light DODGE GRAND CARAVAN 2020 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2020, Model line: GRAND CARAVAN, Model: DODGE GRAND CARAVAN 2020Pages: 380, PDF Size: 14.92 MB

Page 214 of 380

212IN CASE OF EMERGENCY

6. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Wheel And Tire

Torque Specifications” in “Technical

Specifications” for proper wheel lug nut

torque. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten all the lug nuts until the

wheel sits flush onto the hub and there is no

play. The nuts will have to be fully tightened

once the vehicle is lowered. Tightening an

improperly seated wheel under vehicle load

can damage the threads, cause vibration,

and undermine safety. 3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Wheel And Tire

Torque Specifications” in the “Technical

Specifications” section for proper wheel lug

nut torque. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

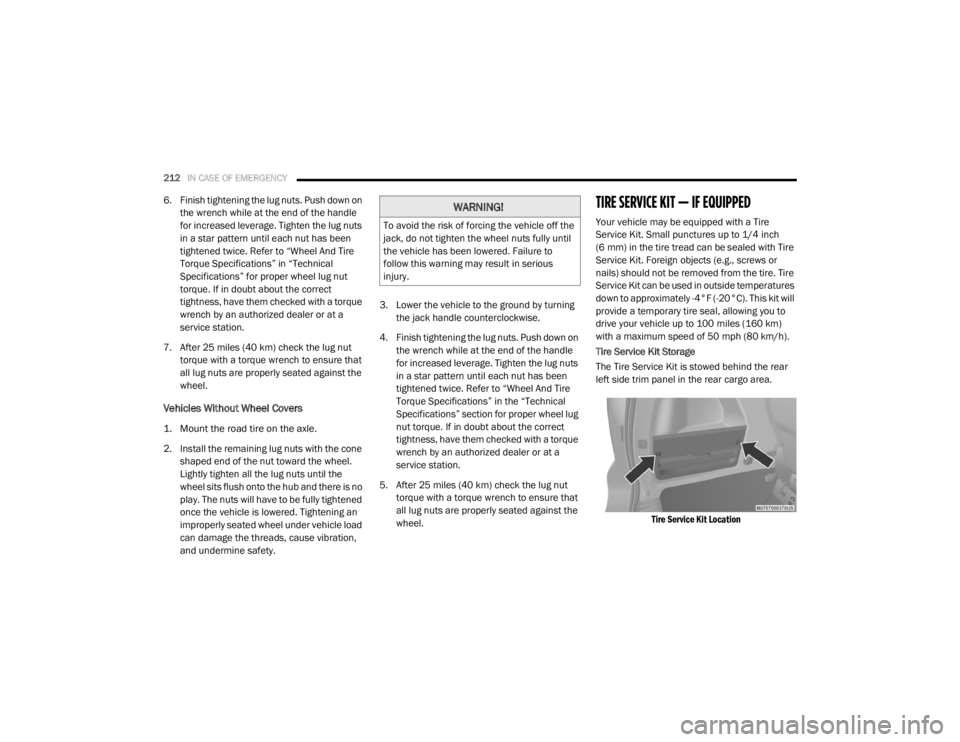

TIRE SERVICE KIT — IF EQUIPPED

Your vehicle may be equipped with a Tire

Service Kit. Small punctures up to 1/4 inch

(6 mm) in the tire tread can be sealed with Tire

Service Kit. Foreign objects (e.g., screws or

nails) should not be removed from the tire. Tire

Service Kit can be used in outside temperatures

down to approximately -4°F (-20°C). This kit will

provide a temporary tire seal, allowing you to

drive your vehicle up to 100 miles (160 km)

with a maximum speed of 50 mph (80 km/h).

Tire Service Kit Storage

The Tire Service Kit is stowed behind the rear

left side trim panel in the rear cargo area.

Tire Service Kit Location

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

20_RT_OM_EN_USC_t.book Page 212

Page 228 of 380

226

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

This vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent

short-trips, trailer tow, extremely hot or cold

ambient temperatures, and E85 fuel usage will

influence when the “Oil Change Required”

message is displayed. Severe Operating

Conditions can cause the change oil message

to illuminate as early as 3,500 miles

(5,600 km) since last reset. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km).An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset by

referring to the steps described under

“Instrument Cluster Display” in “Getting To

Know Your Instrument Panel” for further

information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change engine oil at 4,000 miles (6,500 km) if

the vehicle is operated in a dusty and off road

environment or is operated predominately at

idle or only very low engine RPM. This type of

vehicle use is considered Severe Duty.Once A Month Or Before A Long Trip:Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before the

oil indicator system turns on.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering

and fill as needed.

Check function of all interior and exterior

lights.

20_RT_OM_EN_USC_t.book Page 226

Page 234 of 380

232SERVICING AND MAINTENANCE

Checking Oil Level

To ensure proper engine lubrication, the engine

oil must be maintained at the correct level.

Check the oil level at regular intervals, such as

every fuel stop. The best time to check the

engine oil level is about five minutes after a fully

warmed engine is shut off.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

readings. Maintain the oil level within the SAFE

crosshatch marking on the dipstick. Adding one

quart of oil when the reading is at the bottom of

the mark will result in reading the top of the

mark on these engines.

Adding Washer Fluid

The fluid reservoir for the windshield washers

and the rear window washer is shared. It is

located in the engine compartment and should

be checked at regular intervals. Fill the reservoir with windshield washer solvent

(not radiator antifreeze) and operate the system

for a few seconds to flush out any residual

water.

The washer fluid reservoir will hold a full gallon

of fluid when the Low Washer Fluid Light

illuminates.

After the engine has warmed, operate the

defroster for a few minutes to reduce the

possibility of smearing or freezing the fluid on

the cold windshield. Mopar All Weather

Windshield Washer Solution or equivalent, used

with water as directed on the container, aids

cleaning action, reduces the freezing point to

avoid line clogging, and is not harmful to paint

or trim.

Maintenance-Free Battery

Your vehicle is equipped with a

maintenance-free battery. You will never have

to add water, nor is periodic maintenance

required.

CAUTION!

Overfilling or underfilling will cause oil

aeration, or loss of oil pressure. This could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling

or working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps. If acid splashes in eyes

or on skin, flush the area immediately with

large amounts of water. Refer to “Jump

Starting Procedure” in “In Case Of Emer

-

gency” for further information.

Battery gas is flammable and explosive.

Keep flame or sparks away from the

battery. Do not use a booster battery or any

other booster source with an output greater

than 12 Volts. Do not allow cable clamps to

touch each other.

Battery posts, terminals, and related acces -

sories contain lead and lead compounds.

Wash hands after handling.

20_RT_OM_EN_USC_t.book Page 232

Page 245 of 380

SERVICING AND MAINTENANCE243

(Continued)

Master Cylinder — Brake Fluid Level Check

The fluid level in the master cylinder should be

checked when performing underhood services,

or immediately if the “Brake System Warning

Light” indicates system failure.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up

to the top of the “FULL” mark on the side of the

master cylinder reservoir.

Overfilling of fluid is not recommended because

it may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear.

However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only manufacturer's recommended brake

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further

information.

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid.

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder

reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

20_RT_OM_EN_USC_t.book Page 243

Page 247 of 380

SERVICING AND MAINTENANCE245

TIRES

Tire Safety Information

Tire safety information will cover aspects of the

following information: Tire Markings, Tire Identi -

fication Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

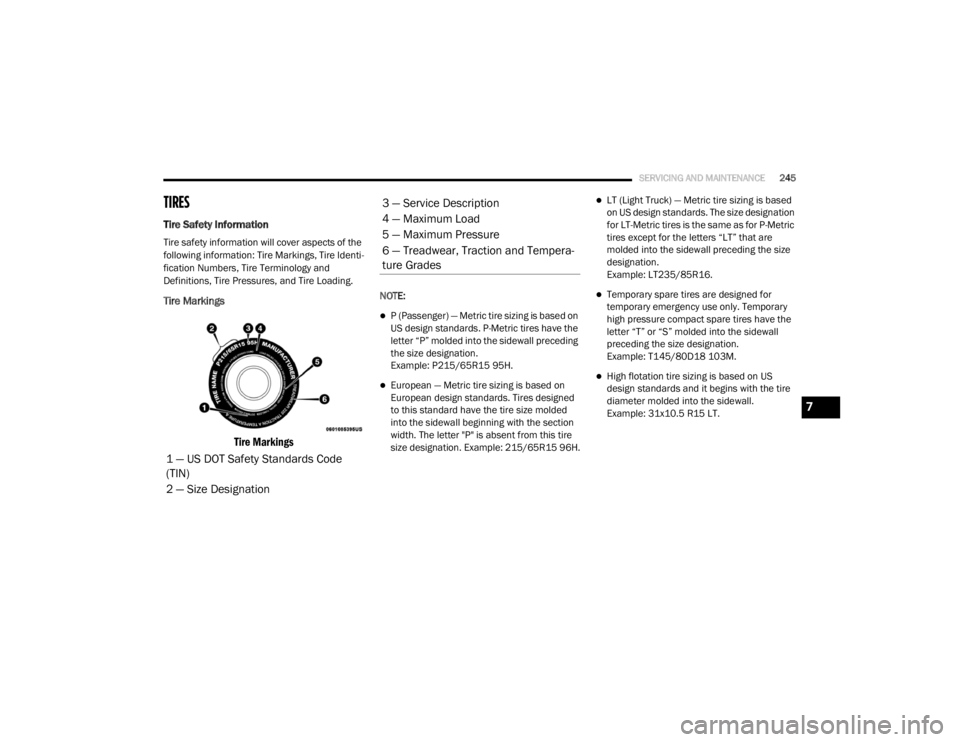

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on

US design standards. P-Metric tires have the

letter “P” molded into the sidewall preceding

the size designation.

Example: P215/65R15 95H.

European — Metric tire sizing is based on

European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section

width. The letter "P" is absent from this tire

size designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based

on US design standards. The size designation

for LT-Metric tires is the same as for P-Metric

tires except for the letters “LT” that are

molded into the sidewall preceding the size

designation.

Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation.

Example: T145/80D18 103M.

High flotation tire sizing is based on US

design standards and it begins with the tire

diameter molded into the sidewall.

Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards Code

(TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

7

20_RT_OM_EN_USC_t.book Page 245

Page 248 of 380

246SERVICING AND MAINTENANCE

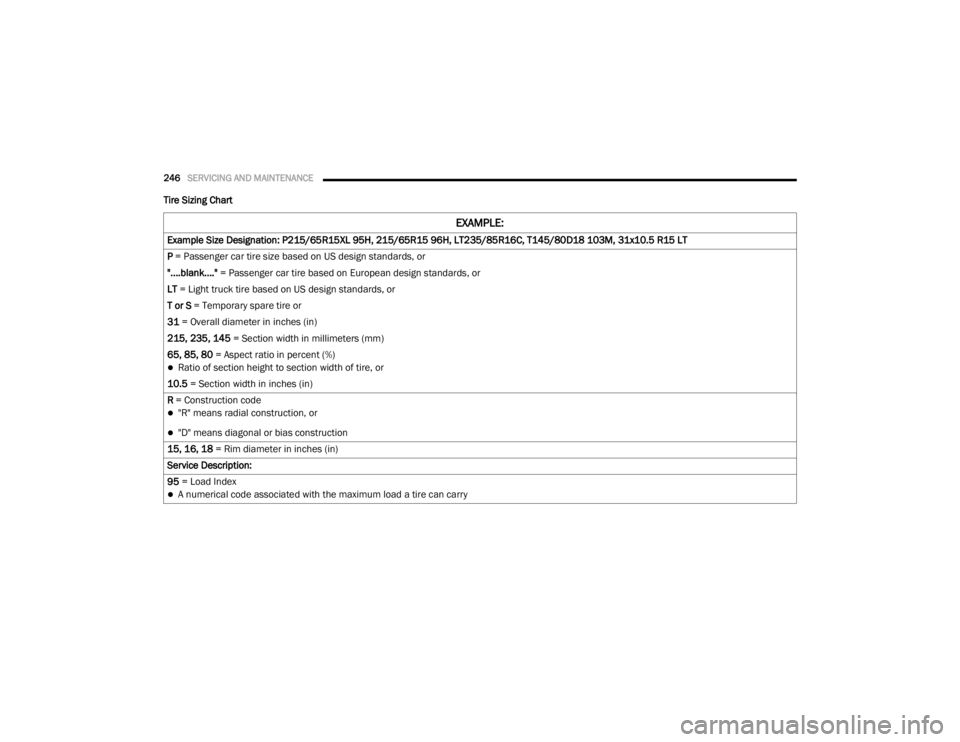

Tire Sizing Chart

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

20_RT_OM_EN_USC_t.book Page 246

Page 249 of 380

SERVICING AND MAINTENANCE247

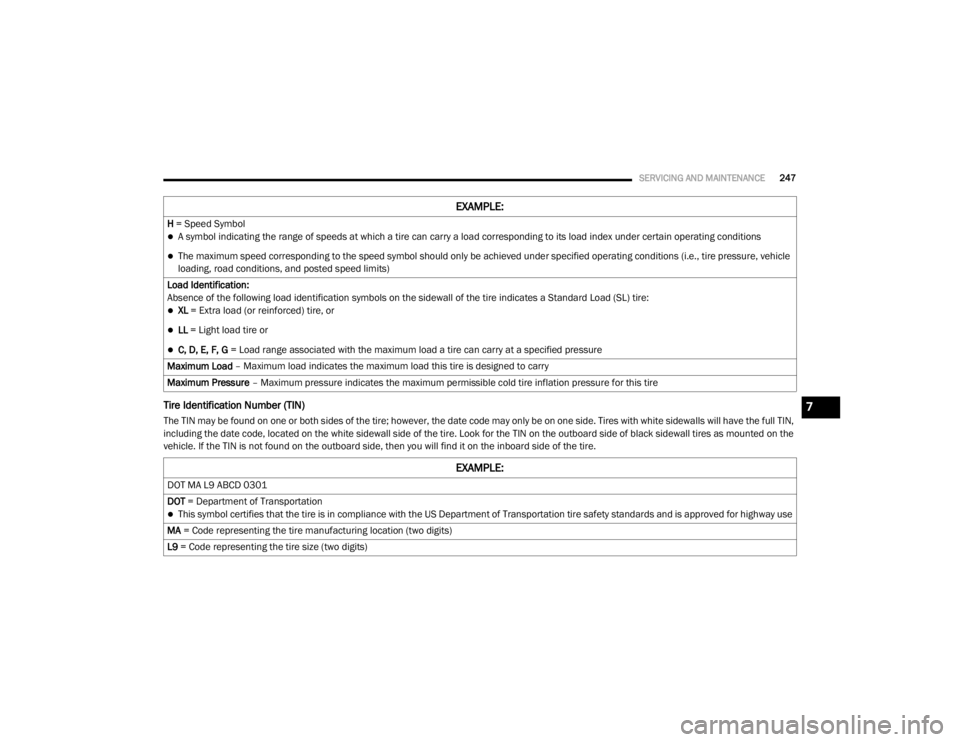

Tire Identification Number (TIN)

The TIN may be found on one or both sides of the tire; however, the date code may only be on one side. Tires with white sidewalls will have the full TIN,

including the date code, located on the white sidewall side of the tire. Look for the TIN on the outboard side of black sidewall tires as mounted on the

vehicle. If the TIN is not found on the outboard side, then you will find it on the inboard side of the tire.H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

EXAMPLE:

DOT MA L9 ABCD 0301

DOT = Department of Transportation

This symbol certifies that the tire is in compliance with the US Department of Transportation tire safety standards and is approved for highway use

MA = Code representing the tire manufacturing location (two digits)

L9 = Code representing the tire size (two digits)

7

20_RT_OM_EN_USC_t.book Page 247

Page 257 of 380

SERVICING AND MAINTENANCE255

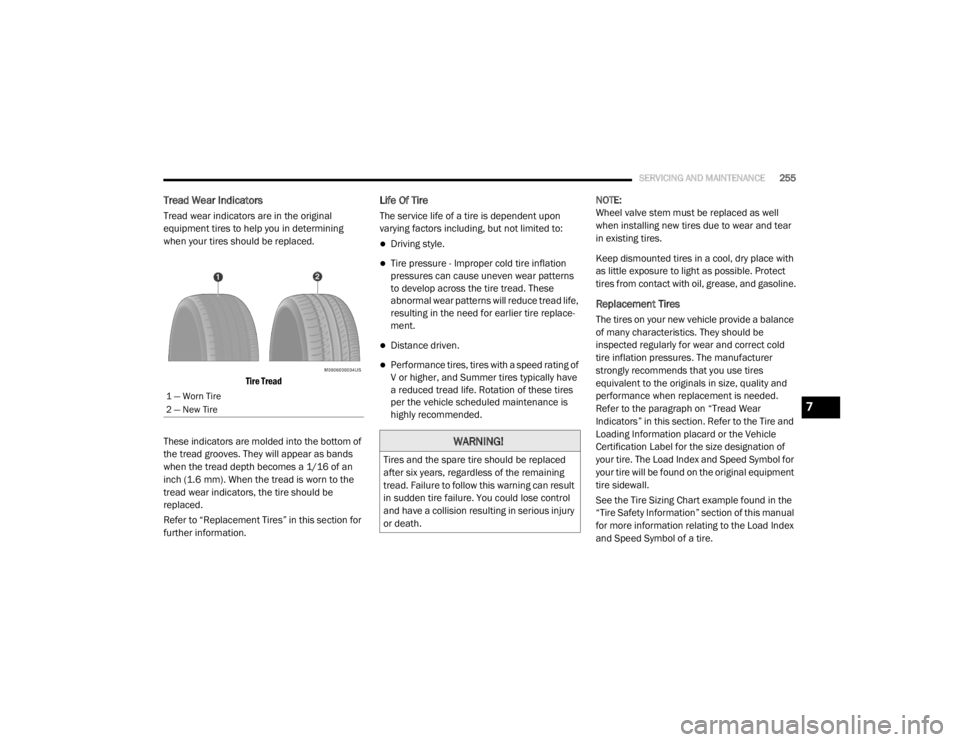

Tread Wear Indicators

Tread wear indicators are in the original

equipment tires to help you in determining

when your tires should be replaced.

Tire Tread

These indicators are molded into the bottom of

the tread grooves. They will appear as bands

when the tread depth becomes a 1/16 of an

inch (1.6 mm). When the tread is worn to the

tread wear indicators, the tire should be

replaced.

Refer to “Replacement Tires” in this section for

further information.

Life Of Tire

The service life of a tire is dependent upon

varying factors including, but not limited to:

Driving style.

Tire pressure - Improper cold tire inflation

pressures can cause uneven wear patterns

to develop across the tire tread. These

abnormal wear patterns will reduce tread life,

resulting in the need for earlier tire replace -

ment.

Distance driven.

Performance tires, tires with a speed rating of

V or higher, and Summer tires typically have

a reduced tread life. Rotation of these tires

per the vehicle scheduled maintenance is

highly recommended. NOTE:

Wheel valve stem must be replaced as well

when installing new tires due to wear and tear

in existing tires.

Keep dismounted tires in a cool, dry place with

as little exposure to light as possible. Protect

tires from contact with oil, grease, and gasoline.

Replacement Tires

The tires on your new vehicle provide a balance

of many characteristics. They should be

inspected regularly for wear and correct cold

tire inflation pressures. The manufacturer

strongly recommends that you use tires

equivalent to the originals in size, quality and

performance when replacement is needed.

Refer to the paragraph on “Tread Wear

Indicators” in this section. Refer to the Tire and

Loading Information placard or the Vehicle

Certification Label for the size designation of

your tire. The Load Index and Speed Symbol for

your tire will be found on the original equipment

tire sidewall.

See the Tire Sizing Chart example found in the

“Tire Safety Information” section of this manual

for more information relating to the Load Index

and Speed Symbol of a tire.

1 — Worn Tire

2 — New Tire

WARNING!

Tires and the spare tire should be replaced

after six years, regardless of the remaining

tread. Failure to follow this warning can result

in sudden tire failure. You could lose control

and have a collision resulting in serious injury

or death.

7

20_RT_OM_EN_USC_t.book Page 255

Page 265 of 380

SERVICING AND MAINTENANCE263

What Causes Corrosion?

Corrosion is the result of deterioration or

removal of paint and protective coatings from

your vehicle.

The most common causes are:

Road salt, dirt and moisture accumulation.

Stone and gravel impact.

Insects, tree sap and tar.

Salt in the air near seacoast localities.

Atmospheric fallout/industrial pollutants.

Body And Underbody Maintenance

Cleaning Headlights

Your vehicle is equipped with plastic headlights

and fog lights that are lighter and less

susceptible to stone breakage than glass

headlights.

Plastic is not as scratch resistant as glass and

therefore different lens cleaning procedures

must be followed. To minimize the possibility of scratching the

lenses and reducing light output, avoid wiping

with a dry cloth. To remove road dirt, wash with

a mild soap solution followed by rinsing.

Do not use abrasive cleaning components,

solvents, steel wool or other aggressive

material to clean the lenses.

Preserving The Bodywork

Washing

Wash your vehicle regularly. Always wash

your vehicle in the shade using Mopar Car

Wash, or a mild car wash soap, and rinse the

panels completely with clear water.

If insects, tar, or other similar deposits have

accumulated on your vehicle, use Mopar

Super Kleen Bug and Tar Remover to

remove.

Use a high quality cleaner wax, such as

Mopar Cleaner Wax to remove road film,

stains and to protect your paint finish. Take

care never to scratch the paint.

Avoid using abrasive compounds and power

buffing that may diminish the gloss or thin

out the paint finish.

CAUTION!

Do not use abrasive or strong cleaning

materials such as steel wool or scouring

powder that will scratch metal and painted

surfaces.

Use of power washers exceeding 1,200 psi

(8,274 kPa) can result in damage or

removal of paint and decals.

7

20_RT_OM_EN_USC_t.book Page 263

Page 268 of 380

266

TECHNICAL SPECIFICATIONS

IDENTIFICATION DATA

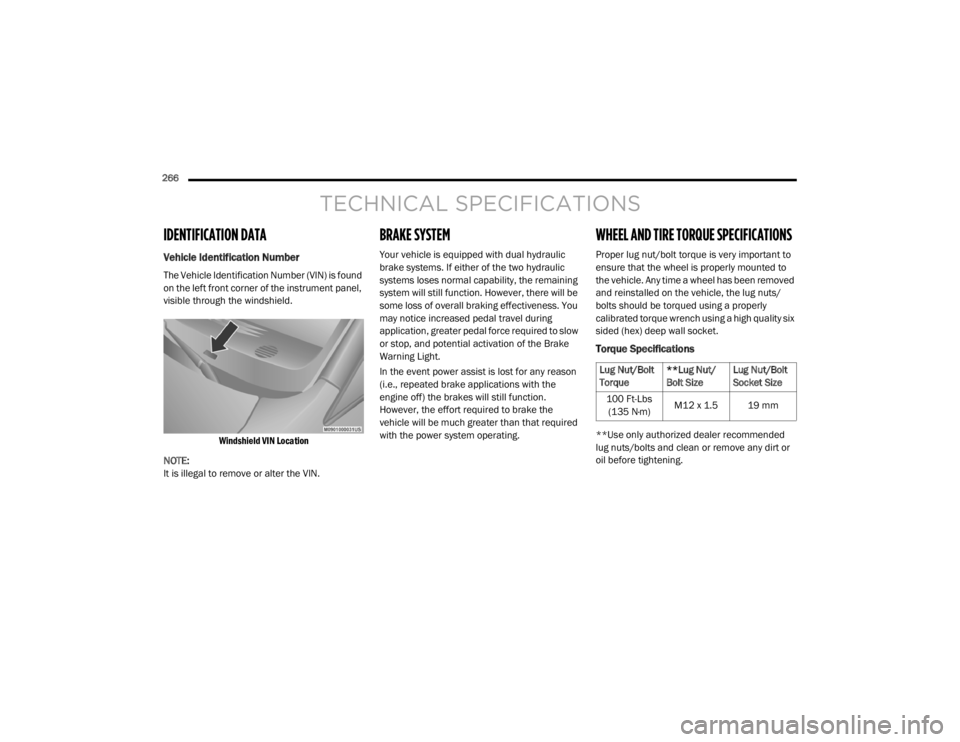

Vehicle Identification Number

The Vehicle Identification Number (VIN) is found

on the left front corner of the instrument panel,

visible through the windshield.

Windshield VIN Location

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems loses normal capability, the remaining

system will still function. However, there will be

some loss of overall braking effectiveness. You

may notice increased pedal travel during

application, greater pedal force required to slow

or stop, and potential activation of the Brake

Warning Light.

In the event power assist is lost for any reason

(i.e., repeated brake applications with the

engine off) the brakes will still function.

However, the effort required to brake the

vehicle will be much greater than that required

with the power system operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

Torque Specifications

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs (135 N·m) M12 x 1.5 19 mm

20_RT_OM_EN_USC_t.book Page 266