technical specification DODGE CHALLENGER 2020 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: CHALLENGER, Model: DODGE CHALLENGER 2020Pages: 396, PDF Size: 16.64 MB

Page 3 of 396

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

10

11

1 INTRODUCTION .............................................................................................................................. 8

2 GETTING TO KNOW YOUR VEHICLE ...................................................................................11

3 GETTING TO KNOW YOUR INSTRUMENT PANEL ....................................................... 68

4 SAFETY .......................................................................................................................................... 93 5 STARTING AND OPERATING ............................................................................................... 148

6 IN CASE OF EMERGENCY ..................................................................................................... 199 7 SERVICING AND MAINTENANCE ...................................................................................... 234

8 TECHNICAL SPECIFICATIONS ............................................................................................. 291

9 MULTIMEDIA ..............................................................................................................................305

10 CUSTOMER ASSISTANCE ..................................................................................................... 376 11 INDEX .............................................................................................................................................380

20_LA_OM_EN_USC_t.book Page 1

Page 8 of 396

6

DEALER SERVICE .............................................. 252 Engine Oil ...................................................252

Engine Oil Filter .........................................255

Engine Air Cleaner Filter ...........................255

Air Conditioner Maintenance ....................257

Accessory Drive Belt Inspection................258Body Lubrication ........................................259

Windshield Wiper Blades ..........................259

Exhaust System .........................................261

Cooling System ........................................262

Brake System ............................................266

Clutch Hydraulic System — Manual

Transmission (If Equipped) .......................267 Manual Transmission — If Equipped ........267Automatic Transmission — If Equipped ....267

All Wheel Drive (AWD) — If Equipped .......268

Rear Axle ....................................................268

RAISING THE VEHICLE ...................................... 269

TIRES ................................................................... 269

Tire Safety Information .............................. 269

Tires — General Information .....................276Tire Types ...................................................280

Spare Tires — If Equipped .........................281

Wheel And Wheel Trim Care .....................283Tire Chains And Traction Devices —

Non-SRT......................................................284 Tire Chains And Traction Devices —

SRT .............................................................285 Tire Rotation Recommendations —

Non-SRT ..................................................... 285 Tire Rotation Recommendations —

SRT ............................................................ 285 Tire Rotation—Different Tire Size On

Front And Rear Axle ................................... 286

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES ................... 286

Treadwear .................................................. 286

Traction Grades ......................................... 286

Temperature Grades ................................. 287

VEHICLE STORAGE ...........................................287

BODYWORK ........................................................ 287

Protection From Atmospheric Agents ...... 287

Body And Underbody Maintenance .......... 288Preserving The Bodywork .......................... 288

INTERIORS ......................................................... 289

Seats And Fabric Parts .............................. 289

Plastic And Coated Parts ........................... 290

Leather Parts ............................................. 290

Glass Surfaces .......................................... 290

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA .......................................291Vehicle Identification Number .................. 291

BRAKE SYSTEM ................................................. 291 WHEEL AND TIRE TORQUE

SPECIFICATIONS .............................................. 291

Torque Specifications................................ 292

FUEL REQUIREMENTS ....................................... 293

3.6L Engine ................................................ 293

5.7L Engine (With Automatic

Transmission) ............................................ 293 5.7L Engine (With Manual

Transmission) ............................................ 293 6.2L Supercharged Engine ....................... 2946.4L Engine ................................................ 294

Reformulated Gasoline ............................. 294

Materials Added To Fuel ........................... 295

Gasoline/Oxygenate Blends ..................... 295

Do Not Use E-85 In Non-Flex Fuel

Vehicles ...................................................... 295 CNG And LP Fuel System

Modifications ............................................. 295 MMT In Gasoline........................................ 296

Fuel System Cautions................................ 296

Carbon Monoxide Warnings...................... 296

FLUID CAPACITIES — NON-SRT ........................ 297

FLUID CAPACITIES — SRT ................................. 298

FLUIDS AND LUBRICANTS — NON-SRT .......... 299

Engine ....................................................... 299

Chassis ................................................... 301

FLUIDS AND LUBRICANTS — SRT .................... 302

Engine ........................................................ 302

Chassis ....................................................... 304

20_LA_OM_EN_USC_t.book Page 6

Page 155 of 396

STARTING AND OPERATING153

While cruising, brief full-throttle acceleration

within the limits of local traffic laws contributes

to a good break-in. However, wide-open throttle

acceleration in low gear can be detrimental and

should be avoided.

The engine oil, transmission fluid, and axle

lubricant installed at the factory are high-quality

and energy-conserving. Oil, fluid, and lubricant

changes should be consistent with anticipated

climate and conditions under which vehicle

operations will occur. For the recommended

viscosity and quality grades, refer to “Fluids And

Lubricants” in “Technical Specifications”.

NOTE:

A new engine may consume some oil during its

first few thousand miles (kilometers) of opera -

tion. This should be considered a normal part of

the break-in and not interpreted as an indica -

tion of difficulty. Please check your oil level with

the engine oil indicator often during the break in

period. Add oil as required.ENGINE BREAK-IN RECOMMENDATIONS —

6.2L & 6.4L

The following tips will be helpful in obtaining

optimum performance and maximum durability

for your new vehicle.

Despite modern technology and World Class

manufacturing methods, the moving parts of

the vehicle must still wear in with each other.

This wearing in occurs mainly during the first

500 miles (805 km) and continues through the

first oil change interval.

It is recommended for the operator to observe

the following driving behaviors during the new

vehicle break-in period:

0 to 100 miles (0 to 161 km):

Do not allow the engine to operate at idle for

an extended period of time.

Depress the accelerator pedal slowly and not

more than halfway to avoid rapid accelera -

tion.

Avoid aggressive braking.

Drive with the engine speed less than

3,500 RPM.

Maintain vehicle speed below 55 mph

(88 km/h) and observe local speed limits. 100 to 300 miles (161 to 483 km):

Depress the accelerator pedal slowly and not

more than halfway to avoid rapid accelera -

tion in lower gears (FIRST to THIRD gears).

Avoid aggressive braking.

Drive with the engine speed less than

5,000 RPM.

Maintain vehicle speed below 70 mph

(112 km/h) and observe local speed limits.

300 to 500 miles (483 to 805 km) :

Exercise the full engine RPM range, shifting

manually at higher RPM when possible.

Do not perform sustained operation with the

accelerator pedal at wide open throttle.

Maintain vehicle speed below 85 mph

(136 km/h) and observe local speed limits.

For the first 1,500 miles (2,414 km):

Do not participate in track events, sport

driving schools, or similar activities during

the first 1,500 miles (2,414 km).

NOTE:

Check engine oil with every refueling and add if

necessary. Oil and fuel consumption may be

higher through the first oil change interval.

Running the engine with an oil level below the

add mark can cause severe engine damage.

CAUTION!

Never use Non-Detergent Oil or Straight

Mineral Oil in the engine or damage may

result.

5

20_LA_OM_EN_USC_t.book Page 153

Page 222 of 396

220IN CASE OF EMERGENCY

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires” in

“Servicing And Maintenance” for additional

warnings, cautions, and information about

the spare tire, its use, and operation.

8. Install the lug nuts with the cone shaped end of the lug nut toward the wheel. Lightly

tighten the lug nuts.

9. Lower the vehicle to the ground by turning the jack handle counterclockwise.

10. Refer to “Wheel And Tire Torque Specifi -

cations” in “Technical Specifications”

section for proper lug nut torque. 11. Stow the jack, tools and flat tire. Make sure

the base of the jack faces the front of the

vehicle before tightening down the fastener.

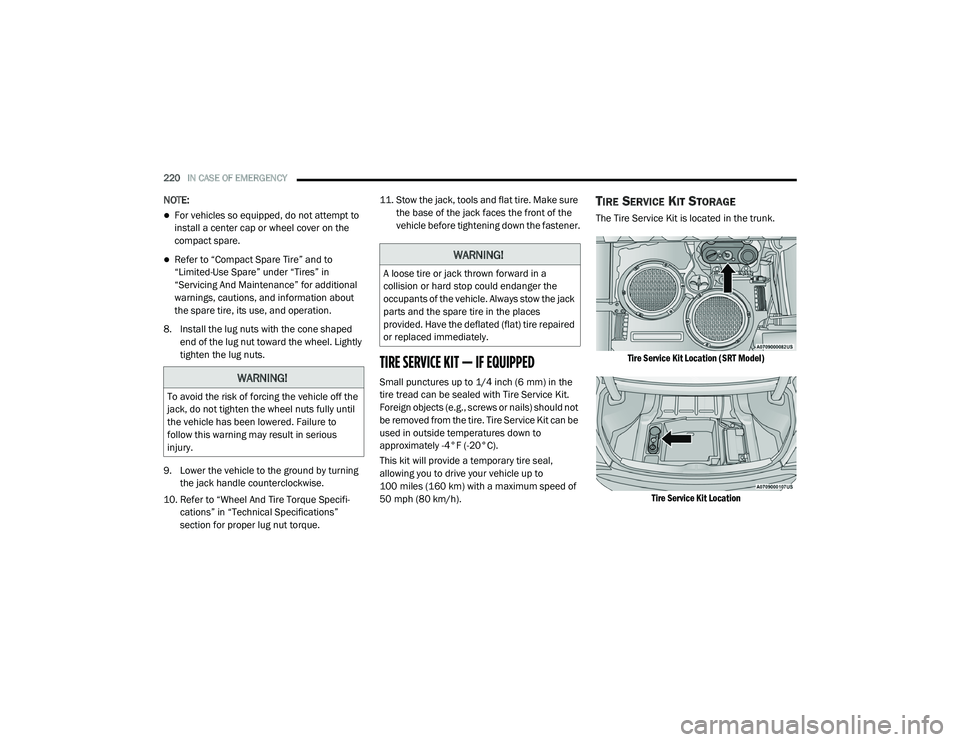

TIRE SERVICE KIT — IF EQUIPPED

Small punctures up to 1/4 inch (6 mm) in the

tire tread can be sealed with Tire Service Kit.

Foreign objects (e.g., screws or nails) should not

be removed from the tire. Tire Service Kit can be

used in outside temperatures down to

approximately -4°F (-20°C).

This kit will provide a temporary tire seal,

allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of 50 mph (80 km/h).

TIRE SERVICE KIT STORAGE

The Tire Service Kit is located in the trunk.

Tire Service Kit Location (SRT Model)Tire Service Kit Location

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

20_LA_OM_EN_USC_t.book Page 220

Page 265 of 396

SERVICING AND MAINTENANCE263

Cooling System — Drain, Flush And Refill

NOTE:

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added to

the system please contact an authorized

dealer.

If the engine coolant (antifreeze) is dirty or

contains visible sediment, have an authorized

dealer clean and flush with OAT coolant

(antifreeze) (conforming to MS.90032).

NOTE:

If equipped with the 6.2L Supercharged engine

the intercooler must be vacuum flushed and

filled. If any coolant is needed to be added to

the system please contact an local authorized

dealer.

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

Selection Of Coolant

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information. NOTE:

Mixing of engine coolant (antifreeze) other

than specified Organic Additive Technology

(OAT) engine coolant (antifreeze), may result

in engine damage and may decrease corro

-

sion protection. Organic Additive Technology

(OAT) engine coolant is different and should

not be mixed with Hybrid Organic Additive

Technology (HOAT) engine coolant (anti -

freeze) or any “globally compatible” coolant

(antifreeze).

If a non-OAT engine coolant (antifreeze) is

introduced into the cooling system in an

emergency, the cooling system will need to

be drained, flushed, and refilled with fresh

OAT coolant (conforming to MS.90032), by

an authorized dealer as soon as possible.

Do not use water alone or alcohol-based

engine coolant (antifreeze) products. Do not

use additional rust inhibitors or antirust prod -

ucts, as they may not be compatible with the

radiator engine coolant and may plug the

radiator.

This vehicle has not been designed for

use with propylene glycol-based engine

coolant (antifreeze). Use of propylene

glycol-based engine coolant (antifreeze) is

not recommended.

Some vehicles require special tools to add

coolant properly. Failure to fill these systems

properly could lead to severe internal engine

damage. If any coolant is needed to be added

to the system please contact an authorized

dealer.

Adding Coolant

Your vehicle has been built with an improved

engine coolant (OAT coolant conforming to

MS.90032) that allows extended maintenance

intervals. This engine coolant (antifreeze) can

be used up to 10 years or 150,000 miles

(240,000 km) before replacement. To prevent

reducing this extended maintenance period, it

is important that you use the same engine

coolant (OAT coolant conforming to MS.90032)

throughout the life of your vehicle.

Please review these recommendations for

using Organic Additive Technology (OAT) engine

coolant (antifreeze) that meets the

requirements of FCA Material Standard

MS.90032. When adding engine coolant

(antifreeze):

7

20_LA_OM_EN_USC_t.book Page 263

Page 268 of 396

266SERVICING AND MAINTENANCE

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder

immediately if the brake system warning light

indicates system failure.

Check the fluid level in the master cylinder

when performing underhood services.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up

to the top of the “FULL” mark on the side of the

master cylinder reservoir.Overfilling of fluid is not recommended because

it may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear.

However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only brake fluid that has been

recommended by the manufacturer, and has

been kept in a tightly closed container to avoid

contamination from foreign matter or moisture.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

20_LA_OM_EN_USC_t.book Page 266

Page 269 of 396

SERVICING AND MAINTENANCE267

CLUTCH HYDRAULIC SYSTEM — MANUAL

T

RANSMISSION (IF EQUIPPED)

The clutch hydraulic system is fed by a

segregated volume of fluid within the brake

system master cylinder reservoir. In the event of

leakage or wear, use only the manufacturer's

recommended brake fluid. Refer to “Fluids And

Lubricants” in “Technical Specifications” for

further information.

MANUAL TRANSMISSION — IF EQUIPPED

Fluid Level Check

Check the fluid level by removing the fill plug on

the left side of the transmission. The fluid level

should be 1/4 inch (6.4mm) below the bottom

of the fill hole. Add fluid, if necessary, to

maintain the proper level. Refer to “Fluids And

Lubricants” in “Technical Specifications” for

further information.

Change Transmission Fluid

If contaminated with water, change the fluid

immediately. See an authorized dealer for

service.

Refer to the “Maintenance Plan” in this section

for the proper maintenance intervals.

AUTOMATIC TRANSMISSION — IF

E

QUIPPED

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid.

NOTE:

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the

transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supplemental

additives. Therefore, do not add any fluid

additives to the transmission. Avoid using

transmission sealers as they may adversely

affect seals.

CAUTION!

Using a transmission fluid other than the

manufacturer's recommended fluid may

cause deterioration in transmission shift

quality and/or damage to the transmission.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

7

20_LA_OM_EN_USC_t.book Page 267

Page 293 of 396

291

TECHNICAL SPECIFICATIONS

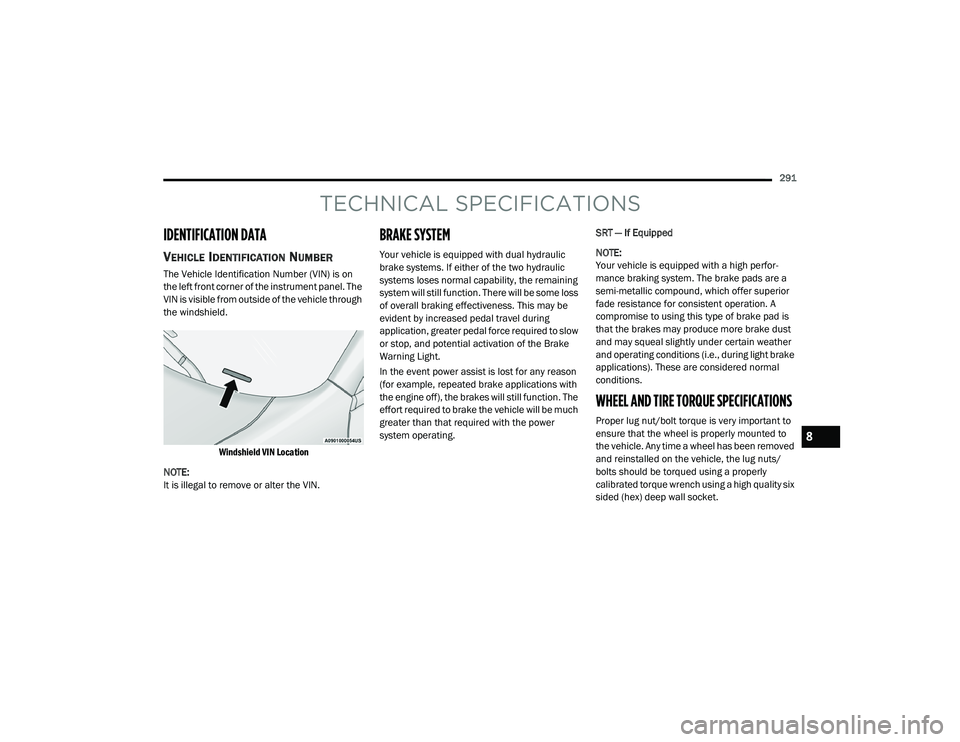

IDENTIFICATION DATA

VEHICLE IDENTIFICATION NUMBER

The Vehicle Identification Number (VIN) is on

the left front corner of the instrument panel. The

VIN is visible from outside of the vehicle through

the windshield.

Windshield VIN Location

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems loses normal capability, the remaining

system will still function. There will be some loss

of overall braking effectiveness. This may be

evident by increased pedal travel during

application, greater pedal force required to slow

or stop, and potential activation of the Brake

Warning Light.

In the event power assist is lost for any reason

(for example, repeated brake applications with

the engine off), the brakes will still function. The

effort required to brake the vehicle will be much

greater than that required with the power

system operating. SRT — If Equipped

NOTE:

Your vehicle is equipped with a high perfor

-

mance braking system. The brake pads are a

semi-metallic compound, which offer superior

fade resistance for consistent operation. A

compromise to using this type of brake pad is

that the brakes may produce more brake dust

and may squeal slightly under certain weather

and operating conditions (i.e., during light brake

applications). These are considered normal

conditions.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

8

20_LA_OM_EN_USC_t.book Page 291

Page 294 of 396

292TECHNICAL SPECIFICATIONS

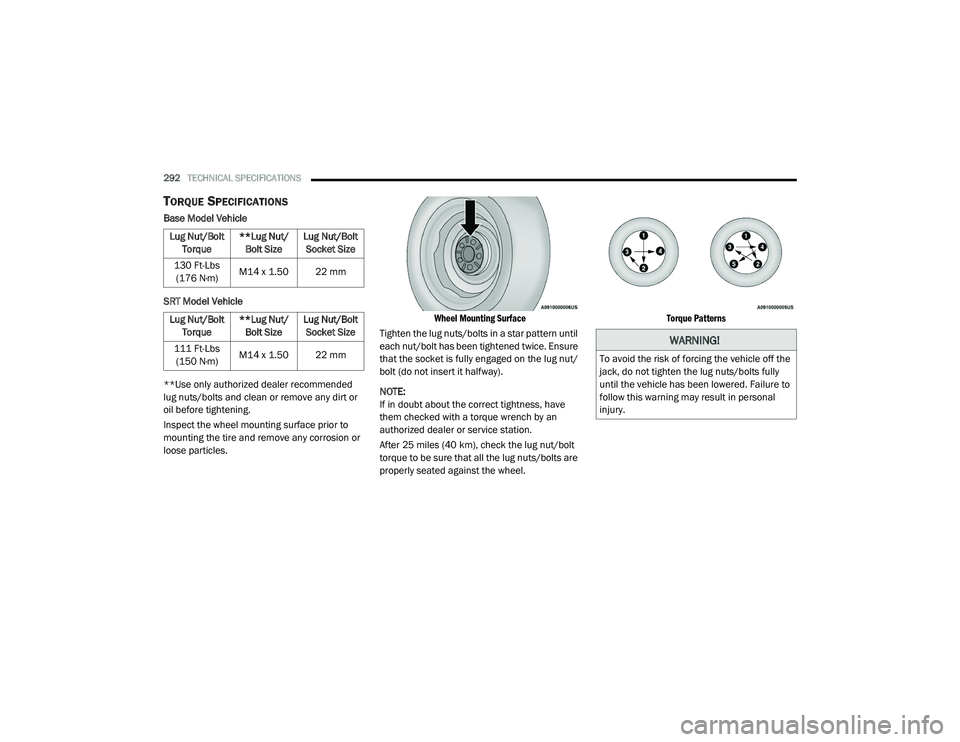

TORQUE SPECIFICATIONS

Base Model Vehicle

SRT Model Vehicle

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/

bolt (do not insert it halfway).

NOTE:

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station.

After 25 miles (40 km), check the lug nut/bolt torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

Torque Patterns

Lug Nut/Bolt

Torque **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

130 Ft-Lbs (176 N·m) M14 x 1.50 22 mm

Lug Nut/Bolt Torque **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

111 Ft-Lbs (150 N·m) M14 x 1.50 22 mm

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully

until the vehicle has been lowered. Failure to

follow this warning may result in personal

injury.

20_LA_OM_EN_USC_t.book Page 292

Page 295 of 396

TECHNICAL SPECIFICATIONS293

FUEL REQUIREMENTS

3.6L ENGINE

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine.

This engine is designed to meet all

emissions regulations and provide

excellent fuel economy and

performance when using high-quality

unleaded “Regular” gasoline having an

octane rating of 87 as specified by the

(R+M)/2 method. The use of higher octane

“Premium” gasoline will not provide any benefit

over “Regular” gasoline in these engines.

While operating on gasoline with an octane

number of 87, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an authorized dealer

immediately. Use of gasoline with an octane

number lower than 87 can cause engine failure

and may void or not be covered by the New

Vehicle Limited Warranty. Poor quality gasoline can cause problems such

as hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand

of gasoline before considering service for the

vehicle.

5.7L ENGINE (WITH AUTOMATIC

T

RANSMISSION)

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine.

This engine is designed to meet all

emissions regulations and provide

satisfactory fuel economy and

performance when using high quality

unleaded gasoline having a posted octane

number range of 87 to 89 as specified by the

(R+M)/2 method. The use of 89 octane “Plus”

gasoline is recommended for optimum

performance and fuel economy.

While operating on gasoline with an octane

number of 87, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an authorized dealer

immediately. Use of gasoline with an octane

number lower than 87 can cause engine failure

and may void or not be covered by the New

Vehicle Limited Warranty. Poor quality gasoline can cause problems such

as hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand

of gasoline before considering service for the

vehicle.

5.7L ENGINE (WITH MANUAL

T

RANSMISSION)

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine.

This engine is designed to meet all

emission regulations, provide optimal

fuel economy and performance when

using high-quality unleaded

“Premium” gasoline having a posted

octane number of 91 as specified by the

(R+M)/2 method. The use of 91 or higher

octane “Premium” gasoline is required for

this engine.

While operating on gasoline with the required

octane number, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an authorized dealer

immediately. Use of gasoline with a lower than

recommended octane number can cause

engine failure and may void or not be covered

by the New Vehicle Limited Warranty.

8

20_LA_OM_EN_USC_t.book Page 293