DODGE DURANGO 1998 1.G Owner's Guide

Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 31 of 193

Downloaded from www.Manualslib.com manuals search engine ENGINE ASSEMBLY

REMOVAL

NOTE: This procedure applies to both the 4X2 and

4X4 vehicles, steps that apply to the 4X4 vehicle

only, are identified.

(1) Disconnect the battery negative and positive

cables.

(2) Remove the battery and the battery tray. Refer

to BATTERY.

(3) Raise vehicle on hoist.

(4) Remove exhaust crossover pipe from exhaust

manifolds. Refer to EXHAUST SYSTEM.

(5)4X4 vehiclesDisconnect axle vent tube from

left side engine mount.

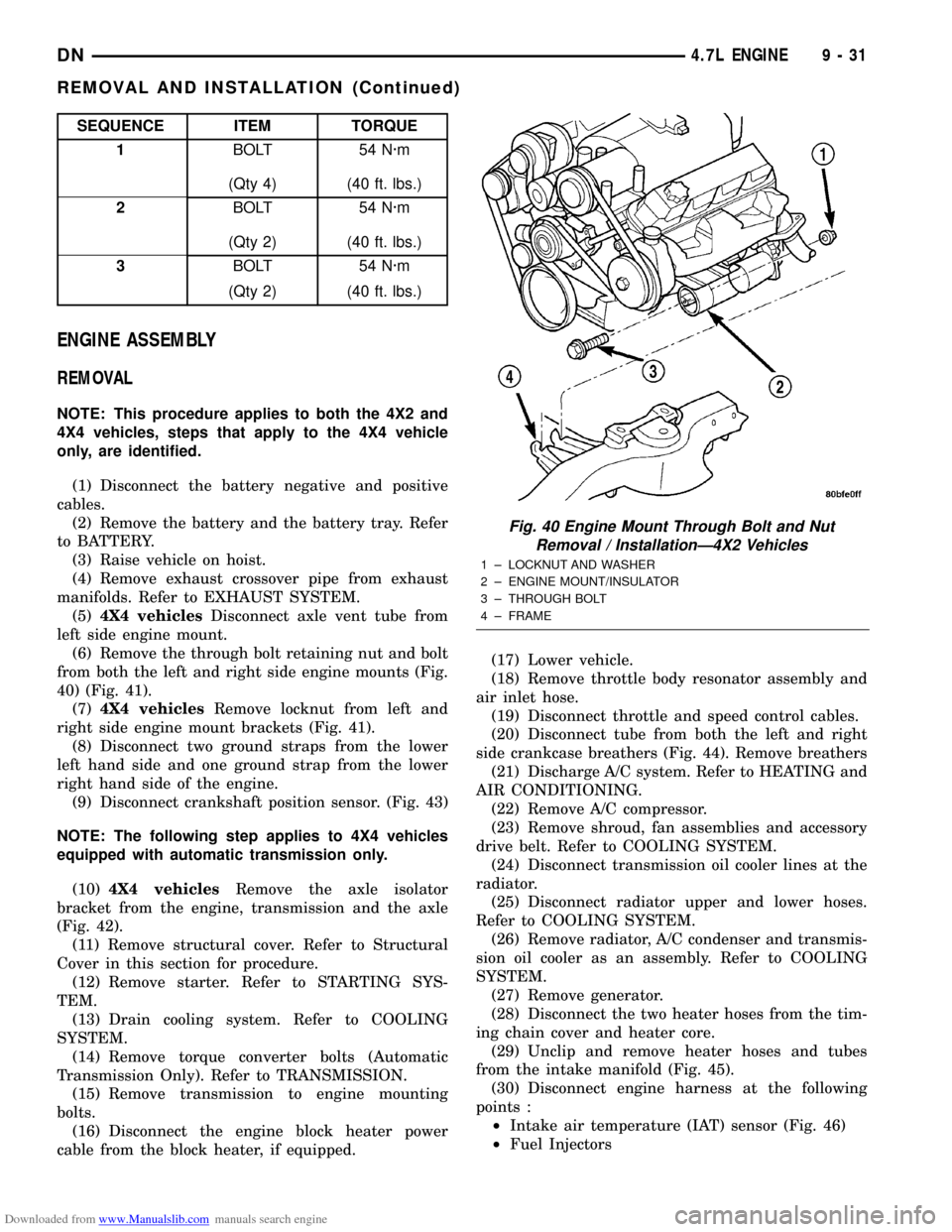

(6) Remove the through bolt retaining nut and bolt

from both the left and right side engine mounts (Fig.

40) (Fig. 41).

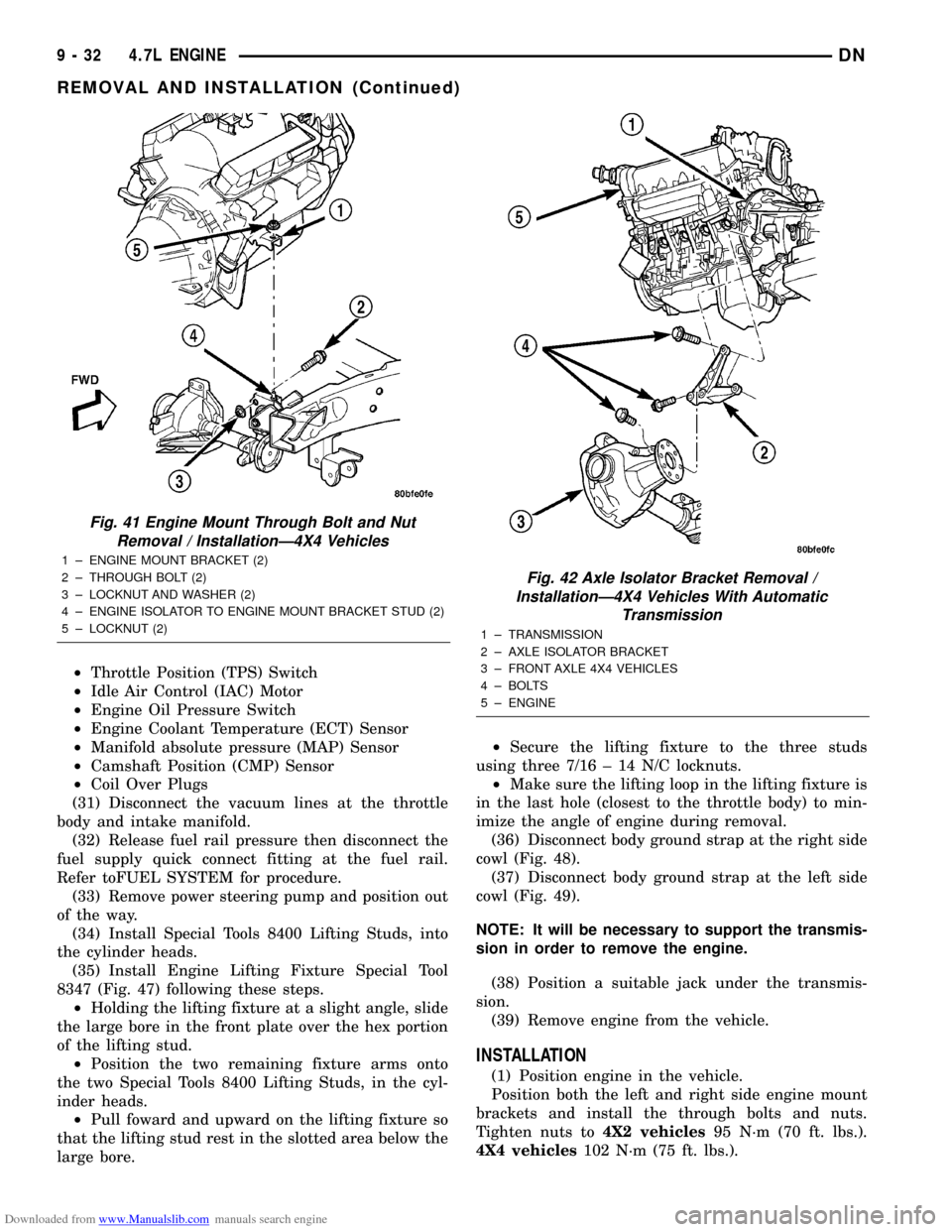

(7)4X4 vehiclesRemove locknut from left and

right side engine mount brackets (Fig. 41).

(8) Disconnect two ground straps from the lower

left hand side and one ground strap from the lower

right hand side of the engine.

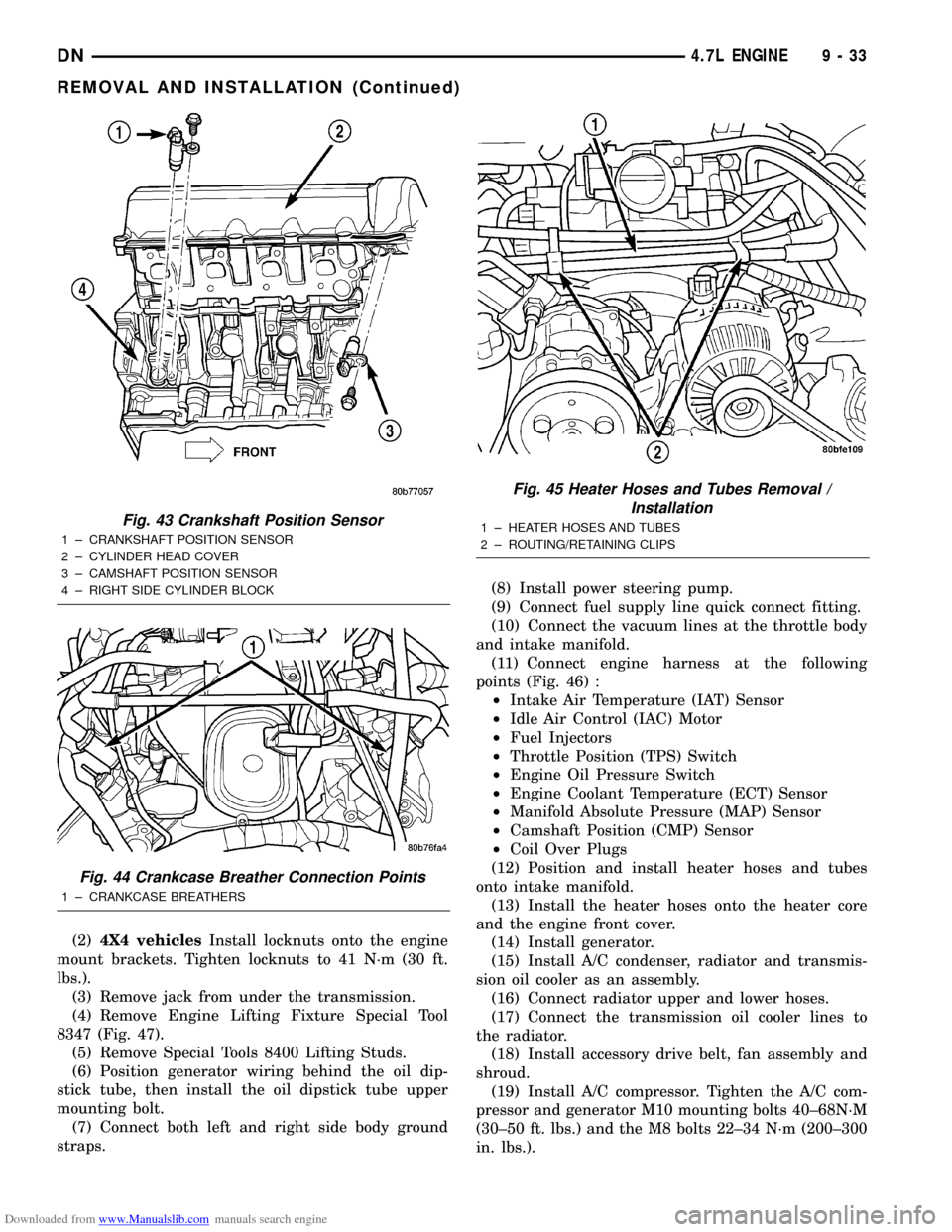

(9) Disconnect crankshaft position sensor. (Fig. 43)

NOTE: The following step applies to 4X4 vehicles

equipped with automatic transmission only.

(10)4X4 vehiclesRemove the axle isolator

bracket from the engine, transmission and the axle

(Fig. 42).

(11) Remove structural cover. Refer to Structural

Cover in this section for procedure.

(12) Remove starter. Refer to STARTING SYS-

TEM.

(13) Drain cooling system. Refer to COOLING

SYSTEM.

(14) Remove torque converter bolts (Automatic

Transmission Only). Refer to TRANSMISSION.

(15) Remove transmission to engine mounting

bolts.

(16) Disconnect the engine block heater power

cable from the block heater, if equipped.(17) Lower vehicle.

(18) Remove throttle body resonator assembly and

air inlet hose.

(19) Disconnect throttle and speed control cables.

(20) Disconnect tube from both the left and right

side crankcase breathers (Fig. 44). Remove breathers

(21) Discharge A/C system. Refer to HEATING and

AIR CONDITIONING.

(22) Remove A/C compressor.

(23) Remove shroud, fan assemblies and accessory

drive belt. Refer to COOLING SYSTEM.

(24) Disconnect transmission oil cooler lines at the

radiator.

(25) Disconnect radiator upper and lower hoses.

Refer to COOLING SYSTEM.

(26) Remove radiator, A/C condenser and transmis-

sion oil cooler as an assembly. Refer to COOLING

SYSTEM.

(27) Remove generator.

(28) Disconnect the two heater hoses from the tim-

ing chain cover and heater core.

(29) Unclip and remove heater hoses and tubes

from the intake manifold (Fig. 45).

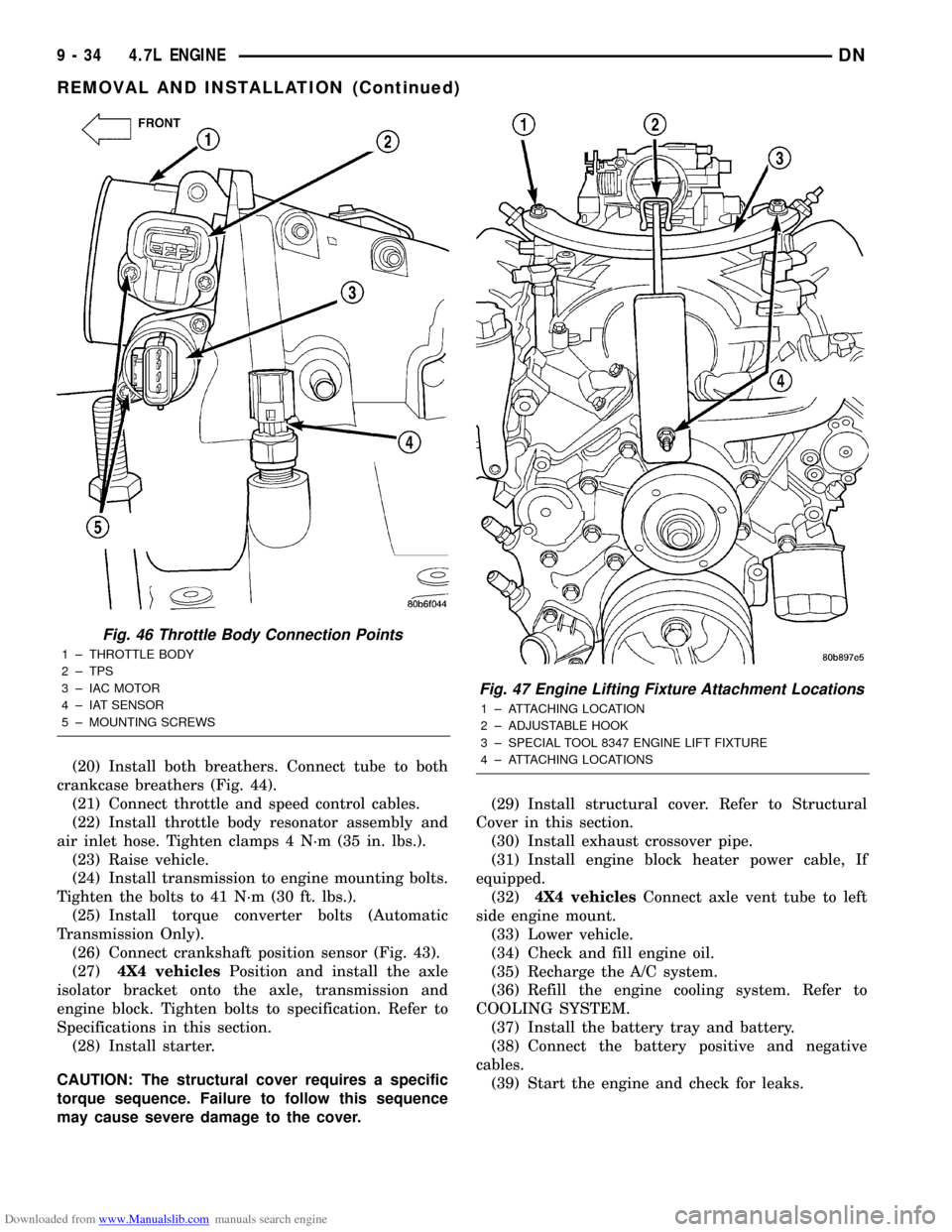

(30) Disconnect engine harness at the following

points :

²Intake air temperature (IAT) sensor (Fig. 46)

²Fuel Injectors

SEQUENCE ITEM TORQUE

1BOLT 54 N´m

(Qty 4) (40 ft. lbs.)

2BOLT 54 N´m

(Qty 2) (40 ft. lbs.)

3BOLT 54 N´m

(Qty 2) (40 ft. lbs.)

Fig. 40 Engine Mount Through Bolt and Nut

Removal / InstallationÐ4X2 Vehicles

1 ± LOCKNUT AND WASHER

2 ± ENGINE MOUNT/INSULATOR

3 ± THROUGH BOLT

4 ± FRAME

DN4.7L ENGINE 9 - 31

REMOVAL AND INSTALLATION (Continued)

Page 32 of 193

Downloaded from www.Manualslib.com manuals search engine ²Throttle Position (TPS) Switch

²Idle Air Control (IAC) Motor

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold absolute pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(31) Disconnect the vacuum lines at the throttle

body and intake manifold.

(32) Release fuel rail pressure then disconnect the

fuel supply quick connect fitting at the fuel rail.

Refer toFUEL SYSTEM for procedure.

(33) Remove power steering pump and position out

of the way.

(34) Install Special Tools 8400 Lifting Studs, into

the cylinder heads.

(35) Install Engine Lifting Fixture Special Tool

8347 (Fig. 47) following these steps.

²Holding the lifting fixture at a slight angle, slide

the large bore in the front plate over the hex portion

of the lifting stud.

²Position the two remaining fixture arms onto

the two Special Tools 8400 Lifting Studs, in the cyl-

inder heads.

²Pull foward and upward on the lifting fixture so

that the lifting stud rest in the slotted area below the

large bore.²Secure the lifting fixture to the three studs

using three 7/16 ± 14 N/C locknuts.

²Make sure the lifting loop in the lifting fixture is

in the last hole (closest to the throttle body) to min-

imize the angle of engine during removal.

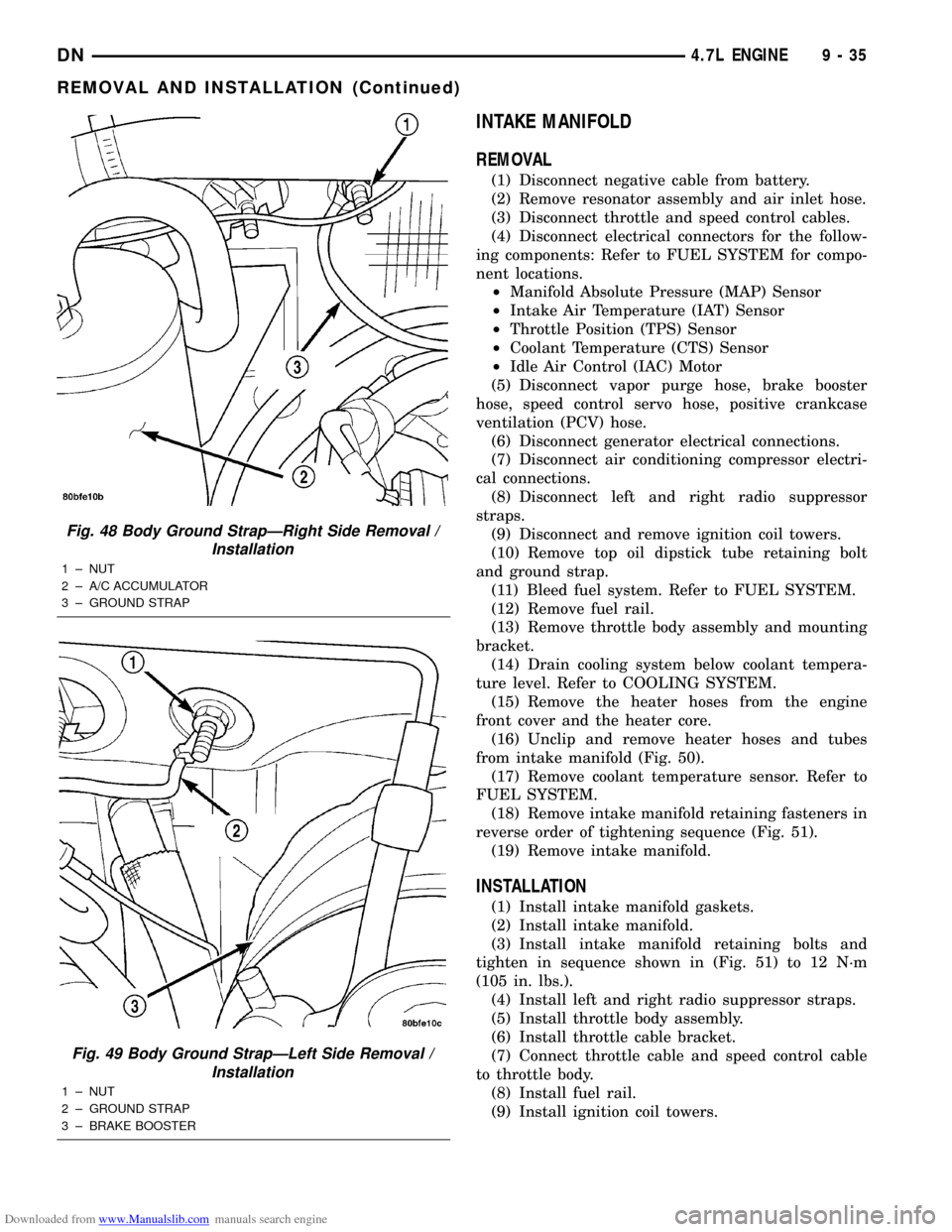

(36) Disconnect body ground strap at the right side

cowl (Fig. 48).

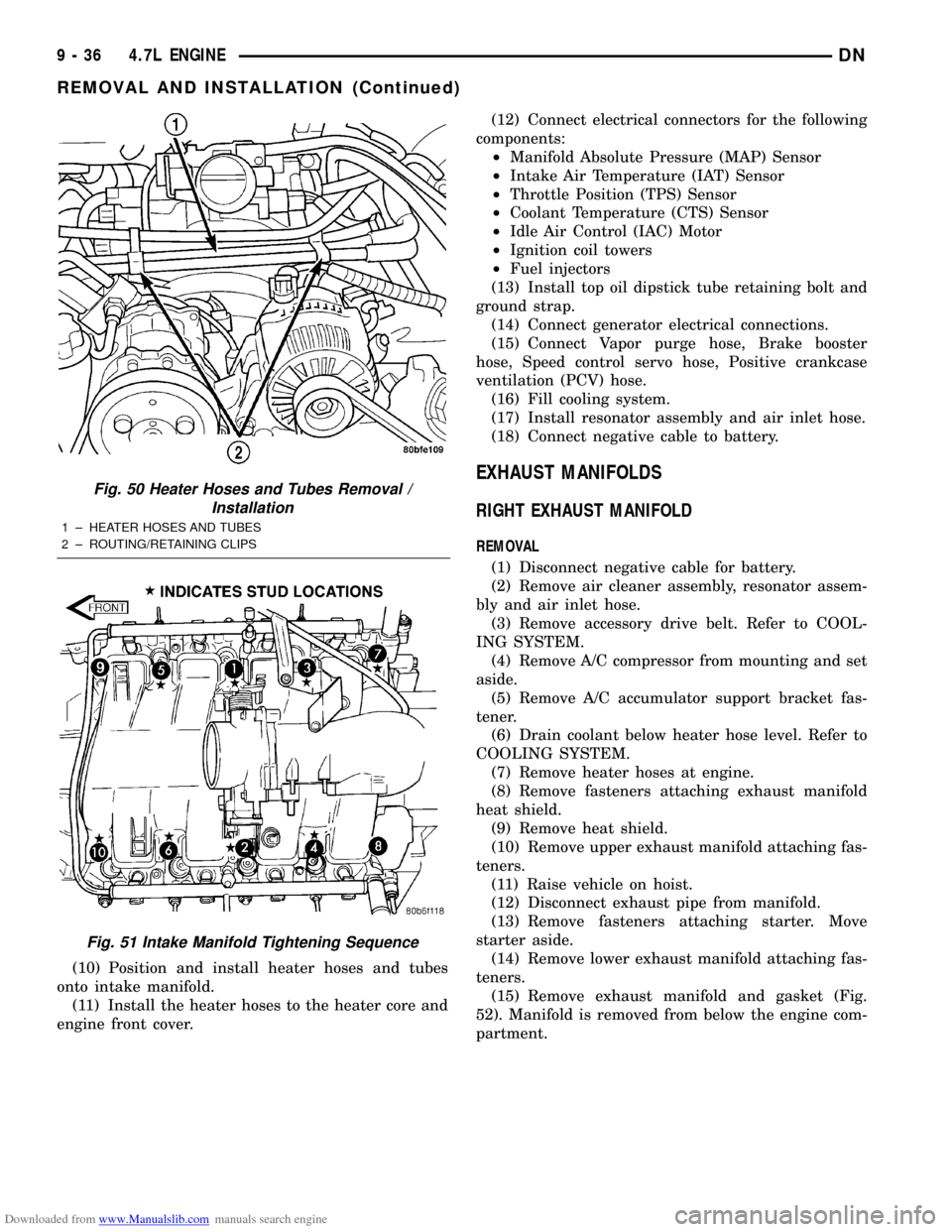

(37) Disconnect body ground strap at the left side

cowl (Fig. 49).

NOTE: It will be necessary to support the transmis-

sion in order to remove the engine.

(38) Position a suitable jack under the transmis-

sion.

(39) Remove engine from the vehicle.

INSTALLATION

(1) Position engine in the vehicle.

Position both the left and right side engine mount

brackets and install the through bolts and nuts.

Tighten nuts to4X2 vehicles95 N´m (70 ft. lbs.).

4X4 vehicles102 N´m (75 ft. lbs.).

Fig. 41 Engine Mount Through Bolt and Nut

Removal / InstallationÐ4X4 Vehicles

1 ± ENGINE MOUNT BRACKET (2)

2 ± THROUGH BOLT (2)

3 ± LOCKNUT AND WASHER (2)

4 ± ENGINE ISOLATOR TO ENGINE MOUNT BRACKET STUD (2)

5 ± LOCKNUT (2)

Fig. 42 Axle Isolator Bracket Removal /

InstallationÐ4X4 Vehicles With Automatic

Transmission

1 ± TRANSMISSION

2 ± AXLE ISOLATOR BRACKET

3 ± FRONT AXLE 4X4 VEHICLES

4 ± BOLTS

5 ± ENGINE

9 - 32 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 33 of 193

Downloaded from www.Manualslib.com manuals search engine (2)4X4 vehiclesInstall locknuts onto the engine

mount brackets. Tighten locknuts to 41 N´m (30 ft.

lbs.).

(3) Remove jack from under the transmission.

(4) Remove Engine Lifting Fixture Special Tool

8347 (Fig. 47).

(5) Remove Special Tools 8400 Lifting Studs.

(6) Position generator wiring behind the oil dip-

stick tube, then install the oil dipstick tube upper

mounting bolt.

(7) Connect both left and right side body ground

straps.(8) Install power steering pump.

(9) Connect fuel supply line quick connect fitting.

(10) Connect the vacuum lines at the throttle body

and intake manifold.

(11) Connect engine harness at the following

points (Fig. 46) :

²Intake Air Temperature (IAT) Sensor

²Idle Air Control (IAC) Motor

²Fuel Injectors

²Throttle Position (TPS) Switch

²Engine Oil Pressure Switch

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Camshaft Position (CMP) Sensor

²Coil Over Plugs

(12) Position and install heater hoses and tubes

onto intake manifold.

(13) Install the heater hoses onto the heater core

and the engine front cover.

(14) Install generator.

(15) Install A/C condenser, radiator and transmis-

sion oil cooler as an assembly.

(16) Connect radiator upper and lower hoses.

(17) Connect the transmission oil cooler lines to

the radiator.

(18) Install accessory drive belt, fan assembly and

shroud.

(19) Install A/C compressor. Tighten the A/C com-

pressor and generator M10 mounting bolts 40±68N´M

(30±50 ft. lbs.) and the M8 bolts 22±34 N´m (200±300

in. lbs.).

Fig. 43 Crankshaft Position Sensor

1 ± CRANKSHAFT POSITION SENSOR

2 ± CYLINDER HEAD COVER

3 ± CAMSHAFT POSITION SENSOR

4 ± RIGHT SIDE CYLINDER BLOCK

Fig. 44 Crankcase Breather Connection Points

1 ± CRANKCASE BREATHERS

Fig. 45 Heater Hoses and Tubes Removal /

Installation

1 ± HEATER HOSES AND TUBES

2 ± ROUTING/RETAINING CLIPS

DN4.7L ENGINE 9 - 33

REMOVAL AND INSTALLATION (Continued)

Page 34 of 193

Downloaded from www.Manualslib.com manuals search engine (20) Install both breathers. Connect tube to both

crankcase breathers (Fig. 44).

(21) Connect throttle and speed control cables.

(22) Install throttle body resonator assembly and

air inlet hose. Tighten clamps 4 N´m (35 in. lbs.).

(23) Raise vehicle.

(24) Install transmission to engine mounting bolts.

Tighten the bolts to 41 N´m (30 ft. lbs.).

(25) Install torque converter bolts (Automatic

Transmission Only).

(26) Connect crankshaft position sensor (Fig. 43).

(27)4X4 vehiclesPosition and install the axle

isolator bracket onto the axle, transmission and

engine block. Tighten bolts to specification. Refer to

Specifications in this section.

(28) Install starter.

CAUTION: The structural cover requires a specific

torque sequence. Failure to follow this sequence

may cause severe damage to the cover.(29) Install structural cover. Refer to Structural

Cover in this section.

(30) Install exhaust crossover pipe.

(31) Install engine block heater power cable, If

equipped.

(32)4X4 vehiclesConnect axle vent tube to left

side engine mount.

(33) Lower vehicle.

(34) Check and fill engine oil.

(35) Recharge the A/C system.

(36) Refill the engine cooling system. Refer to

COOLING SYSTEM.

(37) Install the battery tray and battery.

(38) Connect the battery positive and negative

cables.

(39) Start the engine and check for leaks.

Fig. 46 Throttle Body Connection Points

1 ± THROTTLE BODY

2 ± TPS

3 ± IAC MOTOR

4 ± IAT SENSOR

5 ± MOUNTING SCREWS

Fig. 47 Engine Lifting Fixture Attachment Locations

1 ± ATTACHING LOCATION

2 ± ADJUSTABLE HOOK

3 ± SPECIAL TOOL 8347 ENGINE LIFT FIXTURE

4 ± ATTACHING LOCATIONS

9 - 34 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 35 of 193

Downloaded from www.Manualslib.com manuals search engine INTAKE MANIFOLD

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove resonator assembly and air inlet hose.

(3) Disconnect throttle and speed control cables.

(4) Disconnect electrical connectors for the follow-

ing components: Refer to FUEL SYSTEM for compo-

nent locations.

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

(5) Disconnect vapor purge hose, brake booster

hose, speed control servo hose, positive crankcase

ventilation (PCV) hose.

(6) Disconnect generator electrical connections.

(7) Disconnect air conditioning compressor electri-

cal connections.

(8) Disconnect left and right radio suppressor

straps.

(9) Disconnect and remove ignition coil towers.

(10) Remove top oil dipstick tube retaining bolt

and ground strap.

(11) Bleed fuel system. Refer to FUEL SYSTEM.

(12) Remove fuel rail.

(13) Remove throttle body assembly and mounting

bracket.

(14) Drain cooling system below coolant tempera-

ture level. Refer to COOLING SYSTEM.

(15) Remove the heater hoses from the engine

front cover and the heater core.

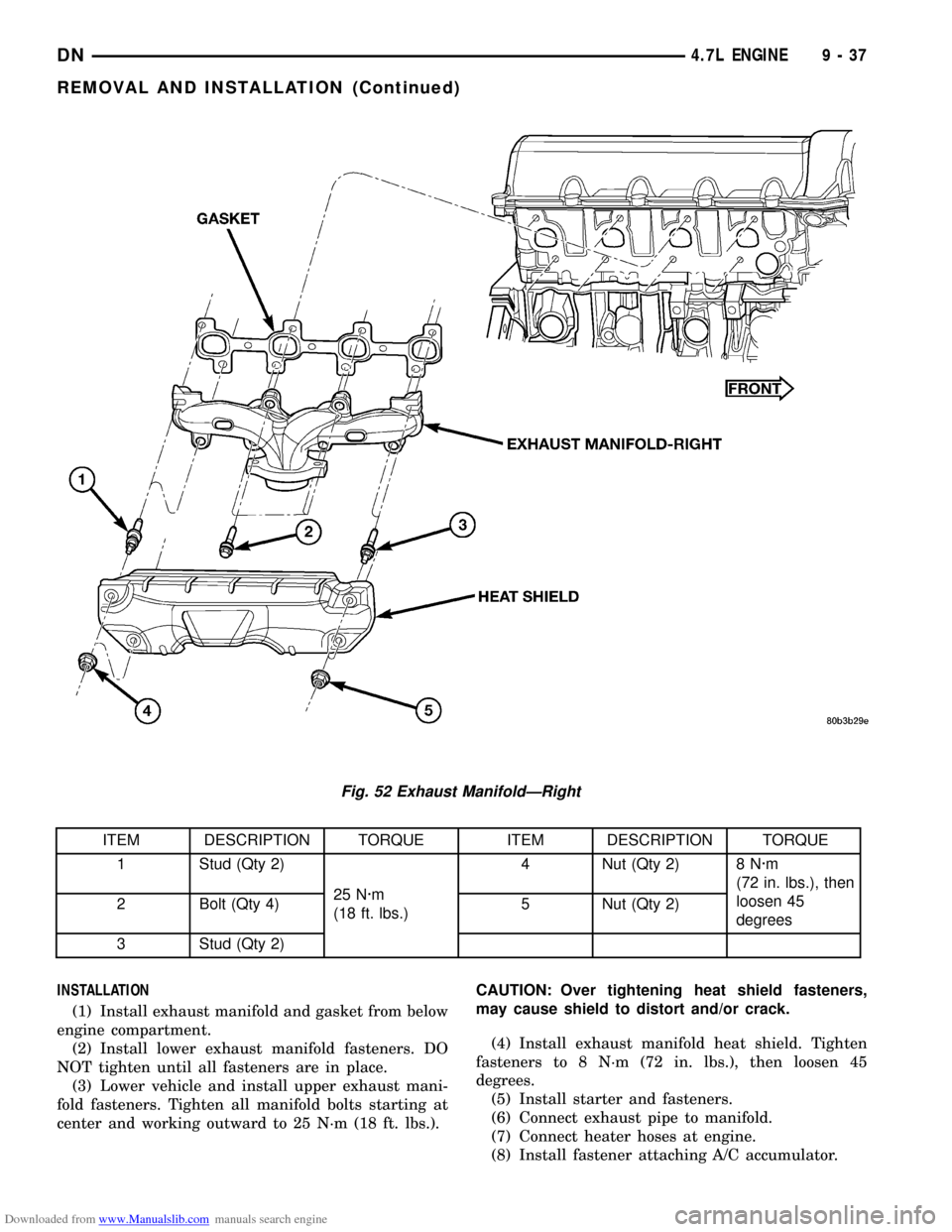

(16) Unclip and remove heater hoses and tubes

from intake manifold (Fig. 50).

(17) Remove coolant temperature sensor. Refer to

FUEL SYSTEM.

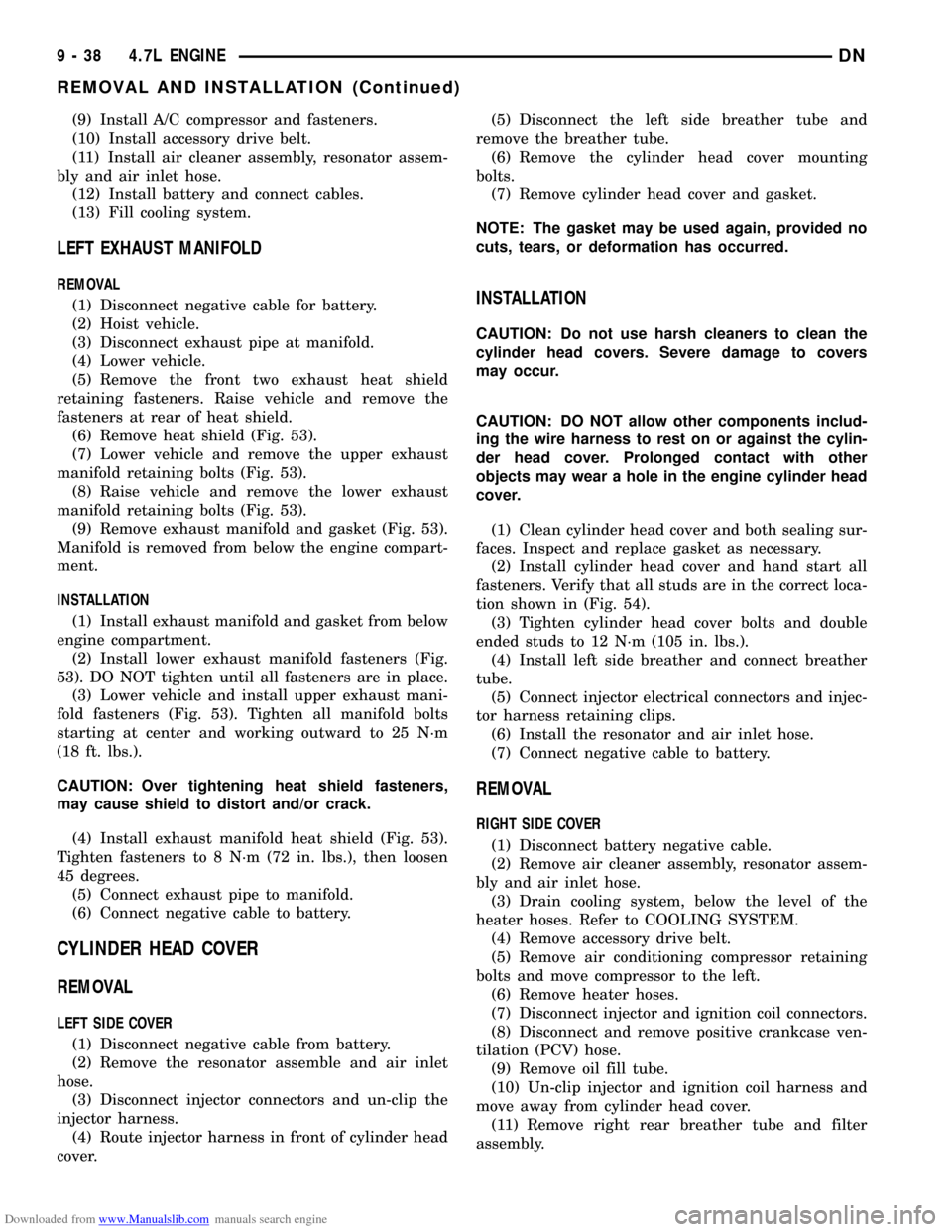

(18) Remove intake manifold retaining fasteners in

reverse order of tightening sequence (Fig. 51).

(19) Remove intake manifold.

INSTALLATION

(1) Install intake manifold gaskets.

(2) Install intake manifold.

(3) Install intake manifold retaining bolts and

tighten in sequence shown in (Fig. 51) to 12 N´m

(105 in. lbs.).

(4) Install left and right radio suppressor straps.

(5) Install throttle body assembly.

(6) Install throttle cable bracket.

(7) Connect throttle cable and speed control cable

to throttle body.

(8) Install fuel rail.

(9) Install ignition coil towers.

Fig. 48 Body Ground StrapÐRight Side Removal /

Installation

1 ± NUT

2 ± A/C ACCUMULATOR

3 ± GROUND STRAP

Fig. 49 Body Ground StrapÐLeft Side Removal /

Installation

1 ± NUT

2 ± GROUND STRAP

3 ± BRAKE BOOSTER

DN4.7L ENGINE 9 - 35

REMOVAL AND INSTALLATION (Continued)

Page 36 of 193

Downloaded from www.Manualslib.com manuals search engine (10) Position and install heater hoses and tubes

onto intake manifold.

(11) Install the heater hoses to the heater core and

engine front cover.(12) Connect electrical connectors for the following

components:

²Manifold Absolute Pressure (MAP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Coolant Temperature (CTS) Sensor

²Idle Air Control (IAC) Motor

²Ignition coil towers

²Fuel injectors

(13) Install top oil dipstick tube retaining bolt and

ground strap.

(14) Connect generator electrical connections.

(15) Connect Vapor purge hose, Brake booster

hose, Speed control servo hose, Positive crankcase

ventilation (PCV) hose.

(16) Fill cooling system.

(17) Install resonator assembly and air inlet hose.

(18) Connect negative cable to battery.

EXHAUST MANIFOLDS

RIGHT EXHAUST MANIFOLD

REMOVAL

(1) Disconnect negative cable for battery.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Remove accessory drive belt. Refer to COOL-

ING SYSTEM.

(4) Remove A/C compressor from mounting and set

aside.

(5) Remove A/C accumulator support bracket fas-

tener.

(6) Drain coolant below heater hose level. Refer to

COOLING SYSTEM.

(7) Remove heater hoses at engine.

(8) Remove fasteners attaching exhaust manifold

heat shield.

(9) Remove heat shield.

(10) Remove upper exhaust manifold attaching fas-

teners.

(11) Raise vehicle on hoist.

(12) Disconnect exhaust pipe from manifold.

(13) Remove fasteners attaching starter. Move

starter aside.

(14) Remove lower exhaust manifold attaching fas-

teners.

(15) Remove exhaust manifold and gasket (Fig.

52). Manifold is removed from below the engine com-

partment.

Fig. 50 Heater Hoses and Tubes Removal /

Installation

1 ± HEATER HOSES AND TUBES

2 ± ROUTING/RETAINING CLIPS

Fig. 51 Intake Manifold Tightening Sequence

9 - 36 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 37 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners. DO

NOT tighten until all fasteners are in place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners. Tighten all manifold bolts starting at

center and working outward to 25 N´m (18 ft. lbs.).CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield. Tighten

fasteners to 8 N´m (72 in. lbs.), then loosen 45

degrees.

(5) Install starter and fasteners.

(6) Connect exhaust pipe to manifold.

(7) Connect heater hoses at engine.

(8) Install fastener attaching A/C accumulator.

Fig. 52 Exhaust ManifoldÐRight

ITEM DESCRIPTION TORQUE ITEM DESCRIPTION TORQUE

1 Stud (Qty 2)

25 N´m

(18 ft. lbs.)4 Nut (Qty 2) 8 N´m

(72 in. lbs.), then

loosen 45

degrees 2 Bolt (Qty 4) 5 Nut (Qty 2)

3 Stud (Qty 2)

DN4.7L ENGINE 9 - 37

REMOVAL AND INSTALLATION (Continued)

Page 38 of 193

Downloaded from www.Manualslib.com manuals search engine (9) Install A/C compressor and fasteners.

(10) Install accessory drive belt.

(11) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(12) Install battery and connect cables.

(13) Fill cooling system.

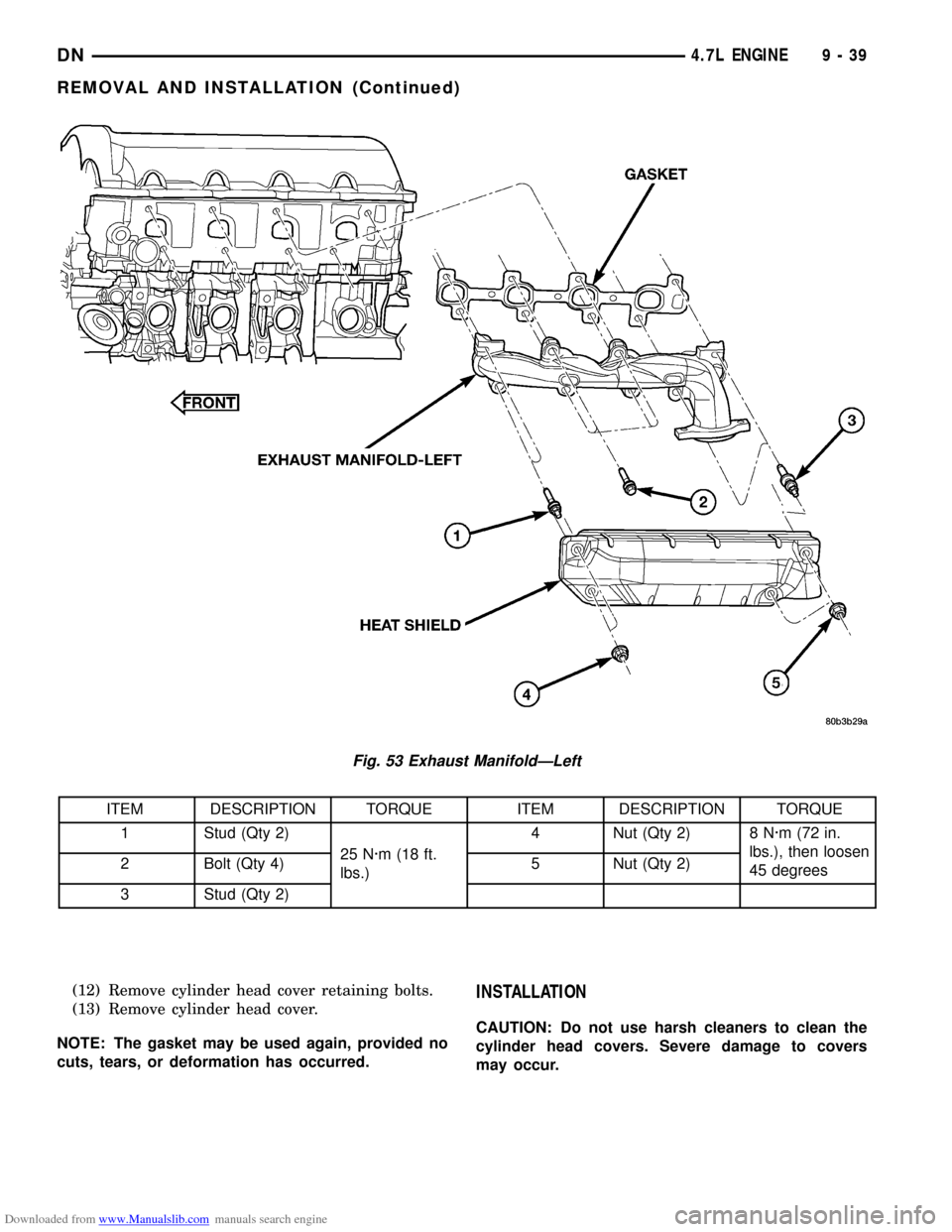

LEFT EXHAUST MANIFOLD

REMOVAL

(1) Disconnect negative cable for battery.

(2) Hoist vehicle.

(3) Disconnect exhaust pipe at manifold.

(4) Lower vehicle.

(5) Remove the front two exhaust heat shield

retaining fasteners. Raise vehicle and remove the

fasteners at rear of heat shield.

(6) Remove heat shield (Fig. 53).

(7) Lower vehicle and remove the upper exhaust

manifold retaining bolts (Fig. 53).

(8) Raise vehicle and remove the lower exhaust

manifold retaining bolts (Fig. 53).

(9) Remove exhaust manifold and gasket (Fig. 53).

Manifold is removed from below the engine compart-

ment.

INSTALLATION

(1) Install exhaust manifold and gasket from below

engine compartment.

(2) Install lower exhaust manifold fasteners (Fig.

53). DO NOT tighten until all fasteners are in place.

(3) Lower vehicle and install upper exhaust mani-

fold fasteners (Fig. 53). Tighten all manifold bolts

starting at center and working outward to 25 N´m

(18 ft. lbs.).

CAUTION: Over tightening heat shield fasteners,

may cause shield to distort and/or crack.

(4) Install exhaust manifold heat shield (Fig. 53).

Tighten fasteners to 8 N´m (72 in. lbs.), then loosen

45 degrees.

(5) Connect exhaust pipe to manifold.

(6) Connect negative cable to battery.

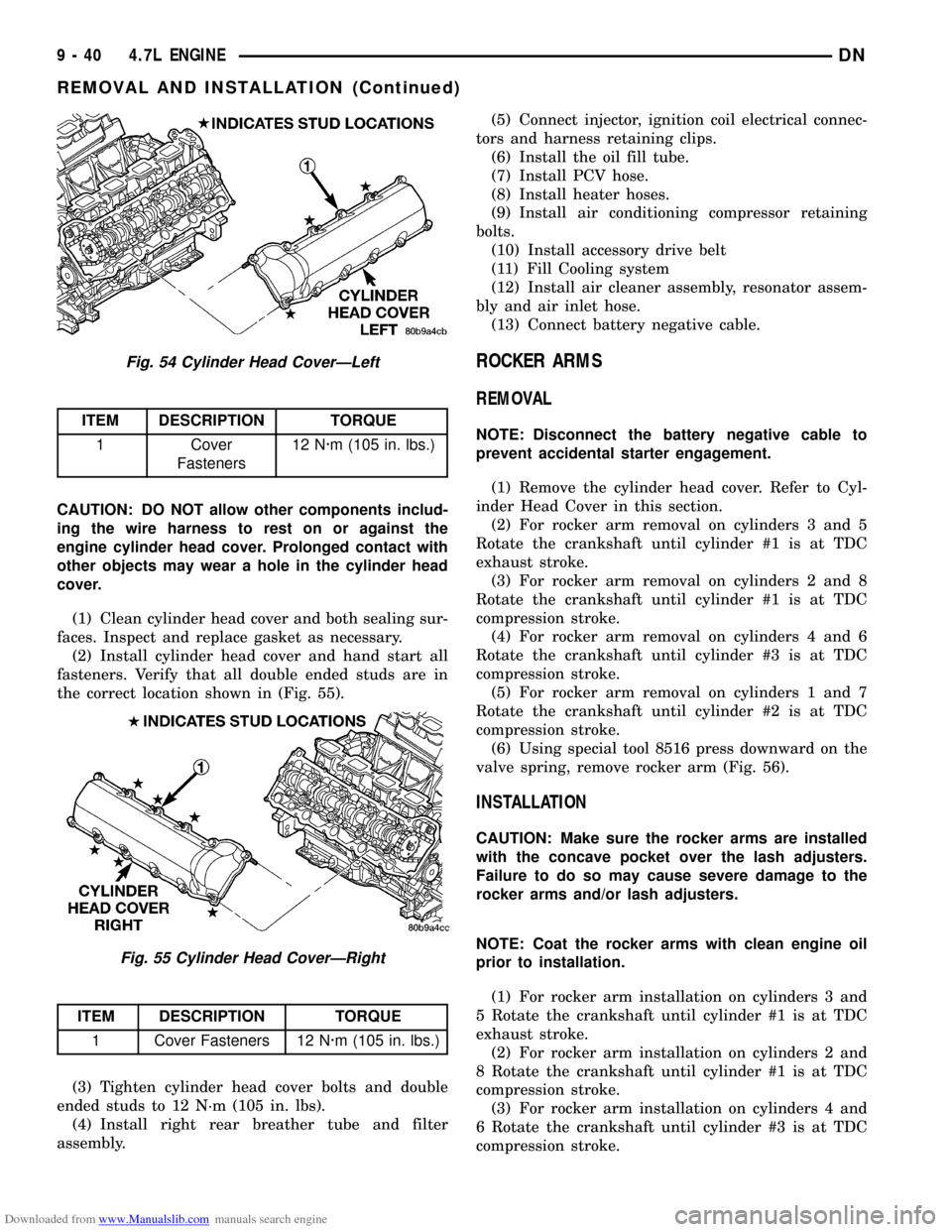

CYLINDER HEAD COVER

REMOVAL

LEFT SIDE COVER

(1) Disconnect negative cable from battery.

(2) Remove the resonator assemble and air inlet

hose.

(3) Disconnect injector connectors and un-clip the

injector harness.

(4) Route injector harness in front of cylinder head

cover.(5) Disconnect the left side breather tube and

remove the breather tube.

(6) Remove the cylinder head cover mounting

bolts.

(7) Remove cylinder head cover and gasket.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.

INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the cylin-

der head cover. Prolonged contact with other

objects may wear a hole in the engine cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Install cylinder head cover and hand start all

fasteners. Verify that all studs are in the correct loca-

tion shown in (Fig. 54).

(3) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs.).

(4) Install left side breather and connect breather

tube.

(5) Connect injector electrical connectors and injec-

tor harness retaining clips.

(6) Install the resonator and air inlet hose.

(7) Connect negative cable to battery.

REMOVAL

RIGHT SIDE COVER

(1) Disconnect battery negative cable.

(2) Remove air cleaner assembly, resonator assem-

bly and air inlet hose.

(3) Drain cooling system, below the level of the

heater hoses. Refer to COOLING SYSTEM.

(4) Remove accessory drive belt.

(5) Remove air conditioning compressor retaining

bolts and move compressor to the left.

(6) Remove heater hoses.

(7) Disconnect injector and ignition coil connectors.

(8) Disconnect and remove positive crankcase ven-

tilation (PCV) hose.

(9) Remove oil fill tube.

(10) Un-clip injector and ignition coil harness and

move away from cylinder head cover.

(11) Remove right rear breather tube and filter

assembly.

9 - 38 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)

Page 39 of 193

Downloaded from www.Manualslib.com manuals search engine (12) Remove cylinder head cover retaining bolts.

(13) Remove cylinder head cover.

NOTE: The gasket may be used again, provided no

cuts, tears, or deformation has occurred.INSTALLATION

CAUTION: Do not use harsh cleaners to clean the

cylinder head covers. Severe damage to covers

may occur.

Fig. 53 Exhaust ManifoldÐLeft

ITEM DESCRIPTION TORQUE ITEM DESCRIPTION TORQUE

1 Stud (Qty 2)

25 N´m (18 ft.

lbs.)4 Nut (Qty 2) 8 N´m (72 in.

lbs.), then loosen

45 degrees 2 Bolt (Qty 4) 5 Nut (Qty 2)

3 Stud (Qty 2)

DN4.7L ENGINE 9 - 39

REMOVAL AND INSTALLATION (Continued)

Page 40 of 193

Downloaded from www.Manualslib.com manuals search engine CAUTION: DO NOT allow other components includ-

ing the wire harness to rest on or against the

engine cylinder head cover. Prolonged contact with

other objects may wear a hole in the cylinder head

cover.

(1) Clean cylinder head cover and both sealing sur-

faces. Inspect and replace gasket as necessary.

(2) Install cylinder head cover and hand start all

fasteners. Verify that all double ended studs are in

the correct location shown in (Fig. 55).

(3) Tighten cylinder head cover bolts and double

ended studs to 12 N´m (105 in. lbs).

(4) Install right rear breather tube and filter

assembly.(5) Connect injector, ignition coil electrical connec-

tors and harness retaining clips.

(6) Install the oil fill tube.

(7) Install PCV hose.

(8) Install heater hoses.

(9) Install air conditioning compressor retaining

bolts.

(10) Install accessory drive belt

(11) Fill Cooling system

(12) Install air cleaner assembly, resonator assem-

bly and air inlet hose.

(13) Connect battery negative cable.

ROCKER ARMS

REMOVAL

NOTE: Disconnect the battery negative cable to

prevent accidental starter engagement.

(1) Remove the cylinder head cover. Refer to Cyl-

inder Head Cover in this section.

(2) For rocker arm removal on cylinders 3 and 5

Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(3) For rocker arm removal on cylinders 2 and 8

Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(4) For rocker arm removal on cylinders 4 and 6

Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

(5) For rocker arm removal on cylinders 1 and 7

Rotate the crankshaft until cylinder #2 is at TDC

compression stroke.

(6) Using special tool 8516 press downward on the

valve spring, remove rocker arm (Fig. 56).

INSTALLATION

CAUTION: Make sure the rocker arms are installed

with the concave pocket over the lash adjusters.

Failure to do so may cause severe damage to the

rocker arms and/or lash adjusters.

NOTE: Coat the rocker arms with clean engine oil

prior to installation.

(1) For rocker arm installation on cylinders 3 and

5 Rotate the crankshaft until cylinder #1 is at TDC

exhaust stroke.

(2) For rocker arm installation on cylinders 2 and

8 Rotate the crankshaft until cylinder #1 is at TDC

compression stroke.

(3) For rocker arm installation on cylinders 4 and

6 Rotate the crankshaft until cylinder #3 is at TDC

compression stroke.

Fig. 54 Cylinder Head CoverÐLeft

ITEM DESCRIPTION TORQUE

1 Cover

Fasteners12 N´m (105 in. lbs.)

Fig. 55 Cylinder Head CoverÐRight

ITEM DESCRIPTION TORQUE

1 Cover Fasteners 12 N´m (105 in. lbs.)

9 - 40 4.7L ENGINEDN

REMOVAL AND INSTALLATION (Continued)