jump start DODGE DURANGO 2022 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2022, Model line: DURANGO, Model: DODGE DURANGO 2022Pages: 332, PDF Size: 19.82 MB

Page 8 of 332

6

OCCUPANT RESTRAINT SYSTEMS .................... 196 Occupant Restraint Systems Features ........ 196

Important Safety Precautions....................... 197

Seat Belt Systems ........................................ 197

Supplemental Restraint Systems (SRS) ...... 203

Child Restraints ........................................... 216

SAFETY TIPS ......................................................... 231

Transporting Passengers .............................. 231Transporting Pets ....................................... 232

Connected Vehicles....................................... 232

Safety Checks You Should Make

Inside The Vehicle ........................................ 232

Periodic Safety Checks You Should

Make Outside The Vehicle ............................ 233

Exhaust Gas ................................................... 234Carbon Monoxide Warnings ......................... 234

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS ......................... 235

SOS AND ASSIST MIRROR — IF EQUIPPED...... 235

JACKING AND TIRE CHANGING.......................... 239 Preparations For Jacking .............................. 239Jack Location ................................................. 240

Spare Tire Stowage ....................................... 240

Spare Tire Removal ....................................... 241

Jacking Instructions ...................................... 242 JUMP STARTING ................................................. 246

Preparations For Jump Start ........................ 246

Jump Starting Procedure .............................. 247

REFUELING IN EMERGENCY –

IF EQUIPPED ........................................................ 248

IF YOUR ENGINE OVERHEATS ........................... 249

MANUAL PARK RELEASE ................................... 250

FREEING A STUCK VEHICLE .............................. 252

TOWING A DISABLED VEHICLE ........................ 253

Rear Wheel Drive Models ............................. 254

All Wheel Drive Models ................................. 254

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) .................................................................. 254

EVENT DATA RECORDER (EDR) ........................ 254

SERVICING AND MAINTENANCE

SCHEDULED SERVICING..................................... 255

Maintenance Plan ......................................... 256

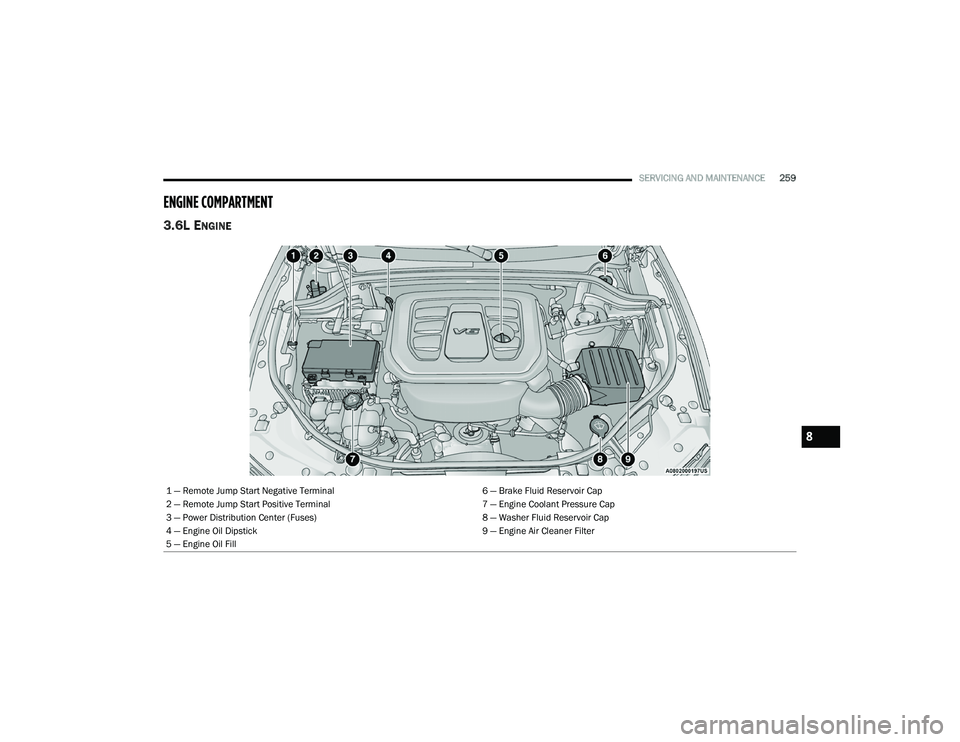

ENGINE COMPARTMENT .................................... 259

3.6L Engine ................................................... 259

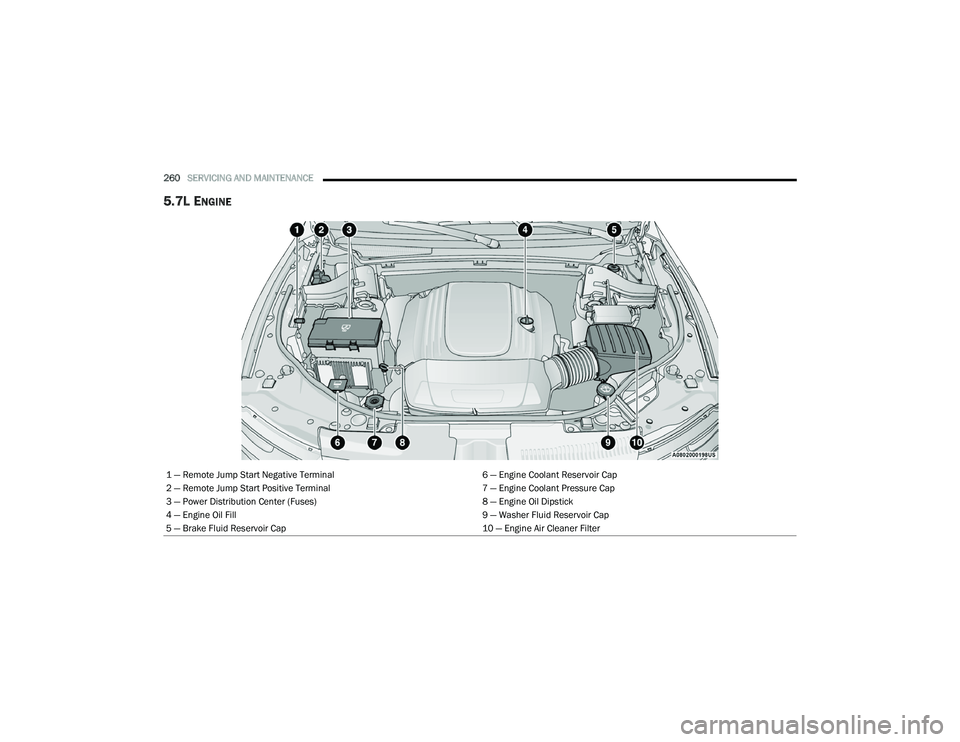

5.7L Engine ................................................... 260

Checking Oil Level ......................................... 261

Adding Washer Fluid .................................... 261

Maintenance-Free Battery ........................... 261Pressure Washing ......................................... 262 VEHICLE MAINTENANCE ..................................... 262

Engine Oil ...................................................... 262

Engine Oil Filter ............................................ 263

Engine Air Cleaner Filter ............................... 263

Air Conditioner Maintenance ....................... 264

Accessory Drive Belt Inspection ................... 267Body Lubrication .......................................... 267Windshield Wiper Blades ............................. 268Exhaust System ............................................ 271

Cooling System.............................................. 272

Brake System ............................................... 274Automatic Transmission ............................... 275

Front/Rear Axle Fluid ................................... 276

Transfer Case ............................................... 276Fuses.............................................................. 277

Bulb Replacement ...................................... 284

TIRES ..................................................................... 286

Tire Safety Information ................................. 286

Tires — General Information ......................... 293

Tire Types....................................................... 296Spare Tires — If Equipped ............................ 297

Wheel And Wheel Trim Care ........................ 299Snow Traction Devices ................................ 300Tire Rotation Recommendations ................ 302

22_WD_OM_EN_USC_t.book Page 6

Page 103 of 332

STARTING AND OPERATING101

If the vehicle is not in PARK and the driver turns off

the engine, the vehicle may AutoPark.

AutoPark will engage when all of these conditions

are met:

Vehicle is equipped with an 8-speed transmis -

sion

Vehicle is not in PARK

Vehicle speed is 1.2 mph (1.9 km/h) or less

Ignition switched from ON/RUN to ACC

NOTE:For Keyless Enter ‘n Go™ equipped vehicles, the

engine will turn off and the ignition switch will

change to the ACC position. After 60 seconds, the

ignition switches to OFF automatically, unless the

driver turns the ignition switch OFF.

If the vehicle is not in PARK and the driver exits the

vehicle with the engine running, the vehicle may

AutoPark.

AutoPark will engage when all of these conditions

are met:

Vehicle is equipped with an 8-speed transmis -

sion

Vehicle is not in PARK

Vehicle speed is 1.2 mph (1.9 km/h) or less

Driver’s seat belt is unbuckled

Driver’s door is ajar

Brake pedal is not pressed The message “

AutoPark Engaged Shift to P then

Shift to Gear ” will display in the instrument cluster.

NOTE:In some cases the ParkSense graphic will be

displayed in the instrument cluster. In these cases,

the gear selector must be returned to “P” to select

desired gear.

If the driver shifts into PARK while moving, the

vehicle may AutoPark.

AutoPark will engage ONLY when vehicle speed is

1.2 mph (1.9 km/h) or less.

The message “ Vehicle Speed is Too High to Shift

to P ” will be displayed in the instrument cluster if

vehicle speed is above 1.2 mph (1.9 km/h).

4WD LOW — If Equipped

AutoPark will be disabled when operating the

vehicle in 4WD LOW.

The message “ AutoPark Disabled ” will be

displayed in the instrument cluster. Additional customer warnings will be given when

both of these conditions are met:Vehicle is not in PARK

Driver’s door is ajar

The message “ AutoPark Not Engaged” will be

displayed in the instrument cluster. A warning

chime will continue until you shift the vehicle into

PARK or the driver’s door is closed.

ALWAYS DO A VISUAL CHECK

that your vehicle is in

PARK by looking for the "P" in the instrument

cluster display and on the gear selector. As an

added precaution, always apply the parking brake

when exiting the vehicle.

EXTENDED PARK STARTING

NOTE:Extended Park condition occurs when the vehicle

has not been started or driven for at least 30 days.

1. Install a battery charger or jumper cables to the battery to ensure a full battery charge

during the crank cycle.

2. Place the ignition in the START position and release it when the engine starts.

3. If the engine fails to start within 10 seconds, place the ignition in the OFF position, wait

10 to 15 seconds to allow the starter to cool,

then repeat the “Extended Park Starting”

procedure.

WARNING!

If vehicle speed is above 1.2 mph (1.9 km/h), the

transmission will default to NEUTRAL until the

vehicle speed drops below 1.2 mph (1.9 km/h).

A vehicle left in the NEUTRAL position can roll. As

an added precaution, always apply the parking

brake when exiting the vehicle.

4

22_WD_OM_EN_USC_t.book Page 101

Page 248 of 332

246IN CASE OF EMERGENCY

14. Lower the jack to the fully closed position. Return the tools to the proper positions in the

tool bag. Fold the flap on the tool bag under

the tools and roll the tools in the bag

underneath the others. Use the hook and loop

fasteners to secure the tool bag to the jack

with the lug wrench on the forward side of the

jack. Expand the jack on the bracket by turning

the thumb screw clockwise until it is tight to

prevent rattles.

15. Reinstall the plastic plug into the floor of the cargo area. Roll up and store the Jack, Tool Kit

and Tire Changing Instructions. Reinstall the

cover for the jack in the rear storage bin.

16. Have the aluminum road wheel and tire repaired as soon as possible and properly

secure the spare tire, jack and tool kit.

JUMP STARTING

If your vehicle has a discharged battery, it can be

jump started using a set of jumper cables and a

battery in another vehicle, or by using a portable

battery booster pack. Jump starting can be

dangerous if done improperly, so please follow the

procedures in this section carefully.

NOTE:When using a portable battery booster pack, follow

the manufacturer's operating instructions and

precautions.

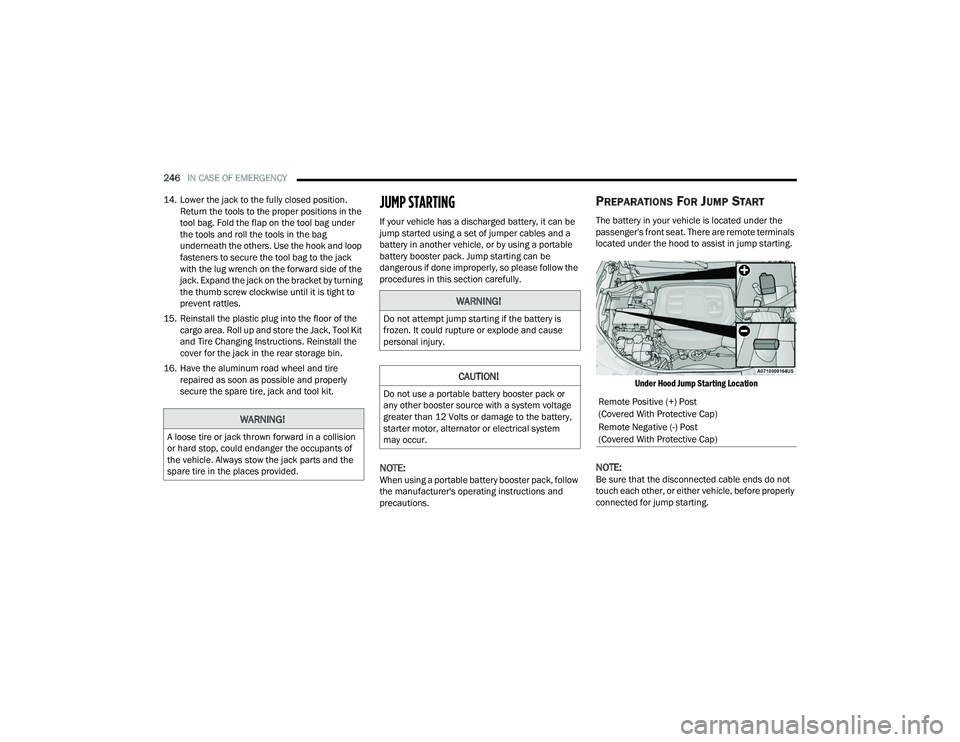

PREPARATIONS FOR JUMP START

The battery in your vehicle is located under the

passenger's front seat. There are remote terminals

located under the hood to assist in jump starting.

Under Hood Jump Starting Location

NOTE:Be sure that the disconnected cable ends do not

touch each other, or either vehicle, before properly

connected for jump starting.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop, could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system voltage

greater than 12 Volts or damage to the battery,

starter motor, alternator or electrical system

may occur.Remote Positive (+) Post

(Covered With Protective Cap)

Remote Negative (-) Post

(Covered With Protective Cap)

22_WD_OM_EN_USC_t.book Page 246

Page 249 of 332

IN CASE OF EMERGENCY247

See the following steps to prepare for jump

starting:

1. Apply the parking brake, shift the automatic transmission into PARK (P) and turn the

ignition OFF.

2. Turn off the heater, radio, and all electrical accessories.

3. Remove the protective cover over the remote positive (+) battery post. Pull upward on the

cover to remove it.

4. Remove the protective cover over the remote negative (-) battery post.

5. If using another vehicle to jump start the battery, park the vehicle within the jumper

cable’s reach, apply the parking brake and

make sure the ignition is OFF.

JUMP STARTING PROCEDURE

NOTE:Make sure at all times that unused ends of jumper

cables are not contacting each other or either

vehicle while making connections.

Connecting The Jumper Cables

1. Connect the positive

(+) end of the jumper

cable to the remote positive (+)

post of the

discharged vehicle.

2. Connect the opposite end of the positive (+)

jumper cable to the positive (+) post of the

booster battery.

3. Connect the negative (-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to the remote negative (-) post

(exposed metallic/unpainted post of the

discharge vehicle) located on the right hand

side next to the underhood fuse box.

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and

personal injury could result.

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be

injured by moving fan blades.

Remove any metal jewelry such as rings,

watch bands and bracelets that could make

an inadvertent electrical contact. You could be

seriously injured.

Batteries contain sulfuric acid that can burn

your skin or eyes and generate hydrogen gas

which is flammable and explosive. Keep open

flames or sparks away from the battery.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster

vehicle or the discharged vehicle.

WARNING!

Do not connect the jumper cable to the

negative (-) post of the discharged battery.

The resulting electrical spark could cause the

battery to explode and could result in personal

injury.

7

22_WD_OM_EN_USC_t.book Page 247

Page 250 of 332

248IN CASE OF EMERGENCY

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, follow the discon -

necting procedure.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-) end of the jumper

cable from the remote negative (-)

post of the

discharged vehicle.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) end of the jumper

cable from the positive (+) post of the booster

battery. 4. Disconnect the opposite end of the positive

(+)

jumper cable from the remote positive (+) post

of the discharged vehicle.

5. Reinstall the protective covers over the remote positive (+) and negative (-) posts of the

discharged vehicle.

If frequent jump starting is required to start your

vehicle have the battery and charging system

tested at an authorized dealer.

REFUELING IN EMERGENCY – IF EQUIPPED

The vehicle is equipped with a refueling funnel for

a Cap-Less Fuel System. The fuel funnel can be

found in the rear cargo area with the jack and

tools. If refueling is necessary, while using an

approved gas can, insert the refueling funnel into

the filler neck opening. Take care to open both

flappers with the funnel to avoid spills.

CAUTION!

Do not run the booster vehicle engine above

2,000 RPM since it provides no charging benefit,

wastes fuel, and can damage booster vehicle

engine.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

22_WD_OM_EN_USC_t.book Page 248

Page 261 of 332

SERVICING AND MAINTENANCE259

ENGINE COMPARTMENT

3.6L ENGINE

1 — Remote Jump Start Negative Terminal 6 — Brake Fluid Reservoir Cap

2 — Remote Jump Start Positive Terminal 7 — Engine Coolant Pressure Cap

3 — Power Distribution Center (Fuses) 8 — Washer Fluid Reservoir Cap

4 — Engine Oil Dipstick 9 — Engine Air Cleaner Filter

5 — Engine Oil Fill

8

22_WD_OM_EN_USC_t.book Page 259

Page 262 of 332

260SERVICING AND MAINTENANCE

5.7L ENGINE

1 — Remote Jump Start Negative Terminal 6 — Engine Coolant Reservoir Cap

2 — Remote Jump Start Positive Terminal 7 — Engine Coolant Pressure Cap

3 — Power Distribution Center (Fuses) 8 — Engine Oil Dipstick

4 — Engine Oil Fill 9 — Washer Fluid Reservoir Cap

5 — Brake Fluid Reservoir Cap 10 — Engine Air Cleaner Filter

22_WD_OM_EN_USC_t.book Page 260

Page 269 of 332

SERVICING AND MAINTENANCE267

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts, small

cracks that run across the ribbed surface of the

belt from rib to rib, are considered normal. This is

not a reason to replace belt. However, cracks

running along a rib (not across) are not normal.

Any belt with cracks running along a rib must be

replaced. Also have the belt replaced if it has

excessive wear, frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two

ribs)

Belt slips

Groove jumping (belt does not maintain correct

position on pulley)

Belt broken (identify and correct problem before

new belt is installed)

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation) Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools. We recommend having your

vehicle serviced at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically. Use

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and to

protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WARNING!

Do not attempt to inspect an accessory drive

belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could be

injured by the moving fan blades.

You can be badly injured working on or around

a motor vehicle. Only do service work for which

you have the knowledge and the proper equip

-

ment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

8

22_WD_OM_EN_USC_t.book Page 267

Page 279 of 332

SERVICING AND MAINTENANCE277

FUSES

General Information

The fuses protect electrical systems against

excessive current.

When a device does not work, you must check the

fuse element inside the blade fuse for a break/

melt.

Also, please be aware that using power outlets for

extended periods of time with the engine off may

result in vehicle battery discharge.

Blade Fuses

Underhood Fuses

The Power Distribution Center is located in the

engine compartment near the battery jump start

posts. This center contains cartridge fuses, micro

fuses, relays, and circuit breakers. A description of

each fuse and component may be stamped on the

inside cover, otherwise the cavity number of each

fuse is stamped on the inside cover that

corresponds to the following chart.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

The use of a fuse with a rating other than indi -

cated may result in a dangerous electrical

system overload. If a properly rated fuse

continues to blow, it indicates a problem in the

circuit that must be corrected. Never replace a

blown fuse with metal wires or any other mate -

rial. Do not place a fuse inside a circuit

breaker cavity or vice versa. Failure to use

proper fuses may result in serious personal

injury, fire and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems (engine system, transmission

system) or steering system blows, contact an

authorized dealer.

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)

CAUTION!

When installing the power distribution center

cover, it is important to ensure the cover is

properly positioned and fully latched. Failure

to do so may allow water to get into the power

distribution center and possibly result in an

electrical system failure.

8

22_WD_OM_EN_USC_t.book Page 277

Page 321 of 332

319

Disabled Vehicle Towing

................................ 253Disposal Antifreeze (Engine Coolant)....................... 273Door Ajar................................................... 90, 91Door Ajar Light.......................................... 90, 91Door Locks............................................... 22, 25Child-Protection Door Lock — Rear Doors.... 25Doors............................................................... 22Driver’s Seat Back Tilt..................................... 29Driving........................................................... 153

E

Economy (Fuel) Mode.................................... 105Electric Brake Control System....................... 183Anti-Lock Brake System............................. 182Electronic Roll Mitigation................. 184, 187Electric Remote Mirrors................................... 42Electrical Outlet, Auxiliary (Power Outlet)......... 66Electronic Speed Control (Cruise Control)...... 117Electronic Stability Control (ESC)...................184Electronic Throttle Control Warning Light........ 91Electronically Shifted Transfer Case.............. 109Emergency Gas Can Refueling...................... 248Emergency, In Case OfFreeing Vehicle When Stuck...................... 252Hazard Warning Flasher............................ 235Jacking...................................................... 239Jump Starting............................................ 246

Emission Control System Maintenance........... 98Engine........................................................... 259Air Cleaner................................................ 263Break-In Recommendations..................... 102Checking Oil Level.................................... 261Compartment.................................. 259, 260Compartment Identification............. 259, 260Cooling..................................................... 272Exhaust Gas Caution................................ 234Fails To Start............................................ 102Flooded, Starting...................................... 102Fuel Requirements.......................... 308, 311Jump Starting........................................... 246Oil.................................................... 262, 311Oil Filler Cap............................................. 259Oil Filter.................................................... 263Oil Selection........................... 262, 311, 312Oil Synthetic............................................. 263Starting........................................................ 99Enhanced Accident

Response Feature............................... 214, 254Ethanol......................................................... 309Exhaust Gas Cautions................................... 234Exhaust System................................... 234, 271Exterior Lights............................... 47, 234, 284

F

FiltersAir Cleaner

................................................ 263Air Conditioning........................ 61, 264, 265Engine Oil................................................. 263Engine Oil Disposal................................... 263Flashers........................................................ 235Hazard Warning........................................ 235Turn Signals.............................. 96, 234, 285Flash-To-Pass...................................................49Flooded Engine Starting................................ 102Fluid Capacities............................................ 311Fluid Leaks.................................................... 234Fluid Level ChecksBrake........................................................ 274Engine Oil................................................. 261Fluids And Lubricants.................................... 312Fog Lights..................................................... 285Fog Lights, Service........................................ 285Fold-Flat Seats.................................................29Folding Rear Seats...........................................31Forward Collision Warning............................ 191Four-Way Hazard Flasher.............................. 235Freeing A Stuck Vehicle................................. 252Front Axle (Differential)................................. 276

11

22_WD_OM_EN_USC_t.book Page 319