

the

standard

values

it

indicates

that

one

or

more

clutches

in

the

transmission

are

slipping

and

therefore

no

further

test

is

required

For

the

following

abnormalities

the

respective

causes

are

presumed

High

rpm

in

all

ranges

low

Iine

pressure

High

rpm

in

D

2

and

I

and

normal

rpm

in

R

Rear

clutch

slipping

High

rpm

in

0

and

normal

rpm

in

I

clutch

slipping

High

rpm

in

R

only

Front

clutch

or

low

and

reverse

brake

slipping

To

determine

which

is

slipping

front

clutch

or

low

and

reverse

brake

a

road

test

is

nceded

If

whilc

coasting

after

starting

with

the

lever

in

1

range

engine

braking

does

not

work

properly

the

low

and

reverse

brake

is

slipping

Otherwise

the

front

clutch

is

slipping

Slipping

of

the

band

brake

is

diffi

cult

to

ascertain

However

if

it

occurs

with

the

lever

in

2

range

engine

revolution

increases

Jp

to

thesarne

level

as

in

I

strange

It

is

impossible

to

check

it

in

the

stall

test

2

and

One

way

2

Standard

stall

revolution

If

the

engine

revolution

in

stall

condition

is

within

the

standard

values

the

control

elements

are

nor

mally

operating

in

the

ranges

0

2

I

and

R

Also

tIle

engine

and

one

way

clutch

of

the

torque

converter

are

normal

in

performance

and

operation

The

one

way

clutch

of

the

torque

converter

however

sometimes

sticks

This

is

determined

in

the

road

test

3

Lower

stall

revolution

than

stand

ard

revolution

If

the

engine

revolution

in

stall

condition

is

lower

than

the

standard

Page 474 of 537

HEATER

UNIT

ASSEMBLY

Removal

L

Disconnect

battery

ground

cable

2

Drain

engine

coolant

3

Remove

defroster

hoses

4

Remove

three

cable

retaining

clips

and

disconnect

control

cables

from

valves

and

water

cock

5

Disconnect

two

fan

motor

lead

wires

from

each

connector

6

Disconnect

two

resistor

lead

wires

from

each

connector

7

Disconnect

water

hoses

from

core

and

water

cock

8

Remove

three

heater

housing

mounting

bolts

and

dismount

heater

unit

from

vehicle

Installation

1

Position

heater

unit

under

instru

ment

panel

and

install

three

heater

unit

securing

bolts

2

Install

water

hoses

3

Position

heater

control

cables

to

room

valve

air

intake

valve

and

water

cock

4

Adjust

control

cable

length

for

proper

operation

as

outlined

in

Adjust

ment

5

Connect

fan

motor

wires

and

resistance

wires

to

each

connector

plug

6

Install

defroster

hoses

7

Connect

battery

ground

cable

8

Fill

cooling

systeIT

9

Run

engine

at

2

000

rpm

with

AIR

lever

in

the

HOT

position

Make

sure

that

engine

coolant

is

fIlled

up

to

correct

level

HEATER

CORE

Removal

and

installation

L

Drain

engine

coolant

2

Remove

defroster

hoses

3

Disconnect

water

hoses

from

inlet

and

outlet

pipes

of

heater

core

4

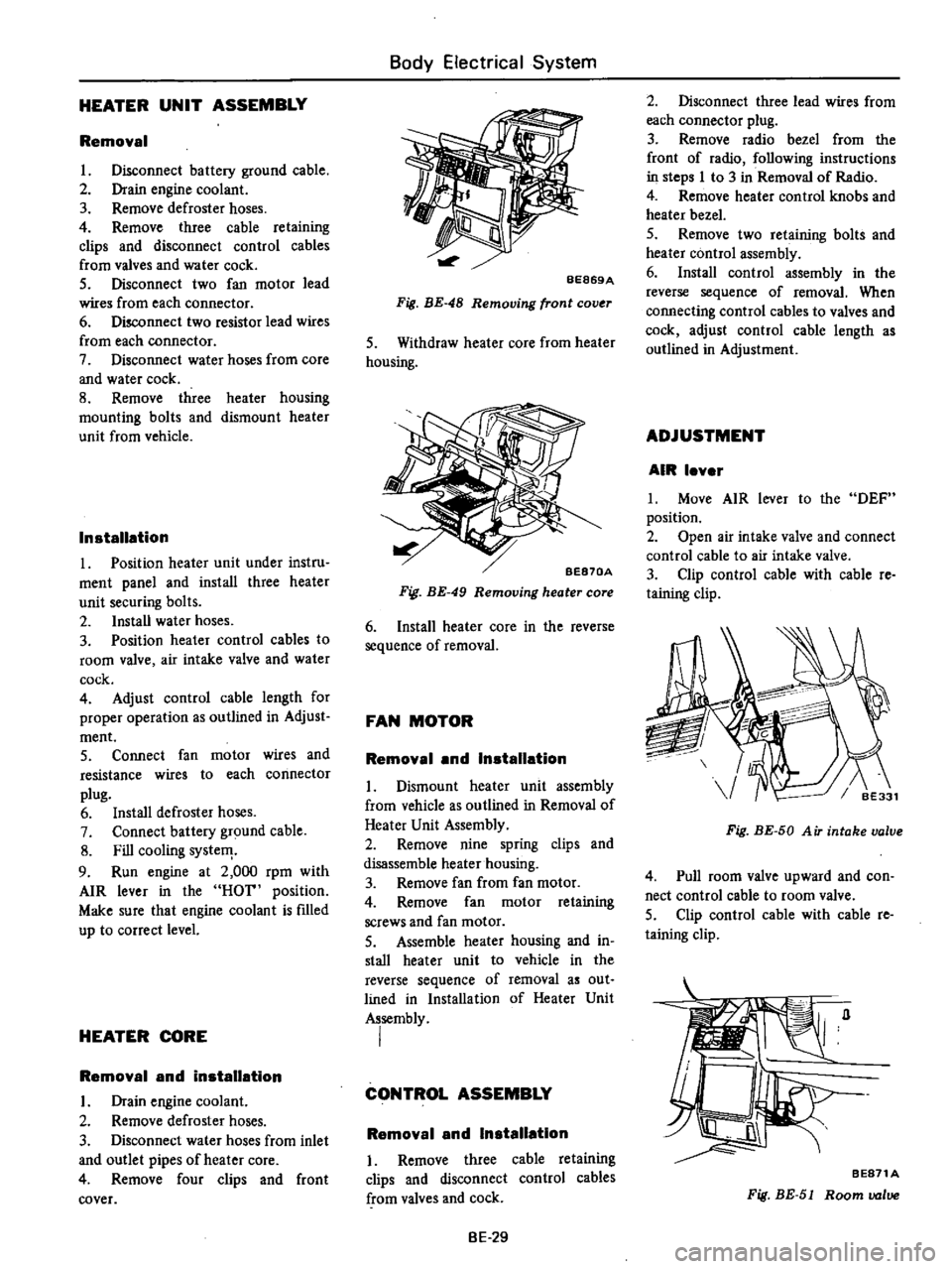

Remove

four

clips

and

front

cover

Body

Electrical

System

BE869A

Fig

BE

48

Removing

front

cov

r

S

Withdraw

heater

core

from

heater

housing

BE870A

Fig

BE

49

Removing

heater

core

6

Install

heater

core

in

the

reverse

sequence

of

removal

FAN

MOTOR

Removal

and

Installation

L

Dismount

heater

unit

assembly

from

vehicle

as

outlined

in

Removal

of

Heater

Unit

Assembly

2

Remove

nine

spring

clips

and

disassemble

heater

housing

3

Remove

fan

from

fan

motor

4

Remove

fan

motor

retaining

screws

and

fan

motor

S

Assemble

heater

housing

and

in

stall

heater

unit

to

vehicle

in

the

reverse

sequence

of

removal

as

out

lined

in

Installation

of

Heater

Unit

Assembly

I

CONTROL

ASSEMBLY

Removal

and

Installation

I

Remove

three

cable

retaining

clips

and

disconnect

control

cables

from

valves

and

cock

BE

29

2

Disconnect

three

lead

wires

from

each

connector

plug

3

Remove

radio

bezel

from

the

front

of

radio

following

instructions

in

steps

I

to

3

in

Removal

of

Radio

4

Remove

heater

control

knobs

and

heater

bezel

5

Remove

two

retaining

bolts

and

heater

control

assembly

6

Install

control

assembly

in

the

reverse

sequence

of

removal

When

connecting

control

cables

to

valves

and

cock

adjust

control

cable

length

as

outlined

in

Adjustment

ADJUSTMENT

AIR

lever

L

Move

AIR

lever

to

the

DEF

position

2

Open

air

intake

valve

and

connect

control

cable

to

air

intake

valve

3

Clip

control

cable

with

cable

re

taining

clip

Fig

BE

50

A

iT

intake

valve

4

Pull

room

valve

upward

and

con

nect

control

cable

to

room

valve

5

Clip

control

cable

with

cable

re

taining

clip

BE871A

Fig

BE

51

Room

valve