Light DODGE DURANGO 1998 1.G Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1998, Model line: DURANGO, Model: DODGE DURANGO 1998 1.GPages: 193, PDF Size: 5.65 MB

Page 140 of 193

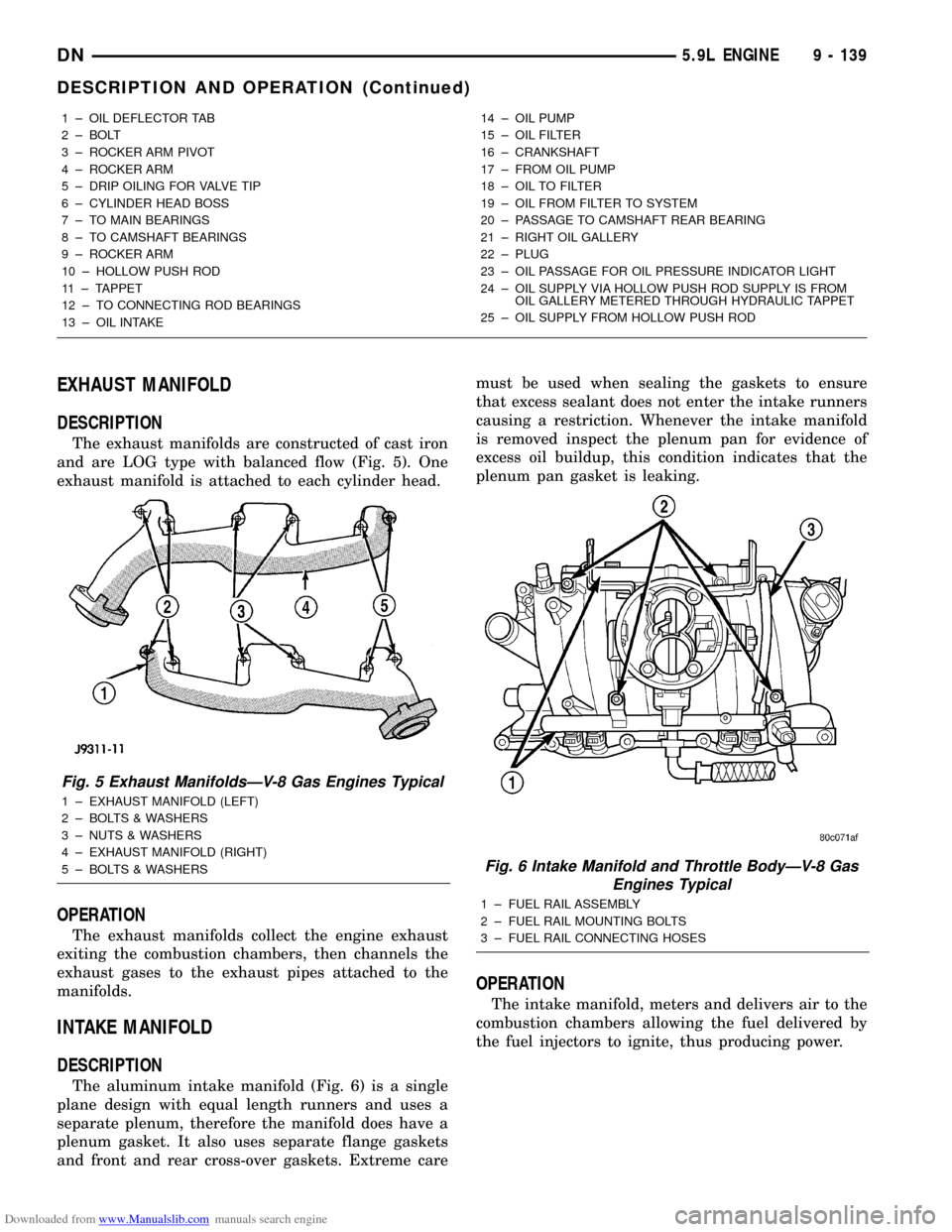

Downloaded from www.Manualslib.com manuals search engine EXHAUST MANIFOLD

DESCRIPTION

The exhaust manifolds are constructed of cast iron

and are LOG type with balanced flow (Fig. 5). One

exhaust manifold is attached to each cylinder head.

OPERATION

The exhaust manifolds collect the engine exhaust

exiting the combustion chambers, then channels the

exhaust gases to the exhaust pipes attached to the

manifolds.

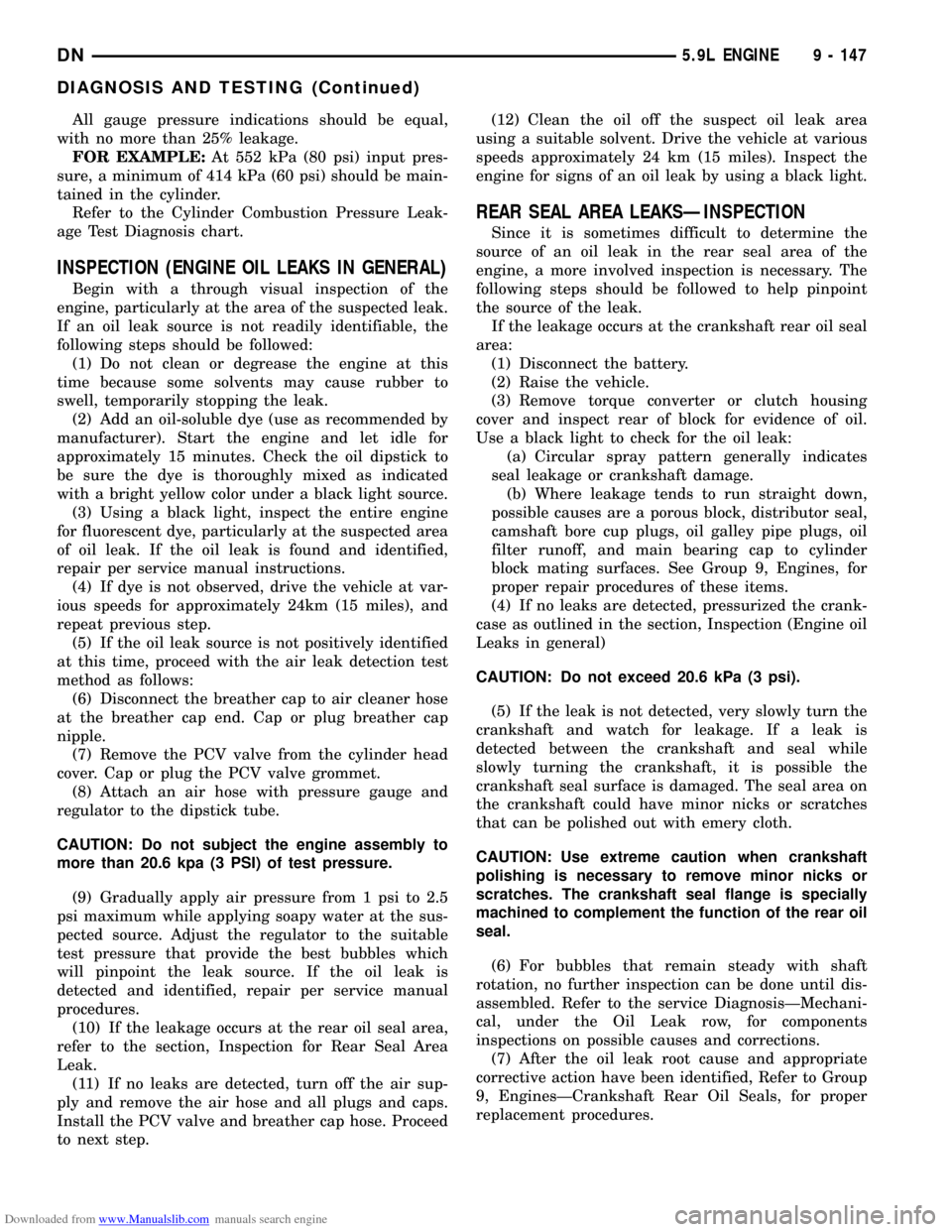

INTAKE MANIFOLD

DESCRIPTION

The aluminum intake manifold (Fig. 6) is a single

plane design with equal length runners and uses a

separate plenum, therefore the manifold does have a

plenum gasket. It also uses separate flange gaskets

and front and rear cross-over gaskets. Extreme caremust be used when sealing the gaskets to ensure

that excess sealant does not enter the intake runners

causing a restriction. Whenever the intake manifold

is removed inspect the plenum pan for evidence of

excess oil buildup, this condition indicates that the

plenum pan gasket is leaking.

OPERATION

The intake manifold, meters and delivers air to the

combustion chambers allowing the fuel delivered by

the fuel injectors to ignite, thus producing power.

1 ± OIL DEFLECTOR TAB

2 ± BOLT

3 ± ROCKER ARM PIVOT

4 ± ROCKER ARM

5 ± DRIP OILING FOR VALVE TIP

6 ± CYLINDER HEAD BOSS

7 ± TO MAIN BEARINGS

8 ± TO CAMSHAFT BEARINGS

9 ± ROCKER ARM

10 ± HOLLOW PUSH ROD

11 ± TAPPET

12 ± TO CONNECTING ROD BEARINGS

13 ± OIL INTAKE14 ± OIL PUMP

15 ± OIL FILTER

16 ± CRANKSHAFT

17 ± FROM OIL PUMP

18 ± OIL TO FILTER

19 ± OIL FROM FILTER TO SYSTEM

20 ± PASSAGE TO CAMSHAFT REAR BEARING

21 ± RIGHT OIL GALLERY

22 ± PLUG

23 ± OIL PASSAGE FOR OIL PRESSURE INDICATOR LIGHT

24 ± OIL SUPPLY VIA HOLLOW PUSH ROD SUPPLY IS FROM

OIL GALLERY METERED THROUGH HYDRAULIC TAPPET

25 ± OIL SUPPLY FROM HOLLOW PUSH ROD

Fig. 5 Exhaust ManifoldsÐV-8 Gas Engines Typical

1 ± EXHAUST MANIFOLD (LEFT)

2 ± BOLTS & WASHERS

3 ± NUTS & WASHERS

4 ± EXHAUST MANIFOLD (RIGHT)

5 ± BOLTS & WASHERS

Fig. 6 Intake Manifold and Throttle BodyÐV-8 Gas

Engines Typical

1 ± FUEL RAIL ASSEMBLY

2 ± FUEL RAIL MOUNTING BOLTS

3 ± FUEL RAIL CONNECTING HOSES

DN5.9L ENGINE 9 - 139

DESCRIPTION AND OPERATION (Continued)

Page 148 of 193

Downloaded from www.Manualslib.com manuals search engine All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

Refer to the Cylinder Combustion Pressure Leak-

age Test Diagnosis chart.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil-soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

be sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light source.

(3) Using a black light, inspect the entire engine

for fluorescent dye, particularly at the suspected area

of oil leak. If the oil leak is found and identified,

repair per service manual instructions.

(4) If dye is not observed, drive the vehicle at var-

ious speeds for approximately 24km (15 miles), and

repeat previous step.

(5) If the oil leak source is not positively identified

at this time, proceed with the air leak detection test

method as follows:

(6) Disconnect the breather cap to air cleaner hose

at the breather cap end. Cap or plug breather cap

nipple.

(7) Remove the PCV valve from the cylinder head

cover. Cap or plug the PCV valve grommet.

(8) Attach an air hose with pressure gauge and

regulator to the dipstick tube.

CAUTION: Do not subject the engine assembly to

more than 20.6 kpa (3 PSI) of test pressure.

(9) Gradually apply air pressure from 1 psi to 2.5

psi maximum while applying soapy water at the sus-

pected source. Adjust the regulator to the suitable

test pressure that provide the best bubbles which

will pinpoint the leak source. If the oil leak is

detected and identified, repair per service manual

procedures.

(10) If the leakage occurs at the rear oil seal area,

refer to the section, Inspection for Rear Seal Area

Leak.

(11) If no leaks are detected, turn off the air sup-

ply and remove the air hose and all plugs and caps.

Install the PCV valve and breather cap hose. Proceed

to next step.(12) Clean the oil off the suspect oil leak area

using a suitable solvent. Drive the vehicle at various

speeds approximately 24 km (15 miles). Inspect the

engine for signs of an oil leak by using a black light.

REAR SEAL AREA LEAKSÐINSPECTION

Since it is sometimes difficult to determine the

source of an oil leak in the rear seal area of the

engine, a more involved inspection is necessary. The

following steps should be followed to help pinpoint

the source of the leak.

If the leakage occurs at the crankshaft rear oil seal

area:

(1) Disconnect the battery.

(2) Raise the vehicle.

(3) Remove torque converter or clutch housing

cover and inspect rear of block for evidence of oil.

Use a black light to check for the oil leak:

(a) Circular spray pattern generally indicates

seal leakage or crankshaft damage.

(b) Where leakage tends to run straight down,

possible causes are a porous block, distributor seal,

camshaft bore cup plugs, oil galley pipe plugs, oil

filter runoff, and main bearing cap to cylinder

block mating surfaces. See Group 9, Engines, for

proper repair procedures of these items.

(4) If no leaks are detected, pressurized the crank-

case as outlined in the section, Inspection (Engine oil

Leaks in general)

CAUTION: Do not exceed 20.6 kPa (3 psi).

(5) If the leak is not detected, very slowly turn the

crankshaft and watch for leakage. If a leak is

detected between the crankshaft and seal while

slowly turning the crankshaft, it is possible the

crankshaft seal surface is damaged. The seal area on

the crankshaft could have minor nicks or scratches

that can be polished out with emery cloth.

CAUTION: Use extreme caution when crankshaft

polishing is necessary to remove minor nicks or

scratches. The crankshaft seal flange is specially

machined to complement the function of the rear oil

seal.

(6) For bubbles that remain steady with shaft

rotation, no further inspection can be done until dis-

assembled. Refer to the service DiagnosisÐMechani-

cal, under the Oil Leak row, for components

inspections on possible causes and corrections.

(7) After the oil leak root cause and appropriate

corrective action have been identified, Refer to Group

9, EnginesÐCrankshaft Rear Oil Seals, for proper

replacement procedures.

DN5.9L ENGINE 9 - 147

DIAGNOSIS AND TESTING (Continued)

Page 149 of 193

Downloaded from www.Manualslib.com manuals search engine HYDRAULIC TAPPETS

Before disassembling any part of the engine to cor-

rect tappet noise, check the oil pressure. If vehicle

has no oil pressure gauge, install a reliable gauge at

the pressure sending-unit. The pressure should be

between 207-552 kPa (30-80 psi) at 3,000 RPM.

Check the oil level after the engine reaches normal

operating temperature. Allow 5 minutes to stabilize

oil level, check dipstick. The oil level in the pan

should never be above the FULL mark or below the

ADD OIL mark on dipstick. Either of these two con-

ditions could be responsible for noisy tappets.

OIL LEVEL

HIGH

If oil level is above the FULL mark, it is possible

for the connecting rods to dip into the oil. With the

engine running, this condition could create foam in

the oil pan. Foam in oil pan would be fed to the

hydraulic tappets by the oil pump causing them to

lose length and allow valves to seat noisily.

LOW

Low oil level may allow oil pump to take in air.

When air is fed to the tappets, they lose length,

which allows valves to seat noisily. Any leaks on

intake side of oil pump through which air can be

drawn will create the same tappet action. Check the

lubrication system from the intake strainer to the

pump cover, including the relief valve retainer cap.

When tappet noise is due to aeration, it may be

intermittent or constant, and usually more than one

tappet will be noisy. When oil level and leaks have

been corrected, operate the engine at fast idle. Run

engine for a sufficient time to allow all of the air

inside the tappets to be bled out.

TAPPET NOISE DIAGNOSIS

(1) To determine source of tappet noise, operate

engine at idle with cylinder head covers removed.

(2) Feel each valve spring or rocker arm to detect

noisy tappet. The noisy tappet will cause the affected

spring and/or rocker arm to vibrate or feel rough in

operation.

NOTE: Worn valve guides or cocked springs are

sometimes mistaken for noisy tappets. If such is

the case, noise may be dampened by applying side

thrust on the valve spring. If noise is not apprecia-

bly reduced, it can be assumed the noise is in the

tappet. Inspect the rocker arm push rod sockets

and push rod ends for wear.

(3) Valve tappet noise ranges from light noise to a

heavy click. A light noise is usually caused by exces-

sive leak-down around the unit plunger, or by theplunger partially sticking in the tappet body cylinder.

The tappet should be replaced. A heavy click is

caused by a tappet check valve not seating, or by for-

eign particles wedged between the plunger and the

tappet body. This will cause the plunger to stick in

the down position. This heavy click will be accompa-

nied by excessive clearance between the valve stem

and rocker arm as valve closes. In either case, tappet

assembly should be removed for inspection and clean-

ing.

(4) The valve train generates a noise very much

like a light tappet noise during normal operation.

Care must be taken to ensure that tappets are mak-

ing the noise. If more than one tappet seems to be

noisy, it's probably not the tappets.

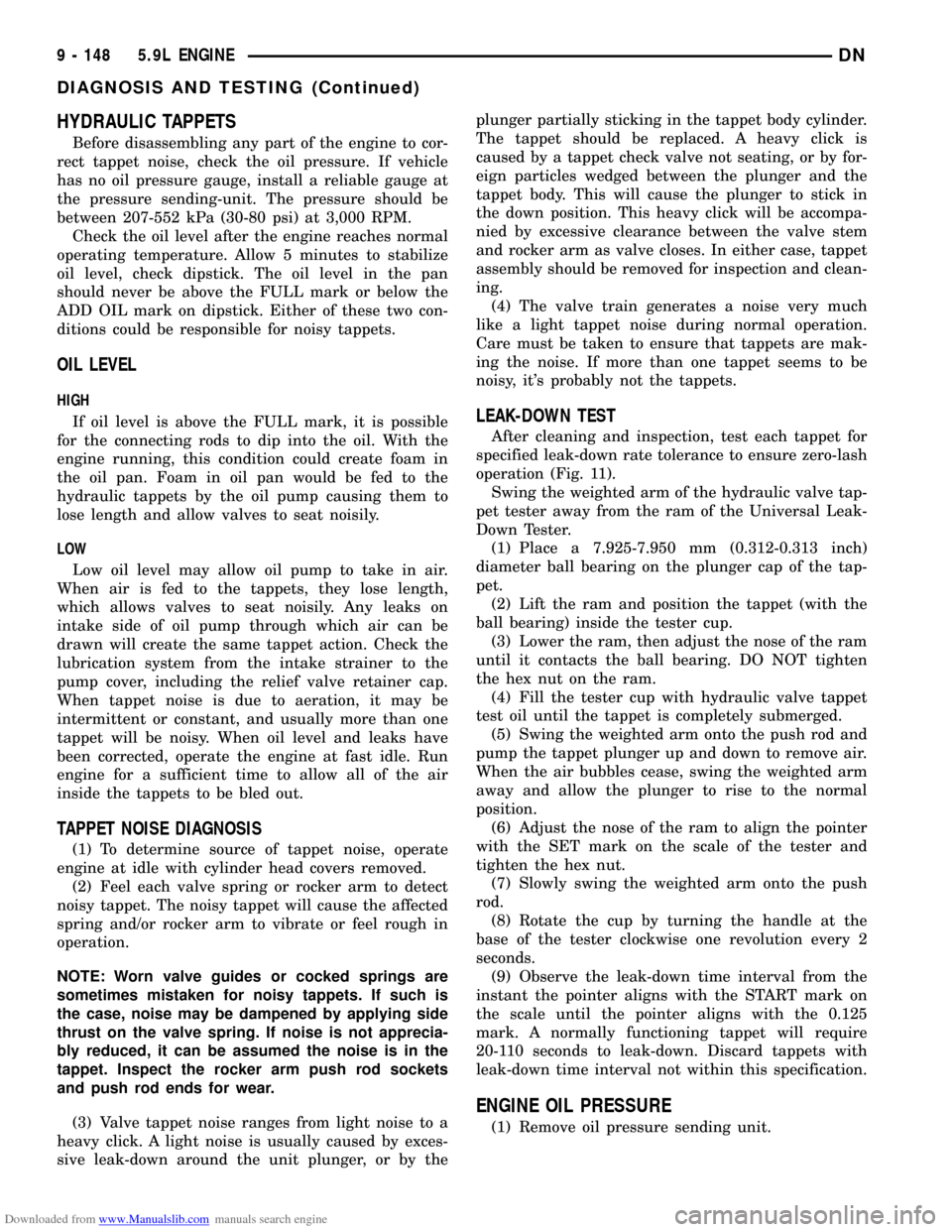

LEAK-DOWN TEST

After cleaning and inspection, test each tappet for

specified leak-down rate tolerance to ensure zero-lash

operation (Fig. 11).

Swing the weighted arm of the hydraulic valve tap-

pet tester away from the ram of the Universal Leak-

Down Tester.

(1) Place a 7.925-7.950 mm (0.312-0.313 inch)

diameter ball bearing on the plunger cap of the tap-

pet.

(2) Lift the ram and position the tappet (with the

ball bearing) inside the tester cup.

(3) Lower the ram, then adjust the nose of the ram

until it contacts the ball bearing. DO NOT tighten

the hex nut on the ram.

(4) Fill the tester cup with hydraulic valve tappet

test oil until the tappet is completely submerged.

(5) Swing the weighted arm onto the push rod and

pump the tappet plunger up and down to remove air.

When the air bubbles cease, swing the weighted arm

away and allow the plunger to rise to the normal

position.

(6) Adjust the nose of the ram to align the pointer

with the SET mark on the scale of the tester and

tighten the hex nut.

(7) Slowly swing the weighted arm onto the push

rod.

(8) Rotate the cup by turning the handle at the

base of the tester clockwise one revolution every 2

seconds.

(9) Observe the leak-down time interval from the

instant the pointer aligns with the START mark on

the scale until the pointer aligns with the 0.125

mark. A normally functioning tappet will require

20-110 seconds to leak-down. Discard tappets with

leak-down time interval not within this specification.

ENGINE OIL PRESSURE

(1) Remove oil pressure sending unit.

9 - 148 5.9L ENGINEDN

DIAGNOSIS AND TESTING (Continued)

Page 150 of 193

Downloaded from www.Manualslib.com manuals search engine (2) Install Oil Pressure Line and Gauge Tool

C-3292. Start engine and record pressure. Refer to

Oil Pressure in Engine Specifications for the proper

pressures.

SERVICE PROCEDURES

FORM-IN-PLACE GASKETS

There are several places where form-in-place gas-

kets are used on the engine.DO NOT use form-in-

place gasket material unless specified.Care

must be taken when applying form-in-place gaskets.

Bead size, continuity and location are of great impor-

tance. Too thin a bead can result in leakage while too

much can result in spill-over. A continuous bead of

the proper width is essential to obtain a leak-free

joint.

Two types of form-in-place gasket materials are

used in the engine area (Mopar Silicone Rubber

Adhesive Sealant and Mopar Gasket Maker). Each

have different properties and cannot be used inter-

changeably.

MOPAR SILICONE RUBBER ADHESIVE SEALANT

Mopar Silicone Rubber Adhesive Sealant, normally

black in color, is available in 3 ounce tubes. Moisture

in the air causes the sealant material to cure. This

material is normally used on flexible metal flanges.

It has a shelf life of a year and will not properly cure

if over aged. Always inspect the package for the expi-

ration date before use.

MOPAR GASKET MAKER

Mopar Gasket Maker, normally red in color, is

available in 6 cc tubes. This anaerobic type gasket

material cures in the absence of air when squeezed

between smooth machined metallic surfaces. It will

not cure if left in the uncovered tube. DO NOT use

on flexible metal flanges.

SURFACE PREPARATION

Parts assembled with form-in-place gaskets may be

disassembled without unusual effort. In some

instances, it may be necessary to lightly tap the part

with a mallet or other suitable tool to break the seal

between the mating surfaces. A flat gasket scraper

may also be lightly tapped into the joint but care

must be taken not to damage the mating surfaces.

Scrape or wire brush all gasket surfaces to remove

all loose material. Inspect stamped parts to ensure

gasket rails are flat. Flatten rails with a hammer on

a flat plate, if required. Gasket surfaces must be free

of oil and dirt. Make sure the old gasket material is

removed from blind attaching holes.

GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care.

Mopar Silicone Rubber Adhesive Sealant should be

applied in a continuous bead approximately 3 mm

(0.12 inch) in diameter. All mounting holes must be

circled. For corner sealing,a3or6mm(1/8 or 1/4

inch) drop is placed in the center of the gasket con-

tact area. Uncured sealant may be removed with a

shop towel. Components should be torqued in place

while the sealant is still wet to the touch (within 10

minutes). The use of a locating dowel is recom-

mended during assembly to prevent smearing the

material off location.

Mopar Gasket Maker should be applied sparingly

to one gasket surface. The sealant diameter should

be 1.00 mm (0.04 inch) or less. Be certain the mate-

rial surrounds each mounting hole. Excess material

can easily be wiped off. Components should be

torqued in place within 15 minutes. The use of a

locating dowel is recommended during assembly to

prevent smearing the material off location.

ENGINE PERFORMANCE

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and the lowest emission levels. If vehicle is not oper-

ating to these standards, refer to Engine Diagnosis

outlined in this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Electri-

cal Group 8B, Cold Cranking Test.

Fig. 11 Leak-Down Tester

1 ± POINTER

2 ± WEIGHTED ARM

3 ± RAM

4 ± CUP

5 ± HANDLE

6 ± PUSH ROD

DN5.9L ENGINE 9 - 149

DIAGNOSIS AND TESTING (Continued)

Page 152 of 193

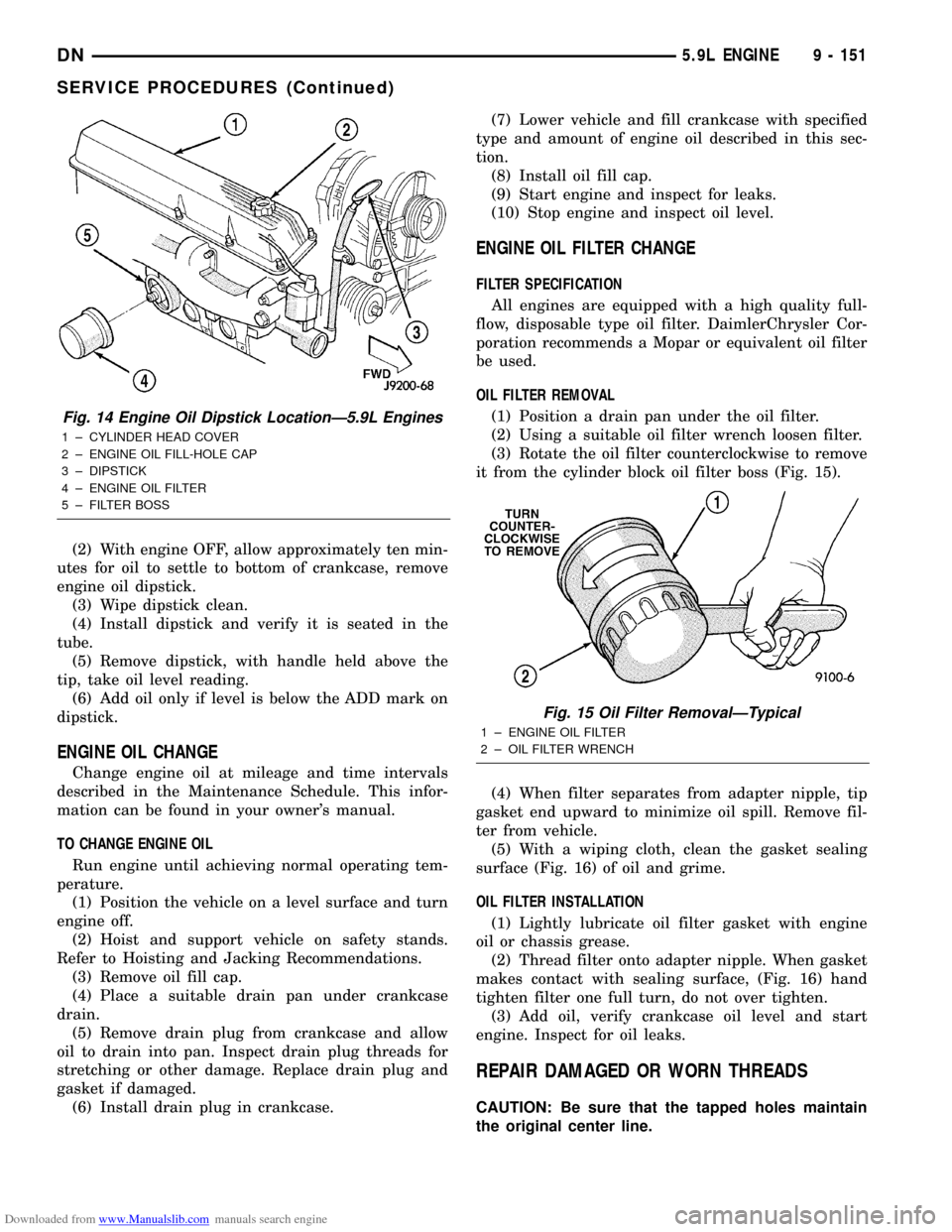

Downloaded from www.Manualslib.com manuals search engine (2) With engine OFF, allow approximately ten min-

utes for oil to settle to bottom of crankcase, remove

engine oil dipstick.

(3) Wipe dipstick clean.

(4) Install dipstick and verify it is seated in the

tube.

(5) Remove dipstick, with handle held above the

tip, take oil level reading.

(6) Add oil only if level is below the ADD mark on

dipstick.

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule. This infor-

mation can be found in your owner's manual.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

(1) Position the vehicle on a level surface and turn

engine off.

(2) Hoist and support vehicle on safety stands.

Refer to Hoisting and Jacking Recommendations.

(3) Remove oil fill cap.

(4) Place a suitable drain pan under crankcase

drain.

(5) Remove drain plug from crankcase and allow

oil to drain into pan. Inspect drain plug threads for

stretching or other damage. Replace drain plug and

gasket if damaged.

(6) Install drain plug in crankcase.(7) Lower vehicle and fill crankcase with specified

type and amount of engine oil described in this sec-

tion.

(8) Install oil fill cap.

(9) Start engine and inspect for leaks.

(10) Stop engine and inspect oil level.

ENGINE OIL FILTER CHANGE

FILTER SPECIFICATION

All engines are equipped with a high quality full-

flow, disposable type oil filter. DaimlerChrysler Cor-

poration recommends a Mopar or equivalent oil filter

be used.

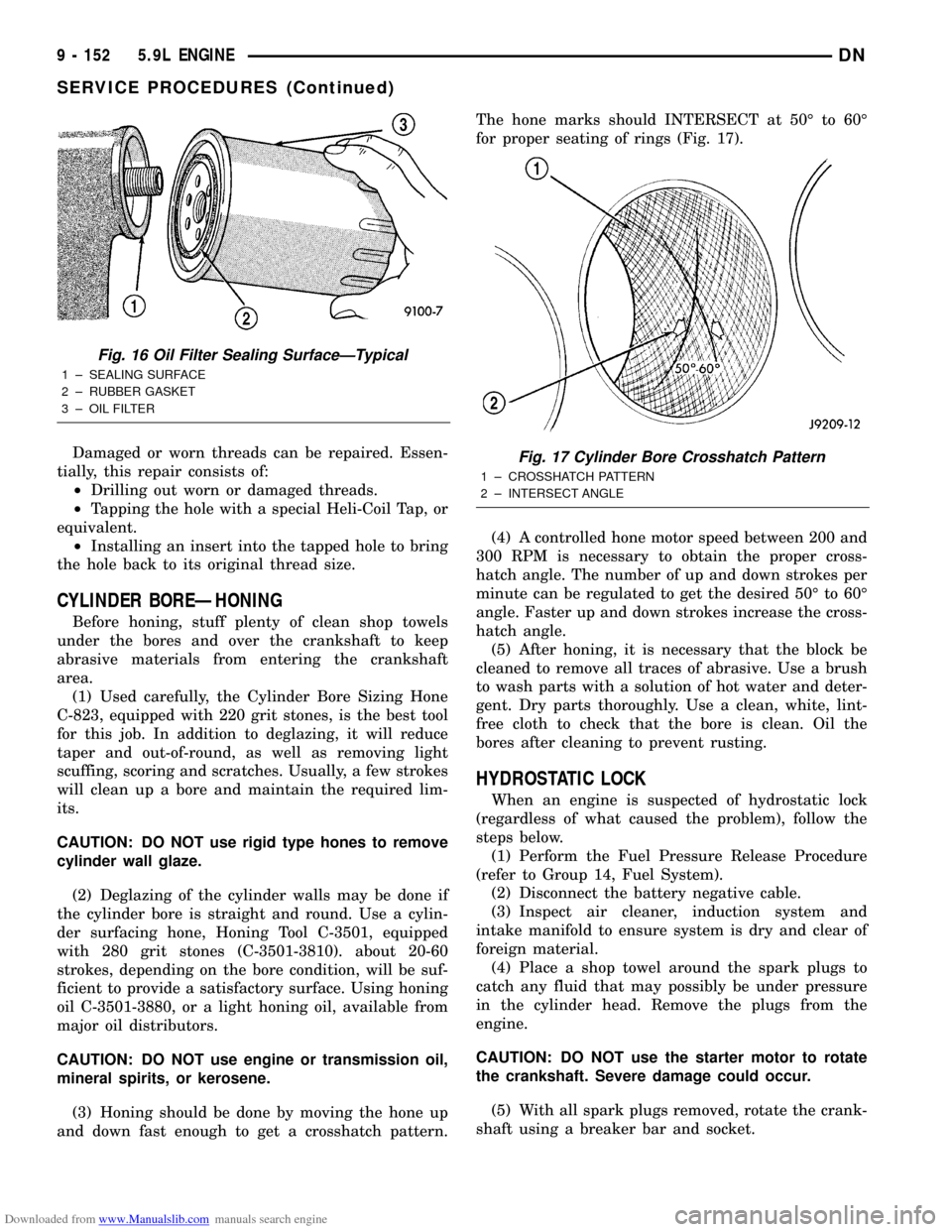

OIL FILTER REMOVAL

(1) Position a drain pan under the oil filter.

(2) Using a suitable oil filter wrench loosen filter.

(3) Rotate the oil filter counterclockwise to remove

it from the cylinder block oil filter boss (Fig. 15).

(4) When filter separates from adapter nipple, tip

gasket end upward to minimize oil spill. Remove fil-

ter from vehicle.

(5) With a wiping cloth, clean the gasket sealing

surface (Fig. 16) of oil and grime.

OIL FILTER INSTALLATION

(1) Lightly lubricate oil filter gasket with engine

oil or chassis grease.

(2) Thread filter onto adapter nipple. When gasket

makes contact with sealing surface, (Fig. 16) hand

tighten filter one full turn, do not over tighten.

(3) Add oil, verify crankcase oil level and start

engine. Inspect for oil leaks.

REPAIR DAMAGED OR WORN THREADS

CAUTION: Be sure that the tapped holes maintain

the original center line.

Fig. 14 Engine Oil Dipstick LocationÐ5.9L Engines

1 ± CYLINDER HEAD COVER

2 ± ENGINE OIL FILL-HOLE CAP

3 ± DIPSTICK

4 ± ENGINE OIL FILTER

5 ± FILTER BOSS

Fig. 15 Oil Filter RemovalÐTypical

1 ± ENGINE OIL FILTER

2 ± OIL FILTER WRENCH

DN5.9L ENGINE 9 - 151

SERVICE PROCEDURES (Continued)

Page 153 of 193

Downloaded from www.Manualslib.com manuals search engine Damaged or worn threads can be repaired. Essen-

tially, this repair consists of:

²Drilling out worn or damaged threads.

²Tapping the hole with a special Heli-Coil Tap, or

equivalent.

²Installing an insert into the tapped hole to bring

the hole back to its original thread size.

CYLINDER BOREÐHONING

Before honing, stuff plenty of clean shop towels

under the bores and over the crankshaft to keep

abrasive materials from entering the crankshaft

area.

(1) Used carefully, the Cylinder Bore Sizing Hone

C-823, equipped with 220 grit stones, is the best tool

for this job. In addition to deglazing, it will reduce

taper and out-of-round, as well as removing light

scuffing, scoring and scratches. Usually, a few strokes

will clean up a bore and maintain the required lim-

its.

CAUTION: DO NOT use rigid type hones to remove

cylinder wall glaze.

(2) Deglazing of the cylinder walls may be done if

the cylinder bore is straight and round. Use a cylin-

der surfacing hone, Honing Tool C-3501, equipped

with 280 grit stones (C-3501-3810). about 20-60

strokes, depending on the bore condition, will be suf-

ficient to provide a satisfactory surface. Using honing

oil C-3501-3880, or a light honing oil, available from

major oil distributors.

CAUTION: DO NOT use engine or transmission oil,

mineral spirits, or kerosene.

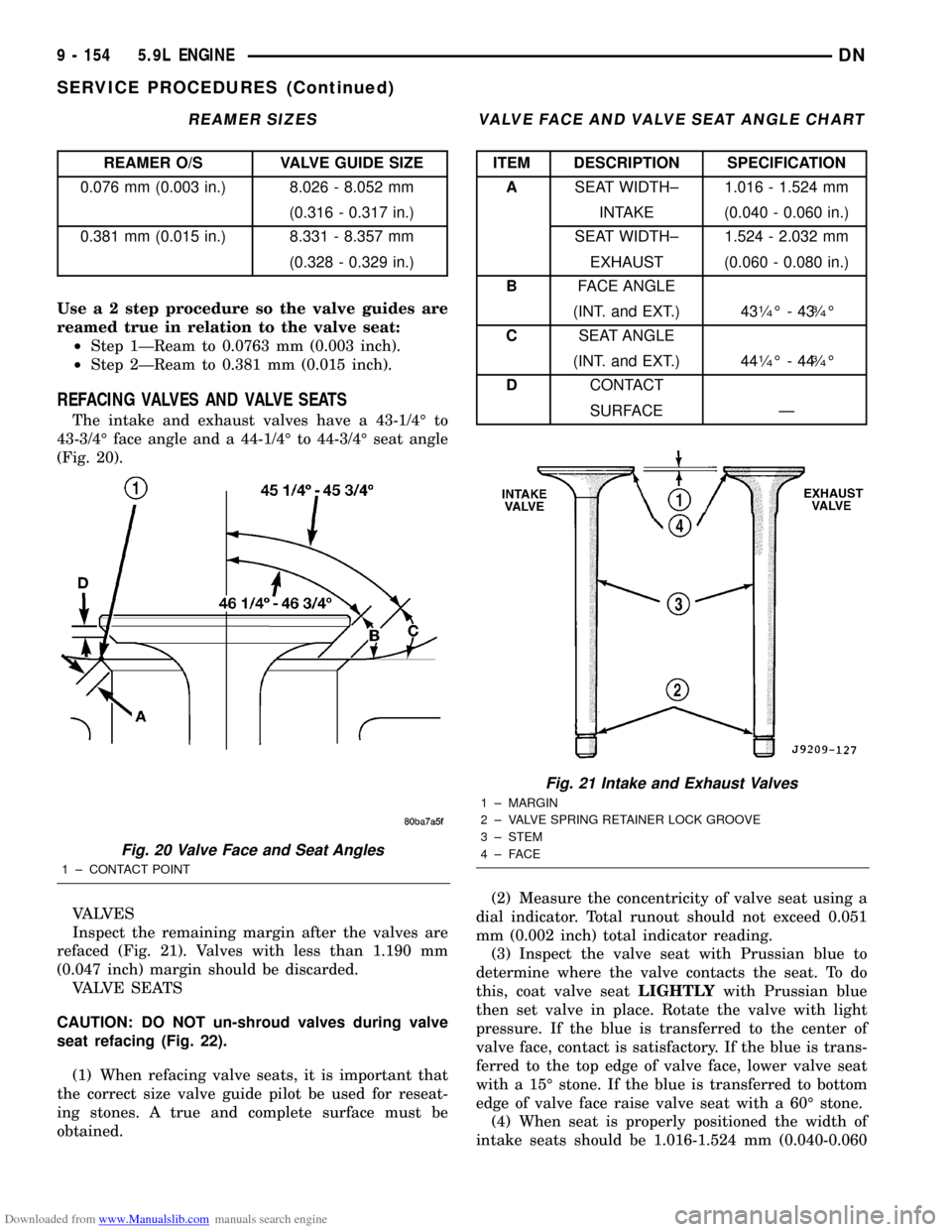

(3) Honing should be done by moving the hone up

and down fast enough to get a crosshatch pattern.The hone marks should INTERSECT at 50É to 60É

for proper seating of rings (Fig. 17).

(4) A controlled hone motor speed between 200 and

300 RPM is necessary to obtain the proper cross-

hatch angle. The number of up and down strokes per

minute can be regulated to get the desired 50É to 60É

angle. Faster up and down strokes increase the cross-

hatch angle.

(5) After honing, it is necessary that the block be

cleaned to remove all traces of abrasive. Use a brush

to wash parts with a solution of hot water and deter-

gent. Dry parts thoroughly. Use a clean, white, lint-

free cloth to check that the bore is clean. Oil the

bores after cleaning to prevent rusting.

HYDROSTATIC LOCK

When an engine is suspected of hydrostatic lock

(regardless of what caused the problem), follow the

steps below.

(1) Perform the Fuel Pressure Release Procedure

(refer to Group 14, Fuel System).

(2) Disconnect the battery negative cable.

(3) Inspect air cleaner, induction system and

intake manifold to ensure system is dry and clear of

foreign material.

(4) Place a shop towel around the spark plugs to

catch any fluid that may possibly be under pressure

in the cylinder head. Remove the plugs from the

engine.

CAUTION: DO NOT use the starter motor to rotate

the crankshaft. Severe damage could occur.

(5) With all spark plugs removed, rotate the crank-

shaft using a breaker bar and socket.

Fig. 16 Oil Filter Sealing SurfaceÐTypical

1 ± SEALING SURFACE

2 ± RUBBER GASKET

3 ± OIL FILTER

Fig. 17 Cylinder Bore Crosshatch Pattern

1 ± CROSSHATCH PATTERN

2 ± INTERSECT ANGLE

9 - 152 5.9L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 155 of 193

Downloaded from www.Manualslib.com manuals search engine Use a 2 step procedure so the valve guides are

reamed true in relation to the valve seat:

²Step 1ÐReam to 0.0763 mm (0.003 inch).

²Step 2ÐReam to 0.381 mm (0.015 inch).

REFACING VALVES AND VALVE SEATS

The intake and exhaust valves have a 43-1/4É to

43-3/4É face angle and a 44-1/4É to 44-3/4É seat angle

(Fig. 20).

VALVES

Inspect the remaining margin after the valves are

refaced (Fig. 21). Valves with less than 1.190 mm

(0.047 inch) margin should be discarded.

VALVE SEATS

CAUTION: DO NOT un-shroud valves during valve

seat refacing (Fig. 22).

(1) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained.(2) Measure the concentricity of valve seat using a

dial indicator. Total runout should not exceed 0.051

mm (0.002 inch) total indicator reading.

(3) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to the top edge of valve face, lower valve seat

with a 15É stone. If the blue is transferred to bottom

edge of valve face raise valve seat with a 60É stone.

(4) When seat is properly positioned the width of

intake seats should be 1.016-1.524 mm (0.040-0.060

REAMER SIZES

REAMER O/S VALVE GUIDE SIZE

0.076 mm (0.003 in.) 8.026 - 8.052 mm

(0.316 - 0.317 in.)

0.381 mm (0.015 in.) 8.331 - 8.357 mm

(0.328 - 0.329 in.)

Fig. 20 Valve Face and Seat Angles

1 ± CONTACT POINT

VALVE FACE AND VALVE SEAT ANGLE CHART

ITEM DESCRIPTION SPECIFICATION

ASEAT WIDTH± 1.016 - 1.524 mm

INTAKE (0.040 - 0.060 in.)

SEAT WIDTH± 1.524 - 2.032 mm

EXHAUST (0.060 - 0.080 in.)

BFACE ANGLE

(INT. and EXT.) 43

1¤4É-433¤4É

CSEAT ANGLE

(INT. and EXT.) 44

1¤4É-443¤4É

DCONTACT

SURFACE Ð

Fig. 21 Intake and Exhaust Valves

1 ± MARGIN

2 ± VALVE SPRING RETAINER LOCK GROOVE

3 ± STEM

4±FACE

9 - 154 5.9L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 159 of 193

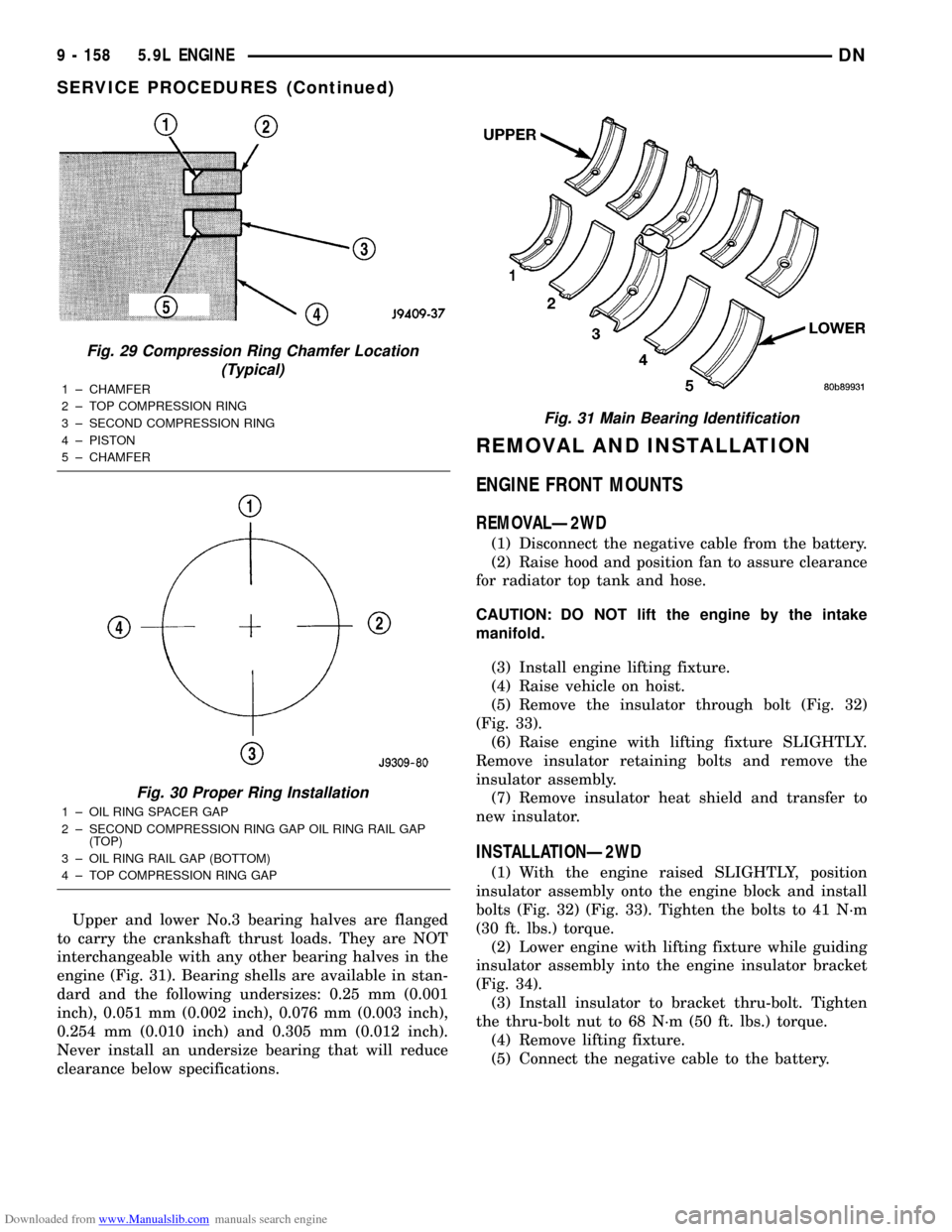

Downloaded from www.Manualslib.com manuals search engine Upper and lower No.3 bearing halves are flanged

to carry the crankshaft thrust loads. They are NOT

interchangeable with any other bearing halves in the

engine (Fig. 31). Bearing shells are available in stan-

dard and the following undersizes: 0.25 mm (0.001

inch), 0.051 mm (0.002 inch), 0.076 mm (0.003 inch),

0.254 mm (0.010 inch) and 0.305 mm (0.012 inch).

Never install an undersize bearing that will reduce

clearance below specifications.

REMOVAL AND INSTALLATION

ENGINE FRONT MOUNTS

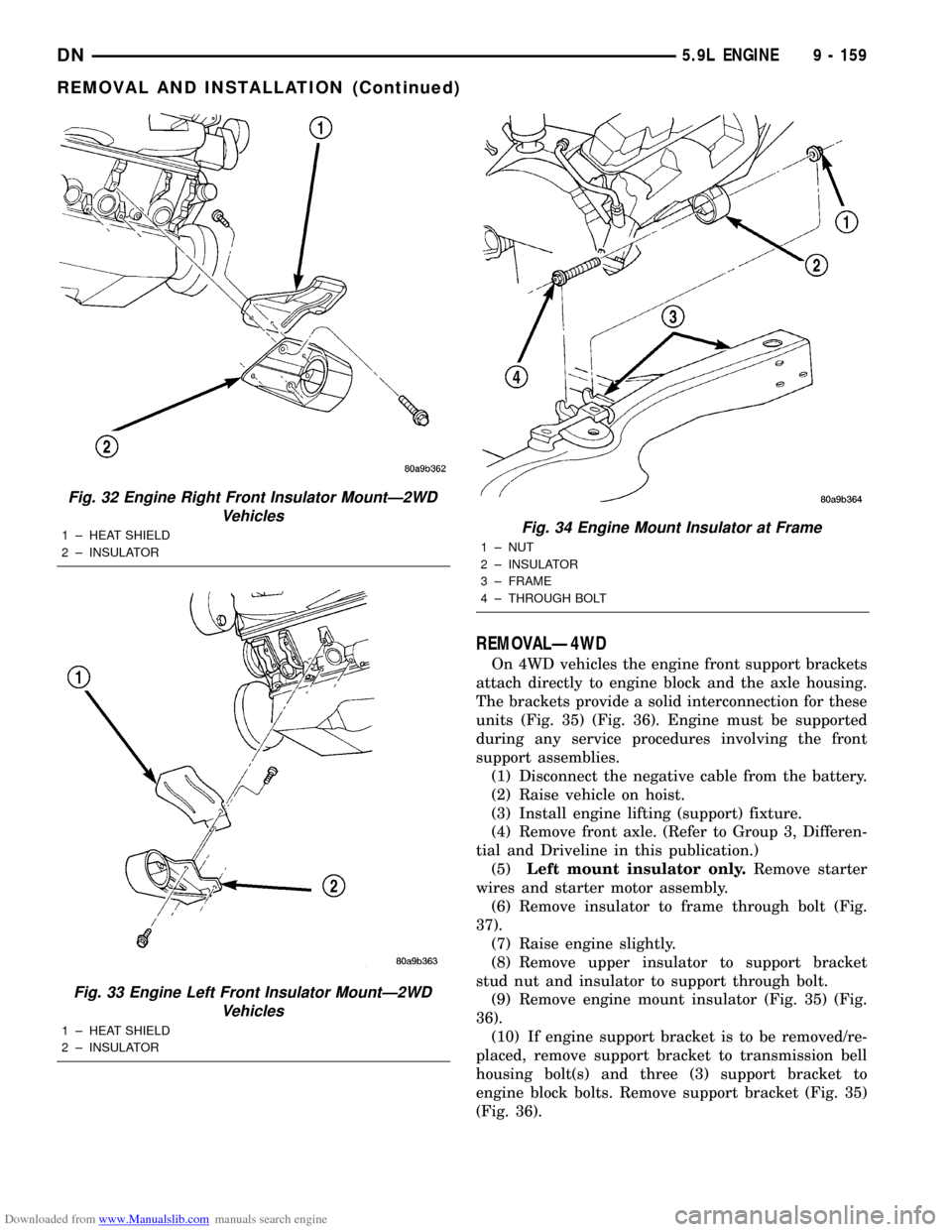

REMOVALÐ2WD

(1) Disconnect the negative cable from the battery.

(2) Raise hood and position fan to assure clearance

for radiator top tank and hose.

CAUTION: DO NOT lift the engine by the intake

manifold.

(3) Install engine lifting fixture.

(4) Raise vehicle on hoist.

(5) Remove the insulator through bolt (Fig. 32)

(Fig. 33).

(6) Raise engine with lifting fixture SLIGHTLY.

Remove insulator retaining bolts and remove the

insulator assembly.

(7) Remove insulator heat shield and transfer to

new insulator.

INSTALLATIONÐ2WD

(1) With the engine raised SLIGHTLY, position

insulator assembly onto the engine block and install

bolts (Fig. 32) (Fig. 33). Tighten the bolts to 41 N´m

(30 ft. lbs.) torque.

(2) Lower engine with lifting fixture while guiding

insulator assembly into the engine insulator bracket

(Fig. 34).

(3) Install insulator to bracket thru-bolt. Tighten

the thru-bolt nut to 68 N´m (50 ft. lbs.) torque.

(4) Remove lifting fixture.

(5) Connect the negative cable to the battery.

Fig. 29 Compression Ring Chamfer Location

(Typical)

1 ± CHAMFER

2 ± TOP COMPRESSION RING

3 ± SECOND COMPRESSION RING

4 ± PISTON

5 ± CHAMFER

Fig. 30 Proper Ring Installation

1 ± OIL RING SPACER GAP

2 ± SECOND COMPRESSION RING GAP OIL RING RAIL GAP

(TOP)

3 ± OIL RING RAIL GAP (BOTTOM)

4 ± TOP COMPRESSION RING GAP

Fig. 31 Main Bearing Identification

9 - 158 5.9L ENGINEDN

SERVICE PROCEDURES (Continued)

Page 160 of 193

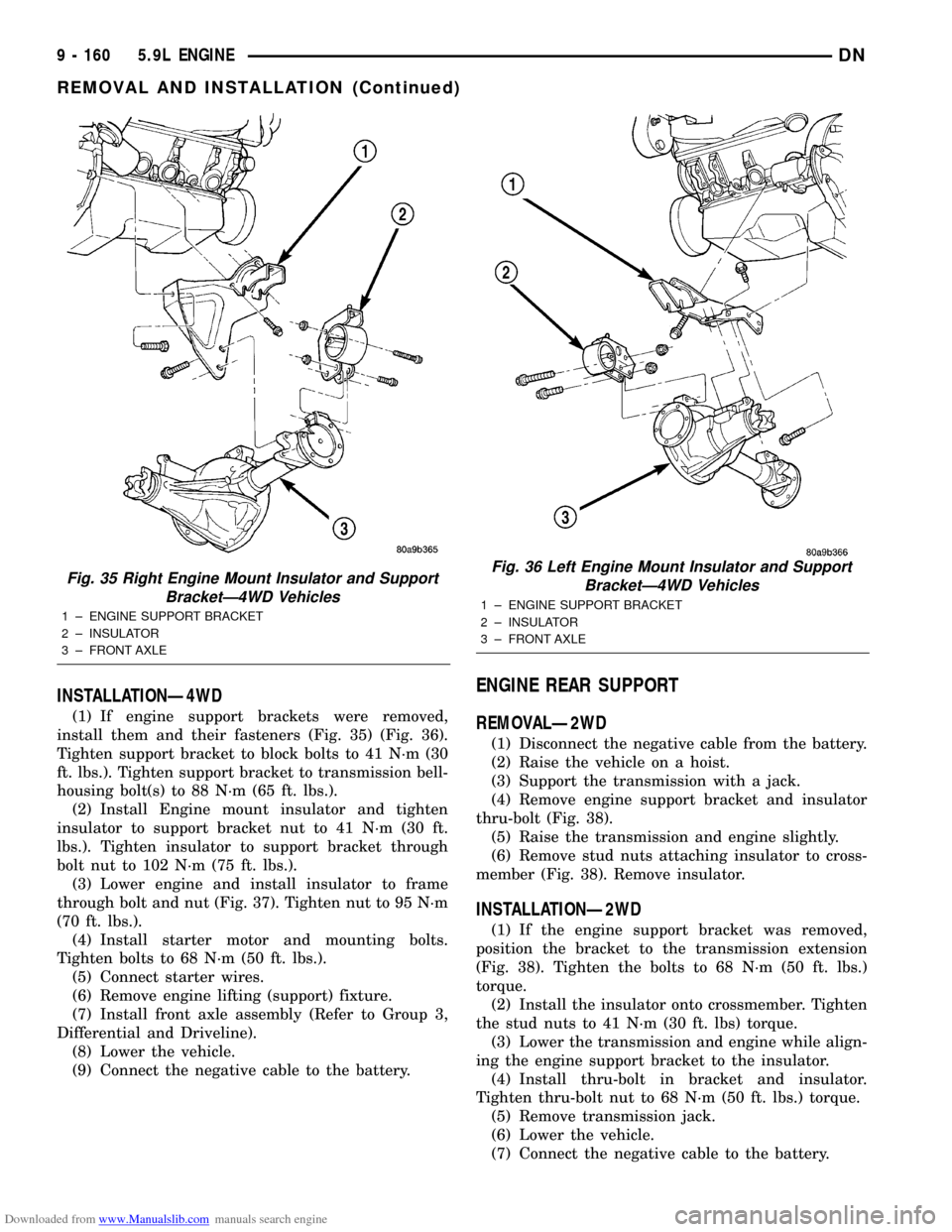

Downloaded from www.Manualslib.com manuals search engine REMOVALÐ4WD

On 4WD vehicles the engine front support brackets

attach directly to engine block and the axle housing.

The brackets provide a solid interconnection for these

units (Fig. 35) (Fig. 36). Engine must be supported

during any service procedures involving the front

support assemblies.

(1) Disconnect the negative cable from the battery.

(2) Raise vehicle on hoist.

(3) Install engine lifting (support) fixture.

(4) Remove front axle. (Refer to Group 3, Differen-

tial and Driveline in this publication.)

(5)Left mount insulator only.Remove starter

wires and starter motor assembly.

(6) Remove insulator to frame through bolt (Fig.

37).

(7) Raise engine slightly.

(8) Remove upper insulator to support bracket

stud nut and insulator to support through bolt.

(9) Remove engine mount insulator (Fig. 35) (Fig.

36).

(10) If engine support bracket is to be removed/re-

placed, remove support bracket to transmission bell

housing bolt(s) and three (3) support bracket to

engine block bolts. Remove support bracket (Fig. 35)

(Fig. 36).

Fig. 32 Engine Right Front Insulator MountÐ2WD

Vehicles

1 ± HEAT SHIELD

2 ± INSULATOR

Fig. 33 Engine Left Front Insulator MountÐ2WD

Vehicles

1 ± HEAT SHIELD

2 ± INSULATOR

Fig. 34 Engine Mount Insulator at Frame

1 ± NUT

2 ± INSULATOR

3 ± FRAME

4 ± THROUGH BOLT

DN5.9L ENGINE 9 - 159

REMOVAL AND INSTALLATION (Continued)

Page 161 of 193

Downloaded from www.Manualslib.com manuals search engine INSTALLATIONÐ4WD

(1) If engine support brackets were removed,

install them and their fasteners (Fig. 35) (Fig. 36).

Tighten support bracket to block bolts to 41 N´m (30

ft. lbs.). Tighten support bracket to transmission bell-

housing bolt(s) to 88 N´m (65 ft. lbs.).

(2) Install Engine mount insulator and tighten

insulator to support bracket nut to 41 N´m (30 ft.

lbs.). Tighten insulator to support bracket through

bolt nut to 102 N´m (75 ft. lbs.).

(3) Lower engine and install insulator to frame

through bolt and nut (Fig. 37). Tighten nut to 95 N´m

(70 ft. lbs.).

(4) Install starter motor and mounting bolts.

Tighten bolts to 68 N´m (50 ft. lbs.).

(5) Connect starter wires.

(6) Remove engine lifting (support) fixture.

(7) Install front axle assembly (Refer to Group 3,

Differential and Driveline).

(8) Lower the vehicle.

(9) Connect the negative cable to the battery.

ENGINE REAR SUPPORT

REMOVALÐ2WD

(1) Disconnect the negative cable from the battery.

(2) Raise the vehicle on a hoist.

(3) Support the transmission with a jack.

(4) Remove engine support bracket and insulator

thru-bolt (Fig. 38).

(5) Raise the transmission and engine slightly.

(6) Remove stud nuts attaching insulator to cross-

member (Fig. 38). Remove insulator.

INSTALLATIONÐ2WD

(1) If the engine support bracket was removed,

position the bracket to the transmission extension

(Fig. 38). Tighten the bolts to 68 N´m (50 ft. lbs.)

torque.

(2) Install the insulator onto crossmember. Tighten

the stud nuts to 41 N´m (30 ft. lbs) torque.

(3) Lower the transmission and engine while align-

ing the engine support bracket to the insulator.

(4) Install thru-bolt in bracket and insulator.

Tighten thru-bolt nut to 68 N´m (50 ft. lbs.) torque.

(5) Remove transmission jack.

(6) Lower the vehicle.

(7) Connect the negative cable to the battery.

Fig. 35 Right Engine Mount Insulator and Support

BracketÐ4WD Vehicles

1 ± ENGINE SUPPORT BRACKET

2 ± INSULATOR

3 ± FRONT AXLE

Fig. 36 Left Engine Mount Insulator and Support

BracketÐ4WD Vehicles

1 ± ENGINE SUPPORT BRACKET

2 ± INSULATOR

3 ± FRONT AXLE

9 - 160 5.9L ENGINEDN

REMOVAL AND INSTALLATION (Continued)