light DODGE CARAVAN 2004 4.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: CARAVAN, Model: DODGE CARAVAN 2004 4.GPages: 397, PDF Size: 6.83 MB

Page 286 of 397

properly engaged in the described location.Do not raise

the vehicle until you are sure the jack is securely

engaged.

5. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

6. Remove the wheel lug nuts, for vehicles with wheel

covers, remove the cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.7. Install the spare wheel, for vehicles with wheel covers,

align the notch in the wheel cover with the valve stem on

the wheel. Install the cover on the wheel by hand only

and install the wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the nuts. To

avoid the risk of forcing the vehicle off the jack, do not

tighten the lug nuts fully until the vehicle has been

lowered.

NOTE:Do not install the wheel cover on the compact

spare.

Do not use a hammer or force to install the wheel covers.

8. Lower the vehicle by turning the jack screw to the left.

9. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N´m (95 ft. lbs). If in doubt

286 WHAT TO DO IN EMERGENCIES

Page 296 of 397

NFront Suspension Ball Joints..............314

NSteering Shaft Seal....................314

NSteering Linkage......................315

NDrive Shaft Universal Joints..............315

NBody Lubrication.....................315

NWindshield Wiper Blades................316

NWindshield And Rear Window Washers.....316

NExhaust System......................317

NCooling System.......................318

NHoses And Vacuum/Vapor Harnesses.......322

NBrakes.............................323

NMaster Cylinder Ð ABS Brakes Brake Fluid

Level Check.........................324NFuel System Hoses....................326

NAutomatic Transmission................326

NAll Wheel Drive (AWD).................329

NFront And Rear Wheel Bearings...........330

NAppearance Care And Protection From

Corrosion...........................330

NCleaning The Instrument Panel And

Underseat Cup Holders.................334

mIntegrated Power Module (IPM)............336

mVehicle Storage........................337

mReplacement Light Bulbs.................338

mBulb Replacement......................339

NHeadlights..........................339

296 MAINTAINING YOUR VEHICLE

Page 297 of 397

NFront Park/Turn Signal And Sidemarker

Lights.............................340

NFront Fog Light......................341

NRear Tail, Stop, Turn Signal, Side Marker

And Back-Up Lights...................342

NCenter High Mounted Stop Light (CHMSL) . . . 343

NLicense Light........................343mFluid Capacities........................343

mRecommended Fluids, Lubricants And Genuine

Parts................................344

NEngine.............................344

NChassis............................345

MAINTAINING YOUR VEHICLE 297

7

Page 300 of 397

ONBOARD DIAGNOSTIC SYSTEM Ð OBD II

Your vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the ªMalfunction Indicator Light.º It will

also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your dealer for service as soon as

possible.CAUTION!

Prolonged driving with the ªMalfunction Indicator

Lightº on could cause further damage to the emis-

sion control system. It could also affect fuel economy

and driveability. The vehicle must be serviced before

any emissions tests can be performed.

If the ªMalfunction Indicator Lightº is flashing

while the engine is running, severe catalytic con-

verter damage and power loss will soon occur. Im-

mediate service is required.

300 MAINTAINING YOUR VEHICLE

Page 316 of 397

Windshield Wiper Blades

The rubber edges of the wiper blades and the windshield

should be cleaned periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove accu-

mulations of salt or road film.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

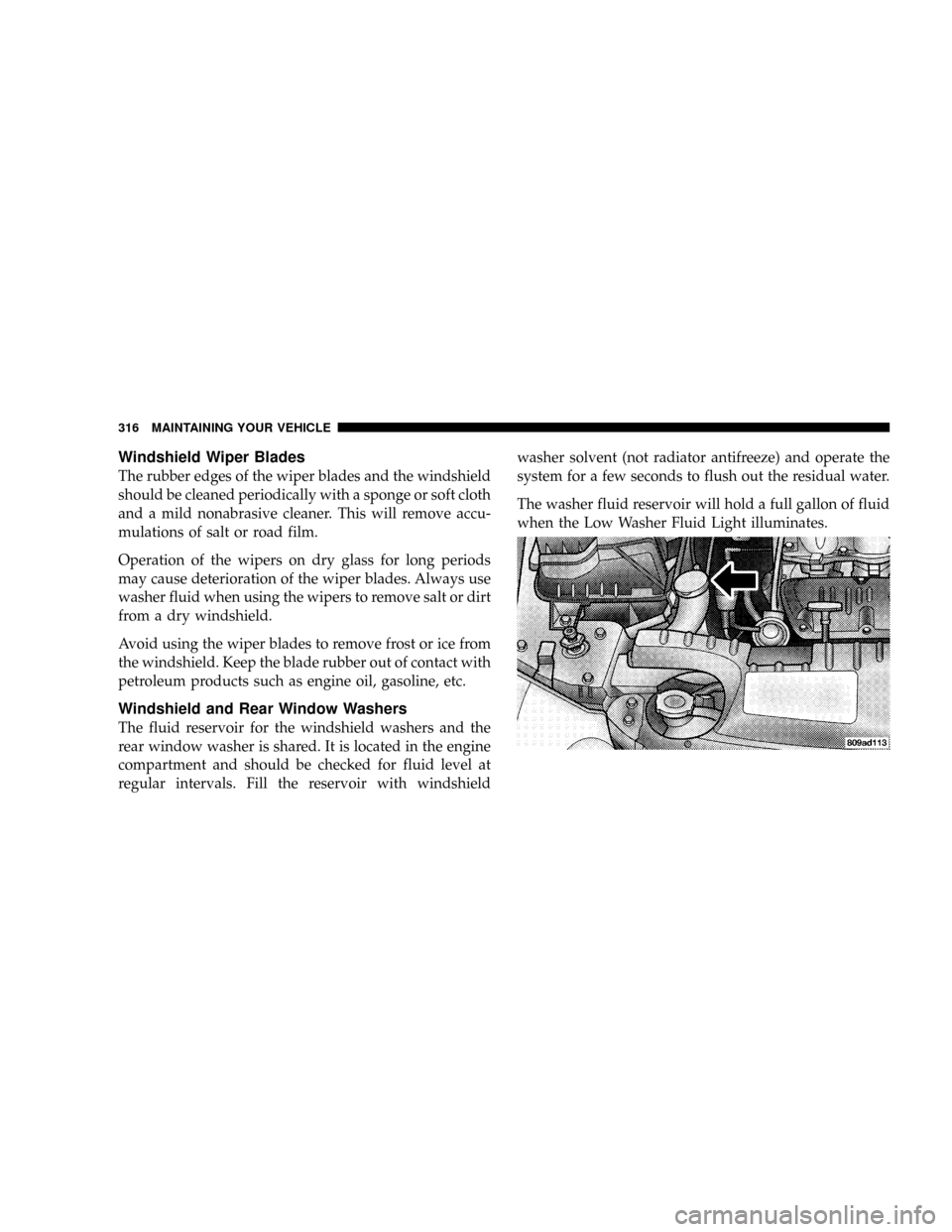

Windshield and Rear Window Washers

The fluid reservoir for the windshield washers and the

rear window washer is shared. It is located in the engine

compartment and should be checked for fluid level at

regular intervals. Fill the reservoir with windshieldwasher solvent (not radiator antifreeze) and operate the

system for a few seconds to flush out the residual water.

The washer fluid reservoir will hold a full gallon of fluid

when the Low Washer Fluid Light illuminates.

316 MAINTAINING YOUR VEHICLE

Page 324 of 397

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:Often, fluid such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to facilitate the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation), should be noted before hose is re-

placed based on leakage.

NOTE:Inspection of brake hoses should be performed

whenever the brake system is serviced and every engine

oil change. Inspect hydraulic brake hoses for surface

cracking, scuffing, or worn spots. If there is any evidence

of cracking, scuffing, or worn spots, the hose should bereplaced immediately! Eventual deterioration of the hose

can take place resulting in a possibility of a burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Master Cylinder Ð ABS Brakes Brake Fluid Level

Check

The fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the brake system warning light indicates system failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

ªFULLº mark on the side of the master cylinder reservoir.

324 MAINTAINING YOUR VEHICLE

Page 338 of 397

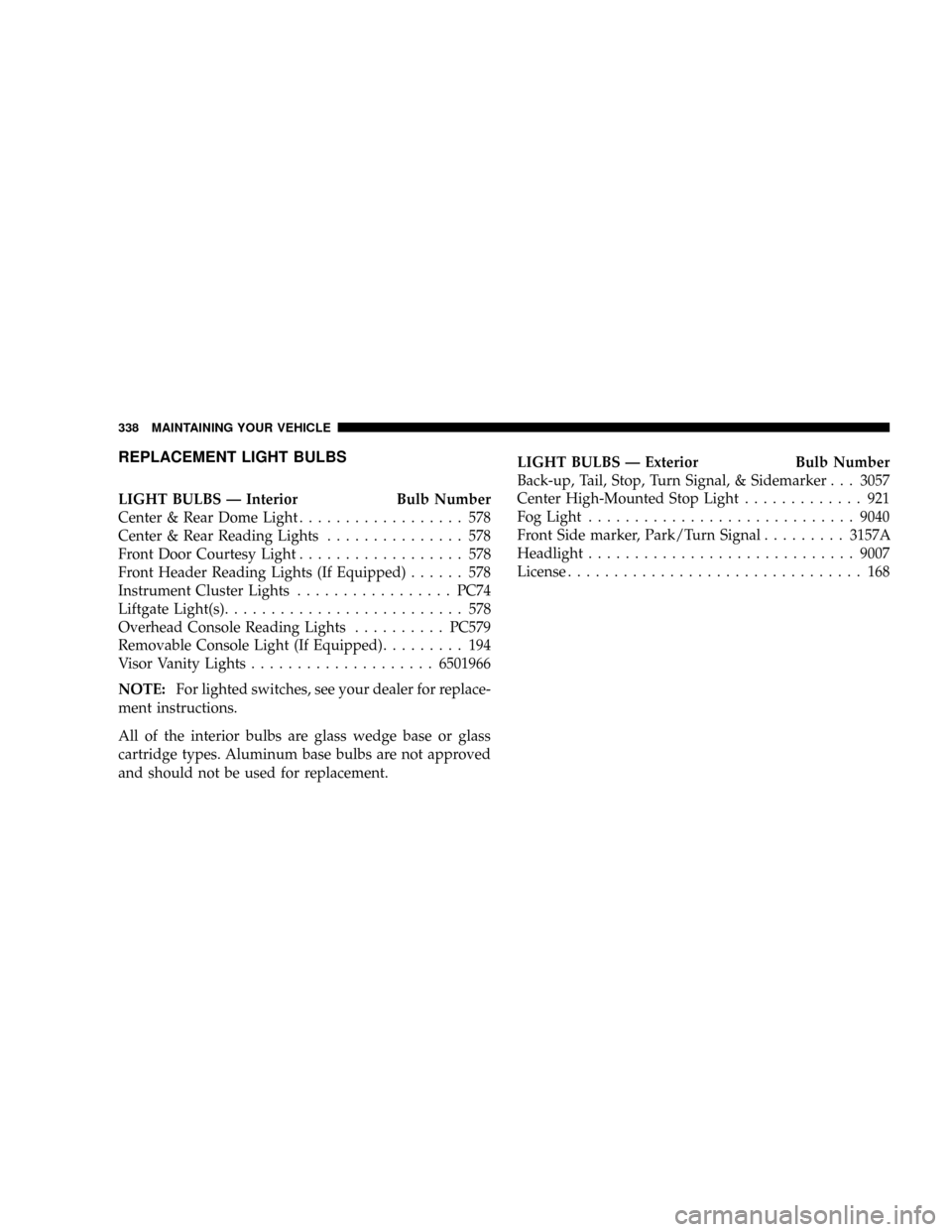

REPLACEMENT LIGHT BULBS

LIGHT BULBS Ð Interior Bulb Number

Center & Rear Dome Light.................. 578

Center & Rear Reading Lights............... 578

Front Door Courtesy Light.................. 578

Front Header Reading Lights (If Equipped)...... 578

Instrument Cluster Lights.................PC74

Liftgate Light(s).......................... 578

Overhead Console Reading Lights..........PC579

Removable Console Light (If Equipped)......... 194

Visor Vanity Lights....................6501966

NOTE:For lighted switches, see your dealer for replace-

ment instructions.

All of the interior bulbs are glass wedge base or glass

cartridge types. Aluminum base bulbs are not approved

and should not be used for replacement.LIGHT BULBS Ð Exterior Bulb Number

Back-up, Tail, Stop, Turn Signal, & Sidemarker. . . 3057

Center High-Mounted Stop Light............. 921

Fog Light.............................9040

Front Side marker, Park/Turn Signal.........3157A

Headlight.............................9007

License................................ 168

338 MAINTAINING YOUR VEHICLE

Page 339 of 397

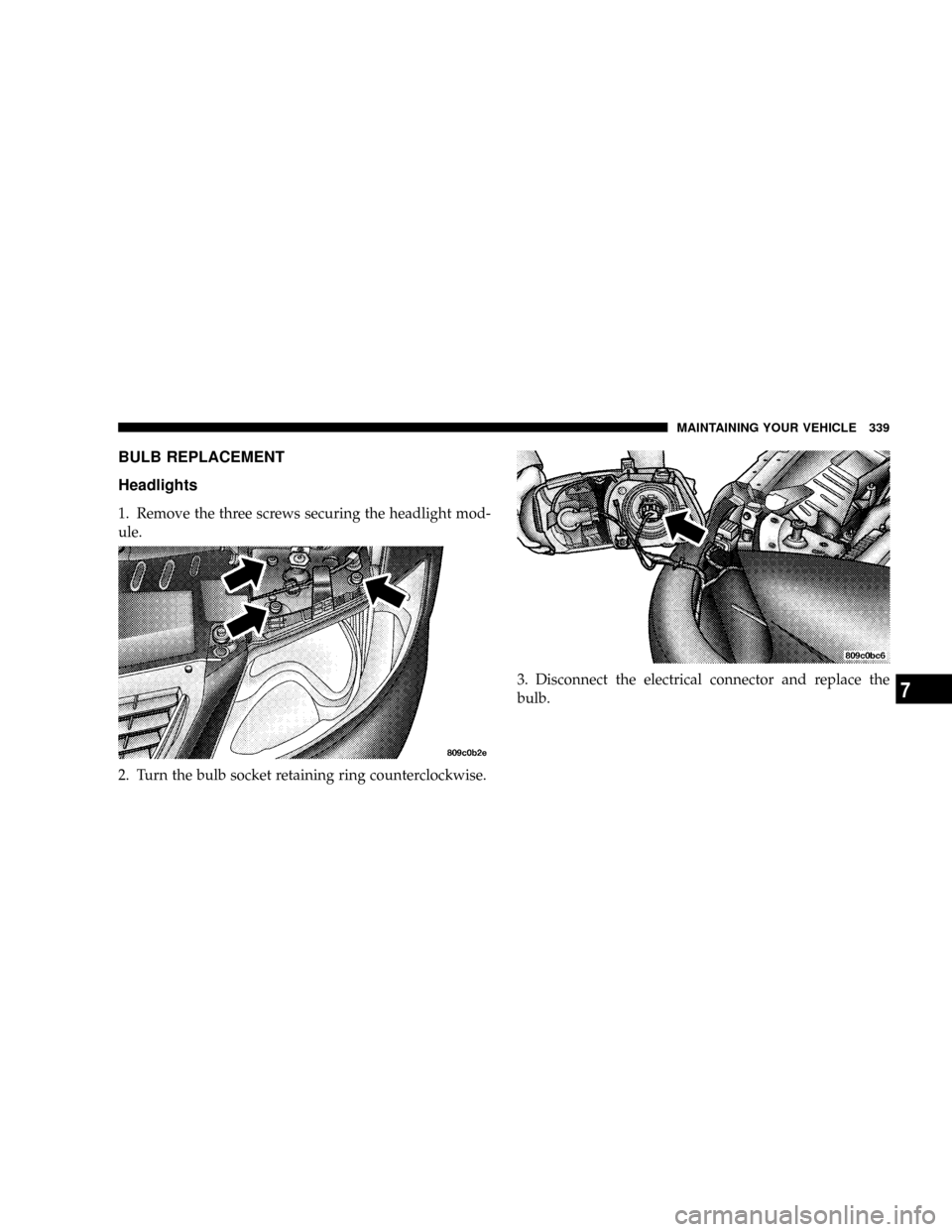

BULB REPLACEMENT

Headlights

1. Remove the three screws securing the headlight mod-

ule.

2. Turn the bulb socket retaining ring counterclockwise.3. Disconnect the electrical connector and replace the

bulb.

MAINTAINING YOUR VEHICLE 339

7

Page 340 of 397

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

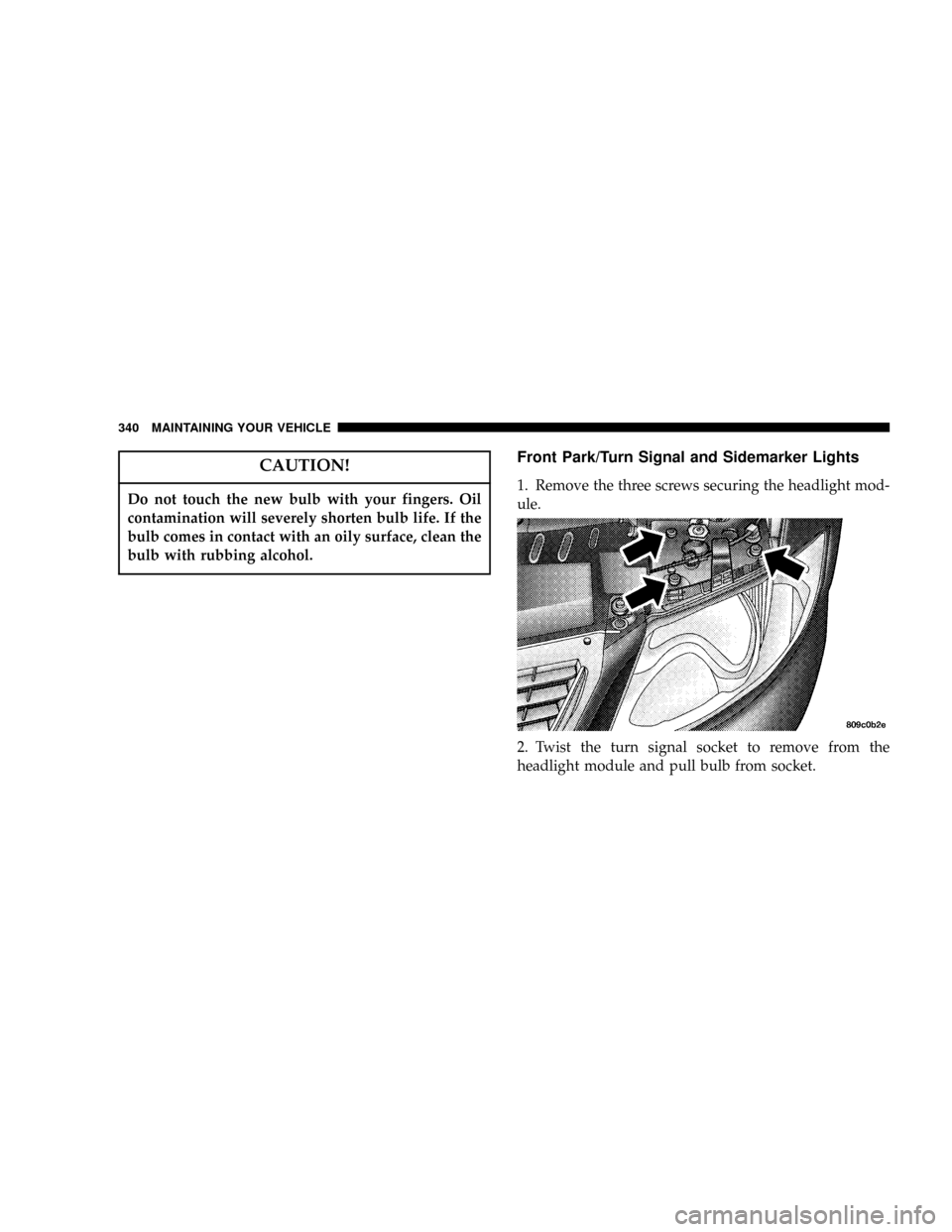

Front Park/Turn Signal and Sidemarker Lights

1. Remove the three screws securing the headlight mod-

ule.

2. Twist the turn signal socket to remove from the

headlight module and pull bulb from socket.

340 MAINTAINING YOUR VEHICLE

Page 341 of 397

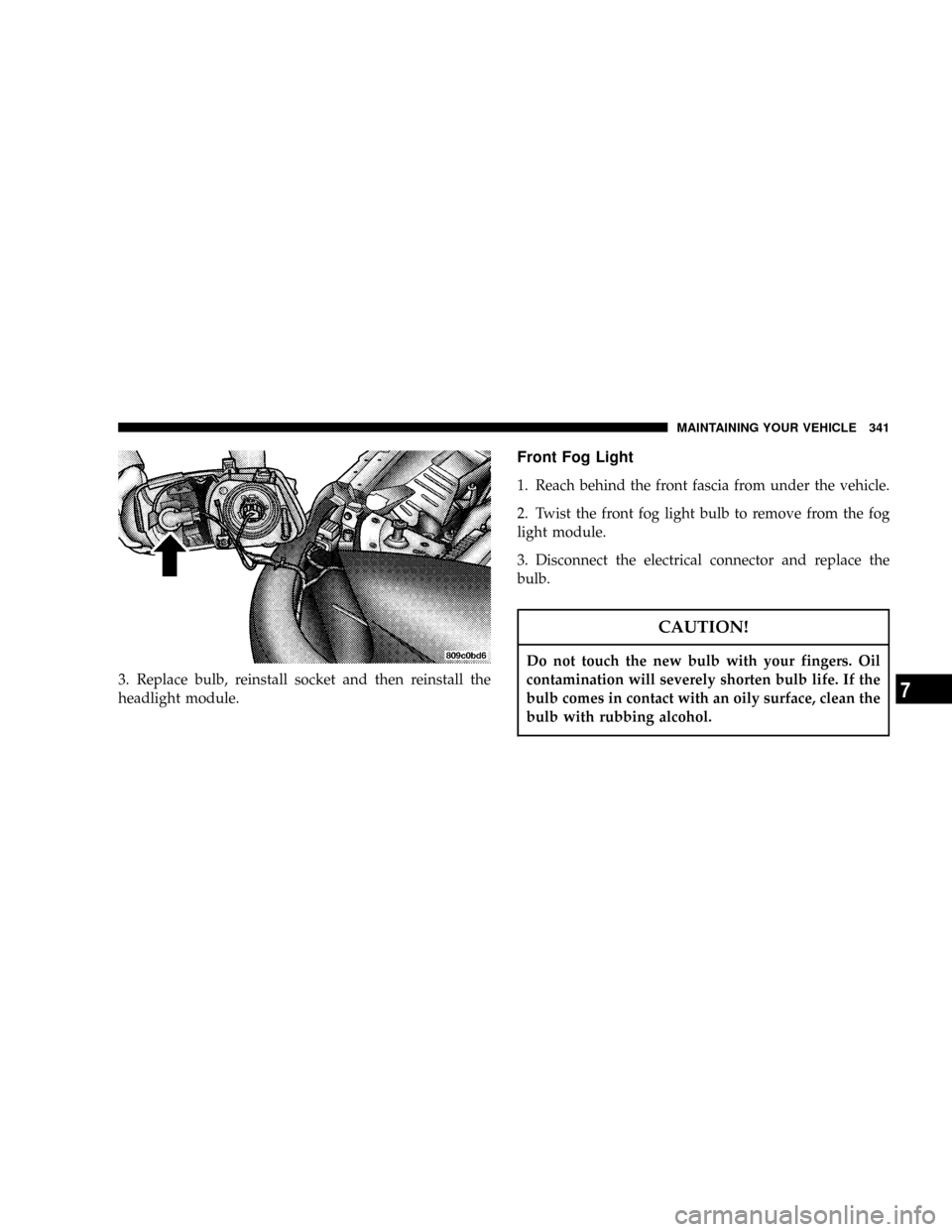

3. Replace bulb, reinstall socket and then reinstall the

headlight module.

Front Fog Light

1. Reach behind the front fascia from under the vehicle.

2. Twist the front fog light bulb to remove from the fog

light module.

3. Disconnect the electrical connector and replace the

bulb.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

MAINTAINING YOUR VEHICLE 341

7