wheel size DODGE DURANGO 2023 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2023, Model line: DURANGO, Model: DODGE DURANGO 2023Pages: 328, PDF Size: 13.82 MB

Page 95 of 328

GETTING TO KNOW YOUR INSTRUMENT PANEL93

Service Adaptive Cruise Control (ACC)

Warning Light — If Equipped

This light will turn on when the ACC is not

operating and needs service

Úpage 117.

Service AWD Warning Light — If Equipped

This telltale will turn on to indicate the

All-Wheel Drive (AWD) system is not

functioning properly and that service is

required. Contact an authorized dealer.

Service Stop/Start System Warning Light —

If Equipped

This warning light will illuminate when the

Stop/Start system is not functioning

properly and service is required. Contact

an authorized dealer for service.

Cruise Control Fault Warning Light —

If Equipped

This warning light will illuminate to

indicate the Cruise Control System is not

functioning properly and service is

required. Contact an authorized dealer.

Tire Pressure Monitoring System (TPMS)

Warning Light

The warning light switches on and a

message is displayed to indicate that the

tire pressure is lower than the

recommended value and/or that slow

pressure loss is occurring. In these cases, optimal

tire duration and fuel consumption may not be

guaranteed.

Should one or more tires be in the condition

mentioned previously, the display will show the

indications corresponding to each tire.

Each tire, including the spare (if provided), should

be checked monthly when cold and inflated to the

inflation pressure recommended by the vehicle

manufacturer on the vehicle placard or tire

inflation pressure label. If your vehicle has tires of

a different size than the size indicated on the

vehicle placard or tire inflation pressure label, you

should determine the proper tire inflation pressure

for those tires. As an added safety feature, your vehicle has been

equipped with a TPMS that illuminates a low tire

pressure telltale when one or more of your tires is

significantly underinflated. Accordingly, when the

low tire pressure telltale illuminates, you should

stop and check your tires as soon as possible, and

inflate them to the proper pressure. Driving on a

significantly underinflated tire causes the tire to

overheat and can lead to tire failure. Underinflation

also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping

ability.

Please note that the TPMS is not a substitute for

proper tire maintenance, and it is the driver’s

responsibility to maintain correct tire pressure,

even if underinflation has not reached the level to

trigger illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system

is not operating properly. The TPMS malfunction

indicator is combined with the low tire pressure

telltale. When the system detects a malfunction,

the telltale will flash for approximately one minute

and then remain continuously illuminated. This

sequence will continue upon subsequent vehicle

start-ups as long as the malfunction exists. When

the malfunction indicator is illuminated, the

system may not be able to detect or signal low tire

pressure as intended. TPMS malfunctions may

CAUTION!

Do not continue driving with one or more flat

tires as handling may be compromised. Stop the

vehicle, avoiding sharp braking and steering. If a

tire puncture occurs, repair immediately using

the dedicated tire repair kit and contact an

authorized dealer as soon as possible.

3

23_WD_OM_EN_USC_t.book Page 93

Page 96 of 328

94GETTING TO KNOW YOUR INSTRUMENT PANEL

occur for a variety of reasons, including the

installation of replacement or alternate tires or

wheels on the vehicle that prevent the TPMS from

functioning properly. Always check the TPMS

malfunction telltale after replacing one or more

tires or wheels on your vehicle to ensure that the

replacement or alternate tires and wheels allow

the TPMS to continue to function properly.

YELLOW INDICATOR LIGHTS

All-Wheel Drive (AWD) Low Indicator Light —

If Equipped

This light alerts the driver that the vehicle

is in the AWD Low mode. The front and

rear driveshafts are mechanically locked

together forcing the front and rear

wheels to rotate at the same speed. AWD Low is

designed for loose, slippery road surfaces only

Ú page 108.

Forward Collision Warning (FCW) OFF

Indicator Light — If Equipped

This indicator light illuminates to indicate

that Forward Collision Warning is off

Úpage 186.

NEUTRAL Indicator Light — If Equipped

This light alerts the driver that the 4WD

power transfer case is in the NEUTRAL

mode and the front and rear driveshafts

are disengaged from the powertrain.

GREEN INDICATOR LIGHTS

Adaptive Cruise Control (ACC) Set With

Target Indicator Light — If Equipped

This will display when the ACC is set and

the vehicle in front is detected

Úpage 117.

Adaptive Cruise Control (ACC) Set Without

Target Indicator Light — If Equipped

This will display when the ACC is set and

the vehicle in front is not detected

Úpage 117.

Cruise Control Set Indicator Light —

If Equipped

This indicator light will illuminate when

the cruise control is set to the desired

speed Ú page 115.

Front Fog Indicator Light — If Equipped

This indicator light will illuminate when

the front fog lights are on Ú page 45.

LaneSense Indicator Light — If Equipped

The LaneSense indicator light illuminates

solid green when both lane markings

have been detected and the system is

“armed” and ready to provide visual and

torque warnings if an unintentional lane departure

occurs Ú page 131.

Parking/Headlights On Indicator Light

This indicator light will illuminate when

the parking lights or headlights are

turned on Ú page 45.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warning have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may result

when using replacement equipment that is not

of the same size, type, and/or style. Aftermarket

wheels can cause sensor damage. Using

aftermarket tire sealants may cause the Tire

Pressure Monitoring System (TPMS) sensor to

become inoperable. After using an aftermarket

tire sealant it is recommended that you take

your vehicle to an authorized dealer to have your

sensor function checked.

23_WD_OM_EN_USC_t.book Page 94

Page 112 of 328

110STARTING AND OPERATING

When operating your vehicle in AWD LOW, the

engine speed is approximately three times that of

the AWD AUTO position at a given road speed. Take

care not to overspeed the engine and do not

exceed 25 mph (40 km/h).

Proper operation of all-wheel drive vehicles

depends on tires of equal size, type and

circumference on each wheel. Any difference in

tire size can cause damage to the transfer case.

Because all-wheel drive provides improved

traction, there is a tendency to exceed safe turning

and stopping speeds. Do not go faster than road

conditions permit.

For additional information on the appropriate use

of each transfer case position, see the following:

AWD LOW

All-Wheel Drive Low Range – This range provides

low speed all-wheel drive. Locks the front and rear

driveshafts together forcing the front and rear

wheels to rotate at the same speed. Additional

traction and maximum pulling power for loose,

slippery road surfaces only. Do not exceed 25 mph

(40 km/h).

N (Neutral)

This range disengages both the front and rear

driveshafts from the powertrain. To be used for flat

towing behind another vehicle Ú page 146.

SHIFTING PROCEDURE

NOTE:

If any of the requirements to select a new

transfer case position have not been met, the

transfer case will not shift. The position indi -

cator light for the previous position will remain

on and the newly selected position indicator

light will continue to flash until all the require -

ments for the selected position have been met.

To retry a shift: return the control switch back to

the original position, make certain all shift

requirements have been met, wait five seconds

and try the shift again.

If all the requirements to select a new transfer

case position have been met, the current posi -

tion indicator light will turn off, the selected posi -

tion indicator light will flash until the transfer case completes the shift. When the shift is

complete, the position indicator light for the

selected position will stop flashing and remain

on.

AWD AUTO To AWD LOW

NOTE:When shifting into or out of AWD LOW some gear

noise may be heard. This noise is normal and is not

detrimental to the vehicle or occupants.

Shifting can be performed with the vehicle rolling 2

to 3 mph (3 to 5 km/h) or completely stopped. Use

either of the following procedures:

Preferred Procedure

1. With the engine running, slow the vehicle to 2

to 3 mph (3 to 5 km/h).

2. Shift the transmission into NEUTRAL.

3. While still rolling, push the AWD LOW control switch.

4. After the AWD LOW position indicator light is on (not flashing), shift the transmission back into

gear.

Alternate Procedure

1. Bring the vehicle to complete stop.

2. With the ignition in ON/RUN position and engine running, shift the transmission to

NEUTRAL.

3. Push the AWD LOW control switch.

WARNING!

You or others could be injured or killed if you

leave the vehicle unattended with the transfer

case in the N (Neutral) position without first fully

engaging the parking brake. The transfer case N

(Neutral) position disengages both the front and

rear drive shafts from the powertrain and will

allow the vehicle to roll, even if the transmission

is in PARK. The parking brake should always be

applied when the driver is not in the vehicle.

23_WD_OM_EN_USC_t.book Page 110

Page 133 of 328

STARTING AND OPERATING131

(Continued)

result in the system not working properly. The

ParkSense system might not detect an obstacle

behind or in front of the fascia/bumper, or it

could provide a false indication that an obstacle

is behind or in front of the fascia/bumper.

Use the ParkSense switch to turn the ParkSense

system off if objects such as bicycle carriers,

trailer hitches, etc. are placed within 12 inches

(30 cm) of the rear fascia/bumper. Failure to do

so can result in the system misinterpreting a

close object as a sensor problem, causing the

“PARKSENSE UNAVAILABLE SERVICE

REQUIRED” message to be displayed in the

instrument cluster.

ParkSense should be disabled when the liftgate

is in the open position. An opened liftgate could

provide a false indication that an obstacle is

behind the vehicle.

LANESENSE — IF EQUIPPED

LANESENSE OPERATION

The LaneSense system is operational at speeds

above 37 mph (60 km/h) and below 112 mph

(180 km/h). The LaneSense system uses a

forward looking camera to detect lane markings

and measure vehicle position within the lane

boundaries.

When both lane markings are detected and the

driver drifts out of the lane (no turn signal applied),

the LaneSense system provides a haptic warning

in the form of torque applied to the steering wheel

to prompt the driver to remain within the lane

boundaries. If the driver continues to drift out of

the lane, the LaneSense system provides a visual

warning through the instrument cluster display to

prompt the driver to remain within the lane

boundaries.

The driver may manually override the haptic

warning by applying force to the steering wheel at

any time.

When only a single lane marking is detected and

the driver drifts across the lane marking (no turn

signal applied), the LaneSense system provides

visual warnings through the instrument cluster

display to prompt the driver to remain within the

lane. When only a single lane marking is detected,

a haptic or a torque warning will not be provided.

WARNING!

Drivers must be careful when backing up even

when using ParkSense. Always check carefully

behind your vehicle, look behind you, and be

sure to check for pedestrians, animals, other

vehicles, obstructions, and blind spots before

backing up. You are responsible for safety and

must continue to pay attention to your

surroundings. Failure to do so can result in

serious injury or death.

Before using ParkSense, it is strongly recom

-

mended that the ball mount and hitch ball

assembly be disconnected from the vehicle

when the vehicle is not used for towing.

Failure to do so can result in injury or damage

to vehicles or obstacles because the hitch ball

will be much closer to the obstacle than the

rear fascia when the vehicle sounds the

continuous tone. Also, the sensors could

detect the ball mount and hitch ball assembly,

depending on its size and shape, giving a false

indication that an obstacle is behind the

vehicle.

CAUTION!

ParkSense is only a parking aid and it is

unable to recognize every obstacle, including

small obstacles. Parking curbs might be

temporarily detected or not detected at all.

Obstacles located above or below the sensors

will not be detected when they are in close

proximity.

The vehicle must be driven slowly when using

ParkSense in order to be able to stop in time

when an obstacle is detected. It is recom -

mended that the driver looks over his/her

shoulder when using ParkSense.

WARNING!

4

23_WD_OM_EN_USC_t.book Page 131

Page 138 of 328

136STARTING AND OPERATING

VEHICLE LOADING

CERTIFICATION LABEL

As required by National Highway Traffic Safety

Administration regulations, your vehicle has a

certification label affixed to the driver's side door or

pillar.

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear (GAWR).

Total load must be limited so GVWR and front and

rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by

purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

Loading

The actual total weight and the weight of the front

and rear of your vehicle at the ground can best be

determined by weighing it when it is loaded and

ready for operation.

The entire vehicle should first be weighed on a

commercial scale to ensure that the GVWR has not

been exceeded. The weight on the front and rear of

the vehicle should then be determined separately

to be sure that the load is properly distributed over

the front and rear axle. Weighing the vehicle may

show that the GAWR of either the front or rear axles

has been exceeded but the total load is within the

specified GVWR and maximum Payload. If so,

weight must be shifted from front to rear or rear to

front as appropriate until the specified weight

limitations are met. Store the heavier items down

low and be sure that the weight is distributed

equally. Stow all loose items securely before

driving.

Improper weight distributions can have an adverse

effect on the way your vehicle steers and handles

and the way the brakes operate.

23_WD_OM_EN_USC_t.book Page 136

Page 140 of 328

138STARTING AND OPERATING

Weight-Carrying Hitch

A weight-carrying hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

Weight-Distributing Hitch

A weight-distributing system works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and the

trailer axle(s). When used in accordance with the

manufacturer's directions, it provides for a more

level ride, offering more consistent steering and

brake control thereby enhancing towing safety. The

addition of a friction/hydraulic sway control also

dampens sway caused by traffic and crosswinds and

contributes positively to tow vehicle and trailer

stability. Trailer Sway Control (TSC) and a weight

distributing (load equalizing) hitch are

recommended for heavier Tongue Weights (TW) and

may be required depending on vehicle and trailer

configuration/loading to comply with Gross Axle

Weight Rating (GAWR) requirements.

RECOMMENDED DISTRIBUTION HITCH

ADJUSTMENT

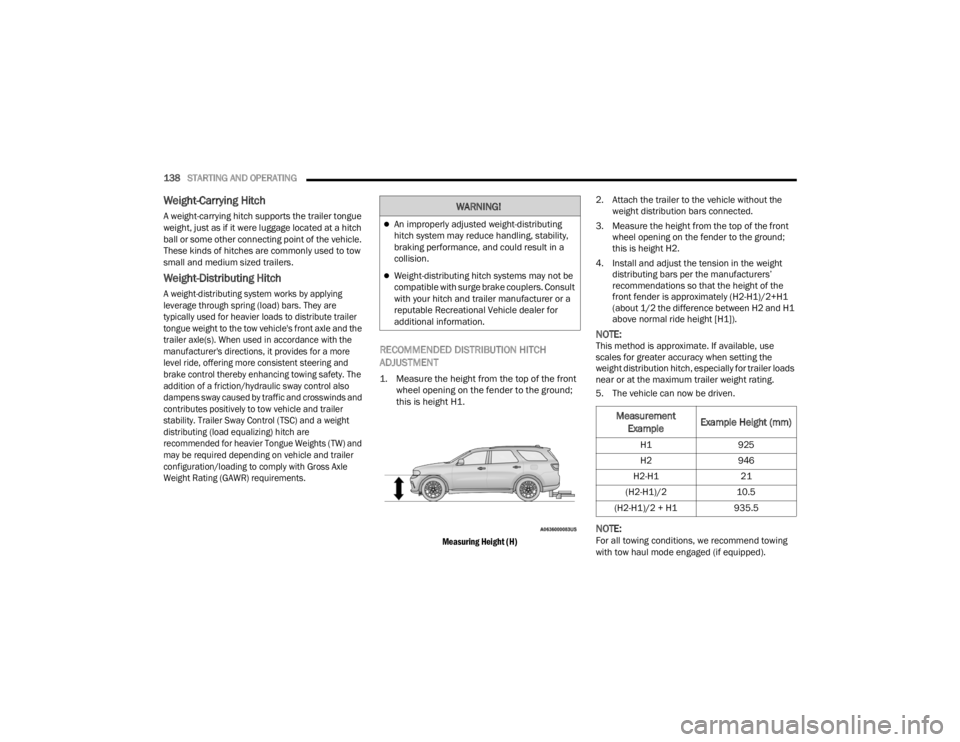

1. Measure the height from the top of the front

wheel opening on the fender to the ground;

this is height H1.

Measuring Height (H)

2. Attach the trailer to the vehicle without the

weight distribution bars connected.

3. Measure the height from the top of the front wheel opening on the fender to the ground;

this is height H2.

4. Install and adjust the tension in the weight distributing bars per the manufacturers’

recommendations so that the height of the

front fender is approximately (H2-H1)/2+H1

(about 1/2 the difference between H2 and H1

above normal ride height [H1]).

NOTE:This method is approximate. If available, use

scales for greater accuracy when setting the

weight distribution hitch, especially for trailer loads

near or at the maximum trailer weight rating.

5. The vehicle can now be driven.

NOTE:For all towing conditions, we recommend towing

with tow haul mode engaged (if equipped).

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability,

braking performance, and could result in a

collision.

Weight-distributing hitch systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

Measurement

Example Example Height (mm)

H1

925

H2 946

H2-H1 21

(H2-H1)/2 10.5

(H2-H1)/2 + H1 935.5

23_WD_OM_EN_USC_t.book Page 138

Page 146 of 328

144STARTING AND OPERATING

7. Push the RIGHT arrow and then push the UP or DOWN buttons until the proper Trailer Brake

Type appears on the screen.

8. In a traffic-free environment, tow the trailer on a dry, level surface at a speed of 20–25 mph

(30–40 km/h) and squeeze the manual brake

control lever completely.

9. If the trailer wheels lockup (indicated by squealing tires), reduce the GAIN setting; if the

trailer wheels turn freely, increase the GAIN

setting.

Repeat steps 8 and 9 until the GAIN setting is at a point

just below trailer wheel lockup. If towing a heavier

trailer, trailer wheel lockup may not be attainable even

with the maximum GAIN setting of 10.

Display Messages

The trailer brake control interacts with the instrument

cluster display. Display messages, along with a single

chime, will be displayed when a malfunction is

determined in the trailer connection, trailer brake

control, or on the trailer

Ú

page 79.

NOTE:

An aftermarket controller may be available for

use with trailers with air or EOH trailer brake

systems. To determine the type of brakes on

your trailer and the availability of controllers,

check with your trailer manufacturer or dealer.

Removal of the ITBM will cause errors and it

may cause damage to the electrical system and

electronic modules of the vehicle. See an autho -

rized dealer if an aftermarket module is to be

installed.

Towing Requirements — Trailer Lights And

Wiring

Whenever pulling a trailer, regardless of the trailer

size, stoplights and turn signals on the trailer are

required for motoring safety.

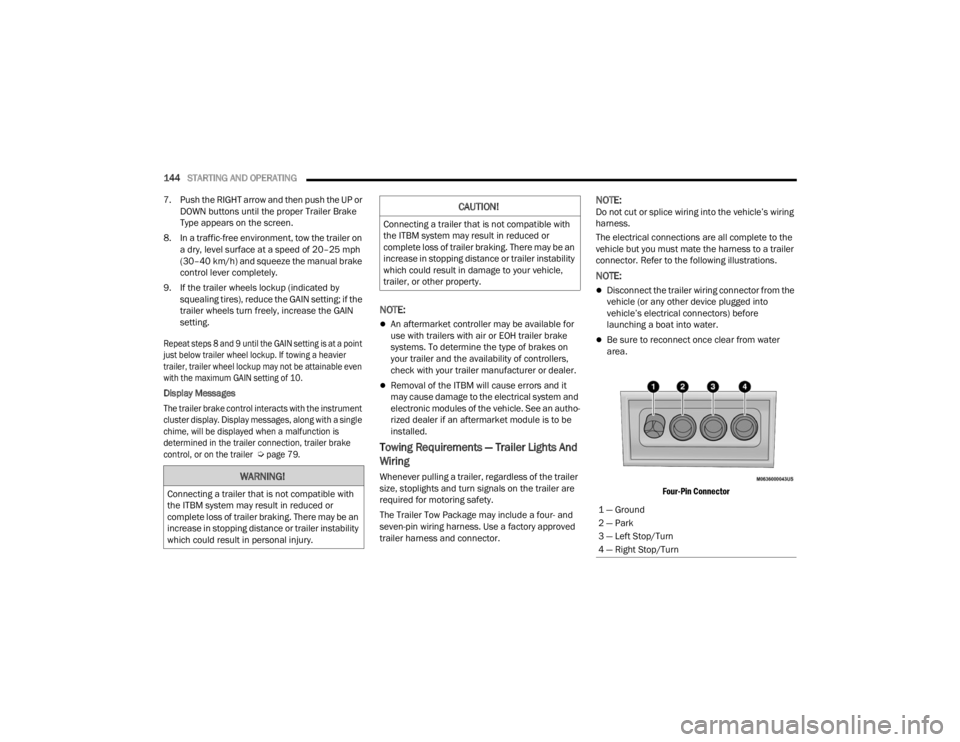

The Trailer Tow Package may include a four- and

seven-pin wiring harness. Use a factory approved

trailer harness and connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the

vehicle but you must mate the harness to a trailer

connector. Refer to the following illustrations.

NOTE:

Disconnect the trailer wiring connector from the

vehicle (or any other device plugged into

vehicle’s electrical connectors) before

launching a boat into water.

Be sure to reconnect once clear from water

area.

Four-Pin Connector

WARNING!

Connecting a trailer that is not compatible with

the ITBM system may result in reduced or

complete loss of trailer braking. There may be an

increase in stopping distance or trailer instability

which could result in personal injury.

CAUTION!

Connecting a trailer that is not compatible with

the ITBM system may result in reduced or

complete loss of trailer braking. There may be an

increase in stopping distance or trailer instability

which could result in damage to your vehicle,

trailer, or other property.

1 — Ground

2 — Park

3 — Left Stop/Turn

4 — Right Stop/Turn

23_WD_OM_EN_USC_t.book Page 144

Page 182 of 328

180SAFETY

(Continued)

Electronic Stability Control (ESC)

ESC enhances directional control and stability of

the vehicle under various driving conditions. ESC

corrects for oversteering or understeering of the

vehicle by applying the brake of the appropriate

wheel(s) to counteract the previous conditions.

Engine power may also be reduced to help the

vehicle maintain the desired path.

Oversteer — when the vehicle is turning more

than appropriate for the steering wheel position.

Understeer — when the vehicle is turning less

than appropriate for the steering wheel position.

ESC uses sensors in the vehicle to determine the

vehicle path intended by the driver and compares

it to the actual path of the vehicle. When the actual

path does not match the intended path, ESC

applies the brake of the appropriate wheel to

assist in counteracting the oversteer or understeer

condition.

The ESC Activation/Malfunction Indicator Light

located in the instrument cluster will start to flash

as soon as the ESC system becomes active. The

ESC Activation/Malfunction Indicator Light also

flashes when the Traction Control System (TCS) is

active. If the ESC Activation/Malfunction Indicator

Light begins to flash during acceleration, ease up

on the accelerator and apply as little throttle as

possible. Be sure to adapt your speed and driving

to the prevailing road conditions.

ESC Operating Modes

Depending upon model and mode of operation, the

ESC system may have multiple operating modes.

ESC On

This is the normal operating mode for the ESC.

Whenever the vehicle is started, the ESC system

will be in this mode. This mode should be used for

most driving conditions. Alternate ESC modes

should only be used for specific reasons as noted

in the following paragraphs.

WARNING!

Electronic Stability Control (ESC) cannot

prevent the natural laws of physics from

acting on the vehicle, nor can it increase the

traction afforded by prevailing road condi -

tions. ESC cannot prevent accidents, including

those resulting from excessive speed in turns,

driving on very slippery surfaces, or hydro -

planing. ESC also cannot prevent accidents

resulting from loss of vehicle control due to

inappropriate driver input for the conditions.

Only a safe, attentive, and skillful driver can

prevent accidents. The capabilities of an ESC

equipped vehicle must never be exploited in a

reckless or dangerous manner which could

jeopardize the user’s safety or the safety of

others.Vehicle modifications, or failure to properly

maintain your vehicle, may change the

handling characteristics of your vehicle, and

may negatively affect the performance of the

ESC system. Changes to the steering system,

suspension, braking system, tire type and size

or wheel size may adversely affect ESC perfor -

mance. Improperly inflated and unevenly worn

tires may also degrade ESC performance. Any

vehicle modification or poor vehicle mainte -

nance that reduces the effectiveness of the

ESC system can increase the risk of loss of

vehicle control, vehicle rollover, personal

injury and death.

WARNING!

23_WD_OM_EN_USC_t.book Page 180

Page 191 of 328

SAFETY189

(Continued)

For example, your vehicle has a recommended cold

(parked for more than three hours) tire pressure of

33 psi (227 kPa). If the ambient temperature is

68°F (20°C) and the measured tire pressure is

28 psi (193 kPa), a temperature drop to 20°F (-7°C)

will decrease the tire pressure to approximately

24 psi (165 kPa). This tire pressure is sufficiently low

enough to turn on the TPMS Warning Light. Driving

the vehicle may cause the tire pressure to rise to

approximately 28 psi (193 kPa), but the TPMS

Warning Light will still be on. In this situation, the

TPMS Warning Light will turn off only after the tires

have been inflated to the vehicle’s recommended

cold tire pressure value.

NOTE:

The TPMS is not intended to replace normal tire

care and maintenance, or to provide warning of

a tire failure or condition.

The TPMS should not be used as a tire pressure

gauge while adjusting your tire pressure.

Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire

failure. Underinflation also reduces fuel effi

-

ciency and tire tread life, and may affect the

vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire

maintenance, and it is the driver’s responsibility

to maintain correct tire pressure using an accu -

rate tire gauge, even if underinflation has not reached the level to trigger illumination of the

TPMS Warning Light.

Seasonal temperature changes will affect tire

pressure, and the TPMS will monitor the actual

tire pressure in the tire.

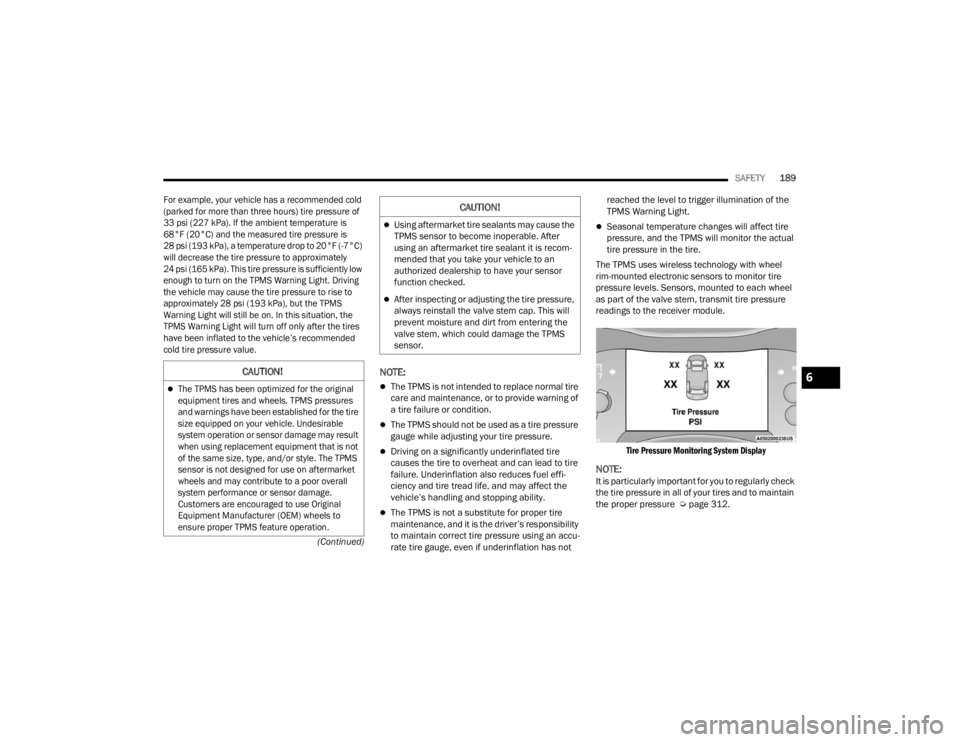

The TPMS uses wireless technology with wheel

rim-mounted electronic sensors to monitor tire

pressure levels. Sensors, mounted to each wheel

as part of the valve stem, transmit tire pressure

readings to the receiver module.

Tire Pressure Monitoring System Display

NOTE:It is particularly important for you to regularly check

the tire pressure in all of your tires and to maintain

the proper pressure Ú page 312.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures

and warnings have been established for the tire

size equipped on your vehicle. Undesirable

system operation or sensor damage may result

when using replacement equipment that is not

of the same size, type, and/or style. The TPMS

sensor is not designed for use on aftermarket

wheels and may contribute to a poor overall

system performance or sensor damage.

Customers are encouraged to use Original

Equipment Manufacturer (OEM) wheels to

ensure proper TPMS feature operation.

Using aftermarket tire sealants may cause the

TPMS sensor to become inoperable. After

using an aftermarket tire sealant it is recom -

mended that you take your vehicle to an

authorized dealership to have your sensor

function checked.

After inspecting or adjusting the tire pressure,

always reinstall the valve stem cap. This will

prevent moisture and dirt from entering the

valve stem, which could damage the TPMS

sensor.

CAUTION!

6

23_WD_OM_EN_USC_t.book Page 189

Page 203 of 328

SAFETY201

(Continued)

This vehicle may be equipped with a driver and/or

front passenger seat belt buckle switch that detects

whether the driver or front passenger seat belt is

buckled. The seat belt buckle switch may adjust the

inflation rate of the Advanced Front Air Bags.

This vehicle may be equipped with driver and/or

front passenger seat track position sensors that

may adjust the inflation rate of the Advanced Front

Air Bags based upon seat position.

This vehicle is equipped with a right front

passenger Occupant Classification System (OCS)

that is designed to provide Passenger Advanced

Front Air Bag output appropriate to the occupant’s

seated weight input, as determined by the OCS.

Front Air Bag Operation

Front Air Bags are designed to provide additional

protection by supplementing the seat belts. Front

air bags are not expected to reduce the risk of

injury in rear, side, or rollover collisions. The front

air bags will not deploy in all frontal collisions,

including some that may produce substantial

vehicle damage — for example, some pole

collisions, truck underrides, and angle offset

collisions.

On the other hand, depending on the type and

location of impact, front air bags may deploy in

crashes with little vehicle front-end damage but

that produce a severe initial deceleration.

Because air bag sensors measure vehicle

deceleration over time, vehicle speed and damage

by themselves are not good indicators of whether

or not an air bag should have deployed.

Seat belts are necessary for your protection in all

collisions, and also are needed to help keep you in

position, away from an inflating air bag.

When the Occupant Restraint Controller (ORC)

detects a collision requiring the front air bags, it

signals the inflator units. A large quantity of

non-toxic gas is generated to inflate the front air

bags.

The steering wheel hub trim cover and the upper

passenger side of the instrument panel separate

and fold out of the way as the air bags inflate to

their full size. The front air bags fully inflate in less

time than it takes to blink your eyes. The front air

bags then quickly deflate while helping to restrain

the driver and front passenger.

Occupant Classification System (OCS) —

Front Passenger Seat

The Occupant Classification System (OCS) is part

of a Federally regulated safety system for this

vehicle. It is designed to provide Passenger

Advanced Front Air Bag output appropriate to the

occupant’s seated weight, as determined by the

OCS.

WARNING!

No objects should be placed over or near the

air bag on the instrument panel or steering

wheel because any such objects could cause

harm if the vehicle is in a collision severe

enough to cause the air bag to inflate.

Do not put anything on or around the air bag

covers or attempt to open them manually. You

may damage the air bags and you could be

injured because the air bags may no longer be

functional. The protective covers for the air

bag cushions are designed to open only when

the air bags are inflating.

Relying on the air bags alone could lead to

more severe injuries in a collision. The air

bags work with your seat belt to restrain you

properly. In some collisions, air bags won’t

deploy at all. Always wear your seat belts even

though you have air bags.

WARNING!

6

23_WD_OM_EN_USC_t.book Page 201