vehicle DODGE DURANGO 1998 1.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 56 of 193

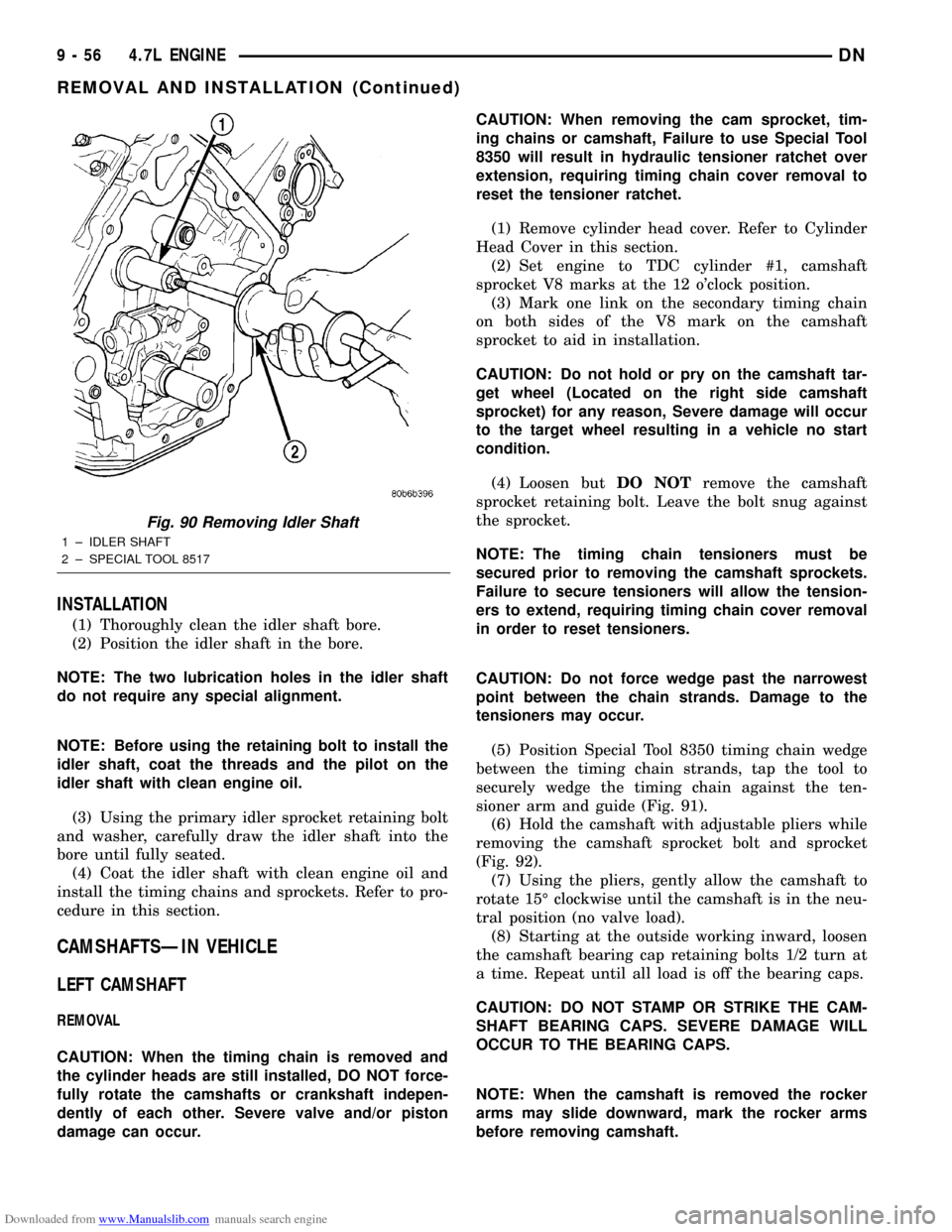

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

(1) Thoroughly clean the idler shaft bore.

(2) Position the idler shaft in the bore.

NOTE: The two lubrication holes in the idler shaft

do not require any special alignment.

NOTE: Before using the retaining bolt to install the

idler shaft, coat the threads and the pilot on the

idler shaft with clean engine oil.

(3) Using the primary idler sprocket retaining bolt

and washer, carefully draw the idler shaft into the

bore until fully seated.

(4) Coat the idler shaft with clean engine oil and

install the timing chains and sprockets. Refer to pro-

cedure in this section.

CAMSHAFTSÐIN VEHICLE

LEFT CAMSHAFT

REMOVAL

CAUTION: When the timing chain is removed and

the cylinder heads are still installed, DO NOT force-

fully rotate the camshafts or crankshaft indepen-

dently of each other. Severe valve and/or piston

damage can occur.CAUTION: When removing the cam sprocket, tim-

ing chains or camshaft, Failure to use Special Tool

8350 will result in hydraulic tensioner ratchet over

extension, requiring timing chain cover removal to

reset the tensioner ratchet.

(1) Remove cylinder head cover. Refer to Cylinder

Head Cover in this section.

(2) Set engine to TDC cylinder #1, camshaft

sprocket V8 marks at the 12 o'clock position.

(3) Mark one link on the secondary timing chain

on both sides of the V8 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel (Located on the right side camshaft

sprocket) for any reason, Severe damage will occur

to the target wheel resulting in a vehicle no start

condition.

(4) Loosen butDO NOTremove the camshaft

sprocket retaining bolt. Leave the bolt snug against

the sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

ers to extend, requiring timing chain cover removal

in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

(5) Position Special Tool 8350 timing chain wedge

between the timing chain strands, tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide (Fig. 91).

(6) Hold the camshaft with adjustable pliers while

removing the camshaft sprocket bolt and sprocket

(Fig. 92).

(7) Using the pliers, gently allow the camshaft to

rotate 15É clockwise until the camshaft is in the neu-

tral position (no valve load).

(8) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

Fig. 90 Removing Idler Shaft

1 ± IDLER SHAFT

2 ± SPECIAL TOOL 8517

9 - 56 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 59 of 193

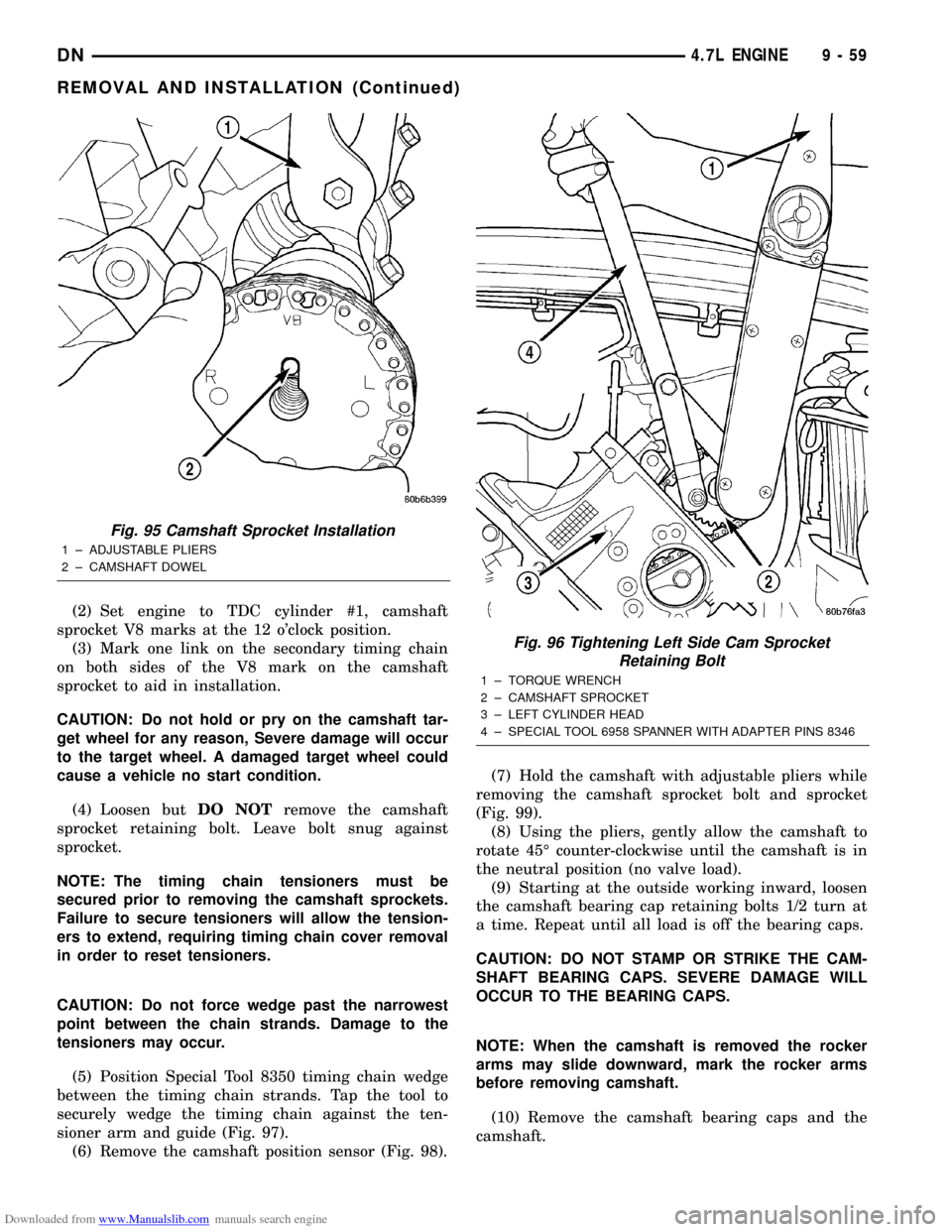

Downloaded from www.Manualslib.com manuals search engine (2) Set engine to TDC cylinder #1, camshaft

sprocket V8 marks at the 12 o'clock position.

(3) Mark one link on the secondary timing chain

on both sides of the V8 mark on the camshaft

sprocket to aid in installation.

CAUTION: Do not hold or pry on the camshaft tar-

get wheel for any reason, Severe damage will occur

to the target wheel. A damaged target wheel could

cause a vehicle no start condition.

(4) Loosen butDO NOTremove the camshaft

sprocket retaining bolt. Leave bolt snug against

sprocket.

NOTE: The timing chain tensioners must be

secured prior to removing the camshaft sprockets.

Failure to secure tensioners will allow the tension-

ers to extend, requiring timing chain cover removal

in order to reset tensioners.

CAUTION: Do not force wedge past the narrowest

point between the chain strands. Damage to the

tensioners may occur.

(5) Position Special Tool 8350 timing chain wedge

between the timing chain strands. Tap the tool to

securely wedge the timing chain against the ten-

sioner arm and guide (Fig. 97).

(6) Remove the camshaft position sensor (Fig. 98).(7) Hold the camshaft with adjustable pliers while

removing the camshaft sprocket bolt and sprocket

(Fig. 99).

(8) Using the pliers, gently allow the camshaft to

rotate 45É counter-clockwise until the camshaft is in

the neutral position (no valve load).

(9) Starting at the outside working inward, loosen

the camshaft bearing cap retaining bolts 1/2 turn at

a time. Repeat until all load is off the bearing caps.

CAUTION: DO NOT STAMP OR STRIKE THE CAM-

SHAFT BEARING CAPS. SEVERE DAMAGE WILL

OCCUR TO THE BEARING CAPS.

NOTE: When the camshaft is removed the rocker

arms may slide downward, mark the rocker arms

before removing camshaft.

(10) Remove the camshaft bearing caps and the

camshaft.

Fig. 95 Camshaft Sprocket Installation

1 ± ADJUSTABLE PLIERS

2 ± CAMSHAFT DOWEL

Fig. 96 Tightening Left Side Cam Sprocket

Retaining Bolt

1 ± TORQUE WRENCH

2 ± CAMSHAFT SPROCKET

3 ± LEFT CYLINDER HEAD

4 ± SPECIAL TOOL 6958 SPANNER WITH ADAPTER PINS 8346

DN4.7L ENGINE 9 - 59

REMOVAL AND INSTALLATION (Continued)

Page 61 of 193

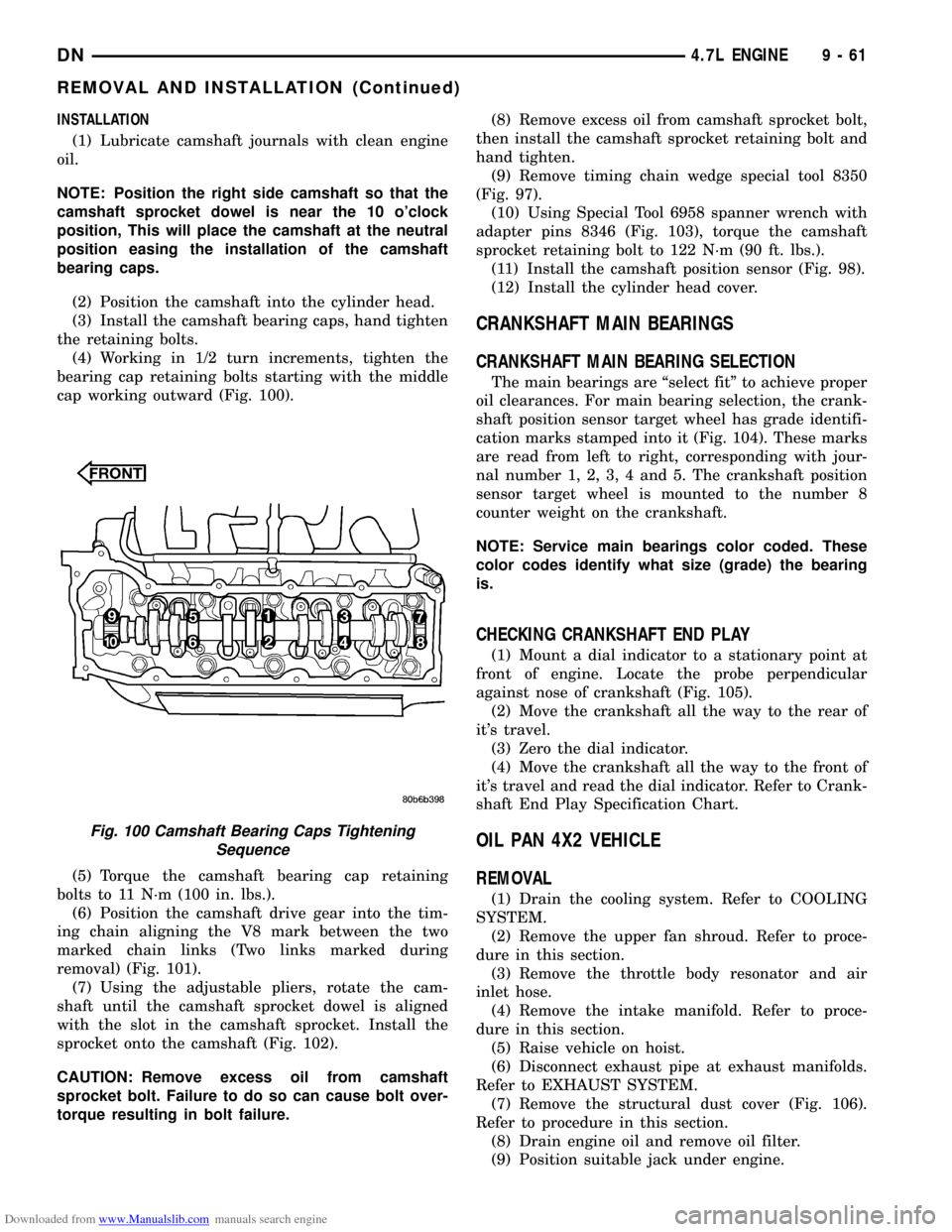

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

(1) Lubricate camshaft journals with clean engine

oil.

NOTE: Position the right side camshaft so that the

camshaft sprocket dowel is near the 10 o'clock

position, This will place the camshaft at the neutral

position easing the installation of the camshaft

bearing caps.

(2) Position the camshaft into the cylinder head.

(3) Install the camshaft bearing caps, hand tighten

the retaining bolts.

(4) Working in 1/2 turn increments, tighten the

bearing cap retaining bolts starting with the middle

cap working outward (Fig. 100).

(5) Torque the camshaft bearing cap retaining

bolts to 11 N´m (100 in. lbs.).

(6) Position the camshaft drive gear into the tim-

ing chain aligning the V8 mark between the two

marked chain links (Two links marked during

removal) (Fig. 101).

(7) Using the adjustable pliers, rotate the cam-

shaft until the camshaft sprocket dowel is aligned

with the slot in the camshaft sprocket. Install the

sprocket onto the camshaft (Fig. 102).

CAUTION: Remove excess oil from camshaft

sprocket bolt. Failure to do so can cause bolt over-

torque resulting in bolt failure.(8) Remove excess oil from camshaft sprocket bolt,

then install the camshaft sprocket retaining bolt and

hand tighten.

(9) Remove timing chain wedge special tool 8350

(Fig. 97).

(10) Using Special Tool 6958 spanner wrench with

adapter pins 8346 (Fig. 103), torque the camshaft

sprocket retaining bolt to 122 N´m (90 ft. lbs.).

(11) Install the camshaft position sensor (Fig. 98).

(12) Install the cylinder head cover.

CRANKSHAFT MAIN BEARINGS

CRANKSHAFT MAIN BEARING SELECTION

The main bearings are ªselect fitº to achieve proper

oil clearances. For main bearing selection, the crank-

shaft position sensor target wheel has grade identifi-

cation marks stamped into it (Fig. 104). These marks

are read from left to right, corresponding with jour-

nal number 1, 2, 3, 4 and 5. The crankshaft position

sensor target wheel is mounted to the number 8

counter weight on the crankshaft.

NOTE: Service main bearings color coded. These

color codes identify what size (grade) the bearing

is.

CHECKING CRANKSHAFT END PLAY

(1) Mount a dial indicator to a stationary point at

front of engine. Locate the probe perpendicular

against nose of crankshaft (Fig. 105).

(2) Move the crankshaft all the way to the rear of

it's travel.

(3) Zero the dial indicator.

(4) Move the crankshaft all the way to the front of

it's travel and read the dial indicator. Refer to Crank-

shaft End Play Specification Chart.

OIL PAN 4X2 VEHICLE

REMOVAL

(1) Drain the cooling system. Refer to COOLING

SYSTEM.

(2) Remove the upper fan shroud. Refer to proce-

dure in this section.

(3) Remove the throttle body resonator and air

inlet hose.

(4) Remove the intake manifold. Refer to proce-

dure in this section.

(5) Raise vehicle on hoist.

(6) Disconnect exhaust pipe at exhaust manifolds.

Refer to EXHAUST SYSTEM.

(7) Remove the structural dust cover (Fig. 106).

Refer to procedure in this section.

(8) Drain engine oil and remove oil filter.

(9) Position suitable jack under engine.

Fig. 100 Camshaft Bearing Caps Tightening

Sequence

DN4.7L ENGINE 9 - 61

REMOVAL AND INSTALLATION (Continued)

Page 64 of 193

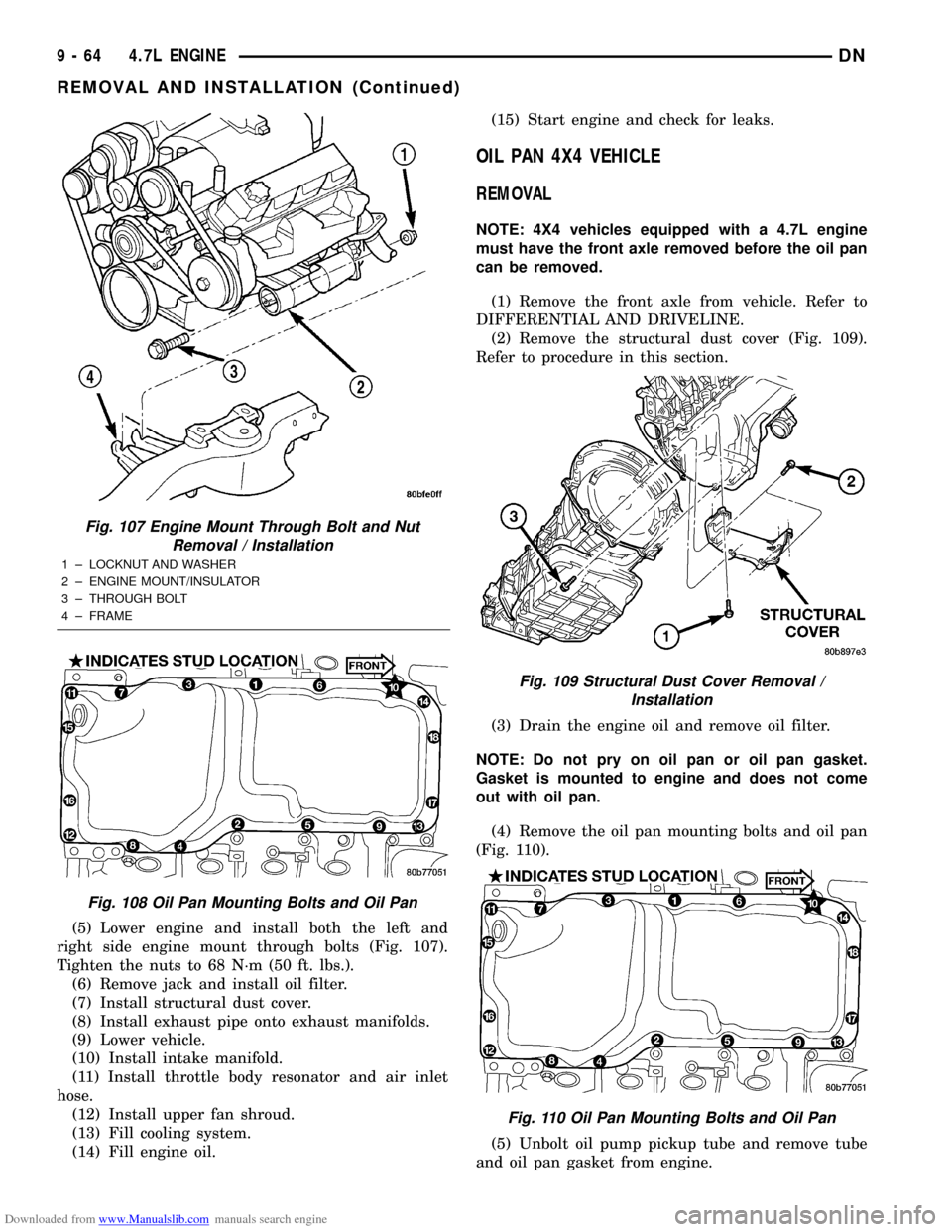

Downloaded from www.Manualslib.com manuals search engine (5) Lower engine and install both the left and

right side engine mount through bolts (Fig. 107).

Tighten the nuts to 68 N´m (50 ft. lbs.).

(6) Remove jack and install oil filter.

(7) Install structural dust cover.

(8) Install exhaust pipe onto exhaust manifolds.

(9) Lower vehicle.

(10) Install intake manifold.

(11) Install throttle body resonator and air inlet

hose.

(12) Install upper fan shroud.

(13) Fill cooling system.

(14) Fill engine oil.(15) Start engine and check for leaks.

OIL PAN 4X4 VEHICLE

REMOVAL

NOTE: 4X4 vehicles equipped with a 4.7L engine

must have the front axle removed before the oil pan

can be removed.

(1) Remove the front axle from vehicle. Refer to

DIFFERENTIAL AND DRIVELINE.

(2) Remove the structural dust cover (Fig. 109).

Refer to procedure in this section.

(3) Drain the engine oil and remove oil filter.

NOTE: Do not pry on oil pan or oil pan gasket.

Gasket is mounted to engine and does not come

out with oil pan.

(4) Remove the oil pan mounting bolts and oil pan

(Fig. 110).

(5) Unbolt oil pump pickup tube and remove tube

and oil pan gasket from engine.

Fig. 107 Engine Mount Through Bolt and Nut

Removal / Installation

1 ± LOCKNUT AND WASHER

2 ± ENGINE MOUNT/INSULATOR

3 ± THROUGH BOLT

4 ± FRAME

Fig. 108 Oil Pan Mounting Bolts and Oil Pan

Fig. 109 Structural Dust Cover Removal /

Installation

Fig. 110 Oil Pan Mounting Bolts and Oil Pan

9 - 64 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 65 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

(1) Clean the oil pan gasket mating surface of the

bedplate and oil pan.

(2) Position the oil pan gasket and pickup tube

with new o-ring. Install the mounting bolt and nuts.

Tighten bolt and nuts to 28 N´m (20 ft. lbs.).

(3) Position the oil pan and install the mounting

bolts. Tighten the mounting bolts to 15 N´m (11 ft.

lbs.) in the sequence shown (Fig. 110).

(4) Install structural dust cover.

(5) Install oil filter.

(6) Install front axle. Refer to DIFFERENTIAL

AND DRIVELINE.

(7) Lower vehicle.

(8) Fill engine oil.

(9) Start engine check for leaks.

PISTON AND CONNECTING ROD

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove the following components: (Refer to

procedures in this section)

²Oil pan and gasket/windage tray.

²Cylinder head covers.

²Timing chain cover.

²Cylinder head(s).

(3) If necessary, remove top ridge of cylinder bores

with a reliable ridge reamer before removing pistons

from cylinder block.Be sure to keep tops of pis-

tons covered during this operation.Pistons and

connecting rods must be removed from top of cylinder

block. When removing piston and connecting rod

assemblies from the engine, rotate crankshaft so the

each connecting rod is centered in cylinder bore.

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods or caps, as damage to

connecting rods could occur

NOTE: Connecting rods and bearing caps are not

interchangeable and should be marked before

removing to ensure correct reassembly.

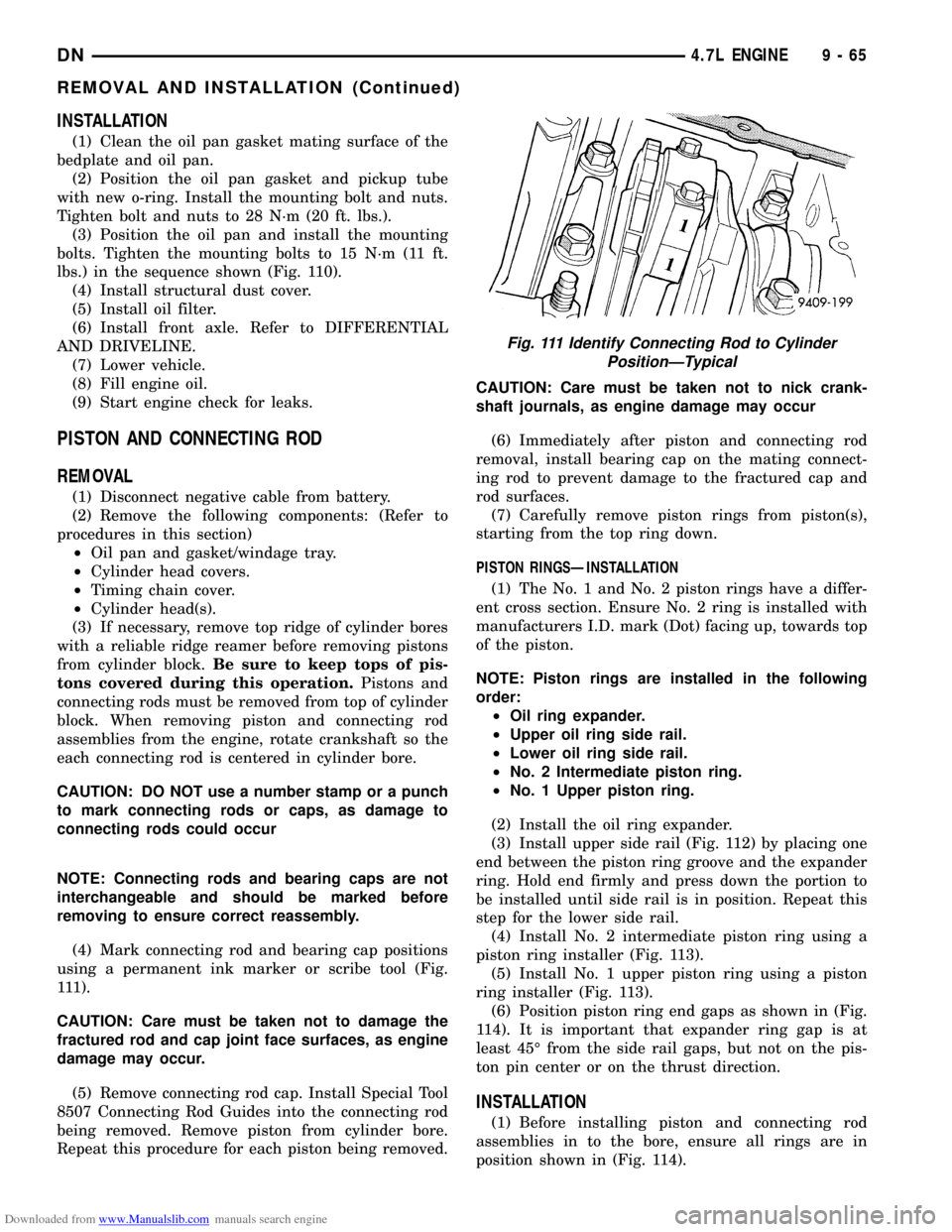

(4) Mark connecting rod and bearing cap positions

using a permanent ink marker or scribe tool (Fig.

111).

CAUTION: Care must be taken not to damage the

fractured rod and cap joint face surfaces, as engine

damage may occur.

(5) Remove connecting rod cap. Install Special Tool

8507 Connecting Rod Guides into the connecting rod

being removed. Remove piston from cylinder bore.

Repeat this procedure for each piston being removed.CAUTION: Care must be taken not to nick crank-

shaft journals, as engine damage may occur

(6) Immediately after piston and connecting rod

removal, install bearing cap on the mating connect-

ing rod to prevent damage to the fractured cap and

rod surfaces.

(7) Carefully remove piston rings from piston(s),

starting from the top ring down.

PISTON RINGSÐINSTALLATION

(1) The No. 1 and No. 2 piston rings have a differ-

ent cross section. Ensure No. 2 ring is installed with

manufacturers I.D. mark (Dot) facing up, towards top

of the piston.

NOTE: Piston rings are installed in the following

order:

²Oil ring expander.

²Upper oil ring side rail.

²Lower oil ring side rail.

²No. 2 Intermediate piston ring.

²No. 1 Upper piston ring.

(2) Install the oil ring expander.

(3) Install upper side rail (Fig. 112) by placing one

end between the piston ring groove and the expander

ring. Hold end firmly and press down the portion to

be installed until side rail is in position. Repeat this

step for the lower side rail.

(4) Install No. 2 intermediate piston ring using a

piston ring installer (Fig. 113).

(5) Install No. 1 upper piston ring using a piston

ring installer (Fig. 113).

(6) Position piston ring end gaps as shown in (Fig.

114). It is important that expander ring gap is at

least 45É from the side rail gaps, but not on the pis-

ton pin center or on the thrust direction.

INSTALLATION

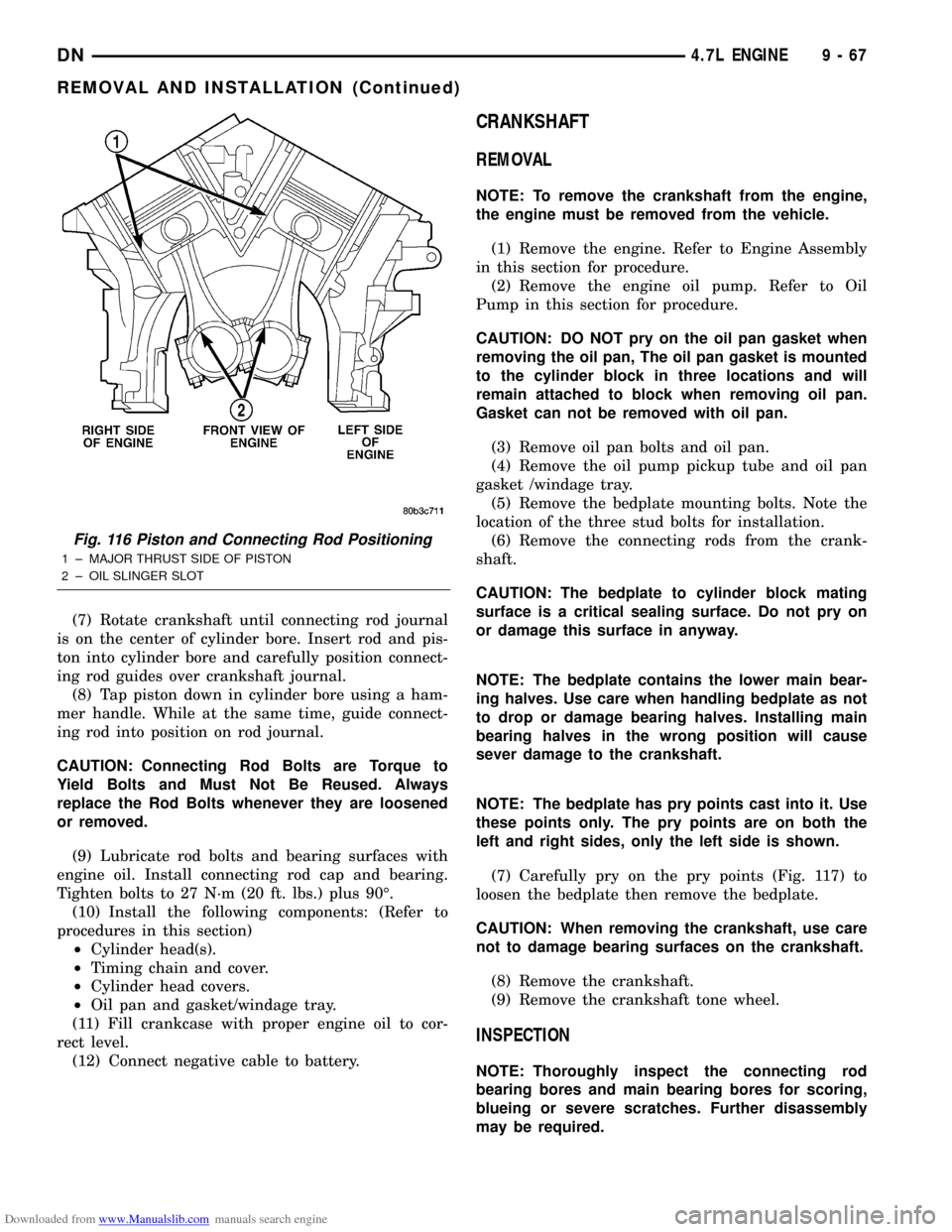

(1) Before installing piston and connecting rod

assemblies in to the bore, ensure all rings are in

position shown in (Fig. 114).

Fig. 111 Identify Connecting Rod to Cylinder

PositionÐTypical

DN4.7L ENGINE 9 - 65

REMOVAL AND INSTALLATION (Continued)

Page 67 of 193

Downloaded from www.Manualslib.com manuals search engine (7) Rotate crankshaft until connecting rod journal

is on the center of cylinder bore. Insert rod and pis-

ton into cylinder bore and carefully position connect-

ing rod guides over crankshaft journal.

(8) Tap piston down in cylinder bore using a ham-

mer handle. While at the same time, guide connect-

ing rod into position on rod journal.

CAUTION: Connecting Rod Bolts are Torque to

Yield Bolts and Must Not Be Reused. Always

replace the Rod Bolts whenever they are loosened

or removed.

(9) Lubricate rod bolts and bearing surfaces with

engine oil. Install connecting rod cap and bearing.

Tighten bolts to 27 N´m (20 ft. lbs.) plus 90É.

(10) Install the following components: (Refer to

procedures in this section)

²Cylinder head(s).

²Timing chain and cover.

²Cylinder head covers.

²Oil pan and gasket/windage tray.

(11) Fill crankcase with proper engine oil to cor-

rect level.

(12) Connect negative cable to battery.

CRANKSHAFT

REMOVAL

NOTE: To remove the crankshaft from the engine,

the engine must be removed from the vehicle.

(1) Remove the engine. Refer to Engine Assembly

in this section for procedure.

(2) Remove the engine oil pump. Refer to Oil

Pump in this section for procedure.

CAUTION: DO NOT pry on the oil pan gasket when

removing the oil pan, The oil pan gasket is mounted

to the cylinder block in three locations and will

remain attached to block when removing oil pan.

Gasket can not be removed with oil pan.

(3) Remove oil pan bolts and oil pan.

(4) Remove the oil pump pickup tube and oil pan

gasket /windage tray.

(5) Remove the bedplate mounting bolts. Note the

location of the three stud bolts for installation.

(6) Remove the connecting rods from the crank-

shaft.

CAUTION: The bedplate to cylinder block mating

surface is a critical sealing surface. Do not pry on

or damage this surface in anyway.

NOTE: The bedplate contains the lower main bear-

ing halves. Use care when handling bedplate as not

to drop or damage bearing halves. Installing main

bearing halves in the wrong position will cause

sever damage to the crankshaft.

NOTE: The bedplate has pry points cast into it. Use

these points only. The pry points are on both the

left and right sides, only the left side is shown.

(7) Carefully pry on the pry points (Fig. 117) to

loosen the bedplate then remove the bedplate.

CAUTION: When removing the crankshaft, use care

not to damage bearing surfaces on the crankshaft.

(8) Remove the crankshaft.

(9) Remove the crankshaft tone wheel.

INSPECTION

NOTE: Thoroughly inspect the connecting rod

bearing bores and main bearing bores for scoring,

blueing or severe scratches. Further disassembly

may be required.

Fig. 116 Piston and Connecting Rod Positioning

1 ± MAJOR THRUST SIDE OF PISTON

2 ± OIL SLINGER SLOT

DN4.7L ENGINE 9 - 67

REMOVAL AND INSTALLATION (Continued)

Page 70 of 193

Downloaded from www.Manualslib.com manuals search engine ENGINE OIL PRESSURE SENDING UNIT

REMOVAL

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Remove front splash shield.

(4) Disconnect oil pressure sender wire (Fig. 125).

(5) Remove the pressure sender (Fig. 125).

INSTALLATION

(1) Install oil pressure sender.

(2) Connect oil pressure sender wire.

(3) Install front splash shield.

(4) Lower vehicle.

(5) Connect the negative battery cable.CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Disconnect negative cable from battery.

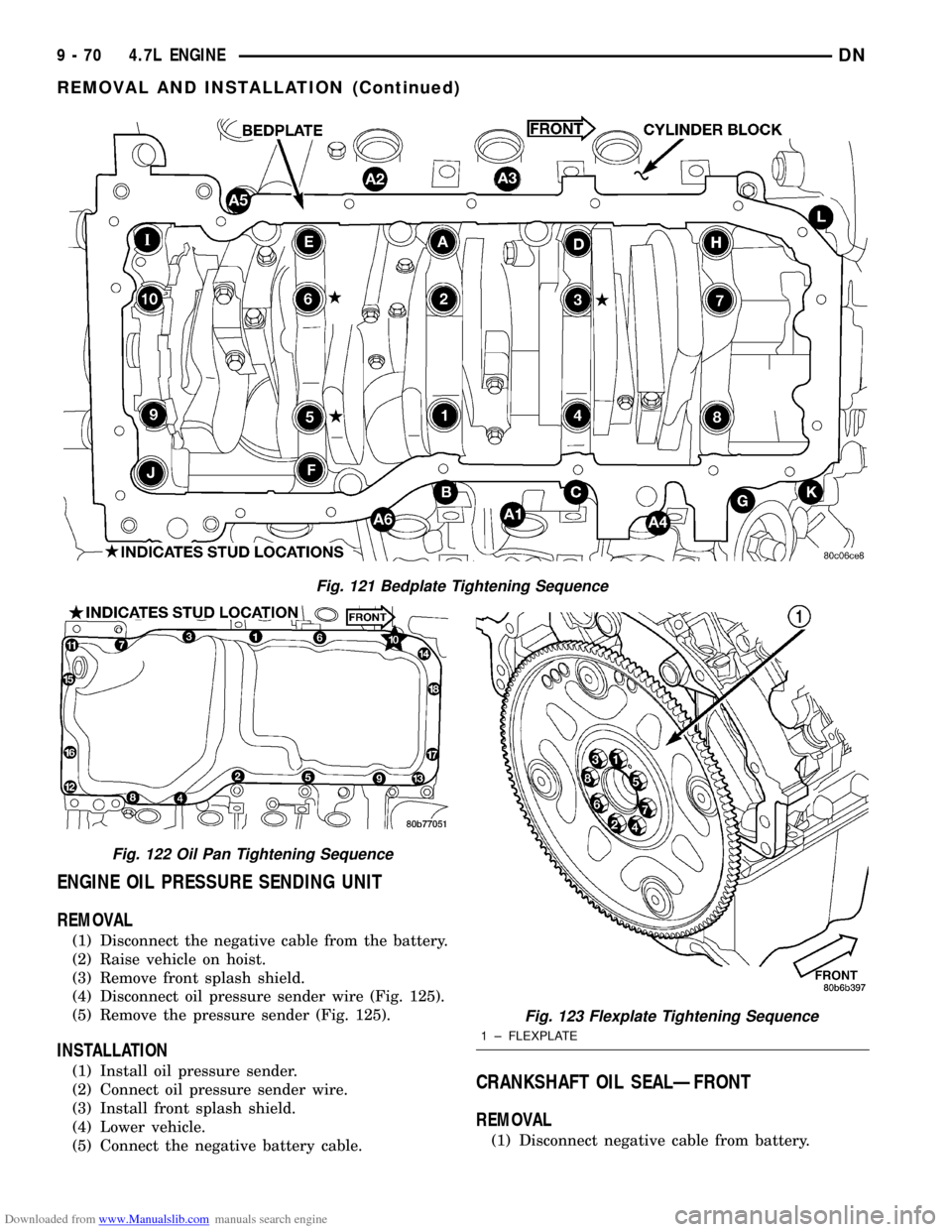

Fig. 121 Bedplate Tightening Sequence

Fig. 122 Oil Pan Tightening Sequence

Fig. 123 Flexplate Tightening Sequence

1 ± FLEXPLATE

9 - 70 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 73 of 193

Downloaded from www.Manualslib.com manuals search engine CRANKSHAFT OIL SEALÐREAR

REMOVAL

NOTE: This procedure can be preformed in vehicle.(1) If being preformed in vehicle, remove the

transmission. Refer to Group 21, Transmission and

Transfer Case.

(2) Remove the flexplate. Refer to procedure in

this section.

NOTE: The crankshaft oil seal CAN NOT be reused

after removal.

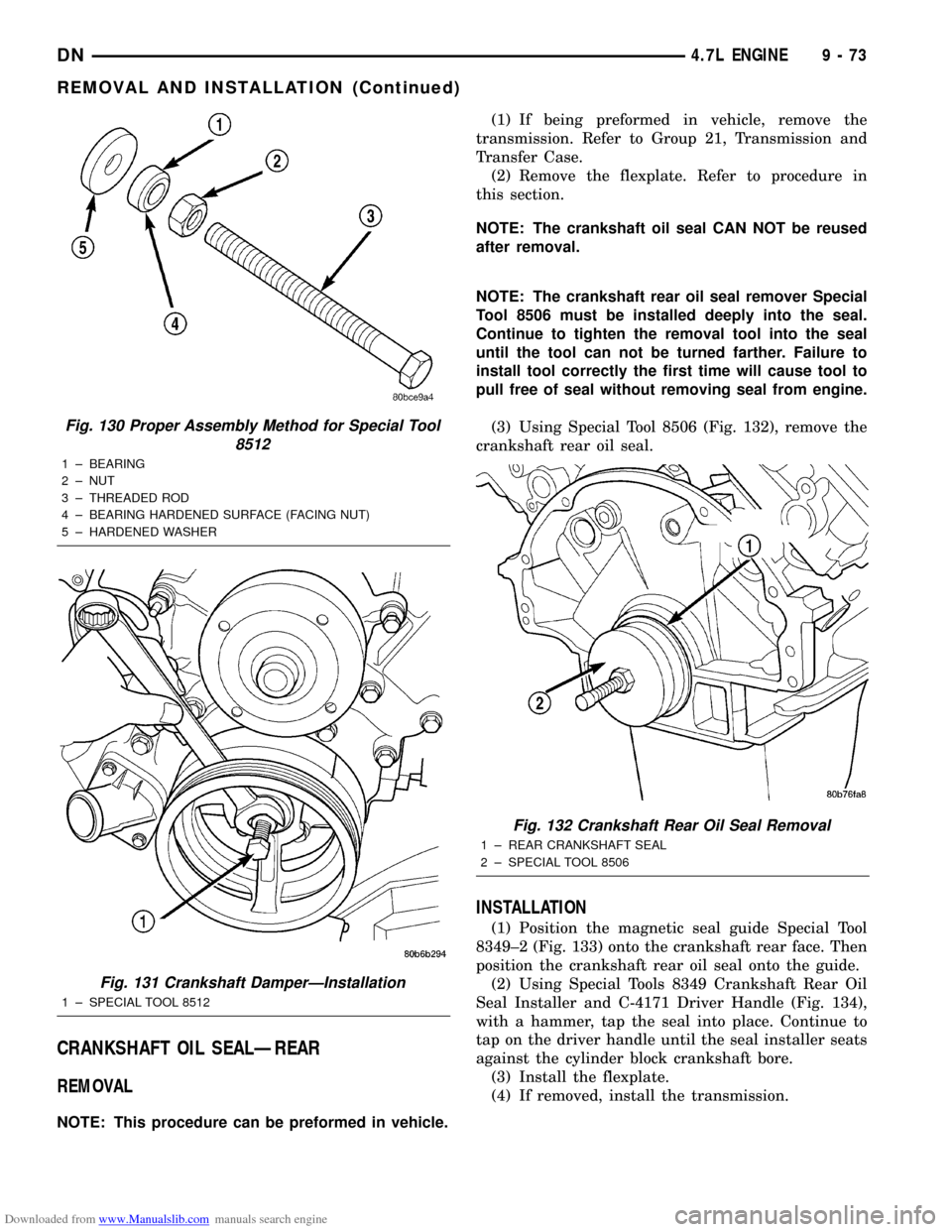

NOTE: The crankshaft rear oil seal remover Special

Tool 8506 must be installed deeply into the seal.

Continue to tighten the removal tool into the seal

until the tool can not be turned farther. Failure to

install tool correctly the first time will cause tool to

pull free of seal without removing seal from engine.

(3) Using Special Tool 8506 (Fig. 132), remove the

crankshaft rear oil seal.

INSTALLATION

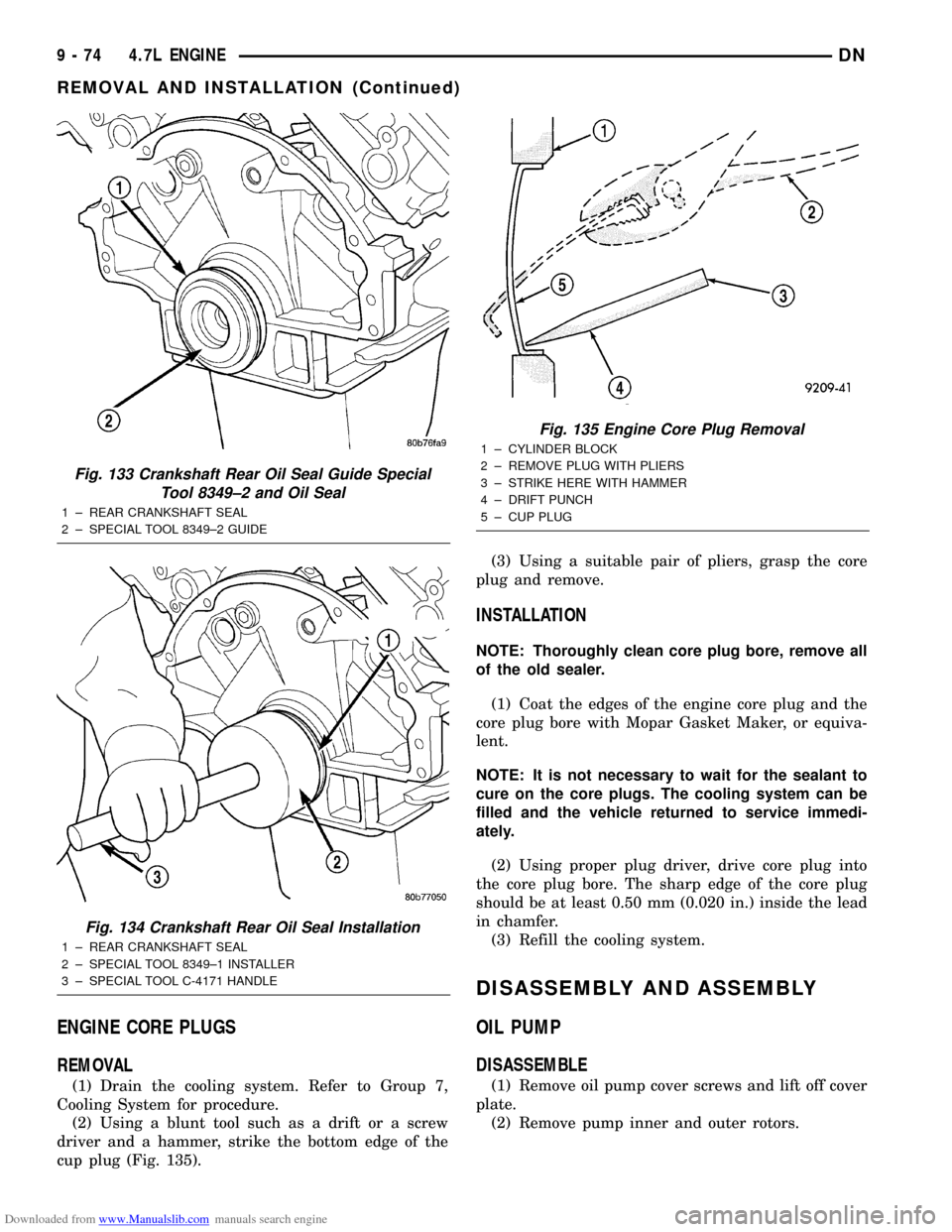

(1) Position the magnetic seal guide Special Tool

8349±2 (Fig. 133) onto the crankshaft rear face. Then

position the crankshaft rear oil seal onto the guide.

(2) Using Special Tools 8349 Crankshaft Rear Oil

Seal Installer and C-4171 Driver Handle (Fig. 134),

with a hammer, tap the seal into place. Continue to

tap on the driver handle until the seal installer seats

against the cylinder block crankshaft bore.

(3) Install the flexplate.

(4) If removed, install the transmission.

Fig. 130 Proper Assembly Method for Special Tool

8512

1 ± BEARING

2 ± NUT

3 ± THREADED ROD

4 ± BEARING HARDENED SURFACE (FACING NUT)

5 ± HARDENED WASHER

Fig. 131 Crankshaft DamperÐInstallation

1 ± SPECIAL TOOL 8512

Fig. 132 Crankshaft Rear Oil Seal Removal

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8506

DN4.7L ENGINE 9 - 73

REMOVAL AND INSTALLATION (Continued)

Page 74 of 193

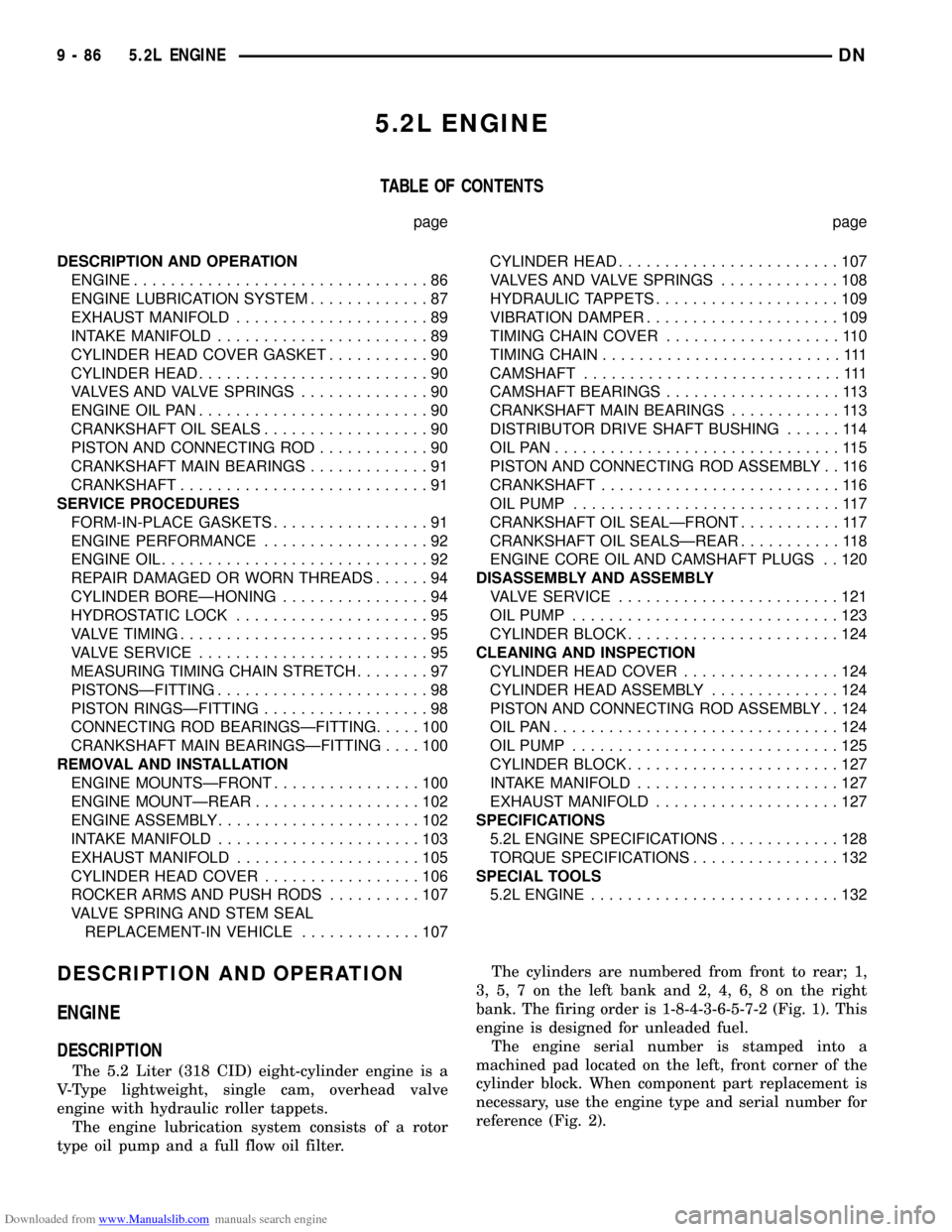

Downloaded from www.Manualslib.com manuals search engine ENGINE CORE PLUGS

REMOVAL

(1) Drain the cooling system. Refer to Group 7,

Cooling System for procedure.

(2) Using a blunt tool such as a drift or a screw

driver and a hammer, strike the bottom edge of the

cup plug (Fig. 135).(3) Using a suitable pair of pliers, grasp the core

plug and remove.

INSTALLATION

NOTE: Thoroughly clean core plug bore, remove all

of the old sealer.

(1) Coat the edges of the engine core plug and the

core plug bore with Mopar Gasket Maker, or equiva-

lent.

NOTE: It is not necessary to wait for the sealant to

cure on the core plugs. The cooling system can be

filled and the vehicle returned to service immedi-

ately.

(2) Using proper plug driver, drive core plug into

the core plug bore. The sharp edge of the core plug

should be at least 0.50 mm (0.020 in.) inside the lead

in chamfer.

(3) Refill the cooling system.

DISASSEMBLY AND ASSEMBLY

OIL PUMP

DISASSEMBLE

(1) Remove oil pump cover screws and lift off cover

plate.

(2) Remove pump inner and outer rotors.

Fig. 133 Crankshaft Rear Oil Seal Guide Special

Tool 8349±2 and Oil Seal

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8349±2 GUIDE

Fig. 134 Crankshaft Rear Oil Seal Installation

1 ± REAR CRANKSHAFT SEAL

2 ± SPECIAL TOOL 8349±1 INSTALLER

3 ± SPECIAL TOOL C-4171 HANDLE

Fig. 135 Engine Core Plug Removal

1 ± CYLINDER BLOCK

2 ± REMOVE PLUG WITH PLIERS

3 ± STRIKE HERE WITH HAMMER

4 ± DRIFT PUNCH

5 ± CUP PLUG

9 - 74 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 86 of 193

Downloaded from www.Manualslib.com manuals search engine 5.2L ENGINE

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

ENGINE................................86

ENGINE LUBRICATION SYSTEM.............87

EXHAUST MANIFOLD.....................89

INTAKE MANIFOLD.......................89

CYLINDER HEAD COVER GASKET...........90

CYLINDER HEAD.........................90

VALVES AND VALVE SPRINGS..............90

ENGINE OIL PAN.........................90

CRANKSHAFT OIL SEALS..................90

PISTON AND CONNECTING ROD............90

CRANKSHAFT MAIN BEARINGS.............91

CRANKSHAFT...........................91

SERVICE PROCEDURES

FORM-IN-PLACE GASKETS.................91

ENGINE PERFORMANCE..................92

ENGINE OIL.............................92

REPAIR DAMAGED OR WORN THREADS......94

CYLINDER BOREÐHONING................94

HYDROSTATIC LOCK.....................95

VALVE TIMING...........................95

VALVE SERVICE.........................95

MEASURING TIMING CHAIN STRETCH........97

PISTONSÐFITTING.......................98

PISTON RINGSÐFITTING..................98

CONNECTING ROD BEARINGSÐFITTING.....100

CRANKSHAFT MAIN BEARINGSÐFITTING....100

REMOVAL AND INSTALLATION

ENGINE MOUNTSÐFRONT................100

ENGINE MOUNTÐREAR..................102

ENGINE ASSEMBLY......................102

INTAKE MANIFOLD......................103

EXHAUST MANIFOLD....................105

CYLINDER HEAD COVER.................106

ROCKER ARMS AND PUSH RODS..........107

VALVE SPRING AND STEM SEAL

REPLACEMENT-IN VEHICLE.............107CYLINDER HEAD........................107

VALVES AND VALVE SPRINGS.............108

HYDRAULIC TAPPETS....................109

VIBRATION DAMPER.....................109

TIMING CHAIN COVER...................110

TIMING CHAIN..........................111

CAMSHAFT............................111

CAMSHAFT BEARINGS...................113

CRANKSHAFT MAIN BEARINGS............113

DISTRIBUTOR DRIVE SHAFT BUSHING......114

OILPAN...............................115

PISTON AND CONNECTING ROD ASSEMBLY . . 116

CRANKSHAFT..........................116

OIL PUMP.............................117

CRANKSHAFT OIL SEALÐFRONT...........117

CRANKSHAFT OIL SEALSÐREAR...........118

ENGINE CORE OIL AND CAMSHAFT PLUGS . . 120

DISASSEMBLY AND ASSEMBLY

VALVE SERVICE........................121

OIL PUMP.............................123

CYLINDER BLOCK.......................124

CLEANING AND INSPECTION

CYLINDER HEAD COVER.................124

CYLINDER HEAD ASSEMBLY..............124

PISTON AND CONNECTING ROD ASSEMBLY . . 124

OILPAN...............................124

OIL PUMP.............................125

CYLINDER BLOCK.......................127

INTAKE MANIFOLD......................127

EXHAUST MANIFOLD....................127

SPECIFICATIONS

5.2L ENGINE SPECIFICATIONS.............128

TORQUE SPECIFICATIONS................132

SPECIAL TOOLS

5.2L ENGINE...........................132

DESCRIPTION AND OPERATION

ENGINE

DESCRIPTION

The 5.2 Liter (318 CID) eight-cylinder engine is a

V-Type lightweight, single cam, overhead valve

engine with hydraulic roller tappets.

The engine lubrication system consists of a rotor

type oil pump and a full flow oil filter.The cylinders are numbered from front to rear; 1,

3, 5, 7 on the left bank and 2, 4, 6, 8 on the right

bank. The firing order is 1-8-4-3-6-5-7-2 (Fig. 1). This

engine is designed for unleaded fuel.

The engine serial number is stamped into a

machined pad located on the left, front corner of the

cylinder block. When component part replacement is

necessary, use the engine type and serial number for

reference (Fig. 2).

9 - 86 5.2L ENGINEDN