instrument panel DODGE DURANGO 2005 2.G Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2005, Model line: DURANGO, Model: DODGE DURANGO 2005 2.GPages: 416, PDF Size: 14.25 MB

Page 209 of 416

Front Unit to Rear Unit Chart

If the Front Control is

selectedRear Airflow will come

from

Panel Headliner

Bi-Level Headliner

•Between Bi-Level Floor Bi-Level

Floor Floor

Mix Floor

Defrost Floor

Operating Tips

Fast Cooldown

For a fast cooldown, set the blower fan to the highest

setting, set the mode control to the panel fresh position,

press the snowflake button to turn on the air condition-

ing, and drive with the windows open for the first few

minutes. Once the hot air has been expelled, close the

windows and set the mode selector to the Recirculationpanel or Recirculation Bi-level position. When a comfort-

able condition has been reached, choose a mode position

and adjust the temperature control and blower speed as

necessary to maintain comfort. For high humidity condi-

tions it may be necessary to remain in the Recirculation

mode to maintain comfort.

Window Fogging

Windows will fog on the inside when the humidity inside

the vehicle is high. This often occurs in mild or cool

temperatures when it’s rainy or humid. In most cases

turning on the Air-conditioning (pressing the snowflake

button) will clear the fog. Adjust the temperature control,

air direction and blower speed to maintain comfort.

As the temperature gets colder it may be necessary to

direct air onto the windshield by using MIX Mode

position on the control. Adjust the temperature control

INSTRUMENT PANEL AND CONTROLS 209

4

Page 210 of 416

and blower speed to maintain comfort. Interior fogging

on the windshield can be quickly removed by selecting

the defrost mode.

Regular cleaning of the inside of the windows with a

non-filming cleaning solution (vinegar and water works

very well) will help prevent contaminates (cigarette

smoke, perfumes, etc.) from sticking to the windows.

Contaminates increase the rate of window fogging.

Summer Operation

Air conditioned vehicles must be protected with a high

quality antifreeze coolant during summer to provide

proper corrosion protection and to raise the boiling point

of the coolant for protection against overheating. A 50 %

concentration is recommended.

When using the air conditioner in extremely heavy traffic

in hot weather especially when towing a trailer, addi-

tional engine cooling may be required. If this situation is

encountered, operate the transmission in a lower gear.When stopped in heavy traffic, it may be necessary to

shift into NEUTRAL and press the accelerator slightly for

fast idle operation.

Winter Operation

When operating the system during the winter months,

make sure the air intake, located directly in front of the

windshield, is free of ice, slush, snow, or other obstruc-

tions.

210 INSTRUMENT PANEL AND CONTROLS

Page 211 of 416

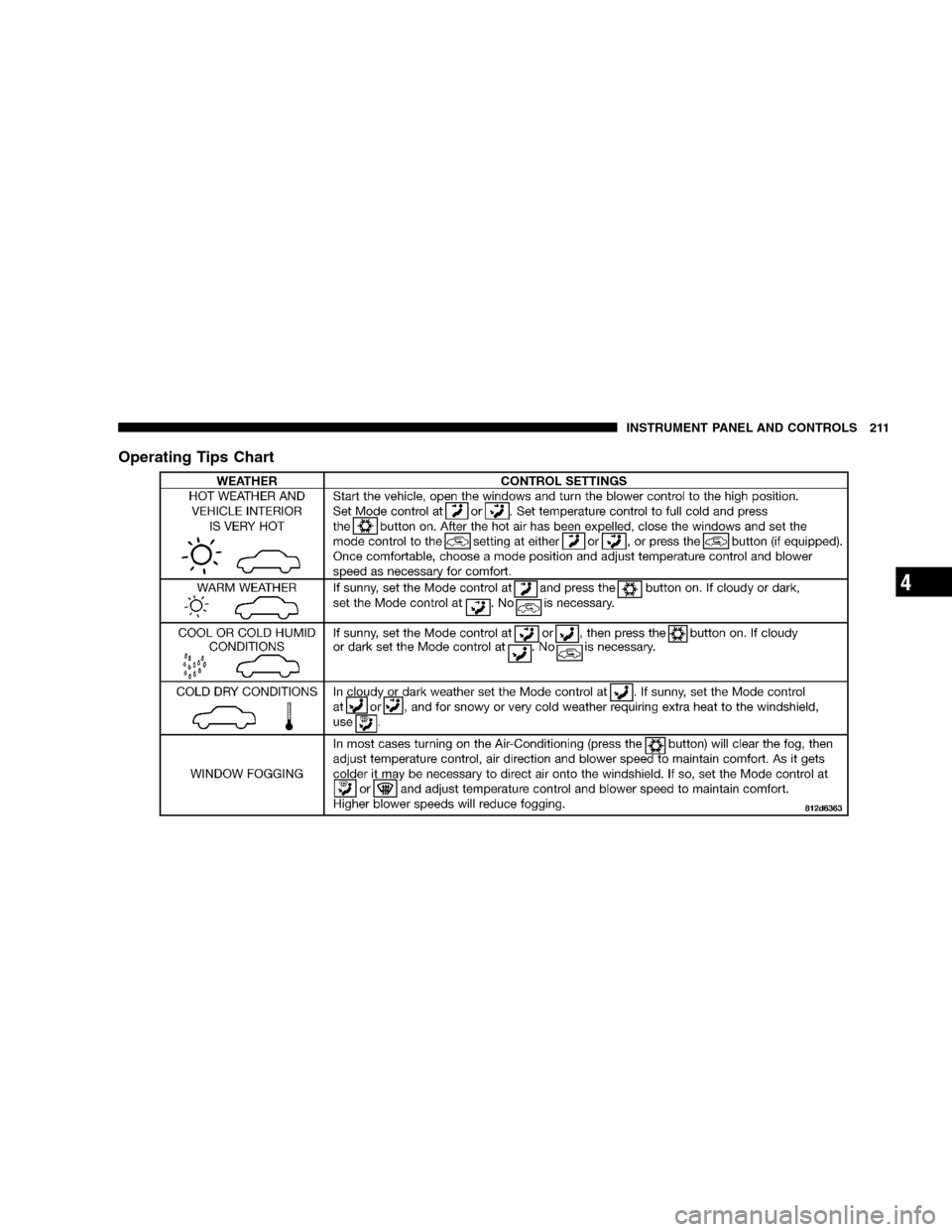

Operating Tips Chart

INSTRUMENT PANEL AND CONTROLS 211

4

Page 212 of 416

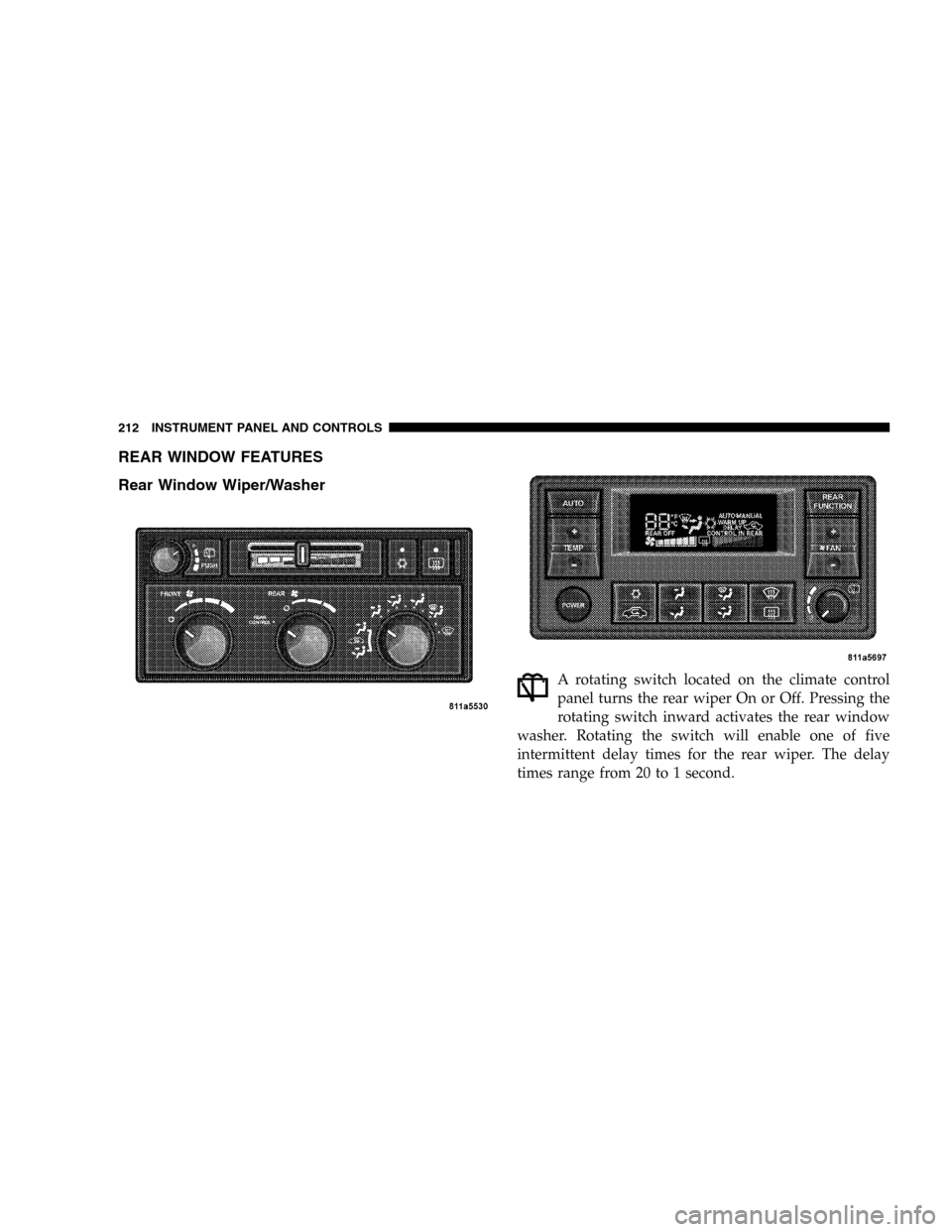

REAR WINDOW FEATURES

Rear Window Wiper/Washer

A rotating switch located on the climate control

panel turns the rear wiper On or Off. Pressing the

rotating switch inward activates the rear window

washer. Rotating the switch will enable one of five

intermittent delay times for the rear wiper. The delay

times range from 20 to 1 second.

212 INSTRUMENT PANEL AND CONTROLS

Page 213 of 416

If the rear wiper is operating when the ignition is turned

off, the wiper will automatically return to the “Park”

position. When the vehicle is restarted, the wiper will

resume operation.

Rear Window Defrosting

A push-button type switch is located in the climate

control panel. Press the switch and the rear win-

dow defroster and electric remote control heated mirrors

(if equipped) will turn On. An amber indicator on the

push-button will light when the defroster is turned On.

An symbol will be displayed when the defroster is turned

on with an ATC control. Push again to turn Off prior to

time-out. The defroster will automatically turn Off after

fifteen minutes. For ten more minutes of operation, push

the button again. To prevent excessive battery drain, use

the defroster only when the engine is operating.

CAUTION!

Use care when washing the inside of the rear win-

dow to prevent damage to heating elements. Use a

soft cloth and a mild washing solution, wiping

parallel to the heating elements. Also, keep all

objects a safe distance from the window to prevent

damaging the heating elements.

INSTRUMENT PANEL AND CONTROLS 213

4

Page 226 of 416

the fluid partially draining from the torque converter into

the transmission. This condition is normal and will not

cause damage to the transmission. The torque converter

will refill within five seconds of shifting from Park into

any other gear position.

FOUR-WHEEL DRIVE OPERATION

NV 144 Transfer Case Operating

Information/Precautions

The NV 144 is an electric shift transfer case and is

operated by the Four-Wheel-Drive (4WD) Control

Switch, which is located on the instrument panel.

The NV 144 transfer case provides 2 mode positions:

All-Wheel Drive (AWD) and 4-Wheel-Drive LOCK.

The NV 144 transfer case is designed to be driven in for

AWD for normal street and highway conditions (all road

surfaces roads).When additional traction is required, the transfer case

4LOCK position can be used to lock the front and rear

driveshafts together and force the front and rear wheels

to rotate at the same speed. This is accomplished by

rotating the 4WD Control Switch to the 4LOCK position

- see Shifting Procedure section for specific shifting

instructions. The 4LOCK position is designed for loose,

slippery road surfaces only. Driving in the 4LOCK posi-

tion on dry hard surfaced roads may cause increased tire

wear and damage to the driveline components.

Transfer Case Position Indicator Lights

Transfer case position indicator lights are located on the

instrument cluster, and indicate the current and desired

transfer case selection. If there are no indicator lights on

or flashing the transfer case position is All-Wheel Drive

(AWD).

The “SVC 4WD” warning light monitors the electric shift

4WD system. If this light remains on after engine start up

226 STARTING AND OPERATING

Page 228 of 416

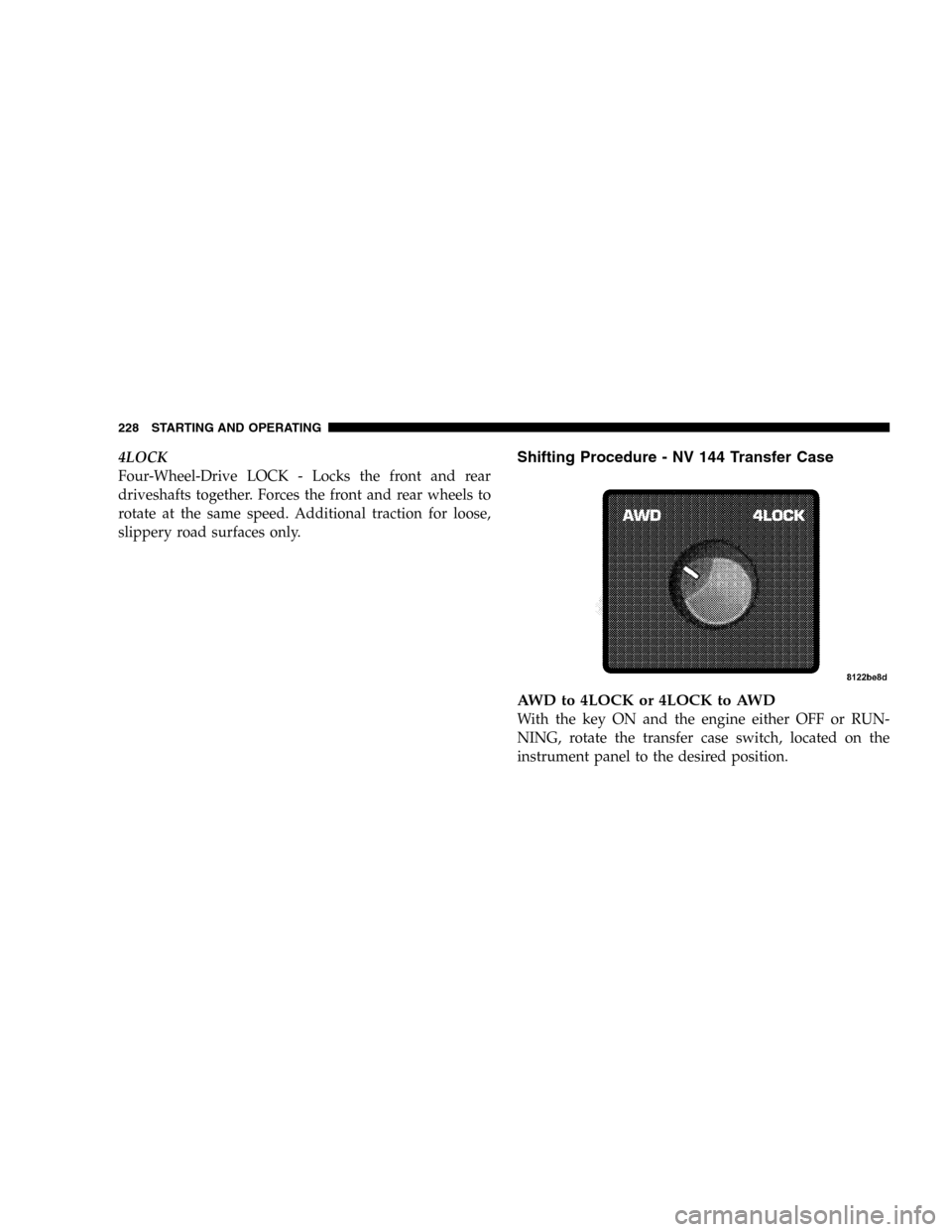

4LOCK

Four-Wheel-Drive LOCK - Locks the front and rear

driveshafts together. Forces the front and rear wheels to

rotate at the same speed. Additional traction for loose,

slippery road surfaces only.Shifting Procedure - NV 144 Transfer Case

AWD to 4LOCK or 4LOCK to AWD

With the key ON and the engine either OFF or RUN-

NING, rotate the transfer case switch, located on the

instrument panel to the desired position.

228 STARTING AND OPERATING

Page 229 of 416

NOTE:Delayed shifting out of 4LOCK may be experi-

enced due to uneven tire wear, low tire pressure, or

excessive vehicle loading.

NOTE:If any of the requirements to select a new

transfer case position have not been met, the transfer case

will not shift.The indicator light will flash and the current

transfer case position will be maintained.To retry a

selection, turn the control knob back to the current

position, wait five (5) seconds, and retry the shift.

NOTE:The 4x4 system will not allow shifts between

AWD/4LOCK if the rear wheels are spinning (no trac-

tion). In this situation the position indicator light will

continue to flash. At this time, reduce speed and stop

spinning the wheels to complete the shift. There may be

a delay up to 13 seconds for the shift to complete after the

wheels have stopped spinning.

NOTE:The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.If the key is not ON then the shift will not take place and

no position indicator lights will be on or flashing.

NV 244 Generation II Transfer Case Operating

Information / Precautions

The NV 244 Generation II is an electric shift transfer case

and is operated by the 4WD Control Switch, which is

located on the instrument panel.

The NV 244 Generation II transfer case provides 4 mode

positions - Normal all-wheel-drive high range, four-

wheel-drive LOCK, four-wheel-drive low range, and

neutral.

This transfer case is equipped with an inter-axle differ-

ential that allows driving the vehicle in the normal

all-wheel-drive position (AWD) at all times on any given

road surface, including dry hard surfaced roads. The

AWD mode allows the front and rear wheels to rotate at

different speeds. This eliminates driveline binding and

component wear normally associated with driving the

STARTING AND OPERATING 229

5

Page 234 of 416

3. While still rolling, rotate the transfer case control

switch to the desired position.

4. After the position indicator light has stopped flashing,

shift the transmission back into gear.

Alternate Procedure

1. Bring the vehicle to complete stop.

2. With the key ON and the engine either OFF or

RUNNING, shift the transmission into NEUTRAL.

3. Rotate the transfer case control switch to the desired

position.

4. After the position indicator light has stopped flashing,

shift the transmission back into gear.

NOTE:The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key is not ON then the shift will not take place and

no position indicator lights will be on or flashing.NOTE:If any of the requirements to select a new

transfer case position have not been met, the transfer case

will not shift. The indicator light will flash and the

current transfer case position will be maintained. To retry

the selection, turn the control knob back to the current

position, wait five (5) seconds, and retry the shift.

PARKING BRAKE

The foot operated parking brake is positioned below the

lower left corner of the instrument panel. To release the

parking brake, pull the parking brake release handle.

234 STARTING AND OPERATING

Page 276 of 416

In Canada, refer to the following website address:http://

www.dodge.ca.

Trailer Towing Requirements

All Dodge Durango trucks are intended to tow trailers up

to 2,000 lbs. (907 kg) without added equipment or

alterations to standard equipment. Your vehicle may be

factory equipped for safe towing of trailers over 2,000 lbs.

(907 kg) with the trailer tow package.The electrical part of

this package includes an instruction sheet and wiring

pigtail for an aftermarket electric trailer brake controller.

These items are stored in the glove box.

If you regularly pull a trailer, regardless of the trailer size,

stop and turn signals on the trailer are recommended for

motoring safety.

When the additional trailer lighting is connected to the

vehicle, the flasher does not provide an indication ofoutside lamp/bulb failure. Therefore, an occasional vi-

sual check around the vehicle is recommended. Once the

trailer is removed the above indication will return to the

vehicle.

WARNING!

The direct connection of hydraulic brake lines from

vehicle brake system to trailer system is not accept-

able. The extra load may cause brake failure and you

may be injured.

All Durango models are equipped with an Anti-Lock

Brake System and require an electrically actuated electric

brake controller. A blue colored connector for electric

brake hookup is located under the instrument panel

above the brake pedal.

276 STARTING AND OPERATING