light DODGE CALIBER 2006 1.G Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2006, Model line: CALIBER, Model: DODGE CALIBER 2006 1.GPages: 322, PDF Size: 5.99 MB

Page 181 of 322

Never drive with your foot resting on the clutch pedal, or

try to hold the vehicle on a hill with the clutch pedal

partially engaged. This will cause abnormal wear on the

clutch.

Never shift into REVERSE until the vehicle has come to a

complete stop.

NOTE:During cold weather, until the transaxle lubri-

cant is warm, you may experience slightly higher shift

efforts. This is normal and not harmful to the transaxle.

Recommended Shift Speeds

To use your manual transaxle for optimal fuel economy,

it should be upshifted as listed in table.

If you exceed these speeds, you may notice the engine cut

in and out. This is caused by an electronic limiter in the

engine computer. The engine will run normally when

you reduce engine speed.

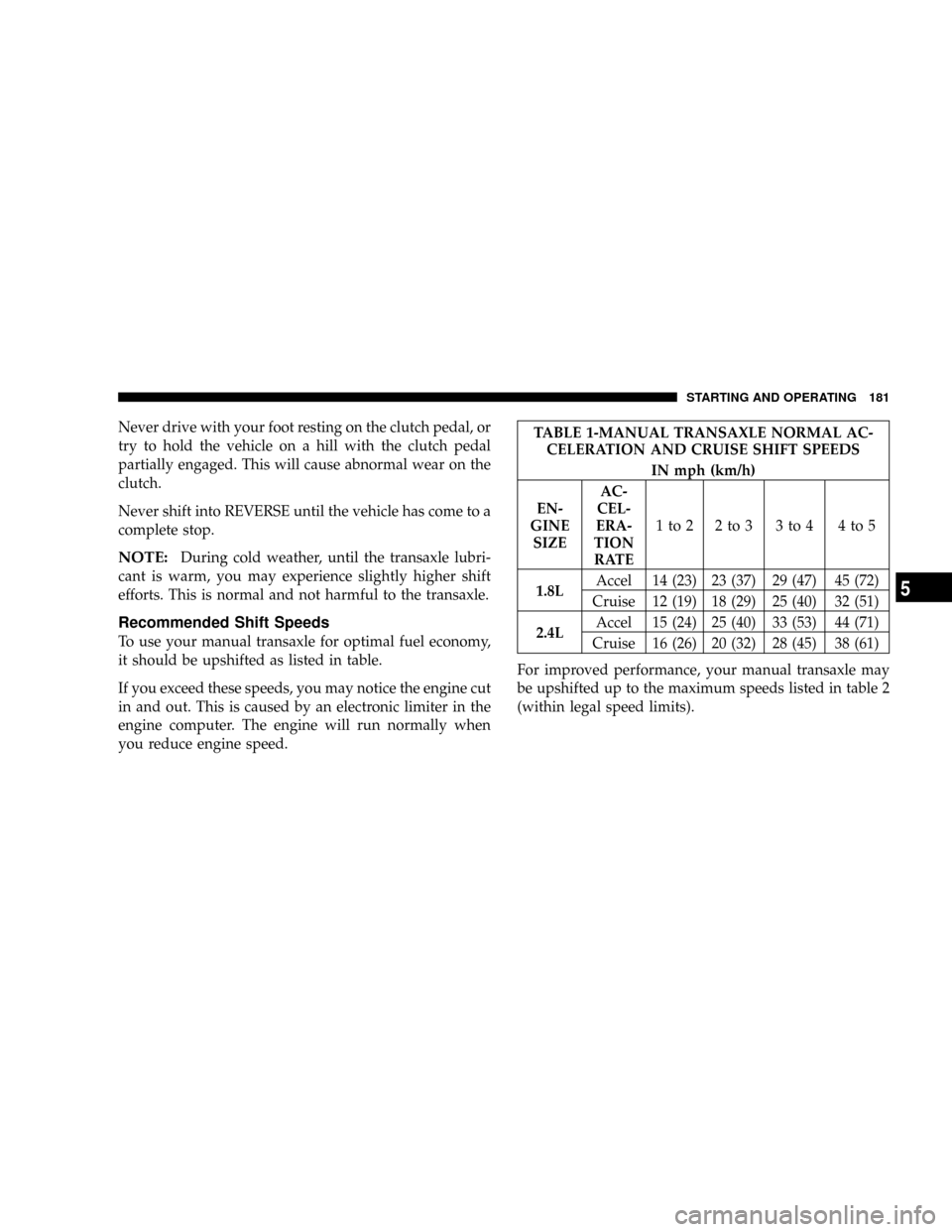

TABLE 1-MANUAL TRANSAXLE NORMAL AC-

CELERATION AND CRUISE SHIFT SPEEDS

IN mph (km/h)

EN-

GINE

SIZEAC-

CEL-

ERA-

TION

RATE1to2 2to3 3to4 4to5

1.8LAccel 14 (23) 23 (37) 29 (47) 45 (72)

Cruise 12 (19) 18 (29) 25 (40) 32 (51)

2.4LAccel 15 (24) 25 (40) 33 (53) 44 (71)

Cruise 16 (26) 20 (32) 28 (45) 38 (61)

For improved performance, your manual transaxle may

be upshifted up to the maximum speeds listed in table 2

(within legal speed limits).

STARTING AND OPERATING 181

5

Page 183 of 322

All Wheel Drive System Ð If Equipped

This feature provides full time, on-demand, All Wheel

Drive (AWD).

The system is automatic with no driver gear selection or

additional driving skills required. Under normal driving

conditions, the front wheels provide most of the traction.

If the front wheels begin to lose traction, power is shifted

automatically to the rear wheels to equalize front and

rear wheels speeds. The greater the front wheel traction

loss the greater the power transfer to the rear wheels.

Additionally, on dry pavement under heavy throttle

input (where one may have no wheel spin), torque will be

sent to the rear in a preemptive effort to improve vehicle

launch and performance characteristics.

PARKING BRAKE

When the parking brake is applied with the

ignition on, the Brake Light in the instrument

cluster will come on.

NOTE:This light only shows that the parking brake is

on. It does not show the degree of brake application.

If the parking brake is applied while the vehicle is

moving, a chime will sound to alert the driver. The

chime will sound up to 10 times or until the vehicle

has returned to a stop.

Before leaving the vehicle, make sure that the parking

brake is set. To set the parking brake, pull up firmly on

the lever. Also place the gear selector in the Park position

(automatic transaxle) or Reverse (manual transaxle). To

release the parking brake, apply the brake pedal, pull up

slightly on the lever, then depress the button on the end

of the lever and push the lever fully down toward the

floor.

STARTING AND OPERATING 183

5

Page 184 of 322

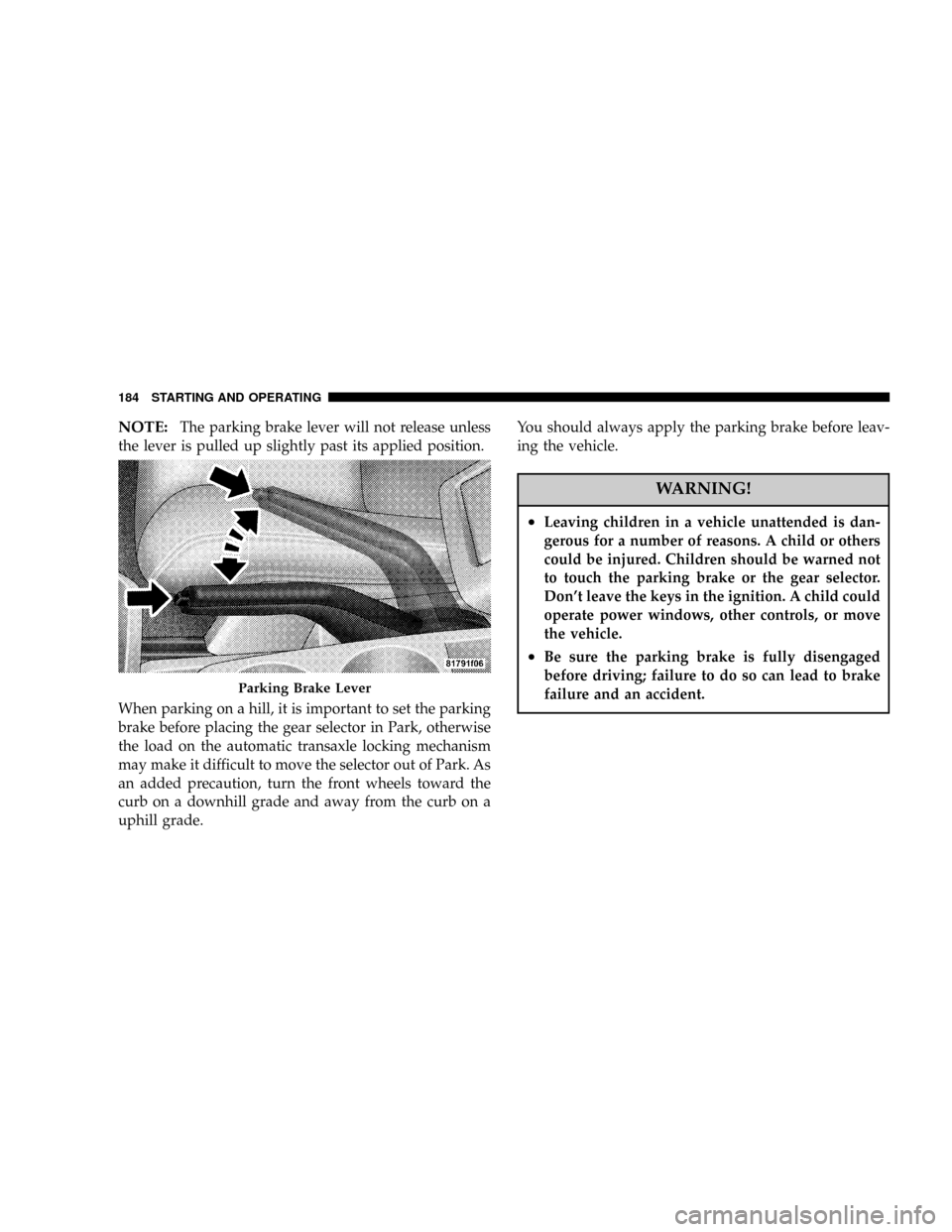

NOTE:The parking brake lever will not release unless

the lever is pulled up slightly past its applied position.

When parking on a hill, it is important to set the parking

brake before placing the gear selector in Park, otherwise

the load on the automatic transaxle locking mechanism

may make it difficult to move the selector out of Park. As

an added precaution, turn the front wheels toward the

curb on a downhill grade and away from the curb on a

uphill grade.You should always apply the parking brake before leav-

ing the vehicle.

WARNING!

²Leaving children in a vehicle unattended is dan-

gerous for a number of reasons. A child or others

could be injured. Children should be warned not

to touch the parking brake or the gear selector.

Don't leave the keys in the ignition. A child could

operate power windows, other controls, or move

the vehicle.

²Be sure the parking brake is fully disengaged

before driving; failure to do so can lead to brake

failure and an accident.

Parking Brake Lever

184 STARTING AND OPERATING

Page 185 of 322

BRAKE SYSTEM

Your vehicle is equipped with power assisted brakes as

standard equipment. In the event power assist is lost for

any reason (for example, repeated brake applications

with the engine off), the brakes will still function. How-

ever, the effort required to brake the vehicle will be much

greater than that required with the power system oper-

ating.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

If either of the two hydraulic systems lose normal capa-

bility, the remaining system will still function with some

loss of overall braking effectiveness. This will be evident

by increased pedal travel during application and greater

pedal force required to slow or stop. In addition, if the

malfunction is caused by an internal leak, as the brake

fluid in the master cylinder drops, the brake warning

indicator will light.

WARNING!

Driving a vehicle with the brake light on is danger-

ous. A significant decrease in braking performance

or vehicle stability during braking may occur. It will

take you longer to stop the vehicle or will make your

vehicle harder to control. You could have an acci-

dent. Have the vehicle checked immediately.

STARTING AND OPERATING 185

5

Page 187 of 322

The ABS light monitors the Anti-Lock Brake

System. The light will come on when the

ignition switch is turned to the ON position

and may stay on for as long as four seconds.

If the ABS light remains on or comes on while driving, it

indicates that the Anti-Lock portion of the brake system

is not functioning and that service is required. However,

the conventional brake system will continue to operate

normally if the BRAKE warning light is not on.

If the ABS light is on, the brake system should be serviced

as soon as possible to restore the benefits of Anti-Lock

brakes. If the ABS light does not come on when the

Ignition switch is turned to the ON position, have the

bulb repaired as soon as possible.

If both the Brake Warning Light and the ABS Light

remain on, the Anti-Lock brakes (ABS) and Electronic

Brake Force Distribution (EBD) systems are not function-

ing. Immediate repair to the ABS system is required.

When the vehicle is driven over 7 mph (11 km/h), you

may also hear a slight clicking sound as well as somerelated motor noises. These noises are the system per-

forming its self check cycle to ensure that the ABS system

is working properly. This self check occurs each time the

vehicle is started and accelerated past 7 mph (11 km/h).

ABS is activated during braking under certain road or

stopping conditions. ABS-inducing conditions can in-

clude ice, snow, gravel, bumps, railroad tracks, loose

debris, or panic stops.

You also may experience the following when the brake

system goes into Anti-lock:

²The ABS motor running (it may continue to run for a

short time after the stop),

²the clicking sound of solenoid valves,

²brake pedal pulsations,

²and a slight drop or fall away of the brake pedal at the

end of the stop.

These are all normal characteristics of ABS.

STARTING AND OPERATING 187

5

Page 190 of 322

²European Metric tire sizing is based on European

design standards. Tires designed to this standard have

the tire size molded into the sidewall beginning with

the section width. The letter9P9is absent from this tire

size designation. Example: 215/65R15 96H

²LT (Light Truck)-Metric tire sizing is based on U.S.

design standards. The size designation for LT-Metric

tires is the same as for P-Metric tires except for the

letters ªLTº that are molded into the sidewall preced-

ing the size designation. Example: LT235/85R16.

²Temporary Spare tires are high-pressure compact

spares designed for temporary emergency use only.

Tires designed to this standard have the letter ªTº

molded into the sidewall preceding the size designa-

tion. Example: T145/80D18 103M.

²High Flotation tire sizing is based on U.S. design

standards and it begins with the tire diameter molded

into the sidewall. Example: 31x10.5 R15 LT.

190 STARTING AND OPERATING

Page 191 of 322

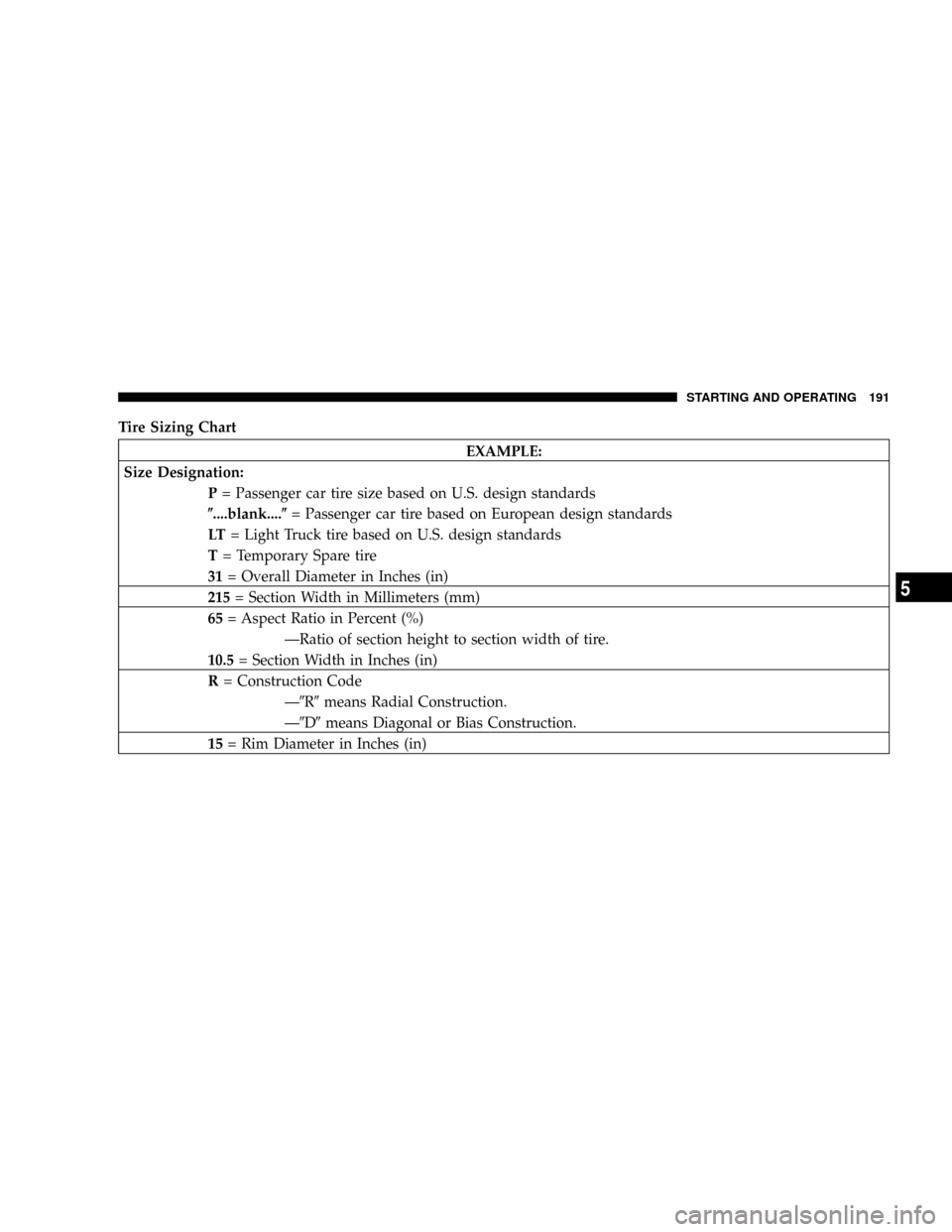

Tire Sizing Chart

EXAMPLE:

Size Designation:

P= Passenger car tire size based on U.S. design standards

(....blank....(= Passenger car tire based on European design standards

LT= Light Truck tire based on U.S. design standards

T= Temporary Spare tire

31= Overall Diameter in Inches (in)

215= Section Width in Millimeters (mm)

65= Aspect Ratio in Percent (%)

ÐRatio of section height to section width of tire.

10.5= Section Width in Inches (in)

R= Construction Code

Ð9R9means Radial Construction.

Ð9D9means Diagonal or Bias Construction.

15= Rim Diameter in Inches (in)

STARTING AND OPERATING 191

5

Page 192 of 322

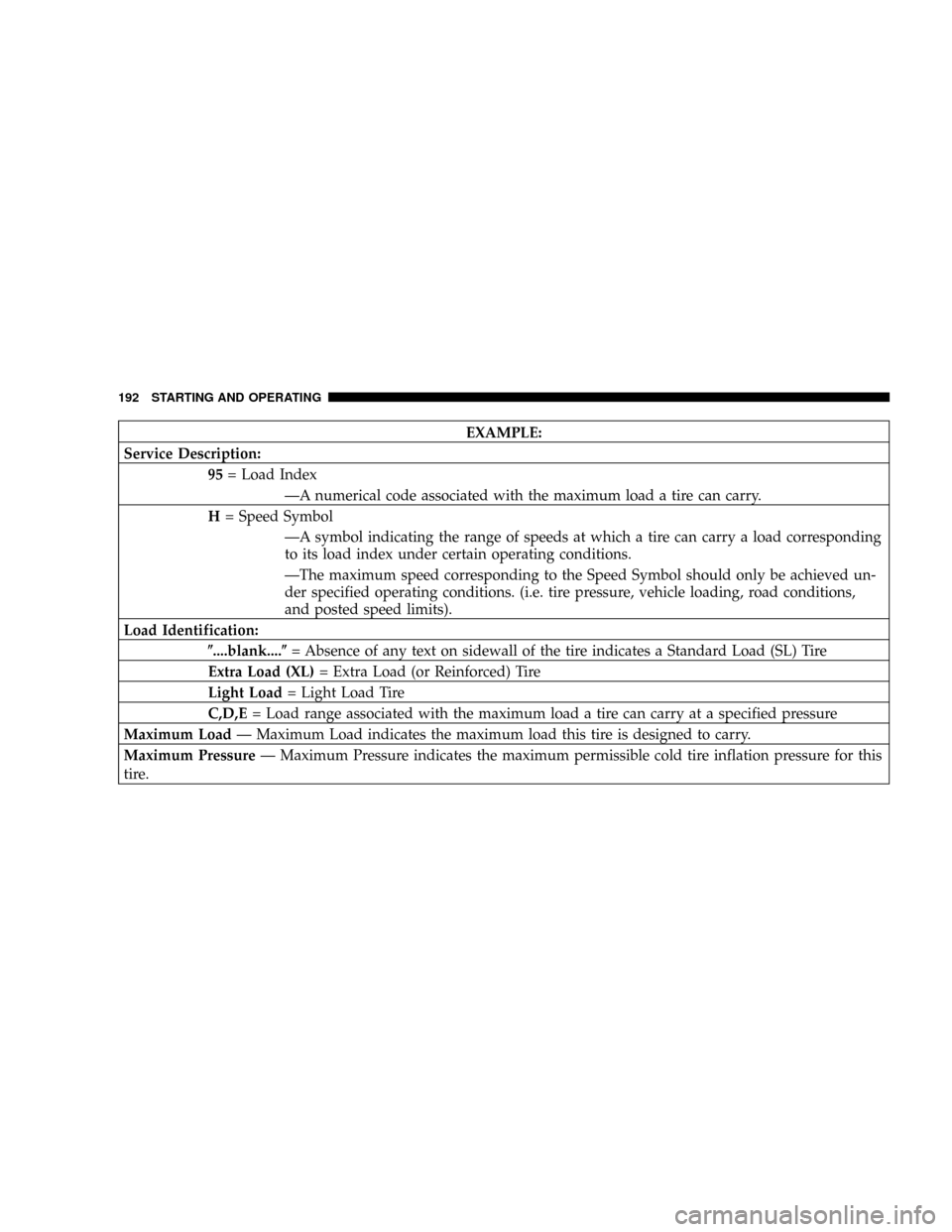

EXAMPLE:

Service Description:

95= Load Index

ÐA numerical code associated with the maximum load a tire can carry.

H= Speed Symbol

ÐA symbol indicating the range of speeds at which a tire can carry a load corresponding

to its load index under certain operating conditions.

ÐThe maximum speed corresponding to the Speed Symbol should only be achieved un-

der specified operating conditions. (i.e. tire pressure, vehicle loading, road conditions,

and posted speed limits).

Load Identification:

(....blank....(= Absence of any text on sidewall of the tire indicates a Standard Load (SL) Tire

Extra Load (XL)= Extra Load (or Reinforced) Tire

Light Load= Light Load Tire

C,D,E= Load range associated with the maximum load a tire can carry at a specified pressure

Maximum LoadÐ Maximum Load indicates the maximum load this tire is designed to carry.

Maximum PressureÐ Maximum Pressure indicates the maximum permissible cold tire inflation pressure for this

tire.

192 STARTING AND OPERATING

Page 204 of 322

Life of Tire

The service life of a tire is dependent upon varying

factors including but not limited to:

²Driving style

²Tire pressure

²Distance driven

WARNING!

Tires and spare tire should be replaced after six

years, regardless of the remaining tread. Failure to

follow this warning can result in sudden tire failure.

You could lose control and have an accident result-

ing in serious injury or death.

Keep dismounted tires in a cool, dry place with as little

exposure to light as possible. Protect tires from contact

with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for

wear and correct cold tire inflation pressure. The manu-

facturer strongly recommends that you use tires equiva-

lent to the originals in size, quality and performance

when replacement is needed (refer to the paragraph on

ªTread Wear Indicatorsº). Refer to the ªTire and Loading

Informationº placard for the size designation of your tire.

The service description and load identification will be

found on the original equipment tire. Failure to use

equivalent replacement tires may adversely affect the

safety, handling, and ride of your vehicle. We recommend

that you contact your original equipment or an autho-

rized tire dealer with any questions you may have on tire

specifications or capability.

204 STARTING AND OPERATING

Page 206 of 322

TIRE PRESSURE MONITORING SYSTEM (TPMS) -

PREMIUM SYSTEM Ð IF EQUIPPED

Tire Pressure Monitoring System (TPMS)

Operation

This system uses wireless technology with wheel rim

mounted electronic sensors to monitor tire pressure lev-

els. Sensors, mounted to each wheel as part of the valve

stem, transmit tire pressure readings to the Receiver

Module. The wheel sensors monitor tire pressure and

status for all four active road tires.

The TPMS consists of the following components:

²Receiver Module

²Wheel Sensors (attached to each wheel through the

valve stem mounting hole)

²Wheel Sensor Trigger Modules (mounted in three of

the four wheel wells)

²Various Tire Pressure Monitoring System Messages,

which display in the Electronic Vehicle Information

Center (EVIC)

²Yellow Tire Pressure Monitoring Telltale Light

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warnings have been established for the tire size

equipped on your vehicle. Undesirable system op-

eration or sensor damage may result when using

replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Do not use tire sealant from a can, or

balance beads if your vehicle is equipped with a

TPMS, as damage to the sensors may result.

Tire Pressure Monitoring Low Pressure Warnings

The Tire Pressure Monitoring Telltale Light is located in

the instrument cluster. The light will illuminate and an

audible chime will sound when one or more of the tires

on your vehicle are significantly under-inflated. The

audible chime will sound once every ignition cycle for

each condition that it detects.

206 STARTING AND OPERATING