steering DODGE DAKOTA 2008 3.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: DAKOTA, Model: DODGE DAKOTA 2008 3.GPages: 426, PDF Size: 6.39 MB

Page 261 of 426

WARNING!

Overloading of your tires is dangerous. Overloading

can cause tire failure, affect vehicle handling, and

increase your stopping distance. Use tires of the

recommended load capacity for your vehicle. Never

overload them.

TIRES Ð GENERAL INFORMATION

Tire Pressure

Proper tire inflation pressure is essential to the safe and

satisfactory operation of your vehicle. Three primary

areas are affected by improper tire pressure:1. SafetyÐ

WARNING!

²Improperly inflated tires are dangerous and can cause

accidents.

²Under inflation increases tire flexing and can result in

tire failure.

²Over inflation reduces a tire's ability to cushion

shock. Objects on the road and chuckholes can cause

damage that result in tire failure.

²Unequal tire pressures can cause steering problems.

You could lose control of your vehicle.

²Over inflated or under inflated tires can affect vehicle

handling and can fail suddenly, resulting in loss of

vehicle control.

²Unequal tire pressures from one side of the vehicle to

the other can cause the vehicle to drift to the right or left.

²Always drive with each tire inflated to the recom-

mended cold tire inflation pressure.

STARTING AND OPERATING 261

5

Page 269 of 426

WARNING!

²Do not use a tire, wheel size or rating other than

that specified for your vehicle. Some combinations

of unapproved tires and wheels may change sus-

pension dimensions and performance characteris-

tics, resulting in changes to steering, handling, and

braking of your vehicle. This can cause unpredict-

able handling and stress to steering and suspen-

sion components. You could lose control and have

an accident resulting in serious injury or death.

Use only the tire and wheel sizes with load ratings

approved for your vehicle.

²Never use a tire with a smaller load index or

capacity, other than what was originally equipped

on your vehicle. Using a tire with a smaller load

index could result in tire overloading and failure.

You could lose control and have an accident.

²Failure to equip your vehicle with tires having

adequate speed capability can result in sudden tire

failure and loss of vehicle control.

CAUTION!

Replacing original tires with tires of a different size

may result in false speedometer and odometer

readings.

Alignment And Balance

Poor suspension alignment may result in:

²Fast tire wear.

²Uneven tire wear, such as feathering and one-sided

wear.

²Vehicle pull to right or left.

Tires may also cause the vehicle to pull to the left or right.

Alignment will not correct this condition. See your dealer

for proper diagnosis.

STARTING AND OPERATING 269

5

Page 272 of 426

SNOW TIRES

Snow tires should be of the same size and type construc-

tion as the front tires. Consult the manufacturer of the

snow tire to determine any maximum vehicle speed

requirement associated with the tire. These tires should

always be operated at the vehicle maximum capacity

inflation pressures under any load condition.

While studded tires improve performance on ice, skid

and traction capability on wet or dry surfaces may be

poorer than that of non-studded tires. Some states pro-

hibit studded tires; therefore, local laws should be

checked before using these tire types.

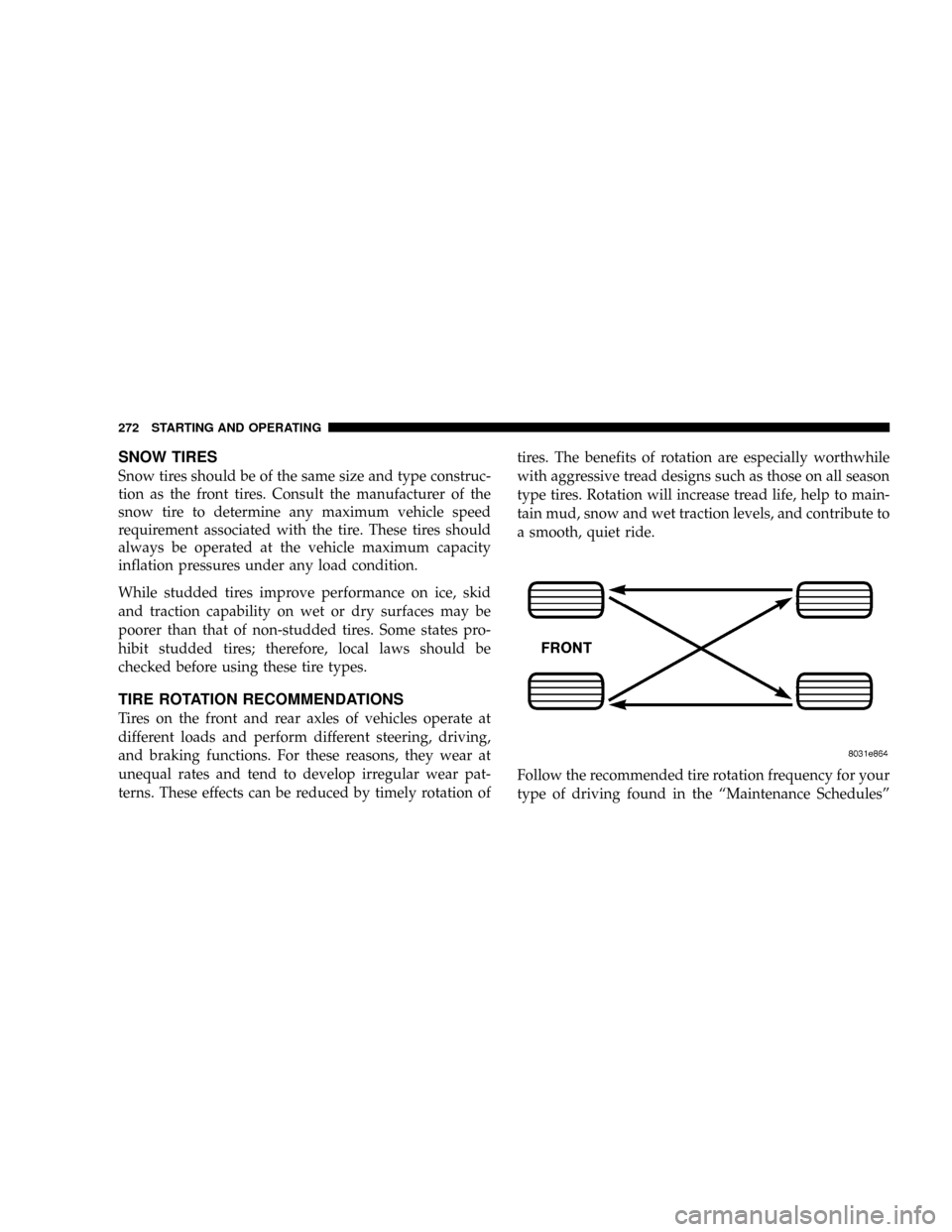

TIRE ROTATION RECOMMENDATIONS

Tires on the front and rear axles of vehicles operate at

different loads and perform different steering, driving,

and braking functions. For these reasons, they wear at

unequal rates and tend to develop irregular wear pat-

terns. These effects can be reduced by timely rotation oftires. The benefits of rotation are especially worthwhile

with aggressive tread designs such as those on all season

type tires. Rotation will increase tread life, help to main-

tain mud, snow and wet traction levels, and contribute to

a smooth, quiet ride.

Follow the recommended tire rotation frequency for your

type of driving found in the ªMaintenance Schedulesº

272 STARTING AND OPERATING

Page 293 of 426

TSC (Trailer Sway Control) ± If Equipped

²

Trailer Sway Control ± Electronic

TSC uses sensors in the vehicle to recognize a swaying

trailer and will take the appropriate actions to attempt to

stop the sway. The system will reduce engine power and

apply individual brakes that will counter act the sway of

the trailer. TSC will become active automatically once the

swaying trailer is recognized. No driver action is re-

quired. TSC can not stop all trailers from swaying.

Always use caution when towing a trailer and follow the

tongue weight recommendations. Even if your vehicle is

equipped with electronic trailer sway control, mechanical

sway control is recommended when appropriate for the

size of your trailer.

²Trailer Sway Control ± Mechanical

The trailer sway control is a telescoping link that can be

installed between the hitch receiver and the trailer tonguethat typically provides adjustable friction associated with

the telescoping motion to dampen any unwanted trailer

swaying motions while traveling.

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch ball or

some other connecting point of the truck. These kind of

hitches are the most popular on the market today and

they're commonly used to tow small- and medium-sized

trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying lever-

age through spring (load) bars. They are typically used

for heavier loads, to distribute trailer tongue weight to

the tow vehicle's front axle and the trailer axle(s). When

used in accordance with the manufacturers' directions, it

provides for a more level ride, offering more consistent

steering and brake control thereby enhancing towing

STARTING AND OPERATING 293

5

Page 298 of 426

Towing Requirements

To promote proper break-in of your new vehicle driv-

etrain components the following guidelines are recom-

mended:

CAUTION!

²Avoid towing a trailer for the first 500 miles (805

km) of vehicle operation. Doing so may damage

your vehicle.

²During the first 500 miles (805 km) of trailer

towing, limit your speed to 50 mph (80 km/h).

Perform the maintenance listed in Section 8 of this

manual. When towing a trailer, never exceed the GAWR,

or GCWR, ratings.

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

²When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

298 STARTING AND OPERATING

Page 312 of 426

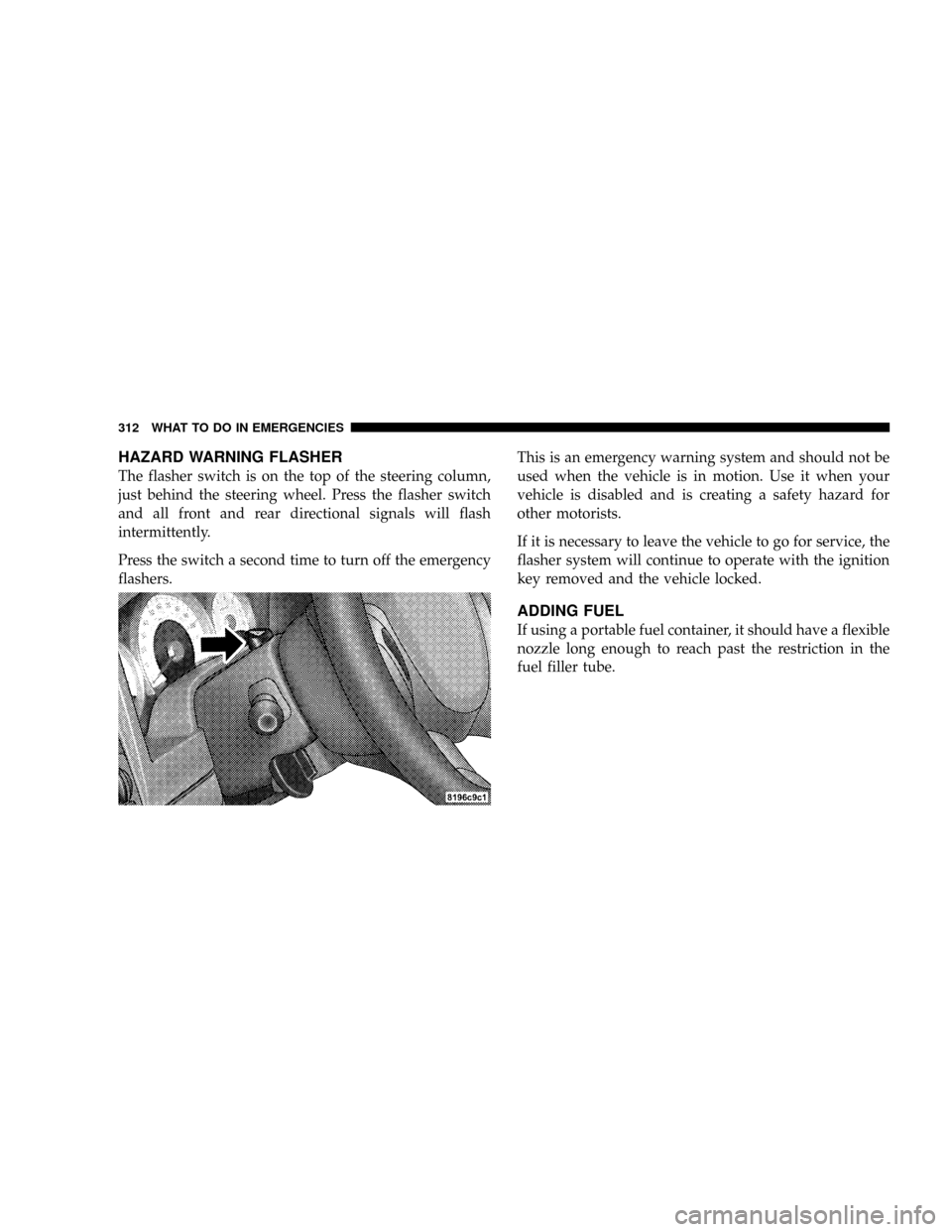

HAZARD WARNING FLASHER

The flasher switch is on the top of the steering column,

just behind the steering wheel. Press the flasher switch

and all front and rear directional signals will flash

intermittently.

Press the switch a second time to turn off the emergency

flashers.This is an emergency warning system and should not be

used when the vehicle is in motion. Use it when your

vehicle is disabled and is creating a safety hazard for

other motorists.

If it is necessary to leave the vehicle to go for service, the

flasher system will continue to operate with the ignition

key removed and the vehicle locked.

ADDING FUEL

If using a portable fuel container, it should have a flexible

nozzle long enough to reach past the restriction in the

fuel filler tube.

312 WHAT TO DO IN EMERGENCIES

Page 330 of 426

NPower Steering Ð Fluid Check............347

NFront Suspension Ball Joints..............348

NDrive Shaft Constant Velocity Joints........348

NBody Lubrication.....................348

NWindshield Wiper Blades................349

NWindshield Washers...................349

NExhaust System......................350

NCooling System.......................351

NEmission Related Components............356

NBrake System........................357

NClutch Hydraulic System................359

NManual Transmission..................359

NAutomatic Transmission................359NTransfer Case........................362

NAxles..............................362

NAppearance Care And Protection

From Corrosion......................363

mFuses (Power Distribution Center)...........367

mVehicle Storage........................373

mReplacement Light Bulbs.................373

mBulb Replacement......................374

NHeadlight (Halogen)/Front Park And

Turn Lights.........................374

NRear Side Marker, Taillamps/Stoplamp,

And Turn Signal Bulbs Ð Replacement......377

NCenter High-Mounted Stoplamp And

Cargo Lamp.........................379

330 MAINTAINING YOUR VEHICLE

Page 347 of 426

Refrigerant Recovery and Recycling

R-134a Air Conditioning Refrigerant is a hydrofluorocar-

bon (HFC) that is endorsed by the Environmental Pro-

tection Agency and is an ozone-saving product. How-

ever, the manufacturer recommends that air conditioning

service be performed by dealers or other service facilities

using recovery and recycling equipment.

Power Steering Ð Fluid Check

Checking the power steering fluid level at a defined

service interval is not required. The fluid should only be

checked if a leak is suspected, abnormal noises are

apparent, and/or the system is not functioning as antici-

pated. Coordinate inspection efforts through a certified

DaimlerChrysler Dealership.9

WARNING!

Fluid level should be checked on a level surface and

with the engine off to prevent injury from moving

parts and to insure accurate fluid level reading. Do

not overfill. Use only manufacturers recommended

power steering fluid.

If necessary, add fluid to restore to the proper indicated

level. With a clean cloth, wipe any spilled fluid from all

surfaces. Refer to Fluids, Lubricants, and Genuine Parts

for correct fluid type.

MAINTAINING YOUR VEHICLE 347

7

Page 386 of 426

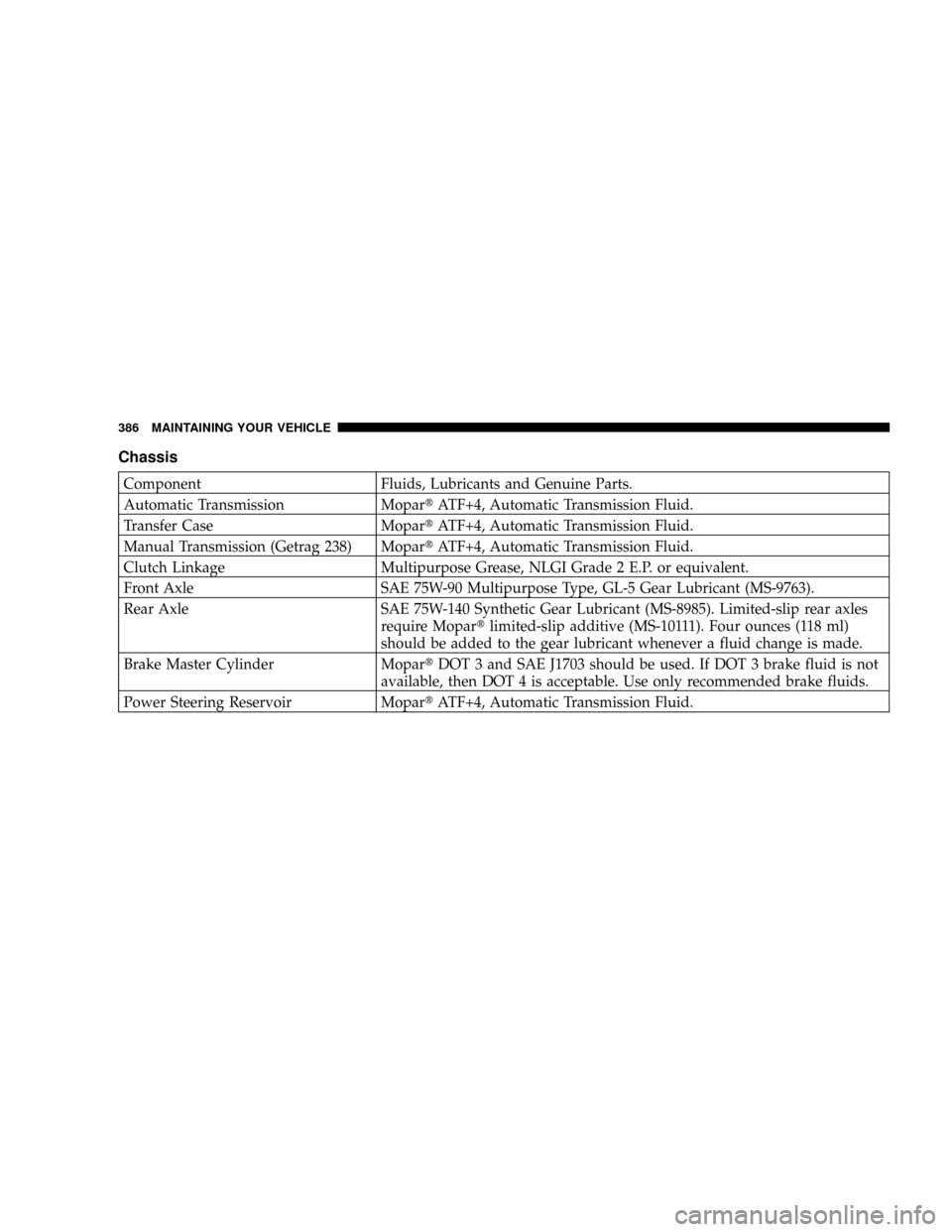

Chassis

Component Fluids, Lubricants and Genuine Parts.

Automatic Transmission MopartATF+4, Automatic Transmission Fluid.

Transfer Case MopartATF+4, Automatic Transmission Fluid.

Manual Transmission (Getrag 238) MopartATF+4, Automatic Transmission Fluid.

Clutch Linkage Multipurpose Grease, NLGI Grade 2 E.P. or equivalent.

Front Axle SAE 75W-90 Multipurpose Type, GL-5 Gear Lubricant (MS-9763).

Rear Axle SAE 75W-140 Synthetic Gear Lubricant (MS-8985). Limited-slip rear axles

require Mopartlimited-slip additive (MS-10111). Four ounces (118 ml)

should be added to the gear lubricant whenever a fluid change is made.

Brake Master Cylinder MopartDOT 3 and SAE J1703 should be used. If DOT 3 brake fluid is not

available, then DOT 4 is acceptable. Use only recommended brake fluids.

Power Steering Reservoir MopartATF+4, Automatic Transmission Fluid.

386 MAINTAINING YOUR VEHICLE

Page 389 of 426

²Change your engine oil more often if you drive your

vehicle off-road for an extended period of time.

²Under no circumstances should oil change intervals

exceed 6,000 miles (10,000 km) or 6 months, whichever

comes first.

Your dealer will reset the oil change indicator message

after completing the scheduled oil change. If this sched-

uled oil change is performed by someone other than your

dealer the message can be reset by referring to the steps

described under ªOil Change Requiredº in ªUse Factory

Settingsº of the EVIC section in this manual or under

ªOdometer/Trip Odometerº in the ªInstrument Cluster

Descriptions section of this manual.

At Each Stop for Fuel

²Check the engine oil level about 5 minutes after a fully

warmed engine is shut off. Checking the oil level whilethe vehicle is on level ground will improve the accu-

racy of the oil level reading. Add oil only when the

level is at or below the ADD or MIN mark.

²Check the windshield washer solvent and add if

required.

Once a Month

²Check tire pressure and look for unusual wear or

damage.

²Inspect the battery and clean and tighten the terminals

as required.

²Check the fluid levels of coolant reservoir, brake

master cylinder, power steering and transmission and

add as needed.

²Check all lights and other electrical items for correct

operation.

MAINTENANCE SCHEDULES 389

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S