spare wheel DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 360 of 537

Note

When

installing

fulcrum

pin

insert

it

from

rearward

of

vehicle

12

Install

tension

rod

shock

ab

sorber

I

stabilizer

torsion

bar

spring

and

knuckle

arm

referring

to

the

related

paragraphs

13

Install

brake

disc

to

knuckle

spindle

and

torque

securing

bolt

to

4

2

to

5

0

kg

m

30

to

36

ft

Ib

14

Install

wheel

and

brake

drum

as

an

assembly

and

torque

knuckle

spin

dle

nut

to

8

0

to

9

0

kg

m

58

to

65

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Upper

link

I

Detach

upper

link

spindle

from

upper

links

and

remove

clamp

dust

cover

and

dust

seal

Secure

upper

link

in

a

vise

and

loosen

screw

bushing

Assemble

link

spindle

in

reverse

sequence

to

disassembling

noting

the

following

instructions

2

Torque

screw

bushing

on

upper

link

to

3S

to

55

kg

m

253

to

398

ft

Ib

Install

new

dust

seal

and

dust

cover

and

secure

them

with

clamp

3

Coat

grease

to

screw

bushing

in

side

and

the

thread

portion

of

upper

link

spindle

liberally

Screw

front

and

rear

links

to

upper

link

spindle

in

the

same

length

so

as

to

obtain

the

speci

fied

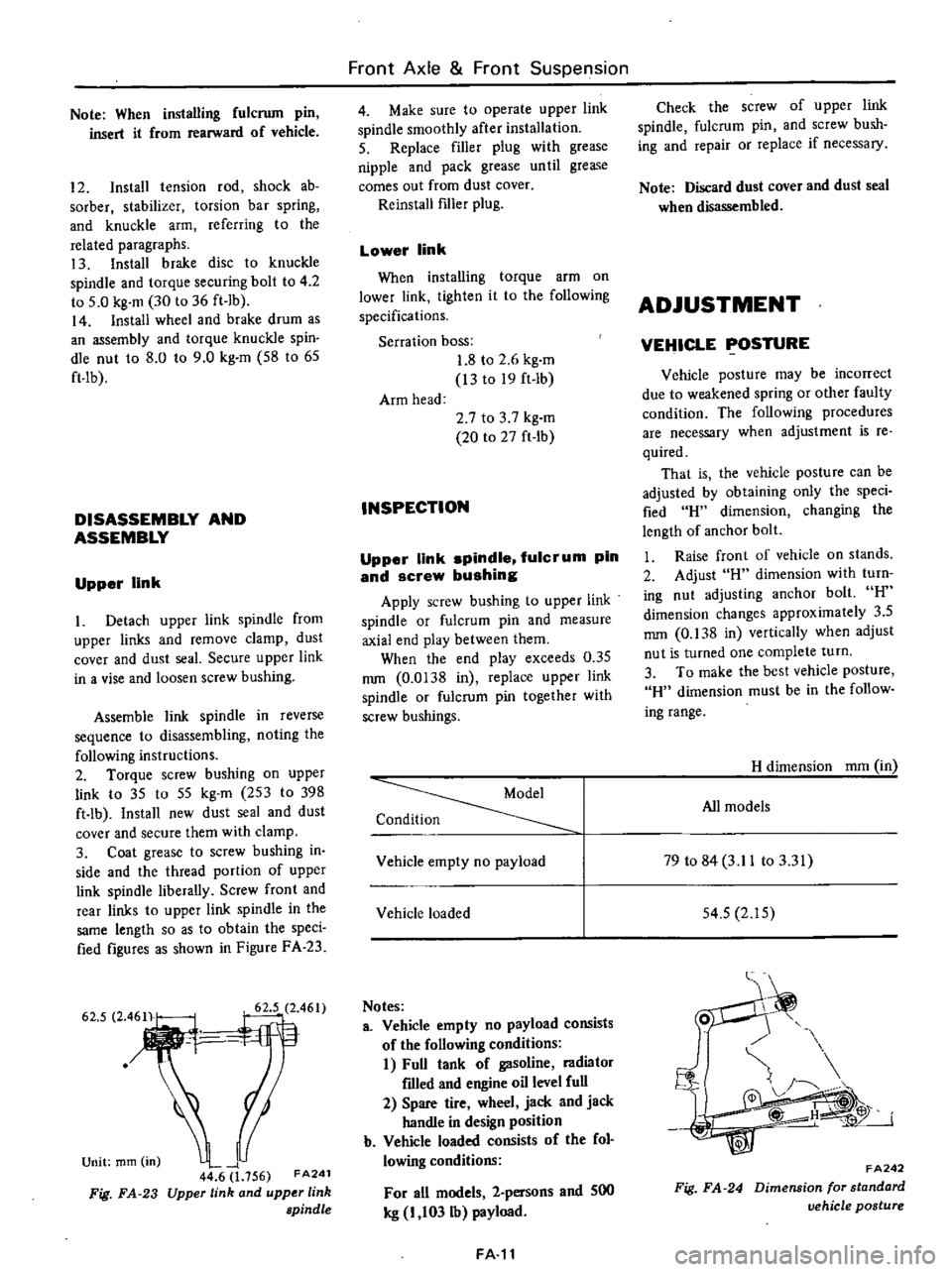

figures

as

shown

in

Figure

FA

23

Unit

mm

in

I

44

6

1

156

FA2

Upper

link

and

upper

link

spindle

Fig

FA

23

Front

Axle

Front

Suspension

4

Make

sure

to

operate

upper

link

spindle

smoothly

after

installation

5

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

f1ller

plug

Lower

link

When

installing

torque

arm

on

lower

link

tighten

it

to

the

following

specifications

Serration

boss

1

8

to

2

6

kg

m

13

to

19

ft

Ib

Arm

head

2

7

to

3

7

kg

m

20

to

27

ft

tb

INSPECTION

Upper

link

spindle

fulcrum

pin

and

screw

bushing

Apply

screw

bushing

to

upper

link

spindle

or

fulcrum

pin

and

measure

axial

end

play

between

them

When

the

end

play

exceeds

0

35

mm

0

0138

in

replace

upper

link

spindle

or

fulcrum

pin

together

with

screw

bushings

Condition

Vehicle

empty

no

payload

Vehicle

loaded

Notes

a

Vehicle

empty

no

payload

consists

of

the

following

conditions

I

Full

tank

of

gasoline

radiator

f1lled

and

engine

oil

level

full

2

Spare

tire

wheel

jack

and

jack

handle

in

design

position

b

Vehicle

loaded

consists

of

the

fol

lowing

conditions

For

all

models

2

persons

and

SIlO

leg

I

103lb

payload

FA

Check

the

screw

of

upper

link

spindle

fulcrum

pin

and

screw

bush

ing

and

repair

or

replace

if

necessary

Note

Discard

dust

cover

and

dust

seal

when

disassembled

ADJUSTMENT

VEHICLE

POSTURE

Vehicle

posture

may

be

incorrect

due

to

weakened

spring

or

other

faulty

condition

The

following

procedures

are

necessary

when

adjustment

is

Ie

quired

That

is

the

vehicle

posture

can

be

adjusted

by

obtaining

only

the

speci

fied

H

dimension

changing

the

length

of

anchor

bolt

I

Raise

front

of

vehicle

on

stands

2

Adjust

H

dimension

with

turn

ing

nut

adjusting

anchor

bolt

H

dimension

changes

approximately

3

5

mm

0

J38

in

vertically

when

adjust

nut

is

turned

one

complete

turn

3

To

make

the

best

vehicle

posture

H

dimension

must

be

in

the

follow

ing

range

H

dimension

mOl

in

All

models

79

to

84

3

11

to

3

31

54

5

2

15

o

i

Fig

FA

24

FA242

Dimension

for

standard

vehicle

postl4re

Page 403 of 537

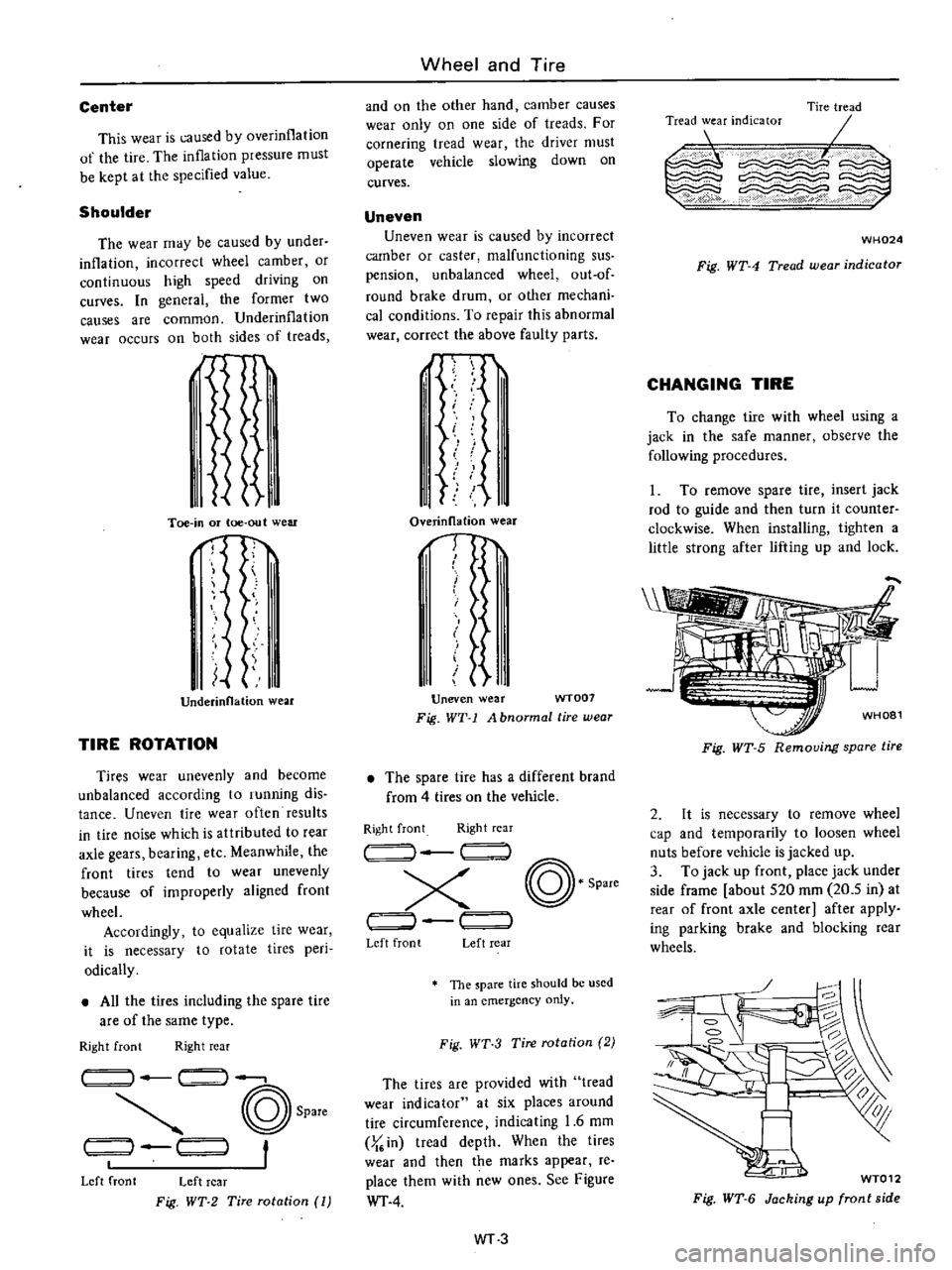

Center

This

wear

is

caused

by

overinflation

of

the

tire

The

inflation

pressure

must

be

kept

at

the

specified

value

Shoulder

The

wear

may

be

caused

by

under

inflation

incorrect

wheel

camber

or

continuous

high

speed

driving

on

curves

In

general

the

former

two

causes

are

common

Underinflation

wear

occurs

on

both

sides

of

treads

d

I

Ii

Toe

in

or

toe

out

wear

nf

I

Underinnation

wear

TIRE

ROTATION

Tires

wear

unevenly

and

become

unbalanced

according

to

running

dis

tance

Uneven

tire

wear

often

results

in

tire

noise

which

is

attributed

to

rear

axle

gears

bearing

etc

Meanwhile

the

front

tires

tend

to

wear

unevenly

because

of

improperly

aligned

front

wheel

Accordingly

to

equalize

tire

wear

it

is

necessary

to

rotate

tires

peri

odically

All

the

tires

including

the

spare

tire

are

of

the

same

type

Right

front

Right

rear

14

1

I

@

Spare

t

t

1

1

Left

front

Left

rear

Fig

WT

2

Tire

rotation

1

Wheel

and

Tire

and

on

the

other

hand

camber

causes

wear

only

on

one

side

of

treads

For

cornering

tread

wear

the

driver

must

operate

vehicle

slowing

down

on

curves

Uneven

Uneven

wear

is

caused

by

incorrect

camber

or

caster

malfunctioning

sus

pension

unbalanced

wheel

out

of

round

brake

drum

or

other

mechani

cal

conditions

To

repair

this

abnormal

wear

correct

the

above

faulty

parts

J

I

II

i

11

I

1

Overinllation

wear

1

I

I

t

Uneven

wear

WT007

Fig

WT

1

A

bnormal

tire

wear

The

spare

lire

has

a

different

brand

from

4

tires

on

the

vehicle

Right

front

Right

rear

I

@

Spare

x

J

r

Left

front

Left

rear

The

pare

tire

should

be

used

in

an

emergency

only

Fig

WT

3

Tire

rotation

2

The

tires

are

provided

with

tread

wear

indicator

at

six

places

around

tire

circumference

indicating

1

6

mm

J

in

tread

depth

When

the

tires

wear

and

then

the

marks

appear

re

place

them

with

new

ones

See

Figure

WT

4

WT3

Tire

tread

0E

I

Tread

wear

indicator

c

WH024

Fig

WT

4

Tread

wear

indicator

CHANGING

TIRE

To

change

tire

with

wheel

using

a

jack

in

the

safe

manner

observe

the

following

procedures

1

To

remove

spare

tire

insert

jack

rod

to

guide

and

then

turn

it

counter

clockwise

When

installing

lighten

a

little

strong

after

lifting

up

and

lock

Fig

WT

5

Removing

spare

tire

2

It

is

necessary

to

remove

wheel

cap

and

temporarily

to

loosen

wheel

nuts

before

vehicle

is

jacked

up

3

To

jack

up

front

place

jack

under

side

frame

about

S20

mOl

20

5

in

at

rear

of

front

axle

center

after

apply

ing

parking

brake

and

blocking

rear

wheels

g

1

WT012

Fig

WT

6

Jacking

up

front

side