ECU DODGE DURANGO 2008 2.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2008, Model line: DURANGO, Model: DODGE DURANGO 2008 2.GPages: 481, PDF Size: 7.75 MB

Page 184 of 481

The side rails between the stantions should be used to tie

down cargo. Check the straps frequently to be sure that

the load remains securely attached.

NOTE:Crossbars are offered by Mopartaccessories.

External racks do not increase the total load carrying

capacity of the vehicle. Be sure that the total occupant

and luggage load inside the vehicle, plus the load on the

luggage rack, do not exceed the maximum vehicle load

capacity.CAUTION!

To avoid damage to the roof rack and vehicle, do not

exceed the maximum roof rack load capacity. Always

distribute heavy loads as evenly as possible and

secure the load appropriately.

Long loads which extend over the windshield, such

as wood panels or surfboards, should be secured to

both the front and rear of the vehicle.

Place a blanket or other protection between the

surface of the roof and the load.

Travel at reduced speeds and turn corners carefully

when carrying large or heavy loads on the roof rack.

Wind forces, due to natural causes or nearby truck

traffic, can add sudden upward loads. This is espe-

cially true on large flat loads and may result in

damage to the cargo or your vehicle.

184 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 185 of 481

WARNING!

Cargo must be securely tied before driving your

vehicle. Improperly secured loads can fly off the

vehicle, particularly at high speeds, resulting in per-

sonal injury or property damage. Follow the roof rack

Cautions when carrying cargo on your roof rack.

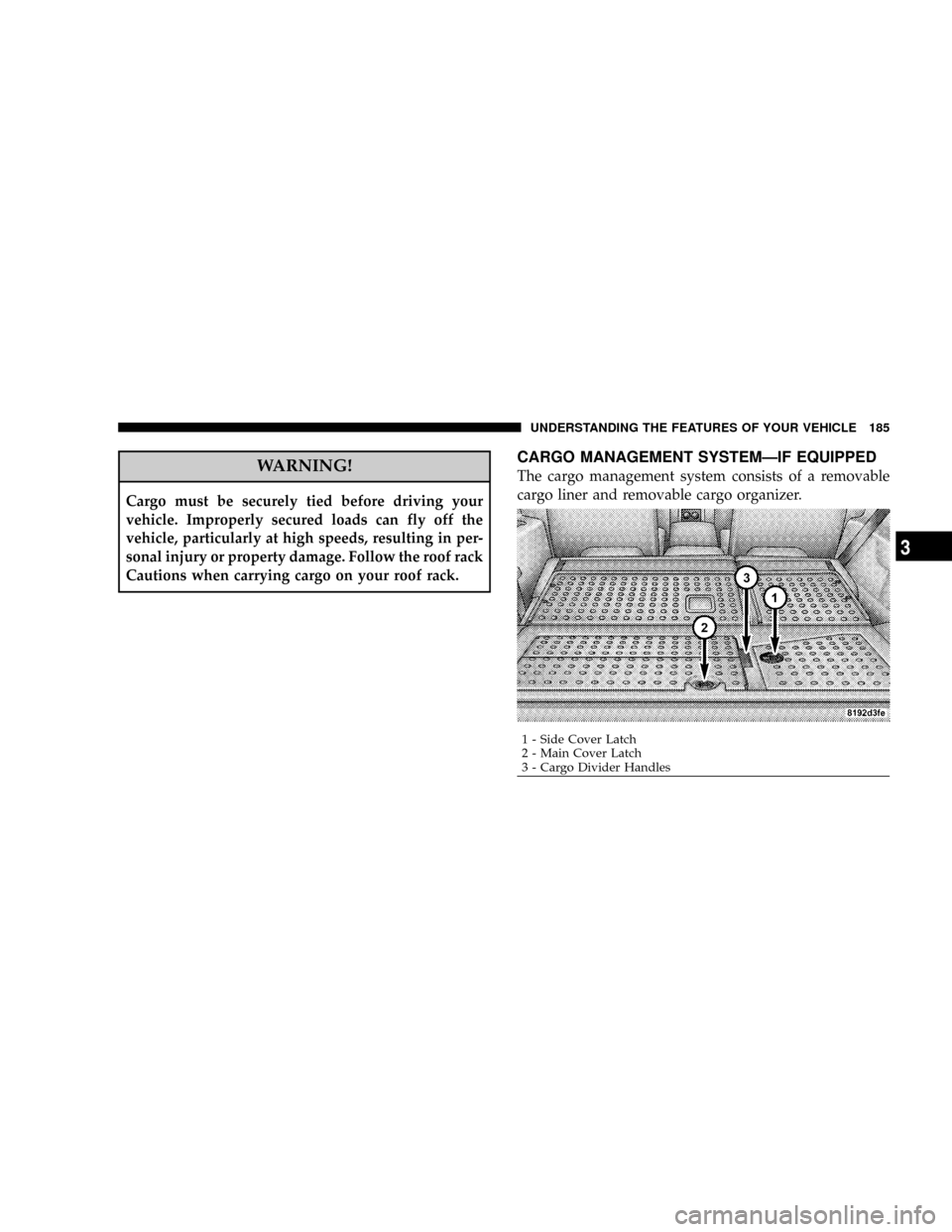

CARGO MANAGEMENT SYSTEMÐIF EQUIPPED

The cargo management system consists of a removable

cargo liner and removable cargo organizer.

1 - Side Cover Latch

2 - Main Cover Latch

3 - Cargo Divider HandlesUNDERSTANDING THE FEATURES OF YOUR VEHICLE 185

3

Page 195 of 481

WARNING!

A hot engine cooling system is dangerous. You or

others could be badly burned by steam or boiling

coolant. You may want to call a service center if your

vehicle overheats. If you decide to look under the

hood yourself, see Section 7 of this manual. Follow

the warnings under the Cooling System Pressure Cap

paragraph.

8. Speedometer

Shows the vehicles speed.

9. Voltage Light

This light monitors the electrical system voltage.

The light should turn on momentarily as the

engine is started. If the light stays on or turns on while

driving, it indicates a problem with the charging system.

Immediate service should be obtained.10. Security Light

This light will flash rapidly for approximately 15 seconds

when the vehicle theft alarm is arming. The light will

flash at a slower speed continuously after the alarm is set.

The security light will also come on for about three

seconds when the ignition is first turned on.

11. ABS Warning Light

This light monitors the Anti-Lock Brake System

which is described elsewhere in this manual.

This light will come on when the ignition key is

turned to the ON position and may stay on for

approximately 3 seconds. If this light remains on or

comes on during driving, it indicates that the Anti-Lock

portion of the brake system is not functioning and that

service is required. See your authorized dealer immedi-

ately. With the ABS malfunctioning, the BAS and ESP are

also switched off. Both malfunction indicator lights illu-

minate with the engine running. If the charging voltage

falls below 10 volts, the malfunction indicator light

INSTRUMENT PANEL AND CONTROLS 195

4

Page 282 of 481

Because four-wheel-drive provides improved traction,

there is a tendency to exceed safe turning and stopping

speeds. Do not go faster than road conditions permit.

4WD

Normal Four-Wheel-Drive High Range - Employs inter-

axle differential. Allows front and rear wheels to rotate at

different speeds. All road surfaces.

NV 244 Generation II Transfer Case Operating

Information / Precautions

The NV 244 Generation II is an electric shift transfer case

and is operated by the 4WD Control Switch, which is

located on the instrument panel.

The NV 244 Generation II transfer case provides 4 mode

positions - Normal four-wheel-drive (4WD) high range,

four-wheel-drive lock (4WD LOCK), four-wheel-drive

low (4WD LOW) range, and neutral (N).This transfer case is equipped with an inter-axle differ-

ential that allows driving the vehicle in the normal

all-wheel-drive position (4WD) at all times on any given

road surface, including dry hard surfaced roads. The

4WD mode allows the front and rear wheels to rotate at

different speeds. This eliminates driveline binding and

component wear normally associated with driving the

vehicle in the 4WD LOCK position on dry hard surfaced

roads. This feature provides the safety, security, and

convenience of operating in all-wheel drive at all times

regardless of road conditions.

When additional traction is required, the 4WD LOCK

and 4WD LOW positions can be used to lock the front

and rear driveshafts together through the transfer case

inter-axle differential and force the front and rear wheels

to rotate at the same speed. This is accomplished by

rotating the 4WD Control Switch to these positions. The

4WD LOCK and 4WD LOW positions are intended for

loose, slippery road surfaces only. Driving in the 4WD

282 STARTING AND OPERATING

Page 345 of 481

then be determined separately to be sure that the load is

properly distributed over front and rear axle. Weighing

the vehicle may show that the GAWR of either the front

or rear axles has been exceeded but the total load is

within the specified GVWR. If so, weight must be shifted

from front to rear or rear to front as appropriate until the

specified weight limitations are met.

Store heavier items down low and be sure that the weight

is distributed equally. Stow all loose items securely before

driving.

Improper weight distribution can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.WARNING!

Do not load your vehicle any heavier than the GVWR

or the maximum front and rear GAWR. If you do,

parts on your vehicle can break, or it can change the

way your vehicle handles. This could cause you to

lose control. Also, overloading can shorten the life of

your vehicle.

A loaded vehicle is shown in the following example. Note

that neither GVWR nor GAWR capabilities are exceeded.

Overloading can cause potential safety hazards and

shorten service life.

NOTE: The weights shown in this chart are not the

weights for your vehicle. Also, the amount of load

added to both the front and rear axles can be computed

STARTING AND OPERATING 345

5

Page 354 of 481

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

²When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

²Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

frame or hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

²Vehicles with trailers should not be parked on a grade.

When parking, apply the parking brake on the tow

vehicle. Put the tow vehicle automatic transmission in

P for Park. With a manual transmission, shift the

transmission into reverse. And with four-wheel-drive

vehicles, make sure the transfer case is not in neutral.

Always, block or9chock9the trailer wheels.

²GCWR must not be exceeded.

²Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded:

1. GVWR

354 STARTING AND OPERATING

Page 367 of 481

JACKING AND TIRE CHANGING

WARNING!

²Being under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never put any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you

need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

²The jack is designed to use as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or

slippery areas.

Jack Location

The scissor jack and tire changing tools are stowed under

the second row seat.

The jack is secured in place with a winged stud and a

fixed stud. It is very important to secure the jack tightly

in place by engaging the slot in the base to the fixed stud

under the middle seat. The winged stud inserts through

the eyelet in the end of the jack's worm screw.

WHAT TO DO IN EMERGENCIES 367

6

Page 374 of 481

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

²Block the wheel diagonally opposite the wheel to be

raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²

Do not let anyone sit in the vehicle when it is on a jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely careful

of motor traffic.

²To assure that spare tires, flat or inflated are securely

stowed, spares must be stowed with the value stem

facing the ground.

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Rotate the winch mechanism until the wheel is drawn

into place against the underside of the vehicle. Continue

to rotate until you feel the winch mechanism slip or click

2 times. It cannot be overtightened. Push against the tire

several times to be sure it is firmly in place.

374 WHAT TO DO IN EMERGENCIES

Page 409 of 481

Emission Related Components

Fuel System Hoses And Vapor/Vacuum Harnesses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be given to examining hose surfaces

nearest to high heat sources, such as the exhaust mani-

fold.

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily anindication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

You are urged to use only the manufacturer's specified

hoses and clamps, or their equivalent in material and

specification, in any fuel system servicing. It is manda-

tory to replace all clamps that have been loosened or

removed during service. Care should be taken in install-

ing new clamps to insure they are properly torqued.

Positive Crankcase Ventilation (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging because of deposits. Deposits can accumulate in the

PCV valve and passage with increasing mileage. Have

the PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valve ±Do not

MAINTAINING YOUR VEHICLE 409

7

Page 436 of 481

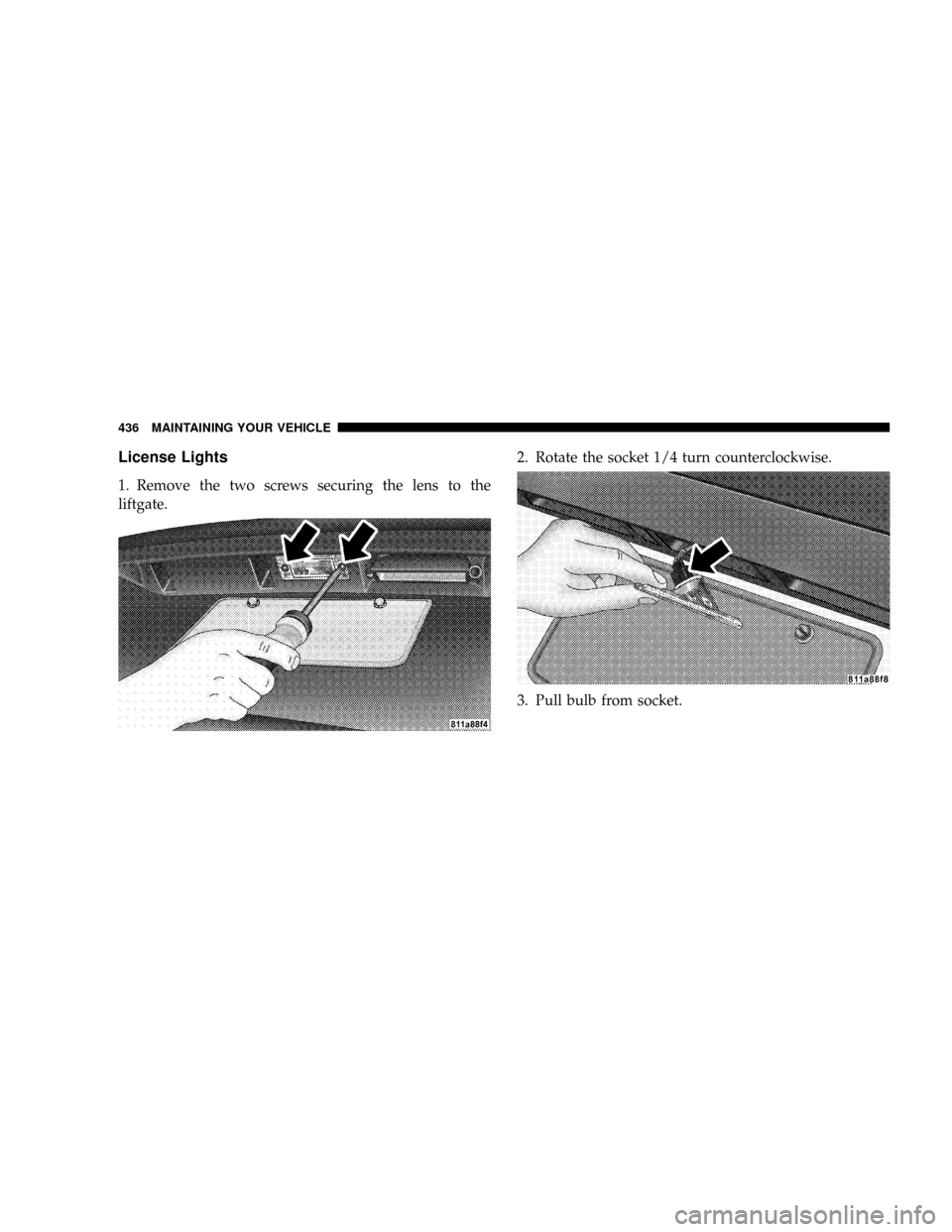

License Lights

1. Remove the two screws securing the lens to the

liftgate.2. Rotate the socket 1/4 turn counterclockwise.

3. Pull bulb from socket.

436 MAINTAINING YOUR VEHICLE