wheel DODGE DART 2014 PF / 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2014, Model line: DART, Model: DODGE DART 2014 PF / 1.GPages: 140, PDF Size: 4.57 MB

Page 92 of 140

3. Remove the fastener securing the jack and spare tire.

4. Remove the scissors jack and wheel boltwrench from the spare wheel as an as-

sembly. Turn the jack screw to the left to

loosen the wheel bolt wrench, and re-

move the wrench from the jack assembly.

5. Remove the spare tire.

Preparations For Jacking

1. Park the vehicle on a firm, level surface as far from the edge of the roadway as possible. Avoid icy or slippery areas.

2. Turn on the Hazard Warning flasher.

3. Set the parking brake.

4. Place the shift lever into PARK.

5. Turn OFF the ignition.

6. Block the front and rear of the wheel diagonally opposite of the jacking position. For example, if changing the right front tire, block the left rear wheel.

NOTE:

Passengers should not remain in the vehicle

when the vehicle is being jacked.

Wheel Blocked

WHAT TO DO IN EMERGENCIES

90

Page 93 of 140

Jacking And Changing A Tire

1. Remove the spare tire, jack, and wheelbolt wrench.

2. If equipped with aluminum wheels where the center cap covers the wheel bolts,

use the wheel bolt wrench to pry the cen-

ter cap off carefully before raising the

vehicle.

3. Before raising the vehicle, use the wheel bolt wrench to loosen, but not remove,

the wheel bolts on the wheel with the flat

tire. Turn the wheel bolts counterclock-

wise one turn while the wheel is still on the ground.

4. Place the jack underneath the lift area that is closest to the flat tire. Turn the jack screw clockwise to firmly engage the jack saddle with the lift area of the sill flange, centering

the jack saddle between the locating notches on the sill flange.

5. Raise the vehicle just enough to remove the flat tire and install the spare tire.

6. Remove the wheel bolts and tire.

WHAT TO DO IN EMERGENCIES

91

Page 94 of 140

7. Mount the spare tire.

8. Install the wheel bolts with the threadedend of the wheel bolt toward the wheel.

Lightly tighten the wheel bolts.

9. Lower the vehicle to the ground by turn- ing the jack handle counterclockwise.

10. Finish tightening the wheel bolts. Push down on the wrench while at the end of

the handle for increased leverage.

Tighten the wheel bolts in a star pattern

until each bolt has been tightened twice.

The correct tightness of each wheel bolt

is 100 ft/lb. (135 N·m). If in doubt about the correct tightness, have them checked with

a torque wrench by your authorized dealer or at a service station.

11. Stow the jack, tools and flat tire. Install the jack with the base facing the front of the vehicle before tightening down the fastener.

Road Tire Installation

Vehicles Equipped With Wheel Covers

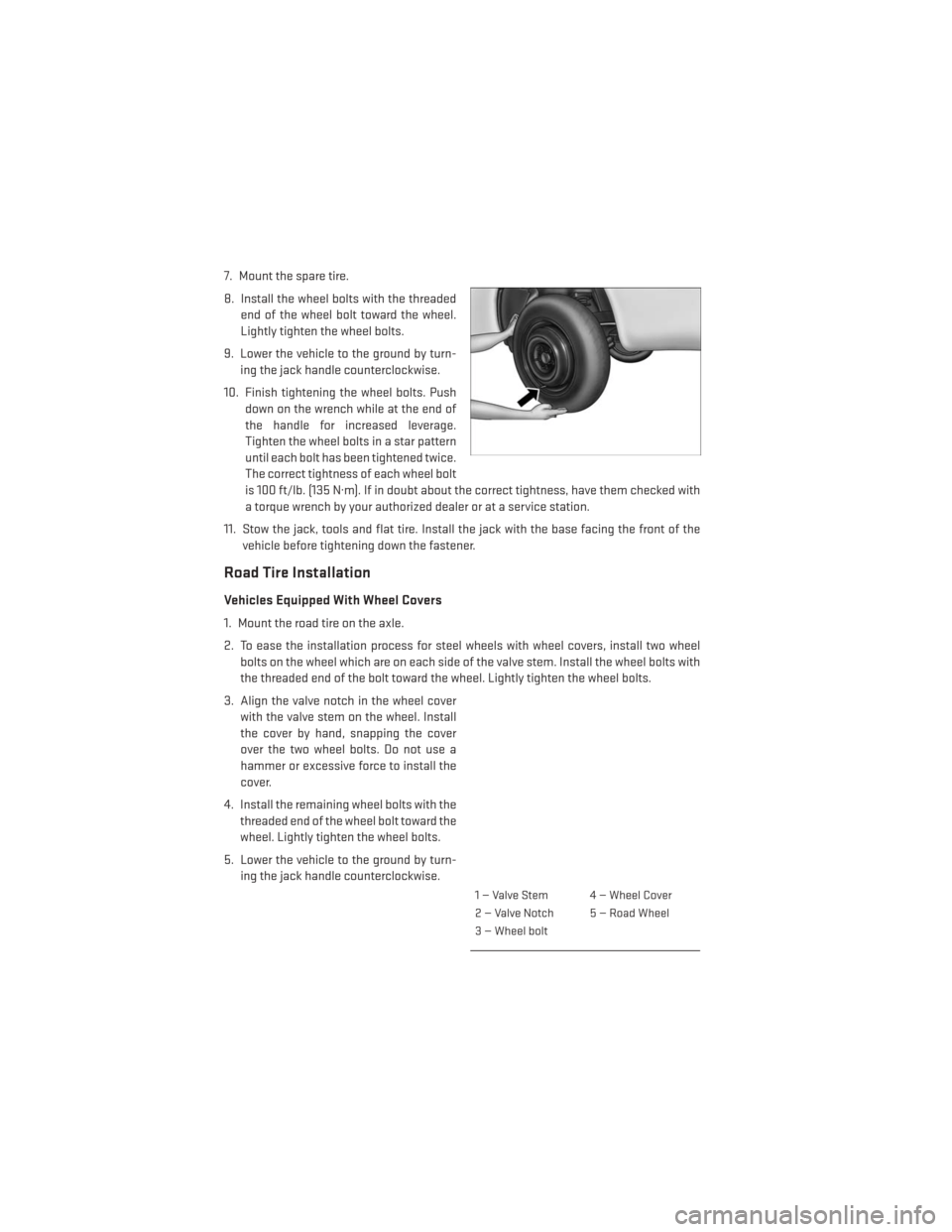

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two wheelbolts on the wheel which are on each side of the valve stem. Install the wheel bolts with

the threaded end of the bolt toward the wheel. Lightly tighten the wheel bolts.

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install

the cover by hand, snapping the cover

over the two wheel bolts. Do not use a

hammer or excessive force to install the

cover.

4. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the

wheel. Lightly tighten the wheel bolts.

5. Lower the vehicle to the ground by turn- ing the jack handle counterclockwise.

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Road Wheel

3 — Wheel bolt

WHAT TO DO IN EMERGENCIES

92

Page 95 of 140

6. Finish tightening the wheel bolts. Push down on the wrench while at the end of thehandle for increased leverage. Tighten the wheel bolts in a star pattern until each wheel

bolt has been tightened twice. The correct tightness of each wheel bolt is 100 ft/lbs

(135 N·m). If in doubt about the correct tightness, have them checked with a torque

wrench by your authorized dealer or service station.

7. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts are properly seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining wheel bolts with the threaded end of the wheel bolt toward the wheel. Lightly tighten the wheel bolts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4.

Finish tightening the wheel bolts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts in a star pattern until each bolt has been

tightened twice. The correct tightness of each wheel bolt is 100 ft/lbs (135 N·m). If in doubt

about the correct tightness, have them checked with a torque wrench by your authorized

dealer or service station.

5. After 25 miles (40 km) check the wheel bolt torque with a torque wrench to ensure that all wheel bolts are properly seated against the wheel.

CAUTION!

• The winch mechanism is designed for use with the jack-handle only. Use of an air wrench or other power tools is not recommended and they can damage the winch.

• Do not attempt to raise the vehicle by jacking on locations other than those indicated

in the Jacking Instructions for this vehicle.

• Be sure to mount the spare tire with the valve stem facing outward. The vehicle could

be damaged if the spare tire is mounted incorrectly.

WHAT TO DO IN EMERGENCIES

93

Page 96 of 140

WARNING!

• Do not attempt to change a tire on the side of the vehicle close to moving traffic. Pullfar enough off the road to avoid the danger of being hit when operating the jack or

changing the wheel.

• Being under a jacked-up vehicle is dangerous. The vehicle could slip off the jack and

fall on you. You could be crushed. Never put any part of your body under a vehicle that

is on a jack. If you need to get under a raised vehicle, take it to an authorized service

center where it can be raised on a lift.

• Never start or run the engine while the vehicle is on a jack.

• The jack is designed to be used as a tool for changing tires only. The jack should not

be used to lift the vehicle for service purposes. The vehicle should be jacked on a firm

level surface only. Avoid ice or slippery areas.

• Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible

before raising the vehicle.

• Turn on the Hazard Warning flasher.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly and set an automatic transmission in PARK.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire

change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be

stowed with the valve stem facing the ground.

• Raising the vehicle higher than necessary can make the vehicle less stable. It could

slip off the jack and hurt someone near it. Raise the vehicle only enough to remove

the tire.

• To avoid possible personal injury, handle the wheel covers with care to avoid contact

with any sharp edges.

•

To avoid the risk of forcing the vehicle off the jack, do not tighten the wheel nuts fully

until the vehicle has been lowered. Failure to follow this warning may result in personal

injury.

• A loose tire or jack, thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired or replaced immediately.

WHAT TO DO IN EMERGENCIES

94

Page 98 of 140

TIREFIT Usage Precautions

• Replace the TIREFIT Sealant Bottle (1) and Sealant Hose (6) prior to the expiration date(printed on the bottle label) to assure optimum operation of the system. Refer to “Sealing

a Tire with TIREFIT” section (F) “Sealant Bottle and Hose Replacement.”

• The Sealant Bottle (1) and Sealant Hose (6) are a one tire application use. After each use, always replace these components immediately at an authorized dealer.

• When the TIREFIT sealant is in a liquid form, clean water, and a damp cloth will remove the material from the vehicle or tire and wheel components. Once the sealant dries, it can

easily be peeled off and properly discarded.

• For optimum performance, make sure the valve stem on the wheel is free of debris before connecting the TIREFIT kit.

• You can use the TIREFIT air pump to inflate bicycle tires. The kit also comes with two needles, located in the Accessory Storage Compartment (on the bottom of the air pump)

for inflating sport balls, rafts, or similar inflatable items. However, use only the Air Pump

Hose (7) and make sure the Mode Select Knob (5) is in the Air Mode when inflating such

items to avoid injecting sealant into them. The TIREFIT Sealant is only intended to seal

punctures less than 1/4” (6 mm) diameter in the tread of your vehicle.

• Do not lift or carry the TIREFIT kit by the hoses.

Sealing A Tire With TIREFIT

(A) Whenever You Stop To Use TIREFIT:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the ground. This will allow the TIREFIT Hoses (6) and (7) to reach the valve stem and

keep the TIREFIT kit flat on the ground. This will provide the best positioning of the kit

when injecting the sealant into the deflated tire and running the air pump. Move the

vehicle as necessary to place the valve stem in this position before proceeding.

3. Place the transmission in PARK (auto transmission) or in Gear (manual transmission) and cycle the ignition to the OFF position.

4. Set the parking brake.

(B) Setting Up To Use TIREFIT:

1. Turn the Mode Select Knob (5) to the Sealant Mode position.

2. Uncoil the Sealant Hose (6) and then remove the cap from the fitting at the end of the hose.

3. Place the TIREFIT kit flat on the ground next to the deflated tire.

4. Remove the cap from the valve stem and then screw the fitting at the end of the Sealant Hose (6) onto the valve stem.

5. Uncoil the Power Plug (8) and insert the plug into the vehicle’s 12 Volt power outlet.

6. Do not remove foreign objects (e.g., screws or nails) from the tire.

WHAT TO DO IN EMERGENCIES

96

Page 102 of 140

WARNING!

• Do not attempt to seal a tire on the side of the vehicle closest to traffic. Pull farenough off the road to avoid the danger of being hit when using the TIREFIT kit.

• Do not use TIREFIT or drive the vehicle under the following circumstances:

• If the puncture in the tire tread is approximately 1/4”. (6 mm) or larger.

• If the tire has any sidewall damage.

• If the tire has any damage from driving with extremely low tire pressure.

• If the tire has any damage from driving on a flat tire.

• If the wheel has any damage.

• If you are unsure of the condition of the tire or the wheel.

• Keep TIREFIT away from open flames or heat source.

• A loose TIREFIT kit thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the TIREFIT kit in the place provided. Failure to

follow these warnings can result in injuries that are serious or fatal to you, your

passengers, and others around you.

• Take care not to allow the contents of TIREFIT to come in contact with hair, eyes, or

clothing. TIREFIT is harmful if inhaled, swallowed, or absorbed through the skin. It

causes skin, eye, and respiratory irritation. Flush immediately with plenty of water if

there is any contact with eyes or skin. Change clothing as soon as possible, if there is

any contact with clothing.

• TIREFIT Sealant solution contains latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep TIREFIT out of reach of children. If swallowed,

rinse mouth immediately with plenty of water and drink plenty of water. Do not induce

vomiting! Consult a physician immediately.

• TIREFIT is not a permanent flat tire repair. Have the tire inspected and repaired or

replaced after using TIREFIT. Do not exceed 55 mph (88 km/h) until the tire is

repaired or replaced. Failure to follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others around you.

WHAT TO DO IN EMERGENCIES

100

Page 106 of 140

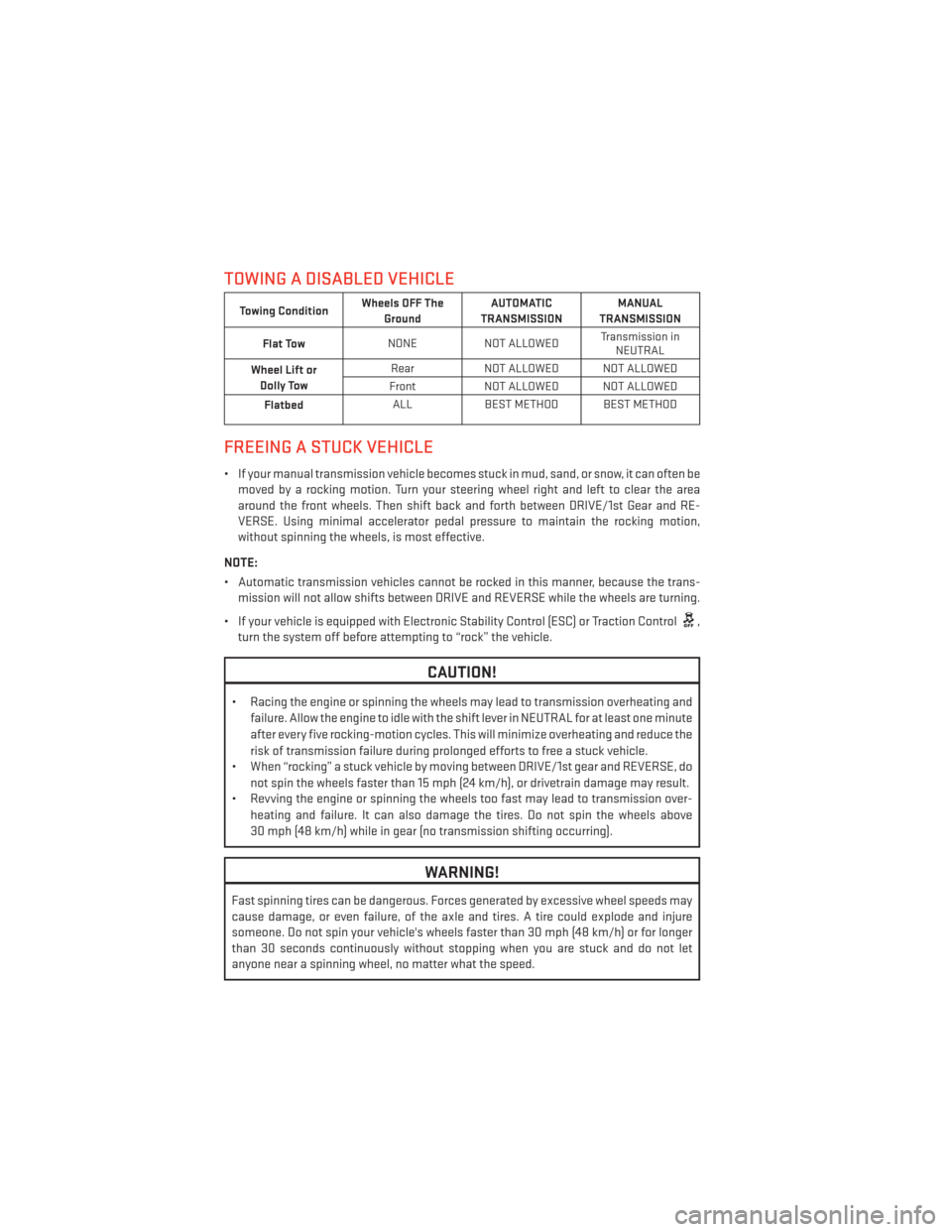

TOWING A DISABLED VEHICLE

Towing ConditionWheels OFF The

Ground AUTOMATIC

TRANSMISSION MANUAL

TRANSMISSION

Flat Tow NONE

NOT ALLOWED Transmission in

NEUTRAL

Wheel Lift or Dolly Tow Rear

NOT ALLOWED NOT ALLOWED

Front NOT ALLOWED NOT ALLOWED

Flatbed ALL

BEST METHOD BEST METHOD

FREEING A STUCK VEHICLE

• If your manual transmission vehicle becomes stuck in mud, sand, or snow, it can often be

moved by a rocking motion. Turn your steering wheel right and left to clear the area

around the front wheels. Then shift back and forth between DRIVE/1st Gear and RE-

VERSE. Using minimal accelerator pedal pressure to maintain the rocking motion,

without spinning the wheels, is most effective.

NOTE:

• Automatic transmission vehicles cannot be rocked in this manner, because the trans- mission will not allow shifts between DRIVE and REVERSE while the wheels are turning.

• If your vehicle is equipped with Electronic Stability Control (ESC) or Traction Control

,

turn the system off before attempting to “rock” the vehicle.

CAUTION!

• Racing the engine or spinning the wheels may lead to transmission overheating and

failure. Allow the engine to idle with the shift lever in NEUTRAL for at least one minute

after every five rocking-motion cycles. This will minimize overheating and reduce the

risk of transmission failure during prolonged efforts to free a stuck vehicle.

• When “rocking” a stuck vehicle by moving between DRIVE/1st gear and REVERSE, do

not spin the wheels faster than 15 mph (24 km/h), or drivetrain damage may result.

• Revving the engine or spinning the wheels too fast may lead to transmission over-

heating and failure. It can also damage the tires. Do not spin the wheels above

30 mph (48 km/h) while in gear (no transmission shifting occurring).

WARNING!

Fast spinning tires can be dangerous. Forces generated by excessive wheel speeds may

cause damage, or even failure, of the axle and tires. A tire could explode and injure

someone. Do not spin your vehicle's wheels faster than 30 mph (48 km/h) or for longer

than 30 seconds continuously without stopping when you are stuck and do not let

anyone near a spinning wheel, no matter what the speed.

WHAT TO DO IN EMERGENCIES

104

Page 119 of 140

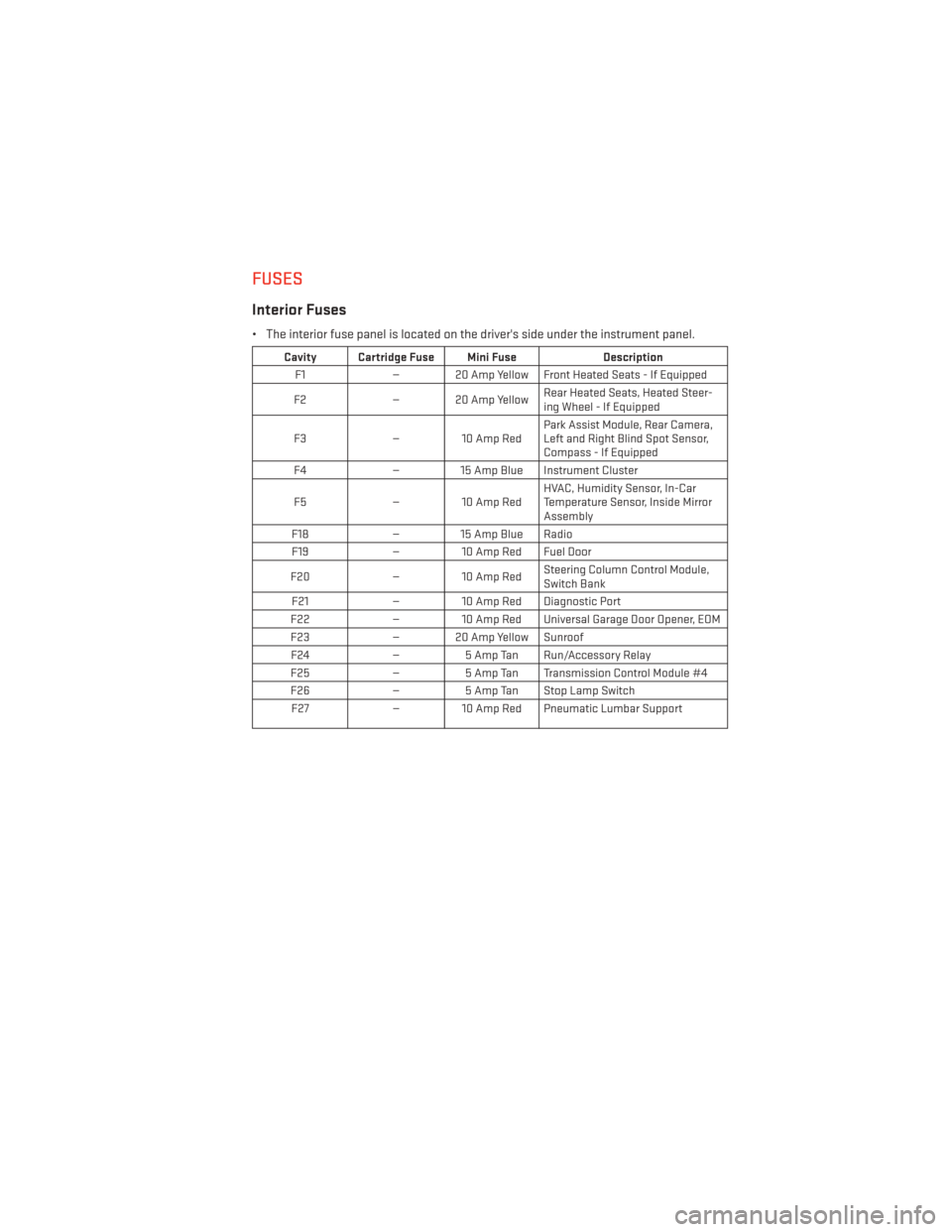

FUSES

Interior Fuses

• The interior fuse panel is located on the driver's side under the instrument panel.

Cavity Cartridge Fuse Mini FuseDescription

F1 — 20 Amp Yellow Front Heated Seats - If Equipped

F2 — 20 Amp Yellow Rear Heated Seats, Heated Steer-

ing Wheel - If Equipped

F3 — 10 Amp Red Park Assist Module, Rear Camera,

Left and Right Blind Spot Sensor,

Compass - If Equipped

F4 — 15 Amp Blue Instrument Cluster

F5 — 10 Amp Red HVAC, Humidity Sensor, In-Car

Temperature Sensor, Inside Mirror

Assembly

F18 — 15 Amp Blue Radio

F19 — 10 Amp Red Fuel Door

F20 — 10 Amp Red Steering Column Control Module,

Switch Bank

F21 — 10 Amp Red Diagnostic Port

F22 — 10 Amp Red Universal Garage Door Opener, EOM

F23 — 20 Amp Yellow Sunroof

F24 —5 Amp Tan Run/Accessory Relay

F25 —5 Amp Tan Transmission Control Module #4

F26 —5 Amp Tan Stop Lamp Switch

F27 — 10 Amp Red Pneumatic Lumbar Support

MAINTAINING YOUR VEHICLE

117

Page 122 of 140

WARNING!

• Overloading of your tires is dangerous. Overloading can cause tire failure, affectvehicle handling, and increase your stopping distance. Use tires of the recom-

mended load capacity for your vehicle. Never overload them.

• Improperly inflated tires are dangerous and can cause collisions. Under-inflation is

the leading cause of tire failure and may result in severe cracking, component

separation, or “blow out”. Over-inflation reduces a tire’s ability to cushion shock.

Objects on the road and chuck holes can cause damage that results in tire failure.

Unequal tire pressures can cause steering problems. You could lose control of your

vehicle. Over-inflated or under-inflated tires can affect vehicle handling and can fail

suddenly, resulting in loss of vehicle control.

WHEEL AND WHEEL TRIM CARE

All wheels and wheel trim, especially aluminum and chrome plated wheels, should be

cleaned regularly with a mild soap and water to prevent corrosion.

To remove heavy soil and/or excessive brake dust, use MOPAR® Wheel Cleaner or equiva-

lent or select a non-abrasive, non-acidic cleaner.

CAUTION!

Do not use scouring pads, steel wool, a bristle brush, or metal polishes. Do not use oven

cleaner. These products may damage the wheel's protective finish. Avoid automatic car

washes that use acidic solutions or harsh brushes that may damage the wheel's protec-

tive finish. Only MOPAR® Wheel Cleaner or equivalent is recommended.

MAINTAINING YOUR VEHICLE

120