roof DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 300 of 537

Automatic

Transmission

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

TORQUE

CONVERTER

INSPECTION

TRANSMISSION

DISASSEMBL

Y

INSPECTION

ASSEMBL

Y

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

I

It

is

advisable

that

repair

opera

tions

be

carried

out

in

a

dust

proof

room

2

Due

to

the

differences

of

the

engine

capacities

the

specifications

of

component

parts

for

each

model

s

transmission

may

be

different

They

do

however

have

common

adjust

ment

and

repair

procedures

as

well

as

cleaning

and

inspection

procedures

outlined

hereinafter

3

During

repair

operations

refer

to

Service

Data

and

Specifications

see

tion

for

the

correct

parts

for

each

model

4

Before

removing

any

of

subas

semblies

thoroughly

clean

the

outside

of

the

transmission

to

prevent

dirt

from

entering

the

mechanical

parts

5

Do

not

use

a

waste

rag

Use

a

nylon

or

paper

cloth

6

After

disassembling

wash

all

dis

assembled

parts

and

examine

them

to

see

if

there

are

any

worn

damaged

or

defective

parts

and

how

they

are

affected

Refer

to

Service

Data

for

the

extent

of

damage

that

justifies

replacement

7

As

a

rule

packings

seals

and

similar

parts

once

disassembled

should

be

replaced

with

new

ones

TORQUE

CONVERTER

The

torque

converter

is

a

welded

construction

and

can

not

be

disas

sembled

CONTENTS

AT

36

AT

36

AT

36

AT

36

AT

36

AT

38

AT

38

COMPONENT

PARTS

FRONT

CLUTCH

REAR

CLUTCH

LOW

REVERSE

BRAKE

SERVO

PISTON

GOVERNOR

OIL

PUMP

PLANETARY

CARRIER

CONTROL

VALVE

AT

40

AT

40

AT

41

AT

42

AT

42

AT

43

AT

43

AT

44

AT

44

INSPECTION

2

Remove

bolts

securing

converter

1

Check

torque

convertf

for

any

housing

to

transmission

case

Remove

sign

of

damage

bending

oil

leak

or

torque

converter

deformation

If

necessary

replace

3

Remove

speedometer

pinion

2

Remove

rust

from

pilots

and

sleeve

bolt

Withdraw

pinion

bosses

completely

4

Remove

downshift

solenoid

and

If

torque

converter

oil

is

fouled

or

vacuum

diaphragm

Do

not

leave

dia

contaminated

due

to

burnt

clutch

phragm

rod

at

this

stage

of

disas

flush

the

torque

converter

as

follows

sembly

Rod

is

assembled

in

top

of

vacuum

diaphragm

See

Figure

I

Drain

oil

in

torque

converter

AT

53

2

Pour

non

lead

gasoline

or

kero

sene

into

torque

converter

approxi

mately

0

5

liter

I

U

S

pt

U

Imp

pt

3

Blow

air

into

torque

converter

and

flush

and

drain

out

gasoline

4

Fill

torque

converter

with

torque

converter

oil

approximately

0

5

liter

I

V

S

pt

U

Imp

pt

5

Again

blow

air

into

torque

con

verter

and

drain

torque

converter

oil

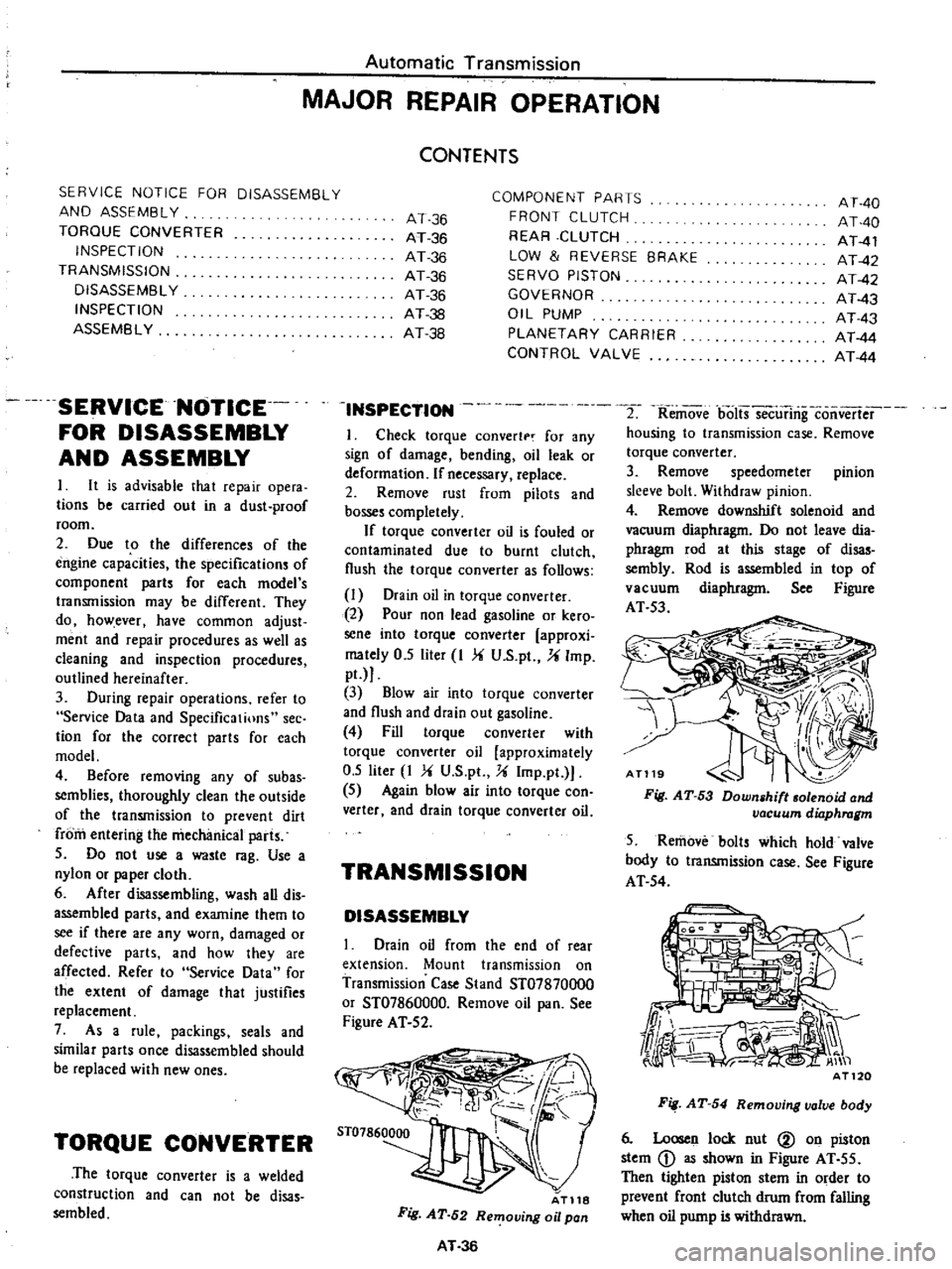

TRANSMISSION

DISASSEMBLY

I

Drain

oil

from

the

end

of

rear

extension

Mount

transmission

on

Transmission

Case

Stand

ST07870000

or

ST07860000

Remove

oil

pan

See

Figure

AT

52

AT118

Fig

AT

52

Removing

oil

pan

AT

36

Fig

AT

53

Down

hilt

olenoid

and

vacuum

dilJphragm

5

Remove

bolts

which

hold

valve

body

to

transmission

case

See

Figure

AT

54

Fig

AT

54

Removing

valve

body

6

Loosen

lock

nut

@

on

piston

stem

D

as

shown

in

Figure

AT

55

Then

tighten

piston

stem

in

order

to

prevent

front

clutch

drum

from

falling

when

oil

pump

is

withdrawn

Page 356 of 537

Components

Rust

Discoloring

Race

and

roller

u

u

e

2

2

0

3

0

t

c

6

6

6

Fig

h

The

wheel

bearing

is

serv

iceable

if

discoloring

can

be

removed

with

solvent

or

by

polishing

f

a

Inner

race

flaking

t

d

Cracked

roller

iT

t

j

t

11

1

1

t

t

I

l

1

t

F

1ll

JJ

J

t

I

1

ollf

oe

c

g

Recess

on

foDer

Front

Axle

Front

Suspension

Cause

Temperature

increased

during

operation

lowers

when

the

bearing

stops

moisture

inside

the

bearing

is

condensed

becoming

fine

drips

and

the

grease

is

moistened

The

bearing

has

been

placed

in

a

highly

moistened

place

for

a

long

period

of

time

Intrusion

of

moisture

chemicals

etc

or

the

bearing

is

touched

with

bare

hand

and

no

rustproof

action

has

been

taken

Slight

discoloring

may

become

like

oxidized

oil

stain

due

to

grease

In

the

most

cases

this

occurs

when

preliminary

pressure

is

too

high

I

I

I

1

v

i

n

dJ

b

RoUer

flaking

c

Cracked

inner

race

c

f

J

Jt

v

l

e

Recess

on

inner

race

f

Recess

on

outer

race

h

Rust

outer

race

F

A007

Fig

FA

12

Defective

conditions

of

bearing

FA

7

Page 442 of 537

Body

Frame

INTERIOR

TRIM

AND

CENTER

CONSOLE

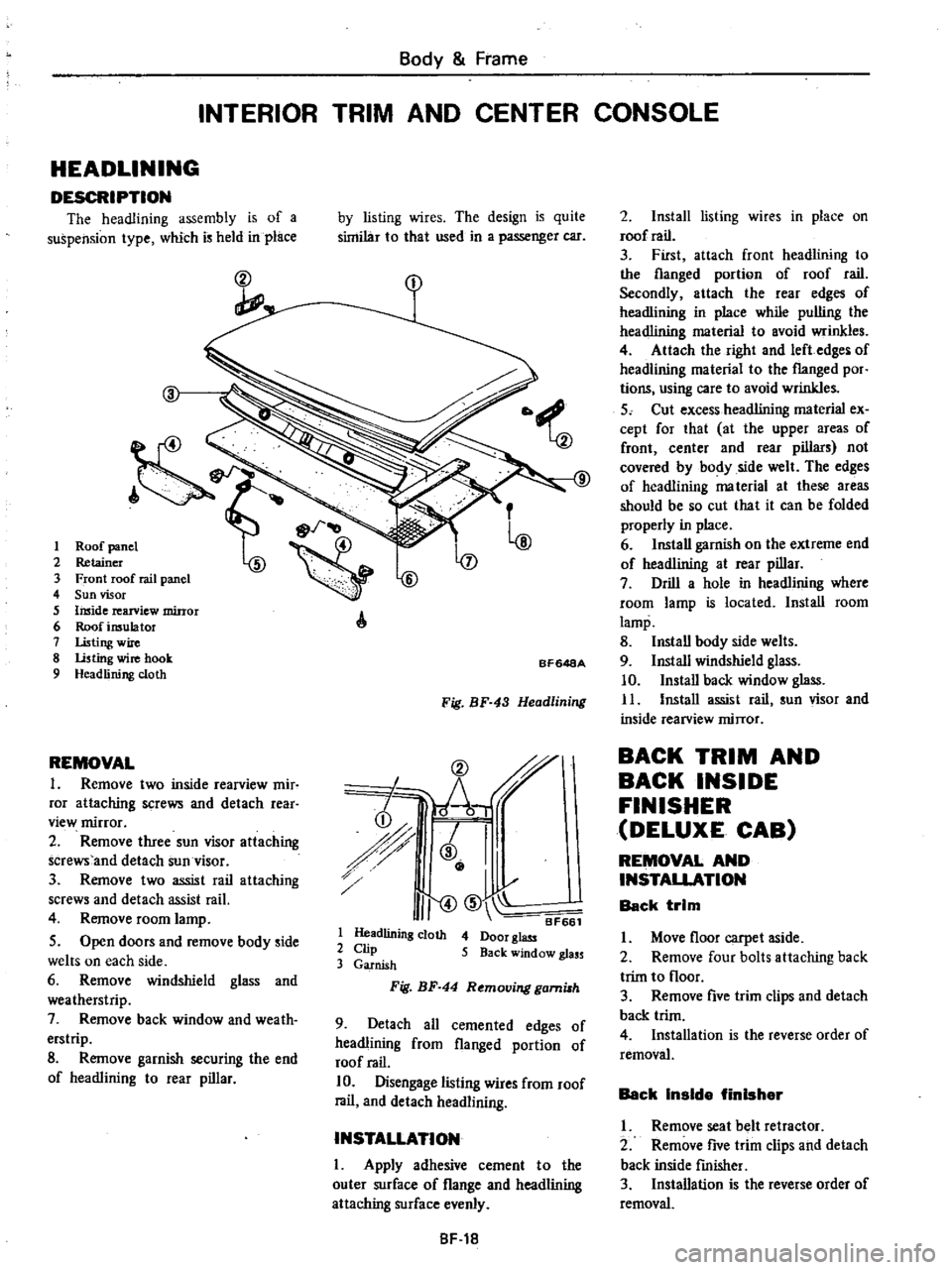

HEADLINING

DESCRIPTION

The

headlining

assembly

is

of

a

suspension

type

which

is

held

in

place

ct

I

2

3

4

5

6

7

8

9

REMOVAL

1

Remove

two

inside

rearview

mir

ror

attaching

screws

and

detach

rear

view

mirror

2

Remove

three

sun

visor

attaching

screws

and

detach

sun

visor

3

Remove

two

assist

rail

attaching

screws

and

detach

assist

rail

4

Remove

room

lamp

5

Open

doors

and

remove

body

side

welts

on

each

side

6

Remove

windshield

glass

and

weatherstrip

7

Remove

back

window

and

weath

erstrip

8

Remove

garnish

securing

the

end

of

headlining

to

rear

pillar

by

listing

wires

The

design

is

quite

similar

to

that

used

in

a

passenger

car

A

BF648A

Fig

BF

43

Headlining

CD

r

h

i

r

J

I

I

I

II

CID

BF661

1

Headlining

cloth

4

Door

glass

2

Clip

5

Back

window

glass

3

Garnish

Fig

BF

44

Removing

gami8h

9

Detach

all

cemented

edges

of

headlining

from

flanged

portion

of

roof

rail

10

Disengage

listing

wires

from

roof

rail

and

detach

headlining

INSTALLATION

I

Apply

adhesive

cement

to

the

outer

surface

of

flange

and

headlining

attaching

surface

evenly

8F

18

2

Install

listing

wires

in

place

on

roof

rail

3

First

attach

front

headlining

to

the

flanged

portion

of

roof

rail

Secondly

attach

the

rear

edges

of

headlining

in

place

while

pulling

the

headlining

material

to

avoid

wrinkles

4

Attach

the

right

and

left

edges

of

headlining

material

to

the

flanged

por

tions

using

care

to

avoid

wrinkles

5

Cut

excess

headlining

material

ex

cept

for

that

at

the

upper

areas

of

front

center

and

rear

pillars

not

covered

by

body

side

welt

The

edges

of

headlining

ma

terial

at

these

areas

should

be

so

cut

that

it

can

be

folded

properly

in

place

6

Install

garnish

on

the

extreme

end

of

headlining

at

rear

pillar

7

Drill

a

hole

in

headlining

where

room

lamp

is

located

Install

room

lamp

8

Install

body

side

welts

9

Install

windshield

glass

10

Install

back

window

glass

11

Install

assist

rail

sun

visor

and

inside

rearview

mirror

BACK

TRIM

AND

BACK

INSIDE

FINISHER

DELUXE

CAB

REMOVAL

AND

INSTALLATION

Back

trim

I

Move

floor

carpet

aside

2

Remove

four

bolts

attaching

back

trim

to

floor

3

Remove

five

trim

clips

and

detach

back

trim

4

Installation

is

the

reverse

order

of

removal

Back

Inside

finisher

I

Remove

seat

belt

retractor

2

Remove

five

trim

clips

and

detach

back

inside

fmisher

3

Installation

is

the

reverse

order

of

removal

Page 453 of 537

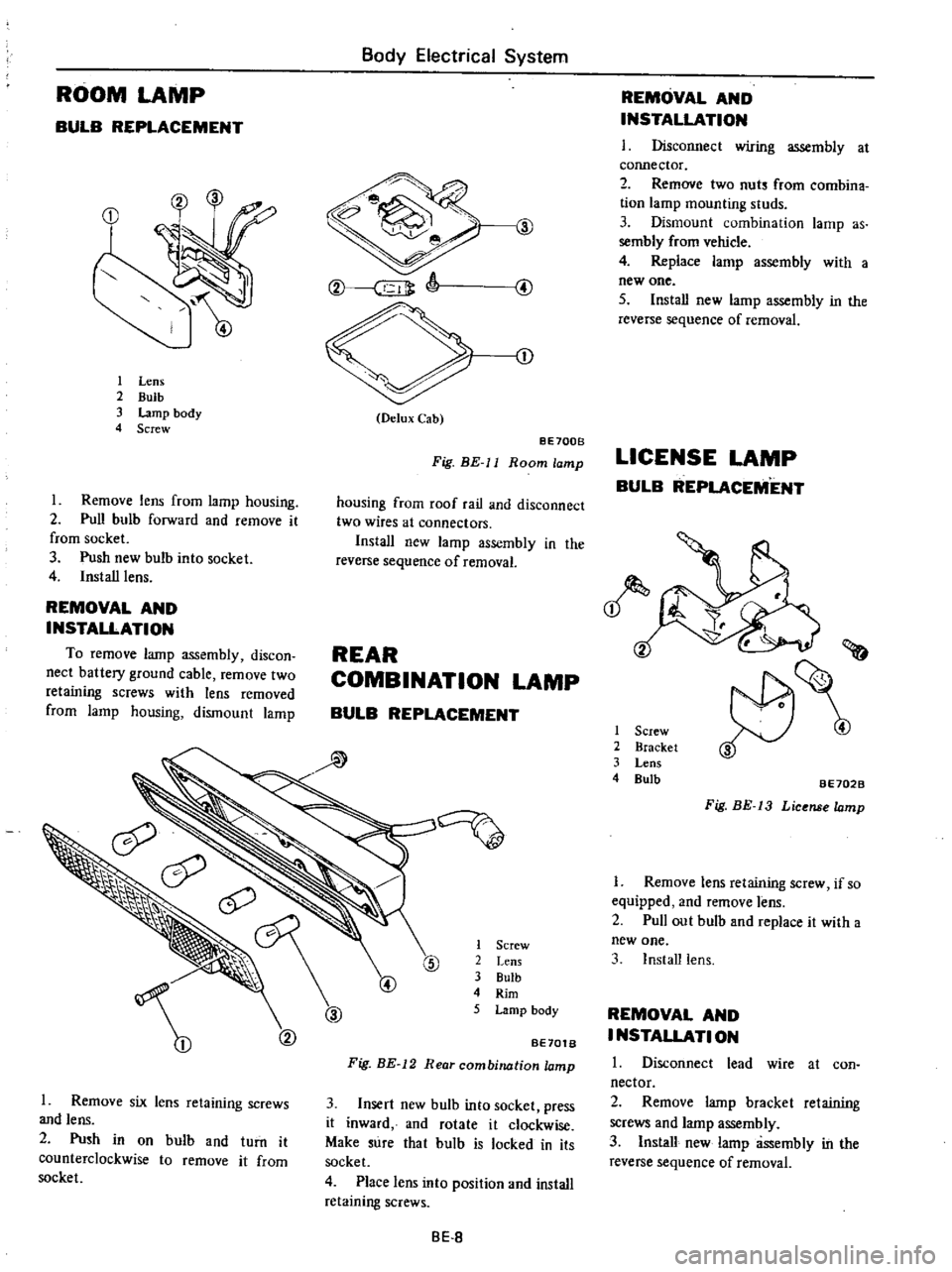

ROOM

LAMP

BULB

REPLACEMENT

1

Lens

2

Bulb

3

Lamp

body

4

Screw

Remove

lens

from

lamp

housing

2

Pull

bulb

forward

and

remove

it

from

socket

3

Push

new

bulb

into

socket

4

Install

lens

REMOVAL

AND

INSTALLATION

To

remove

lamp

assembly

discon

nect

battery

ground

cable

remove

two

retaining

screws

with

lens

removed

from

lamp

housing

dismount

lamp

1

Remove

six

lens

retaining

screws

and

lens

2

Push

in

on

bulb

and

turn

it

counterclockwise

to

remove

it

from

socket

Body

Electrical

System

J

CD

O

lux

Cab

8E700B

Fig

HE

ll

Room

lamp

housing

from

roof

rail

and

disconnect

two

wires

at

connectors

Install

new

lamp

assembly

in

the

reverse

sequence

of

removal

REAR

COMBINATION

LAMP

BULB

REPLACEMENT

1

Screw

2

Lens

3

Bulb

4

Rim

5

Lamp

body

@

BE70tB

Fig

BE

12

Rear

combination

lamp

3

Insert

new

bulb

into

socket

press

it

inward

and

rotate

it

clockwise

Make

sure

that

bulb

is

locked

in

its

socket

4

Place

lens

into

position

and

install

retaining

screws

8E

8

REMOVAL

AND

INSTALLATION

I

Disconnect

wiring

assembly

at

cormector

2

Remove

two

nuts

from

combina

tion

lamp

mounting

studs

3

Dismount

combination

lamp

as

sembly

from

vehicle

4

Replace

lamp

assembly

with

a

new

one

5

Install

new

lamp

assembly

in

the

reverse

sequence

of

removal

LICENSE

LAMP

BULB

REPLACEMENT

1

Screw

2

Bracket

3

Lens

4

Bulb

i

J

BE702B

Fig

HE

13

License

Iomp

1

Remove

lens

retaining

screw

if

so

equipped

and

remove

lens

2

Pull

out

bulb

and

replace

it

with

a

new

one

3

Install

lens

REMOVAL

AND

I

NSTALlATI

ON

1

Disconnect

lead

wire

at

con

nector

2

Remove

lamp

bracket

retaining

screws

and

lamp

assembly

3

Install

new

lamp

assembly

in

the

reverse

sequence

of

removal