warning light DODGE DURANGO 2020 Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: DURANGO, Model: DODGE DURANGO 2020Pages: 464, PDF Size: 22.14 MB

Page 278 of 464

276IN CASE OF EMERGENCY

RUN FLAT TIRES

SRT models are equipped with “run flat” tires.

Run flat tires allow the vehicle to be driven

approximately 50 miles (80 km) at 50 mph

(80 km/h). Tire service should be obtained to

avoid prolonged run flat feature usage.

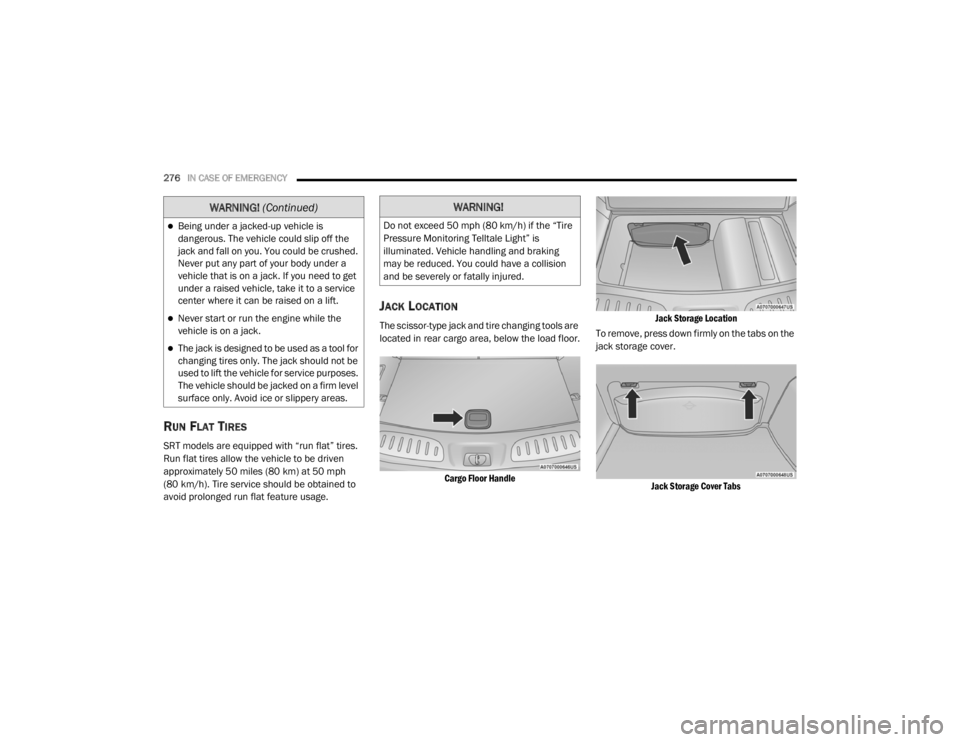

JACK LOCATION

The scissor-type jack and tire changing tools are

located in rear cargo area, below the load floor.

Cargo Floor Handle Jack Storage Location

To remove, press down firmly on the tabs on the

jack storage cover.

Jack Storage Cover Tabs

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING! (Continued)WARNING!

Do not exceed 50 mph (80 km/h) if the “Tire

Pressure Monitoring Telltale Light” is

illuminated. Vehicle handling and braking

may be reduced. You could have a collision

and be severely or fatally injured.

20_WD_OM_EN_USC_t.book Page 276

Page 283 of 464

IN CASE OF EMERGENCY281

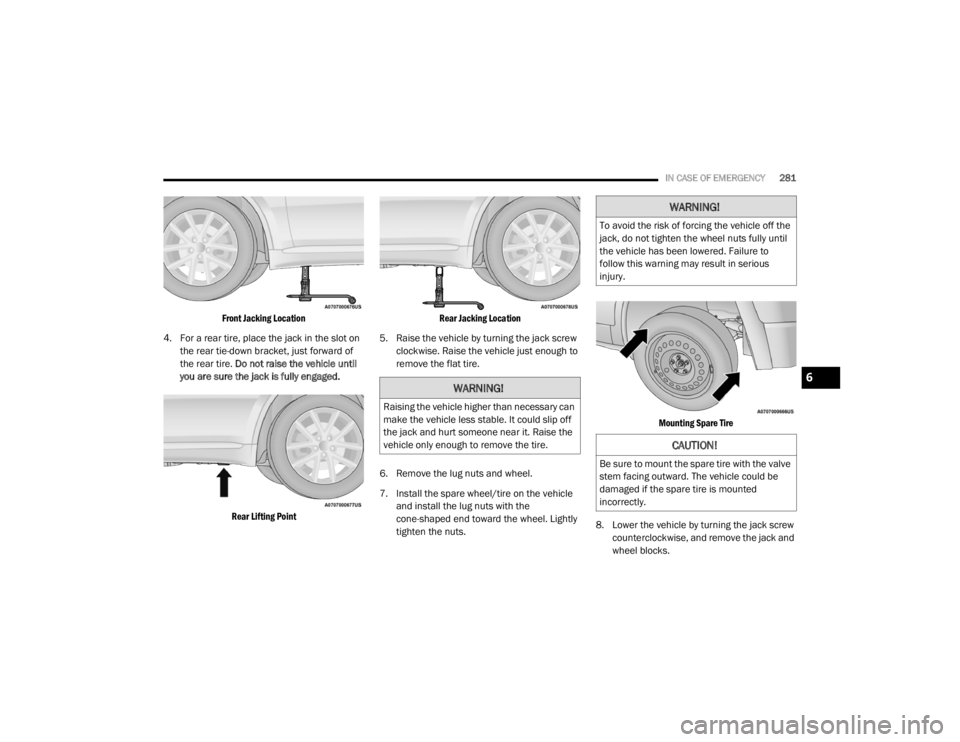

Front Jacking Location

4. For a rear tire, place the jack in the slot on the rear tie-down bracket, just forward of

the rear tire. Do not raise the vehicle until

you are sure the jack is fully engaged.

Rear Lifting Point Rear Jacking Location

5. Raise the vehicle by turning the jack screw clockwise. Raise the vehicle just enough to

remove the flat tire.

6. Remove the lug nuts and wheel.

7. Install the spare wheel/tire on the vehicle and install the lug nuts with the

cone-shaped end toward the wheel. Lightly

tighten the nuts.

Mounting Spare Tire

8. Lower the vehicle by turning the jack screw counterclockwise, and remove the jack and

wheel blocks.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted

incorrectly.

6

20_WD_OM_EN_USC_t.book Page 281

Page 285 of 464

IN CASE OF EMERGENCY283

NOTE:

Double check to ensure the tire is snug against

the underbody of the vehicle. Damage to the

winch cable may result if the vehicle is driven

with the tire loose.

13. Lower the jack to the fully closed position.

Return the tools to the proper positions in

the tool bag. Fold the flap on the tool bag

under the tools and roll the tools in the bag

underneath the others. Use the hook and

loop fasteners to secure the tool bag to the

jack with the lug wrench on the forward side

of the jack. Expand the jack on the bracket

by turning the thumb screw clockwise until

it is tight to prevent rattles.

14. Reinstall the plastic plug into the floor of the cargo area. Roll up and store the Jack, Tool

Kit and Tire Changing Instructions. Reinstall

the cover for the jack in the rear storage bin. 15. Have the aluminum road wheel and tire

repaired as soon as possible and properly

secure the spare tire, jack and tool kit.

ROAD TIRE INSTALLATION

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten the lug nuts. 3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Refer to “Wheel and Tire Torque Specifi -

cations” in “Technical Specifications” for

proper lug nut torque.

5. After 25 miles (40 km), check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so please

follow the procedures in this section carefully.

CAUTION!

The winch mechanism is designed for use

with the jack wrench extension tool only. Use

of air wrench or power tool may damage the

winch.

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop, could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

6

20_WD_OM_EN_USC_t.book Page 283

Page 309 of 464

SERVICING AND MAINTENANCE307

(Continued)

CHECKING OIL LEVEL

To ensure proper lubrication of your vehicle's

engine, the engine oil must be maintained at

the correct level. Check the oil level at regular

intervals, such as every fuel stop. The best time

to check the engine oil level is about five

minutes after a fully warmed up engine is shut

off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Always maintain the oil level within

the SAFE zone on the dipstick. Adding one quart

of oil when the reading is at the bottom of the

SAFE zone will result in a reading at the top of

the safe zone on these engines.

ADDING WASHER FLUID

The instrument cluster display will indicate

when the washer fluid level is low. When the

sensor detects a low fluid level, the windshield

will light on the vehicle graphic outline and the

“WASHER FLUID LOW” message will be

displayed.

The fluid reservoir for the windshield washers

and the rear window washer is shared. The fluid

reservoir is located in the engine compartment,

be sure to check the fluid level at regular

intervals. Fill the reservoir with windshield

washer solvent only (not radiator antifreeze).

When refilling the washer fluid reservoir, take

some washer fluid and apply it to a cloth or

towel and wipe clean the wiper blades, this will

help blade performance. To prevent freeze-up

of your windshield washer system in cold

weather, select a solution or mixture that meets

or exceeds the temperature range of your

climate. This rating information can be found on

most washer fluid containers.

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a

maintenance-free battery. Water will never have

to be added, nor is periodic maintenance

required.

CAUTION!

Overfilling or underfilling will cause oil

aeration or loss of oil pressure. This could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling

or working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps. If acid splashes in eyes

or on skin, flush the area immediately with

large amounts of water. Refer to “Jump

Starting Procedure” in “In Case Of Emer -

gency” for further information.

7

20_WD_OM_EN_USC_t.book Page 307

Page 327 of 464

SERVICING AND MAINTENANCE325

(Continued)

BRAKE SYSTEM

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Fluid Level Check — Brake Master Cylinder

The fluid level of the master cylinder should be

checked whenever the vehicle is serviced, or

immediately if the brake system warning light is

on. If necessary, add fluid to bring level within

the designated marks on the side of the

reservoir of the brake master cylinder. Be sure

to clean the top of the master cylinder area

before removing cap. With disc brakes, fluid level can be expected to

fall as the brake pads wear. Brake fluid level

should be checked when pads are replaced. If

the brake fluid is abnormally low, check the

system for leaks.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri

-

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle

is also identified on the original factory

installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

20_WD_OM_EN_USC_t.book Page 325

Page 340 of 464

338SERVICING AND MAINTENANCE

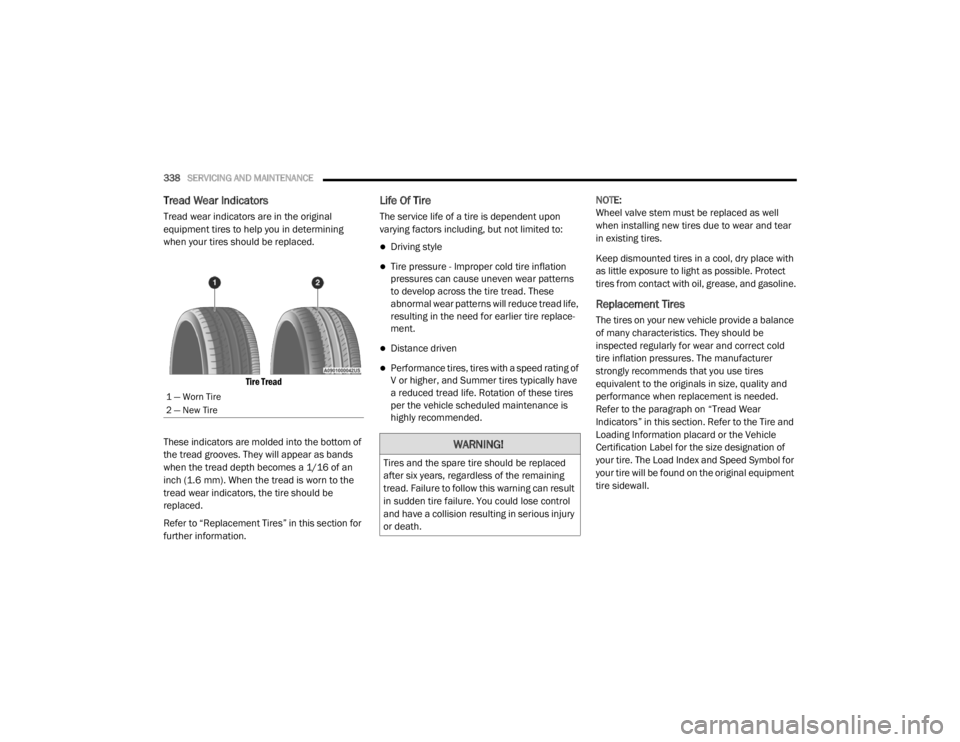

Tread Wear Indicators

Tread wear indicators are in the original

equipment tires to help you in determining

when your tires should be replaced.

Tire Tread

These indicators are molded into the bottom of

the tread grooves. They will appear as bands

when the tread depth becomes a 1/16 of an

inch (1.6 mm). When the tread is worn to the

tread wear indicators, the tire should be

replaced.

Refer to “Replacement Tires” in this section for

further information.

Life Of Tire

The service life of a tire is dependent upon

varying factors including, but not limited to:

Driving style

Tire pressure - Improper cold tire inflation

pressures can cause uneven wear patterns

to develop across the tire tread. These

abnormal wear patterns will reduce tread life,

resulting in the need for earlier tire replace -

ment.

Distance driven

Performance tires, tires with a speed rating of

V or higher, and Summer tires typically have

a reduced tread life. Rotation of these tires

per the vehicle scheduled maintenance is

highly recommended. NOTE:

Wheel valve stem must be replaced as well

when installing new tires due to wear and tear

in existing tires.

Keep dismounted tires in a cool, dry place with

as little exposure to light as possible. Protect

tires from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance

of many characteristics. They should be

inspected regularly for wear and correct cold

tire inflation pressures. The manufacturer

strongly recommends that you use tires

equivalent to the originals in size, quality and

performance when replacement is needed.

Refer to the paragraph on “Tread Wear

Indicators” in this section. Refer to the Tire and

Loading Information placard or the Vehicle

Certification Label for the size designation of

your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

1 — Worn Tire

2 — New Tire

WARNING!

Tires and the spare tire should be replaced

after six years, regardless of the remaining

tread. Failure to follow this warning can result

in sudden tire failure. You could lose control

and have a collision resulting in serious injury

or death.

20_WD_OM_EN_USC_t.book Page 338

Page 352 of 464

350

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

VEHICLE IDENTIFICATION NUMBER

The Vehicle Identification Number (VIN) is found

on a label located on the left front corner of the

instrument panel pad, visible from outside of

the vehicle through the windshield.

Windshield VIN Label Location

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems loses normal capability, the remaining

system will still function. However, there will be

some loss of overall braking effectiveness. You

may notice increased pedal travel during

application, greater pedal force required to slow

or stop, and potential activation of the Brake

Warning Light.

In the event power assist is lost for any reason

(i.e., repeated brake applications with the

engine off) the brakes will still function.

However, the effort required to brake the

vehicle will be much greater than that required

with the power system operating.

NOTE:

Due to the performance nature of our brake

systems, some noise is to be expected.

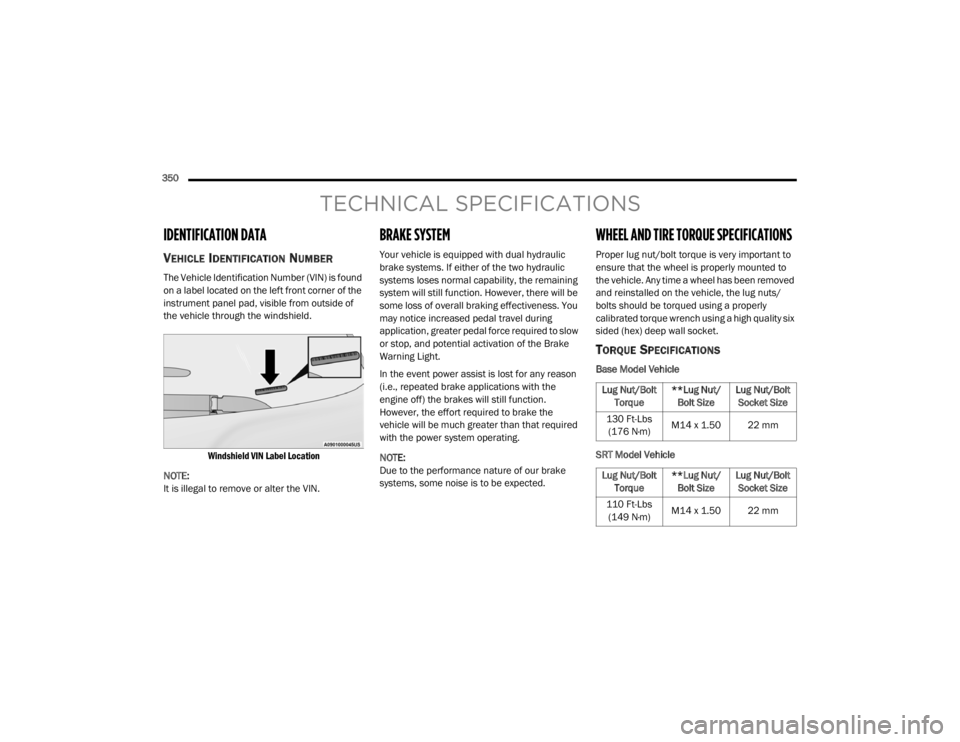

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

TORQUE SPECIFICATIONS

Base Model Vehicle

SRT Model Vehicle

Lug Nut/Bolt Torque **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

130 Ft-Lbs (176 N·m) M14 x 1.50 22 mm

Lug Nut/Bolt Torque **Lug Nut/

Bolt Size Lug Nut/Bolt

Socket Size

110 Ft-Lbs (149 N·m) M14 x 1.50 22 mm

20_WD_OM_EN_USC_t.book Page 350

Page 353 of 464

TECHNICAL SPECIFICATIONS351

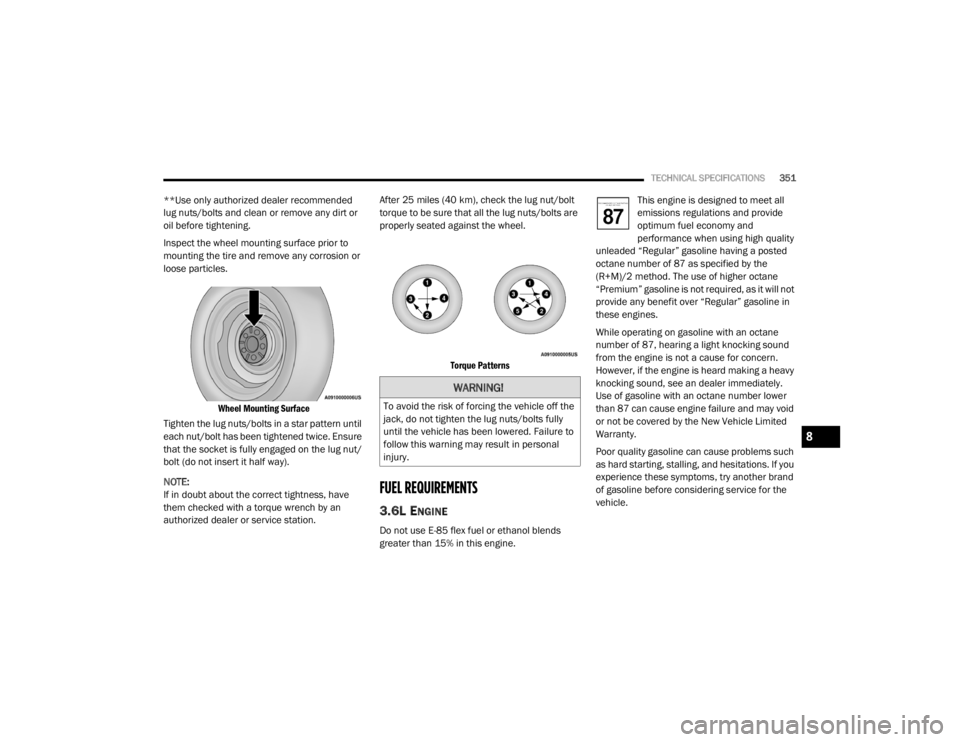

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure

that the socket is fully engaged on the lug nut/

bolt (do not insert it half way).

NOTE:

If in doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or service station. After 25 miles (40 km), check the lug nut/bolt

torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.

Torque Patterns

FUEL REQUIREMENTS

3.6L ENGINE

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine. This engine is designed to meet all

emissions regulations and provide

optimum fuel economy and

performance when using high quality

unleaded “Regular” gasoline having a posted

octane number of 87 as specified by the

(R+M)/2 method. The use of higher octane

“Premium” gasoline is not required, as it will not

provide any benefit over “Regular” gasoline in

these engines.

While operating on gasoline with an octane

number of 87, hearing a light knocking sound

from the engine is not a cause for concern.

However, if the engine is heard making a heavy

knocking sound, see an dealer immediately.

Use of gasoline with an octane number lower

than 87 can cause engine failure and may void

or not be covered by the New Vehicle Limited

Warranty.

Poor quality gasoline can cause problems such

as hard starting, stalling, and hesitations. If you

experience these symptoms, try another brand

of gasoline before considering service for the

vehicle.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully

until the vehicle has been lowered. Failure to

follow this warning may result in personal

injury.

8

20_WD_OM_EN_USC_t.book Page 351

Page 356 of 464

354TECHNICAL SPECIFICATIONS

(Continued)

The MMT content of gasoline may not be

indicated on the gasoline pump; therefore, you

should ask your gasoline retailer whether the

gasoline contains MMT. MMT is prohibited in

Federal and California reformulated gasoline.

FUEL SYSTEM CAUTIONS

NOTE:

Intentional tampering with the emissions

control system can result in civil penalties being

assessed against you.

CARBON MONOXIDE WARNINGS

CAUTION!

Follow these guidelines to maintain your

vehicle’s performance:

The use of leaded gasoline is prohibited by

Federal law. Using leaded gasoline can

impair engine performance and damage

the emissions control system.

An out-of-tune engine or certain fuel or igni -

tion malfunctions can cause the catalytic

converter to overheat. If you notice a

pungent burning odor or some light smoke,

your engine may be out of tune or malfunc -

tioning and may require immediate service.

Contact an authorized dealer for service

assistance.

The use of fuel additives, which are now

being sold as octane enhancers, is not

recommended. Most of these products

contain high concentrations of methanol.

Fuel system damage or vehicle perfor -

mance problems resulting from the use of

such fuels or additives is not the responsi -

bility of the manufacturer and may void or

not be covered under the New Vehicle

Limited Warranty.

CAUTION! (Continued)

WARNING!

Carbon monoxide (CO) in exhaust gases is

deadly. Follow the precautions below to

prevent carbon monoxide poisoning:

Do not inhale exhaust gases. They contain

carbon monoxide, a colorless and odorless

gas, which can kill. Never run the engine in

a closed area, such as a garage, and never

sit in a parked vehicle with the engine

running for an extended period. If the

vehicle is stopped in an open area with the

engine running for more than a short

period, adjust the ventilation system to

force fresh, outside air into the vehicle.

Guard against carbon monoxide with

proper maintenance. Have the exhaust

system inspected every time the vehicle is

raised. Have any abnormal conditions

repaired promptly. Until repaired, drive with

all side windows fully open.

20_WD_OM_EN_USC_t.book Page 354

Page 370 of 464

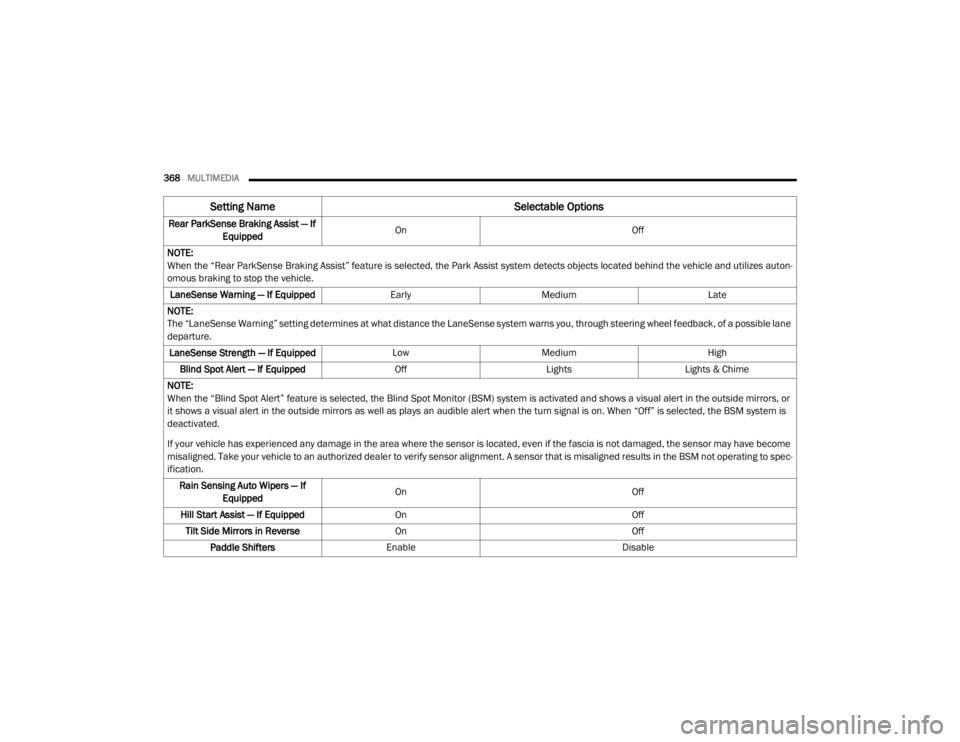

368MULTIMEDIA

Rear ParkSense Braking Assist — If

Equipped On

Off

NOTE:

When the “Rear ParkSense Braking Assist” feature is selected, the Park Assist system detects objects located behind the vehicle and utilizes auton -

omous braking to stop the vehicle.

LaneSense Warning — If Equipped EarlyMedium Late

NOTE:

The “LaneSense Warning” setting determines at what distance the LaneSense system warns you, through steering wheel feedback, of a possible lane

departure. LaneSense Strength — If Equipped LowMedium High

Blind Spot Alert — If Equipped OffLightsLights & Chime

NOTE:

When the “Blind Spot Alert” feature is selected, the Blind Spot Monitor (BSM) system is activated and shows a visual alert in the outside mirrors, or

it shows a visual alert in the outside mirrors as well as plays an audible alert when the turn signal is on. When “Off” is selected, the BSM system is

deactivated.

If your vehicle has experienced any damage in the area where the sensor is located, even if the fascia is not damaged, the sensor may have become

misaligned. Take your vehicle to an authorized dealer to verify sensor alignment. A sensor that is misaligned results in the BSM not operating to spec -

ification.

Rain Sensing Auto Wipers — If Equipped On

Off

Hill Start Assist — If Equipped On Off

Tilt Side Mirrors in Reverse On Off

Paddle Shifters Enable Disable

Setting Name Selectable Options

20_WD_OM_EN_USC_t.book Page 368