inflation pressure DODGE CHARGER 2021 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2021, Model line: CHARGER, Model: DODGE CHARGER 2021Pages: 320, PDF Size: 20.61 MB

Page 81 of 320

GETTING TO KNOW YOUR INSTRUMENT PANEL79

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer

on the vehicle placard or tire inflation pressure label.

If your vehicle has tires of a different size than the

size indicated on the vehicle placard or tire inflation

pressure label, you should determine the proper tire

inflation pressure for those tires.

As an added safety feature, your vehicle has been

equipped with TPMS that illuminates a low tire

pressure telltale when one or more of your tires is

significantly underinflated. Accordingly, when the

low tire pressure telltale illuminates, you should

stop and check your tires as soon as possible, and

inflate them to the proper pressure. Driving on a

significantly underinflated tire causes the tire to

overheat and can lead to tire failure. Underinflation

also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping

ability. Please note that the TPMS is not a substitute for

proper tire maintenance, and it is the driver’s

responsibility to maintain correct tire pressure,

even if underinflation has not reached the level to

trigger illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is

not operating properly. The TPMS malfunction indicator

is combined with the low tire pressure telltale. When

the system detects a malfunction, the telltale will flash

for approximately one minute and then remain

continuously illuminated. This sequence will continue

upon subsequent vehicle start-ups as long as the

malfunction exists. When the malfunction indicator

is illuminated, the system may not be able to detect

or signal low tire pressure as intended. TPMS

malfunctions may occur for a variety of reasons,

including the installation of replacement or alternate

tires or wheels on the vehicle that prevent the TPMS

from functioning properly. Always check the TPMS

malfunction telltale after replacing one or more tires or

wheels on your vehicle to ensure that the replacement

or alternate tires and wheels allow the TPMS to

continue to function properly.

YELLOW INDICATOR LIGHTS

Forward Collision Warning (FCW) OFF

Indicator Light — If Equipped

This indicator light illuminates to indicate

that Forward Collision Warning is off

Ú

page 188.

CAUTION!

Do not continue driving with one or more flat

tires as handling may be compromised. Stop the

vehicle, avoiding sharp braking and steering. If a

tire puncture occurs, repair immediately using

the dedicated tire repair kit and contact an

authorized dealer as soon as possible.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system

operation or sensor damage may result when using

replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Using aftermarket tire sealants may

cause the Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended that you

take your vehicle to an authorized dealer to have

your sensor function checked.

3

21_LD_OM_EN_USC_t.book Page 79

Page 121 of 320

STARTING AND OPERATING119

Perform the maintenance listed in the “Scheduled

Servicing” for the proper maintenance intervals

Ú page 245. When towing a trailer, never exceed

the GAWR or GCWR ratings.

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when

towing while using a full size spare tire.

Proper tire inflation pressures are essential to

the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer. For the proper

inspection procedure.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Ú page 275.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system

or vacuum system of your vehicle with that of

the trailer. This could cause inadequate braking

and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer with

electronically actuated brakes. When towing a

trailer equipped with a hydraulic surge actuated

brake system, an electronic brake controller is

not required.

Trailer brakes are recommended for trailers

over 1,000 lb (453 kg) and required for trailers

in excess of 2,000 lb (907 kg).

CAUTION!

Do not tow a trailer at all during the first

500 miles (805 km) the new vehicle is driven.

The engine, axle or other parts could be

damaged.

Then, during the first 500 miles (805 km) that

a trailer is towed, do not drive over 50 mph

(80 km/h) and do not make starts at full

throttle. This helps the engine and other parts

of the vehicle wear in at the heavier loads.

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your

brake system and cause it to fail. You might

not have brakes when you need them and

could have an accident.

Towing any trailer will increase your stopping

distance. When towing, you should allow for

additional space between your vehicle and the

vehicle in front of you. Failure to do so could

result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do

this could lead to accelerated brake lining wear,

higher brake pedal effort, and longer stopping

distances.

4

21_LD_OM_EN_USC_t.book Page 119

Page 192 of 320

190SAFETY

FCW disables in the same manner as ACC, and

will display a screen indicating that the feature

is unavailable when it has been disabled.

FCW Limited Warning

If the instrument cluster display reads “ACC/FCW

Limited Functionality” or “ACC/FCW Limited

Functionality Clean Front Windshield” momentarily,

there may be a condition that limits FCW functionality.

Although the vehicle is still drivable under normal

conditions, the active braking may not be fully

available. Once the condition that limited the system

performance is no longer present, the system will

return to its full performance state. If the problem

persists, see an authorized dealer.

Service FCW Warning

If the system turns off, and the instrument cluster

display reads:

ACC/FCW Unavailable Service Required

Cruise/FCW Unavailable Service Required

This indicates there is an internal system fault.

Although the vehicle is still drivable under normal

conditions, have the system checked by an

authorized dealer.

TIRE PRESSURE MONITORING

S

YSTEM (TPMS)

The Tire Pressure Monitoring System (TPMS) will

warn the driver of a low tire pressure based on the

vehicle recommended cold placard pressure.

The tire pressure will vary with temperature

by about 1 psi (7 kPa) for every 12°F (6.5°C).

This means that when the outside temperature

decreases, the tire pressure will decrease. Tire

pressure should always be set based on cold

inflation tire pressure. This is defined as the tire

pressure after the vehicle has not been driven for

at least three hours, or driven less than 1 mile

(1.6 km) after a three hour period. The cold tire

inflation pressure must not exceed the maximum

inflation pressure molded into the tire sidewall.

The tire pressure will also increase as the vehicle

is driven — this is normal and there should be no

adjustment for this increased pressure.

See Ú page 275 for information on how to

properly inflate the vehicle’s tires.

The TPMS will warn the driver of a low tire pressure

if the tire pressure falls below the low-pressure

warning limit for any reason, including low

temperature effects and natural pressure loss

through the tire.

The TPMS will continue to warn the driver of low

tire pressure as long as the condition exists, and

will not turn off until the tire pressure is at or above the recommended cold placard pressure. Once the

low tire pressure warning (TPMS Warning Light)

illuminates, you must increase the tire pressure to

the recommended cold placard pressure in order

for the TPMS Warning Light to turn off. The system

will automatically update and the TPMS Warning

Light will turn off once the system receives the

updated tire pressures. The vehicle may need to

be driven for up to 20 minutes above 15 mph

(24 km/h) in order for the TPMS to receive this

information.

NOTE:When filling warm tires, the tire pressure may need

to be increased up to an additional 4 psi (28 kPa)

above the recommended cold placard pressure in

order to turn the TPMS Warning Light off.

For example, your vehicle may have a recommended

cold (parked for more than three hours) placard

pressure of 30 psi (207 kPa). If the ambient

temperature is 68°F (20°C) and the measured tire

pressure is 27 psi (186 kPa), a temperature drop to

20°F (-7°C) will decrease the tire pressure to

approximately 23 psi (158 kPa). This tire pressure is

sufficiently low enough to turn on the TPMS Warning

Light. Driving the vehicle may cause the tire pressure to

rise to approximately 27 psi (186 kPa), but the TPMS

Warning Light will still be on. In this situation, the TPMS

Warning Light will turn off only after the tires are

inflated to the vehicle’s recommended cold placard

pressure value.

21_LD_OM_EN_USC_t.book Page 190

Page 193 of 320

SAFETY191

NOTE:

The TPMS is not intended to replace normal tire

care and maintenance or to provide warning of

a tire failure or condition.

The TPMS should not be used as a tire pressure

gauge while adjusting your tire pressure.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire

failure. Underinflation also reduces fuel effi -

ciency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsibility

to maintain correct tire pressure using an accu -

rate tire pressure gauge, even if underinflation

has not reached the level to trigger illumination

of the TPMS Warning Light.

Seasonal temperature changes will affect tire

pressure, and the TPMS will monitor the actual

tire pressure in the tire Ú page 305.

Premium System

The Tire Pressure Monitoring System (TPMS) uses

wireless technology with wheel rim mounted

electronic sensors to monitor tire pressure levels.

Sensors, mounted to each wheel as part of the

valve stem, transmit tire pressure readings to the

receiver module.

NOTE:It is particularly important for you to check the tire

pressure in all of the tires on your vehicle monthly

and to maintain the proper pressure.

The TPMS consists of the following components:

Receiver module

Four Tire Pressure Monitoring System sensors

Various Tire Pressure Monitoring System

messages, which display in the instrument

cluster

Tire Pressure Monitoring System Warning Light

Tire Pressure Monitoring System Low

Pressure Warnings

The Tire Pressure Monitoring System

(TPMS) Warning Light will illuminate in

the instrument cluster and a chime will

sound when tire pressure is low in one or

more of the four active road tires. In addition, the

instrument cluster will display an “Inflate to XX”

message and a graphic showing the pressure

values of each tire with the low tire pressure values

shown in a different color.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warning have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may

result when using replacement equipment

that is not of the same size, type, and/or style.

The TPMS sensor is not designed for use on

aftermarket wheels and may contribute to a

poor overall system performance or sensor

damage. Customers are encouraged to use

OEM wheels to ensure proper TPMS feature

operation.

Using aftermarket tire sealants may cause the

Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended

that you take your vehicle to your authorized

dealer to have your sensor function checked.

After inspecting or adjusting the tire pressure

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the TPMS

sensor.

6

21_LD_OM_EN_USC_t.book Page 191

Page 194 of 320

192SAFETY

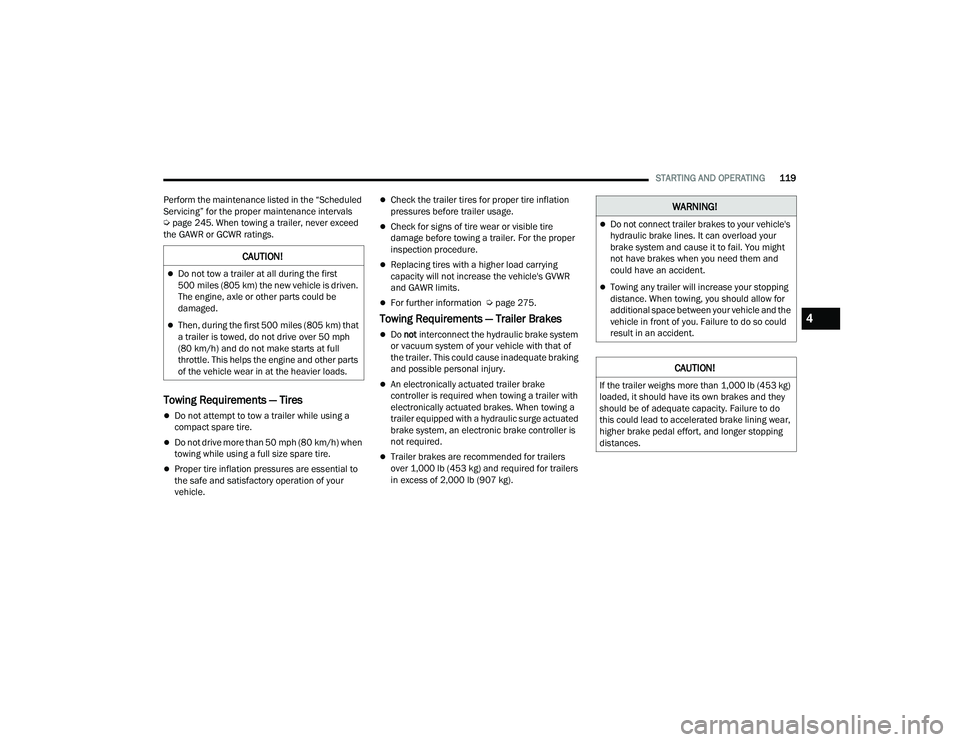

Tire Pressure Monitoring System Display

Should this occur, you should stop as soon as

possible and inflate the tires with a low pressure

condition (those shown in a different color in the

instrument cluster graphic) to the vehicle’s

recommended cold placard pressure inflation

value as shown in the “Inflate to XX” message.

Once the system receives the updated tire

pressures, the system will automatically update,

the graphic display in the instrument cluster will

change color back to the original color, and the

TPMS Warning Light will turn off. The vehicle may

need to be driven for up to 20 minutes above

15 mph (24 km/h) in order for the TPMS to receive

this information.

NOTE:When filling warm tires, the tire pressure may need

to be increased up to an additional 4 psi (28 kPa)

above the recommended cold placard pressure in

order to turn the TPMS Warning Light off.

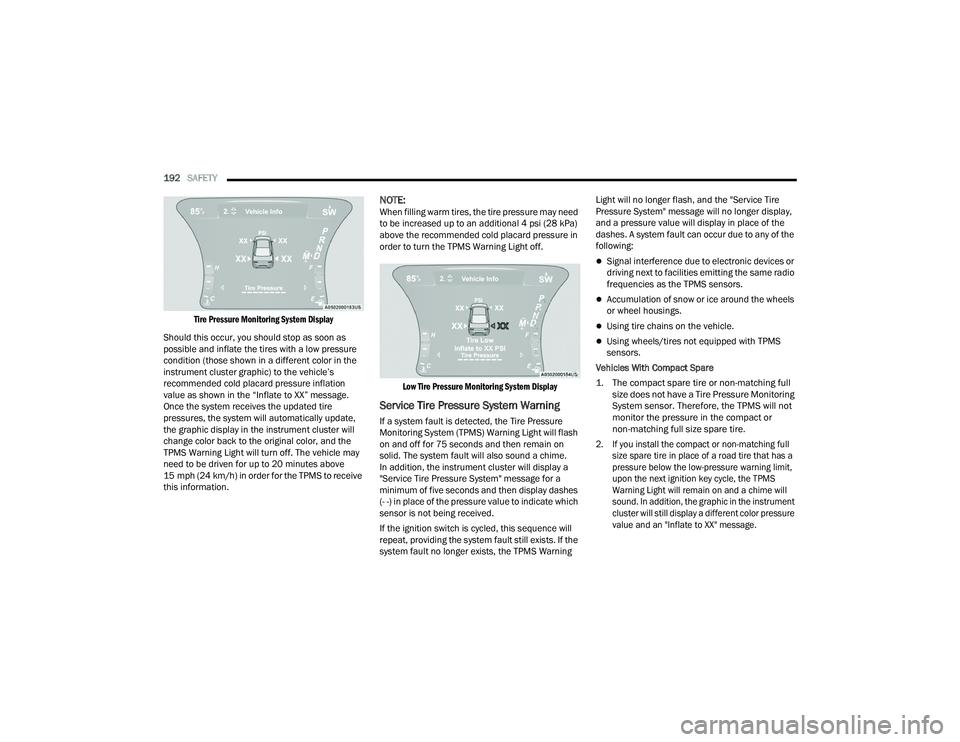

Low Tire Pressure Monitoring System Display

Service Tire Pressure System Warning

If a system fault is detected, the Tire Pressure

Monitoring System (TPMS) Warning Light will flash

on and off for 75 seconds and then remain on

solid. The system fault will also sound a chime.

In addition, the instrument cluster will display a

"Service Tire Pressure System" message for a

minimum of five seconds and then display dashes

(- -) in place of the pressure value to indicate which

sensor is not being received.

If the ignition switch is cycled, this sequence will

repeat, providing the system fault still exists. If the

system fault no longer exists, the TPMS Warning Light will no longer flash, and the "Service Tire

Pressure System" message will no longer display,

and a pressure value will display in place of the

dashes. A system fault can occur due to any of the

following:

Signal interference due to electronic devices or

driving next to facilities emitting the same radio

frequencies as the TPMS sensors.

Accumulation of snow or ice around the wheels

or wheel housings.

Using tire chains on the vehicle.

Using wheels/tires not equipped with TPMS

sensors.

Vehicles With Compact Spare

1. The compact spare tire or non-matching full size does not have a Tire Pressure Monitoring

System sensor. Therefore, the TPMS will not

monitor the pressure in the compact or

non-matching full size spare tire.

2. If you install the compact or non-matching full size spare tire in place of a road tire that has a

pressure below the low-pressure warning limit,

upon the next ignition key cycle, the TPMS

Warning Light will remain on and a chime will

sound. In addition, the graphic in the instrument

cluster will still display a different color pressure

value and an "Inflate to XX" message.

21_LD_OM_EN_USC_t.book Page 192

Page 223 of 320

SAFETY221

(Continued)

(Continued)

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle.

Only use a floor mat that does not interfere with the

operation of the accelerator, brake or clutch pedals.

Only use a floor mat that is securely attached using the

floor mat fasteners so it cannot slip out of position and

interfere with the accelerator, brake or clutch pedals or

impair safe operation of your vehicle in other ways.

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nuts/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

WARNING!

An improperly attached, damaged, folded, or

stacked floor mat, or damaged floor mat

fasteners may cause your floor mat to interfere

with the accelerator, brake, or clutch pedals and

cause a loss of vehicle control. To prevent

SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor mat

using the floor mat fasteners. DO NOT install

your floor mat upside down or turn your floor

mat over. Lightly pull to confirm mat is

secured using the floor mat fasteners on a

regular basis.

ALWAYS REMOVE THE EXISTING FLOOR MAT

FROM THE VEHICLE before installing any

other floor mat. NEVER install or stack an addi -

tional floor mat on top of an existing floor mat.

ONLY install floor mats designed to fit your

vehicle. NEVER install a floor mat that cannot

be properly attached and secured to your

vehicle. If a floor mat needs to be replaced, only

use a FCA approved floor mat for the specific

make, model, and year of your vehicle.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for interfer -

ence, with the vehicle properly parked with the

engine off, fully depress the accelerator, the

brake, and the clutch pedal (if present) to check

for interference. If your floor mat interferes with

the operation of any pedal, or is not secure to

the floor, remove the floor mat from the vehicle

and place the floor mat in your trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide

into the driver’s side floor area when the vehicle

is moving. Objects can become trapped under

accelerator, brake, or clutch pedals and could

cause a loss of vehicle control.

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

WARNING!

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

6

21_LD_OM_EN_USC_t.book Page 221

Page 236 of 320

234IN CASE OF EMERGENCY

If the sealant (white fluid) does not flow within 0 –

10 seconds through the Sealant Hose :

1. Push the Power Button (3) to turn Off the Tire Service Kit. Disconnect the Sealant Hose (4)

from the valve stem. Make sure the valve

stem is free of debris. Reconnect the Sealant

Hose (4) to the valve stem. Check that the

Mode Select Knob (6) is in the Sealant Mode

position and not Air Mode. Push the Power

Button (3) to turn On the Tire Service Kit.

2. Connect the Power Plug (7) to a different 12 Volt power outlet in your vehicle or another

vehicle, if available. Make sure the engine is

running before turning ON the Tire Service Kit.

3. The Sealant Bottle (1) may be empty due to previous use. Call for assistance.

NOTE:If the Mode Select Knob (6) is on Air Mode and the

pump is operating, air will dispense from the Air

Pump Hose (8) only, not the Sealant Hose (4). If the sealant (white fluid) does flow through the

Sealant Hose :

1. Continue to operate the pump until sealant is no

longer flowing through the hose (typically takes

30 - 70 seconds). As the sealant flows through

the Sealant Hose (4), the Pressure Gauge (5)

can read as high as 70 psi (4.8 Bar). The

Pressure Gauge (5) will decrease quickly from

approximately 70 psi (4.8 Bar) to the actual tire

pressure when the Sealant Bottle (1) is empty.

2. The pump will start to inject air into the tire immediately after the Sealant Bottle (1) is

empty. Continue to operate the pump and

inflate the tire to the pressure indicated on the

tire pressure label on the driver-side latch

pillar (recommended pressure). Check the tire

pressure by looking at the Pressure Gauge (5).

If the tire does not inflate to at least 26 psi

(1.8 Bar) pressure within 15 minutes:

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

NOTE:If the tire becomes overinflated, push the Deflation

Button (2) to reduce the tire pressure to the recom -

mended inflation pressure before continuing. If the tire inflates to the recommended pressure or

is at least 26 psi (1.8 Bar) pressure within

15 minutes:

1. Push the Power Button (3) to turn off the Tire

Service Kit.

2. Remove the Speed Limit sticker from the top of the Sealant Bottle (1) and place the sticker on

the instrument panel.

3. Immediately disconnect the Sealant Hose (4) from the valve stem, reinstall the cap on the

fitting at the end of the hose, and place the Tire

Service Kit in the vehicle storage location.

CAUTION!

The metal end fitting from Power Plug (3) may get

hot after use, so it should be handled carefully.

Failure to reinstall the cap on the fitting at the end

of the Sealant Hose (4) can result in sealant

contacting your skin, clothing, and the vehicle’s

interior. It can also result in sealant contacting

internal Tire Service Kit components which may

cause permanent damage to the kit.

21_LD_OM_EN_USC_t.book Page 234

Page 237 of 320

IN CASE OF EMERGENCY235

(D) Drive Vehicle:

Immediately after injecting sealant and inflating the

tire, drive the vehicle 5 miles (8 km) or 10 minutes

to ensure distribution of the Tire Service Kit Sealant

within the tire. Do not exceed 50 mph (80 km/h).

(E) After Driving:

Pull over to a safe location before continuing

Úpage 233.

1. Push in the Mode Select Knob (6) and turn to the Air Mode position.

2. Uncoil the power plug and insert the plug into the vehicle's 12 Volt power outlet.

3. Uncoil the Air Pump Hose (8) (black in color) and screw the fitting at the end of hose (8)

onto the valve stem.

4. Check the pressure in the tire by reading the Pressure Gauge (5). If tire pressure is less than 19 psi (1.3 Bar):

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance.

If the tire pressure is 19 psi (1.3 Bar) or higher:

1. Push the Power Button (3) to turn on Tire

Service Kit and inflate the tire to the pressure

indicated on the tire and loading information

label on the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation

Button (2) to reduce the tire pressure to the recom -

mended inflation pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and

unplug from 12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an

authorized dealer or tire service center.

5. Remove the Speed Limit sticker from the instrument panel after the tire has been

repaired.

6. Replace the Sealant Bottle (1) and Sealant Hose (4) assembly at an authorized dealer as

soon as possible.

NOTE:When having the tire serviced, advise the autho -

rized dealer or service center that the tire has been

sealed using the Tire Service Kit.

(F) Sealant Bottle And Hose Replacement:

1. Uncoil the Sealant Hose (4) (clear in color).

2. Locate the round Sealant Bottle release button in the recessed area under the sealant bottle.

3. Push the Sealant Bottle release button. The Sealant Bottle (1) will pop up. Remove the

bottle and dispose of it accordingly.

4. Clean any remaining sealant from the Tire Service Kit housing.

5. Position the new Sealant Bottle (1) in the housing so that the Sealant Hose (4) aligns

with the hose slot in the front of the housing.

Push the bottle into the housing. An audible

click will be heard indicating the bottle is

locked into place.

6. Verify that the cap is installed on the fitting at the end of the Sealant Hose (4) and return the

hose to its storage area (located on the bottom

of the air pump).

7. Return the Tire Service Kit to its storage location in the vehicle.WARNING!

Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced

after using Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced.

Failure to follow this warning can result in injuries

that are serious or fatal to you, your passengers, and

others around you.

7

21_LD_OM_EN_USC_t.book Page 235

Page 279 of 320

SERVICING AND MAINTENANCE277

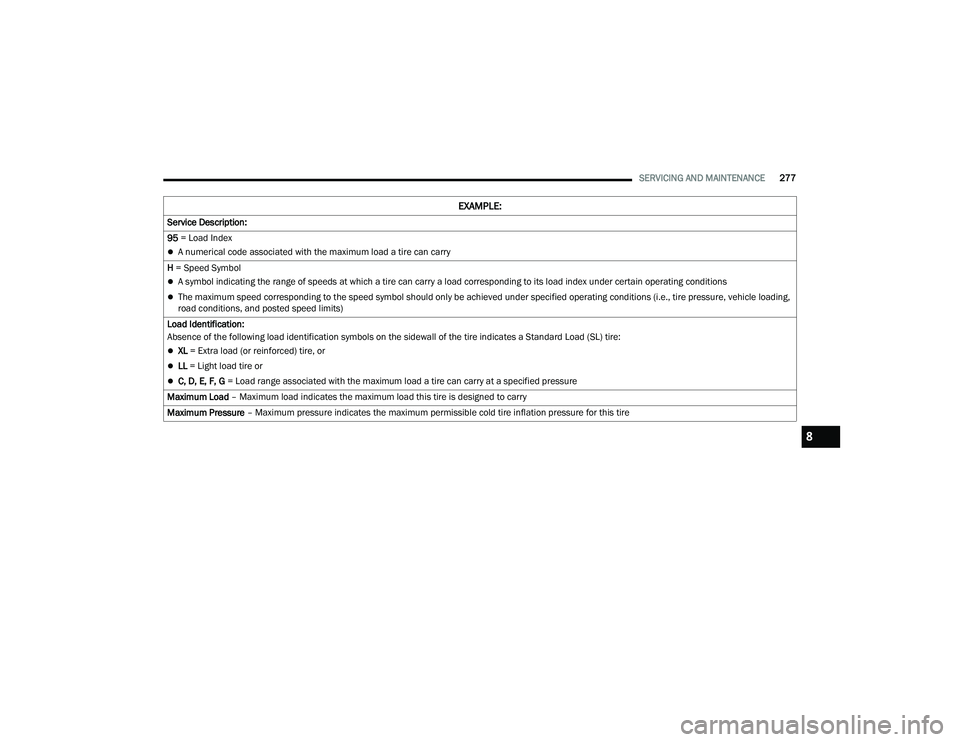

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading,

road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

8

21_LD_OM_EN_USC_t.book Page 277

Page 281 of 320

SERVICING AND MAINTENANCE279

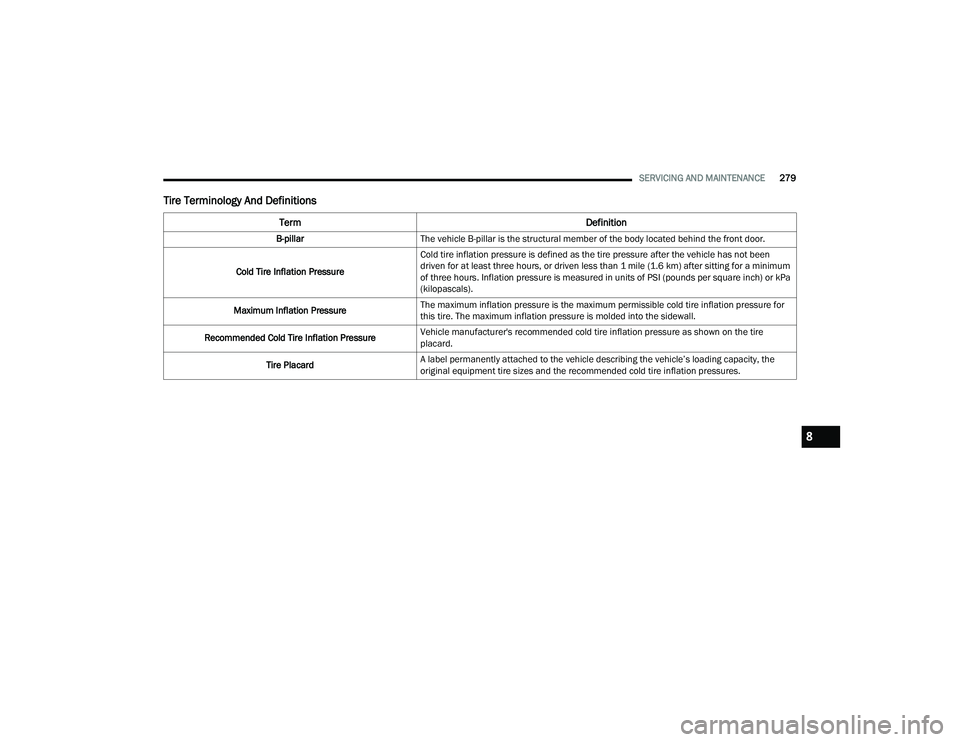

Tire Terminology And Definitions

Term Definition

B-pillarThe vehicle B-pillar is the structural member of the body located behind the front door.

Cold Tire Inflation Pressure Cold tire inflation pressure is defined as the tire pressure after the vehicle has not been

driven for at least three hours, or driven less than 1 mile (1.6 km) after sitting for a minimum

of three hours. Inflation pressure is measured in units of PSI (pounds per square inch) or kPa

(kilopascals).

Maximum Inflation Pressure The maximum inflation pressure is the maximum permissible cold tire inflation pressure for

this tire. The maximum inflation pressure is molded into the sidewall.

Recommended Cold Tire Inflation Pressure Vehicle manufacturer's recommended cold tire inflation pressure as shown on the tire

placard.

Tire Placard A label permanently attached to the vehicle describing the vehicle’s loading capacity, the

original equipment tire sizes and the recommended cold tire inflation pressures.

8

21_LD_OM_EN_USC_t.book Page 279