brakes DODGE DURANGO 2020 Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: DURANGO, Model: DODGE DURANGO 2020Pages: 464, PDF Size: 22.14 MB

Page 251 of 464

STARTING AND OPERATING249

Integrated Trailer Brake Module — If

Equipped

Your vehicle may have an Integrated Trailer

Brake Module (ITBM) for Electric and Electric

Over Hydraulic (EOH) trailer brakes.

NOTE:

This module has been designed and verified

with electric trailer brakes and new Electric Over

Hydraulic systems. Some previous EOH systems

may not be compatible with ITBM.

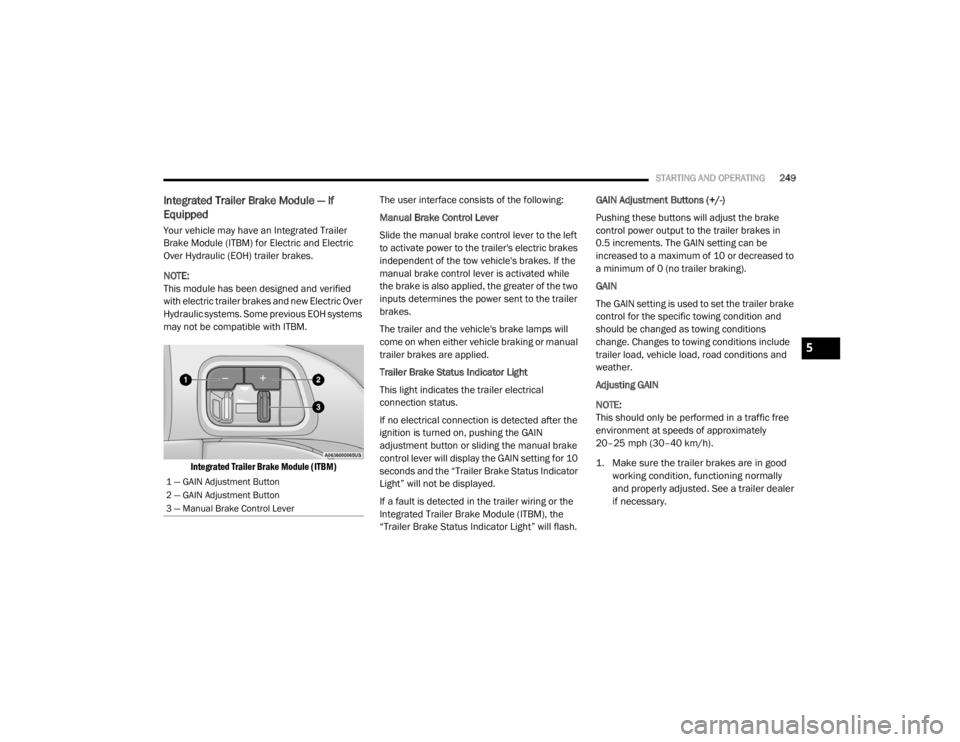

Integrated Trailer Brake Module (ITBM)

The user interface consists of the following:

Manual Brake Control Lever

Slide the manual brake control lever to the left

to activate power to the trailer's electric brakes

independent of the tow vehicle's brakes. If the

manual brake control lever is activated while

the brake is also applied, the greater of the two

inputs determines the power sent to the trailer

brakes.

The trailer and the vehicle's brake lamps will

come on when either vehicle braking or manual

trailer brakes are applied.

Trailer Brake Status Indicator Light

This light indicates the trailer electrical

connection status.

If no electrical connection is detected after the

ignition is turned on, pushing the GAIN

adjustment button or sliding the manual brake

control lever will display the GAIN setting for 10

seconds and the “Trailer Brake Status Indicator

Light” will not be displayed.

If a fault is detected in the trailer wiring or the

Integrated Trailer Brake Module (ITBM), the

“Trailer Brake Status Indicator Light” will flash. GAIN Adjustment Buttons (+/-)

Pushing these buttons will adjust the brake

control power output to the trailer brakes in

0.5 increments. The GAIN setting can be

increased to a maximum of 10 or decreased to

a minimum of 0 (no trailer braking).

GAIN

The GAIN setting is used to set the trailer brake

control for the specific towing condition and

should be changed as towing conditions

change. Changes to towing conditions include

trailer load, vehicle load, road conditions and

weather.

Adjusting GAIN

NOTE:

This should only be performed in a traffic free

environment at speeds of approximately

20–25 mph (30–40 km/h).

1. Make sure the trailer brakes are in good

working condition, functioning normally

and properly adjusted. See a trailer dealer

if necessary.

1 — GAIN Adjustment Button

2 — GAIN Adjustment Button

3 — Manual Brake Control Lever

5

20_WD_OM_EN_USC_t.book Page 249

Page 252 of 464

250STARTING AND OPERATING

2. Hook up the trailer and make the electrical

connections according to the trailer

manufacturer's instructions.

3. When a trailer with electric/EOH brakes is plugged in, the trailer connected message

should appear in the instrument cluster

display (if the connection is not recognized

by the ITBM, braking functions will not be

available), the GAIN setting will illuminate

and the correct type of trailer must be

selected from the instrument cluster display

options.

4. Push the UP or DOWN button on the steering wheel until “TRAILER TOW”

appears on the screen.

5. Push the RIGHT arrow on the steering wheel to enter “TRAILER TOW”.

6. Push the UP or DOWN buttons until the Trailer Brake Type appears on the screen.

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper Trailer

Brake Type appears on the screen. 8. In a traffic-free environment, tow the trailer

on a dry, level surface at a speed of

20–25 mph (30–40 km/h) and squeeze

the manual brake control lever completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting; if

the trailer wheels turn freely, increase the

GAIN setting.

Repeat steps 8 and 9 until the GAIN setting is at

a point just below trailer wheel lockup. If towing

a heavier trailer, trailer wheel lockup may not be

attainable even with the maximum GAIN setting

of 10.

Display Messages

The trailer brake control interacts with the

instrument cluster display. Display messages,

along with a single chime, will be displayed

when a malfunction is determined in the trailer

connection, trailer brake control, or on the

trailer. Refer to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

further information.WARNING!

Connecting a trailer that is not compatible

with the ITBM system may result in reduced

or complete loss of trailer braking. There may

be a increase in stopping distance or trailer

instability which could result in personal

injury.

CAUTION!

Connecting a trailer that is not compatible

with the ITBM system may result in reduced

or complete loss of trailer braking. There may

be a increase in stopping distance or trailer

instability which could result in damage to

your vehicle, trailer, or other property.

20_WD_OM_EN_USC_t.book Page 250

Page 253 of 464

STARTING AND OPERATING251

NOTE:

An aftermarket controller may be available

for use with trailers with air or Electric Over

Hydraulic trailer brake systems. To determine

the type of brakes on your trailer and the

availability of controllers, check with your

trailer manufacturer or dealer.

Removal of the ITBM will cause errors and it

may cause damage to the electrical system

and electronic modules of the vehicle. See an

authorized dealer if an aftermarket module is

to be installed.

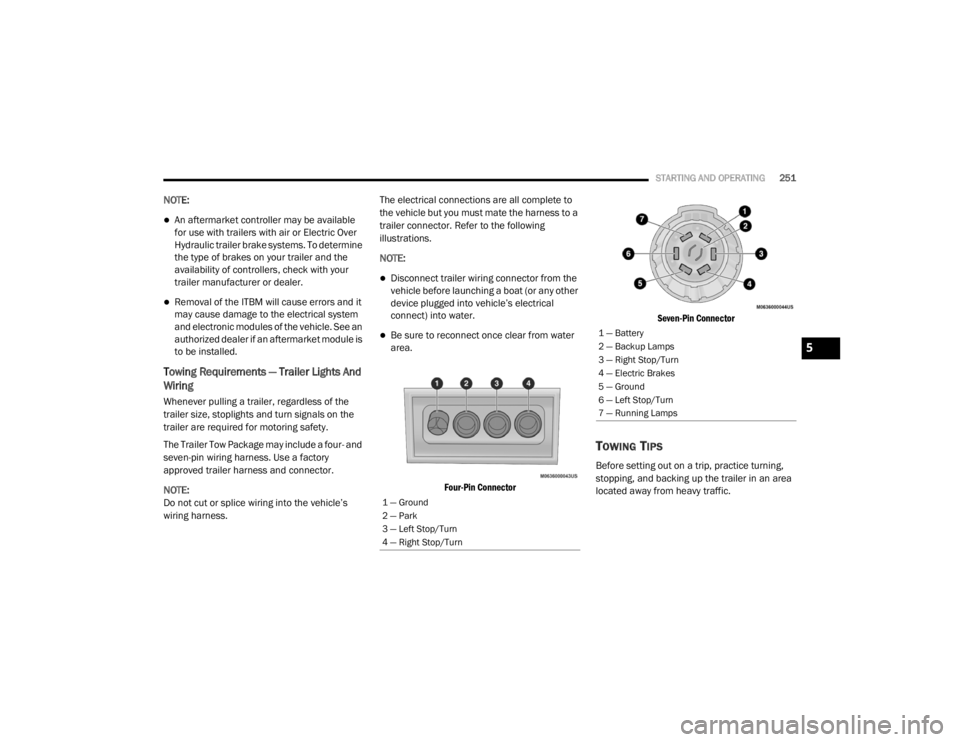

Towing Requirements — Trailer Lights And

Wiring

Whenever pulling a trailer, regardless of the

trailer size, stoplights and turn signals on the

trailer are required for motoring safety.

The Trailer Tow Package may include a four- and

seven-pin wiring harness. Use a factory

approved trailer harness and connector.

NOTE:

Do not cut or splice wiring into the vehicle’s

wiring harness. The electrical connections are all complete to

the vehicle but you must mate the harness to a

trailer connector. Refer to the following

illustrations.

NOTE:

Disconnect trailer wiring connector from the

vehicle before launching a boat (or any other

device plugged into vehicle’s electrical

connect) into water.

Be sure to reconnect once clear from water

area.

Four-Pin Connector Seven-Pin Connector

TOWING TIPS

Before setting out on a trip, practice turning,

stopping, and backing up the trailer in an area

located away from heavy traffic.

1 — Ground

2 — Park

3 — Left Stop/Turn

4 — Right Stop/Turn

1 — Battery

2 — Backup Lamps

3 — Right Stop/Turn

4 — Electric Brakes

5 — Ground

6 — Left Stop/Turn

7 — Running Lamps

5

20_WD_OM_EN_USC_t.book Page 251

Page 261 of 464

STARTING AND OPERATING259

Driving In Snow, Mud And Sand

In heavy snow, when pulling a load, or for

additional control at slower speeds, shift the

transmission to a low gear and shift the transfer

case to LOW if necessary. Refer to “All-Wheel

Drive Operation” in “Starting And Operating” for

further information. Do not shift to a lower gear

than necessary to maintain forward motion.

Over-revving the engine can spin the wheels

and traction will be lost.

Avoid abrupt downshifts on icy or slippery roads,

because engine braking may cause skidding

and loss of control.

Hill Climbing

NOTE:

Before attempting to climb a hill, determine the

conditions at the crest and/or on the other side.

Before climbing a steep hill, shift the

transmission to a lower gear and shift the

transfer case to LOW. Use FIRST gear and LOW

for very steep hills. If you stall or begin to lose forward motion while

climbing a steep hill, allow your vehicle to come

to a stop and immediately apply the brakes.

Restart the engine, and shift into REVERSE.

Back slowly down the hill, allowing the

compression braking of the engine to help

regulate the speed. If the brakes are required to

control vehicle speed, apply them lightly and

avoid locking or skidding the tires.

Remember, never drive diagonally across a hill;

always drive straight up or down.

If the wheels start to slip as you approach the

crest of a hill, ease off the accelerator and

maintain forward motion by turning the front

wheels slowly. This may provide a fresh “bite”

into the surface and will usually provide traction

to complete the climb.

Traction Downhill

Shift the transmission into a low gear, and the

transfer case into LOW range. Let the vehicle go

slowly down the hill with all four wheels turning

against engine compression drag. This will

permit you to control the vehicle speed and

direction.

When descending mountains or hills, repeated

braking can cause brake fade with loss of

braking control. Avoid repeated heavy braking

by downshifting the transmission whenever

possible.WARNING!

If the engine stalls, you lose forward motion,

or cannot make it to the top of a steep hill or

grade, never attempt to turn around. To do so

may result in tipping and rolling the vehicle.

Always back carefully straight down a hill in

REVERSE gear. Never back down a hill in

NEUTRAL using only the brake.5

20_WD_OM_EN_USC_t.book Page 259

Page 262 of 464

260STARTING AND OPERATING

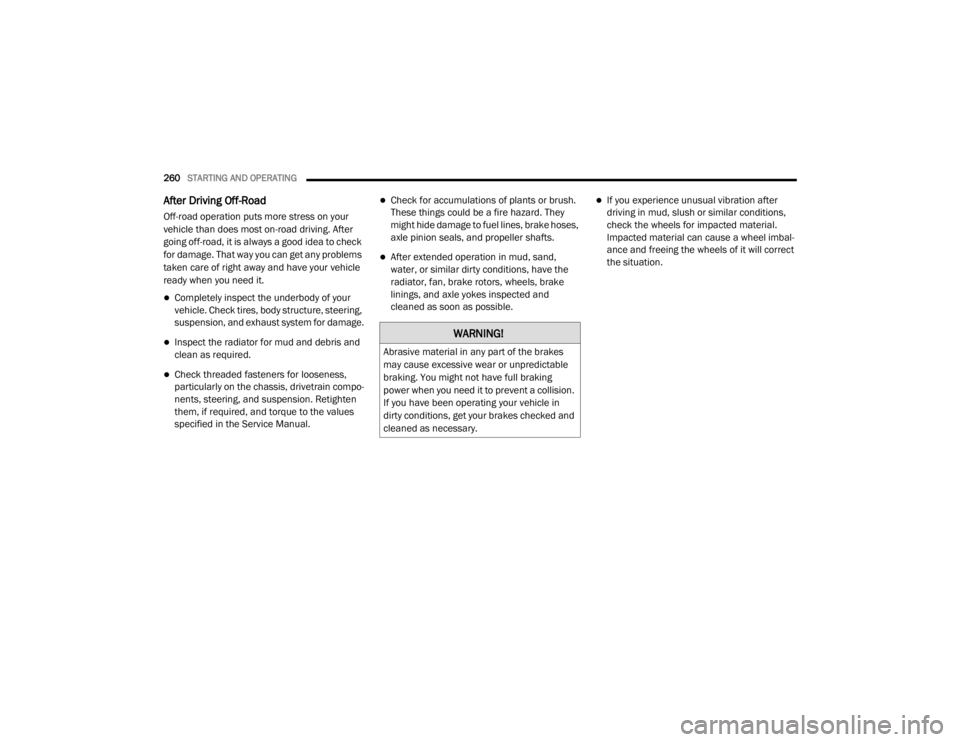

After Driving Off-Road

Off-road operation puts more stress on your

vehicle than does most on-road driving. After

going off-road, it is always a good idea to check

for damage. That way you can get any problems

taken care of right away and have your vehicle

ready when you need it.

Completely inspect the underbody of your

vehicle. Check tires, body structure, steering,

suspension, and exhaust system for damage.

Inspect the radiator for mud and debris and

clean as required.

Check threaded fasteners for looseness,

particularly on the chassis, drivetrain compo -

nents, steering, and suspension. Retighten

them, if required, and torque to the values

specified in the Service Manual.

Check for accumulations of plants or brush.

These things could be a fire hazard. They

might hide damage to fuel lines, brake hoses,

axle pinion seals, and propeller shafts.

After extended operation in mud, sand,

water, or similar dirty conditions, have the

radiator, fan, brake rotors, wheels, brake

linings, and axle yokes inspected and

cleaned as soon as possible.

If you experience unusual vibration after

driving in mud, slush or similar conditions,

check the wheels for impacted material.

Impacted material can cause a wheel imbal-

ance and freeing the wheels of it will correct

the situation.

WARNING!

Abrasive material in any part of the brakes

may cause excessive wear or unpredictable

braking. You might not have full braking

power when you need it to prevent a collision.

If you have been operating your vehicle in

dirty conditions, get your brakes checked and

cleaned as necessary.

20_WD_OM_EN_USC_t.book Page 260

Page 275 of 464

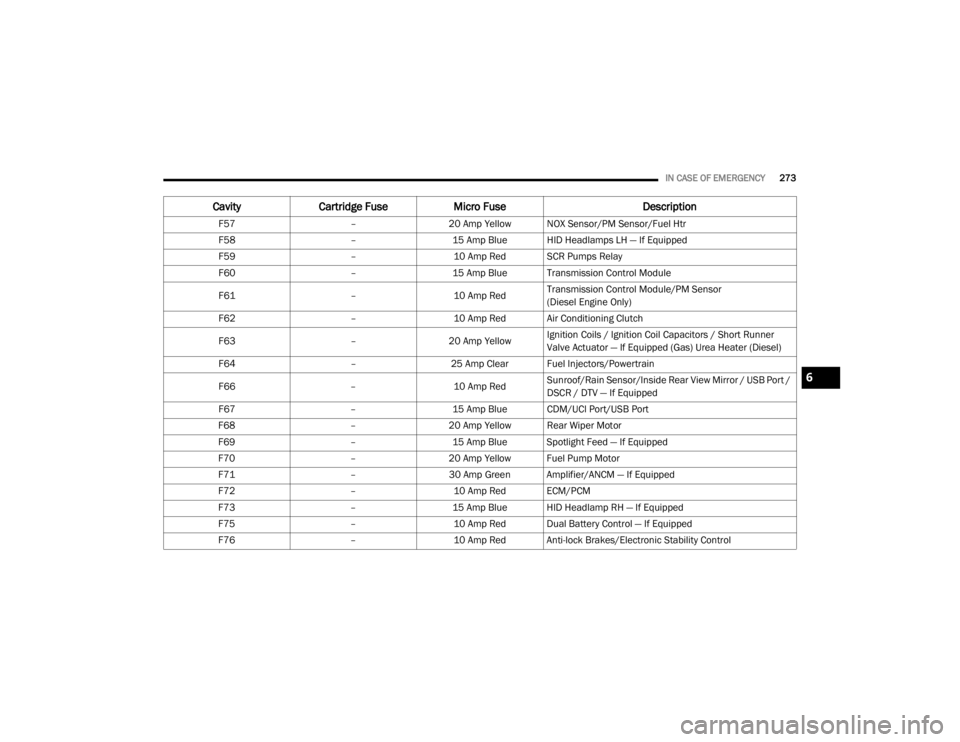

IN CASE OF EMERGENCY273

F57 –20 Amp Yellow NOX Sensor/PM Sensor/Fuel Htr

F58 –15 Amp Blue HID Headlamps LH — If Equipped

F59 –10 Amp Red SCR Pumps Relay

F60 –15 Amp Blue Transmission Control Module

F61 –10 Amp RedTransmission Control Module/PM Sensor

(Diesel Engine Only)

F62 –10 Amp Red Air Conditioning Clutch

F63 –20 Amp Yellow Ignition Coils / Ignition Coil Capacitors / Short Runner

Valve Actuator — If Equipped (Gas) Urea Heater (Diesel)

F64 –25 Amp Clear Fuel Injectors/Powertrain

F66 –10 Amp RedSunroof/Rain Sensor/Inside Rear View Mirror / USB Port /

DSCR / DTV — If Equipped

F67 –15 Amp Blue CDM/UCI Port/USB Port

F68 –20 Amp Yellow Rear Wiper Motor

F69 –15 Amp Blue Spotlight Feed — If Equipped

F70 –20 Amp Yellow Fuel Pump Motor

F71 –30 Amp Green Amplifier/ANCM — If Equipped

F72 –10 Amp Red ECM/PCM

F73 –15 Amp Blue HID Headlamp RH — If Equipped

F75 –10 Amp Red Dual Battery Control — If Equipped

F76 –10 Amp Red Anti-lock Brakes/Electronic Stability Control

CavityCartridge Fuse Micro Fuse Description

6

20_WD_OM_EN_USC_t.book Page 273

Page 289 of 464

IN CASE OF EMERGENCY287

IF YOUR ENGINE OVERHEATS

In any of the following situations, you can

reduce the potential for overheating by taking

the appropriate action.

On the highways — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL (N), but do not increase

the engine idle speed while preventing

vehicle motion with the brakes.

NOTE:

There are steps that you can take to slow down

an impending overheat condition:

If your Air Conditioner (A/C) is on, turn it off.

The A/C system adds heat to the engine

cooling system and turning the A/C off can

help remove this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the

heater core to act as a supplement to the

radiator and aids in removing heat from the

engine cooling system.

MANUAL PARK RELEASE

To move the vehicle in cases where the

transmission will not shift out of PARK (P) (such

as a depleted battery), a Manual Park Release

is available.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from

your radiator. If you see or hear steam coming

from under the hood, do not open the hood

until the radiator has had time to cool. Never

try to open a cooling system pressure cap

when the radiator or coolant bottle is hot.

CAUTION!

Driving with a hot cooling system could

damage your vehicle. If the temperature

gauge reads HOT (H), pull over and stop the

vehicle. Idle the vehicle with the air

conditioner turned off until the pointer drops

back into the normal range. If the pointer

remains on HOT (H), and you hear continuous

chimes, turn the engine off immediately and

call for service.

WARNING!

Always secure your vehicle by fully applying

the parking brake before activating the

Manual Park Release. In addition, you should

be seated in the driver’s seat with your foot

firmly on the brake pedal when activating the

Manual Park Release. Activating the Manual

Park Release will allow your vehicle to roll

away if it is not secured by the parking brake,

or by proper connection to a tow vehicle.

Activating the Manual Park Release on an

unsecured vehicle could lead to serious injury

or death for those in or around the vehicle.

6

20_WD_OM_EN_USC_t.book Page 287

Page 303 of 464

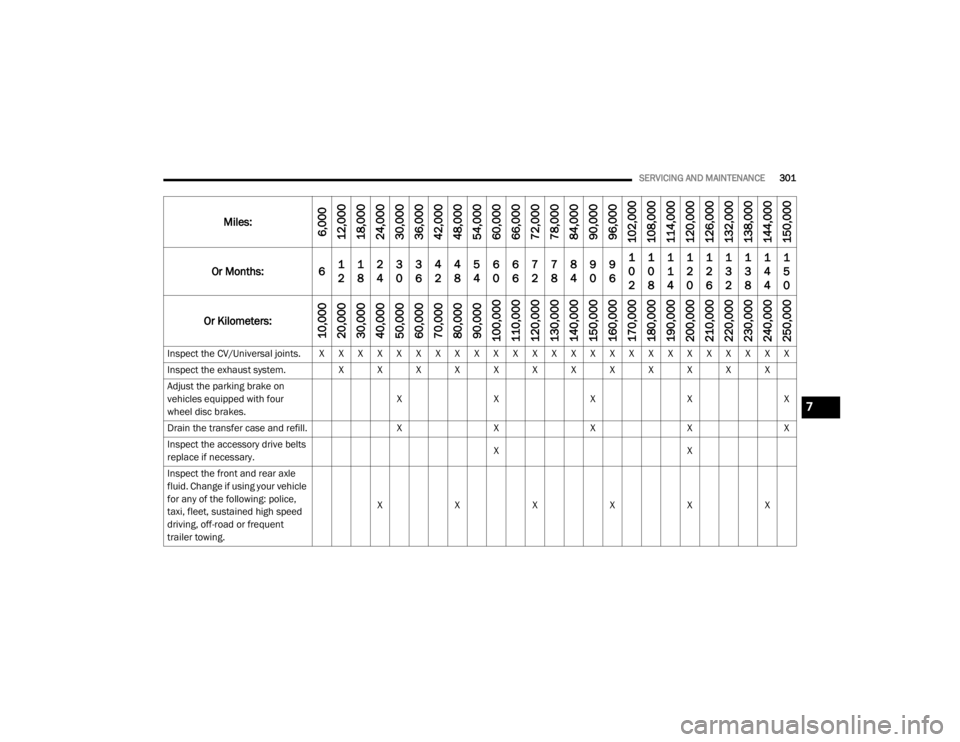

SERVICING AND MAINTENANCE301

Inspect the CV/Universal joints. X X X X X X X X X X X X X X X X X X X X X X X X X

Inspect the exhaust system. X X X X X X X X X X X X

Adjust the parking brake on

vehicles equipped with four

wheel disc brakes. X

XXXX

Drain the transfer case and refill. XXXXX

Inspect the accessory drive belts

replace if necessary. X

X

Inspect the front and rear axle

fluid. Change if using your vehicle

for any of the following: police,

taxi, fleet, sustained high speed

driving, off-road or frequent

trailer towing. X

XXXXX

Miles:6,000

12,000

18,000

24,000

30,000

36,000

42,000

48,000

54,000

60,000

66,000

72,000

78,000

84,000

90,000

96,000

102,000

108,000

114,000

120,000

126,000

132,000

138,000

144,000

150,000

Or Months: 6 1

21

82

43

03

64

24

85

46

06

67

27

88

49

09

61

0

21

0

81

1

41

2

01

2

61

3

21

3

81

4

41

5

0

Or Kilometers:

10,000

20,000

30,000

40,000

50,000

60,000

70,000

80,000

90,000

100,000

110,000

120,000

130,000

140,000

150,000

160,000

170,000

180,000

190,000

200,000

210,000

220,000

230,000

240,000

250,000

7

20_WD_OM_EN_USC_t.book Page 301

Page 327 of 464

SERVICING AND MAINTENANCE325

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked whenever the vehicle is serviced, or

immediately if the brake system warning light is

on. If necessary, add fluid to bring level within

the designated marks on the side of the

reservoir of the brake master cylinder. Be sure

to clean the top of the master cylinder area

before removing cap. With disc brakes, fluid level can be expected to

fall as the brake pads wear. Brake fluid level

should be checked when pads are replaced. If

the brake fluid is abnormally low, check the

system for leaks.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle

is also identified on the original factory

installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

20_WD_OM_EN_USC_t.book Page 325

Page 345 of 464

SERVICING AND MAINTENANCE343

(Continued)

When cleaning extremely dirty wheels including

excessive brake dust, care must be taken in the

selection of tire and wheel cleaning chemicals

and equipment to prevent damage to the

wheels. Mopar Wheel Treatment or Mopar

Chrome Cleaner or their equivalent is

recommended or select a non-abrasive,

non-acidic cleaner for aluminum or chrome

wheels.

NOTE:

If you intend parking or storing your vehicle for

an extended period after cleaning the wheels

with wheel cleaner, drive your vehicle and apply

the brakes to remove the water droplets from

the brake components. This activity will remove

the red rust on the brake rotors and prevent

vehicle vibration when braking. Dark Vapor Chrome, Black Satin Chrome, or

Low Gloss Clear Coat Wheels

TIRE CHAINS AND TRACTION DEVICES —

N

ON-SRT

Use of traction devices require sufficient

tire-to-body clearance. Follow these

recommendations to guard against damage.

Traction device must be of proper size for the

tire, as recommended by the traction device

manufacturer.

Install on rear tires only.

Due to limited clearance, the Koing XG-12

PRO traction device or equivalent is recom -

mended on 265/60R18, P265/60R18, and

265/50R20 tires.

CAUTION!

Do not use scouring pads, steel wool, a bristle

brush, metal polishes or oven cleaner. These

products may damage the wheel's protective

finish. Such damage is not covered by the

New Vehicle Limited Warranty. Only car wash

soap, Mopar Wheel Cleaner or equivalent is

recommended.

CAUTION!

If your vehicle is equipped with these

specialty wheels, DO NOT USE wheel

cleaners, abrasives, or polishing compounds.

They will permanently damage this finish and

such damage is not covered by the New

Vehicle Limited Warranty. HAND WASH ONLY

USING MILD SOAP AND WATER WITH A SOFT

CLOTH. Used on a regular basis; this is all that

is required to maintain this finish.WARNING!

Using tires of different size and type

(M+S, Snow) between front and rear axles

can cause unpredictable handling. You could

lose control and have a collision.

CAUTION!

To avoid damage to your vehicle or tires,

observe the following precautions:

Because of restricted traction device clear -

ance between tires and other suspension

components, it is important that only trac-

tion devices in good condition are used.

Broken devices can cause serious damage.

Stop the vehicle immediately if noise

occurs that could indicate device breakage.

Remove the damaged parts of the device

before further use.

Install device as tightly as possible and

then retighten after driving about ½ mile

(0.8 km).

7

20_WD_OM_EN_USC_t.book Page 343