light DODGE GRAND CARAVAN 2009 5.G Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2009, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2009 5.GPages: 535, PDF Size: 18.61 MB

Page 407 of 535

Towing Requirements — Trailer Lights and WiringWhenever you pull a trailer, regardless of the trailer size,

stop lights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four-pin or a

seven-pin wiring harness. Use a factory approved trailer

harness and connector.

NOTE:

Do not cut or splice wiring into the vehicles

wiring harness.

The electrical connections are all complete to the vehicle

but you must mate the harness to a trailer connector.

Refer to the following four-pin connector and seven-pin

connector illustrations. Four-Pin Connector

1 — Female Pins

4 — Park

2 —

Male Pin 5 — Left Stop/Turn

3 — Ground 6 — Right Stop/Turn

STARTING AND OPERATING 405 5

Page 409 of 535

The automatic transaxle fluid and filter should be

changed if you REGULARLY tow a trailer for more than

45 minutes of continuous operation. Refer to the “Main-

tenance Schedule” in Section 8 of this manual for the

proper maintenance intervals.

NOTE:

Check the automatic transaxle fluid level before tow-

ing.

The six-speed automatic transaxle is sealed and re-

quires an authorized dealer to check the transaxle

fluid.

Electronic Speed Control — If Equipped

Do not use in hilly terrain or with heavy loads.

When using the speed control, if you experience speed

drops greater than 10 mph (16 km/h), disengage until

you can get back to cruising speed.

Use speed control in flat terrain and with light loads to

maximize fuel efficiency.

STARTING AND OPERATING 4075

Page 422 of 535

CAUTION!Do not attempt to raise the vehicle by jacking on

locations other than those indicated in Step 5.

6. Place the wrench on the jack screw and turn to the

right until the jack head is properly engaged in the

described location. Do not raise the vehicle until you are

sure the jack is securely engaged.

7. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability. WARNING!Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.

8. Remove the wheel lug nuts, for vehicles with wheel

covers, remove the cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.

9. Install the compact spare tire. Lightly tighten the lug

nuts. To avoid the risk of forcing the vehicle off the jack,

do not tighten the lug nuts fully until the vehicle has been

lowered.

NOTE:

Do not install the wheel cover on the compact spare.

Do not use a hammer or force to install the wheel

covers.

420 WHAT TO DO IN EMERGENCIES

Page 434 of 535

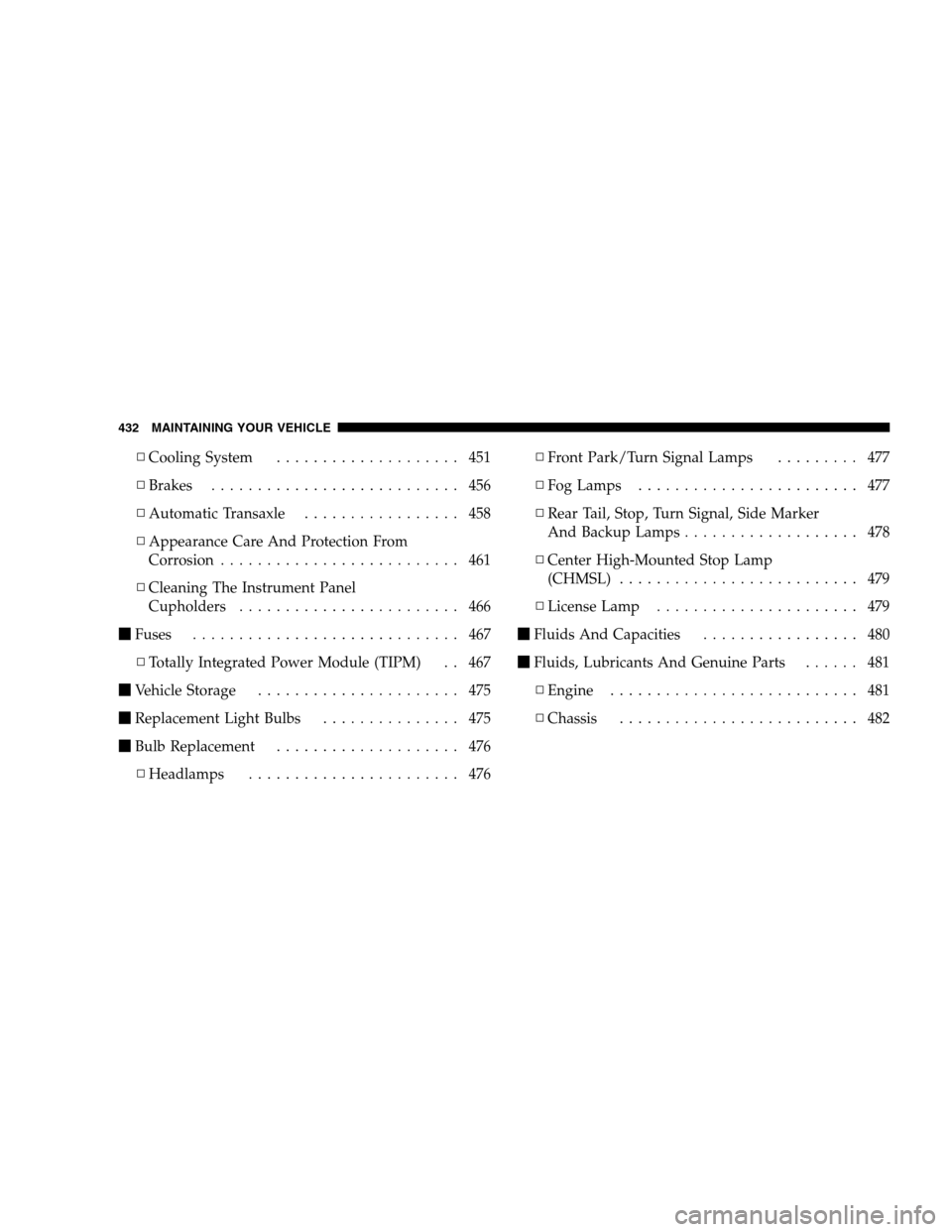

▫Cooling System . . . . . . . . . . . . . . . . . . . . 451

▫ Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . 456

▫ Automatic Transaxle . . . . . . . . . . . . . . . . . 458

▫ Appearance Care And Protection From

Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . 461

▫ Cleaning The Instrument Panel

Cupholders . . . . . . . . . . . . . . . . . . . . . . . . 466

m Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 467

▫ Totally Integrated Power Module (TIPM) . . 467

m Vehicle Storage . . . . . . . . . . . . . . . . . . . . . . 475

m Replacement Light Bulbs . . . . . . . . . . . . . . . 475

m Bulb Replacement . . . . . . . . . . . . . . . . . . . . 476

▫ Headlamps . . . . . . . . . . . . . . . . . . . . . . . 476 ▫

Front Park/Turn Signal Lamps . . . . . . . . . 477

▫ Fog Lamps . . . . . . . . . . . . . . . . . . . . . . . . 477

▫ Rear Tail, Stop, Turn Signal, Side Marker

And Backup Lamps . . . . . . . . . . . . . . . . . . . 478

▫ Center High-Mounted Stop Lamp

(CHMSL) . . . . . . . . . . . . . . . . . . . . . . . . . . 479

▫ License Lamp . . . . . . . . . . . . . . . . . . . . . . 479

m Fluids And Capacities . . . . . . . . . . . . . . . . . 480

m Fluids, Lubricants And Genuine Parts . . . . . . 481

▫ Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . 481

▫ Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . 482

432 MAINTAINING YOUR VEHICLE

Page 437 of 535

ONBOARD DIAGNOSTIC SYSTEM — OBD IIYour vehicle is equipped with a sophisticated onboard

diagnostic system called OBD II. This system monitors

the performance of the emissions, engine, and automatic

transmission control systems. When these systems are

operating properly, your vehicle will provide excellent

performance and fuel economy, as well as engine emis-

sions well within current government regulations.

If any of these systems require service, the OBD II system

will turn on the “Malfunction Indicator Light.” It will

also store diagnostic codes and other information to

assist your service technician in making repairs. Al-

though your vehicle will usually be drivable and not

need towing, see your authorized dealer for service as

soon as possible.

CAUTION!

Prolonged driving with the “Malfunction Indica-

tor Light” on could cause further damage to the

emission control system. It could also affect fuel

economy and driveability. The vehicle must be

serviced before any emissions tests can be per-

formed.

If the “Malfunction Indicator Light” is flashing

while the engine is running, severe catalytic con-

verter damage and power loss will soon occur.

Immediate service is required.

Loose Fuel Filler Cap Message — gASCAP

Should the “Loose Fuel Filler Cap” or “gASCAP” mes-

sage appear, there may be a problem in the evaporative

system. Before taking the vehicle into an authorized

dealer, check first to see if the fuel filler cap is possibly

loose, improperly installed, or damaged. A loose fuel

MAINTAINING YOUR VEHICLE 435 7

Page 438 of 535

filler cap message will be displayed in the instrument

cluster. Tighten the gas cap until a9clicking9sound is

heard. This is an indication that the gas cap is properly

tightened. Press the odometer reset button to turn the

message off. If the problem persists, the message will

appear the next time the vehicle is started. If the problem

is detected twice in a row, the system will turn on the

Malfunction Indicator Light (MIL). Resolving the prob-

lem will turn the MIL light off. Take your vehicle in to an

authorized dealer.

EMISSIONS INSPECTION AND MAINTENANCE

PROGRAMS

In some localities, it may be a legal requirement to pass

an inspection of your vehicle’s emissions control system.

Failure to pass could prevent vehicle registration.

For states that require an Inspection and Mainte-

nance (I/M), this check verifies the “Malfunction Indicator Light (MIL)” is functioning and is not on when

the engine is running, and that the OBD II system is

ready for testing.

Normally, the OBD II system will be ready. The OBD II

system may

notbe ready if your vehicle was recently

serviced, recently had a dead battery or a battery replace-

ment. If the OBD II system should be determined not

ready for the I/M test, your vehicle may fail the test.

Your vehicle has a simple ignition key-actuated test,

which you can use prior to going to the test station. To

check if your vehicle’s OBD II system is ready, you must

do the following:

1. Insert your ignition key into the ignition switch.

2. Turn the ignition to the ON position, but do not crank

or start the engine.

3. If you crank or start the engine, you will have to start

this test over. 436 MAINTAINING YOUR VEHICLE

Page 452 of 535

Avoid using the wiper blades to remove frost or ice from

the windshield. Keep the blade rubber out of contact with

petroleum products such as engine oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depend-

ing on geographical area and frequency of use. Poor

performance of blades may be present with chattering,

marks, water lines or wet spots. If any condition is

present please proceed to clean wiper blades with humid

cloth removing any debris that may be affecting its

function. If performance is not of your entire satisfaction

please visit dealer to have your wiper blades replaced.

Adding Washer Fluid

The fluid reservoir for the windshield washers and the

rear window washer is shared. It is located in the engine

compartment and should be checked at regular intervals.

Fill the reservoir with windshield washer solvent (not

radiator antifreeze) and operate the system for a few

seconds to flush out any residual water. The washer fluid reservoir will hold a full gallon of fluid

when the Low Washer Fluid Light illuminates. WARNING!

Commercially available windshield washer solvents

are flammable. They could ignite and burn you. Care

must be exercised when filling or working around

the washer solution.

After the engine has warmed, operate the defroster for a

few minutes to reduce the possibility of smearing or

freezing the fluid on the cold windshield. MOPARt All

Weather Windshield Washer Solution, used with water as

directed on the container, aids cleaning action, reduces

the freezing point to avoid line clogging, and is not

harmful to paint or trim.

450 MAINTAINING YOUR VEHICLE

Page 459 of 535

Master Cylinder — Brake Fluid Level CheckThe fluid level in the master cylinder should be checked

when performing underhood services, or immediately if

the “Brake System Warning Light” indicates system

failure.

Clean the top of the master cylinder area before removing

the cap. Add fluid to bring the level up to the top of the

“FULL” mark on the side of the master cylinder reservoir.

Overfilling of fluid is not recommended because it may

cause leaking in the system.

Add enough fluid to bring the level up to the require-

ments described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the brake

pads wear. However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer’s recommended brake fluid. Re-

fer to “Fluids, Lubricants, and Genuine Parts” in this

section for the correct fluid type. WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching fire.

Use of a brake fluid that has a lower initial boiling

point than the recommended MOPARt DOT 3

product or a brake fluid that is unidentified as to

FMVSS specification may result in sudden brake

failure during hard prolonged braking. You could

have an accident.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter or

moisture.

MAINTAINING YOUR VEHICLE 457 7

Page 467 of 535

WARNING!Do not use volatile solvents for cleaning purposes.

Many are potentially flammable, and if used in

closed areas they may cause respiratory harm.

Cleaning High Gloss Front Door and Pillar

Appliques

When cleaning the front door B-Pillar appliques, care

must be taken to avoid scratching the plastic.

1. Remove all dirt with a wet soft rag. A mild soap

solution may be used. Do not use high alcohol content or

abrasive cleaners. Glass cleaners are not recommended. If

soap is used, wipe clean with a clean damp rag.

2. To maintain the high gloss shine, apply a scratch and

swirl remover onto a damp cloth and apply to the door

applique. Rub the applique with firm pressure then buff

lightly with a clean cotton cloth until a high gloss shine is

achieved.

Cleaning Headlights

Your vehicle has plastic headlights that are lightweight

and less susceptible to stone breakage than glass head-

lights.

Plastic is not as scratch resistant as glass and therefore

different lens cleaning procedures must be followed.

To minimize the possibility of scratching the lenses and

reducing light output, avoid wiping with a dry cloth. To

remove road dirt, wash with a mild soap solution fol-

lowed by rinsing.

Do not use abrasive cleaning components, solvents, steel

wool or other aggressive material to clean the lenses.

Glass Surfaces

All glass surfaces should be cleaned on a regular basis

with MOPARt

Glass Cleaner or any commercial

household-type glass cleaner. Never use an abrasive type

MAINTAINING YOUR VEHICLE 465 7

Page 471 of 535

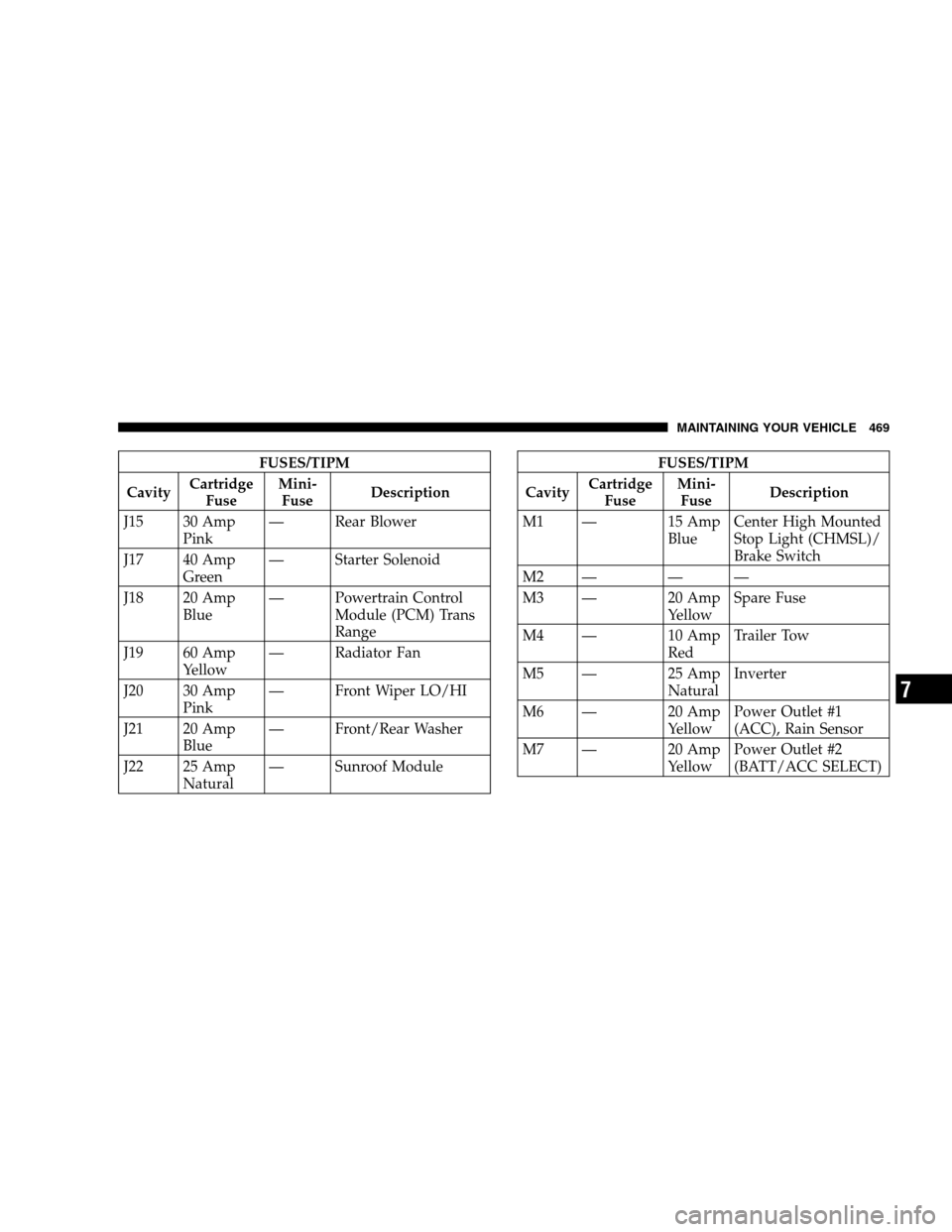

FUSES/TIPM

Cavity Cartridge

Fuse Mini-

Fuse Description

J15 30 Amp Pink — Rear Blower

J17 40 Amp Green — Starter Solenoid

J18 20 Amp Blue — Powertrain Control

Module (PCM) Trans

Range

J19 60 Amp Yellow — Radiator Fan

J20 30 Amp Pink — Front Wiper LO/HI

J21 20 Amp Blue — Front/Rear Washer

J22 25 Amp Natural — Sunroof ModuleFUSES/TIPM

Cavity Cartridge

Fuse Mini-

Fuse Description

M1 — 15 Amp BlueCenter High Mounted

Stop Light (CHMSL)/

Brake Switch

M2 — — —

M3 — 20 Amp YellowSpare Fuse

M4 — 10 Amp RedTrailer Tow

M5 — 25 Amp NaturalInverter

M6 — 20 Amp YellowPower Outlet #1

(ACC), Rain Sensor

M7 — 20 Amp YellowPower Outlet #2

(BATT/ACC SELECT)

MAINTAINING YOUR VEHICLE 469 7