lock DODGE DURANGO 2023 Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: DURANGO, Model: DODGE DURANGO 2023Pages: 328, PDF Size: 13.82 MB

Page 222 of 328

220SAFETY

2. Place the child seat between the lower anchorages for that seating position. If the

second row seat can be reclined, you may

recline the seat and/or raise the head restraint

(if adjustable) to get a better fit. If the rear seat

can be moved forward and rearward in the

vehicle, you may wish to move it to its

rear-most position to make room for the child

seat. You may also move the front seat forward

to allow more room for the child seat.

3. Attach the lower hooks or connectors of the child restraint to the lower anchorages in the

selected seating position.

4. If the child restraint has a tether strap, connect it to the top tether anchorage. See

Úpage 223 for directions to attach a tether

anchor.

5. Tighten all of the straps as you push the child restraint rearward and downward into the

seat. Remove slack in the straps according to

the child restraint manufacturer’s instructions.

6. Test that the child restraint is installed tightly by pulling back and forth on the child seat at

the belt path. It should not move more than

1 inch (25.4 mm) in any direction.

How To Stow An Unused Switchable-ALR

(ALR) Seat Belt:

When using the LATCH attaching system to install

a child restraint, stow all ALR seat belts that are not

being used by other occupants or being used to

secure child restraints. An unused belt could injure

a child if they play with it and accidentally lock the

seat belt retractor. Before installing a child

restraint using the LATCH system, buckle the seat

belt behind the child restraint and out of the child’s

reach. If the buckled seat belt interferes with the

child restraint installation, instead of buckling it

behind the child restraint, route the seat belt

through the child restraint belt path and then

buckle it. Do not lock the seat belt. Remind all

children in the vehicle that the seat belts are not

toys and that they should not play with them.

Installing Child Restraints Using The

Vehicle Seat Belt

Child restraint systems are designed to be secured

in vehicle seats by lap belts or the lap belt portion

of a lap/shoulder belt.

WARNING!

Improper installation of a child restraint to the

LATCH anchorages can lead to failure of the

restraint. The child could be badly injured or

killed. Follow the child restraint manufac -

turer’s directions exactly when installing an

infant or child restraint.

Child restraint anchorages are designed to

withstand only those loads imposed by

correctly-fitted child restraints. Under no

circumstances are they to be used for adult

seat belts, harnesses, or for attaching other

items or equipment to the vehicle.

WARNING!

Improper installation or failure to properly

secure a child restraint can lead to failure of

the restraint. The child could be badly injured

or killed.

Follow the child restraint manufacturer’s

directions exactly when installing an infant or

child restraint.

23_WD_OM_EN_USC_t.book Page 220

Page 223 of 328

SAFETY221

The seat belts in the passenger seating positions are

equipped with a Switchable Automatic Locking

Retractor (ALR) that is designed to keep the lap portion

of the seat belt tight around the child restraint so that it

is not necessary to use a locking clip. The ALR retractor

can be “switched” into a locked mode by pulling all of

the webbing out of the retractor and then letting the

webbing retract back into the retractor. If it is locked,

the ALR will make a clicking noise while the webbing is

pulled back into the retractor

Ú

page 197.

Please see the table below and the following

sections for more information.

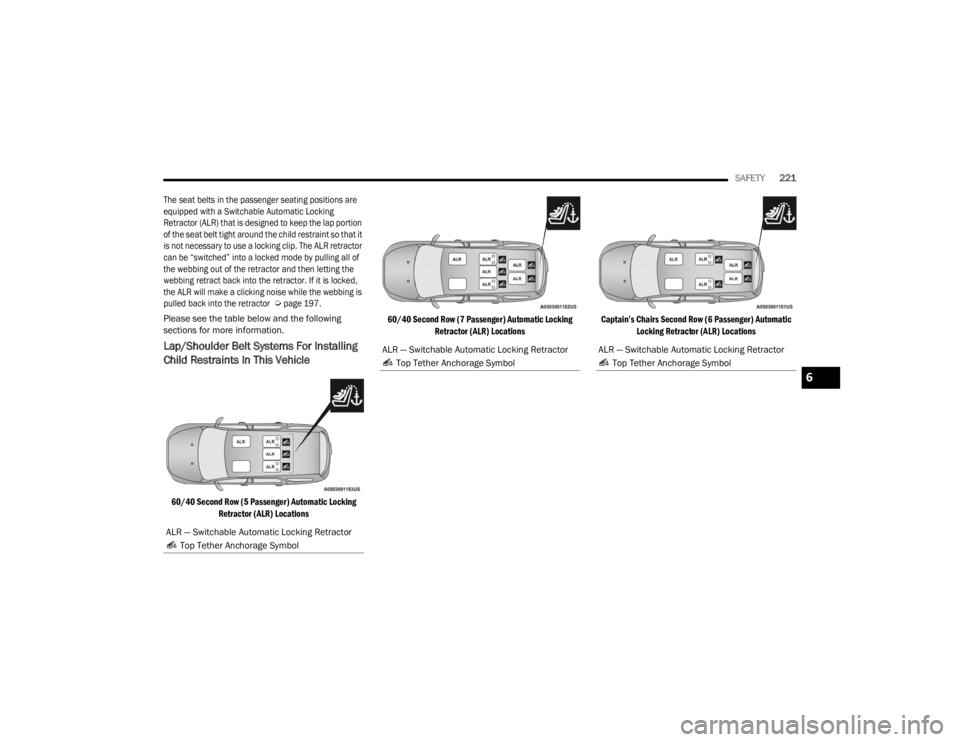

Lap/Shoulder Belt Systems For Installing

Child Restraints In This Vehicle

60/40 Second Row (5 Passenger) Automatic Locking Retractor (ALR) Locations 60/40 Second Row (7 Passenger) Automatic Locking

Retractor (ALR) Locations Captain’s Chairs Second Row (6 Passenger) Automatic

Locking Retractor (ALR) Locations

ALR — Switchable Automatic Locking Retractor Top Tether Anchorage Symbol

ALR — Switchable Automatic Locking Retractor Top Tether Anchorage SymbolALR — Switchable Automatic Locking Retractor Top Tether Anchorage Symbol

6

23_WD_OM_EN_USC_t.book Page 221

Page 224 of 328

222SAFETY

Installing A Child Restraint With A

Switchable Automatic Locking Retractor

(ALR):

Child restraint systems are designed to be secured

in vehicle seats by lap belts or the lap belt portion

of a lap/shoulder belt.

1. Place the child seat in the center of the

seating position. If the second row seat can

be reclined, you may recline the seat and/or

raise the head restraint (if adjustable) to get a

better fit. If the rear seat can be moved

forward and rearward in the vehicle, you may

wish to move it to its rear-most position to

make room for the child seat. You may also

move the front seat forward to allow more

room for the child seat.

2. Pull enough of the seat belt webbing from the retractor to pass it through the belt path of the

child restraint. Do not twist the belt webbing in

the belt path. 3. Slide the latch plate into the buckle until you

hear a “click.”

4. Pull on the webbing to make the lap portion tight against the child seat.

5. To lock the seat belt, pull down on the shoulder part of the belt until you have pulled all the

seat belt webbing out of the retractor. Then,

allow the webbing to retract back into the

retractor. As the webbing retracts, you will hear

a clicking sound. This means the seat belt is

now in the Automatic Locking mode.

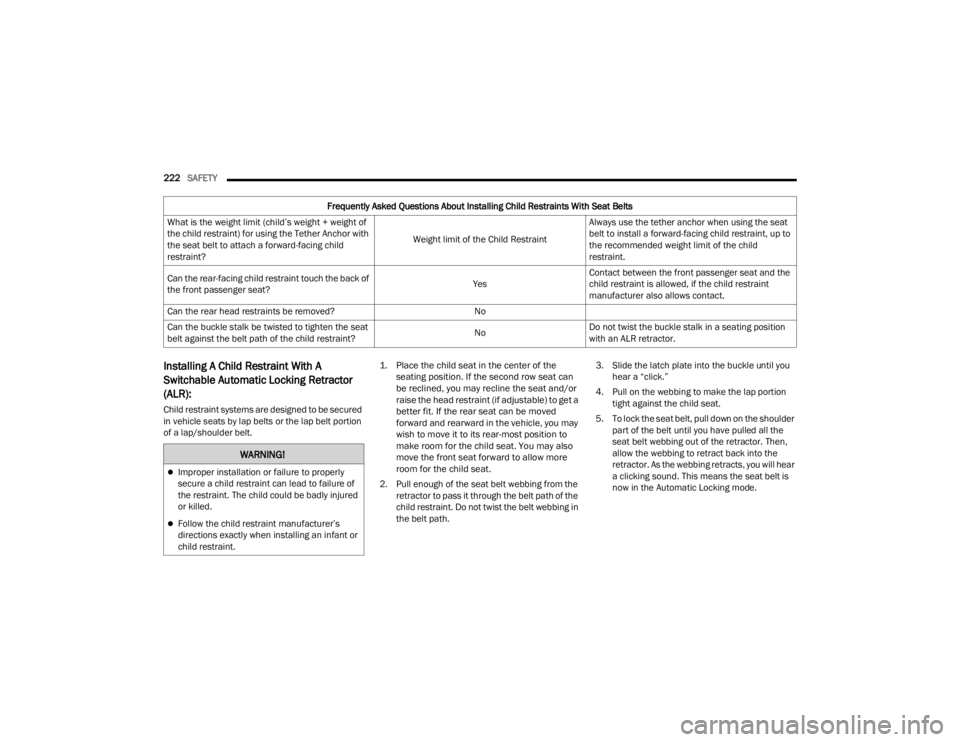

Frequently Asked Questions About Installing Child Restraints With Seat Belts

What is the weight limit (child’s weight + weight of

the child restraint) for using the Tether Anchor with

the seat belt to attach a forward-facing child

restraint? Weight limit of the Child RestraintAlways use the tether anchor when using the seat

belt to install a forward-facing child restraint, up to

the recommended weight limit of the child

restraint.

Can the rear-facing child restraint touch the back of

the front passenger seat? YesContact between the front passenger seat and the

child restraint is allowed, if the child restraint

manufacturer also allows contact.

Can the rear head restraints be removed? No

Can the buckle stalk be twisted to tighten the seat

belt against the belt path of the child restraint? NoDo not twist the buckle stalk in a seating position

with an ALR retractor.

WARNING!

Improper installation or failure to properly

secure a child restraint can lead to failure of

the restraint. The child could be badly injured

or killed.

Follow the child restraint manufacturer’s

directions exactly when installing an infant or

child restraint.

23_WD_OM_EN_USC_t.book Page 222

Page 225 of 328

SAFETY223

6. Try to pull the webbing out of the retractor. If it is locked, you should not be able to pull out any

webbing. If the retractor is not

locked, repeat

step 5.

7. Finally, pull up on any excess webbing to tighten the lap portion around the child

restraint while you push the child restraint

rearward and downward into the vehicle seat.

8. If the child restraint has a top tether strap and the seating position has a top tether

anchorage, connect the tether strap to the

anchorage and tighten the tether strap. For

directions to attach a tether anchor, see

Úpage 223.

9. Test that the child restraint is installed tightly by pulling back and forth on the child seat at

the belt path. It should not move more than

1 inch (25.4 mm) in any direction.

Any seat belt system will loosen with time, so check

the belt occasionally, and pull it tight if necessary.

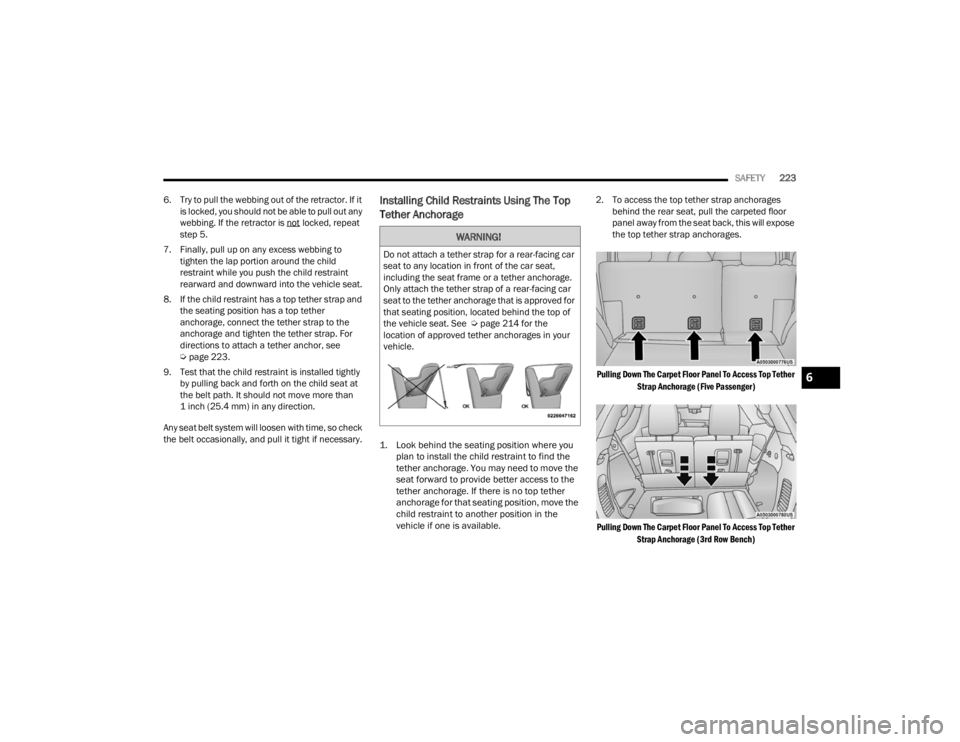

Installing Child Restraints Using The Top

Tether Anchorage

1. Look behind the seating position where you plan to install the child restraint to find the

tether anchorage. You may need to move the

seat forward to provide better access to the

tether anchorage. If there is no top tether

anchorage for that seating position, move the

child restraint to another position in the

vehicle if one is available.

2. To access the top tether strap anchorages

behind the rear seat, pull the carpeted floor

panel away from the seat back, this will expose

the top tether strap anchorages.

Pulling Down The Carpet Floor Panel To Access Top Tether Strap Anchorage (Five Passenger)

Pulling Down The Carpet Floor Panel To Access Top Tether Strap Anchorage (3rd Row Bench)

WARNING!

Do not attach a tether strap for a rear-facing car

seat to any location in front of the car seat,

including the seat frame or a tether anchorage.

Only attach the tether strap of a rear-facing car

seat to the tether anchorage that is approved for

that seating position, located behind the top of

the vehicle seat. See Ú page 214 for the

location of approved tether anchorages in your

vehicle.

6

23_WD_OM_EN_USC_t.book Page 223

Page 229 of 328

SAFETY227

(Continued)

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven

wear patterns. Check for stones, nails, glass, or

other objects lodged in the tread or sidewall.

Inspect the tread for cuts and cracks. Inspect

sidewalls for cuts, cracks, and bulges. Check the

lug nut/bolt torque for tightness. Check the tires

(including spare) for proper cold inflation pressure.

Lights

Have someone observe the operation of brake

lights and exterior lights while you work the

controls. Check turn signal and high beam

indicator lights on the instrument panel.

Door Latches

Check for proper closing, latching, and locking.

ONLY use the driver’s side floor mat on the

driver’s side floor area. To check for interfer -

ence, with the vehicle properly parked with the

engine off, fully depress the accelerator, the

brake, and the clutch pedal (if present) to

check for interference. If your floor mat inter -

feres with the operation of any pedal, or is not

secure to the floor, remove the floor mat from

the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on

the passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide

into the driver’s side floor area when the

vehicle is moving. Objects can become

trapped under accelerator, brake, or clutch

pedals and could cause a loss of vehicle

control.

WARNING!

NEVER place any objects under the floor mat

(e.g., towels, keys, etc.). These objects could

change the position of the floor mat and may

cause interference with the accelerator,

brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to

the floor and check the floor mat fasteners are

secure to the vehicle carpet. Fully depress

each pedal to check for interference with the

accelerator, brake, or clutch pedals then

re-install the floor mats.

It is recommended to only use mild soap and

water to clean your floor mats. After cleaning,

always check your floor mat has been properly

installed and is secured to your vehicle using

the floor mat fasteners by lightly pulling mat.

WARNING!

6

23_WD_OM_EN_USC_t.book Page 227

Page 235 of 328

IN CASE OF EMERGENCY233

6. Block both the front and rear of the wheel diagonally opposite the jacking position. For

example, if changing the driver’s front tire,

block the passenger’s rear tire.

Wheel Blocked

NOTE:Passengers should not remain in the vehicle when

the vehicle is being raised or lifted.

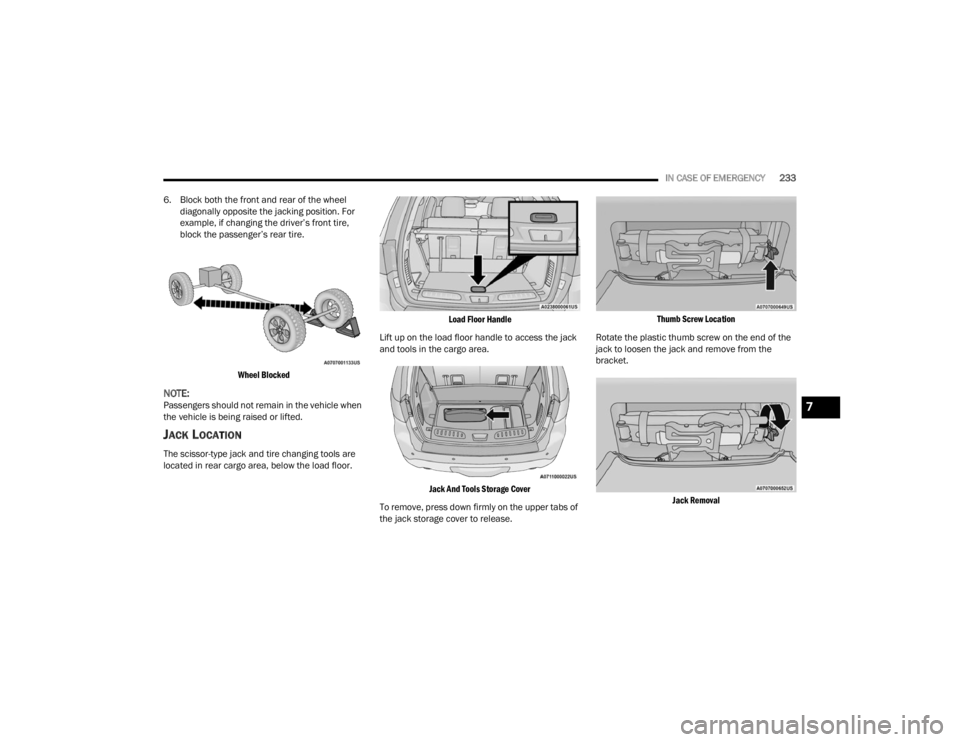

JACK LOCATION

The scissor-type jack and tire changing tools are

located in rear cargo area, below the load floor.

Load Floor Handle

Lift up on the load floor handle to access the jack

and tools in the cargo area.

Jack And Tools Storage Cover

To remove, press down firmly on the upper tabs of

the jack storage cover to release.

Thumb Screw Location

Rotate the plastic thumb screw on the end of the

jack to loosen the jack and remove from the

bracket.

Jack Removal

7

23_WD_OM_EN_USC_t.book Page 233

Page 236 of 328

234IN CASE OF EMERGENCY

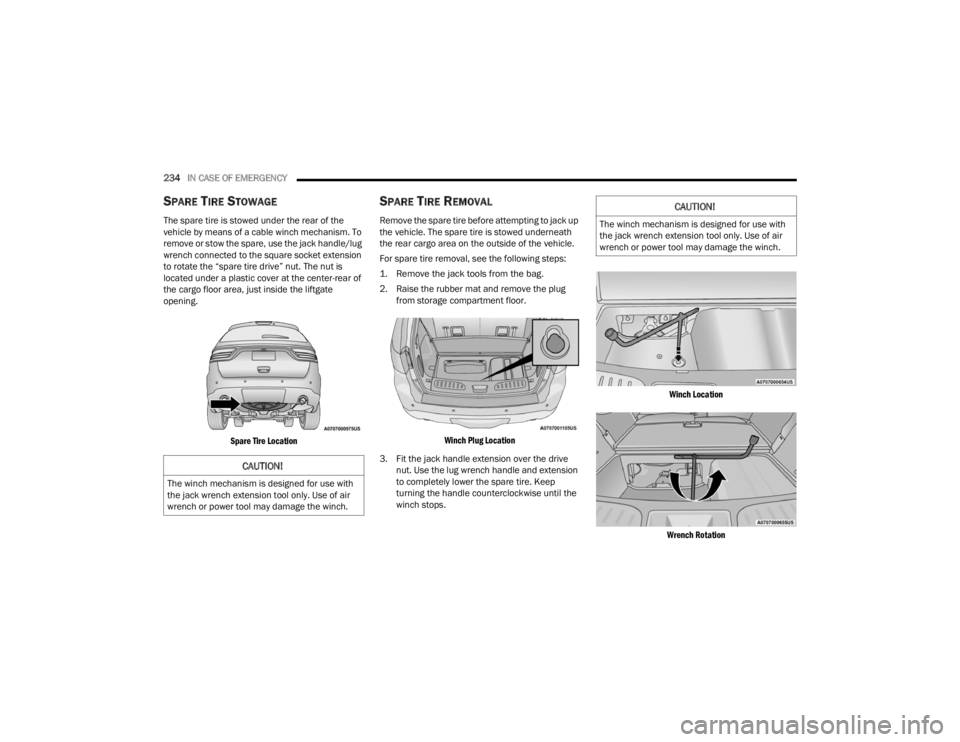

SPARE TIRE STOWAGE

The spare tire is stowed under the rear of the

vehicle by means of a cable winch mechanism. To

remove or stow the spare, use the jack handle/lug

wrench connected to the square socket extension

to rotate the “spare tire drive” nut. The nut is

located under a plastic cover at the center-rear of

the cargo floor area, just inside the liftgate

opening.

Spare Tire Location

SPARE TIRE REMOVAL

Remove the spare tire before attempting to jack up

the vehicle. The spare tire is stowed underneath

the rear cargo area on the outside of the vehicle.

For spare tire removal, see the following steps:

1. Remove the jack tools from the bag.

2. Raise the rubber mat and remove the plug from storage compartment floor.

Winch Plug Location

3. Fit the jack handle extension over the drive nut. Use the lug wrench handle and extension

to completely lower the spare tire. Keep

turning the handle counterclockwise until the

winch stops.

Winch Location

Wrench Rotation

CAUTION!

The winch mechanism is designed for use with

the jack wrench extension tool only. Use of air

wrench or power tool may damage the winch.

CAUTION!

The winch mechanism is designed for use with

the jack wrench extension tool only. Use of air

wrench or power tool may damage the winch.

23_WD_OM_EN_USC_t.book Page 234

Page 238 of 328

236IN CASE OF EMERGENCY

(Continued)

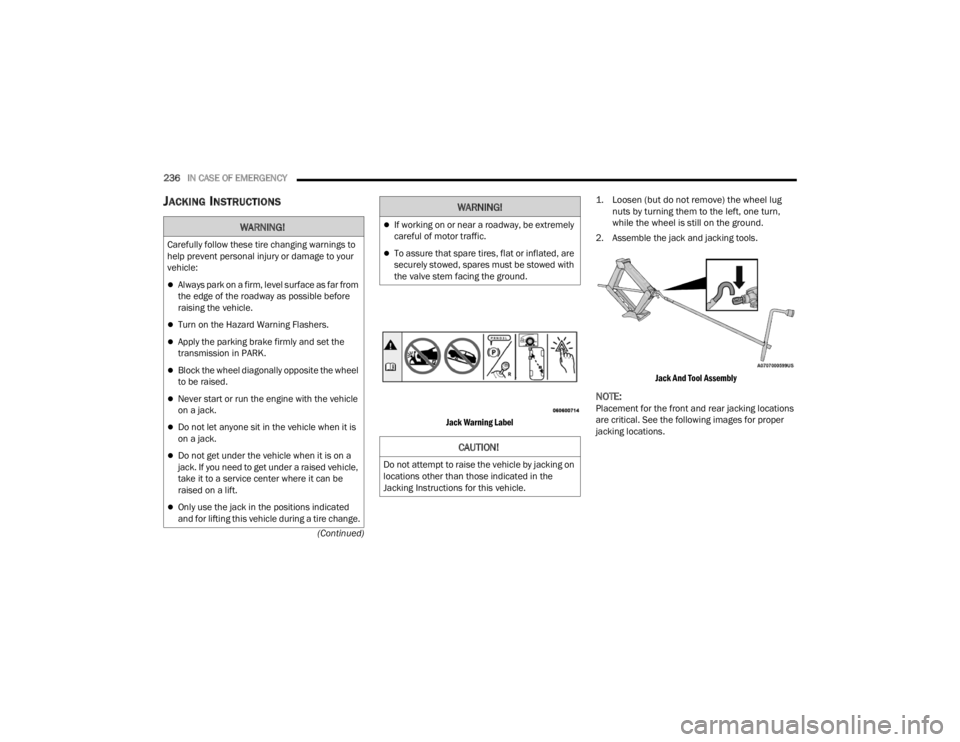

JACKING INSTRUCTIONS

Jack Warning Label

1. Loosen (but do not remove) the wheel lug

nuts by turning them to the left, one turn,

while the wheel is still on the ground.

2. Assemble the jack and jacking tools.

Jack And Tool Assembly

NOTE:Placement for the front and rear jacking locations

are critical. See the following images for proper

jacking locations.

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the wheel

to be raised.

Never start or run the engine with the vehicle

on a jack.

Do not let anyone sit in the vehicle when it is

on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with

the valve stem facing the ground.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated in the

Jacking Instructions for this vehicle.

WARNING!

23_WD_OM_EN_USC_t.book Page 236

Page 239 of 328

IN CASE OF EMERGENCY237

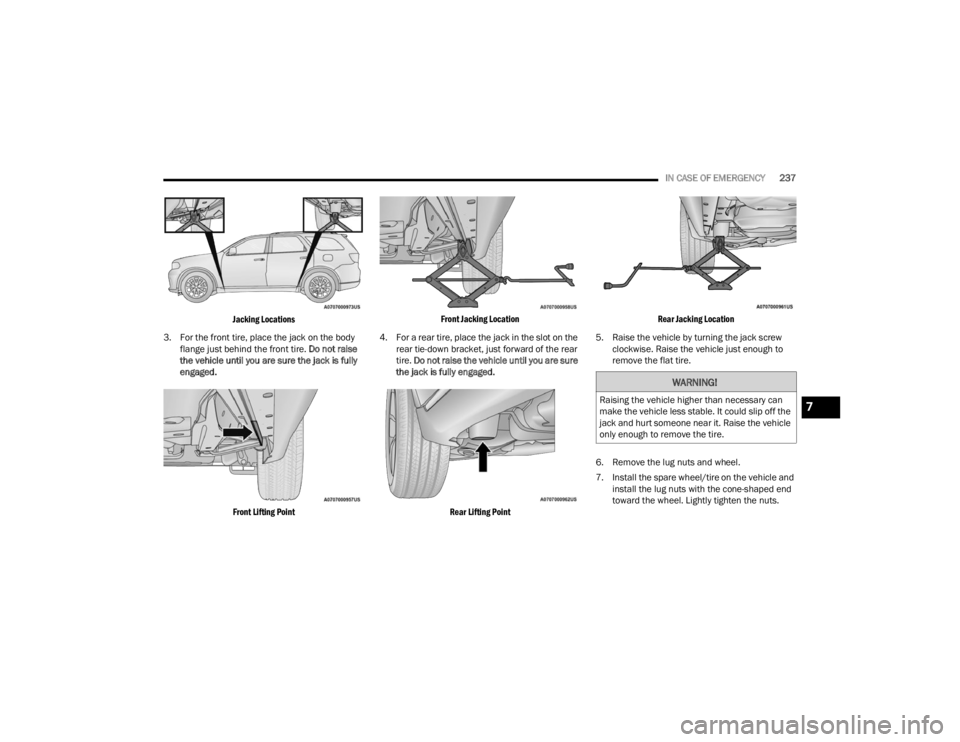

Jacking Locations

3. For the front tire, place the jack on the body flange just behind the front tire. Do not raise

the vehicle until you are sure the jack is fully

engaged.

Front Lifting Point Front Jacking Location

4. For a rear tire, place the jack in the slot on the rear tie-down bracket, just forward of the rear

tire. Do not raise the vehicle until you are sure

the jack is fully engaged.

Rear Lifting Point Rear Jacking Location

5. Raise the vehicle by turning the jack screw clockwise. Raise the vehicle just enough to

remove the flat tire.

6. Remove the lug nuts and wheel.

7. Install the spare wheel/tire on the vehicle and install the lug nuts with the cone-shaped end

toward the wheel. Lightly tighten the nuts.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.7

23_WD_OM_EN_USC_t.book Page 237

Page 240 of 328

238IN CASE OF EMERGENCY

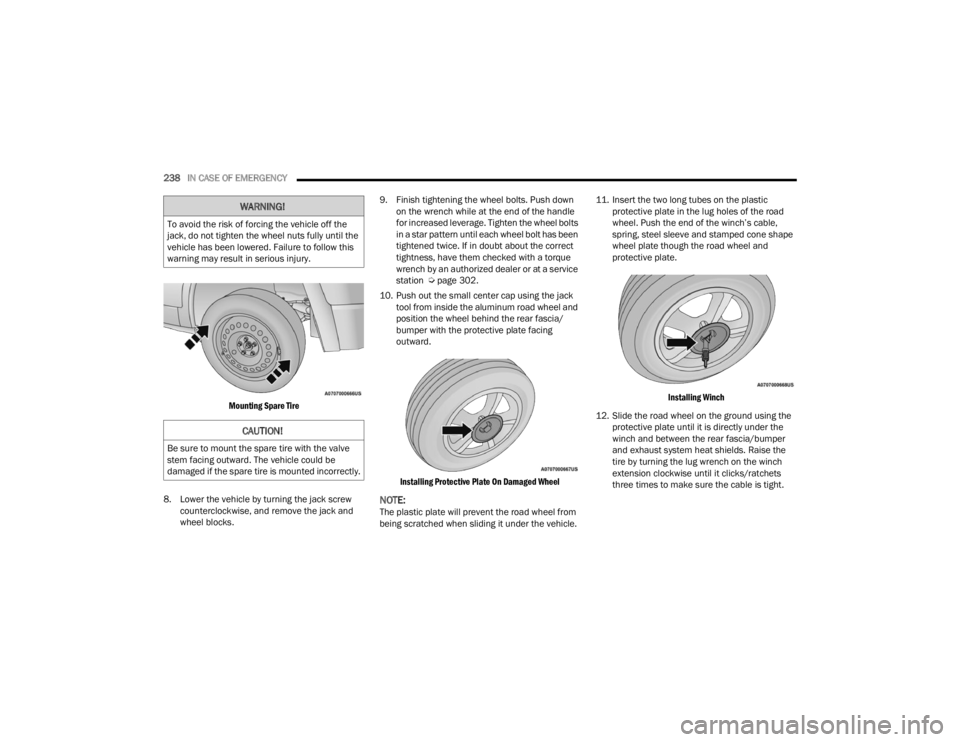

Mounting Spare Tire

8. Lower the vehicle by turning the jack screw counterclockwise, and remove the jack and

wheel blocks. 9. Finish tightening the wheel bolts. Push down

on the wrench while at the end of the handle

for increased leverage. Tighten the wheel bolts

in a star pattern until each wheel bolt has been

tightened twice. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a service

station Ú page 302.

10. Push out the small center cap using the jack tool from inside the aluminum road wheel and

position the wheel behind the rear fascia/

bumper with the protective plate facing

outward.

Installing Protective Plate On Damaged Wheel

NOTE:The plastic plate will prevent the road wheel from

being scratched when sliding it under the vehicle. 11. Insert the two long tubes on the plastic

protective plate in the lug holes of the road

wheel. Push the end of the winch’s cable,

spring, steel sleeve and stamped cone shape

wheel plate though the road wheel and

protective plate.

Installing Winch

12. Slide the road wheel on the ground using the protective plate until it is directly under the

winch and between the rear fascia/bumper

and exhaust system heat shields. Raise the

tire by turning the lug wrench on the winch

extension clockwise until it clicks/ratchets

three times to make sure the cable is tight.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted incorrectly.

23_WD_OM_EN_USC_t.book Page 238